Investigation of MAF for Finishing the Inner Wall of Super-Slim Cardiovascular Stents Tube

Abstract

:1. Introduction

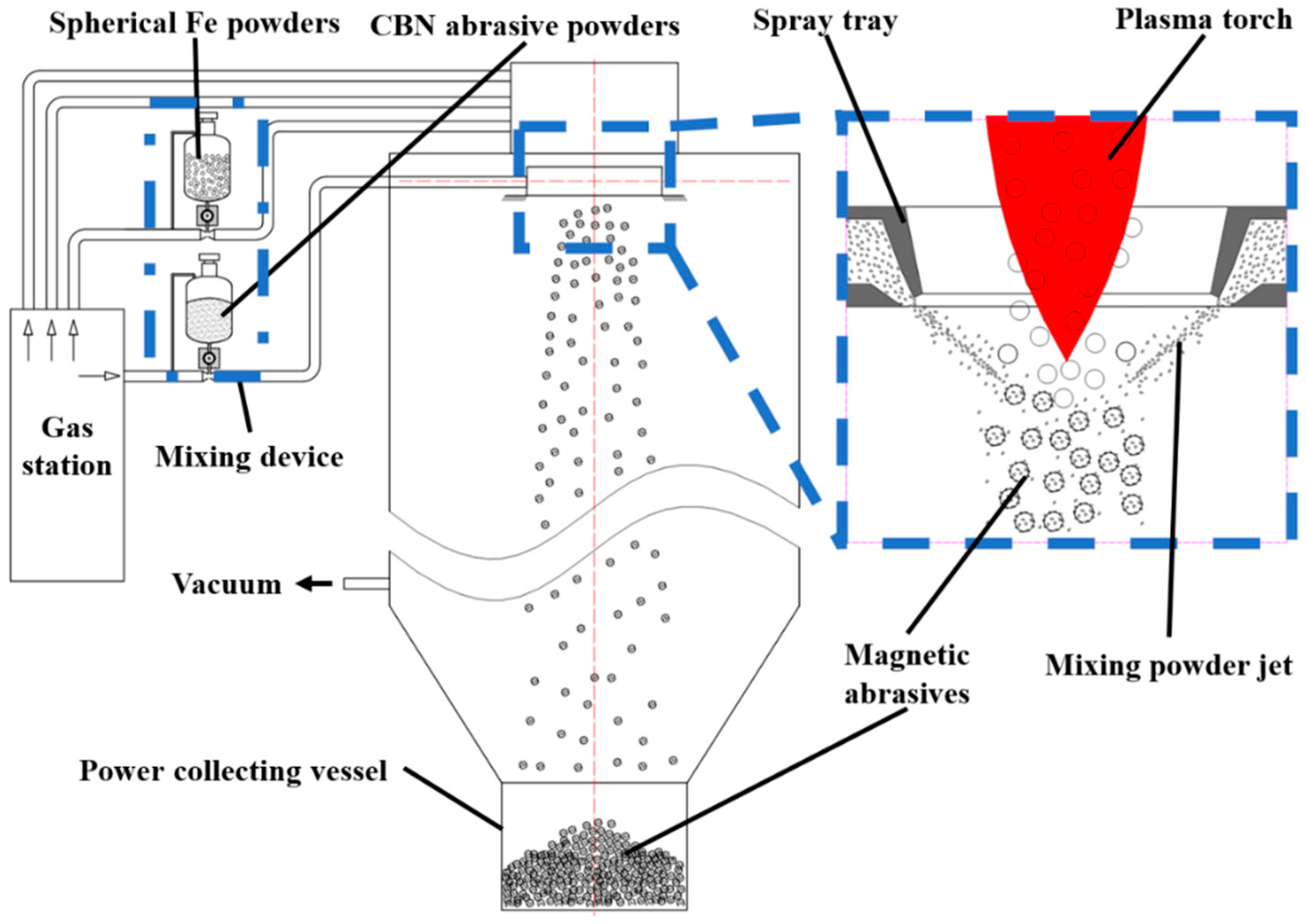

2. Spherical CBN Magnetic Abrasive Preparation Experiment

2.1. Principle of Magnetic Abrasive Preparation

2.2. Magnetic Abrasive Preparation Experiment

3. Spherical CBN Magnetic Abrasives Characterization

