Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review

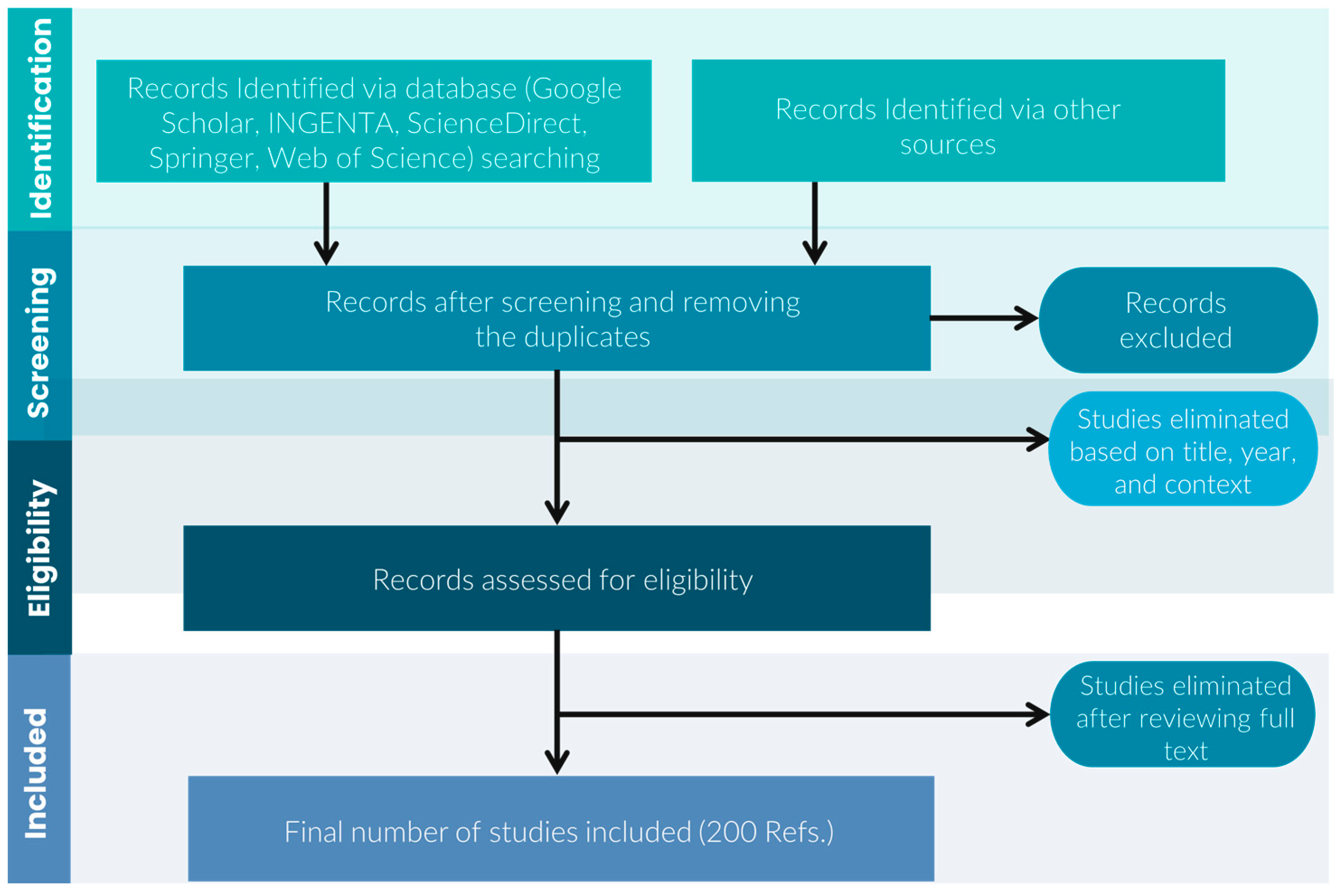

Abstract

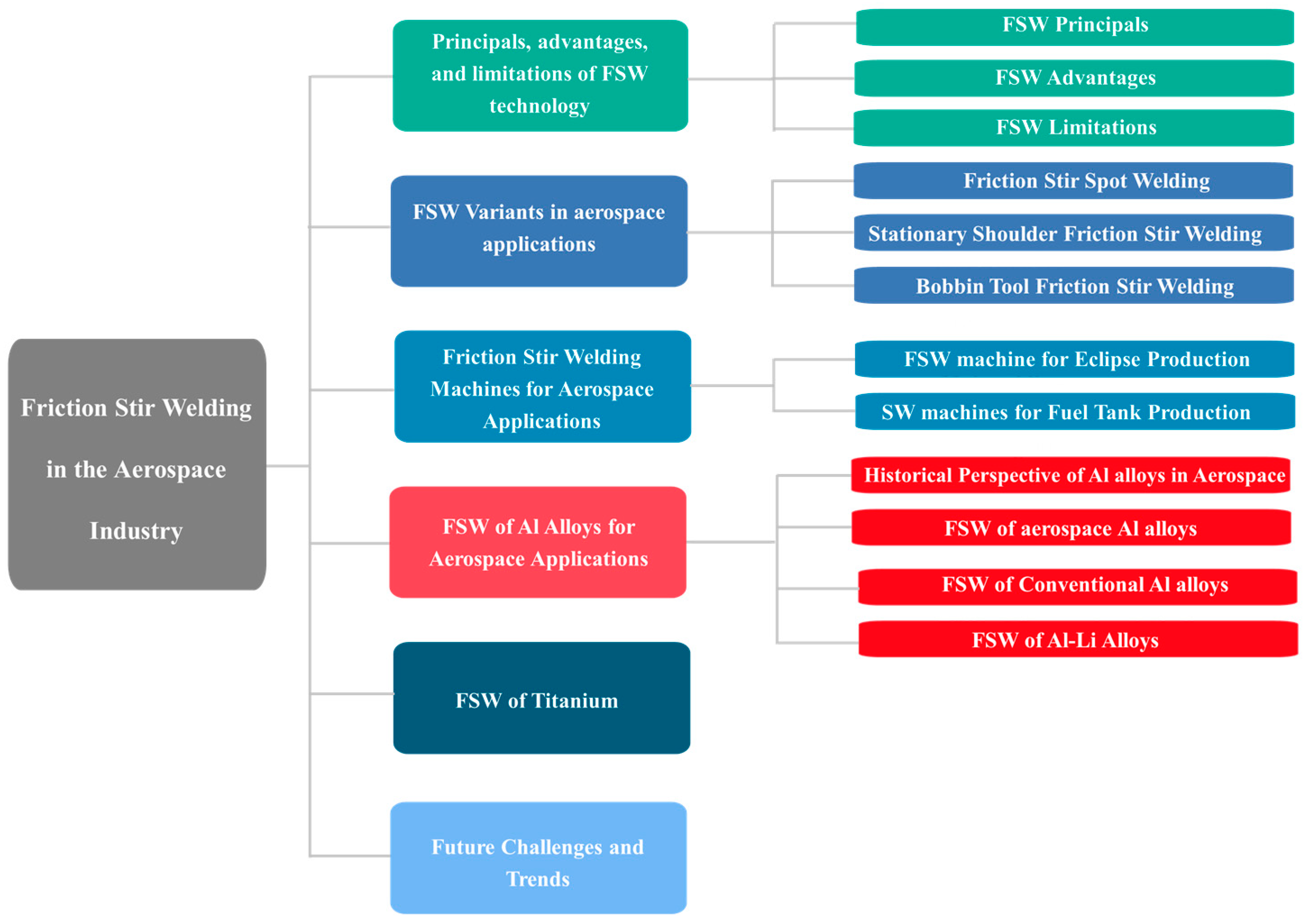

1. Introduction

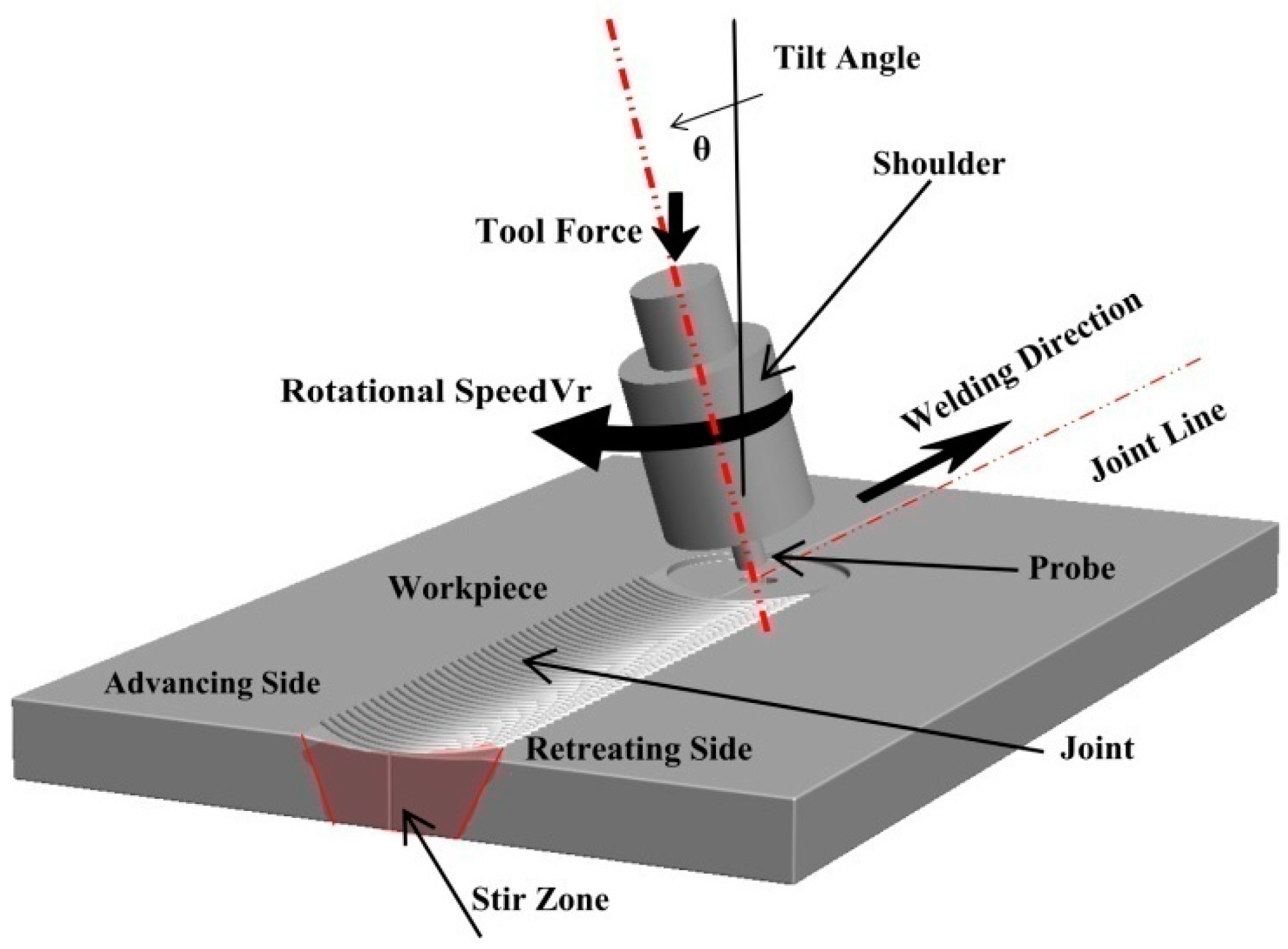

2. FSW Principals, Advantages, and Limitations

2.1. FSW Principals

2.2. Advantages of FSW

- The weld nugget experiences a high-strain-rate plastic deformation process at a relatively high temperature, resulting in a dynamically recrystallized structure that, in most of the alloys, is a refined grain structure.

- The weld zone experiences low heat input, resulting in low distortion in the welded plates.

- It is a fully automated, repeatable process with a limited number of variables involved.

- Different aerospace materials both in similar and dissimilar configurations can be welded in all kinds of joint configurations.

- Joints with improved mechanical properties comparable to conventional fusion welding techniques can be fabricated.

- Significant cost and time savings as the tool is almost non-consumable and the thick sections can be welded in one pass.

2.3. Limitations of FSW

- The workpiece to be welded has to be clamped and strained on top of the backing plate to avoid separation and flowing down the material upon tool plunging and traversing.

- The machines are not flexible in terms of accessibility, and some parts require manual welding. In addition, the FSW machines are specially designed for specific applications that can cause the capital investment to be high.

- The tool life for the FSW of high-melting-point materials is still one of the challenges that limit the use of FSW in some applications.

