The Microstructure and Properties of Ni-Si-La2O3 Coatings Deposited on 304 Stainless Steel by Microwave Cladding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Base Material

2.2. Primary Cladding Particle

2.3. Secondary Cladding Particle

2.4. Tertiary Cladding Particle

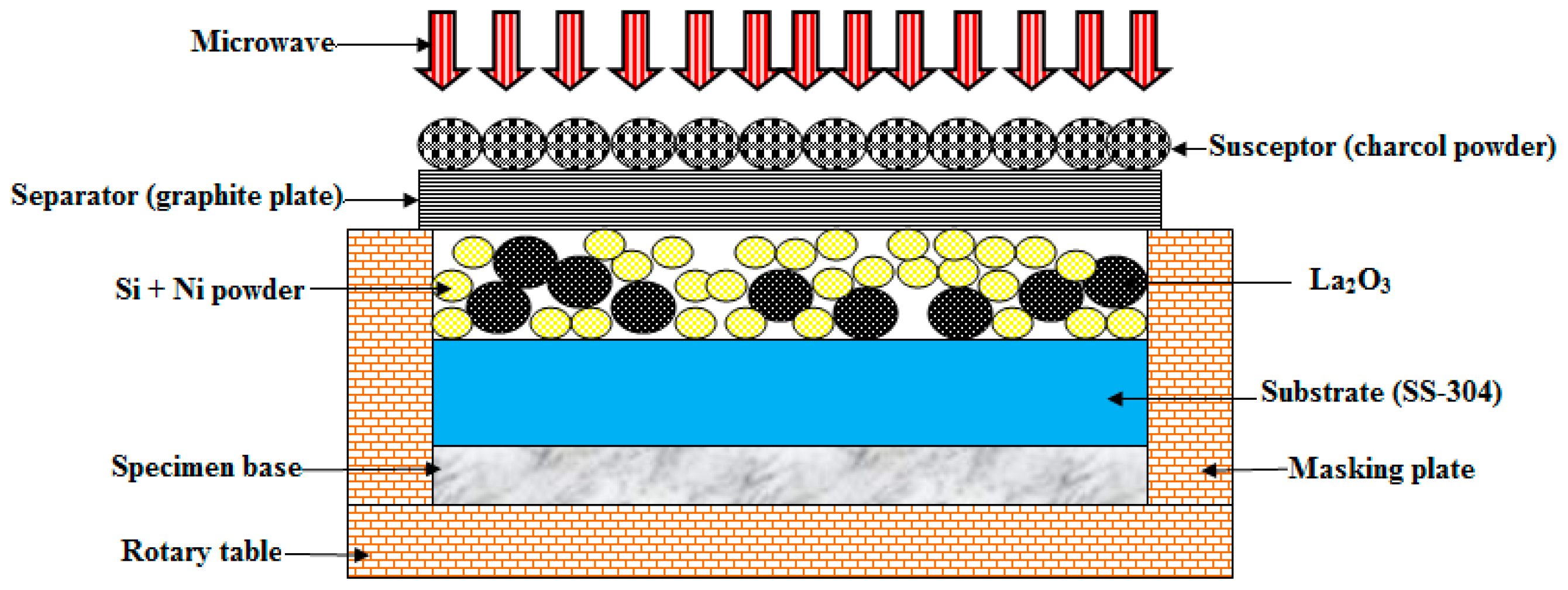

2.5. Development of Cladding

2.6. Response Surface Methodology (RSM)

2.7. Materials Testing Procedure

3. Results and Discussion

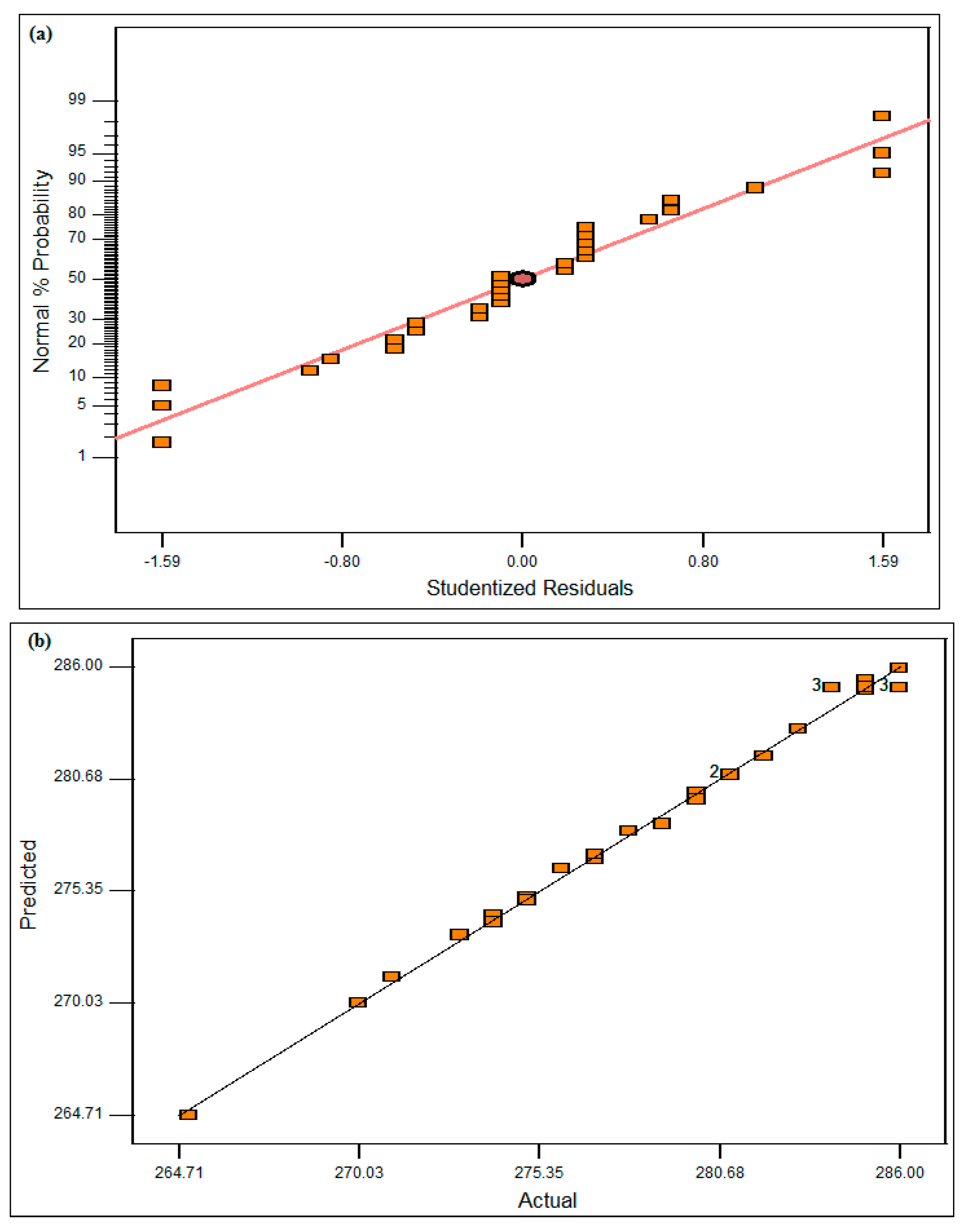

3.1. Analysis of Variance for the Surface Hardness as a Response

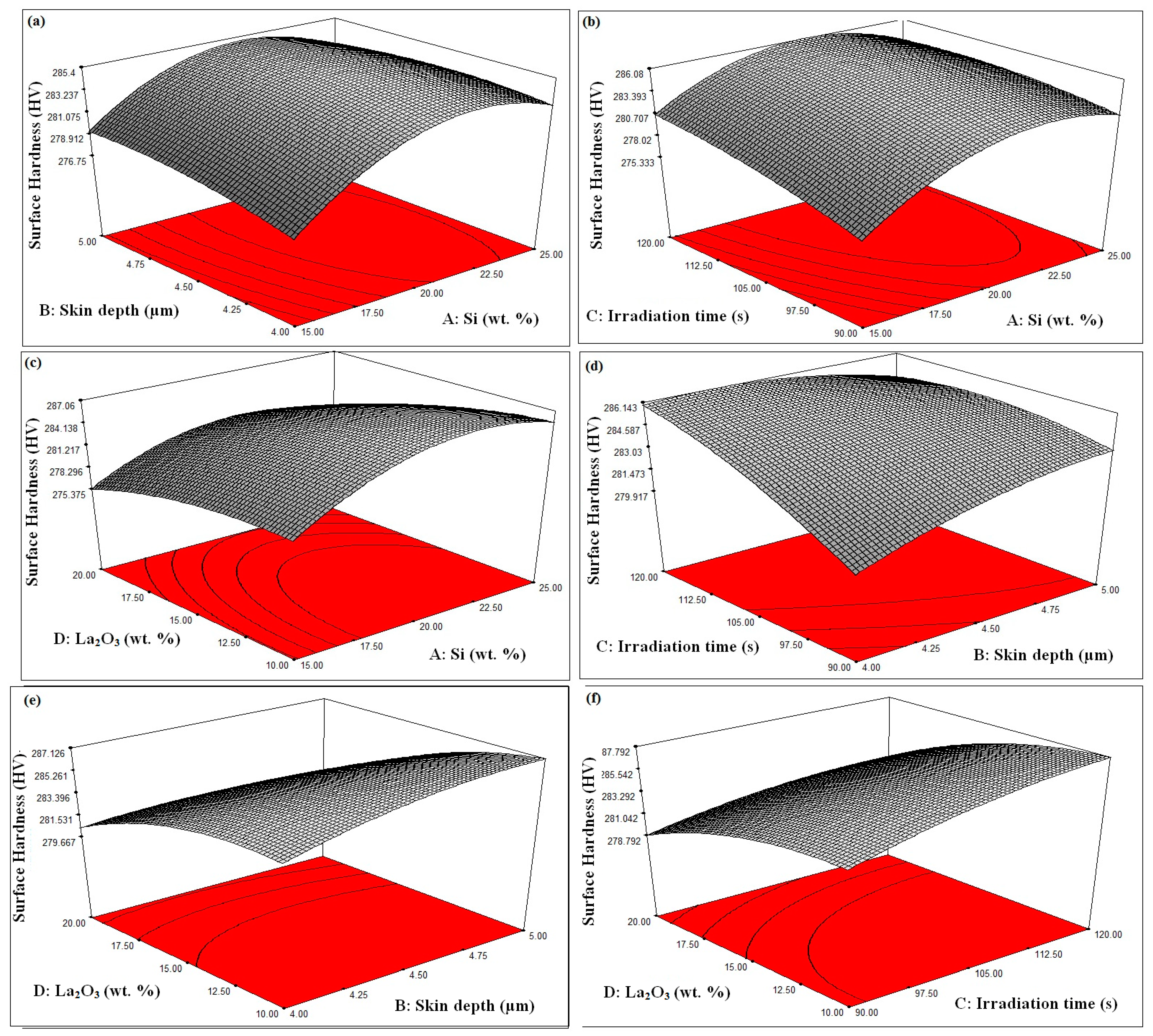