Microscopic Morphology of Spherical CBN Magnetic Abrasives

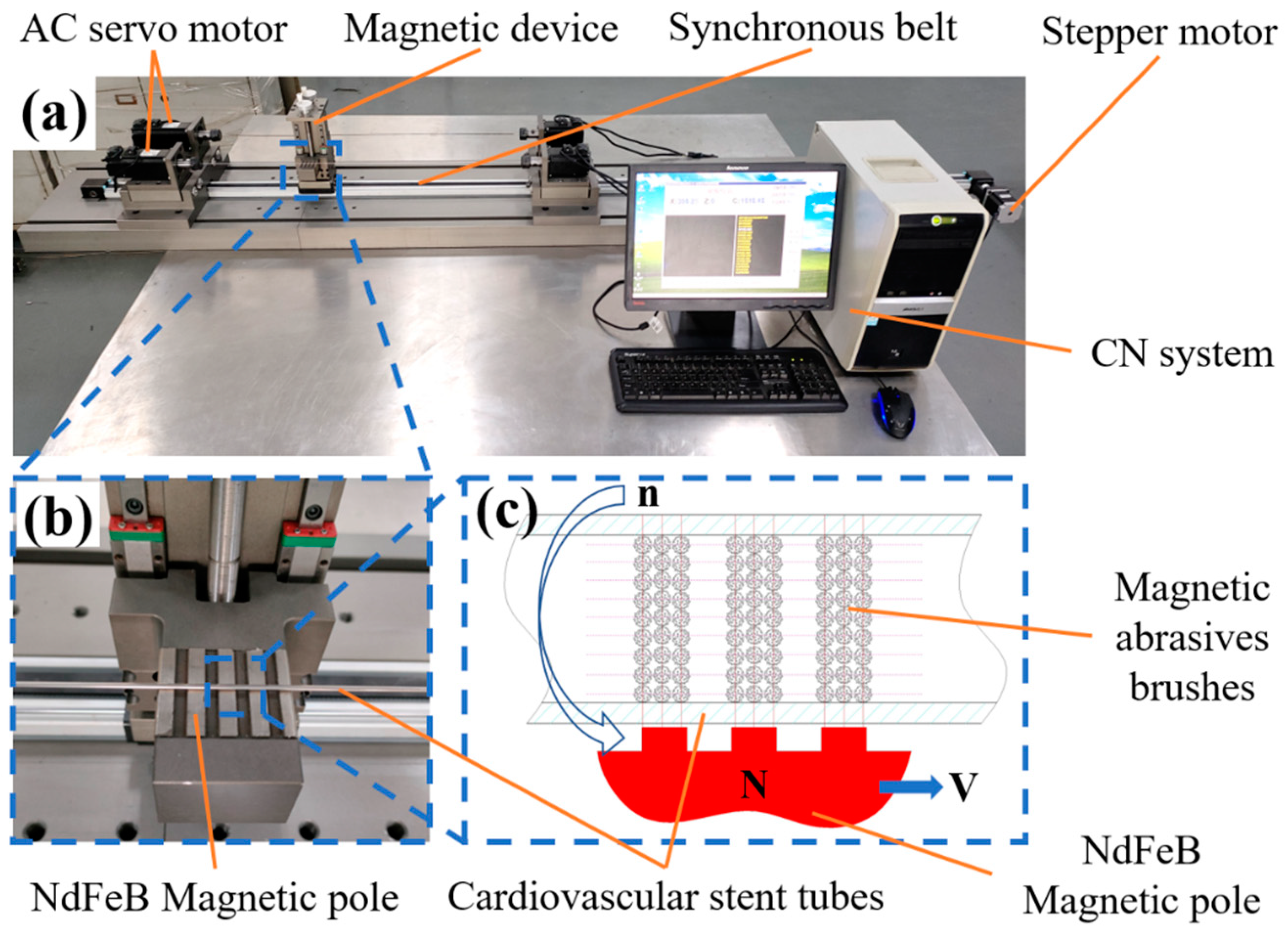

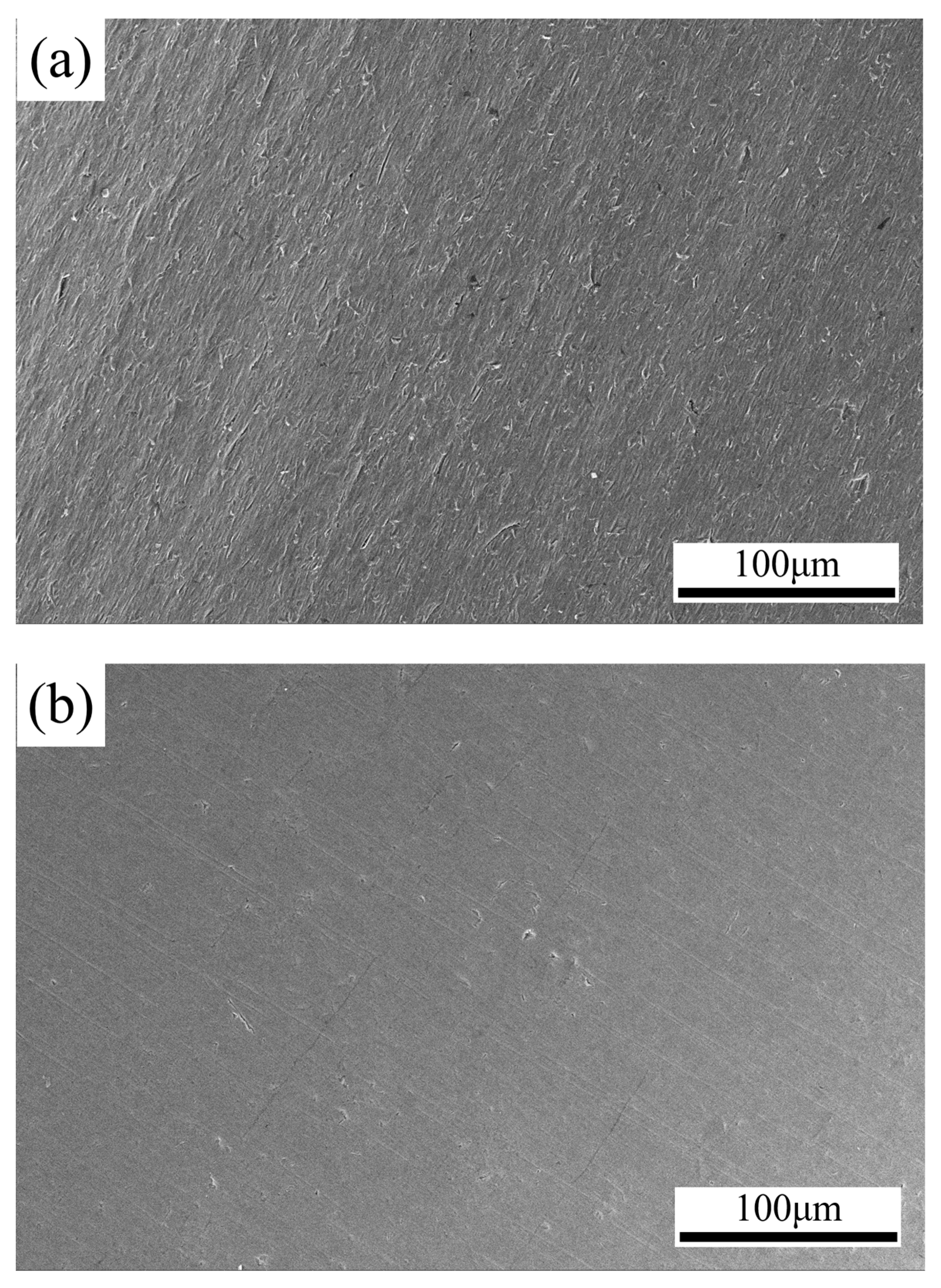

4. Cardiovascular Stent Tube Inner Wall Defect Layer Removal Test

4.1. Principle and Equipment for Magnetic Particle Lithography of the Inner Wall of Vascular Stents

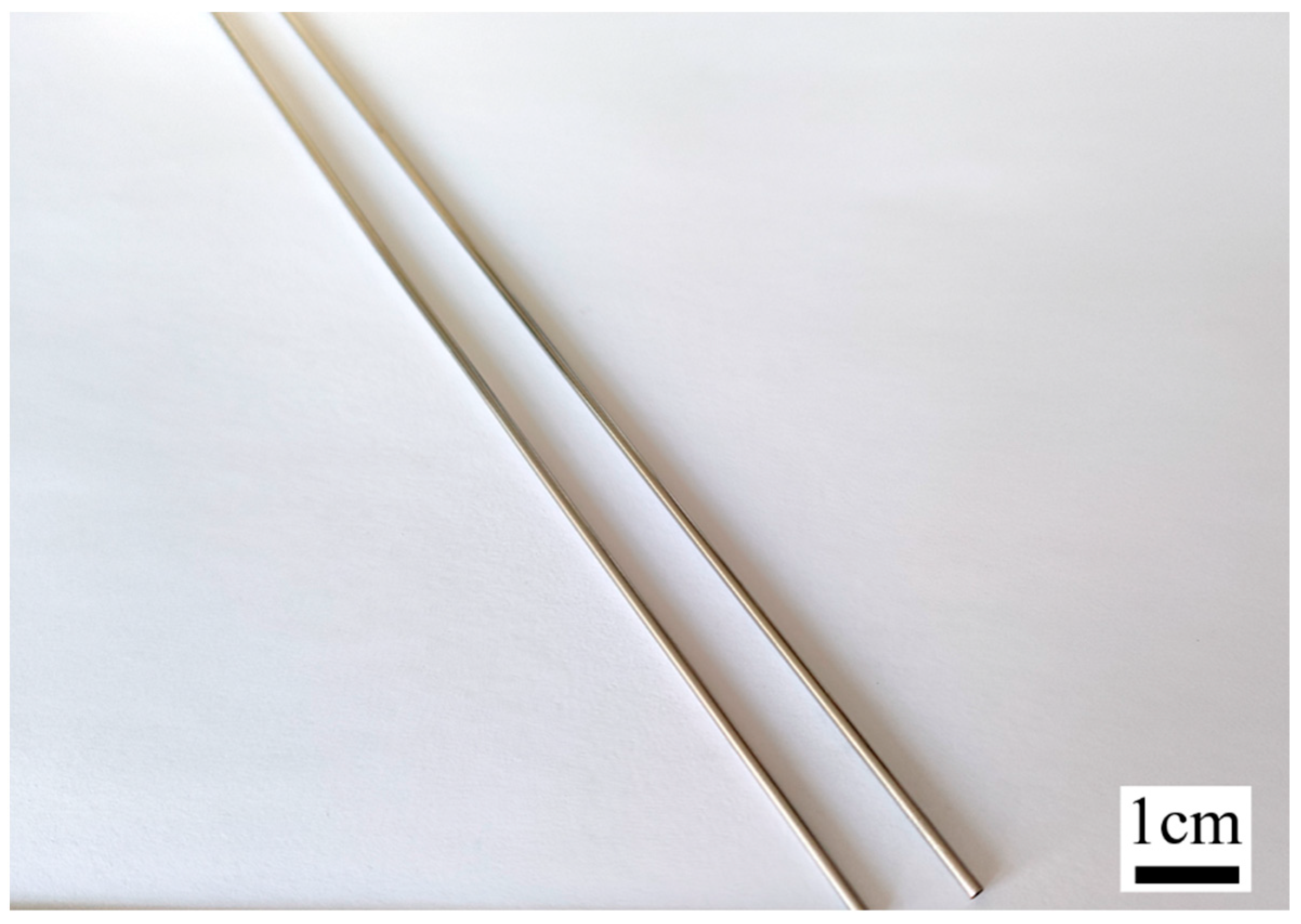

4.2. Experimental Cardiovascular Stent Tube