3. FSW Variants in Aerospace Applications

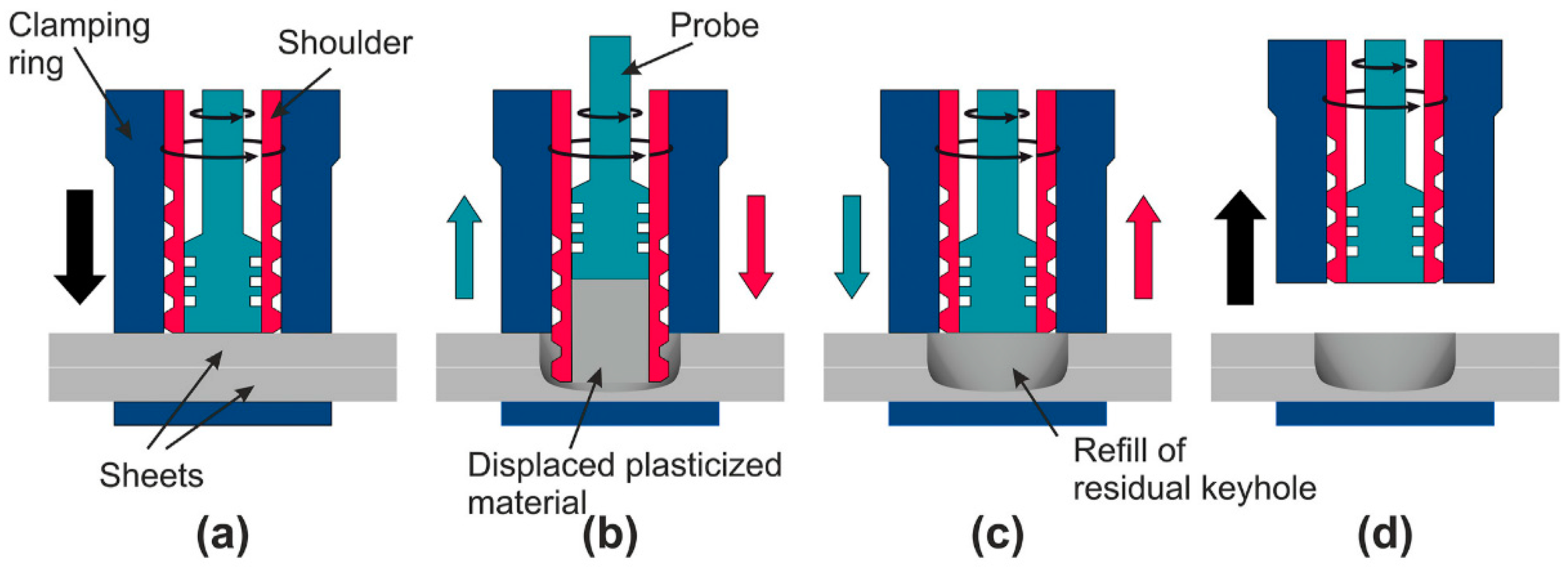

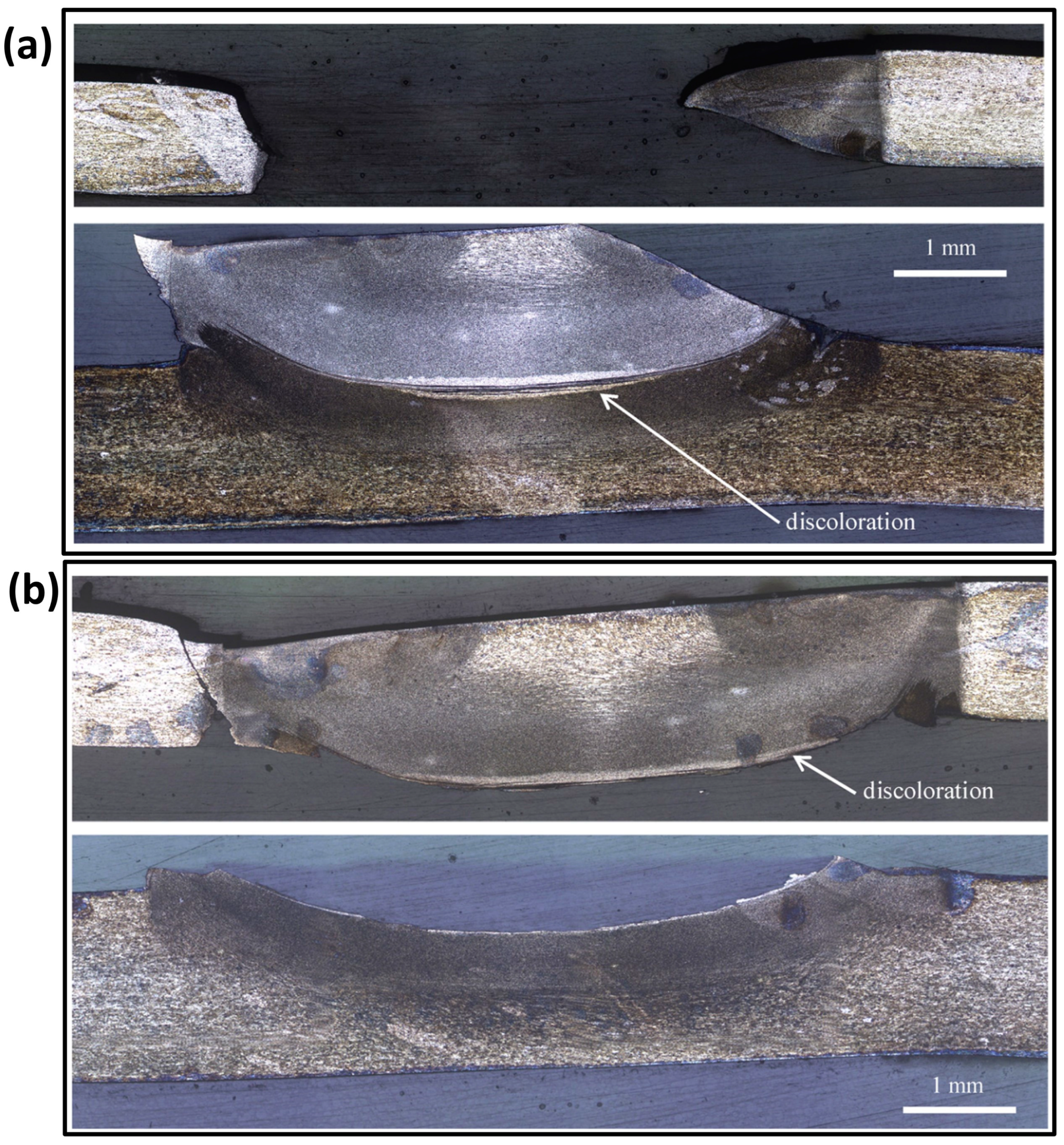

3.1. Friction Stir Spot Welding

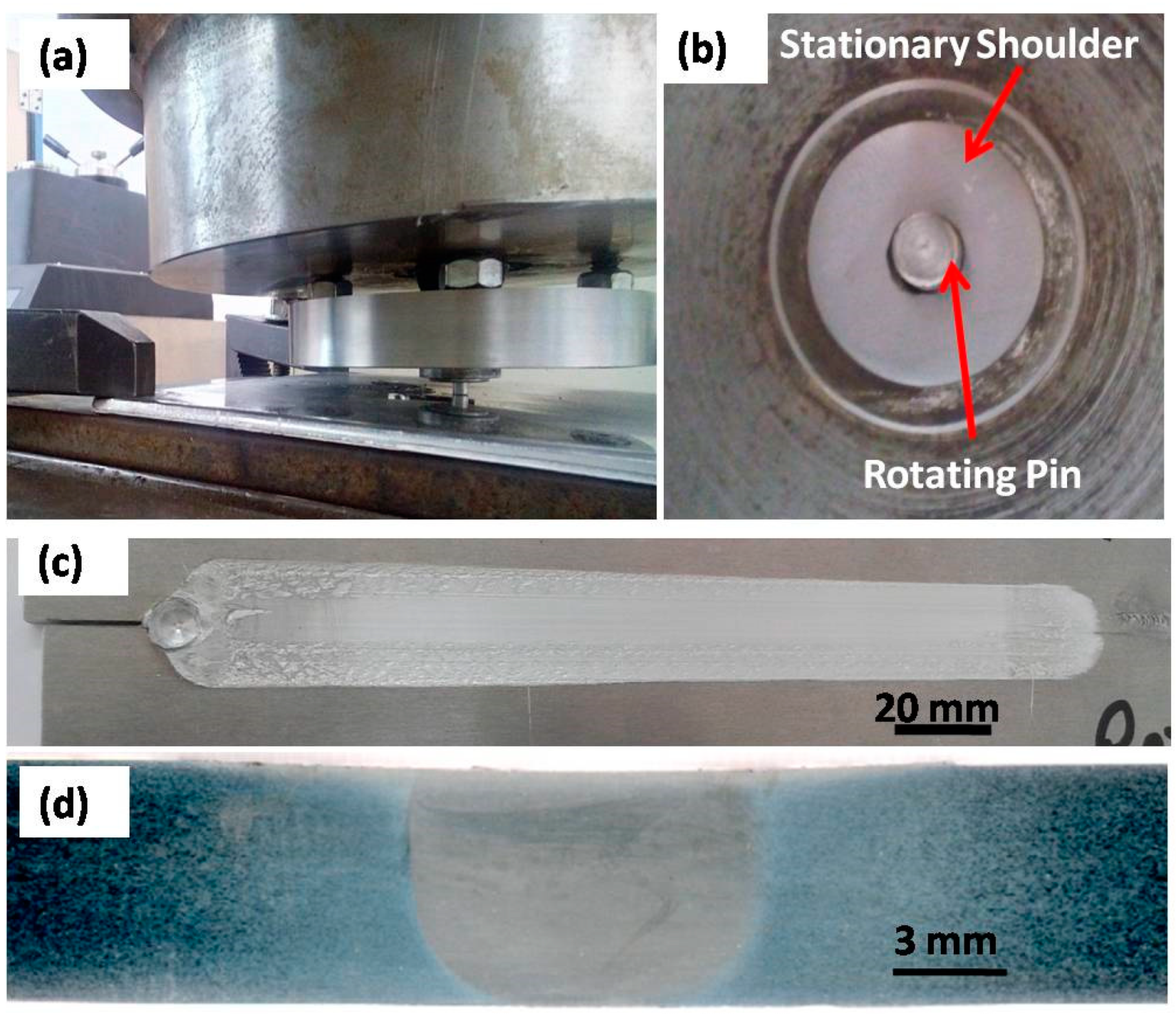

3.2. Stationary Shoulder Friction Stir Welding

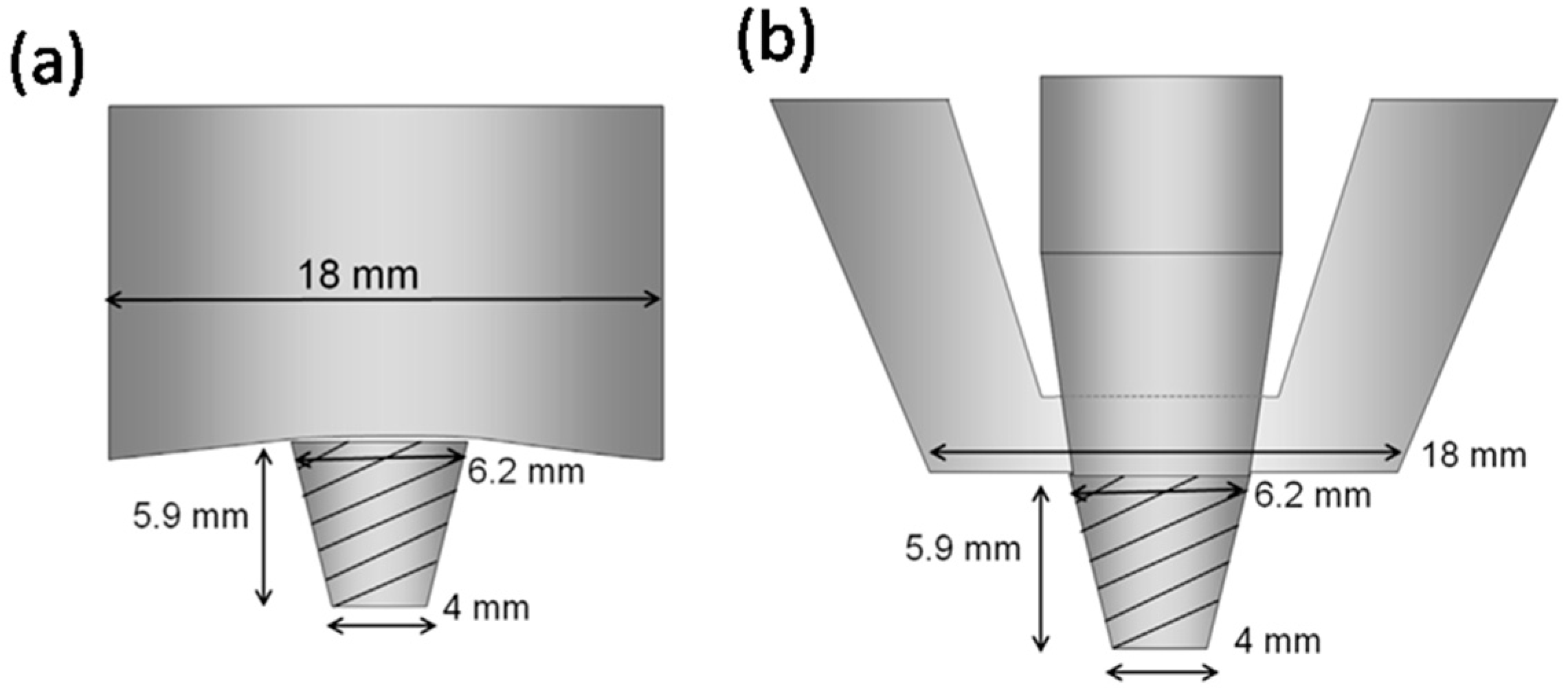

3.3. Bobbin Tool Friction Stir Welding

- The full penetration joint eliminates weld root flaws and leads to a lack of penetration defects.

