Effects of Peroxide and Sulfur Curing Systems on Physical and Mechanical Properties of Nitrile Rubber Composites: A Comparative Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Compounding and Curing Process of Rubber Composites

2.3. Mechanical Properties

2.4. Dynamic Mechanical Thermal Analysis (DMTA)

2.5. Determination of Cross-Link Density

3. Results and Discussion

3.1. Solvent Uptake and Cross-Link Density

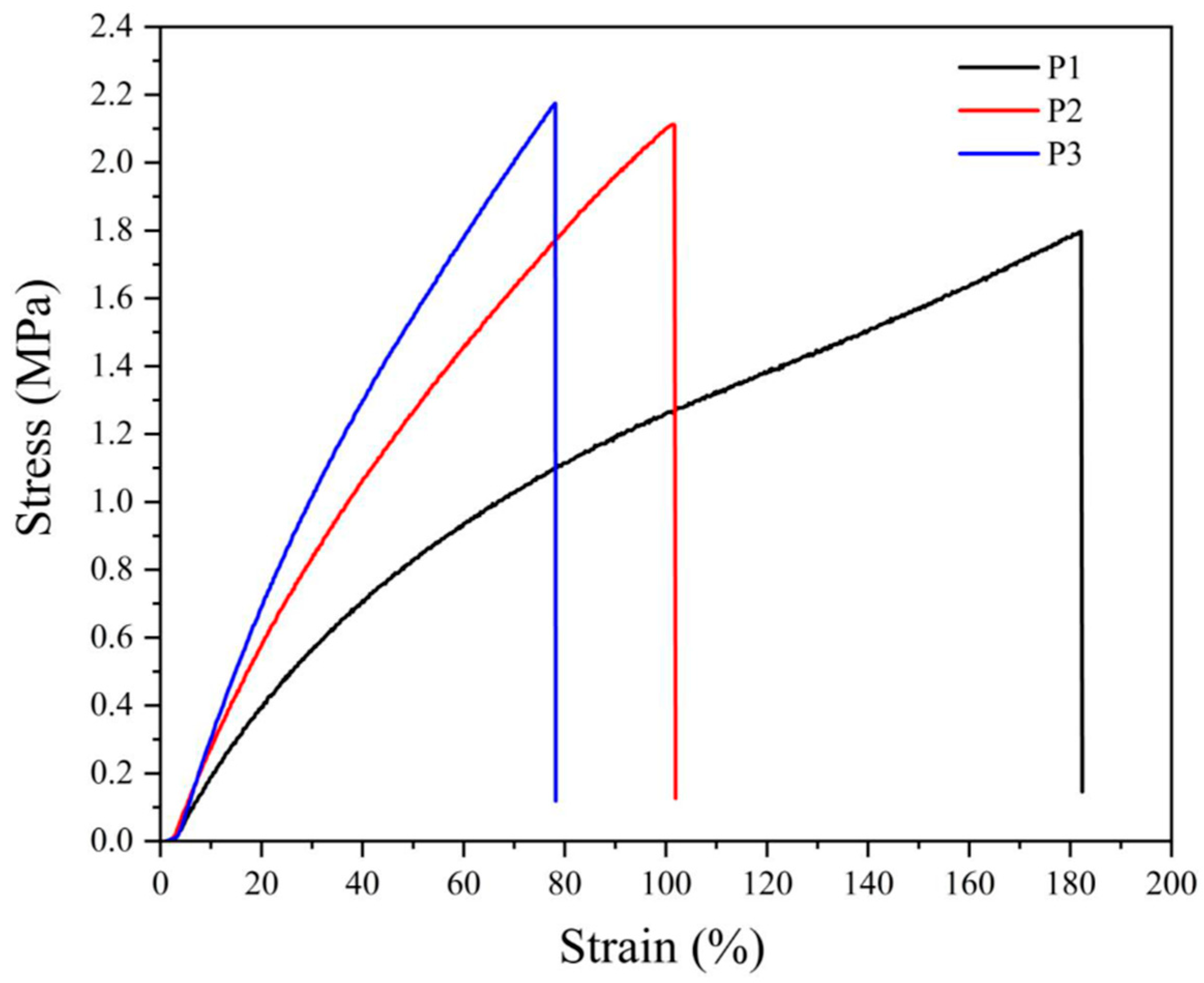

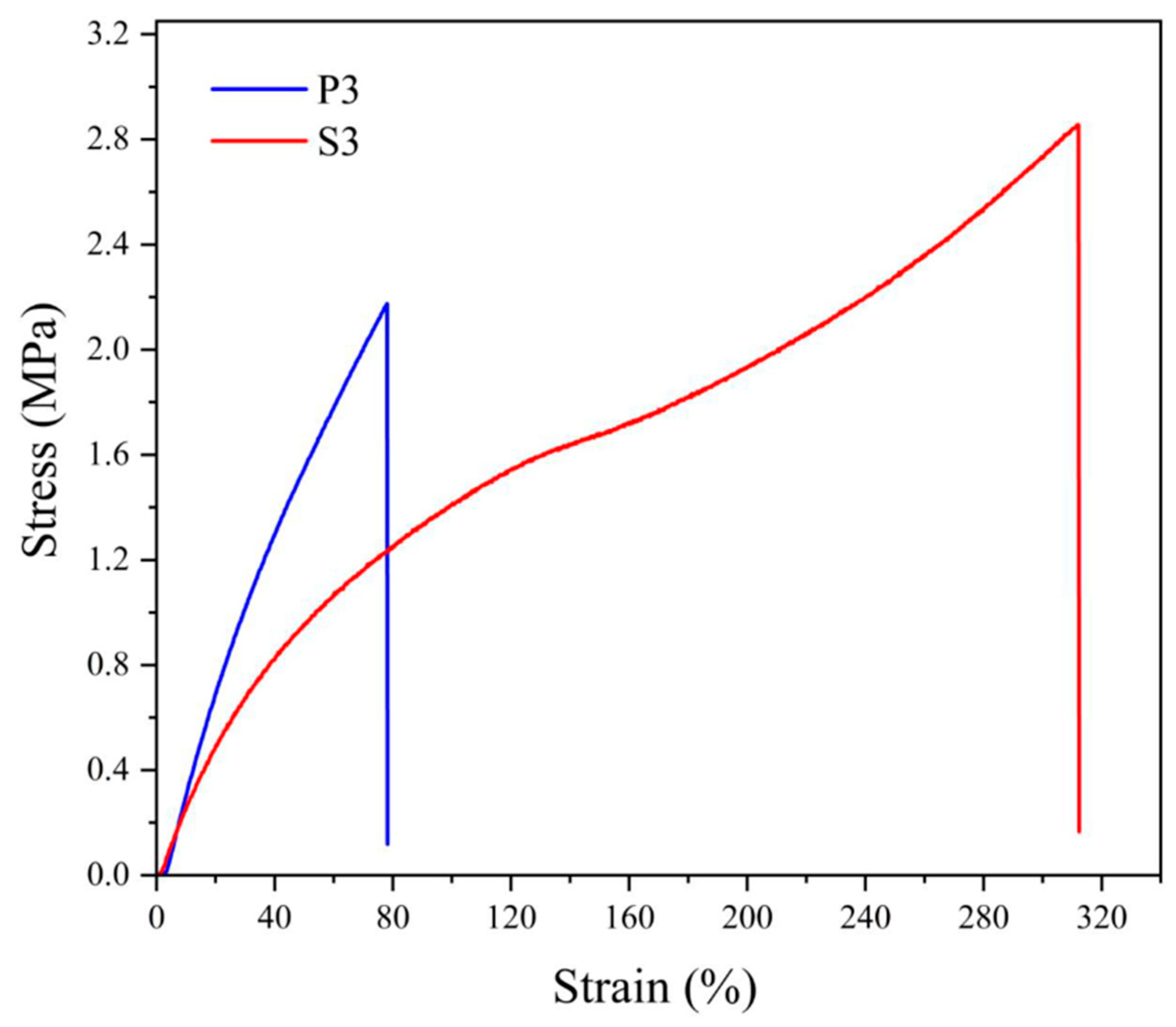

3.2. Mechanical Properties

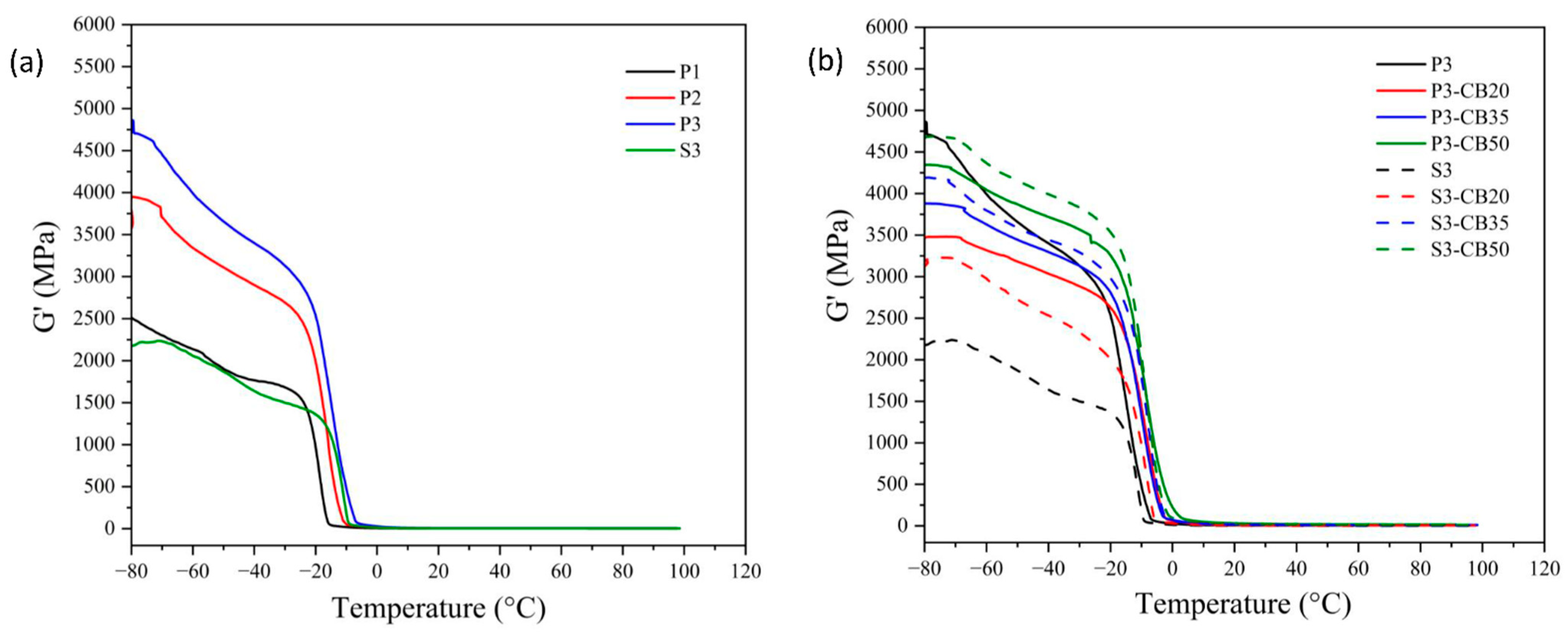

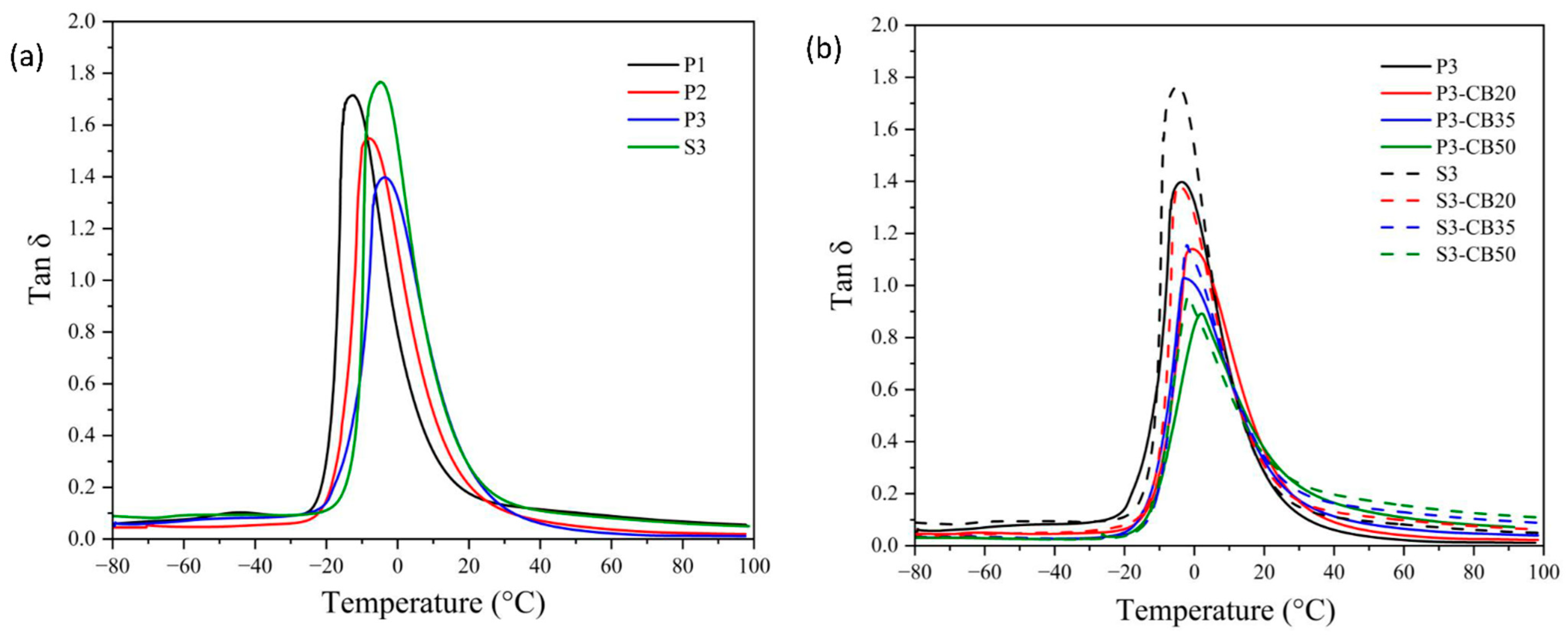