3.2. Process Parameters Effect on Cladding Surface Hardness

3.2.1. Influence of “Silicon Powder Weight” Percent on Cladding Surface Hardness

3.2.2. Effect of Skin Depth of the Major Constituent on Cladding Surface Hardness

3.2.3. Effect of Irradiation Time on Cladding Surface Hardness

3.2.4. Effect of La2O3 Powder Weight Percent on Cladding Surface Hardness

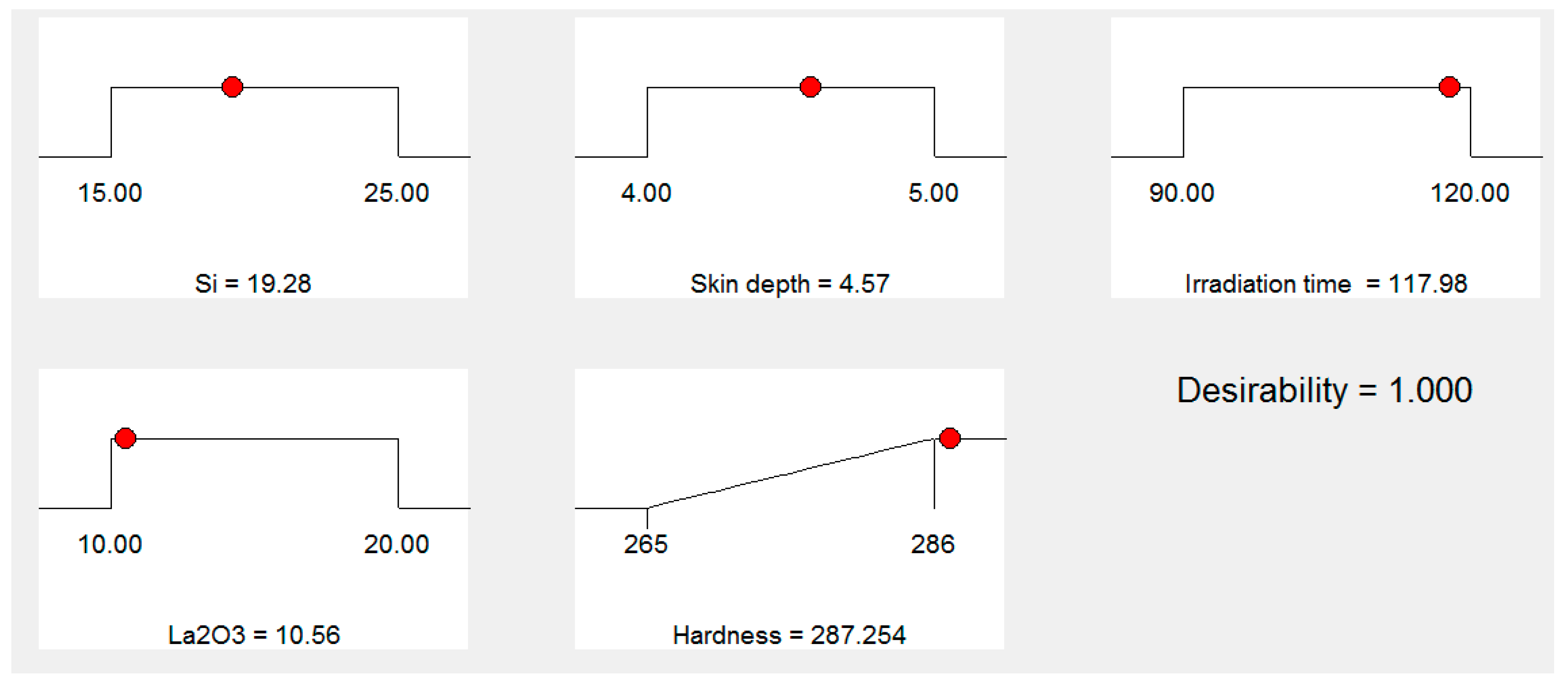

3.3. Microwave Cladding Optimum Parameters and Contribution

3.4. Metallurgical and Tribo-Corrosion Behaviour at Optimum Microwave Process Parameters

3.4.1. Surface Hardness

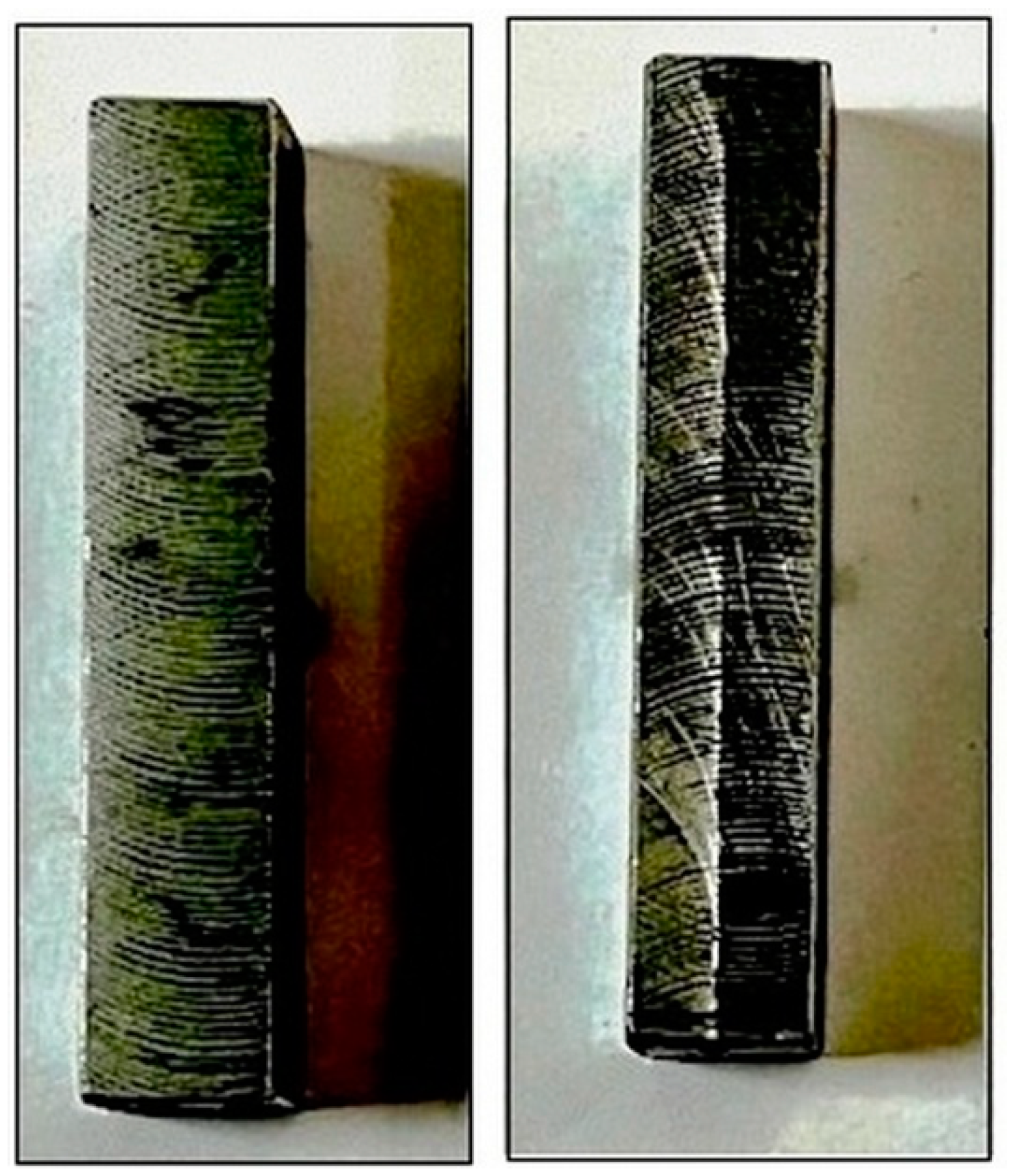