- Low Z forces on fixture and machine.

- Due to the use of the lower shoulder, no backing plate is required.

- Low distortion due to low Z force applied.

- The ability for thickness variation tolerance.

- Capable of joining closed profiles such as hollow extrusions.

- More uniform mechanical properties through the thickness.

4. Friction Stir Welding Machines for Aerospace Applications

4.1. FSW Machine for Eclipse Production

4.2. FSW Machines for Fuel Tank Production

5. FSW of Al Alloys for Aerospace Applications

5.1. Historical Perspective of Al Alloys in Aerospace

5.2. Future Perspective of Al in Aerospace Applications

5.3. FSW of Conventional Al alloys

5.4. FSW of Aluminum–Lithium Alloys

5.5. ISO Standard for Aluminum FSW

- ISO 25239-1:2020 Friction stir welding—Aluminum—Part 1: Vocabulary

- ISO 25239-2:2020 Friction stir welding—Aluminum—Part 2: Design of weld joints

- ISO 25239-3:2020 Friction stir welding—Aluminum—Part 3: Qualification of welding operators

- ISO 25239-4:2020 Friction stir welding—Aluminum—Part 4: Specification and qualification of welding procedures

- ISO 25239-5:2020 Friction stir welding—Aluminum—Part 5: Quality and inspection requirements

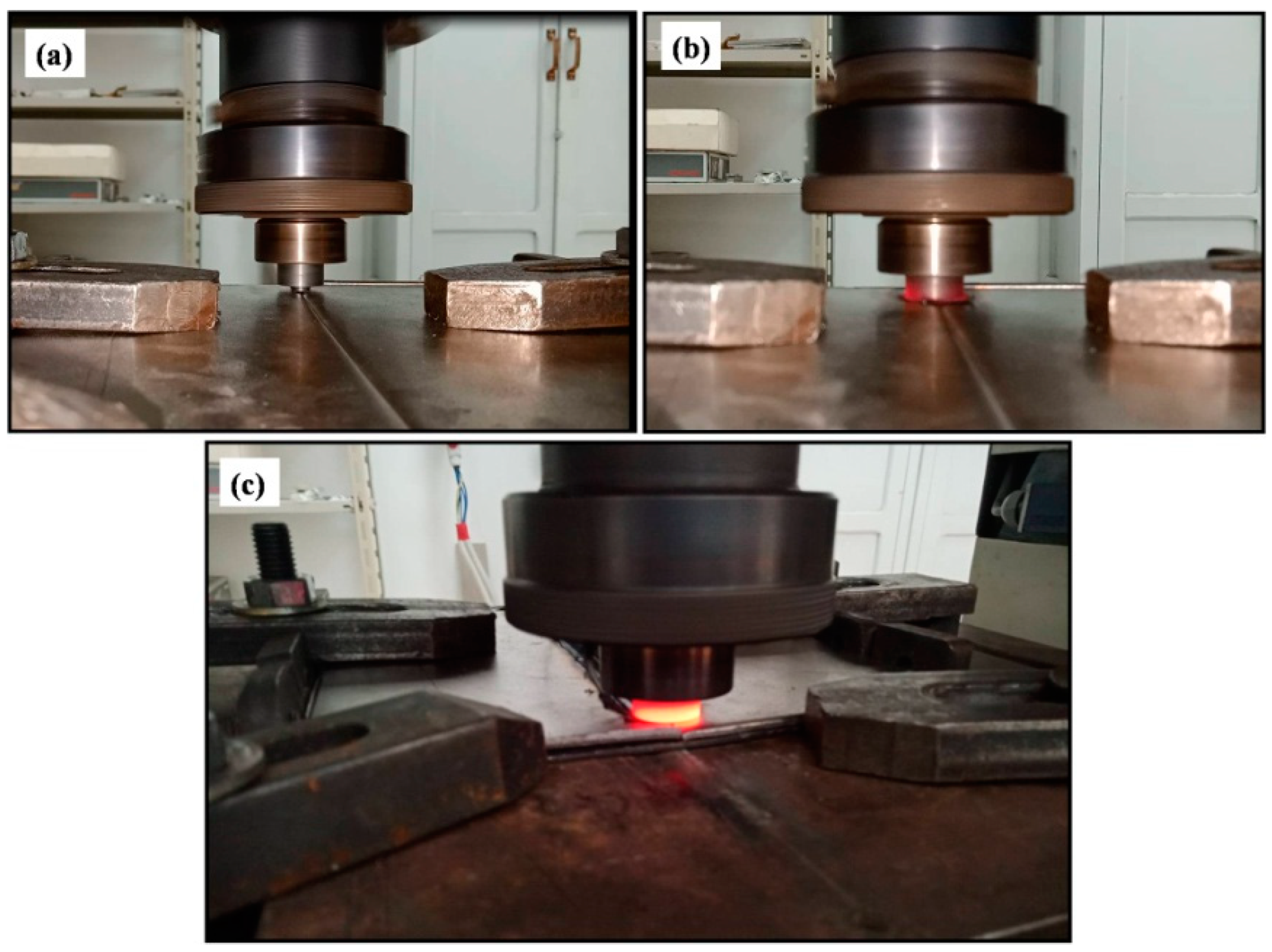

6. FSW of Titanium

7. Future Challenges and Trends in FSW for Aerospace Industries

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Prasad, N.E.; Wanhill, R.J.H. Aerospace Materials and Material Technologies; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Rakshith, M.; Seenuvasaperumal, P. Review on the effect of different processing techniques on the microstructure and mechanical behaviour of AZ31 Magnesium alloy. J. Magnes. Alloy. 2021, 9, 1692–1714. [Google Scholar] [CrossRef]

- Kuai-she, W.; Xun-hong, W. Evaluation of Microstructure and Mechanical Property of FSW Welded MB3 Magnesium Alloy. J. Iron Steel Res. Int. 2006, 13, 75–78. [Google Scholar]

- Hsu, H.H.; Hwang, Y.M. A study on friction stir process of magnesium alloy AZ31 sheet. Key Eng. Mater. 2007, 340–341, 1449–1454. [Google Scholar] [CrossRef]

- Yang, Z.; Li, J.; Zhang, J.; Lorimer, G.; Robson, J. Review on Research and Development of Magnesium Alloys. Acta Metall. Sin. (Engl. Lett.) 2008, 21, 313–328. [Google Scholar] [CrossRef]

- Fu, B.; Shen, J.; Suhuddin, U.F.; Pereira, A.A.; Maawad, E.; dos Santos, J.F.; Klusemann, B.; Rethmeier, M. Revealing joining mechanism in refill friction stir spot welding of AZ31 magnesium alloy to galvanized DP600 steel. Mater. Des. 2021, 209, 109997. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Sobih, A.M.E.-S.; Bakkar, A.; Albaijan, I.; Touileb, K.; Abd El-Aty, A. Friction Stir-Spot Welding of AA5052-H32 Alloy Sheets: Effects of Dwell Time on Mechanical Properties and Microstructural Evolution. Materials 2023, 16, 2818. [Google Scholar] [CrossRef]

- Liu, Z.; Fan, Z.; Liu, L.; Miao, S.; Lin, Z.; Wang, C.; Zhao, Y.; Xin, R.; Dong, C. Refill friction stir spot welding of AZ31 magnesium alloy sheets: Metallurgical features, microstructure, texture and mechanical properties. J. Mater. Res. Technol. 2022, 105242. [Google Scholar] [CrossRef]

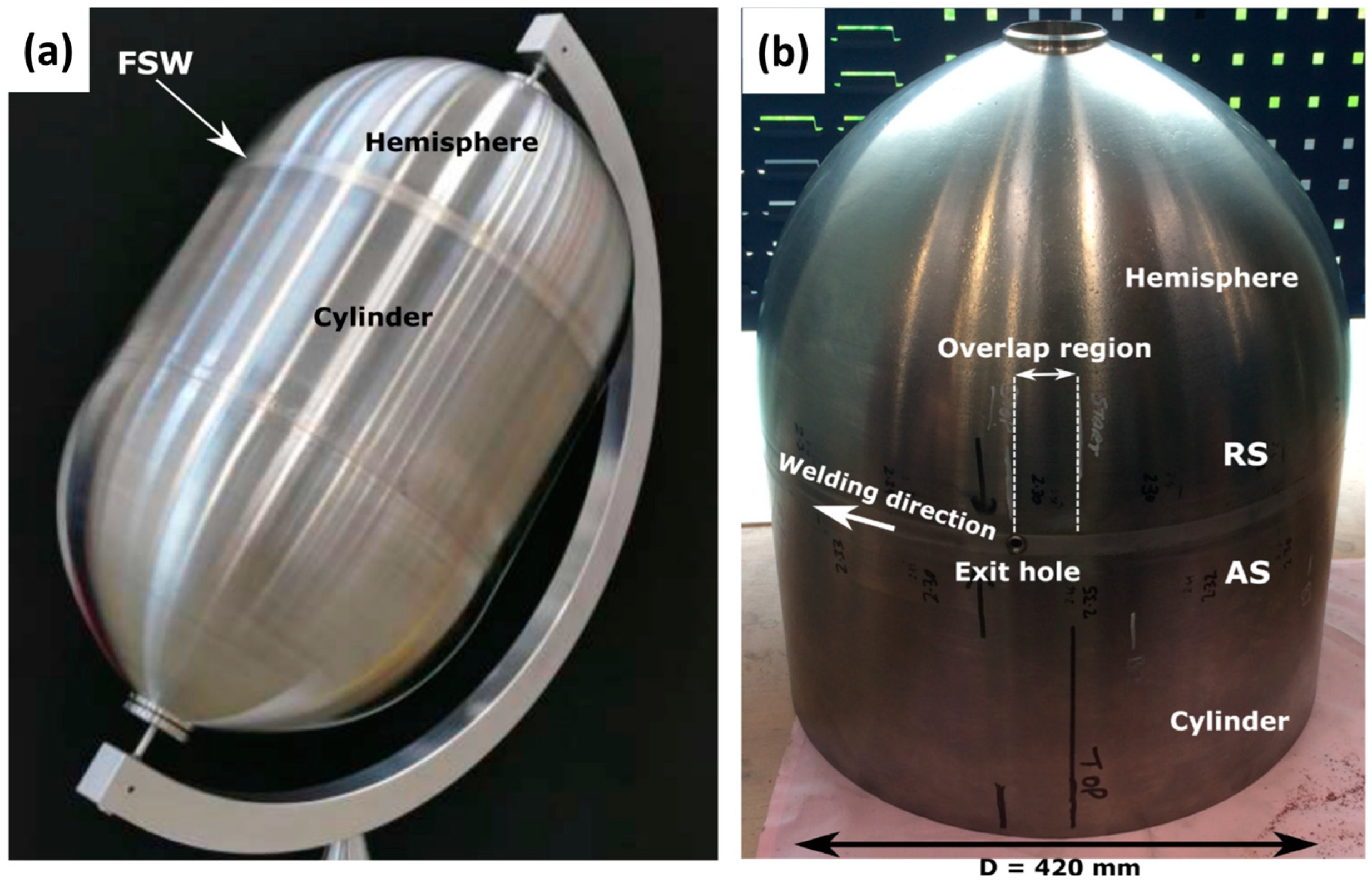

- Robelou, A.; Bellarosa, R.; Norman, A.; Andrews, D.; Martin, J.; Nor, K. Friction Stir Welding of Low Cost Space Hardware-Titanium Propellant Tank (2); Airbus Defence and Space: Stevenage, UK, 2016; pp. 3–4. [Google Scholar]

- Chen, Y.C.; Nakata, K. Microstructural characterization and mechanical properties in friction stir welding of aluminum and titanium dissimilar alloys. Mater. Des. 2009, 30, 469–474. [Google Scholar] [CrossRef]

- Fujii, H.; Sun, Y.; Kato, H.; Nakata, K. Investigation of welding parameter dependent microstructure and mechanical properties in friction stir welded pure Ti joints. Mater. Sci. Eng. A 2010, 527, 3386–3391. [Google Scholar] [CrossRef]

- Nirmal, K.; Jagadesh, T. Numerical simulations of friction stir welding of dual phase titanium alloy for aerospace applications. Mater. Today Proc. 2020, 46, 4702–4708. [Google Scholar] [CrossRef]

- Meikeerthy, S.; Ethiraj, N.; Neme, I.; Masi, C. Evaluation of Pure Titanium Welded Joints Produced by Underwater Friction Stir Welding. Adv. Mater. Sci. Eng. 2023, 2023, 2092339. [Google Scholar] [CrossRef]

- Mabuwa, S.; Msomi, V.; Muribwathoho, O.; Motshwanedi, S.S. The microstructure and mechanical properties of the friction stir processed TIG-welded aerospace dissimilar aluminium alloys. Mater. Today Proc. 2021, 46, 658–664. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Essa, A.R.S.; Ataya, S.; El-Sayed Seleman, M.M.; El-Aty, A.A.; Alzahrani, B.; Touileb, K.; Bakkar, A.; Ponnore, J.J.; Mohamed, A.Y.A. Friction Stir Welding of AA5754-H24: Impact of Tool Pin Eccentricity and Welding Speed on Grain Structure, Crystallographic Texture, and Mechanical Properties. Materials 2023, 16, 2031. [Google Scholar] [CrossRef] [PubMed]