5. Response Surface Method Process Parameter Optimization

5.1. Experimental Design and Results

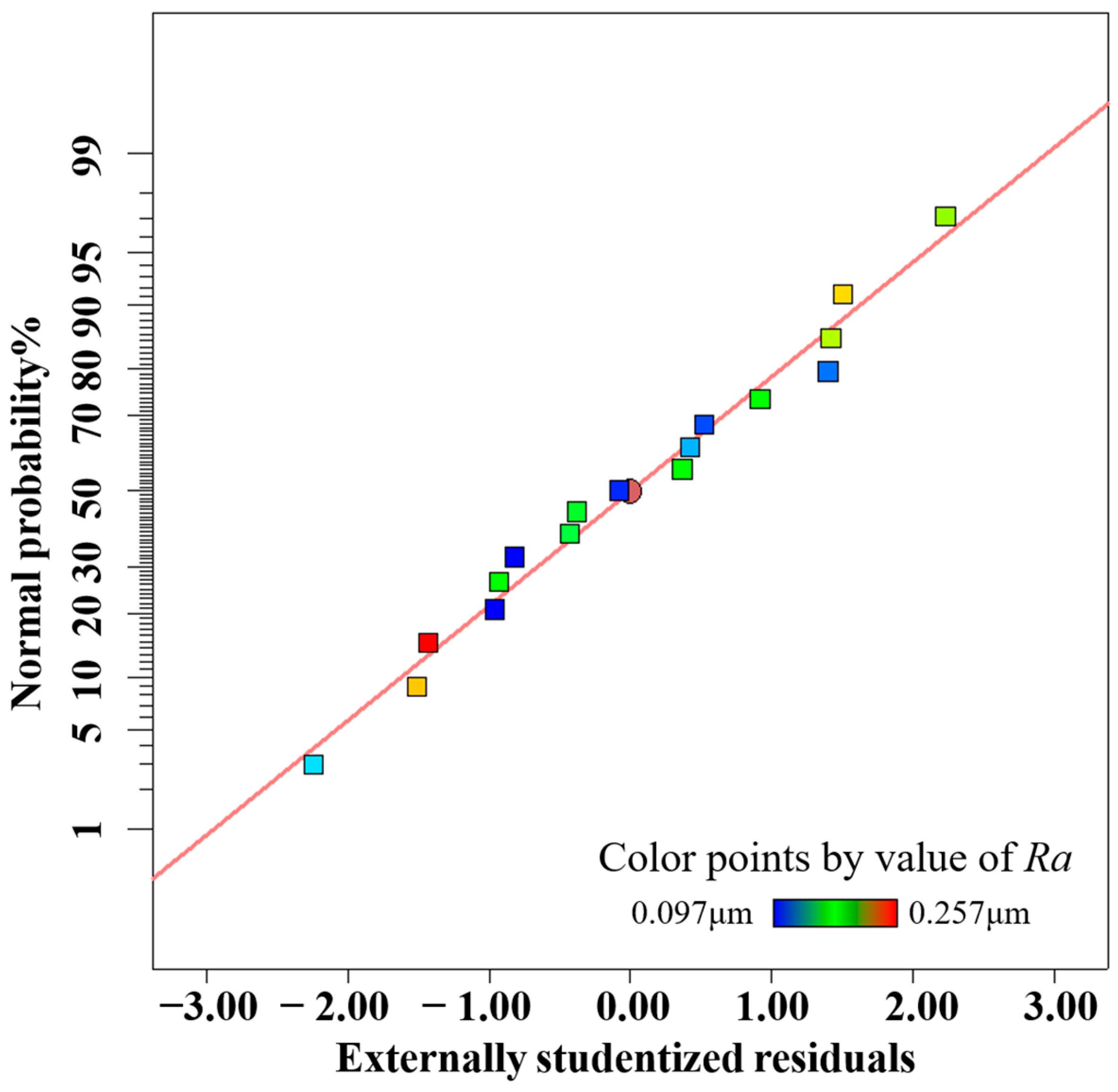

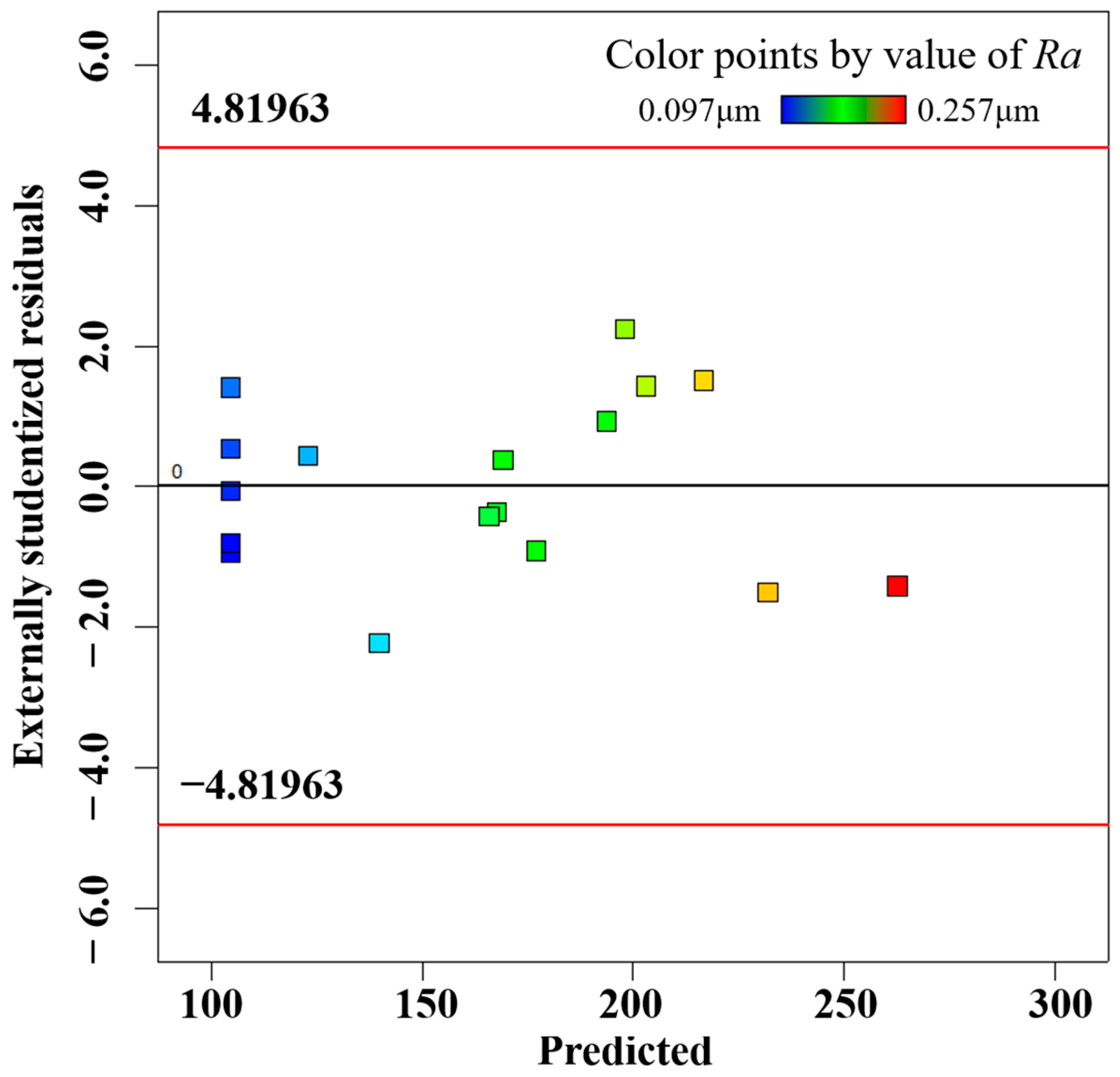

5.2. Surface Roughness Regression Model and Its Analysis

- y is the dependent variable;

- ;

- and are the design variables;

- is the number of design variables;

- are response surface regression coefficients;

- ζ is the fitting error.

