High-Strength β-Phase Magnesium–Lithium Alloy Prepared by Multidirectional Rolling

Abstract

1. Introduction

2. Material and Methods

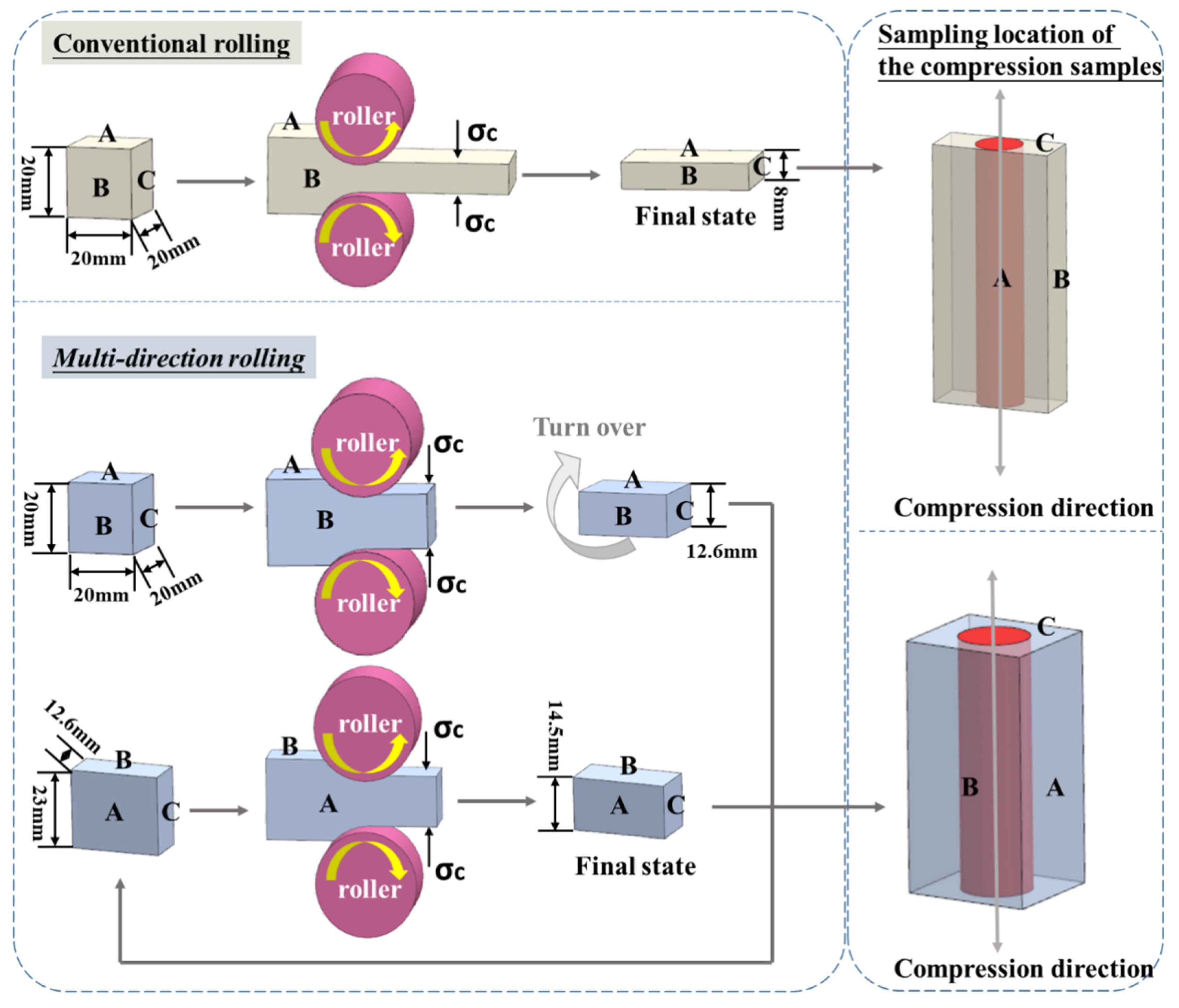

2.1. Alloy Preparation and Processing

2.2. Microstructural Characterization

2.3. Compression Test Analysis

3. Results

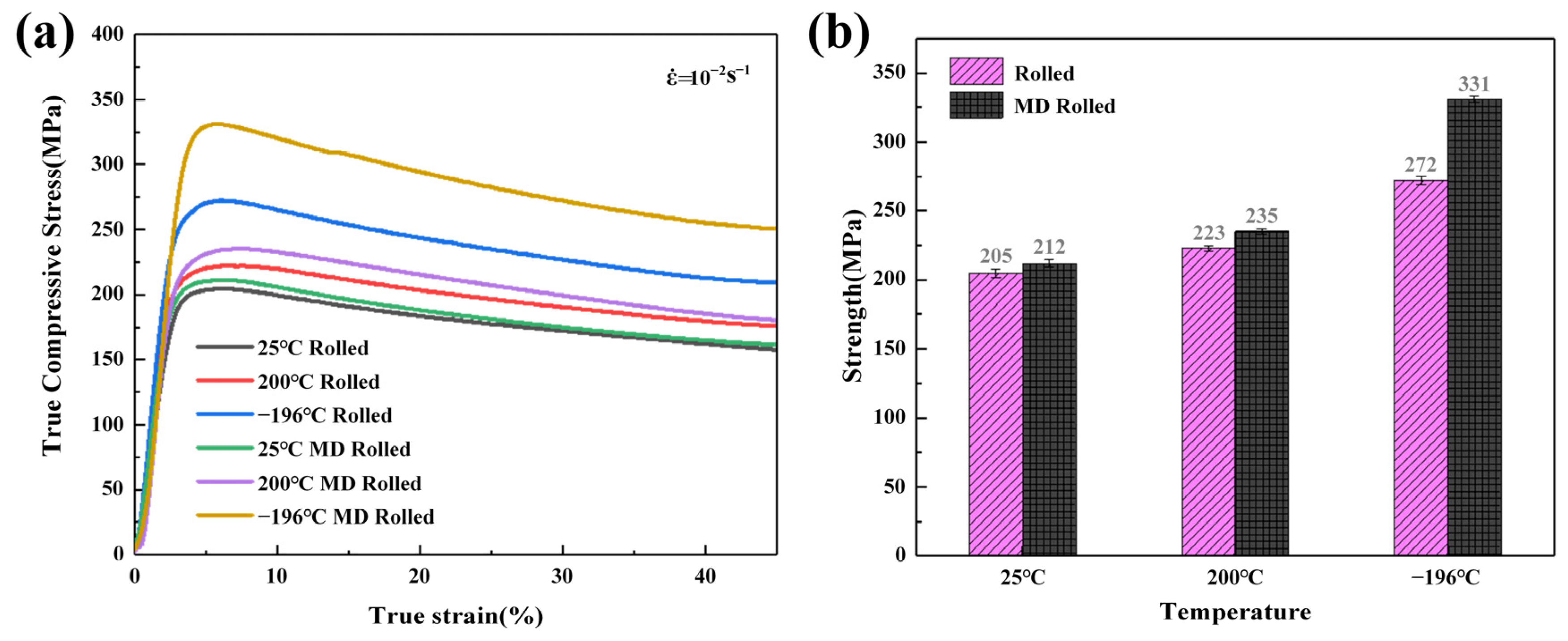

3.1. Mechanical Properties

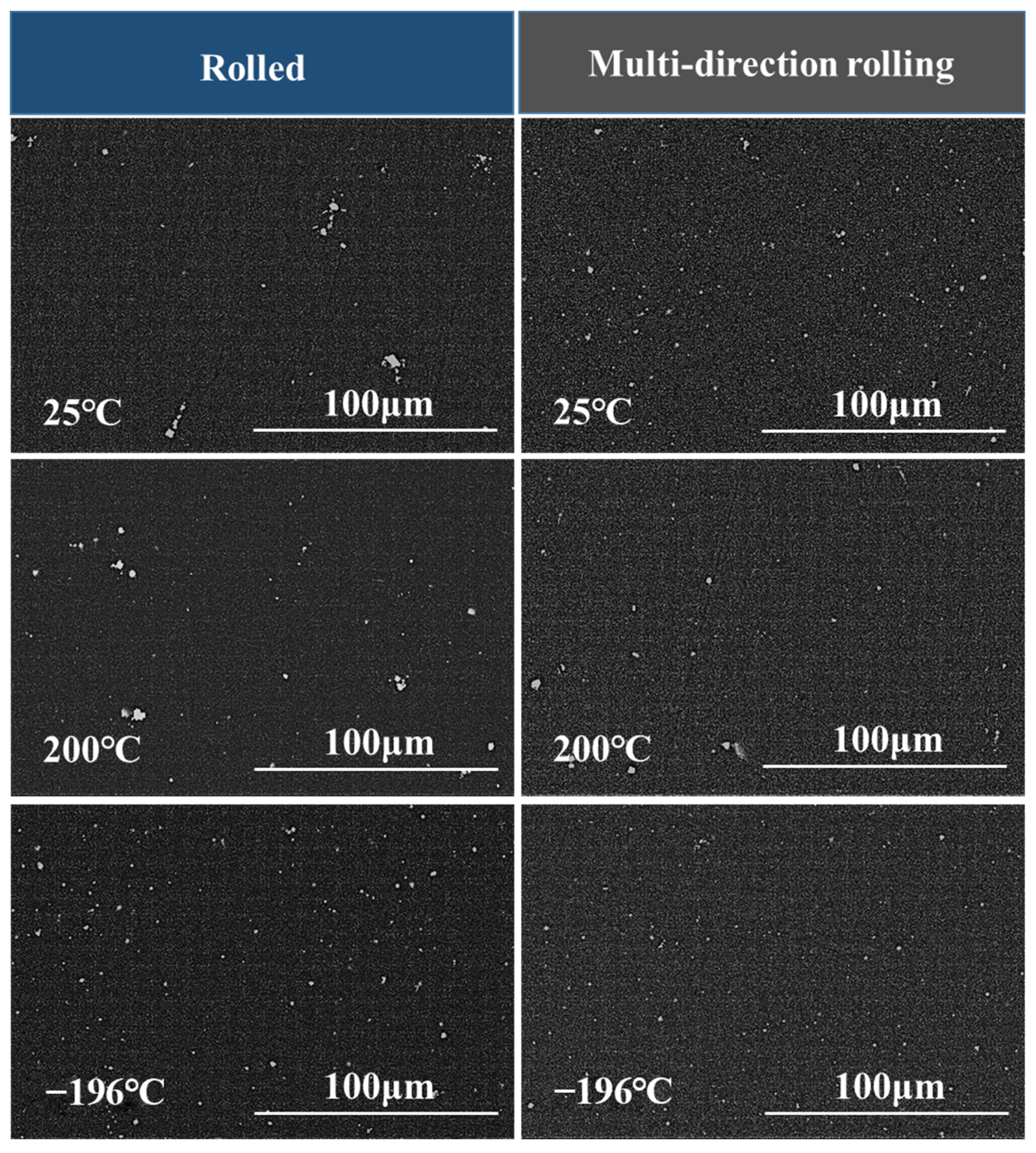

3.2. Microstructures

4. Discussion

- (1)

- The compressive strength of the alloy is proportional to the grain size. When nanoscale grains form in an alloy, the compressive strength of the alloy dramatically increases.

- (2)