- Pandian, V.; Kannan, S. Numerical prediction and experimental investigation of aerospace-grade dissimilar aluminium alloy by friction stir welding. J. Manuf. Process. 2020, 54, 99–108. [Google Scholar] [CrossRef]

- Rajan, D.; Prasad, V.S. Evaluation of NCMRWF numerical weather prediction models for SHAR region Space-Launch programme of India. Adv. Space Res. 2022. [Google Scholar] [CrossRef]

- Ipekoglu, G.; Erim, S.; Kiral, B.G.; Çam, G. Investigation into the effect of temper condition on friction stir weldability of AA6061 Al-alloy plates. Met. Mater. 2021, 51, 155–163. [Google Scholar] [CrossRef]

- Çam, G.; Ipekoğlu, G.; Serindağ, H.T. Effects of use of higher strength interlayer and external cooling on properties of friction stir welded AA6061-T6 joints. Sci. Technol. Weld. Join. 2014, 19, 715–720. [Google Scholar] [CrossRef]

- Su, Y.; Li, W.; Shen, J.; Bergmann, L.; dos Santos, J.F.; Klusemann, B.; Vairis, A. Comparing the fatigue performance of Ti-4Al-0.005B titanium alloy T-joints, welded via different friction stir welding sequences. Mater. Sci. Eng. A 2022, 859, 144227. [Google Scholar] [CrossRef]

- Du, S.; Liu, H.; Jiang, M.; Hu, Y.; Zhou, L. Eliminating the cavity defect and improving mechanical properties of TA5 alloy joint by titanium alloy supporting friction stir welding. J. Manuf. Process. 2021, 69, 215–222. [Google Scholar] [CrossRef]

- Campanella, D.; Buffa, G.; Lamia, D.; Fratini, L. Residual stress and material flow prediction in Friction Stir Welding of Gr2 Titanium T-joints. Manuf. Lett. 2022, 33, 249–258. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, Z.J.; Wang, Y.F.; Ren, D.X.; Li, J.Y. The relationship between microstructures and mechanical properties in friction stir lap welding of titanium alloy. Mater. Chem. Phys. 2023, 296, 127251. [Google Scholar] [CrossRef]

- Çam, G. Friction stir welded structural materials: Beyond Al-alloys. Int. Mater. Rev. 2011, 56, 1–48. [Google Scholar] [CrossRef]

- Liu, J.; Wu, B.; Wang, Z.; Li, C.; Chen, G.; Miao, Y. Microstructure and mechanical properties of aluminum-steel dissimilar metal welded using arc and friction stir hybrid welding. Mater. Des. 2023, 225, 111520. [Google Scholar] [CrossRef]

- Han, S.-C.; Chaudry, U.M.; Yoon, J.-Y.; Jun, T.-S. Investigating local strain rate sensitivity of the individual weld zone in the friction stir welded DP 780 steel. J. Mater. Res. Technol. 2022, 20, 508–515. [Google Scholar] [CrossRef]

- Duan, R.H.; Wang, Y.Q.; Luo, Z.A.; Wang, G.D.; Xie, G.M. Achievement of excellent strength and plasticity in the nugget zone of friction stir welded bainitic steel and its deformation behavior. J. Mater. Res. Technol. 2022, 20, 3381–3390. [Google Scholar] [CrossRef]

- Gain, S.; Das, S.K.; Acharyya, S.K.; Sanyal, D. Friction stir welding of industrial grade AISI 316L and P91 steel pipes: A comparative investigation based on mechanical and metallurgical properties. Int. J. Press. Vessel. Pip. 2023, 201, 104865. [Google Scholar] [CrossRef]

- Varghese, J.; Rajulapati, K.V.; Rao, K.B.S.; Meshram, S.D.; Reddy, G.M. Ambient, elevated temperature tensile properties and origin of strengthening in friction stir welded 6 mm thick reduced activation ferritic-martensitic steel plates in as-welded and post-weld normalised conditions. Mater. Sci. Eng. A 2022, 857, 144019. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Abdelazem, K.A.; El-Sayed Seleman, M.M.; Alzahrani, B.; Touileb, K.; Jouini, N.; El-Batanony, I.G.; El-Aziz, H.M.A. Friction stir welding of 2205 duplex stainless steel: Feasibility of butt joint groove filling in comparison to gas tungsten arc welding. Materials 2021, 14, 4597. [Google Scholar] [CrossRef] [PubMed]

- Chaudry, U.; Han, S.-C.; Alkelae, F.; Jun, T.-S. Efffect of PWHT on the Microstructure and Mechanical Properties of Friction Stir Welded DP780 Steel. Metals 2021, 11, 1097. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Touileb, K.; Albaijan, I.; Habba, M.I.A. Microstructure, crystallographic texture, and mechanical properties of friction stir welded mild steel for shipbuilding applications. Materials 2022, 15, 2905. [Google Scholar] [CrossRef] [PubMed]

- Küçükömero, T.; Aktarer, S.M.; Çam, G. Investigation of mechanical and microstructural properties of friction stir welded dual phase (DP) steel. IOP Conf. Ser. Mater. Sci. Eng. 2019, 629, 012010. [Google Scholar] [CrossRef]

- Ipeko, G.; Küçükömero, T.; Aktarer, S.M.; Sekban, D.; Çam, G. Investigation of microstructure and mechanical properties of friction stir welded dissimilar St37/St52 joints. Mater. Res. Express 2019, 6, 046537. [Google Scholar] [CrossRef]

- Hirata, T.; Tanaka, T.; Chung, S.W.; Takigawa, Y.; Higashi, K. Relationship between deformation behavior and microstructural evolution of friction stir processed Zn–22wt.% Al alloy. Scr. Mater. 2007, 56, 477–480. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and mechanical properties of dissimilar friction stir welded AA2024-T4/AA7075-T6 T-butt joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat input and mechanical properties investigation of friction stir welded aa5083/aa5754 and aa5083/aa7020. Metals 2021, 11, 68. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. Low temperature superplasticity in a friction-stir-processed ultrafine grained Al–Zn–Mg–Sc alloy. Acta Mater. 2005, 53, 4211–4223. [Google Scholar] [CrossRef]

- Gomez, A.; Smith, H. Liquid hydrogen fuel tanks for commercial aviation: Structural sizing and stress analysis. Aerosp. Sci. Technol. 2019, 95, 105438. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Meisnar, M.; Bennett, J.M.; Andrews, D.; Dodds, S.; Freeman, R.; Bellarosa, R.; Adams, D.; Norman, A.F.; Rohr, T.; Ghidini, T. Microstructure characterisation of a friction stir welded hemi-cylinder structure using Ti-6Al-4V castings. Mater. Charact. 2018, 147, 286–294. [Google Scholar] [CrossRef]

- Wang, G.-Q.; Zhao, Y.-H.; Tang, Y.-Y. Research Progress of Bobbin Tool Friction Stir Welding of Aluminum Alloys: A Review. Acta Met. Sin. 2019, 33, 13–29. [Google Scholar] [CrossRef]

- Grimm, A. New Joining Technologies for Future Fuselage Metal Structures; Fraunhofer IWS Annual Report 2014; Fraunhofer-Gesellschaft: München, Germany, 2014. [Google Scholar]