- is the number of actual observations;

- i = 1, 2,..., n;

- p is the model degrees of freedom;

- is the value of the response obtained through the actual model;

- is the actual observed value of the ith response;

- is the predicted value of the response surface model;

- is the mean value of the actual observation.

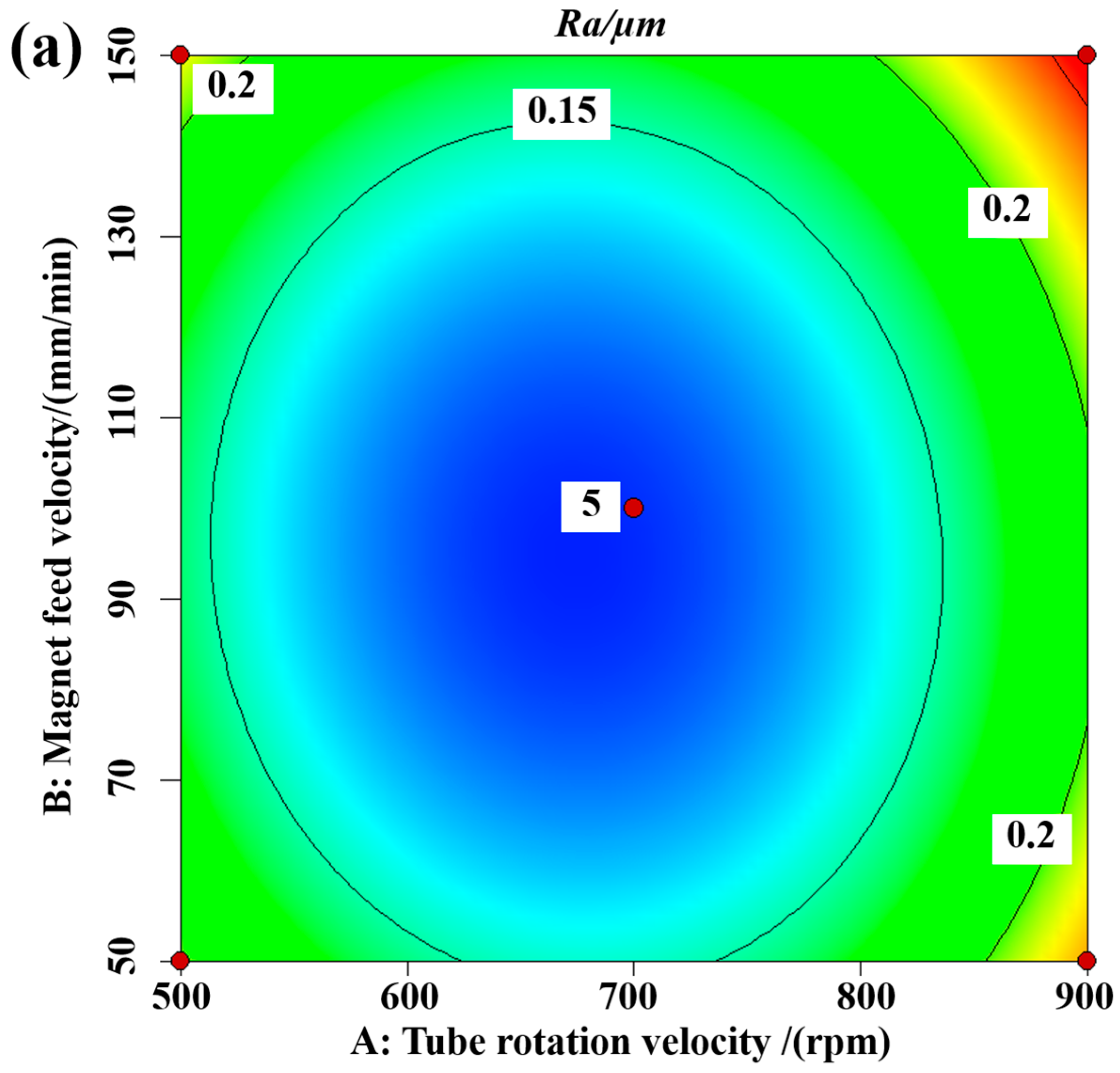

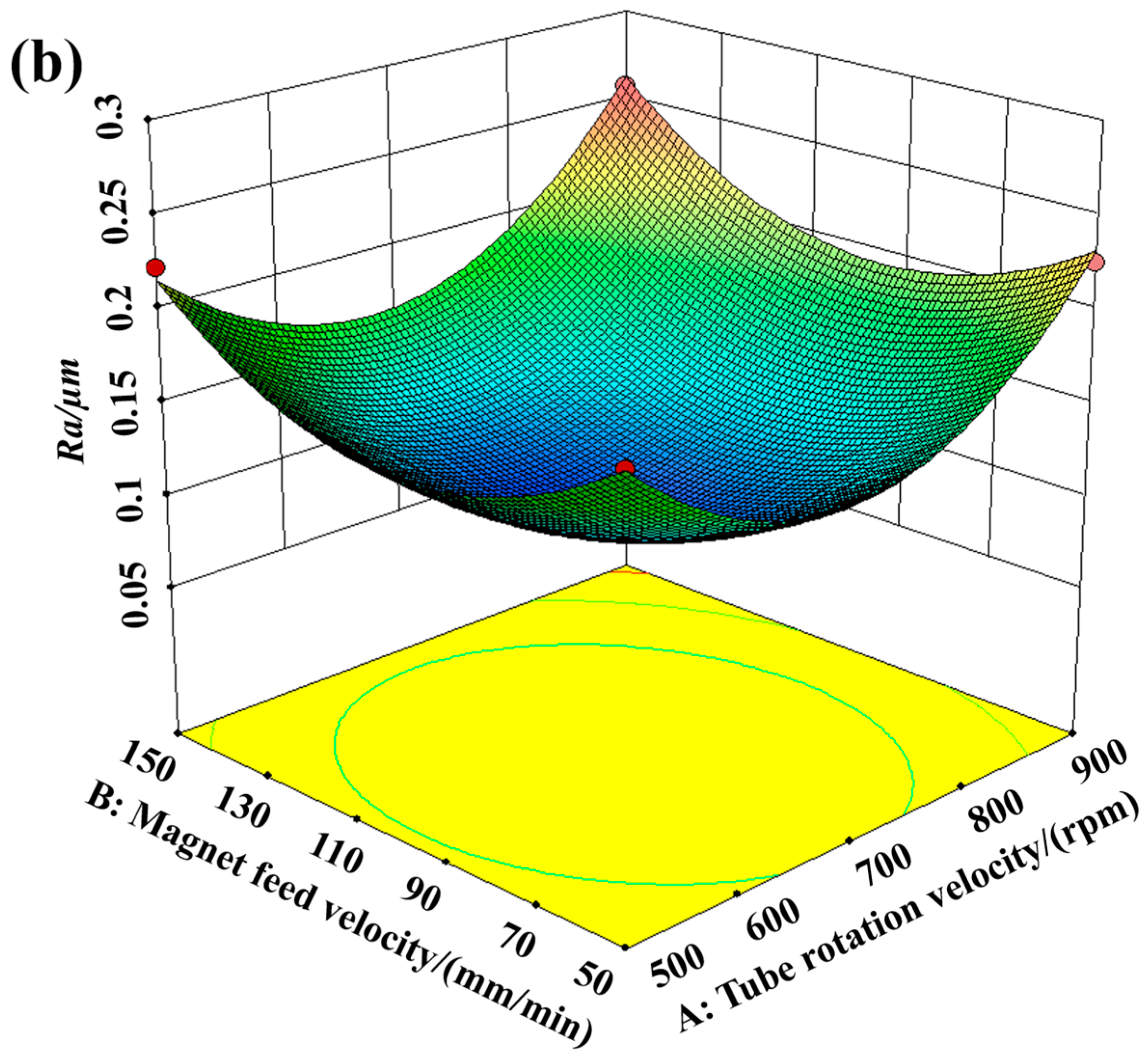

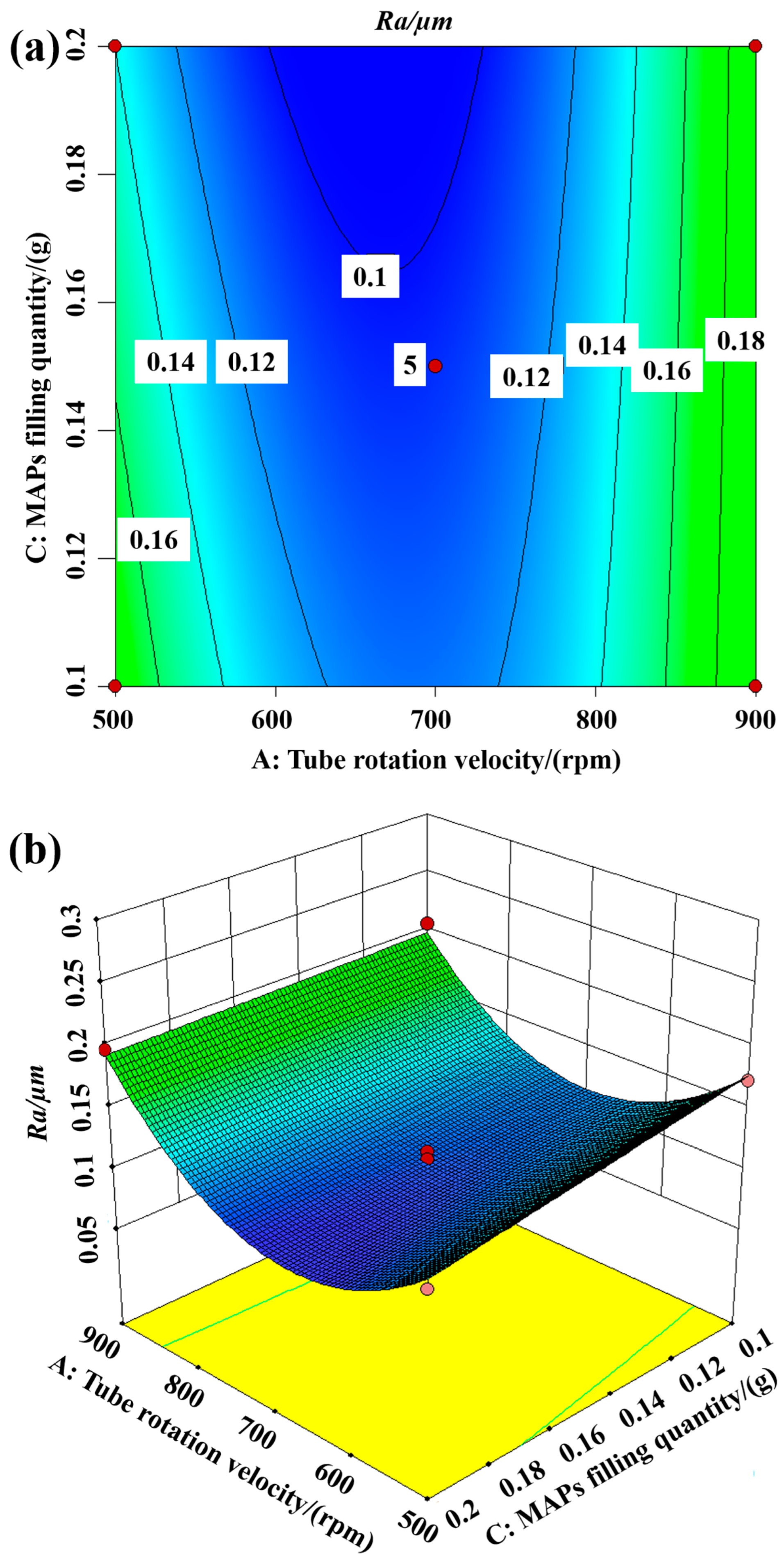

5.3. Response Surface Analysis

5.3.1. Interaction between the Tube Rotation Velocity and the Magnet Feed Velocity

5.3.2. Interaction between Tube Rotation Velocity and MAPS Filling Quantity

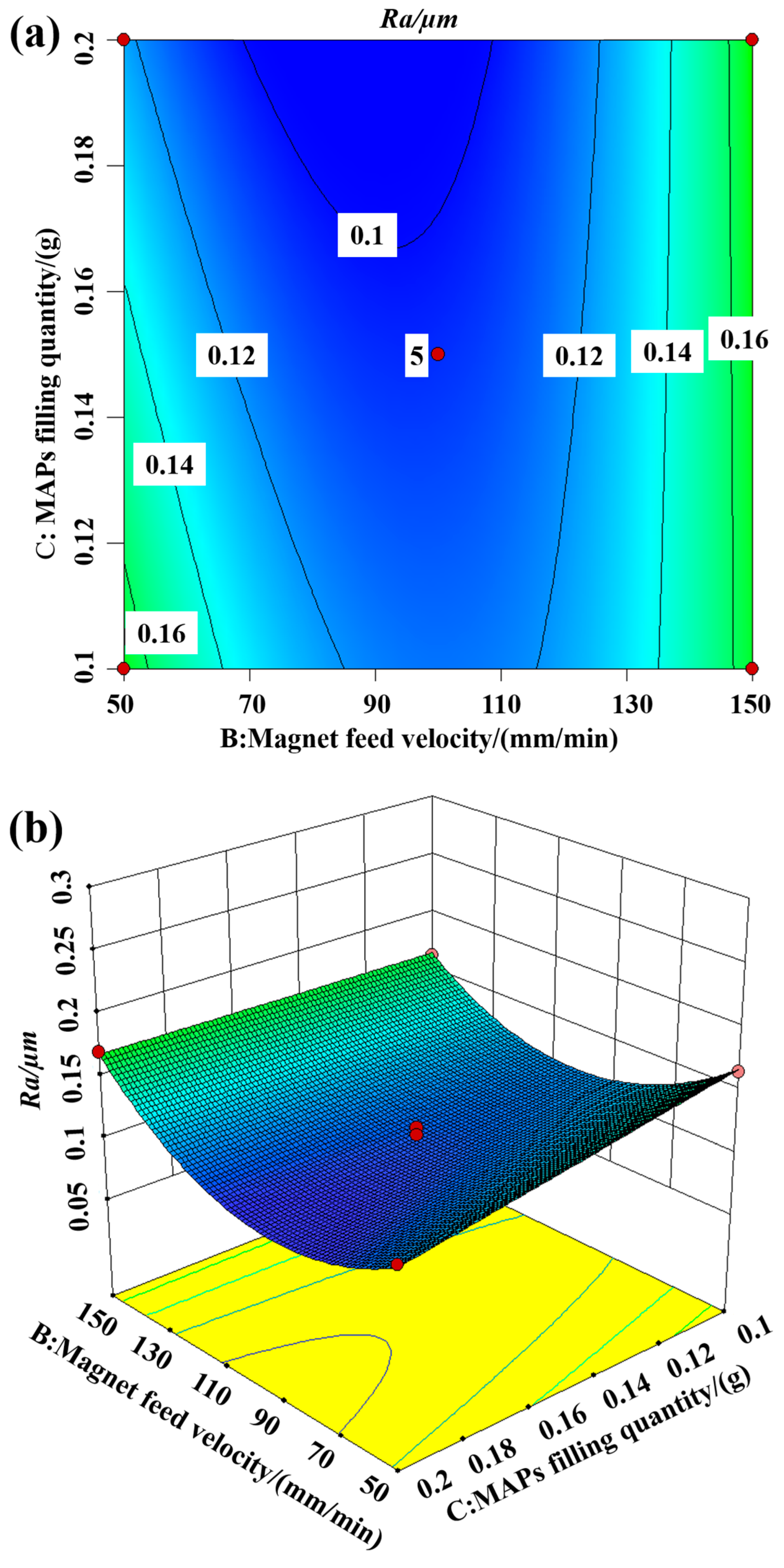

5.3.3. Interaction between Magnetic Feed Velocity and MAPs Filling Quantity

5.4. Parameter Optimization and Experimental Verification

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| y | dependent variable |

| and | design variables |

| n | number of design variables |

| , , , | response surface regression coefficients |

| ζ | fitting error |

| A | tube rotation velocity |

| B | magnet feed velocity |

| C | MAP filling quantity |

| Ra | surface roughness |

| p | model degrees of freedom |

| value of the response obtained through the actual model | |

| actual observed value of the ith response | |

| predicted value of the response surface model | |

| mean value of the actual observation | |

| R2 | coefficient of determination |

| R2Adj | modified coefficient of determination |

References

- Qiu, H.; Tu, Q.; Gao, P.; Li, X.; Maitz, M.F.; Xiong, K.; Huang, N.; Yang, Z. Phenolic-amine chemistry mediated synergistic modification with polyphenols and thrombin inhibitor for combating the thrombosis and inflammation of cardiovascular stents. Biomaterials 2021, 269, 120626. [Google Scholar] [CrossRef] [PubMed]

- Oikonomou, E.K.; Antoniades, C. The role of adipose tissue in cardiovascular health and disease. Nat. Rev. Cardiol. 2019, 16, 83–99. [Google Scholar] [CrossRef] [PubMed]

- Zhao, D.; Ding, S.X.; Karimi, H.R.; Li, Y.; Wang, Y. On robust Kalman filter for two-dimensional uncertain linear discrete time-varying systems: A least squares method. Automatica 2019, 99, 203–212. [Google Scholar] [CrossRef]