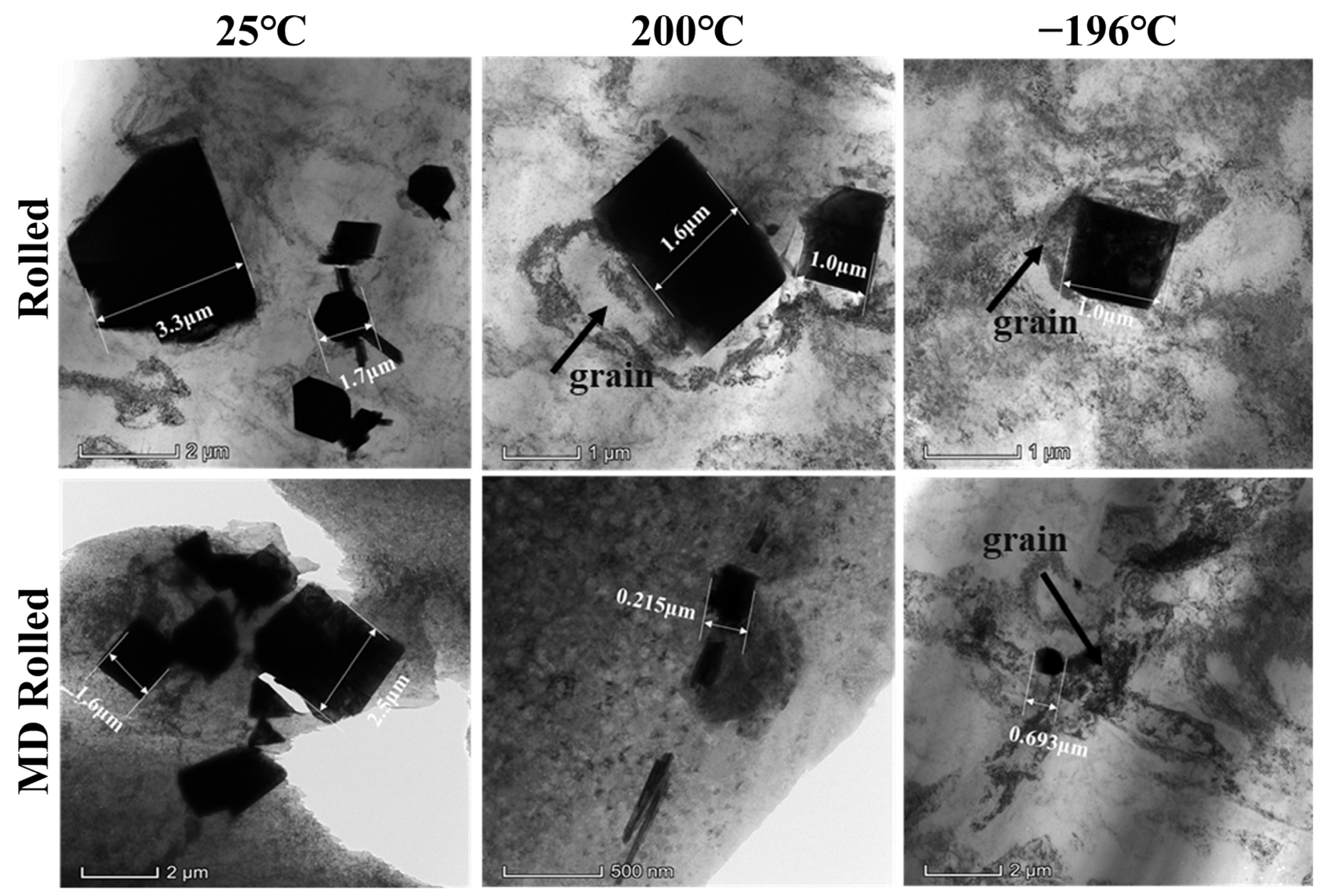

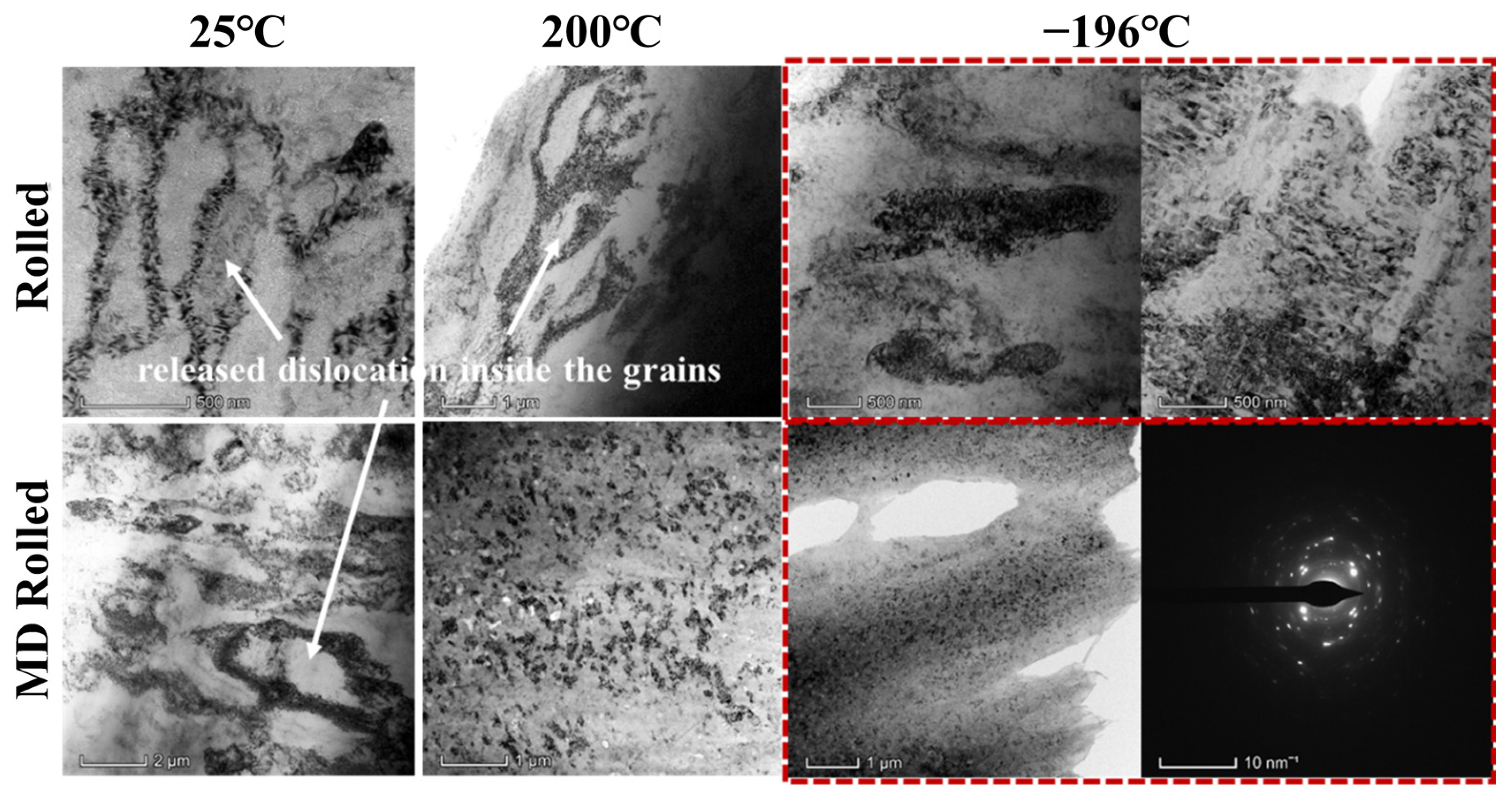

- Whether or not the dislocations inside the grains are released does not depend on the temperature or the method of deformation but only depends on the grain size. When the grain size is below a micrometer-scale level, dislocations are prevented from being released and the alloy’s strength is quite high.

4.1. The Control of Rolling Temperature on DRX Grains and Dislocations

4.1.1. Elevated Temperature

4.1.2. Cryogenic Temperature

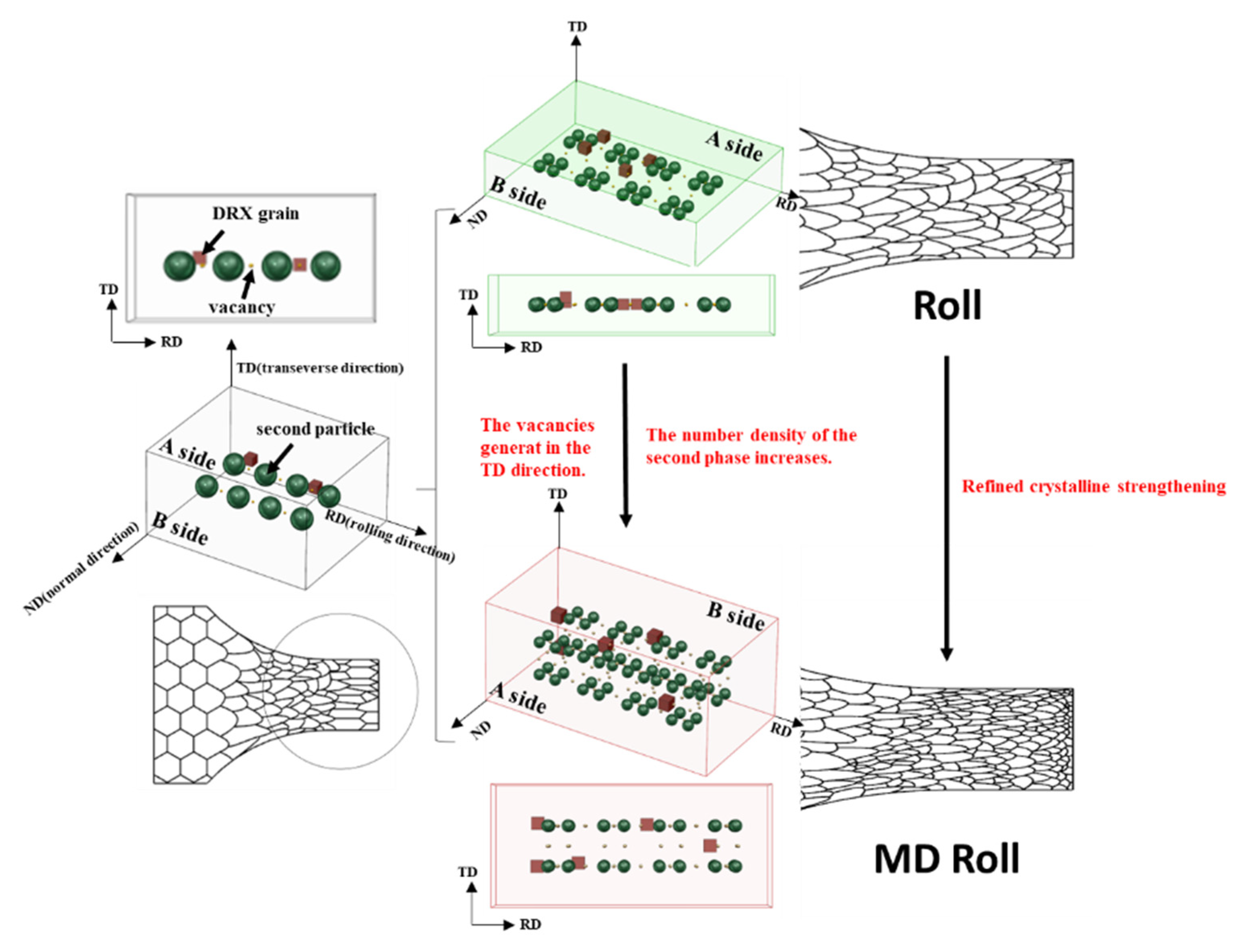

4.2. The Control of MD Rolling on DRX Grains and Dislocations

5. Conclusions

- Rolling temperature and direction can both be used to maximize the alloy strengthening effect. The alloy gained maximum strength, increasing from 204 to 331 MPa, when MD rolled at −196 °C.