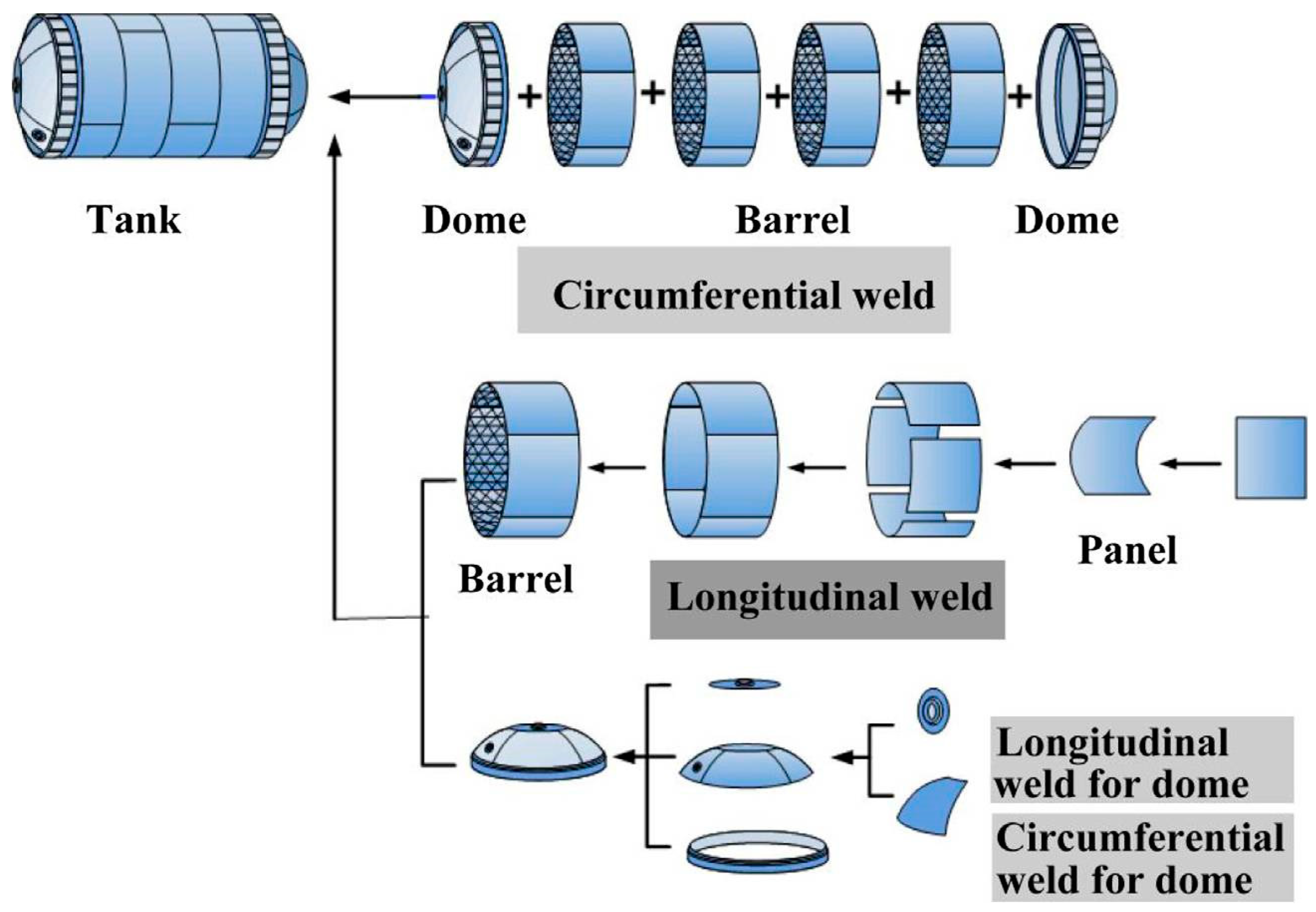

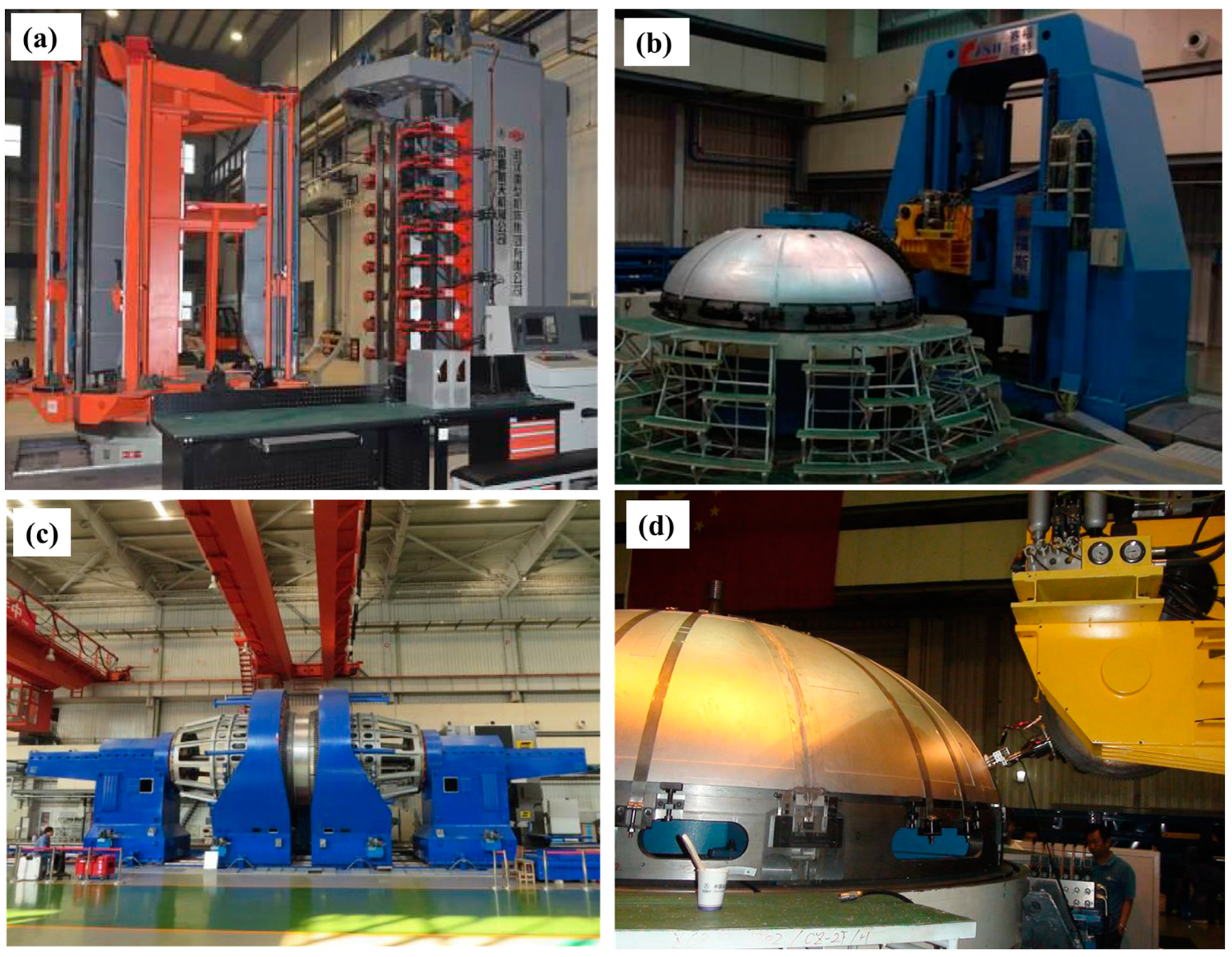

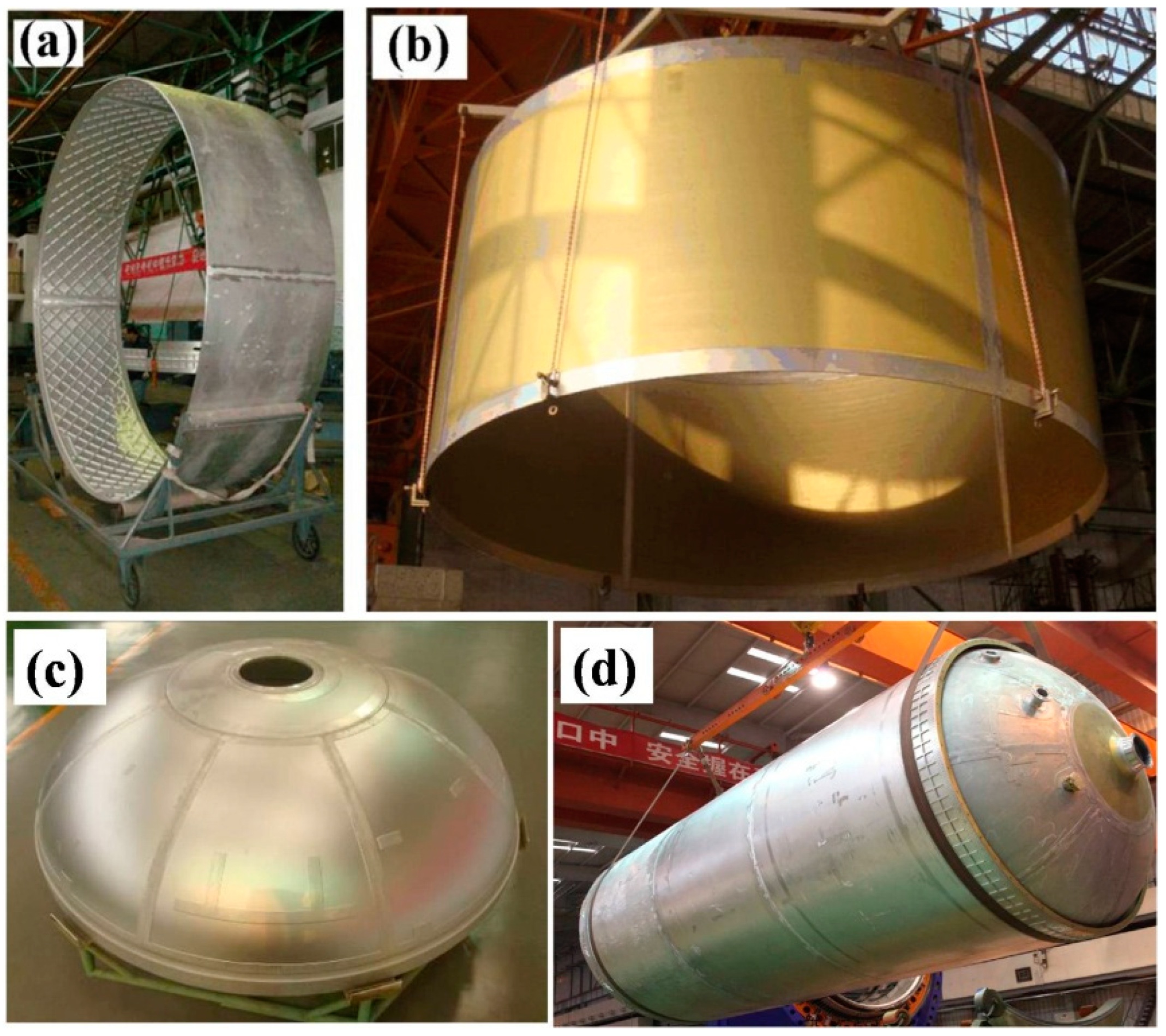

- Wang, G.; Zhao, Y.; Hao, Y. Friction stir welding of high-strength aerospace aluminum alloy and application in rocket tank manufacturing. J. Mater. Sci. Technol. 2018, 34, 73–91. [Google Scholar] [CrossRef]

- Tavares, S.; dos Santos, J.; de Castro, P. Friction stir welded joints of Al-Li Alloys for aeronautical applications: Butt-joints and tailor welded blanks. Theor. Appl. Fract. Mech. 2013, 65, 8–13. [Google Scholar] [CrossRef]

- Boldsaikhan, E.; Fukada, S.; Fujimoto, M.; Kamimuki, K.; Okada, H. Refill friction stir spot welding of surface-treated aerospace aluminum alloys with faying-surface sealant. J. Manuf. Process. 2019, 42, 113–120. [Google Scholar] [CrossRef]

- Christner, B.; Hansen, M.; Skinner, M.; Sylva, G. Friction Stir Welding System Development for Thin-Gauge Aersopace Structures. In Proceedings of the Fourth International Symposium on Friction Stir Welding, Park City, UT, USA, 14–16 May 2003; Volume 332, pp. 1–6. [Google Scholar] [CrossRef]

- Shepherd, G.E. The Evaluation of Friction Stir Welded Joints on Airbus Aircraft Wing Structure. In Proceedings of the Fourth International Symposium on Friction Stir Welding, Park City, UT, USA, 14–16 May 2003; pp. 1–5. [Google Scholar]

- Amini, A.; Asadi, P.; Zolghadr, P. Friction stir welding applications in industry. In Woodhead Publishing Series in Welding and Other Joining Technologies; Givi, M.K.B., Asadi, P., Eds.; Woodhead Publishing: Sawston, UK, 2014; pp. 671–722. [Google Scholar] [CrossRef]

- Kallee, S.W. Industrial applications of friction stir welding. In Woodhead Publishing Series in Welding and Other Joining Technologies; Lohwasser, D., Chen, W., Eds.; Woodhead Publishing: Sawston, UK, 2010; pp. 118–163. [Google Scholar] [CrossRef]

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2020, 115, 100706. [Google Scholar] [CrossRef]

- Mishra, R.S.; Sidhar, H. Chapter 1—Friction Stir Welding; Mishra, R.S., Sidhar, A., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 1–13. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Pahlavani, M.; Gholami, M.D.; Marzbanrad, J.; Hashemi, R. Production of Al/Mg-Li composite by the accumulative roll bonding process. J. Mater. Res. Technol. 2020, 9, 7880–7886. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Tayyebi, M.; Najafizadeh, N.; Hashemi, R.; Rajabi, M. The influence of post-annealing and ultrasonic vibration on the formability of multilayered Al5052/MgAZ31B composite. Mater. Sci. Technol. 2021, 37, 78–85. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Pahlavani, M.; Marzbanrad, J.; Hashemi, R.; Bayati, A. Manufacturing of three-layered sandwich composite of AA1050/LZ91/AA1050 using cold roll bonding process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1363–1372. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Jouini, N.; Alzahrani, B.; El-Sayed Seleman, M.M.; Jhaheen, M. Dissimilar friction stir welding of AA2024 and AISI 1018: Microstructure and mechanical properties. Metals 2021, 11, 330. [Google Scholar] [CrossRef]

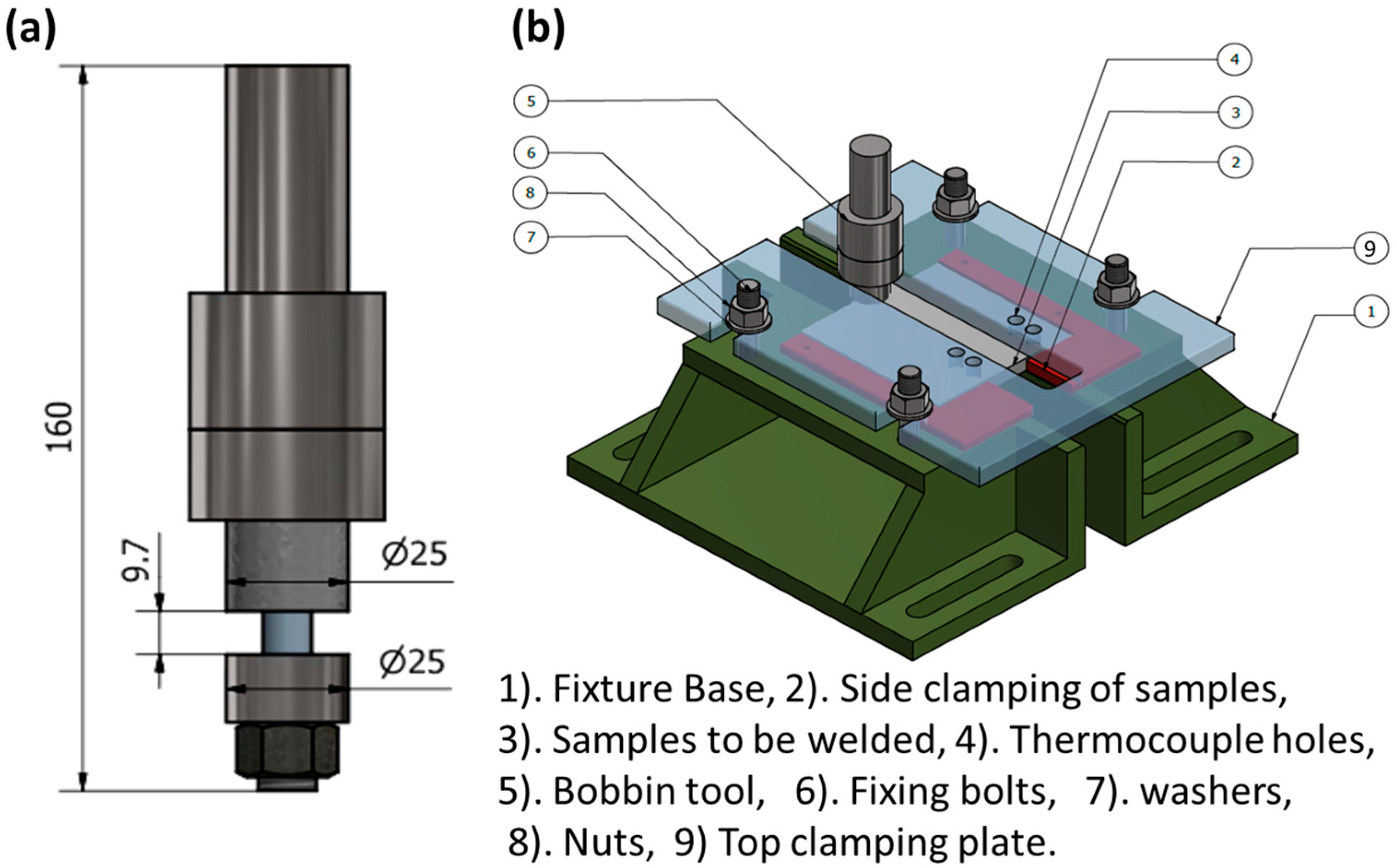

- Ahmed, M.M.Z.; Habba, M.I.A.; El-Sayed Seleman, M.M.; Hajlaoui, K.; Ataya, S.; Latief, F.H.; El-Nikhaily, A.E. Bobbin Tool Friction Stir Welding of Aluminum Thick Lap Joints: Effect of Process Parameters on Temperature Distribution and Joints’ Properties. Materials 2021, 14, 4585. [Google Scholar] [CrossRef]

- Lohwasser, D.; Chen, Z. Friction Stir Welding from Basics to Applications; Woodhead Publishing Limited: Sawston, UK, 2010. [Google Scholar]

- Yu, H.Z.; Jones, M.E.; Brady, G.W.; Griffiths, R.J.; Garcia, D.; Rauch, H.A.; Cox, C.D.; Hardwick, N. Non-beam-based metal additive manufacturing enabled by additive friction stir deposition. Scr. Mater. 2018, 153, 122–130. [Google Scholar] [CrossRef]

