The Use of Sacrificial Graphite-like Coating to Improve Fusion Efficiency of Copper in Selective Laser Melting

Abstract

1. Introduction

2. Methodology

3. Results and Discussions

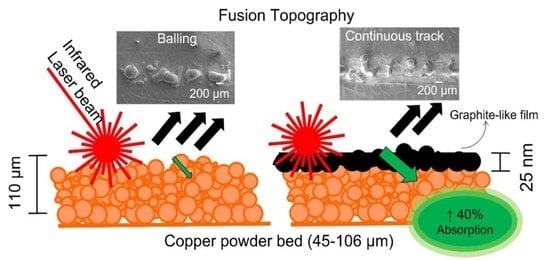

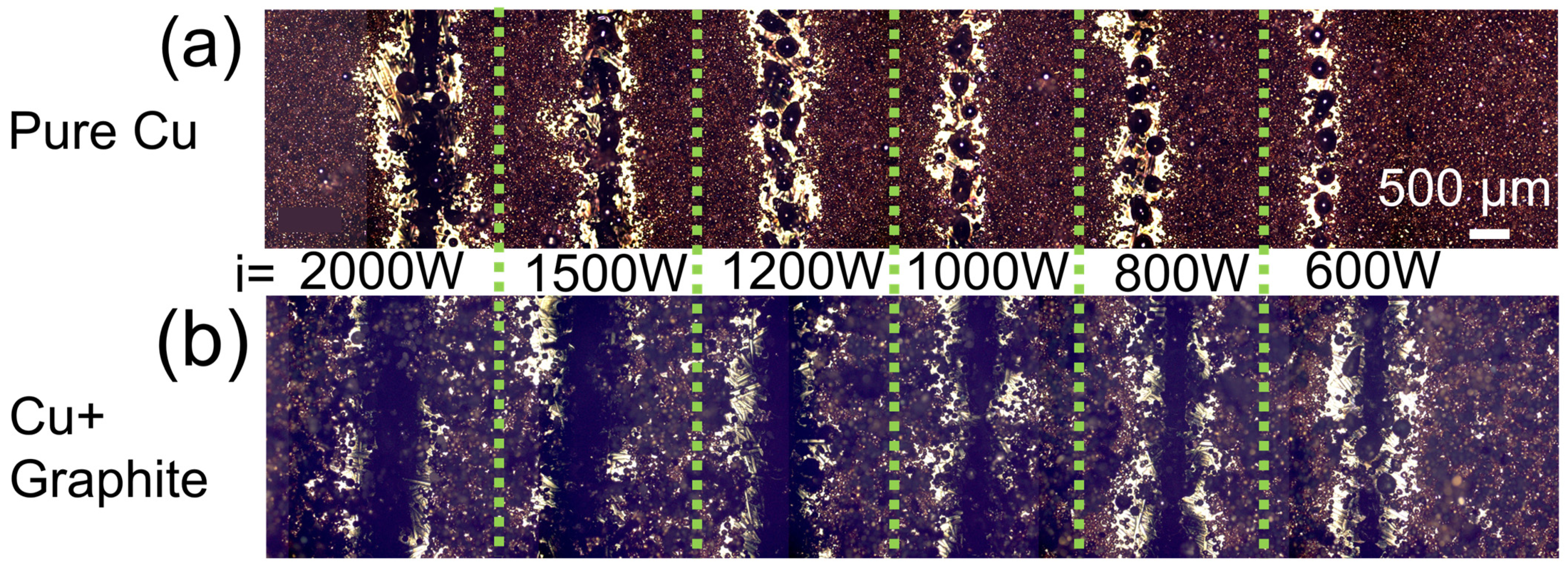

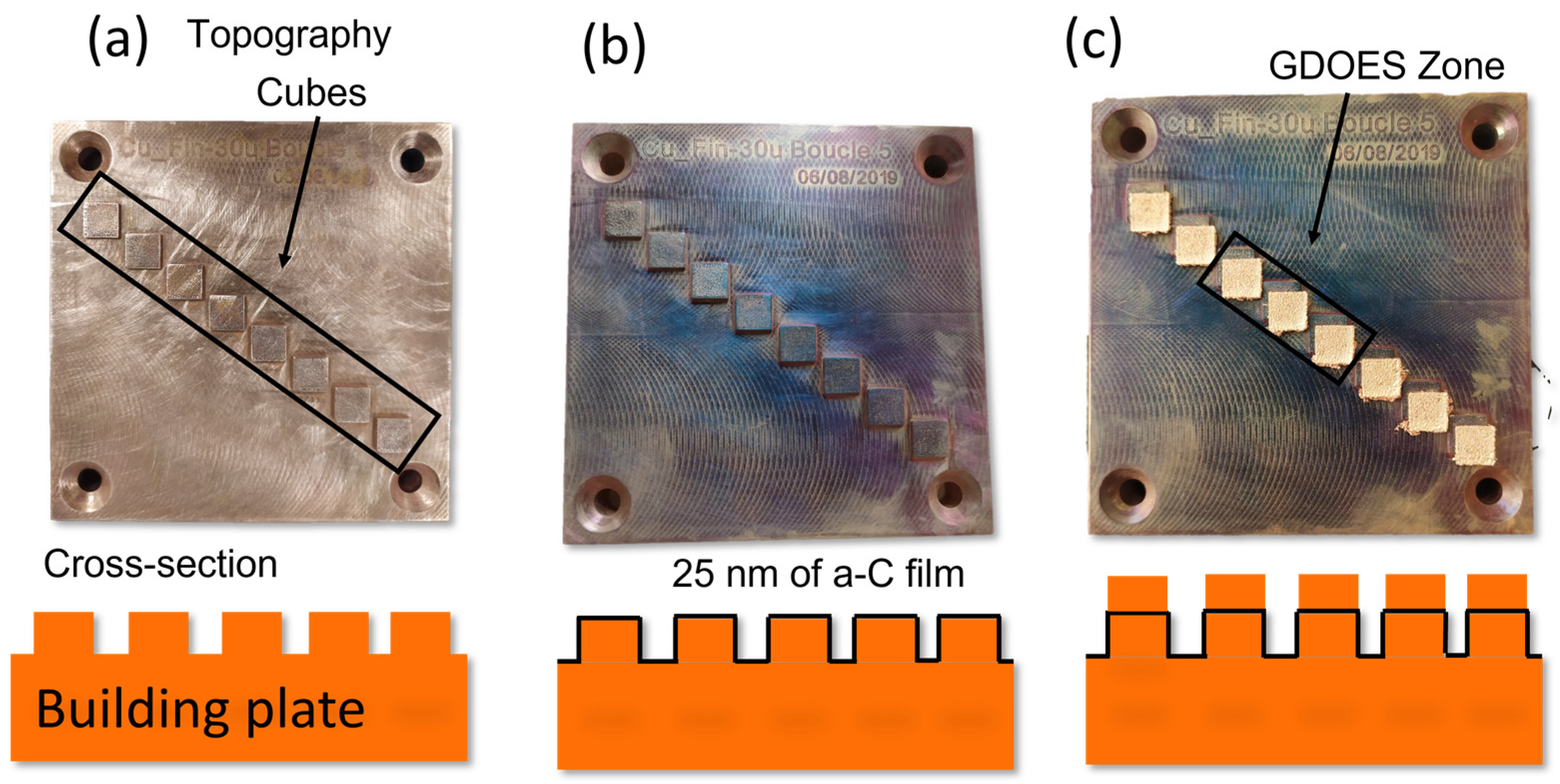

3.1. Topography Analysis

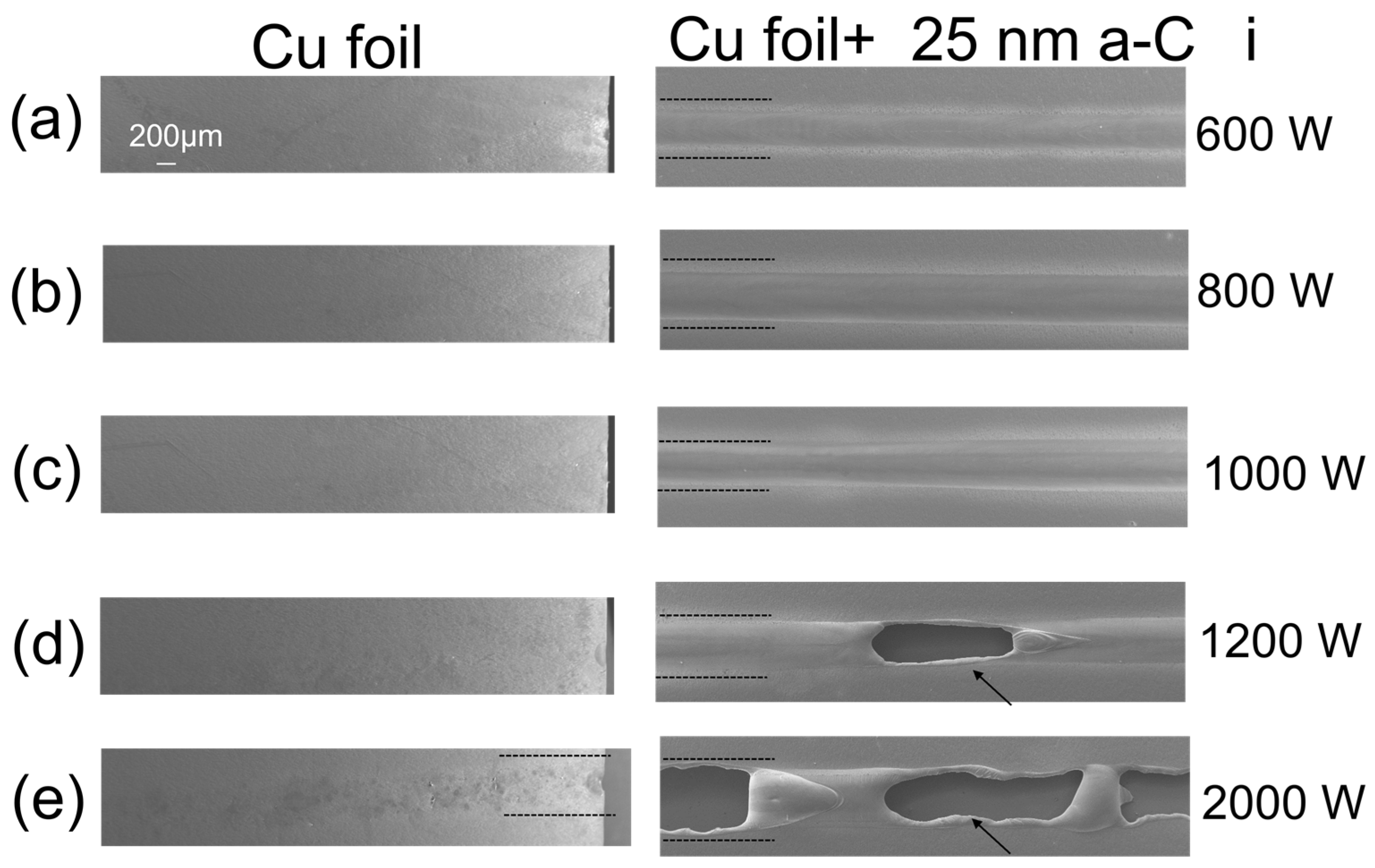

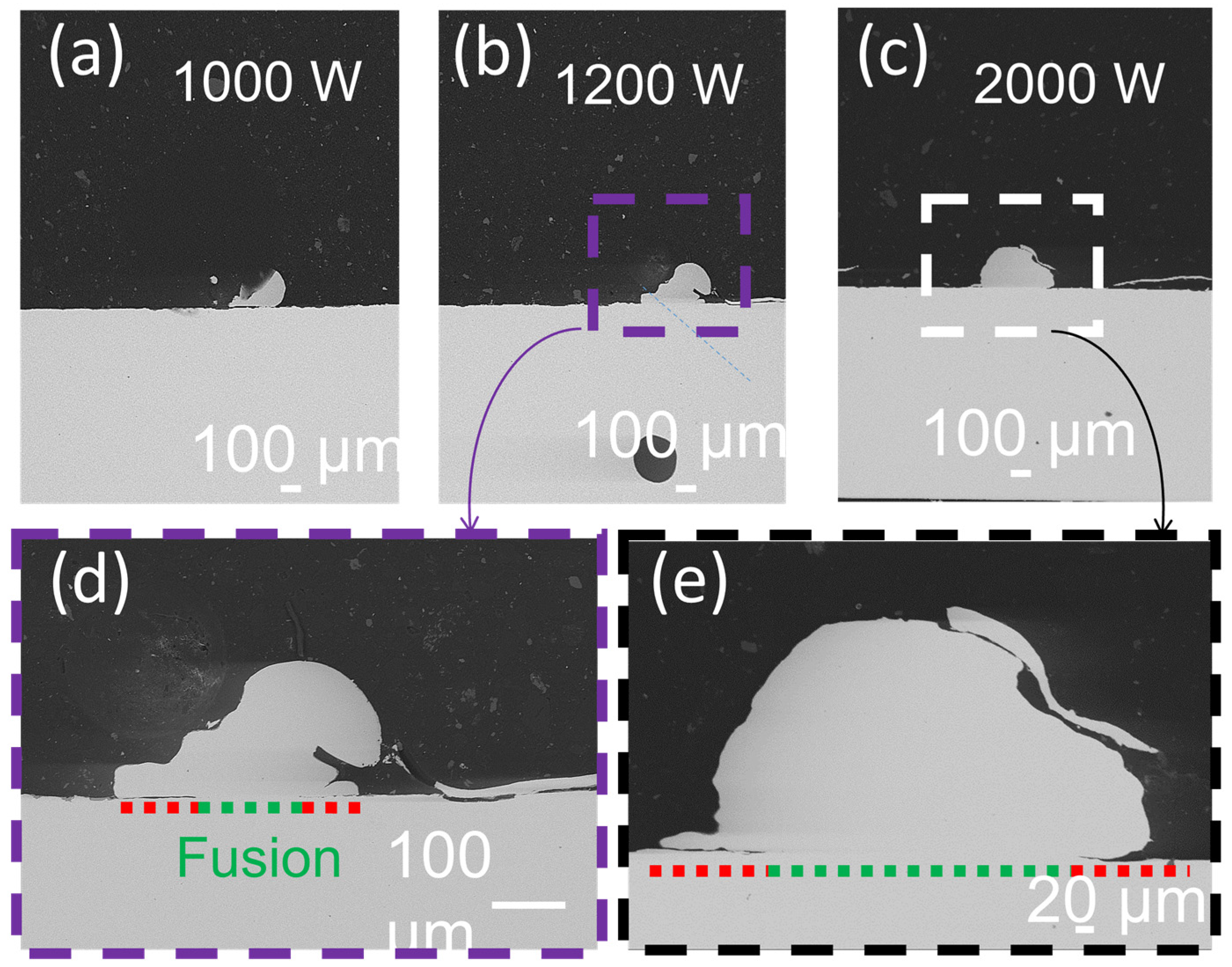

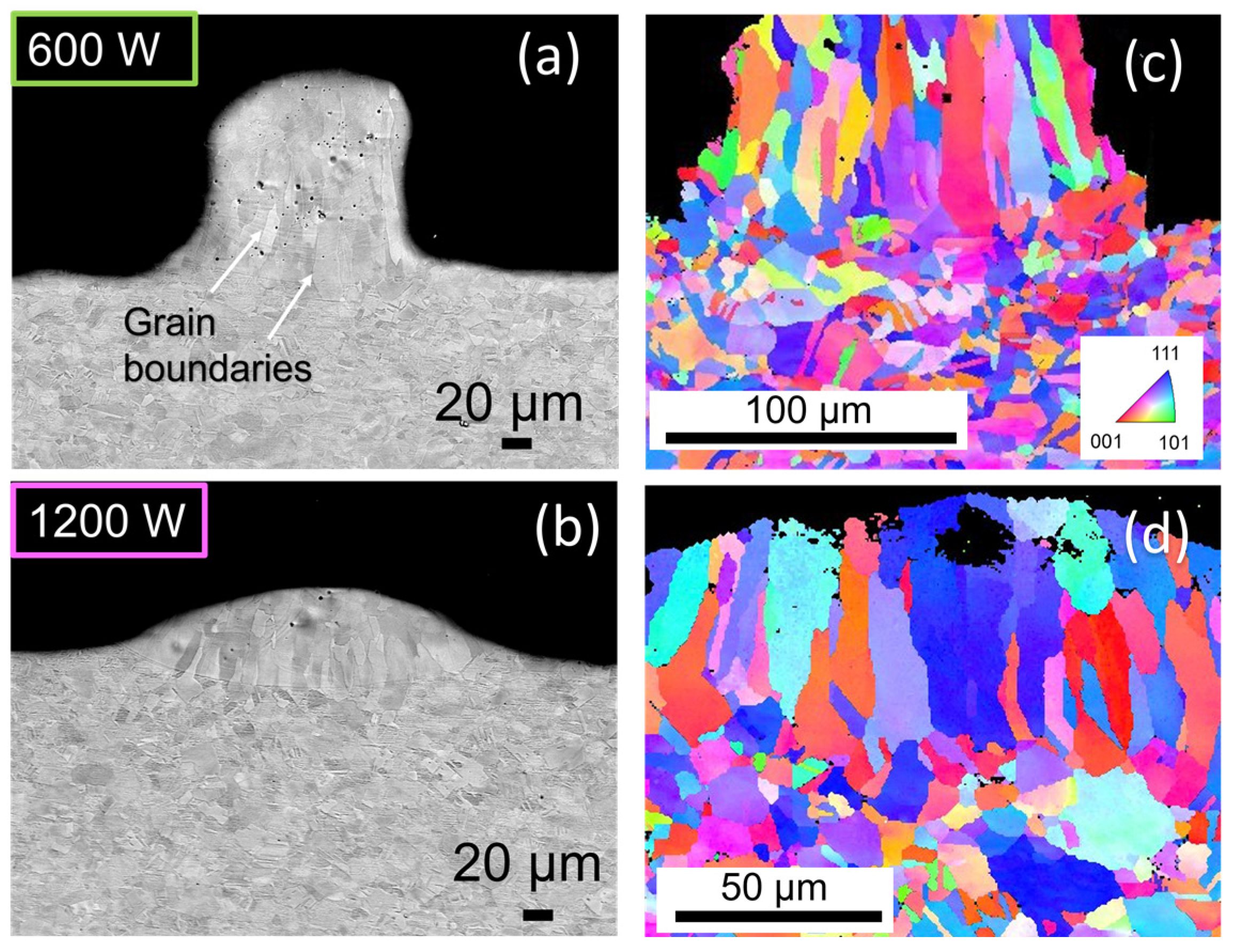

3.2. Cross-Section Analysis

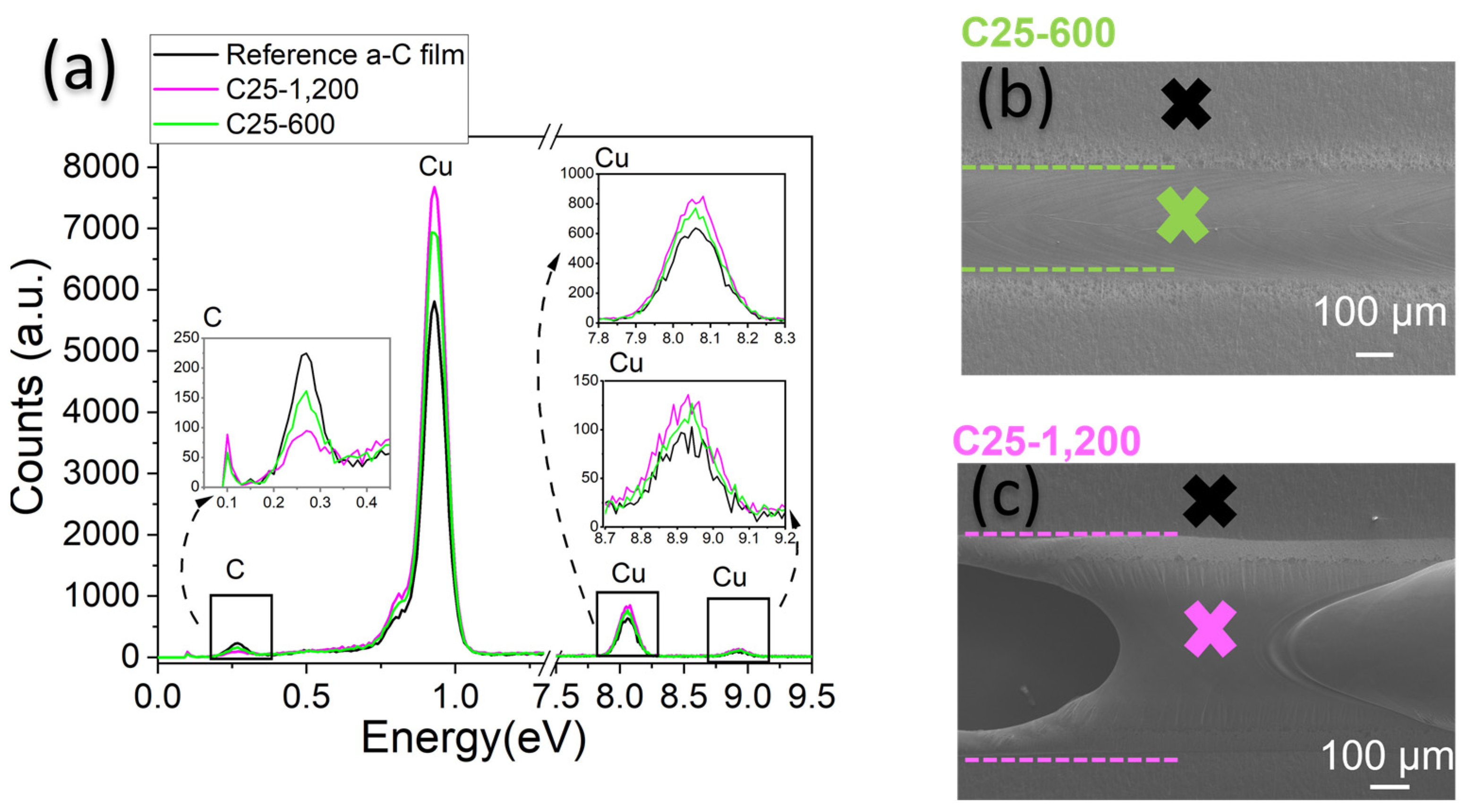

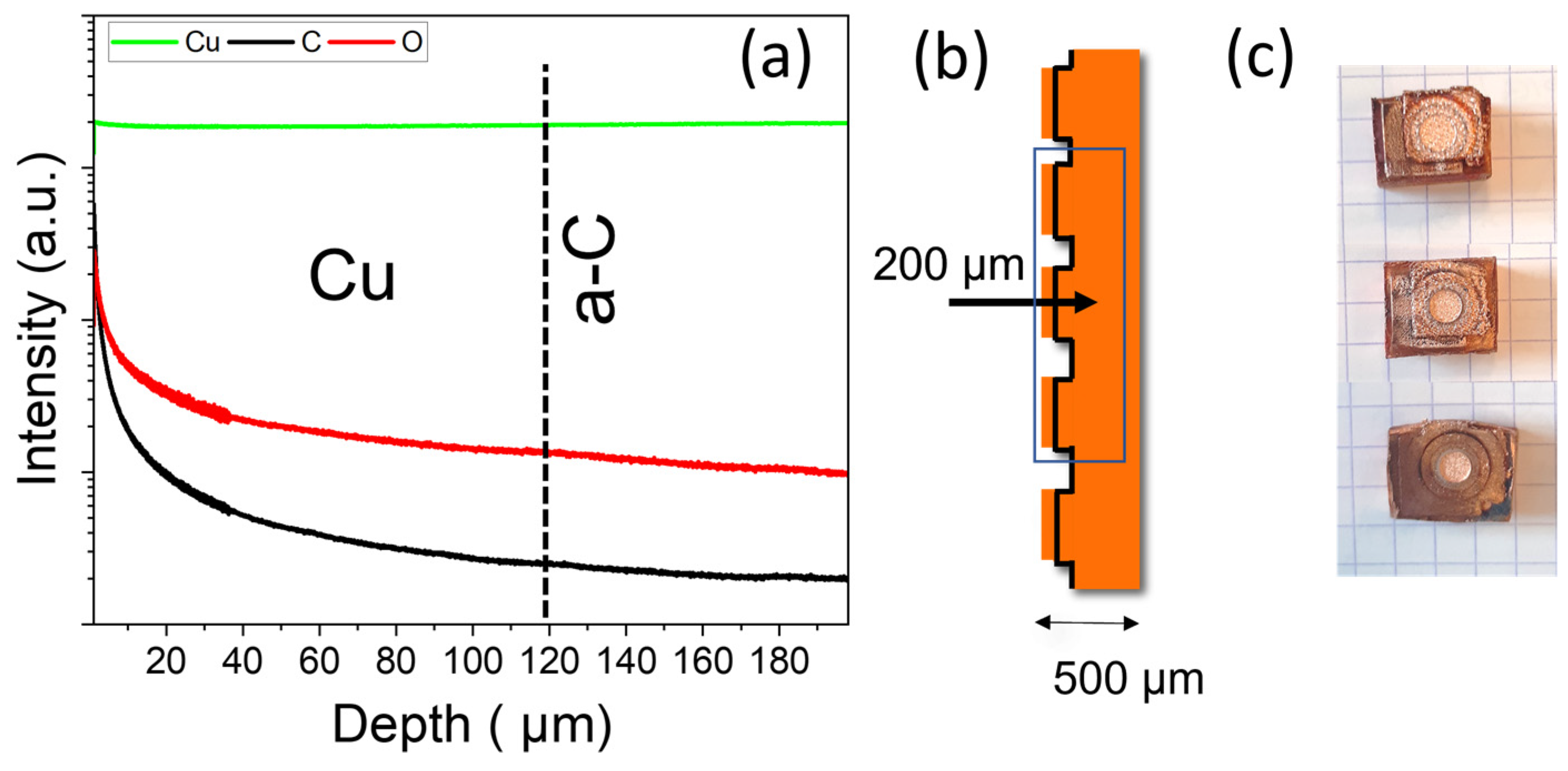

3.3. Composition Analysis Using Ultrathin Carbon Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davis, J.R. Copper and Copper Alloys; ASM International: Almere, The Netherlands, 2001; ISBN 0871707268. [Google Scholar]