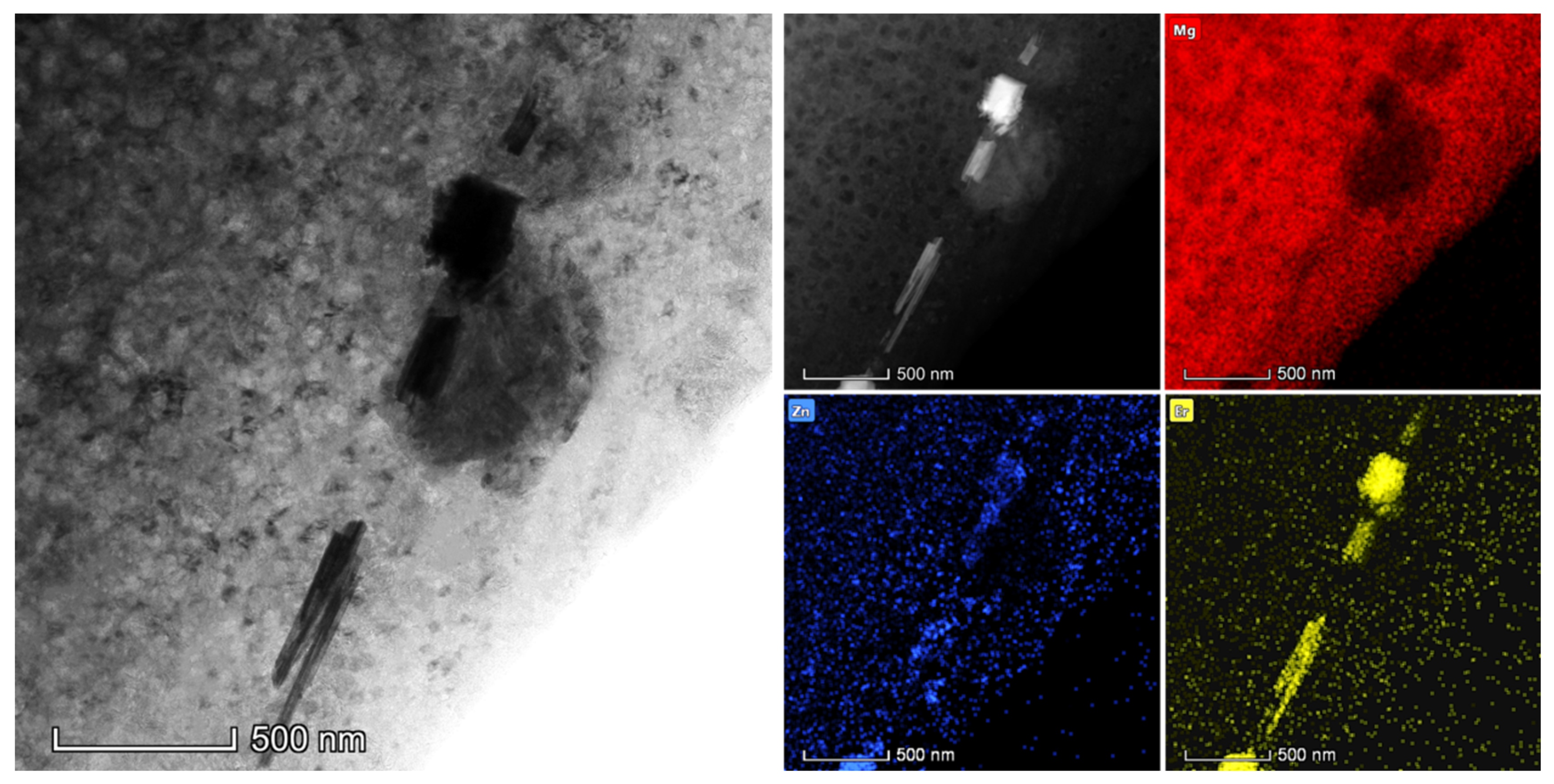

- Multidirectional rolling broke the second phase of the alloy into finer sized and more uniformly distributed pieces than conventional rolling.

- A large number of nanograins with a size of about 56 nm appeared in cryogenic multidirectional rolling. This facilitated the contribution of fine grain strengthening.

- The low temperature effectively maintained the rate of DRX while considerably reducing the DRX grain growth rate, which was far lower than the nucleation rate. The grain refinement and dislocation effects were further optimized.