- Boitsov, A.G.; Kuritsyn, D.N.; Siluyanova, M.V.; Kuritsyna, V.V. Friction Stir Welding in the Aerospace Industry. Russ. Eng. Res. 2018, 38, 1029–1033. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Friction Stir Welding. G.B. Patent Application No. 9125978, 6 December 1991. [Google Scholar]

- Dawes, C.; Thomas, W. Friction Stir Joining of Aluminium Alloys; TWI Bulletin 6; TWI: Cambridge, UK, 1995. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Templesmith, P.; Dawes, C.J. Friction welding. U.S. Patent No. 5,460,317, 24 October 1995. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Çam, G.; Javaheri, V.; Heidarzadeh, A. Advances in FSW and FSSW of dissimilar Al-alloy plates. J. Adhes. Sci. Technol. 2022, 37, 162–194. [Google Scholar] [CrossRef]

- Kashaev, N.; Ventzke, V.; Çam, G. Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J. Manuf. Process. 2018, 36, 571–600. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.; Robson, J.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- Çam, G.; İpekoğlu, G. Recent developments in joining of aluminum alloys. Int. J. Adv. Manuf. Technol. 2016, 91, 1851–1866. [Google Scholar] [CrossRef]

- Çam, G.; Mistikoglu, S. Recent developments in friction stir welding of al-Alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- Ipeko, G.; Çam, G. Formation of weld defects in cold metal transfer arc welded 7075-T6 plates and its effect on joint performance. IOP Conf. Ser. Mater. Sci. Eng. 2019, 629, 012007. [Google Scholar] [CrossRef]

- Çam, G. Prospects of producing aluminum parts by wire arc additive manufacturing (WAAM). Mater. Today Proc. 2022, 62, 77–85. [Google Scholar] [CrossRef]

- Çam, G.; Koçak, M. Microstructural and mechanical characterization of electron beam welded Al-alloy 7020. J. Mater. Sci. 2007, 42, 7154–7161. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z. The Development of Thick Section Welds and Ultra-Fine Grain Aluminium Using Friction Stir Welding and Processing. Ph.D. Thesis, The University of Sheffield, Sheffield, UK, 2009. [Google Scholar]

- Ahmed, M.M.Z.Z.; Wynne, B.P.; Rainforth, W.M.; Addison, A.; Martin, J.P.; Threadgill, P.L. Effect of Tool Geometry and Heat Input on the Hardness, Grain Structure, and Crystallographic Texture of Thick-Section Friction Stir-Welded Aluminium. Met. Mater. Trans. A 2018, 50, 271–284. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Martin, J.P. Effect of friction stir welding speed on mechanical properties and microstructure of nickel based super alloy Inconel 718. Sci. Technol. Weld. Join. 2013, 18, 680–687. [Google Scholar] [CrossRef]

- Li, G.; Zhou, L.; Luo, L.; Wu, X.; Guo, N. Microstructural evolution and mechanical properties of refill friction stir spot welded alclad 2A12-T4 aluminum alloy. J. Mater. Res. Technol. 2019, 8, 4115–4129. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.S.; Ahmed, E.; Reyad, H.A.; Touileb, K.; Albaijan, I. Friction Stir Spot Welding of Different Thickness Sheets of Aluminum Alloy AA6082-T6. Materials 2022, 15, 2971. [Google Scholar] [CrossRef]

- Sun, Y.; Fujii, H.; Zhu, S.; Guan, S. Flat friction stir spot welding of three 6061-T6 aluminum sheets. J. Mater. Process. Technol. 2018, 264, 414–421. [Google Scholar] [CrossRef]

- de Castro, C.C.; Shen, J.; Plaine, A.H.; Suhuddin, U.F.; de Alcântara, N.G.; dos Santos, J.F.; Klusemann, B. Tool wear mechanisms and effects on refill friction stir spot welding of AA2198-T8 sheets. J. Mater. Res. Technol. 2022, 20, 857–866. [Google Scholar] [CrossRef]

- Kubit, A.; Kluz, R.; Trzepieciński, T.; Wydrzyński, D.; Bochnowski, W. Analysis of the mechanical properties and of micrographs of refill friction stir spot welded 7075-T6 aluminium sheets. Arch. Civ. Mech. Eng. 2018, 18, 235–244. [Google Scholar] [CrossRef]

- Kubit, A.; Bucior, M.; Wydrzyński, D.; Trzepieciński, T.; Pytel, M. Failure mechanisms of refill friction stir spot welded 7075-T6 aluminium alloy single-lap joints. Int. J. Adv. Manuf. Technol. 2017, 94, 4479–4491. [Google Scholar] [CrossRef]

- Kubit, A.; Wydrzynski, D.; Trzepiecinski, T. Refill friction stir spot welding of 7075-T6 aluminium alloy single-lap joints with polymer sealant interlayer. Compos. Struct. 2018, 201, 389–397. [Google Scholar] [CrossRef]

- Kubit, A.; Trzepiecinski, T.; Faes, K.; Drabczyk, M.; Bochnowski, W.; Korzeniowski, M. Analysis of the effect of structural defects on the fatigue strength of RFSSW joints using C-scan scanning acoustic microscopy and SEM. Fatigue Fract. Eng. Mater. Struct. 2018, 42, 1308–1321. [Google Scholar] [CrossRef]

- Yang, X.W.; Fu, T.; Li, W.Y. Friction Stir Spot Welding: A Review on Joint Macro- and Microstructure, Property, and Process Modelling. Adv. Mater. Sci. Eng. 2014, 2014, 697170. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Ahmed, E.; Reyad, H.A.; Alsaleh, N.A.; Albaijan, I. A Novel Friction Stir Deposition Technique to Refill Keyhole of Friction Stir Spot Welded AA6082-T6 Dissimilar Joints of Different Sheet Thicknesses. Materials 2022, 15, 6799. [Google Scholar] [CrossRef] [PubMed]

- Rutherford, B.A.; Avery, D.Z.; Phillips, B.J.; Rao, H.M.; Doherty, K.J.; Allison, P.G.; Brewer, L.N.; Jordon, J.B. Effect of thermomechanical processing on fatigue behavior in solid-state additive manufacturing of Al-Mg-Si alloy. Metals 2020, 10, 947. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Elfishawy, E.; Alzahrani, B.; Touileb, K.; Habba, M.I.A. The Effect of Temper Condition and Feeding Speed on the Additive Manufacturing of AA2011 Parts Using Friction Stir Deposition. Materials 2021, 14, 6396. [Google Scholar] [CrossRef] [PubMed]

- El-Sayed Seleman, M.M.; Ataya, S.; Ahmed, M.M.Z.; Hassan, A.M.M.; Latief, F.H.; Hajlaoui, K.; El-Nikhaily, A.E.; Habba, M.I.A. The Additive Manufacturing of Aluminum Matrix Nano Al2O3 Composites Produced via Friction Stir Deposition Using Different Initial Material Conditions. Materials 2022, 15, 2926. [Google Scholar] [CrossRef] [PubMed]

- Jahangir, M.N.; Mamun, M.A.H.; Sealy, M.P. A review of additive manufacturing of magnesium alloys. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 1980, p. 030026. [Google Scholar] [CrossRef]

- Elfishawy, E.; Ahmed, M.M.Z.; El-Sayed Seleman, M.M. Additive Manufacturing of Aluminum Using Friction Stir Deposition. In Proceedings of the TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings, San Diego, CA, USA, 23–27 February 2020; Minerals, Metals & Materials Society, Ed.; The Minerals, Metals & Materials Series. Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Alzahrani, B.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z.; Elfishawy, E.; Ahmed, A.M.Z.; Touileb, K.; Jouini, N.; Habba, M.I.A. The Applicability of Die Cast A356 Alloy to Additive Friction Stir Deposition at Various Feeding Speeds. Materials 2021, 14, 6018. [Google Scholar] [CrossRef] [PubMed]

- Zou, Y.; Li, W.; Yang, X.; Patel, V.; Shen, Z.; Chu, Q.; Wang, F.; Tang, H.; Cui, F.; Chi, M. Characterizations of dissimilar refill friction stir spot welding 2219 aluminum alloy joints of unequal thickness. J. Manuf. Process. 2022, 79, 91–101. [Google Scholar] [CrossRef]

- Zou, Y.; Li, W.; Xu, Y.; Yang, X.; Chu, Q.; Shen, Z. Detailed characterizations of microstructure evolution, corrosion behavior and mechanical properties of refill friction stir spot welded 2219 aluminum alloy. Mater. Charact. 2021, 183, 111594. [Google Scholar] [CrossRef]

- Janga, V.S.R.; Awang, M.; Yamin, M.F.; Suhuddin, U.F.H.; Klusemann, B.; Dos Santos, J.F. Experimental and numerical analysis of refill friction stir spot welding of thin AA7075-T6 sheets. Materials 2021, 14, 7485. [Google Scholar] [CrossRef]

- Janga, V.S.R.; Awang, M. Influence of Plunge Depth on Temperatures and Material Flow Behavior in Refill Friction Stir Spot Welding of thin AA7075-T6 Sheets: A Numerical Study. Metals 2022, 12, 927. [Google Scholar] [CrossRef]

- Fritsche, S.; Draper, J.; Toumpis, A.; Galloway, A.; Amancio-Filho, S.T. Refill friction stir spot welding of AlSi10Mg alloy produced by laser powder bed fusion to wrought AA7075-T6 alloy. Manuf. Lett. 2022, 34, 78–81. [Google Scholar] [CrossRef]

- Zhang, D.; Dong, J.; Xiong, J.; Jiang, N.; Li, J.; Guo, W. Microstructure characteristics and corrosion behavior of refill friction stir spot welded 7050 aluminum alloy. J. Mater. Res. Technol. 2022, 20, 1302–1314. [Google Scholar] [CrossRef]

- Deng, L.; Li, S.; Ke, L.; Liu, J.; Kang, J. Microstructure and fracture behavior of refill friction stir spot welded joints of AA2024 using a novel refill technique. Metals 2019, 9, 286. [Google Scholar] [CrossRef]

- Gera, D.; Fu, B.; Suhuddin, U.F.; Plaine, A.; Alcantara, N.; dos Santos, J.F.; Klusemann, B. Microstructure, mechanical and functional properties of refill friction stir spot welds on multilayered aluminum foils for battery application. J. Mater. Res. Technol. 2021, 13, 2272–2286. [Google Scholar] [CrossRef]

- Wang, S.; Wei, X.; Xu, J.; Hong, J.; Song, X.; Yu, C.; Chen, J.; Chen, X.; Lu, H. Strengthening and toughening mechanisms in refilled friction stir spot welding of AA2014 aluminum alloy reinforced by graphene nanosheets. Mater. Des. 2019, 186, 108212. [Google Scholar] [CrossRef]

- Yousefi, A.; Serjouei, A.; Hedayati, R.; Bodaghi, M. Fatigue modeling and numerical analysis of re-filling probe hole of friction stir spot welded joints in aluminum alloys. Materials 2021, 14, 2171. [Google Scholar] [CrossRef]

- Zou, Y.; Li, W.; Yang, X.; Su, Y.; Chu, Q.; Shen, Z. Microstructure and mechanical properties of refill friction stir spot welded joints: Effects of tool size and welding parameters. J. Mater. Res. Technol. 2022, 21, 5066–5080. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Xiong, J.; Shi, J.; Dou, J.; Zhao, H. Enhance mechanical properties of refill friction stir spot welding joint of alclad 7050/2524 aluminum via suspension rotating process. J. Mater. Res. Technol. 2021, 12, 1243–1251. [Google Scholar] [CrossRef]

- Li, P.; Chen, S.; Dong, H.; Ji, H.; Li, Y.; Guo, X.; Yang, G.; Zhang, X.; Han, X. Interfacial microstructure and mechanical properties of dissimilar aluminum/steel joint fabricated via refilled friction stir spot welding. J. Manuf. Process. 2019, 49, 385–396. [Google Scholar] [CrossRef]

- Fu, B.; Shen, J.; Suhuddin, U.F.; Chen, T.; dos Santos, J.F.; Klusemann, B.; Rethmeier, M. Improved mechanical properties of cast Mg alloy welds via texture weakening by differential rotation refill friction stir spot welding. Scr. Mater. 2021, 203, 114113. [Google Scholar] [CrossRef]

- Sarila, V.; Koneru, H.P.; Cheepu, M.; Chigilipalli, B.K.; Kantumuchu, V.C.; Shanmugam, M. Microstructural and Mechanical Properties of AZ31B to AA6061 Dissimilar Joints Fabricated by Refill Friction Stir Spot Welding. J. Manuf. Mater. Process. 2022, 6, 95. [Google Scholar] [CrossRef]

- Wynne, B.P.; Threadgill, P.L.; Davies, P.S.; Thomas, M.J.; Ng, B.S. Microstructure and Texture in Static Shoulder Friction Stir Welds of Ti–6Al–4V. In Proceedings of the 7th International Friction Stir Welding Symposium, Awaji, Japan, 20–22 May 2008; pp. 1–8. [Google Scholar]

- Russell, M.J.; Blignault, C. Recent developments in friction stir welding of Ti alloys. In Proceedings of the 6th International Symposium on Friction Stir Welding, Saint Sauveur, QC, Canada, 10–13 October 2006. [Google Scholar]