- Yang, L.; Wu, H.; Lu, L.; He, Q.; Xi, B.; Yu, H.; Luo, R.; Wang, Y.; Zhang, X. A tailored extracellular matrix (ECM)—Mimetic coating for cardiovascular stents by stepwise assembly of hyaluronic acid and recombinant human type III collagen. Biomaterials 2021, 276, 121055. [Google Scholar] [CrossRef]

- Cockerill, I.; See, C.W.; Young, M.L.; Wang, Y.; Zhu, D. Designing better cardiovascular stent materials: A learning curve. Adv. Funct. Mater. 2021, 31, 2005361. [Google Scholar] [CrossRef]

- Lyu, N.; Du, Z.; Qiu, H.; Gao, P.; Yao, Q.; Xiong, K.; Tu, Q.; Li, X.; Chen, B.; Wang, M.; et al. Mimicking the nitric oxide-releasing and glycocalyx functions of endothelium on vascular stent surfaces. Adv. Sci. 2020, 7, 2002330. [Google Scholar] [CrossRef]

- Amani, S.; Faraji, G. Processing and Properties of Biodegradable Magnesium Microtubes for Using as Vascular Stents: A Brief Review. Met. Mater. Int. 2019, 25, 1341–1359. [Google Scholar] [CrossRef]

- Ahmed, A.T.; Mohammed, K.; Chehab, M.; Brinjikji, W.; Hassan Murad, M.; Cloft, H.; Bjarnason, H. Comparing Percutaneous Transluminal Angioplasty and Stent Placement for Treatment of Subclavian Arterial Occlusive Disease: A Systematic Review and Meta-Analysis. Cardiovasc. Interv. Radiol. 2016, 39, 652–667. [Google Scholar] [CrossRef]

- Andreini, D.; Mushtaq, S.; Pontone, G.; Conte, E.; Collet, C.; Sonck, J.; D’Errico, A.; Di Odoardo, L.; Guglielmo, M.; Baggiano, A.; et al. CT Perfusion versus Coronary CT Angiography in Patients with Suspected In-Stent Restenosis or CAD Progression. JACC Cardiovasc. Imaging 2020, 13, 732–742. [Google Scholar] [CrossRef]

- Korei, N.; Solouk, A.; Nazarpak, M.H.; Nouri, A. A review on design characteristics and fabrication methods of metallic cardiovascular stents. Mater. Today Commun. 2022, 31, 103467. [Google Scholar] [CrossRef]

- Hanawa, T. Materials for metallic stents. J. Artif. Organs 2009, 12, 73–79. [Google Scholar] [CrossRef]

- Dehghanghadikolaei, A.; Ibrahim, H.; Amerinatanzi, A.; Hashemi, M.; Moghaddam, N.S.; Elahinia, M. Improving corrosion resistance of additively manufactured nickel–titanium biomedical devices by micro-arc oxidation process. J. Mater. Sci. 2019, 54, 7333–7355. [Google Scholar] [CrossRef]