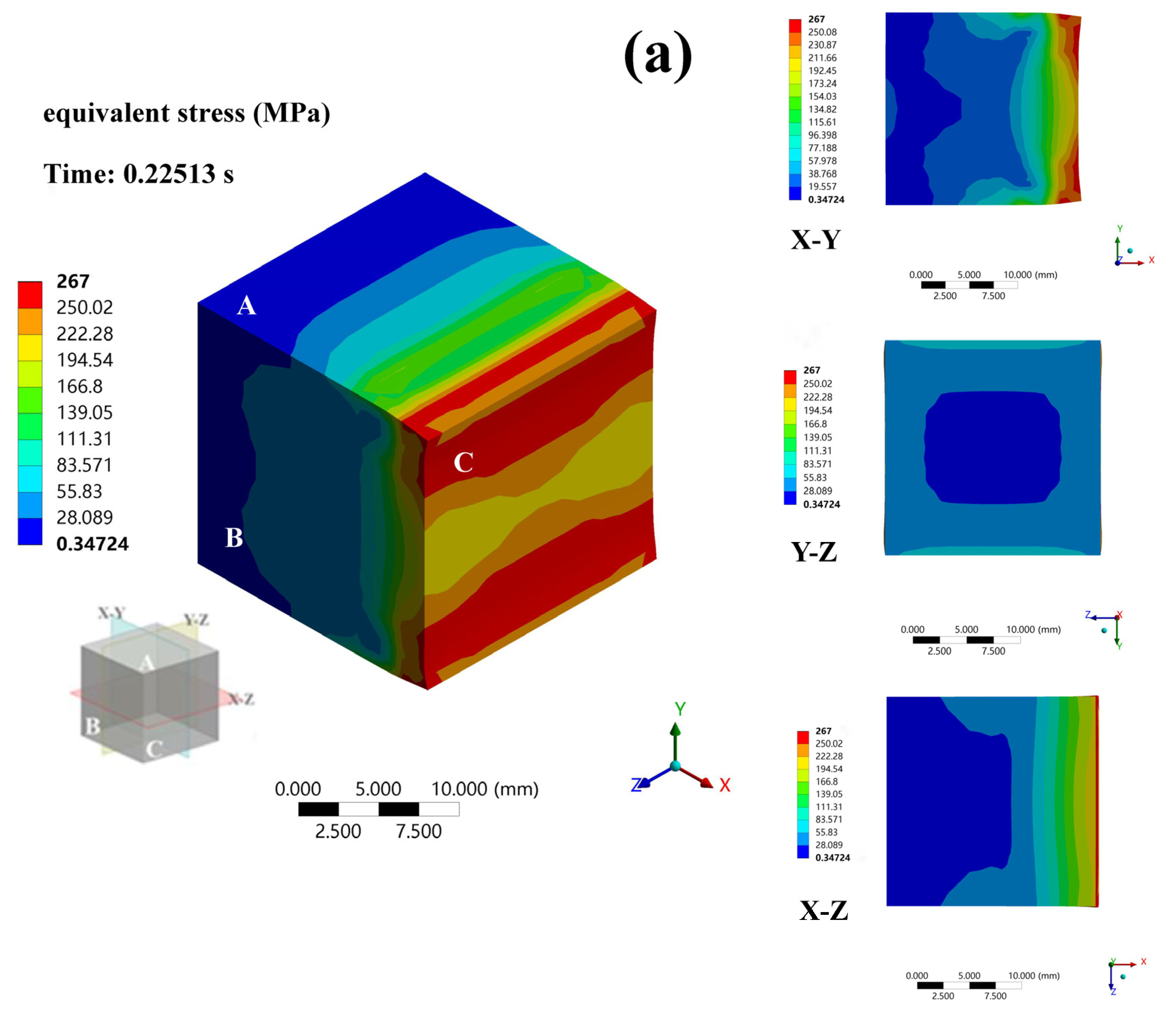

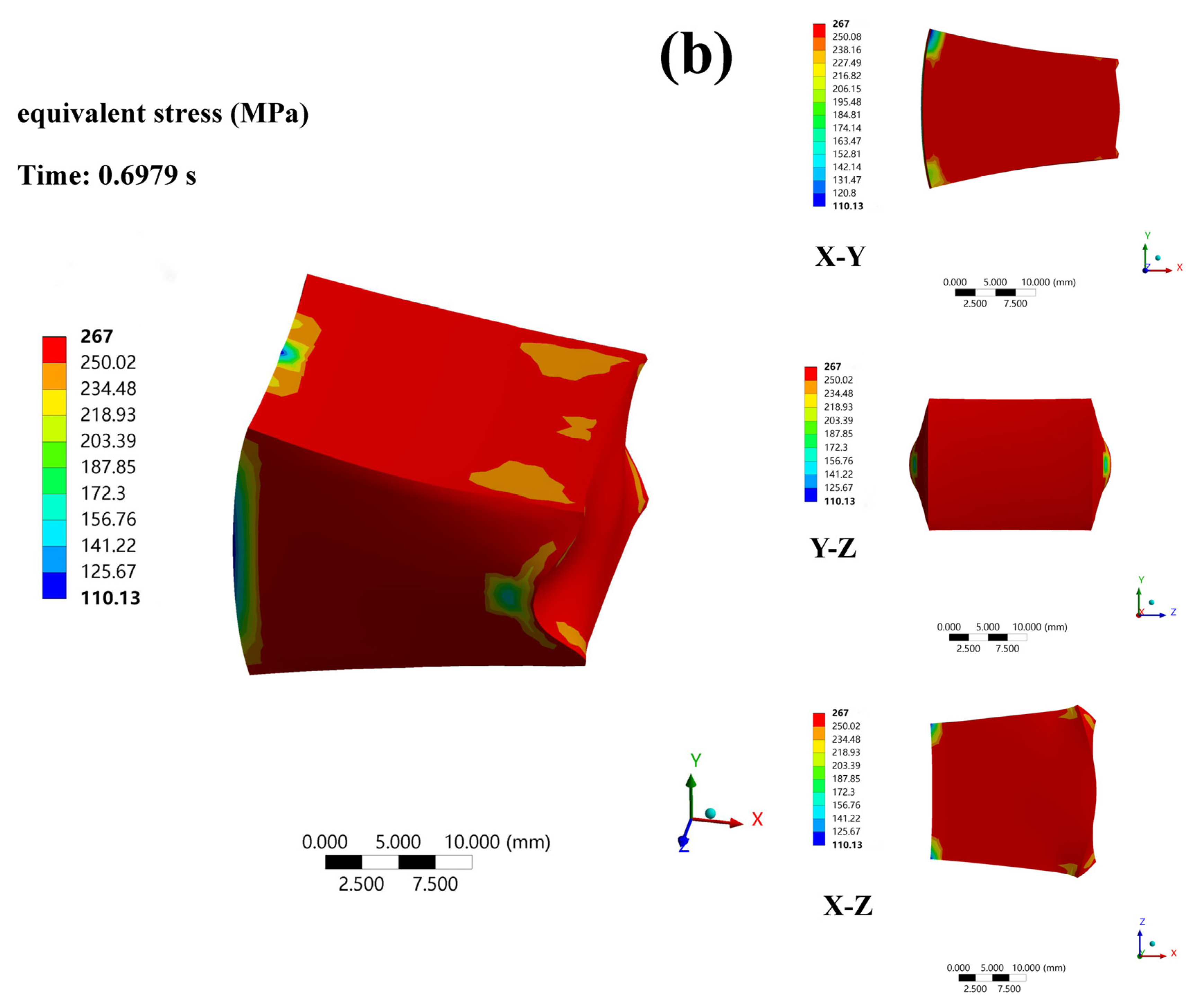

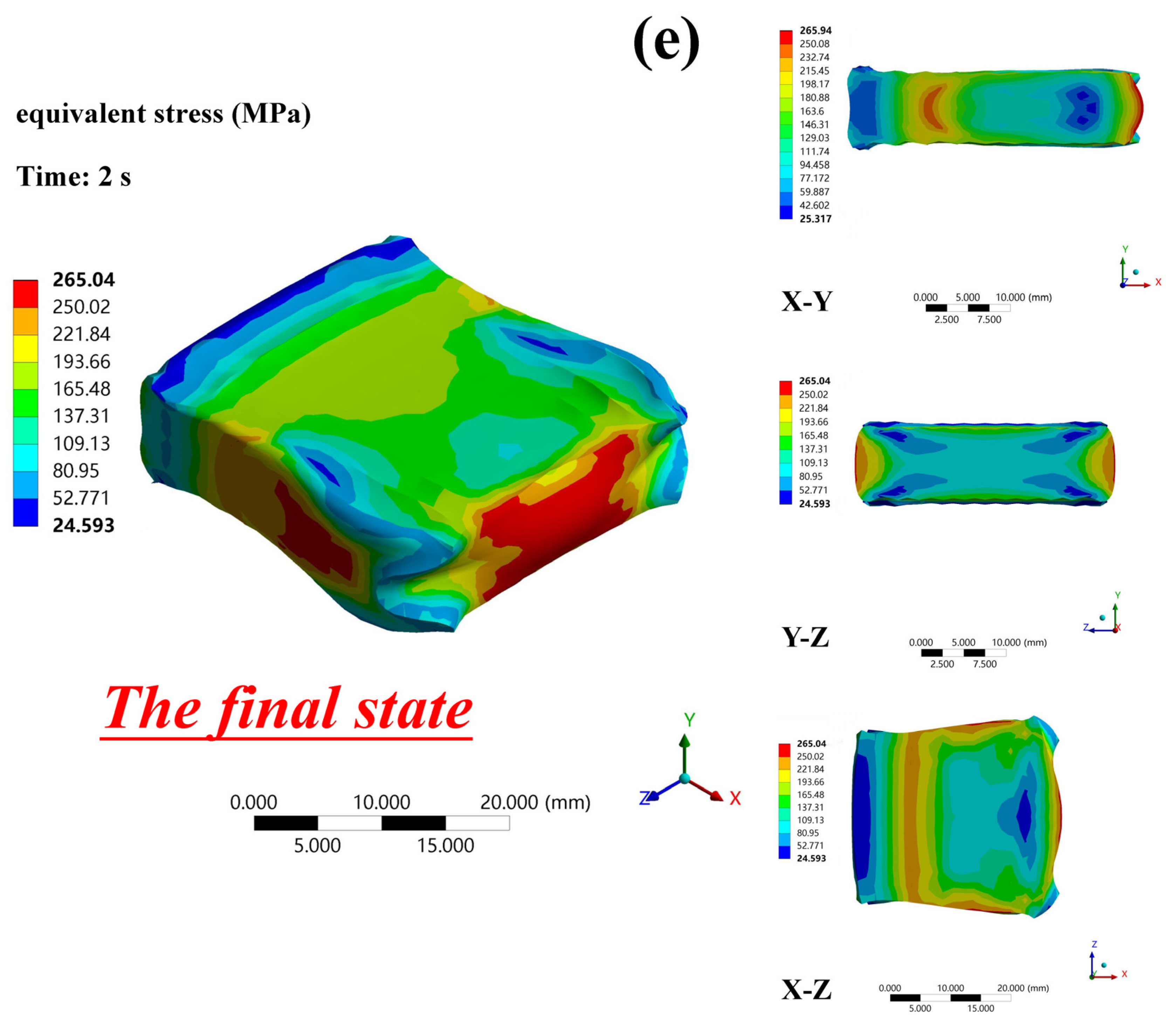

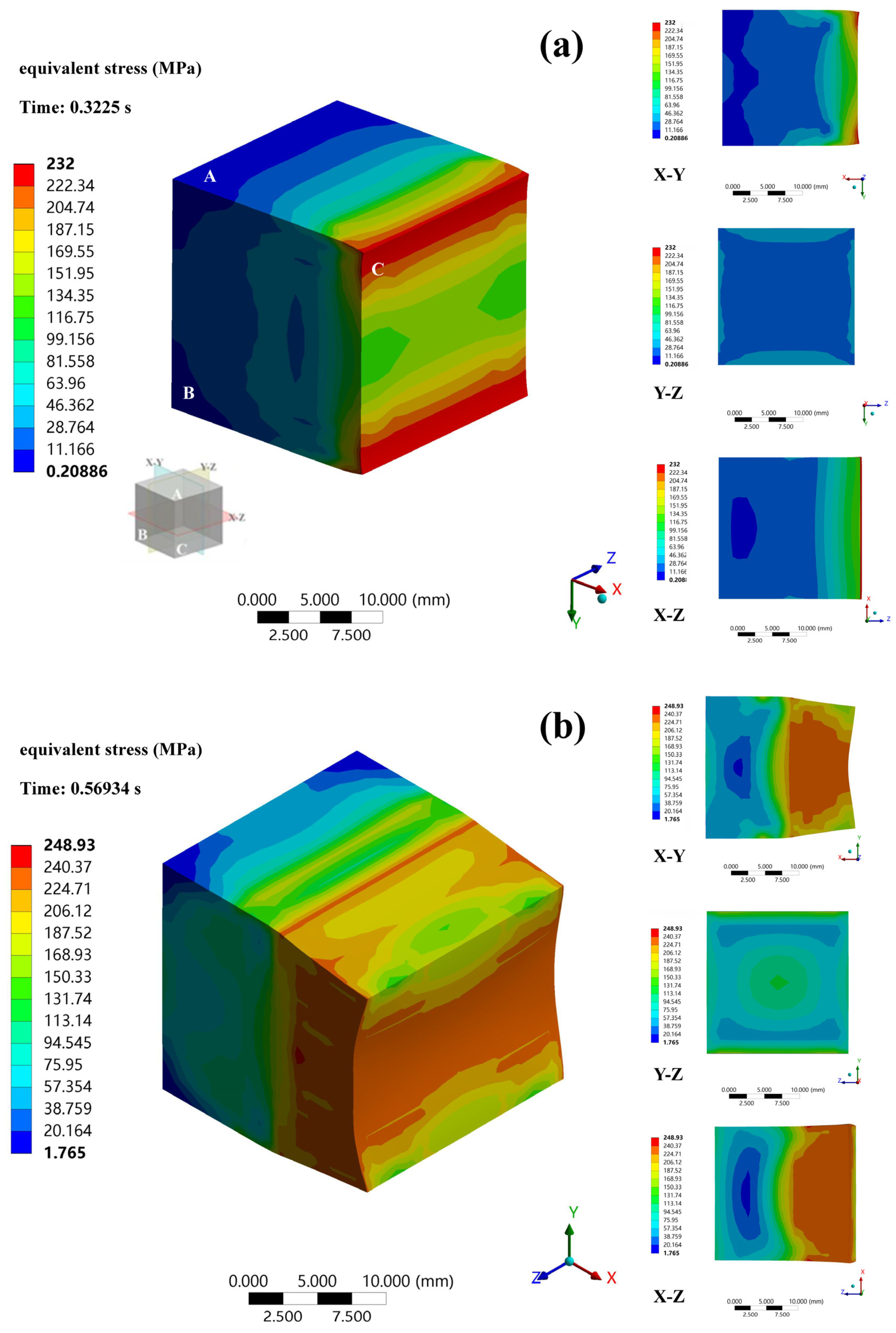

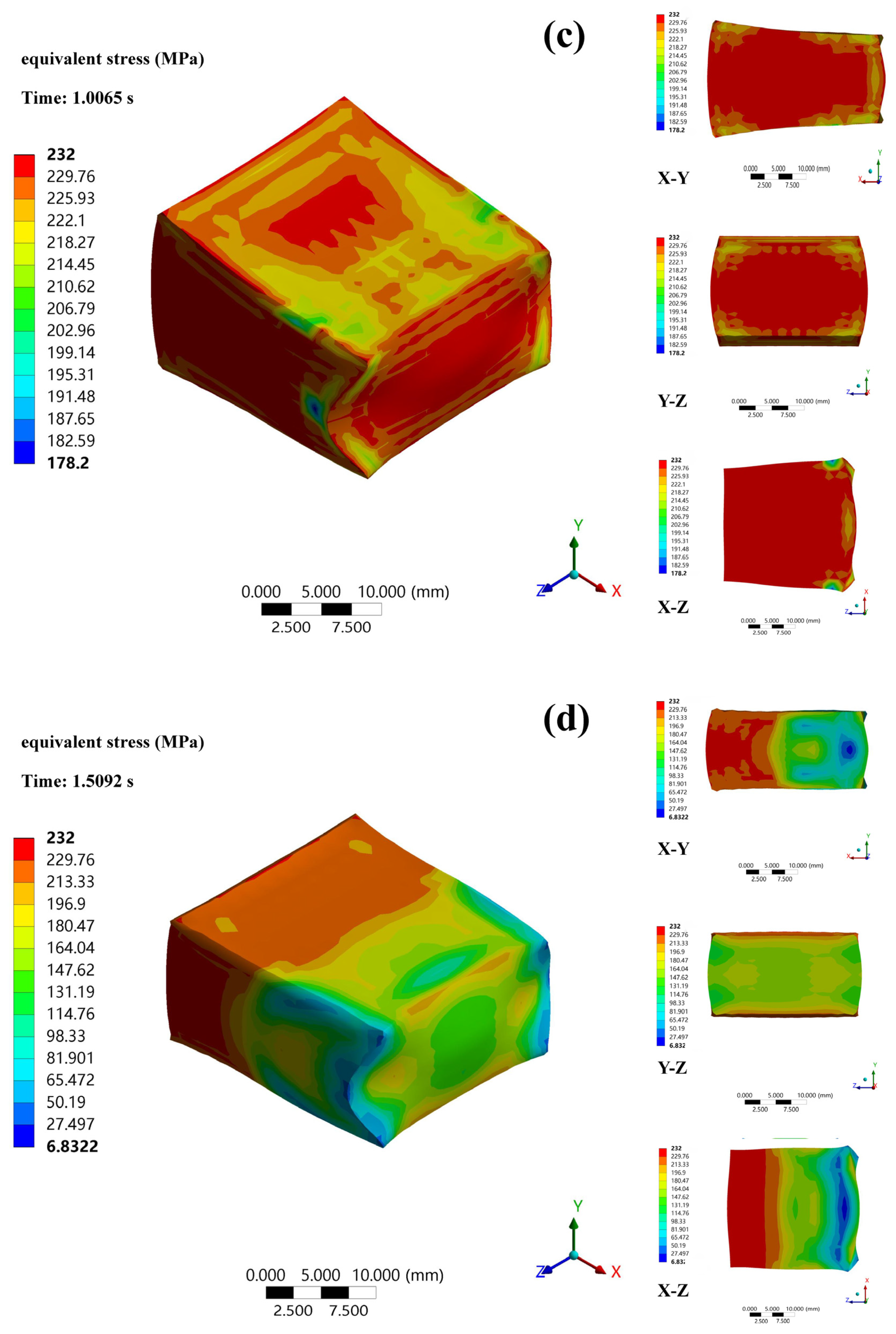

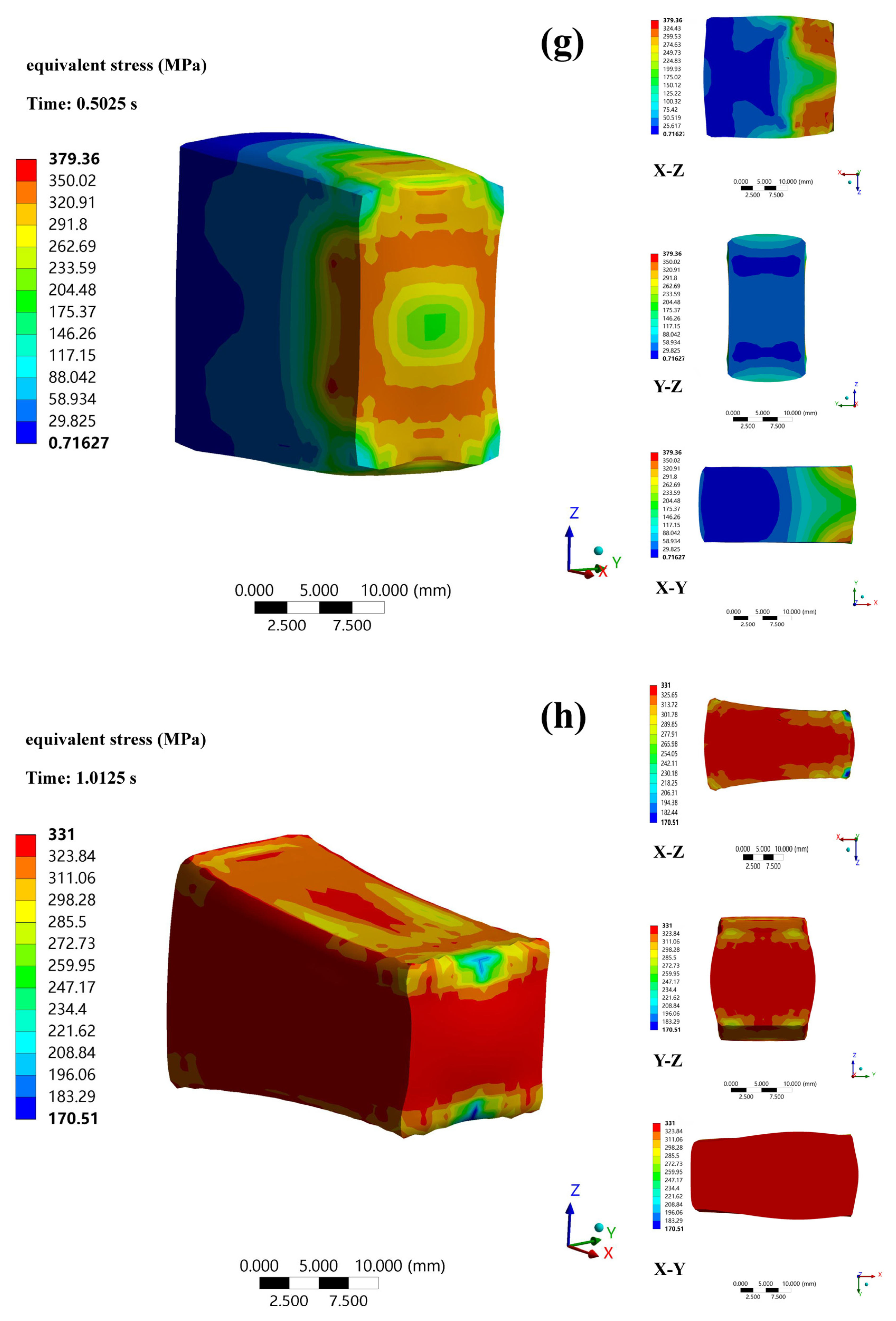

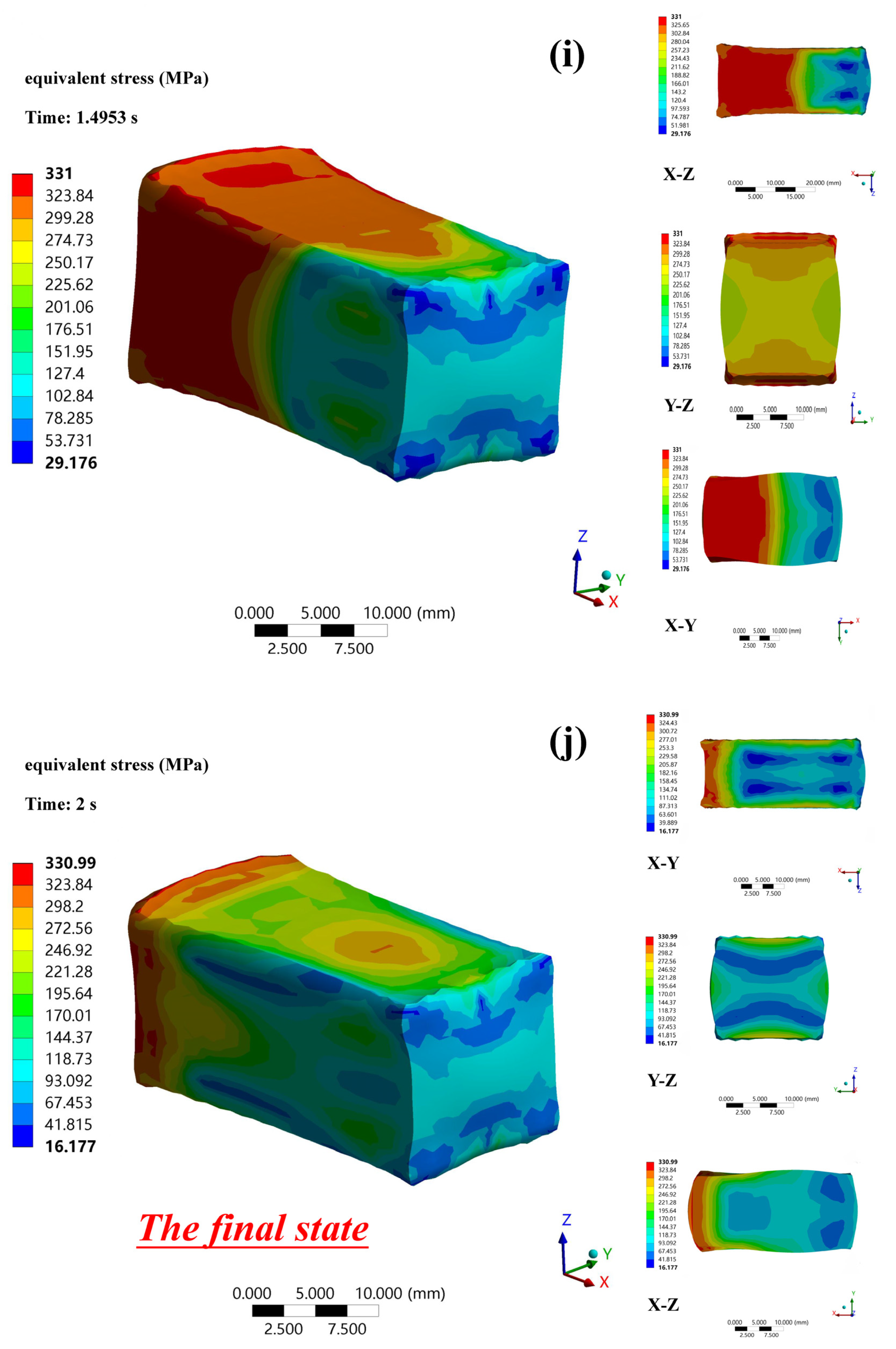

- The results of the stress analysis showed that the modification of conventional rolling to MD rolling prevented the relaxation of high-stress areas while reinforcing weak-stress areas. A small amount of force applied in the microscopic area resulted in high-efficiency stress input.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Xu, L.; Wu, R.; Feng, J.; Zhang, J.; Hou, L.; Zhang, M. Enhanced Electromagnetic Interference Shielding in a Duplex-Phase Mg–9Li–3Al–1Zn Alloy Processed by Accumulative Roll Bonding. Acta Met. Sin. Engl. 2020, 33, 490–499. [Google Scholar] [CrossRef]