3.3. Dynamic Mechanical Thermal Analysis (DMTA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, T.; Chao, Y.; Van Zee, J. Stress relaxation behavior of EPDM seals in polymer electrolyte membrane fuel cell environment. Int. J. Hydrog. Energy 2012, 37, 13478–13483. [Google Scholar] [CrossRef]

- Dong, Y.; Ke, Y.; Zheng, Z.; Yang, H.; Yao, X. Effect of stress relaxation on sealing performance of the fabric rubber seal. Compos. Sci. Technol. 2017, 151, 291–301. [Google Scholar] [CrossRef]

- Han, R.; Wang, Z.; Zhang, Y.; Niu, K. Thermal stability of CeO2/graphene/phenyl silicone rubber composites. Polym. Test. 2019, 75, 277–283. [Google Scholar] [CrossRef]

- Yang, H.; Yao, X.-F.; Ke, Y.-C.; Ma, Y.-j.; Liu, Y.-H. Constitutive behaviors and mechanical characterizations of fabric reinforced rubber composites. Compos. Struct. 2016, 152, 117–123. [Google Scholar] [CrossRef]

- Han, R.; Wu, Y.; Quan, X.; Niu, K. Effects of crosslinking densities on mechanical properties of nitrile rubber composites in thermal oxidative aging environment. J. Appl. Polym. Sci. 2020, 137, 49076. [Google Scholar] [CrossRef]

- Peidayesh, H.; Špitalský, Z.; Chodák, I. Electrical Conductivity of Rubber Composites with Varying Crosslink Density under Cyclic Deformation. Polymers 2022, 14, 3640. [Google Scholar] [CrossRef] [PubMed]

- Evgin, T.; Mičušík, M.; Machata, P.; Peidayesh, H.; Preťo, J.; Omastová, M. Morphological, Mechanical and Gas Penetration Properties of Elastomer Composites with Hybrid Fillers. Polymers 2022, 14, 4043. [Google Scholar] [CrossRef] [PubMed]

- Lendvai, L. Mechanical and morphological properties of PP/XNBR blends produced with rubber latex. J. Polym. Res. 2023, 30, 276. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Q.; Wang, T.; Pan, G. Preparation and tribological properties of graphene oxide/nitrile rubber nanocomposites. J. Mater. Sci. 2012, 47, 730–738. [Google Scholar] [CrossRef]

- Kruželák, J.; Sýkora, R.; Hudec, I. Sulphur and peroxide vulcanisation of rubber compounds–overview. Chem. Pap. 2016, 70, 1533–1555. [Google Scholar] [CrossRef]