- Finazzi, V.; Demir, A.G.; Biffi, C.A.; Migliavacca, F.; Petrini, L.; Previtali, B. Design and functional testing of a novel balloon-expandable cardiovascular stent in CoCr alloy produced by selective laser melting. J. Manuf. Process. 2020, 55, 161–173. [Google Scholar] [CrossRef]

- Kotousov, A.; Bortolan Neto, L.; Rahman, S.S. Theoretical model for roughness induced opening of cracks subjected to compression and shear loading. Int. J. Fract. 2011, 172, 9–18. [Google Scholar] [CrossRef]

- Brencht van Hooreweder, B.; Lietaert, K.; Neirinck, B.; Lippiatt, N.; Wevers, M. CoCr F75 scaffolds produced by additive manufacturing: Influence of chemical etching on powder removal and mechanical performance. J. Mech. Behav. Biomed. Mater. 2017, 70, 60–67. [Google Scholar] [CrossRef]

- Simka, W.; Kaczmarek, M.; Baron-Wiecheć, A.; Nawrat, G.; Marciniak, J.; Żak, J. Electropolishing and passivation of NiTi shape memory alloy. Electrochim. Acta 2010, 55, 2437–2441. [Google Scholar] [CrossRef]

- Li, Y.; Li, Z.; Chai, M.; Song, S.; Huang, Z. Effects of interelectrode distance and temperature on electropolishing of Ni–Ti alloy tube. Electroplat. Finish. 2021, 40, 1262–1265. [Google Scholar] [CrossRef]

- Liu, H. Study on Electrochemical Polishing Process and Surface Properties of Ni-Ti Alloy Cardiovascular Stent. Master’s Thesis, Shandong University of Technology, Zibo, China, 2021. [Google Scholar] [CrossRef]

- Sun, X.; Wei, X.; Li, Z.; Wang, Y.; Liu, H.; Lou, D. Improving Surface Properties of Nitinol Cardiovascular Stent by Electropolishin. China Surf. Eng. 2021, 34, 70–75. [Google Scholar] [CrossRef]

- Huang, Z. Research on Electrochemical Polishing Process and Biocompatibility of Ni-Ti Ally Cardiovascular Sent. Master’s Thesis, Shandong University of Technology, Zibo, China, 2020. [Google Scholar] [CrossRef]

- Xu, F. Experimental Study and Surface Performance Analysis of Nickel-Titanium Alloy Composite Polishing by Magnetic Field and Electrochemical Polishing. Jilin University. 2019. Available online: https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD201902&filename=1019159885.nh (accessed on 16 March 2023).