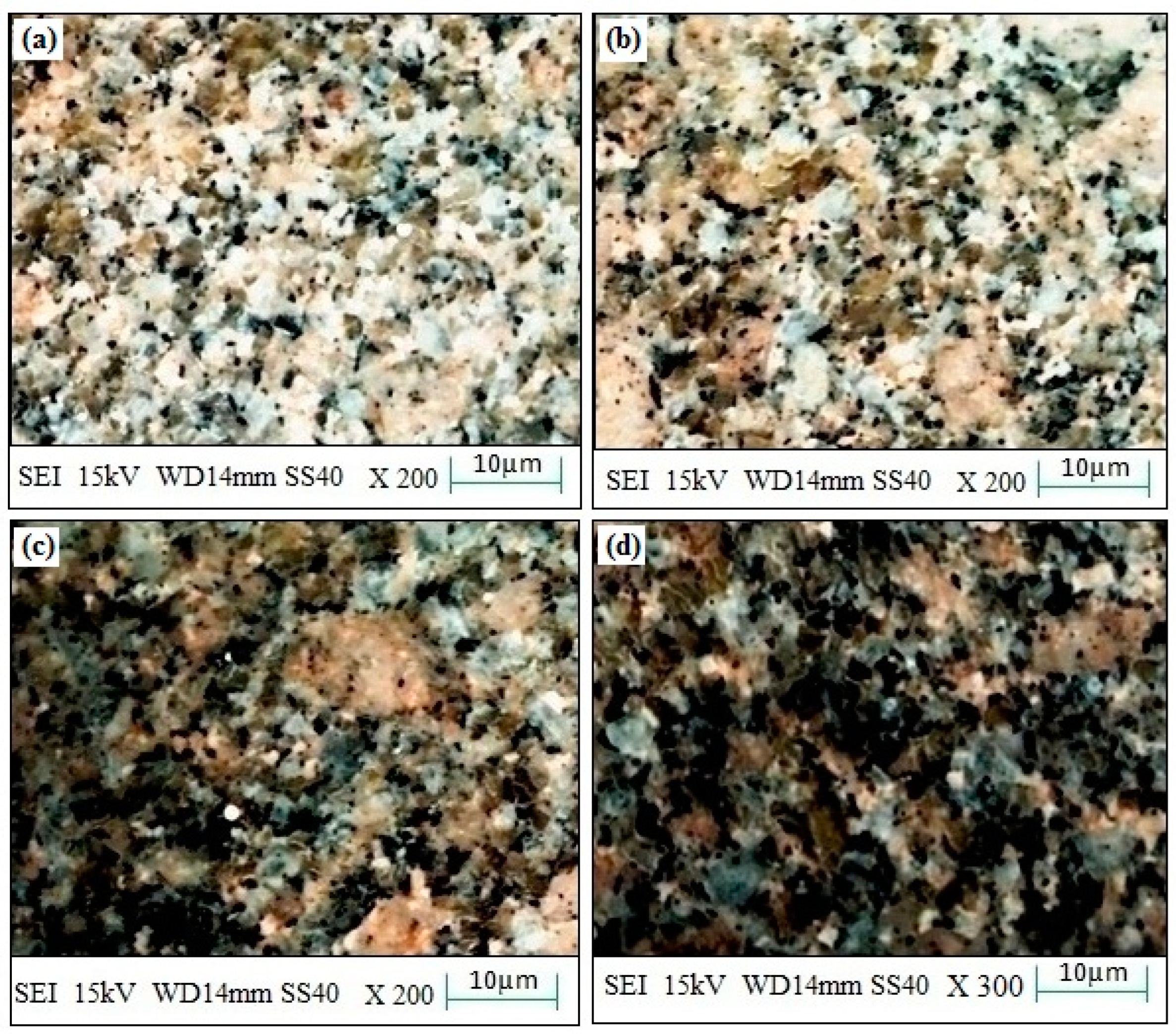

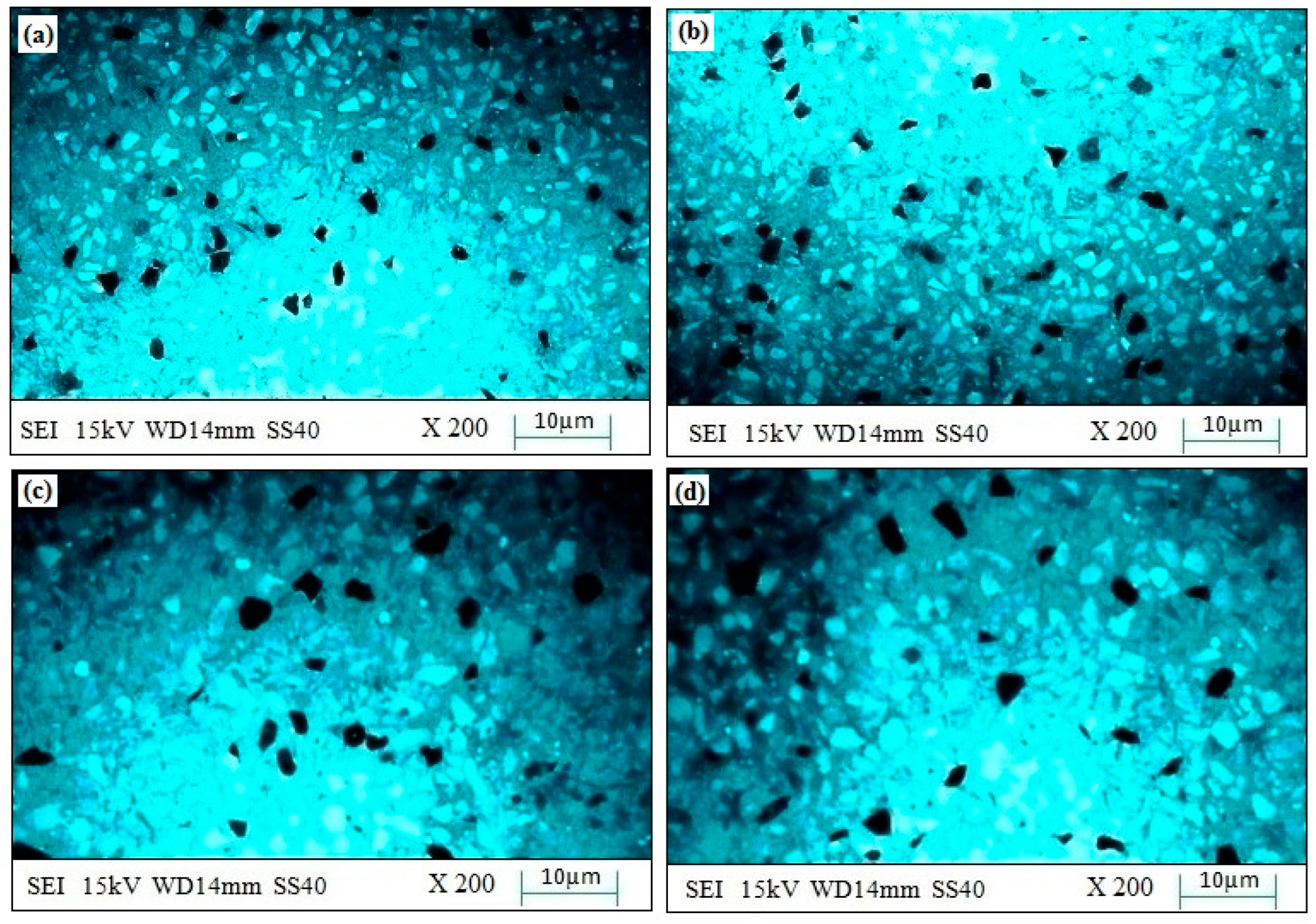

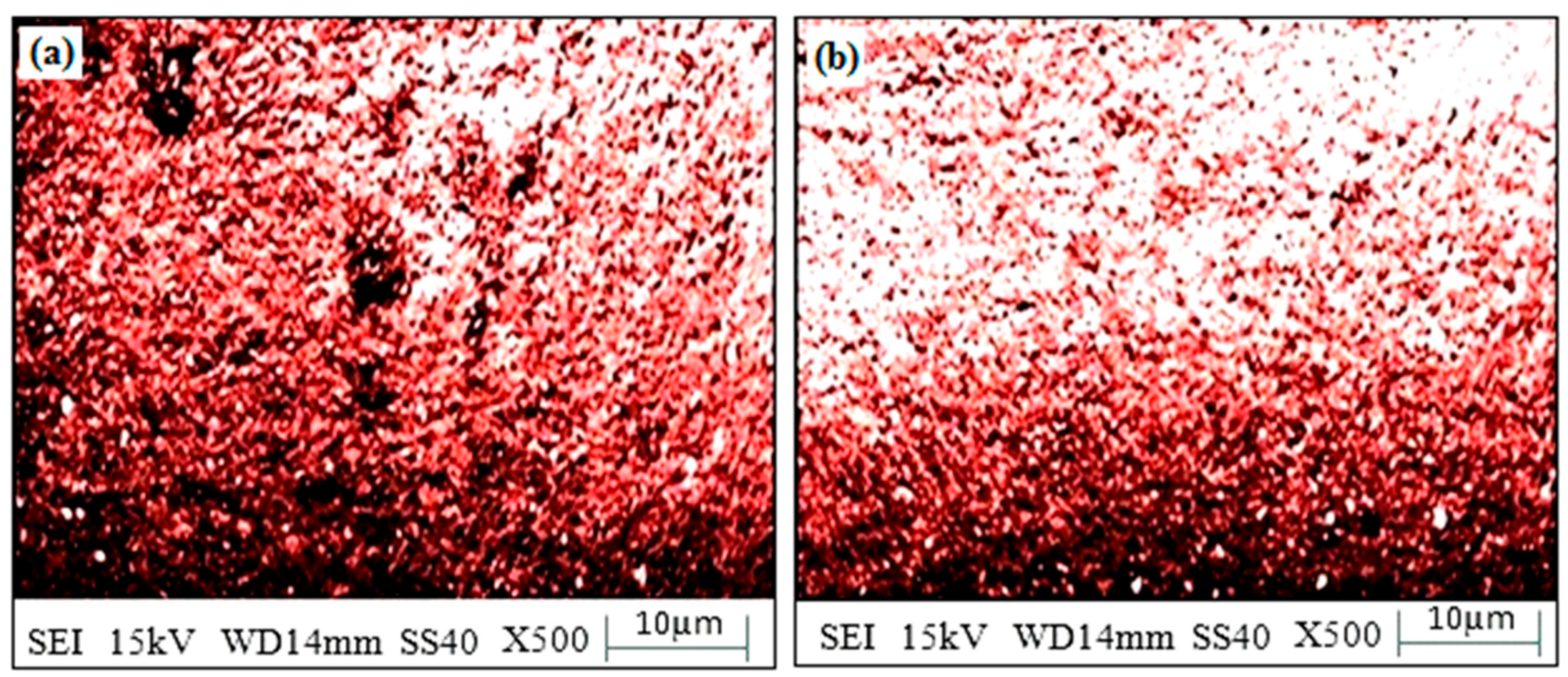

3.4.2. Microstructure Investigation

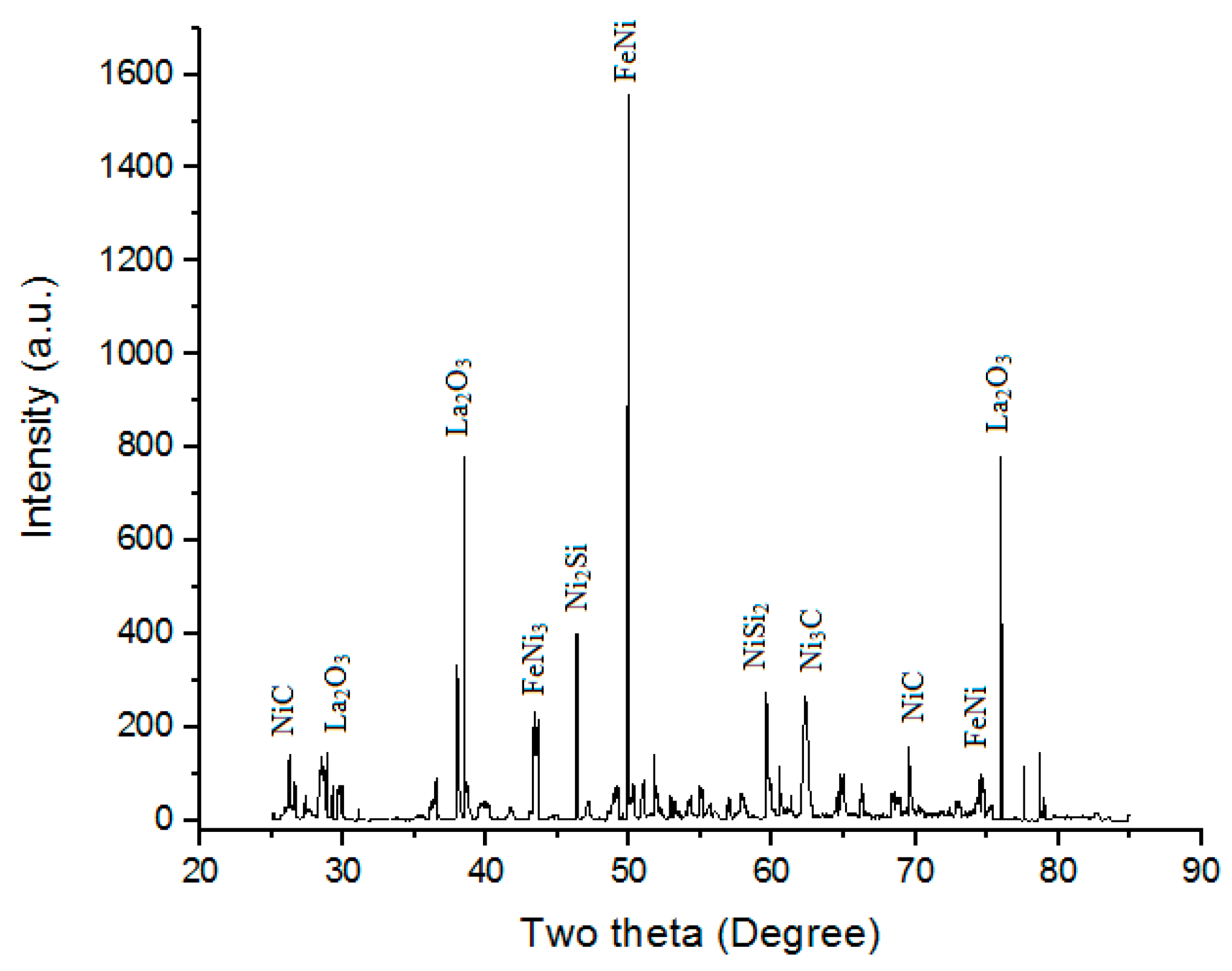

3.4.3. XRD Behavior

3.4.4. Wear Behavior

3.4.5. Corrosion Behavior

4. Conclusions

- The “mixture of 69.72% Ni, 19.28% Si, and 11% La2O3 particles” can be utilized on “SS-304 alloy for microwave cladding via microwave energy”.

- RSM results show that if the values of Si (wt.%), skin depth of the major constituent, irradiation time, and La2O3 (wt.