- Russell, M.J.; Threadgill, P.L.; Thomas, M.J.; Wynne, B.P. Static shoulder friction stir welding of Ti-6Al-4V; process and evaluation. In Proceedings of the 11th World Conference on titanium (Ti-2007), (JIMIC-5), Kyoto, Japan, 3–7 June 2007. [Google Scholar]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Threadgill, P.L. Through-thickness crystallographic texture of stationary shoulder friction stir welded aluminium. Scr. Mater. 2011, 64, 45–48. [Google Scholar] [CrossRef]

- Hammad, A.S.; Ahmed, M.M.; Lu, H.; El-Shabasy, A.B.; Alzahrani, B.; El-Sayed Seleman, M.M.; Zhang, Y.; El Megharbel, A. An investigation on mechanical and microstructural evolution of stationary shoulder friction stir welded aluminum alloy AA7075-T651. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 6665–6676. [Google Scholar] [CrossRef]

- Barbini, A.; Carstensen, J.; Santos, J.F. Influence of a non-rotating shoulder on heat generation, microstructure and mechanical properties of dissimilar AA2024 / AA7050 FSW joints. J. Mater. Sci. Technol. 2018, 34, 119–127. [Google Scholar] [CrossRef]

- Li, D.; Yang, X.; Cui, L.; He, F.; Zhang, X. Journal of Materials Processing Technology Investigation of stationary shoulder friction stir welding of aluminum alloy 7075-T651. J. Mater. Process. Technol. 2015, 222, 391–398. [Google Scholar] [CrossRef]

- Sun, T.; Roy, M.J.; Strong, D.; Simpson, C.; Withers, P.J.; Prangnell, P.B. Weld zone and residual stress development in AA7050 stationary shoulder friction stir T-joint weld. J. Mater. Process. Technol. 2019, 263, 256–265. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, X.; Li, D.; Cui, L. The local strength and toughness for stationary shoulder friction stir weld on AA6061-T6 alloy. Mater. Charact. 2016, 111, 114–121. [Google Scholar] [CrossRef]

- Ji, S.D.; Meng, X.C.; Liu, J.G.; Zhang, L.G.; Gao, S.S. Formation and mechanical properties of stationary shoulder friction stir welded 6005A-T6 aluminum alloy. Mater. Des. 2014, 62, 113–117. [Google Scholar] [CrossRef]

- Wu, H.; Chen, Y.; Strong, D.; Prangnell, P. Stationary shoulder FSW for joining high strength aluminum alloys. J. Mater. Process. Technol. 2015, 221, 187–196. [Google Scholar] [CrossRef]

- Richardson, M. A Stirring Work of Friction. Aerospace Manufacturing Magazine. 2014. Available online: https://www.aero-mag.com/a-stirring-work-of-friction/ (accessed on 11 March 2020).

- Marie, F.; Silvanous, J.; Hahan, S. Joining of dissimilar metals for satellite feedtroughs using DeltaN FS. In Proceedings of the Tenth FSW Symposium, Beijing, China, 20–22 May 2014. [Google Scholar]

- Threadgill, P.L.; Ahmed, M.M.Z.; JMartin, J.P.; Perrett, J.G.; Wynne, B.P. The use of bobbin tools for friction stir welding of aluminium alloys. Mater. Sci. Forum 2010, 638–642, 1179–1184. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Touileb, K.; El-Sayed Seleman, M.M.; Albaijan, I.; Habba, M.I.A. Bobbin Tool Friction Stir Welding of Aluminum: Parameters Optimization Using Taguchi Experimental Design. Materials 2022, 15, 2771. [Google Scholar] [CrossRef]

- Ataya, S.; Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Hajlaoui, K.; Latief, F.H.; Soliman, A.M.; Elshaghoul, Y.G.Y.; Habba, M.I.A. Effective Range of FSSW Parameters for High Load-Carrying Capacity of Dissimilar Steel A283M-C/Brass CuZn40 Joints. Materials 2022, 15, 1394. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.F.; Luo, Y.X.; Fu, M.W. Microstructure evolution in the conventional single side and bobbin tool friction stir welding of thick rolled 7085-T7452 aluminum alloy. Mater. Charact. 2018, 138, 48–55. [Google Scholar] [CrossRef]

- Xu, W.; Luo, Y.; Zhang, W.; Fu, M. Comparative study on local and global mechanical properties of bobbin tool and conventional friction stir welded 7085-T7452 aluminum thick plate. J. Mater. Sci. Technol. 2018, 34, 173–184. [Google Scholar] [CrossRef]

- Yang, C.; Ni, D.; Xue, P.; Xiao, B.; Wang, W.; Wang, K.; Ma, Z. A comparative research on bobbin tool and conventional friction stir welding of Al-Mg-Si alloy plates. Mater. Charact. 2018, 145, 20–28. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Eid, R.G.; Zawrah, M.F. Production of AA1050/silica fume composite by bobbin tool-friction stir processing: Microstructure, composition and mechanical properties. CIRP J. Manuf. Sci. Technol. 2022, 38, 801–812. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Habba, M.I.A.; Jouini, N.; Alzahrani, B.; El-Sayed Seleman, M.M.; El-Nikhaily, A. Bobbin tool friction stir welding of aluminum using different tool pin geometries: Mathematical models for the heat generation. Metals 2021, 11, 438. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.S.; Eid, R.G.; Albaijan, I.; Touileb, K. The Influence of Tool Pin Geometry and Speed on the Mechanical Properties of the Bobbin Tool Friction Stir Processed AA1050. Materials 2022, 15, 4684. [Google Scholar] [CrossRef]

- Albaijan, I.; Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Touileb, K.; Habba, M.I.A.; Fouad, R.A. Optimization of Bobbin Tool Friction Stir Processing Parameters of AA1050 Using Response Surface Methodology. Materials 2022, 15, 6886. [Google Scholar] [CrossRef]

- Mouritz, A.P. Introduction to Aerospace Materials; Woodhead Publishing Limited: Sawston, UK, 2012. [Google Scholar]

- Kaempf and Harris. A Quick History of Metal Fabrication in the Aerospace Industry. Industry Articles from Kaempf and Harris. 2019. Available online: https://www.kaempfandharris.com/industry-news/a-quick-history-of-metal-fabrication-in-the-aerospace-industry (accessed on 4 December 2019).

- Smye, B. Aluminum Alloys for Aerospace. Aerospace Manufacturing and Design. 2018. Available online: https://www.aerospacemanufacturinganddesign.com/article/aluminum-alloys-for-aerospace/ (accessed on 11 March 2020).

- Polmear, I.J. Light Alloys: Metallurgy of the Light Metals, 3rd ed.; Edward Arnold: London, UK, 1995. [Google Scholar]

- Hatch, J.E. Aluminum: Properties and Physical Metallurgy, 1st ed.; ASM: Metals Park, OH, USA, 1984. [Google Scholar]

- Campbell, F.C. Elements of Metallurgy and Engineering Alloys; ASM International: Materials Park, OH, USA, 2008. [Google Scholar]

- Polmear, I. Light Alloys from Traditional Alloys to Nanocrystals, 4th ed.; Elsevier: London, UK, 2005. [Google Scholar]

- Davis, J.R. Light Metals and Alloys, Alloying: Understanding the Basics; ASM International: Novelty, OH, USA, 2001. [Google Scholar]

- Seleman, M.M.E.S.; Ahmed, M.M.Z.; Ramadan, R.M.; Zaki, B.A. Effect of FSW Parameters on The Microstructure and Mechanical Properties of T-joints between Dissimilar Al-Alloys. Int. J. Integr. Eng. 2022, 14, 1–12. [Google Scholar] [CrossRef]

- Polmear, I.J. Recent Developments in light alloys. Mater. Trans. JIM 1996, 37, 12–31. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Hajlaoui, K.; El-Sayed Seleman, M.M.; Elkady, M.F.; Ataya, S.; Latief, F.H.; Habba, M.I.A. Microstructure and Mechanical Properties of Friction Stir Welded 2205 Duplex Stainless Steel Butt Joints. Materials 2021, 14, 6640. [Google Scholar] [CrossRef] [PubMed]

- Wanhill, R.J.H.; Bray, G.H. Aerostructural design and its application to aluminum lithium alloys. In Aluminum-Lithium Alloys: Processing, Properties, and Applications; Prasad, N.E., Gokhale, A.A., Wanhill, R.J.H., Eds.; Butterworth-Heinemann–Elsevier: Amsterdam, The Netherlands, 2014; pp. 27–57. [Google Scholar]

- El-Aty, A.A.; Xu, Y.; Guo, X.; Zhang, S.H.; Ma, Y.; Chen, D. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef]

- Prasad, N.E.; Gokhale, A.; Wanhill, R. Aluminum-Lithium Alloys: Processing, Properties, and Applications; Butterworth-Heinemann–Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Rioja, R.J.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Lequeu, P.; Smith, K.P.; Daniélou, A. Aluminum-copper-lithium alloy 2050 developed for medium to thick plate. J. Mater. Eng. Perform. 2009, 19, 841–847. [Google Scholar] [CrossRef]

- Fridlyander, I.N.; Khokhlatova, L.B.; Kolobnev, N.I.; Rendiks, K.; Tempus, G. Thermally stable aluminum-lithium alloy 1424 for application in welded fuselage. Met. Sci. Heat Treat. 2002, 44, 3–8. [Google Scholar] [CrossRef]

- Khokhlatova, L.B.; Kolobnev, N.I.; Oglodkov, M.S.; Mikhaylov, E.D. Aluminum-lithium alloys for aircraft building. Metallurgist 2012, 56, 336–341. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Hashemi, R.; Tayyebi, M.; Bayati, A. Investigation of mechanical properties, formability, and anisotropy of dual phase Mg-7Li-1Zn. Mater. Res. Express 2019, 6, 096543. [Google Scholar] [CrossRef]

- Pahlavani, M.; Marzbanrad, J.; Rahmatabadi, D.; Hashemi, R.; Bayati, A. A comprehensive study on the effect of heat treatment on the fracture behaviors and structural properties of Mg-Li alloys using RSM. Mater. Res. Express 2019, 6, 076554. [Google Scholar] [CrossRef]

- Sidhar, H.; Martinez, N.Y.; Mishra, R.S.; Silvanus, J. Friction stir welding of Al-Mg-Li 1424 alloy. Mater. Des. 2016, 106, 146–152. [Google Scholar] [CrossRef]

- Mishra, A. Friction Stir Welding of Aerospace Alloys. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 863–870. [Google Scholar] [CrossRef]

- Lee, C.Y.; Lee, W.B.; Kim, J.W.; Choi, D.H.; Yeon, Y.M.; Jung, S.B. Lap joint properties of FSWed dissimilar formed 5052 Al and 6061 Al alloys with different thickness. J. Mater. Sci. 2008, 43, 3296–3304. [Google Scholar] [CrossRef]

- da Silva, A.A.M.; Arruti, E.; Janeiro, G.; Aldanondo, E.; Alvarez, P.; Echeverria, A. Material flow and mechanical behaviour of dissimilar AA2024-T3 and AA7075-T6 aluminium alloys friction stir welds. Mater. Des. 2011, 32, 2021–2027. [Google Scholar] [CrossRef]

- Mehdi, H.; Mishra, R.S. Mechanical and microstructure characterization of friction stir welding for dissimilar alloy-A Review. Int. J. Res. Eng. Innov. 2017, 1, 57–67. Available online: http://www.ijrei.com (accessed on 11 March 2020).

- Dubourg, L.; Merati, A.; Jahazi, M. Process optimisation and mechanical properties of friction stir lap welds of 7075-T6 stringers on 2024-T3 skin. Mater. Des. 2010, 31, 3324–3330. [Google Scholar] [CrossRef]

- Benavides, S.; Li, Y.; Murr, L.; Brown, D.; McClure, J. Low-temperature friction-stir welding of 2024 aluminum. Scr. Mater. 1999, 41, 809–815. [Google Scholar] [CrossRef]

- Sutton, M.; Yang, B.; Reynolds, A.; Taylor, R. Microstructural studies of friction stir welds in 2024-T3 aluminum. Mater. Sci. Eng. A 2002, 323, 160–166. [Google Scholar] [CrossRef]

- Amancio-Filhoa, S.T.; Sheikhia, S.; Santosa, J.F.D.; Bolfarini, C. Preliminary study on the microstructure and mechanical properties of dissimilar friction stir welds in aircraft aluminium alloys 2024-T351 and 6056-T4. J. Mater. Process. Technol. 2008, 206, 132–142. [Google Scholar] [CrossRef]

- Avinash, P.; Manikandan, M.; Arivazhagan, N.; Ramkumar, K.D.; Narayanan, S. Friction stir welded butt joints of AA2024 T3 and AA7075 T6 aluminum alloys. Procedia Eng. 2014, 75, 98–102. [Google Scholar] [CrossRef]

- RaviKumar, S.; Rao, V.S.; Pranesh, R.V. Effect of Welding Parameters on Macro and Microstructure of Friction Stir Welded Dissimilar Butt Joints between AA7075-T651 and AA6061-T651 Alloys. Procedia Mater. Sci. 2014, 5, 1726–1735. [Google Scholar] [CrossRef]

- Shanavas, S.; Dhas, J.E.R.; Murugan, N. Weldability of marine grade AA 5052 aluminum alloy by underwater friction stir welding. Int. J. Adv. Manuf. Technol. 2018, 95, 4535–4546. [Google Scholar] [CrossRef]