- Yan, F. Research on Electrochemical Polishing Test and Performance of Cardiovascular Stent. Master’s Thesis, Shandong University of Technology, Zibo, China, 2019. [Google Scholar] [CrossRef]

- Zhang, G.-X.; Zhao, Y.-G.; Zhao, D.-B.; Yin, F.S.; Zhao, Z.D. Preparation of white alumina spherical composite magnetic abrasive by gas atomization and rapid solidification. Scr. Mater. 2011, 65, 416–419. [Google Scholar] [CrossRef]

- Qian, C.; Fan, Z.; Tian, Y.; Liu, Y.; Han, J.; Wang, J. A review on magnetic abrasive finishing. Int. J. Adv. Manuf. Technol. 2021, 112, 619–634. [Google Scholar] [CrossRef]

- Zou, Y.; Xie, H.; Dong, C.; Wu, J. Study on complex micro surface finishing of alumina ceramic by the magnetic abrasive finishing process using alternating magnetic field. Int. J. Adv. Manuf. Technol. 2018, 97, 2193–2202. [Google Scholar] [CrossRef]

- Fan, Z.; Tian, Y.; Liu, Z.; Shi, C.; Zhao, Y. Investigation of a novel finishing tool in magnetic field assisted finishing for titanium alloy Ti-6Al-4V. J. Manuf. Process. 2019, 43, 74–82. [Google Scholar] [CrossRef]

- Yun, H.; Han, B.; Chen, Y.; Liao, M. Internal finishing process of alumina ceramic tubes by ultrasonic-assisted magnetic abrasive finishing. Int. J. Adv. Manuf. Technol. 2016, 85, 727–734. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, J.; Wang, H.; Kumar, A.S.; Chaudhari, A. A novel magnetically driven polishing technique for internal surface finishing. Precis. Eng. 2018, 54, 222–232. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, H.; Kumar, A.S.; Jin, M. Experimental and theoretical study of internal finishing by a novel magnetically driven polishing tool. Int. J. Mach. Tools Manuf. 2020, 153, 103552. [Google Scholar] [CrossRef]

- Wang, C.; Cheung, C.F.; Ho, L.T.; Yung, K.L.; Kong, L. A novel magnetic field-assisted mass polishing of freeform surfaces. J. Mater. Process. Technol. 2020, 279, 116552. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Srivastava, A.K.; Tan, M.A.; Riveros, R.E.; Hashimoto, F. Magnetic abrasive finishing of cutting tools for machining of titanium alloys. CIRP Ann. 2012, 61, 311–314. [Google Scholar] [CrossRef]

- Guo, J.; Liu, K.; Wang, Z.; Tnay, G.L. Magnetic field-assisted finishing of a mold insert with curved microstructures for injection molding of microfluidic chips. Tribol. Int. 2017, 114, 306–314. [Google Scholar] [CrossRef]

- Ko, S.L.; Baron, Y.M.; Park, J.I. Micro deburring for precision parts using magnetic abrasive finishing method. J. Mater. Process. Technol. 2007, 187–188, 19–25. [Google Scholar] [CrossRef]

- Ahn, B.W.; Lee, S.H. Run-to-run process control of magnetic abrasive finishing using bonded abrasive particles. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2012, 226, 1963–1975. [Google Scholar] [CrossRef]

- Chen, Y.; Song, Q.H.; Wang, X. Study on the characteristics of simply mixed the magnetic abrasive particles. Adv. Mater. Res. 2007, 24–25, 133–138. [Google Scholar] [CrossRef]

- Fan, Z.; Tian, Y.; Zhou, Q.; Shi, C. Enhanced magnetic abrasive finishing of Ti–6Al–4V using shear thickening fluids additives. Precis. Eng. 2020, 64, 300–306. [Google Scholar] [CrossRef]

- Liao, G.B.; Zhang, M.M.; Li, Y.J.; Liu, Z.Q.; Chen, Y. Preparation of magnetic abrasive by sintering method finishing by sintering method. Key Eng. Mater. 2011, 487, 273–277. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Hanada, K. Development of spherical magnetic abrasive made by plasma spray. J. Manuf. Sci. Eng. 2008, 130, 0311071–0311079. [Google Scholar] [CrossRef]

- Hanada, K.; Yamaguchi, H.; Zhou, H. New spherical magnetic abrasives with carried diamond particles for internal finishing of capillary tubes. Diam. Relat. Mater. 2008, 17, 1434–1437. [Google Scholar] [CrossRef]

- Hanada, K.; Yamaguchi, H. Development of spherical iron-based composite powder with carried alumina abrasive grains by plasma spray. Adv. Mater. Res. 2009, 75, 43–46. [Google Scholar] [CrossRef]

- Yang, B.; Lu, W.Z.; Feng, W.; Yang, X.; Zuo, D.W. Adsorption and deposition of micro diamond particles in preparing diamond magnetic abrasives by electroless composite plating. Diam. Relat. Mater. 2017, 73, 137–142. [Google Scholar] [CrossRef]

- Li, W.; Li, J.; Cheng, B.; Zhang, X.; Song, Q.; Wang, Y.; Zhang, T.; Seniuts, U.; Belotsrkovsky, M. Achieving in-situ alloy-hardening core-shell structured carbonyl iron powders for magnetic abrasive finishing. Mater. Des. 2021, 212, 110198. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Shinmura, T.; Sekine, M. Uniform internal finishing of SUS304 stainless steel bent tube using a magnetic abrasive finishing process. J. Manuf. Sci. Eng. 2005, 127, 605–611. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, D. Study on the inner surface finishing of tubing by magnetic abrasive finishing. Int. J. Mach. Tools Manuf. 2005, 45, 43–49. [Google Scholar] [CrossRef]

- Srivastava, A.; Kumar, H.; Singh, S. Investigations into internal surface finishing of titanium (Grade 2) tube with extended magnetic tool. Sci. Direct Procedia Manuf. 2018, 26, 181–189. [Google Scholar] [CrossRef]

- Ihara, I.; Nakano, E.; McLamore, E.; Schueller, J.K.; Toyoda, K.; Umetsu, K.; Yamaguchi, H. Cleanability of milk deposits on inner stainless steel tubing surfaces prepared by magnetic abrasive finishing. Eng. Agric. Environ. Food 2016, 10, 63–68. [Google Scholar] [CrossRef]

- Tippawan, P.; Jienkulsawad, P.; Limleamthong, P.; Arpornwichanop, A. Composting time minimization of mature vermicompost using desirability and response surface methodology approach. Comput. Chem. Eng. 2022, 167, 108037. [Google Scholar] [CrossRef]

- Velayi, E.; Norouzbeigi, R. Fabrication of epoxy/SiO2/ZnO superhydrophobic nanocomposite mesh membranes for oil-water separation: Correlating oil flux to fabrication parameters via Box-Behnken design. Appl. Surf. Sci. 2023, 611, 155594. [Google Scholar] [CrossRef]