- Wang, D.; Liu, S.; Wu, R.; Zhang, S.; Wang, Y.; Wu, H.; Zhang, J.; Hou, L. Synergistically improved damping, elastic modulus and mechanical properties of rolled Mg-8Li-4Y-2Er-2Zn-0.6Zr alloy with twins and long-period stacking ordered phase. J. Alloys Compd. 2021, 881, 160663. [Google Scholar] [CrossRef]

- Ma, X.-C.; Jin, S.-Y.; Wu, R.-Z.; Wang, J.-X.; Wang, G.-X.; Krit, B.; Betsofen, S. Corrosion behavior of Mg−Li alloys: A review. Trans. Nonferrous Met. Soc. 2021, 31, 3228–3254. [Google Scholar] [CrossRef]

- Srivastava, K.; El-Awady, J.A. Deformation of magnesium during c-axis compression at low temperatures. Acta Mater. 2017, 133, 282–292. [Google Scholar] [CrossRef]

- Hu, W.; Yang, Z.; Ye, H. dislocations and their interactions with other crystal defects in a Mg alloy. Acta Mater. 2017, 124, 372–382. [Google Scholar] [CrossRef]

- Somekawa, H.; Egusa, D.; Abe, E. Grain boundary plasticity in solid solution Mg–Li binary alloy. Mater. Sci. Eng. A 2020, 790, 139705. [Google Scholar] [CrossRef]

- Urtekin, L.; Arslan, R.; Bozkurt, F.; Er, U. Investigation of tribological and mechanical properties of biodegradable AZ91 alloy produced by cold chamber high pressure casting method. Arch. Metall. Mater. 2021, 66, 205–216. [Google Scholar]

- Jin, S.; Ma, X.; Wu, R.; Li, T.; Wang, J.; Krit, B.L.; Hou, L.; Zhang, J.; Wang, G. Effect of carbonate additive on the microstructure and corrosion resistance of plasma electrolytic oxidation coating on Mg-9Li-3Al alloy. Int. J. Miner. Met. Mater. 2022, 29, 1453–1463. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, X.; Wu, R.; Ji, Q.; Zhong, F.; Wang, X. Effect of Sn alloying and cold rolling on microstructure and mechanical properties of Mg 14Li alloy. Mater. Charact. 2021, 182, 111491. [Google Scholar] [CrossRef]

- Zeng, Y.; Jiang, B.; Yang, Q.; Quan, G.; He, J.; Jiang, Z.; Pan, F. Effect of Li content on microstructure, texture and mechanical behaviors of the as-extruded Mg-Li sheets. Mater. Sci. Eng. A 2017, 700, 59–65. [Google Scholar] [CrossRef]

- Li, C.; He, Y.; Huang, H. Effect of lithium content on the mechanical and corrosion behaviors of HCP binary Mg–Li alloys. J. Magnes. Alloys 2020, 9, 569–580. [Google Scholar] [CrossRef]

- Tang, Y.; Le, Q.; Misra, R.; Su, G.; Cui, J. Influence of extruding temperature and heat treatment process on microstructure and mechanical properties of three structures containing Mg-Li alloy bars. Mater. Sci. Eng. A 2018, 712, 266–280. [Google Scholar] [CrossRef]