- Heider, A.; Sollinger, J.; Abt, F.; Boley, M.; Weber, R.; Graf, T. High-Speed X-ray Analysis of Spatter Formation in Laser Welding of Copper. Phys. Procedia 2013, 41, 112–118. [Google Scholar] [CrossRef]

- Boley, M.; Abt, F.; Weber, R.; Graf, T. X-ray and Optical Videography for 3D Measurement of Capillary and Melt Pool Geometry in Laser Welding. Phys. Procedia 2013, 41, 488–495. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Leary, M.; Sharabian, E.; Cordova, L.; Gibson, I.; Downing, D.; Bateman, S.; Brandt, M.; Rolfe, B. The Effect of Absorption Ratio on Meltpool Features in Laser-Based Powder Bed Fusion of IN718. Opt. Laser Technol. 2022, 153, 108263. [Google Scholar] [CrossRef]

- Mendeleyev, V.Y.; Kachalov, V.V.; Kurilovich, A.V.; Dombrovsky, L.A. Abnormally Strong Decrease in Reflectance of Molten Copper Due to Possible Generation of Levitating Sub-Micron Melt Droplets. Int. J. Heat Mass Transf. 2017, 113, 53–58. [Google Scholar] [CrossRef]

- Nordet, G.; Gorny, C.; Mayi, Y.; Daligault, J.; Dal, M.; Effernelli, A.; Blanchet, E.; Coste, F.; Peyre, P. Absorptivity Measurements during Laser Powder Bed Fusion of Pure Copper with a 1 KW Cw Green Laser. Opt. Laser Technol. 2022, 147, 107612. [Google Scholar] [CrossRef]