- Lam, M.N.-T.; Le, D.-H.; Nguyen, D.-L. Reuse of clay brick and ceramic waste in concrete: A study on compressive strength and durability using the Taguchi and Box–Behnken design method. Constr. Build. Mater. 2023, 373, 130801. [Google Scholar] [CrossRef]

- Ayan, E.; Baylan, N.; Çehreli, S. Removal of propionic acid from aqueous solutions by tributyl phosphate in a room-temperature ionic liquid using Box-Behnken design. J. Ind. Eng. Chem. 2023, 119, 499–505. [Google Scholar] [CrossRef]

- Mohammed, N.; Palaniandy, P.; Shaik, F.; Mewada, H.; Balakrishnan, D. Comparative studies of RSM Box-Behnken and ANN-Anfis fuzzy statistical analysis for seawater biodegradability using TiO2 photocatalyst. Chemosphere 2023, 314, 137665. [Google Scholar] [CrossRef]

- Zhang, W.; Mao, J.; Wei, T.; He, X. Valve timing optimization of kerosene engine based on response surface method. China Mech. Eng. 2016, 27, 933–938. Available online: https://kns.cnki.net/kcms/detail/42.1294.th.20160414.1536.008.html (accessed on 16 March 2023).

- Mulay, A.; Rathod, V.K. Ultrasound-assisted synthesis of ethyl hexanoate using heterogeneous catalyst: Optimization using Box-Behnken design. J. Indian Chem. Soc. 2022, 99, 100573. [Google Scholar] [CrossRef]

| Nozzle | Ring Seam |

|---|---|

| Nozzle cone angle (°) | 65 |

| Nozzle annular seam diameter (mm) | 3.5 |

| Nozzle bore diameter (mm) | 46 |

| Inlet pressure of nozzle (MPa) | 0.8 |

| Distance between nozzle and plasma generator (mm) | 70 |

| I (A) | 700 |

| Ar (L/h) | 1000 |

| H2 (L/h) | 15 |

| Iron powder (g/min) | 40 |

| CBN powder (g/min) | 240 |

| Equipment power (kW) | 24.34 |

| Element | Ni | Ti | O | N | K | C | Si | Al |

|---|---|---|---|---|---|---|---|---|

| Value | 50~52 | 45~50 | 2~5 | ≤1 | ≤0.5 | ≤0.01 | ≤0.01 | ≤0.01 |

| Indicators | Density/g·cm−3 | Modulus of Elasticity/GPa | Tensile Strength /MPa | Hardness (HRC) | Elongation/% | Shape Memory Recovery Rate/% | Fatigue Limit/MPa |

|---|---|---|---|---|---|---|---|

| Value | 6.48 | 28~41 | 800~1500 | 30~40 | 1~20 | 98 | 100~800 |

| Experiment Number | Tube Rotation Velocity n/(rpm) | Magnet Feed Velocity v/(mm/min) | MAPs Filling Quantity δ/g |

|---|---|---|---|

| −1 | 500 | 50 | 0.1 |

| 0 | 700 | 100 | 0.15 |

| 1 | 900 | 150 | 0.2 |

| Radius of change | 200 | 50 | 0.05 |

| Experiment Number | Tube Rotation Speed n/(rpm) | Magnet Feed Velocity v/(mm/min) | MAP Filling Quantity δ/g | Surface Roughness Ra/μm |

|---|---|---|---|---|

| 1 | 700 | 150 | 0.1 | 0.164 |

| 2 | 700 | 150 | 0.2 | 0.171 |

| 3 | 900 | 100 | 0.1 | 0.206 |

| 4 | 700 | 100 | 0.15 | 0.097 |

| 5 | 700 | 100 | 0.15 | 0.109 |

| 6 | 700 | 100 | 0.15 | 0.115 |

| 7 | 700 | 50 | 0.1 | 0.166 |

| 8 | 500 | 150 | 0.15 | 0.223 |

| 9 | 700 | 50 | 0.2 | 0.125 |

| 10 | 700 | 100 | 0.15 | 0.104 |

| 11 | 900 | 100 | 0.2 | 0.198 |

| 12 | 900 | 50 | 0.15 | 0.226 |

| 13 | 900 | 150 | 0.15 | 0.257 |

| 14 | 700 | 100 | 0.15 | 0.098 |

| 15 | 500 | 50 | 0.15 | 0.209 |

| 16 | 500 | 100 | 0.1 | 0.173 |

| 17 | 500 | 100 | 0.2 | 0.132 |

| Source | Sum of Squares | df | Mean Square | F | Prob > F | |

|---|---|---|---|---|---|---|

| Model | 4.1 × 10−2 | 9 | 4.546 × 10−3 | 58.34 | <0.0001 | significant |

| A—Pipe Rotation Speed | 2.813 × 10−3 | 1 | 2.813 × 10−3 | 36.09 | 0.0005 | |

| B—Magnetic Pole Feed Rate | 9.901 × 10−4 | 1 | 9.901 × 10−4 | 12.71 | 0.0092 | |

| C—Magnetic Abrasive Filling Quantity | 8.611 × 10−4 | 1 | 8.611 × 10−4 | 11.05 | 0.0127 | |

| AB | 7.225 × 10−5 | 1 | 7.225 × 10−5 | 0.93 | 0.3677 | |

| AC | 2.723 × 10−4 | 1 | 2.723 × 10−4 | 3.49 | 0.1038 | |

| BC | 5.760 × 10−4 | 1 | 5.760 × 10−4 | 7.39 | 0.0298 | |

| A2 | 0.022 | 1 | 0.022 | 283.63 | <0.0001 | |

| B2 | 0.011 | 1 | 0.011 | 144.43 | <0.0001 | |

| C2 | 1.684 × 10−7 | 1 | 1.684 × 10−7 | 2.161 × 10−3 | 0.9642 | |

| Residual | 5.454 × 10−4 | 7 | 7.792 × 10−5 | |||

| Lack of Fit | 3.162 × 10−4 | 3 | 1.054 × 10−4 | 1.84 | 0.2802 | not significant |

| Pure Error | 2.292 × 10−4 | 4 | 5.730 × 10−5 | |||

| Cor Total | 0.041 | 16 | ||||

| R-Squared = 0.9868 | Adj R-Squared = 0.9699 | |||||

| Experimental 1 | Experimental 2 | Experimental 3 | Mean Experimental | Predictive | Error |

|---|---|---|---|---|---|

| 0.095 μm | 0.095 μm | 0.083 μm | 0.093 μm | 0.089 μm | 4.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Zhao, Y.; Li, Z.; Cao, C.; Meng, J.; Yu, H.; Zhang, H. Investigation of MAF for Finishing the Inner Wall of Super-Slim Cardiovascular Stents Tube. Materials 2023, 16, 3022. https://doi.org/10.3390/ma16083022

Liu G, Zhao Y, Li Z, Cao C, Meng J, Yu H, Zhang H. Investigation of MAF for Finishing the Inner Wall of Super-Slim Cardiovascular Stents Tube. Materials. 2023; 16(8):3022. https://doi.org/10.3390/ma16083022

Chicago/Turabian StyleLiu, Guangxin, Yugang Zhao, Zhihao Li, Chen Cao, Jianbing Meng, Hanlin Yu, and Haiyun Zhang. 2023. "Investigation of MAF for Finishing the Inner Wall of Super-Slim Cardiovascular Stents Tube" Materials 16, no. 8: 3022. https://doi.org/10.3390/ma16083022

APA StyleLiu, G., Zhao, Y., Li, Z., Cao, C., Meng, J., Yu, H., & Zhang, H. (2023). Investigation of MAF for Finishing the Inner Wall of Super-Slim Cardiovascular Stents Tube. Materials, 16(8), 3022. https://doi.org/10.3390/ma16083022