%) are about 19.28, 4.57 µm, 118 s, and 11, respectively, then the value of cladding surface hardness should be 287.25 HV with a desirability of 1. The ANOVA table shows that La2O3 (wt.%) contributes the most, followed by Si (wt.%), irradiation time, and skin depth of the major constituent.

- An SEM image of the “microwave clad samples” developed using a “mixture of 69.72% Ni, 19.28% Si and 11% La2O3 particles” on “SS-304 developed at optimum cladding parameters” showed “uniform distribution of Ni, Si, and La2O3 particles”. A “Uniform cladding-layer” with “fewer dark pixels” was observed in between the “substrate and cladding surface”.

- XRD of the cladded surface shows the presence of FeNi, Ni2Si, FeNi3, NiSi2, Ni3C, NiC, and La2O3 phases.

- The “hardness of the cladding surface” was enhanced by about 32.85%. The foremost purpose for the enhancement in “hardness is the various hard phases”, developed after “microwave cladding such as Ni3C, NiC, and La2O3 phases”.

- The “wear rate and coefficient of friction” of developed “cladded surfaces” with a mixture of 69.72% Ni, 19.28% Si, and 11% La2O3 particles on SS-304 developed at optimum cladding parameters were found to be 0.00367 mm3/m and 0.312, respectively.

- “Few dark spots” were observed on the “corroded surface of SS-304” with the “microwave cladding