- El-Wardany, T.I.; She, Y.; Jagdale, V.N.; Garofano, J.K.; Liou, J.J.; Schmidt, W.R. Challenges in Three-Dimensional Printing of High-Conductivity Copper. J. Electron. Packag. 2018, 140, 020907. [Google Scholar] [CrossRef]

- Guschlbauer, R.; Momeni, S.; Osmanlic, F.; Körner, C. Process Development of 99.95% Pure Copper Processed via Selective Electron Beam Melting and Its Mechanical and Physical Properties. Mater. Charact. 2018, 143, 163–170. [Google Scholar] [CrossRef]

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D.; Orlov, A. Microstructure and Mechanical Properties of Additive Manufactured Copper Alloy. Mater. Lett. 2016, 179, 38–41. [Google Scholar] [CrossRef]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.-F.; Lu, Y.F. Laser 3D Printing of Complex Copper Structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

- Colopi, M.; Caprio, L.; Demir, A.G.; Previtali, B. Selective Laser Melting of Pure Cu with a 1 KW Single Mode Fiber Laser. Procedia CIRP 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Jadhav, S.; Dadbakhsh, S.; Vleugels, J.; Hofkens, J.; Puyvelde, P.; Yang, S.; Kruth, J.; Humbeeck, J.; Vanmeensel, K. Influence of Carbon Nanoparticle Addition (and Impurities) on Selective Laser Melting of Pure Copper. Materials 2019, 12, 2469. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.-C.; Bi, G.; Nai, M.L.S.; Wei, J. Enhanced Welding Efficiency in Laser Welding of Highly Reflective Pure Copper. J. Mater. Process. Technol. 2015, 216, 287–293. [Google Scholar] [CrossRef]

- Auwal, S.T.; Ramesh, S.; Yusof, F.; Manladan, S.M. A Review on Laser Beam Welding of Copper Alloys. Int. J. Adv. Manuf. Technol. 2018, 96, 475–490. [Google Scholar] [CrossRef]

- Ding, H.; He, P.; Yang, J.; Liu, C.; Zhao, H.; Derby, B. Water-Based Highly Conductive Graphene Inks for Fully Printed Humidity Sensors. J. Phys. D Appl. Phys. 2020, 53, 455304. [Google Scholar] [CrossRef]

- Barwich, S.; Medeiros de Araújo, J.; Rafferty, A.; Gomes da Rocha, C.; Ferreira, M.S.; Coleman, J.N. On the Relationship between Morphology and Conductivity in Nanosheet Networks. Carbon N. Y. 2021, 171, 306–319. [Google Scholar] [CrossRef]