- Kruželák, J.; Chodák, I.; Mošková, D.J.; Dosoudil, R.; Hudec, I. Cross-linking and properties of rubber magnetic composites cured with different curing systems. Polym. Adv. Technol. 2018, 29, 216–225. [Google Scholar] [CrossRef]

- Mora-Barrantes, I.; Malmierca, M.; Valentin, J.; Rodriguez, A.; Ibarra, L. Effect of covalent cross-links on the network structure of thermo-reversible ionic elastomers. Soft Matter 2012, 8, 5201–5213. [Google Scholar] [CrossRef]

- Posadas, P.; Malmierca, M.; González-Jiménez, A.; Ibarra, L.; Rodríguez, A.; Valentin, J.; Nagaoka, T.; Yajima, H.; Toki, S.; Che, J. ESR investigation of NR and IR rubber vulcanized with different cross-linking agents. Express Polym. Lett. 2016, 10, 2–14. [Google Scholar] [CrossRef]

- Shangguan, Y.; Yang, J.; Zheng, Q. Rheology of nitrile rubber with hybrid crosslinked network composed of covalent bonding and hydrogen bonding. RSC Adv. 2017, 7, 15978–15985. [Google Scholar] [CrossRef]

- Fleischmann, D.D.; Ayalur-Karunakaran, S.; Arbeiter, F.; Schaller, R.; Holzner, A.; Kern, W.; Schlögl, S. Influence of crosslinker and water on mechanical properties of carboxylated nitrile butadiene rubber (XNBR). Polym. Test. 2018, 66, 24–31. [Google Scholar] [CrossRef]

- Utrera-Barrios, S.; Araujo-Morera, J.; de Los Reyes, L.P.; Manzanares, R.V.; Verdejo, R.; López-Manchado, M.Á.; Santana, M.H. An effective and sustainable approach for achieving self-healing in nitrile rubber. Eur. Polym. J. 2020, 139, 110032. [Google Scholar] [CrossRef]

- Aprem, A.S.; Joseph, K.; Mathew, T.; Altstaedt, V.; Thomas, S. Studies on accelerated sulphur vulcanization of natural rubber using 1-phenyl-2, 4-dithiobiuret/tertiary butyl benzothiazole sulphenamide. Eur. Polym. J. 2003, 39, 1451–1460. [Google Scholar] [CrossRef]

- Heideman, G.; Noordermeer, J.W.; Datta, R.N.; van Baarle, B. Effect of zinc complexes as activator for sulfur vulcanization in various rubbers. Rubber Chem. Technol. 2005, 78, 245–257. [Google Scholar] [CrossRef]

- Tao, Z.; Viriyabanthorn, N.; Ghumman, B.; Barry, C.; Mead, J. Heat resistant elastomers. Rubber Chem. Technol. 2005, 78, 489–515. [Google Scholar] [CrossRef]

- Seghar, S.; Asaro, L.; Rolland-Monnet, M.; Hocine, N.A. Thermo-mechanical devulcanization and recycling of rubber industry waste. Resour. Conserv. Recycl. 2019, 144, 180–186. [Google Scholar] [CrossRef]

- Dluzneski, P.R. Peroxide vulcanization of elastomers. Rubber Chem. Technol. 2001, 74, 451–492. [Google Scholar] [CrossRef]

- El-Nemr, K.F. Effect of different curing systems on the mechanical and physico-chemical properties of acrylonitrile butadiene rubber vulcanizates. Mater. Des. 2011, 32, 3361–3369. [Google Scholar] [CrossRef]

- Valentín, J.L.; Rodríguez, A.; Marcos-Fernández, A.; González, L. Dicumyl peroxide cross-linking of nitrile rubbers with different content in acrylonitrile. J. Appl. Polym. Sci. 2005, 96, 1–5. [Google Scholar] [CrossRef]

- Ahmed, S.; Basfar, A.; Aziz, M.A. Comparison of thermal stability of sulfur, peroxide and radiation cured NBR and SBR vulcanizates. Polym. Degrad. Stab. 2000, 67, 319–323. [Google Scholar] [CrossRef]

- Rodak, A.; Susik, A.; Kowalkowska-Zedler, D.; Zedler, Ł.; Formela, K. Cross-Linking, Morphology, and Physico-Mechanical Properties of GTR/SBS Blends: Dicumyl Peroxide vs. Sulfur System. Materials 2023, 16, 2807. [Google Scholar] [CrossRef] [PubMed]