- Mineta, T.; Sato, H. Simultaneously improved mechanical properties and corrosion resistance of Mg-Li-Al alloy produced by severe plastic deformation. Mater. Sci. Eng. A 2018, 735, 418–422. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Okotete, E.A. Recrystallization mechanisms and microstructure development in emerging metallic materials: A review. J. Sci. Adv. Mater. Devices 2018, 4, 19–33. [Google Scholar] [CrossRef]

- Liu, X.; Du, G.; Wu, R.; Niu, Z.; Zhang, M. Deformation and microstructure evolution of a high strain rate superplastic Mg–Li–Zn alloy. J. Alloys Compd. 2011, 509, 9558–9561. [Google Scholar] [CrossRef]

- Da Huo, P.; Li, F.; Wang, Y.; Wu, R.Z.; Gao, R.H.; Zhang, A.X. Annealing coordinates the deformation of shear band to improve the microstructure difference and simultaneously promote the strength-plasticity of composite plate. Mater. Des. 2022, 219, 110696. [Google Scholar] [CrossRef]

- Qin, S.; Lee, S.; Tsuchiya, T.; Matsuda, K.; Horita, Z.; Kocisko, R.; Kvackaj, T. Aging behavior of Al-Li-(Cu, Mg) alloys processed by different deformation methods. Mater. Des. 2020, 196, 109139. [Google Scholar] [CrossRef]

- Ji, Q.; Ma, X.; Wu, R.; Jin, S.; Zhang, J.; Hou, L. BCC-Based Mg–Li Alloy with Nano-Precipitated MgZn2 Phase Prepared by Multidirectional Cryogenic Rolling. Metals 2022, 12, 2114. [Google Scholar] [CrossRef]

- Ji, Q.; Wang, Y.; Wu, R.; Wei, Z.; Ma, X.; Zhang, J.; Hou, L.; Zhang, M. High specific strength Mg-Li-Zn-Er alloy processed by multi deformation processes. Mater. Charact. 2020, 160, 110135. [Google Scholar] [CrossRef]

- Lv, B.J.; Peng, J.; Wang, Y.J.; An, X.Q.; Zhong, L.P.; Tang, A.T.; Pan, F.S. Dynamic recrystallization behavior and hot workability of Mg-2.0Zn-0.3Zr-0.9Y alloy by using hot compression test. Mater. Design 2014, 53, 357–365. [Google Scholar] [CrossRef]

- Liu, G.; Xie, W.; Wei, G.; Yang, Y.; Liu, J.; Xu, T.; Xie, W.; Peng, X. Dynamic Recrystallization Behavior and Corrosion Resistance of a Dual-Phase Mg-Li Alloy. Materials 2018, 11, 408. [Google Scholar] [CrossRef] [PubMed]

- Urtekin, L.; Özerkan, H.B.; Cogun, C.; Genc, A.; Esen, Z.; Bozkurt, F. Experimental Investigation on Wire Electric Discharge Machining of Biodegradable AZ91 Mg Alloy. J. Mater. Eng. Perform. 2021, 30, 7752–7761. [Google Scholar] [CrossRef]

- Fjeldberg, E.; Marthinsen, K. A 3D Monte Carlo study of the effect of grain boundary anisotropy and particles on the size distribution of grains after recrystallisation and grain growth. Comput. Mater. Sci. 2010, 48, 267–281. [Google Scholar] [CrossRef]

- Watanabe, T.; Tsurekawa, S.; Kobayashi, S.; Yamaura, S.-I. Structure-dependent grain boundary deformation and fracture at high temperatures. Mater. Sci. Eng. A 2005, 410, 140–147. [Google Scholar] [CrossRef]

- Kacher, J.; Eftink, B.; Cui, B.; Robertson, I. Dislocation interactions with grain boundaries. Curr. Opin. Solid State Mater. Sci. 2014, 18, 227–243. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, S.; Xu, C.-S.; Zeng, X.-S.; Yang, X.-J. Effect of cryogenic treatment on the microstructure and mechanical properties of Mg-1.5Zn-0.15Gd magnesium alloy. Mater. Sci. Eng. A 2013, 588, 76–81. [Google Scholar] [CrossRef]

- He, T.; Feng, M. Combined effects of cooperative grain boundary sliding and migration and reinforced particles on crack growth in fine-grained Mg alloys. J. Alloys Compd. 2018, 749, 705–714. [Google Scholar] [CrossRef]

- Mohapatra, S.; Prasad, R.; Jain, J. Temperature dependence of abnormal grain growth in pure magnesium. Mater. Lett. 2020, 283, 128851. [Google Scholar] [CrossRef]

- Fu, Y.; Cheng, Y.; Cui, Y.; Xin, Y.; Shi, S.; Chen, G. Deformation mechanisms and differential work hardening behavior of AZ31 magnesium alloy during biaxial deformation. J. Magnes. Alloys 2020, 10, 478–491. [Google Scholar] [CrossRef]

- Liu, H.M.; Zheng, Z.Z.; Peng, Y. Streamline strip element method for analysis of the three-dimensional stresses and deformations of strip rolling. Int. J. Numer. Meth. Eng. 2001, 50, 1059–1076. [Google Scholar]

- Liu, H.-M.; Lian, J.-C.; Peng, Y. Third-power spline function strip element method and its simulation of the three-dimensional stresses and deformations of cold strip rolling. J. Mater. Process. Technol. 2001, 116, 235–243. [Google Scholar] [CrossRef]

- Luo, C.; Ståhlberg, U. Deformation of inclusions during hot rolling of steels. J. Mater. Process. Technol. 2001, 114, 87–97. [Google Scholar] [CrossRef]

- Guo, Y.; Collins, D.M.; Tarleton, E.; Hofmann, F.; Wilkinson, A.J.; Ben Britton, T. Dislocation density distribution at slip band-grain boundary intersections. Acta Mater. 2019, 182, 172–183. [Google Scholar] [CrossRef]

- Guan, D.; Rainforth, W.M.; Gao, J.; Ma, L.; Wynne, B. Individual effect of recrystallisation nucleation sites on texture weakening in a magnesium alloy: Part 2—Shear bands. Acta Mater. 2018, 145, 399–412. [Google Scholar] [CrossRef]

- Feng, D.; Zhang, X.M.; Liu, S.D.; Deng, Y.L. Constitutive equation and hot deformation behavior of homogenized Al–7.68Zn–2.12Mg–1.98Cu–0.12Zr alloy during compression at elevated temperature. Mater. Sci. Eng. A. 2014, 608, 63–72. [Google Scholar] [CrossRef]

- Huang, K.; Logé, R. A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 2016, 111, 548–574. [Google Scholar] [CrossRef]

- Sangid, M.D.; Ezaz, T.; Sehitoglu, H.; Robertson, I.M. Energy of slip transmission and nucleation at grain boundaries. Acta Mater. 2011, 59, 283–296. [Google Scholar] [CrossRef]

- Li, J.; Qu, Z.; Wu, R.; Zhang, M. Effects of Cu addition on the microstructure and hardness of Mg-5Li-3Al-2Zn alloy. Acta Mater. 2010, 527, 2780–2783. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Ji, Q.; Wu, R.; Jia, H.; An, D.; Ma, X.; Jin, S.; Li, J.; Liu, J.; Wu, H.; et al. High-Strength β-Phase Magnesium–Lithium Alloy Prepared by Multidirectional Rolling. Materials 2023, 16, 3227. https://doi.org/10.3390/ma16083227

Guo Z, Ji Q, Wu R, Jia H, An D, Ma X, Jin S, Li J, Liu J, Wu H, et al. High-Strength β-Phase Magnesium–Lithium Alloy Prepared by Multidirectional Rolling. Materials. 2023; 16(8):3227. https://doi.org/10.3390/ma16083227

Chicago/Turabian StyleGuo, Zhengyou, Qing Ji, Ruizhi Wu, Haoyang Jia, Di An, Xiaochun Ma, Siyuan Jin, Jiarui Li, Jinyang Liu, Huajie Wu, and et al. 2023. "High-Strength β-Phase Magnesium–Lithium Alloy Prepared by Multidirectional Rolling" Materials 16, no. 8: 3227. https://doi.org/10.3390/ma16083227

APA StyleGuo, Z., Ji, Q., Wu, R., Jia, H., An, D., Ma, X., Jin, S., Li, J., Liu, J., Wu, H., Zhang, J., & Hou, L. (2023). High-Strength β-Phase Magnesium–Lithium Alloy Prepared by Multidirectional Rolling. Materials, 16(8), 3227. https://doi.org/10.3390/ma16083227