- He, P.; Cao, J.; Ding, H.; Liu, C.; Neilson, J.; Li, Z.; Kinloch, I.A.; Derby, B. Screen-Printing of a Highly Conductive Graphene Ink for Flexible Printed Electronics. ACS Appl. Mater. Interfaces 2019, 11, 32225–32234. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Li, S.; Gong, P.; Chen, Q.; Geng, H.; Sun, M.; Sun, Q.; Hao, L. Fabrication of Titanium and Copper-Coated Diamond/Copper Composites via Selective Laser Melting. Micromachines 2022, 13, 724. [Google Scholar] [CrossRef] [PubMed]

- Craig, S.; Harding, G.L. Composition, Optical Properties and Degradation Modes of Cu/(Graded Metal-Carbon) Solar Selective Surfaces. Thin Solid Film. 1983, 101, 97–113. [Google Scholar] [CrossRef]

- Sharabian, E.; Leary, M.; Fraser, D.; Gulizia, S. Electron Beam Powder Bed Fusion of Copper Components: A Review of Mechanical Properties and Research Opportunities. Int. J. Adv. Manuf. Technol. 2022, 122, 513–532. [Google Scholar] [CrossRef]

- Morvan, A.; Grosseau-Poussard, J.-L.; Caillault, N.; Delange, F.; Roure, S.; Lepretre, P.; Silvain, J.-F. Powder Processing Methodology for Fabrication of Copper/Graphite Composite Materials with Enhanced Thermal Properties. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105474. [Google Scholar] [CrossRef]

- Crespi, Â.E.; Ballage, C.; Hugon, M.C.; Robert, J.; Lundin, D.; Vickridge, I.; Alvarez, J.; Minea, T. Low Resistivity Amorphous Carbon-Based Thin Films Employed as Anti-Reflective Coatings on Copper. Thin Solid Films 2020, 712, 138319. [Google Scholar] [CrossRef]

- Vander Voort, G.F. ASM Handbook Volume 9: Metallography and Microstructures; ASM International: Novelty, OH, USA, 2004; pp. 1058–1060. [Google Scholar]

- Crespi, Â.E.; Ballage, C.; Hugon, M.-C.; Robert, J.; Minea, T. The Role of Amorphous Nanocrystalline Carbon Films in Interference on Flexible Copper Foils. ACS Appl. Electron. Mater. 2022, 4, 576–584. [Google Scholar] [CrossRef]

- Boutaous, M.; Liu, X.; Siginer, D.A.; Xin, S. Balling Phenomenon in Metallic Laser Based 3D Printing Process. Int. J. Therm. Sci. 2021, 167, 107011. [Google Scholar] [CrossRef]

- Schiaffino, S.; Sonin, A.A. Molten Droplet Deposition and Solidification at Low Weber Numbers. Phys. Fluids 1997, 9, 3172–3187. [Google Scholar] [CrossRef]

- Fabbro, R.; Dal, M.; Peyre, P.; Coste, F.; Schneider, M.; Gunenthiram, V. Analysis and Possible Estimation of Keyhole Depths Evolution, Using Laser Operating Parameters and Material Properties. J. Laser Appl. 2018, 30, 032410. [Google Scholar] [CrossRef]

- Gunenthiram, V.; Peyre, P.; Schneider, M.; Dal, M.; Coste, F.; Koutiri, I.; Fabbro, R. Experimental Analysis of Spatter Generation and Melt-Pool Behavior during the Powder Bed Laser Beam Melting Process. J. Mater. Process. Technol. 2018, 251, 376–386. [Google Scholar] [CrossRef]

- Matthews, M.J.; Guss, G.; Khairallah, S.A.; Rubenchik, A.M.; Depond, P.J.; King, W.E. Denudation of Metal Powder Layers in Laser Powder Bed Fusion Processes. Acta Mater. 2016, 114, 33–42. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Selective Laser Melting Technology: From the Single Laser Melted Track Stability to 3D Parts of Complex Shape. Phys. Procedia 2010, 5, 551–560. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, X.; Zhang, D.; Shen, Z.; Liu, W. Balling Phenomena in Selective Laser Melted Tungsten. J. Mater. Process. Technol. 2015, 222, 33–42. [Google Scholar] [CrossRef]

- Ren, X.; Liu, H.; Lu, F.; Huang, L.; Yi, X. Effects of Processing Parameters on the Densification, Microstructure and Mechanical Properties of Pure Tungsten Fabricated by Optimized Selective Laser Melting: From Single and Multiple Scan Tracks to Bulk Parts. Int. J. Refract. Met. Hard Mater. 2021, 96, 105490. [Google Scholar] [CrossRef]

- Yuan, P.; Gu, D. Molten Pool Behaviour and Its Physical Mechanism during Selective Laser Melting of TiC/AlSi10Mg Nanocomposites: Simulation and Experiments. J. Phys. D Appl. Phys. 2015, 48, 035303. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of Selective Laser Melting Process Parameters on Texture Evolution in Pure Copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Aksa, H.C.; Hacısalihoğlu, İ.; Yıldız, F.; Varol, T.; Güler, O.; Kaya, G.; Akçay, S.B. Effects of Fabrication Parameters and Post-Processing Treatments on the Mechanical and Tribological Behavior of Surface-Enhanced Copper Based Materials by Selective Laser Melting. J. Mater. Process. Technol. 2022, 304, 117564. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of Build Geometry on the β-Grain Structure and Texture in Additive Manufacture of Ti6Al4V by Selective Electron Beam Melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