- Basfar, A.; Abdel-Aziz, M.; Mofti, S. Influence of different curing systems on the physico-mechanical properties and stability of SBR and NR rubbers. Radiat. Phys. Chem. 2002, 63, 81–87. [Google Scholar] [CrossRef]

- Ikeda, Y.; Yasuda, Y.; Hijikata, K.; Tosaka, M.; Kohjiya, S. Comparative study on strain-induced crystallization behavior of peroxide cross-linked and sulfur cross-linked natural rubber. Macromolecules 2008, 41, 5876–5884. [Google Scholar] [CrossRef]

- Kruželák, J.; Sýkora, R.; Dosoudil, R.; Hudec, I. Relationship between the cross-link structure and properties of peroxide and sulfur-cured magnetic composites based on NR and NBR. J. Elastomers Plast. 2017, 49, 459–480. [Google Scholar] [CrossRef]

- Vázquez-Martínez, Y.; Ramírez-Herrera, C.A.; Mondragón, M.; Elías-Zúñiga, A.; Elizalde, L.E. Effect of Single-Walled Carbon Nanotubes on the Cross-Linking Process in Natural Rubber Vulcanization. Polymers 2022, 15, 126. [Google Scholar] [CrossRef]

- Cong, C.; Liu, Q.; Li, J.; Meng, X.; Zhou, Q. The effect of peroxide crosslinking on the synergistic crosslink of double bond and nitrile group of nitrile rubber in H2S environment. Polym. Test. 2019, 76, 298–304. [Google Scholar] [CrossRef]

- Zedler, Ł.; Colom, X.; Cañavate, J.; Formela, K. GTR/NBR/silica composites performance properties as a function of curing system: Sulfur versus peroxides. Materials 2021, 14, 5345. [Google Scholar] [CrossRef] [PubMed]

- Zou, H.; Qiu, G.; Liu, G.; Soddemann, M.; Xu, J. A Novel Approach to Investigating Effect of Sulfur as a Coagent on the Quasi-Static and Cyclic–Dynamic Fatigue Properties of Peroxide Cured EPDM. Polym. Eng. Sci. 2020, 60, 455–463. [Google Scholar] [CrossRef]

- Ketikis, P.; Ketikis, I.; Tarantili, P.A. The effect of cross-linking system and reinforcement on the cross-linking reaction of peroxide vulcanized ethylene-propylene-diene terpolymer (EPDM) matrix. J. Macromol. Sci. A 2023, 60, 801–815. [Google Scholar] [CrossRef]

- Choi, S.S. Effect of bound rubber on characteristics of highly filled styrene–butadiene rubber compounds with different types of carbon black. J. Appl. Polym. Sci. 2004, 93, 1001–1006. [Google Scholar] [CrossRef]

- Gabriel, D.; Karbach, A.; Drechsler, D.; Gutmann, J.; Graf, K.; Kheirandish, S. Bound rubber morphology and loss tangent properties of carbon-black-filled rubber compounds. Colloid Polym. Sci. 2016, 294, 501–511. [Google Scholar] [CrossRef]

- Peidayesh, H.; Mosnáčková, K.; Špitalský, Z.; Heydari, A.; Šišková, A.O.; Chodák, I. Thermoplastic starch–based composite reinforced by conductive filler networks: Physical properties and electrical conductivity changes during cyclic deformation. Polymers 2021, 13, 3819. [Google Scholar] [CrossRef]

- Peidayesh, H.; Ahmadi, Z.; Khonakdar, H.A.; Abdouss, M.; Chodák, I. Fabrication and properties of thermoplastic starch/montmorillonite composite using dialdehyde starch as a crosslinker. Polym. Int. 2020, 69, 317–327. [Google Scholar] [CrossRef]