- Khalaf, H.I.; Al-sabur, R.; Abdullah, M.E.; Kubit, A.; Derazkola, H.A. Effects of Underwater Friction Stir Welding Heat Generation on Residual Stress of AA6068-T6 Aluminum Alloy. Materials 2022, 15, 2223. [Google Scholar] [CrossRef]

- Saravanakumar, R.; Rajasekaran, T.; Pandey, C. Underwater Friction Stir Welded Armour Grade AA5083 Aluminum Alloys: Experimental Ballistic Performance and Corrosion Investigation. J. Mater. Eng. Perform. 2023, 1–16. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Javidani, M.; Mofarrehi, M.; Farzaneh, A.; Chen, X.G. Submerged dissimilar friction stir welding of aa6061 and AA7075 aluminum alloys: Microstructure characterization and mechanical property. Metals 2021, 11, 1592. [Google Scholar] [CrossRef]

- Kumbhar, N.T.; Bhanumurthy, K. Friction stir welding of 6061 alloy. Asian J. Exp. Sci. 2008, 22, 63–74. [Google Scholar] [CrossRef]

- Scialpi, A.; De Filippis, L.A.C.; Cavaliere, P. Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminium alloy. Mater. Des. 2007, 28, 1124–1129. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Met. Mater. Trans. A 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Kimura, M.; Kusaka, M.; Seo, K.; Fuji, A. Joining phenomena during friction stage of A7075-T6 aluminium alloy friction weld. Sci. Technol. Weld. Join. 2005, 10, 378–383. [Google Scholar] [CrossRef]

- Fu, R.; Sun, Z.; Sun, R.; Li, Y.; Liu, H.; Liu, L. Improvement of weld temperature distribution and mechanical properties of 7050 aluminum alloy butt joints by submerged friction stir welding. Mater. Des. 2011, 32, 4825–4831. [Google Scholar] [CrossRef]

- Venugopal, T.; Rao, K.S.; Rao, K.P. Studies on friction stir welded aa 7075 aluminum alloy. Trans. Indian Inst. Met. 2004, 57, 659–663. [Google Scholar]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction stir welding of similar and dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Yang, Y.; Bi, J.; Liu, H.; Li, Y.; Li, M.; Ao, S.; Luo, Z. Research progress on the microstructure and mechanical properties of friction stir welded AlLi alloy joints. J. Manuf. Process. 2022, 82, 230–244. [Google Scholar] [CrossRef]

- Mishra, R.S.; Sidhar, H. Chapter 5—Friction Stir Welding of Al–Li Alloys; Mishra, R.S., Sidhar, A., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 79–95. [Google Scholar] [CrossRef]

- Wei, S.; Hao, C.; Chen, J. Study of friction stir welding of 01420 aluminum-lithium alloy. Mater. Sci. Eng. A 2007, 452–453, 170–177. [Google Scholar] [CrossRef]

- Altenkirch, J.; Steuwer, A.; Withers, P.J. Process—Microstructure—Property correlations in Al–Li AA2199 friction stir welds. Sci. Technol. Weld. Join. 2010, 15, 522–527. [Google Scholar] [CrossRef]

- Shukla, A.K.; Baeslack, W.A. Study of microstructural evolution in friction-stir welded thin-sheet Al–Cu–Li alloy using transmission-electron microscopy. Scr. Mater. 2007, 56, 513–516. [Google Scholar] [CrossRef]

- Cavaliere, P.; Cabibbo, M.; Panella, F.; Squillace, A. 2198 Al–Li plates joined by Friction Stir Welding: Mechanical and microstructural behavior. Mater. Des. 2009, 30, 3622–3631. [Google Scholar] [CrossRef]

- Cavaliere, P.; De Santis, A.; Panella, F.; Squillace, A. Effect of anisotropy on fatigue properties of 2198 Al–Li plates joined by friction stir welding. Eng. Fail. Anal. 2009, 16, 1856–1865. [Google Scholar] [CrossRef]

- Steuwer, A.; Dumont, M.; Altenkirch, J.; Birosca, S.; Deschamps, A.; Prangnell, P.B.; Withers, P.J. A combined approach to microstructure mapping of an Al–Li AA2199 friction stir weld. Acta Mater. 2011, 59, 3002–3011. [Google Scholar] [CrossRef]

- Ma, Y.E.; Zhao, Z.; Liu, B.; Li, W. Mechanical properties and fatigue crack growth rates in friction stir welded nugget of 2198-T8 Al–Li alloy joints. Mater. Sci. Eng. A 2013, 569, 41–47. [Google Scholar] [CrossRef]

- De Geuser, F.; Malard, B.; Deschamps, A. Microstructure mapping of a friction stir welded AA2050 Al–Li–Cu in the T8 state. Philos. Mag. 2014, 94, 1451–1462. [Google Scholar] [CrossRef]

- Gao, C.; Zhu, Z.; Han, J.; Li, H. Correlation of microstructure and mechanical properties in friction stir welded 2198-T8 Al–Li alloy. Mater. Sci. Eng. A 2015, 639, 489–499. [Google Scholar] [CrossRef]

- Qin, H.; Zhang, H.; Wu, H. The evolution of precipitation and microstructure in friction stir welded 2195-T8 Al–Li alloy. Mater. Sci. Eng. A 2015, 626, 322–329. [Google Scholar] [CrossRef]

- Muthumanickam, A. Effect of Friction Stir Welding Parameters on Mechanical Properties and Microstructure of AA2195 Al—Li Alloy Welds. Trans. Indian Inst. Met. 2019, 72, 1557–1561. [Google Scholar] [CrossRef]

- Yan, K.; Wang, T.; Liang, H.; Zhao, Y. Effects of Rotation Speed on Microstructure and Mechanical Properties of 2060 Al-Cu-Li Alloy in Friction Stir Welding. J. Mater. Eng. Perform. 2018, 27, 5803–5814. [Google Scholar] [CrossRef]

- Wang, F.F.; Li, W.Y.; Shen, J.; Zhang, Z.H.; Li, J.L.; dos Santos, J.F. Global and local mechanical properties and microstructure of Bobbin tool friction-stir-welded Al–Li alloy. Sci. Technol. Weld. Join. 2016, 21, 479–483. [Google Scholar] [CrossRef]

- Alam, M.P.; Sinha, A.N. Effect of heat assisting backing plate in friction stir welding of high strength Al-Li alloy. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 44, 2851–2862. [Google Scholar] [CrossRef]

- Cisko, A.R.; Jordon, J.B.; Amaro, R.L.; Allison, P.G.; Wlodarski, J.S.; McClelland, Z.B.; Garcia, L.; Rushing, T.W. A parametric investigation on friction stir welding of Al-Li 2099. Mater. Manuf. Process. 2020, 35, 1069–1076. [Google Scholar] [CrossRef]

- Wang, F.F.; Li, W.Y.; Shen, J.; Hu, S.Y.; dos Santos, J.F. Effect of tool rotational speed on the microstructure and mechanical properties of bobbin tool friction stir welding of Al–Li alloy. Mater. Des. 2015, 86, 933–940. [Google Scholar] [CrossRef]

- Zhang, Y.; Sato, Y.S.; Kokawa, H.; Hwan, S.; Park, C.; Hirano, S. Stir zone microstructure of commercial purity titanium friction stir welded using pcBN tool. Mater. Sci. Eng. A 2008, 488, 25–30. [Google Scholar] [CrossRef]

- Ramulu, M.; Edwards, P.D.; Sanders, D.G.; Reynolds, A.P.; Trapp, T. Tensile properties of friction stir welded and friction stir welded-superplastically formed Ti-6Al-4V butt joints. Mater. Des. 2010, 31, 3056–3061. [Google Scholar] [CrossRef]

- Farias, A.; Batalha, G.F.; Prados, E.F.; Magnabosco, R.; Delijaicov, S. Tool wear evaluations in friction stir processing of commercial titanium Ti-6Al-4V. Wear 2013, 302, 1327–1333. [Google Scholar] [CrossRef]

- Yoon, S.; Ueji, R.; Fujii, H. Microstructure and texture distribution of Ti-6Al-4V alloy joints friction stir welded below β-transus temperature. J. Mater. Process. Technol. 2016, 229, 390–397. [Google Scholar] [CrossRef]

- Yoon, S.; Ueji, R.; Fujii, H. Effect of initial microstructure on Ti-6Al-4V joint by friction stir welding. Mater. Des. 2015, 88, 1269–1276. [Google Scholar] [CrossRef]

- Yoon, S.; Ueji, R.; Fujii, H. Effect of rotation rate on microstructure and texture evolution during friction stir welding of Ti-6Al-4V plates. Mater. Charact. 2015, 106, 352–358. [Google Scholar] [CrossRef]

- Ji, S.; Li, Z.; Wang, Y.; Ma, L. Joint formation and mechanical properties of back heating assisted friction stir welded Ti–6Al–4V alloy. Mater. Des. 2017, 113, 37–46. [Google Scholar] [CrossRef]

- Ji, S.; Li, Z.; Zhang, L.; Wang, Y. Eliminating the tearing defect in Ti-6Al-4V alloy joint by back heating assisted friction stir welding. Mater. Lett. 2016, 188, 21–24. [Google Scholar] [CrossRef]

- Li, J.; Shen, Y.; Hou, W.; Qi, Y. Friction stir welding of Ti-6Al-4V alloy: Friction tool, microstructure, and mechanical properties. J. Manuf. Process. 2020, 58, 344–354. [Google Scholar] [CrossRef]

- Amirov, A.; Chumaevskii, A.; Savchenko, N.; Gurianov, D.; Nikolaeva, A.; Krasnoveykin, V.; Ivanov, A.; Rubtsov, V.; Kolubaev, E. Features of Permanent Joints of Titanium (α+β)-Alloys Obtained by Friction Stir Welding Using a Nickel Superalloy Tool. Metals 2023, 13, 222. [Google Scholar] [CrossRef]

| Al Alloy Series | Representative Alloys | Applications |

|---|---|---|

| 2xxx | Al clad 2024 AA2014 AA2219 | Wing and fuselage sheet structures, fasteners, screws and rivets [41,134,139,140]. Aircraft internal structure, External fuel tank [41,138,140] |

| 3xxx | AA3003, AA3005, AA3105 | Air conditional tube, heat exchange Parts for aircraft engines [131,134,135] |

| 5xxx | AA 5052 | Engine components, fittings, inner body panels and structural parts [41,137,138,140] |

| 6xxx | AA6061 AA6063 | Light aircraft applications (wing and fuselage structures) Finer details of an aircraft (aesthetic and architectural finishes) [131,139,140]. |

| 7xxx | AA7050, AA7068 AA7075, AA7475 | Military aircraft (wing skins and fuselage) Fuselage bulkheads of larger aircraft, aerospace applications [41,131,134,138,139,140] |

| 8xxx | AA8009, AA8019, AA8090 | Helicopter components [131,138,140] |

| Al–Li Alloys | Required Property | Traditional Al Alloy | Aircraft Parts |

|---|---|---|---|

| Sheets | |||

|

|

|

|

| Plates | |||

|

|

|

|

| Forging | |||

|

|

|

|

| Extrusions | |||

|

|

|

|

| Alloy, Thickness (mm) | Tool Shape | Rotation Rate, (rpm) | Traverse Speed, (mm/min) | UTS(FSW)/UTS(BM) (%) | Hardness Profile Shape | Refs. |

|---|---|---|---|---|---|---|

| AA2195-T87, 5 | Taper threaded pin | 200–1000 | 100–300 | 390/573 (68%)–425/573 (74%) | W | [185] |

| AA2060-T8, 2 | Cylindrical straight pin | 300–1400 | 100 | 375/530 (71%)–443/530 (83%) | W | [186] |

| AA2198-T851 3.2 | Bobbin with cylindrical pin | 800 | 42 | 380/473 (80%) | W | [187] |

| AA2099 T8, 5 | Threaded Cylindrical pin | 700–1100 | 45 | 275/540 (51%)–340/540 (64%) | W | [188] |

| AA2099-T83, 5 | threaded, tapered, triangular pin | 400–1200 | 75–550 | 343/558 (61%)–390/558 (70%) | Not available | [189] |

| AA2050-T8, 15 | Threaded pin with 3 flats | 400 | 200 | Not available | W | [182] |

| AA2198-T8, 2 | Tapered pin | 600 | 200 | 300/491 (60%) | W | [181] |

| AA2198-T8, 1.8 | Tapered pin | 800 | 300 | 386/518 (70%) | W | [183] |

| AA2198-T8, 3.2 | Bobbin tool | 400–1000 | 42 | 270/473 (57%)–380/473 (80%) | W | [190] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Fydrych, D.; Çam, G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials 2023, 16, 2971. https://doi.org/10.3390/ma16082971

Ahmed MMZ, El-Sayed Seleman MM, Fydrych D, Çam G. Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials. 2023; 16(8):2971. https://doi.org/10.3390/ma16082971

Chicago/Turabian StyleAhmed, Mohamed M. Z., Mohamed M. El-Sayed Seleman, Dariusz Fydrych, and Gürel Çam. 2023. "Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review" Materials 16, no. 8: 2971. https://doi.org/10.3390/ma16082971

APA StyleAhmed, M. M. Z., El-Sayed Seleman, M. M., Fydrych, D., & Çam, G. (2023). Friction Stir Welding of Aluminum in the Aerospace Industry: The Current Progress and State-of-the-Art Review. Materials, 16(8), 2971. https://doi.org/10.3390/ma16082971