- Milewski, J.O. Lasers, Electron Beams, Plasma Arcs. In Additive Manufacturing of Metals; Springer Series in Materials Science; Springer International Publishing: Cham, Switzerland, 2017; Volume 258, pp. 85–99. [Google Scholar]

- Lykov, P.A.; Safonov, E.V.; Akhmedianov, A.M. Selective Laser Melting of Copper. Mater. Sci. Forum 2016, 843, 284–288. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A Review on Additive Manufacturing of Pure Copper. Coatings 2021, 11, 740. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dhekne, P.P.; Dadbakhsh, S.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Surface Modified Copper Alloy Powder for Reliable Laser-Based Additive Manufacturing. Addit. Manuf. 2020, 35, 101418. [Google Scholar] [CrossRef]

- Qu, S.; Ding, J.; Fu, J.; Fu, M.; Zhang, B.; Song, X. High-Precision Laser Powder Bed Fusion Processing of Pure Copper. Addit. Manuf. 2021, 48, 102417. [Google Scholar] [CrossRef]

- Voelkel, R.; Weible, K.J. Laser Beam Homogenizing: Limitations and Constraints. In Optical Fabrication, Testing, and Metrology III, Proceedings of the Optical Systems Design, Scotland, UK, 2–5 September 2008; Duparré, A., Geyl, R., Eds.; SPIE: Bellingham, WA, USA, 2008; p. 71020J. [Google Scholar]

- Leary, M. Powder Bed Fusion. In Design for Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2020; pp. 295–319. [Google Scholar]

- Semak, V.; Matsunawa, A. The Role of Recoil Pressure in Energy Balance during Laser Materials Processing. J. Phys. D Appl. Phys. 1997, 30, 2541–2552. [Google Scholar] [CrossRef]

- Di Pietro, P.; Yao, Y.L. A New Technique to Characterize and Predict Laser Cut Striations. Int. J. Mach. Tools Manuf. 1995, 35, 993–1002. [Google Scholar] [CrossRef]

- Powell, D.; Rennie, A.E.W.; Geekie, L.; Burns, N. Understanding Powder Degradation in Metal Additive Manufacturing to Allow the Upcycling of Recycled Powders. J. Clean. Prod. 2020, 268, 122077. [Google Scholar] [CrossRef]

- Linstrom, P.J. Base de Données Standard de Référence NIST Numéro 69. Available online: https://webbook.nist.gov/chemistry/# (accessed on 10 June 2021).

- Zhou, B.; Zhou, J.; Li, H.; Lin, F. A Study of the Microstructures and Mechanical Properties of Ti6Al4V Fabricated by SLM under Vacuum. Mater. Sci. Eng. A 2018, 724, 1–10. [Google Scholar] [CrossRef]

- Kumar, S.; Pityana, S. Laser-Based Additive Manufacturing of Metals. Adv. Mater. Res. 2011, 227, 92–95. [Google Scholar] [CrossRef]

| Power Range (W) | Power Density (kW/mm2) | Spot (µm) | Scan Speed (mm/s) | Focal Length (mm) | Scan Strategy | Powder Temperature | Powder Bed Height (µm) |

|---|---|---|---|---|---|---|---|

| 600–2000 | 19–64 | 200 ± 20 | 500 | 200 | Single tracks | Room temperature | ~100 |

| Sample Name | Description |

|---|---|

| PCu-i | Pure Cu powder |

| C-i | Cu powder +3.5 µm GRAPHIT 33 |

| FCu-i | Pure Cu foil |

| a-C25-i | Cu foil +25 nm a-C film |

| Reference-a-C-film | Cu foil +25 nm a-C |

| Printed-part-Cu/a-C | Printed cubes +25 nm of a-C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crespi, A.E.; Nordet, G.; Peyre, P.; Ballage, C.; Hugon, M.-C.; Chapon, P.; Minea, T. The Use of Sacrificial Graphite-like Coating to Improve Fusion Efficiency of Copper in Selective Laser Melting. Materials 2023, 16, 2460. https://doi.org/10.3390/ma16062460

Crespi AE, Nordet G, Peyre P, Ballage C, Hugon M-C, Chapon P, Minea T. The Use of Sacrificial Graphite-like Coating to Improve Fusion Efficiency of Copper in Selective Laser Melting. Materials. 2023; 16(6):2460. https://doi.org/10.3390/ma16062460

Chicago/Turabian StyleCrespi, Angela Elisa, Guillaume Nordet, Patrice Peyre, Charles Ballage, Marie-Christine Hugon, Patrick Chapon, and Tiberiu Minea. 2023. "The Use of Sacrificial Graphite-like Coating to Improve Fusion Efficiency of Copper in Selective Laser Melting" Materials 16, no. 6: 2460. https://doi.org/10.3390/ma16062460

APA StyleCrespi, A. E., Nordet, G., Peyre, P., Ballage, C., Hugon, M.-C., Chapon, P., & Minea, T. (2023). The Use of Sacrificial Graphite-like Coating to Improve Fusion Efficiency of Copper in Selective Laser Melting. Materials, 16(6), 2460. https://doi.org/10.3390/ma16062460