- Bermejo, J.S.; Ugarte, C.M. Influence of cross-linking density on the glass transition and structure of chemically cross-linked PVA: A molecular dynamics study. Macromol. Theory Simul. 2009, 18, 317–327. [Google Scholar] [CrossRef]

| Component | P1 | P2 | P3 | S3 | P3-CB20 | P3-CB35 | P3-CB50 | S3-CB20 | S3-CB35 | S3-CB50 |

|---|---|---|---|---|---|---|---|---|---|---|

| Rubber | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| CB | 0 | 0 | 0 | 0 | 20 | 35 | 50 | 20 | 35 | 50 |

| ZnO | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 3 | 3 | 3 |

| Stearic acid | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1 |

| CBS | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 1 |

| Sulfur | 0 | 0 | 0 | 3 | 0 | 0 | 0 | 3 | 3 | 3 |

| DCP | 1 | 2 | 3 | 0 | 3 | 3 | 3 | 0 | 0 | 0 |

| Sample Code | Solvent Uptake (%) | Cross-Link Density ν (mol·m–3) | Glass Transition Tg (°C) |

|---|---|---|---|

| P1 | 181 ± 14 | 658 ± 20 | −12.6 |

| P2 | 135 ± 3 | 1091 ± 16 | −7.9 |

| P3 | 109 ± 7 | 1557 ± 13 | −3.6 |

| P3-CB20 | 77 ± 2 | 2710 ± 34 | −0.6 |

| P3-CB35 | 64 ± 3 | 3621 ± 19 | −3.0 |

| P3-CB50 | 55 ± 2 | 4504 ± 7 | 2.1 |

| S3 | 170 ± 4 | 735 ± 15 | −5.0 |

| S3-CB20 | 107 ± 8 | 1619 ± 21 | −4.4 |

| S3-CB35 | 85 ± 3 | 2323 ± 14 | −2.2 |

| S3-CB50 | 71 ± 2 | 3071 ± 24 | −1.6 |

| Sample Code | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | M 100 (MPa) | M 200 (MPa) | M 300 (MPa) |

|---|---|---|---|---|---|---|

| P1 | 1.8 ± 0.1 | 179 ± 14 | 2.3 ± 0.1 | 1.3 ± 0.1 | n/a * | n/a |

| P2 | 2.0 ± 0.1 | 102 ± 7 | 3.4 ± 0.1 | 2.0 ± 0.1 | n/a | n/a |

| P3 | 2.2 ± 0.2 | 78 ± 12 | 4.4 ± 0.1 | n/a | n/a | n/a |

| P3-CB20 | 5.0 ± 1.2 | 83 ± 16 | 8.3 ± 0.8 | n/a | n/a | n/a |

| P3-CB35 | 5.9 ± 1.8 | 68 ± 16 | 12.3 ± 1.6 | n/a | n/a | n/a |

| P3-CB50 | 8.0 ± 1.3 | 65 ± 7 | 17.3 ± 2.0 | n/a | n/a | n/a |

| S3 | 2.8 ± 0.1 | 313 ± 9 | 2.4 ± 0.1 | 1.4 ± 0.0 | 1.9 ± 0.0 | 2.7 ± 0.1 |

| S3-CB20 | 13.1 ± 2.3 | 377 ± 44 | 5.8 ± 0.4 | 2.2 ± 0.1 | 4.6 ± 0.1 | 8.8 ± 0.2 |

| S3-CB35 | 19.3 ± 2.6 | 341 ± 27 | 8.8 ± 0.3 | 3.2 ± 0.2 | 8.1 ± 0.4 | 15.7 ± 0.7 |

| S3-CB50 | 21.2 ± 5.2 | 255 ± 41 | 12.1 ± 1.2 | 5.3 ± 0.2 | 14.5 ± 0.4 | n/a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peidayesh, H.; Nógellová, Z.; Chodák, I. Effects of Peroxide and Sulfur Curing Systems on Physical and Mechanical Properties of Nitrile Rubber Composites: A Comparative Study. Materials 2024, 17, 71. https://doi.org/10.3390/ma17010071

Peidayesh H, Nógellová Z, Chodák I. Effects of Peroxide and Sulfur Curing Systems on Physical and Mechanical Properties of Nitrile Rubber Composites: A Comparative Study. Materials. 2024; 17(1):71. https://doi.org/10.3390/ma17010071

Chicago/Turabian StylePeidayesh, Hamed, Zuzana Nógellová, and Ivan Chodák. 2024. "Effects of Peroxide and Sulfur Curing Systems on Physical and Mechanical Properties of Nitrile Rubber Composites: A Comparative Study" Materials 17, no. 1: 71. https://doi.org/10.3390/ma17010071

APA StylePeidayesh, H., Nógellová, Z., & Chodák, I. (2024). Effects of Peroxide and Sulfur Curing Systems on Physical and Mechanical Properties of Nitrile Rubber Composites: A Comparative Study. Materials, 17(1), 71. https://doi.org/10.3390/ma17010071