of the mixture of 69.72% Ni, 19.28% Si, and 11% La2O3 particles”. These “dark spots” displayed some “corrosion in 3.5 wt.% NaCl environment”.

- Steel plate coating with 69.72% Ni, 19.28% Si, and 11% La2O3 may be used in the application of condensers for power plants; central air conditioning; and tube sheets used for heat exchangers, reactor columns, and pressure vessels in the oil and gas chemical industries, such as those used in storage tanks, etc.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharma, A.K.; Aravindhan, S.; Krishnamurthy, R. Microwaveglazing of alumina–titania ceramic composite coatings. Mater Lett. 2011, 50, 295–301. [Google Scholar] [CrossRef]

- Zhou, S.; Zeng, X.; Qianwu, H.; Huang, S. Analysis of crackbehavior for Ni-based WC composite coatings by lasercladding and crack-free realization. Appl. Surf. Sci. 2008, 255, 1646–1653. [Google Scholar] [CrossRef]

- Leonelli, R.C.; Veronesi, P.; Denti, L.; Gatto, A.; Iuliano, L. Microwaveassisted sintering of green metal parts. J. Mater. Process Technol. 2008, 205, 489–496. [Google Scholar] [CrossRef]

- Mateos, J.; Cuetos, J.M.; Fernandez, E.; Vijande, R. Tribologicalbehavior of plasma-sprayed WC coatings with and withoutlaser remelting. Wear 2000, 239, 274–281. [Google Scholar] [CrossRef]

- Roy Agrawal, D.; Cheng, J.; Gedevanishvili, S. Full sintering of powdered-metal bodies in a microwave field. Nature 1999, 339, 668–670. [Google Scholar]

- Mondal, A.; Upadhyaya, A.; Agrawal, D. Microwave sintering ofrefractory metals/alloys. J. Microw. Power Electromagn Energy 2009, 44, 28–44. [Google Scholar] [CrossRef] [PubMed]

- Chhillar, P.; Agrawal, D.; Adair, J.H. Sintering of molybdenummetal powder using microwave energy. Powder Met. 2008, 51, 182–187. [Google Scholar] [CrossRef]

- Zambon, A.; Ramous, E. Laser beam energy absorptionenhancement by means of coatings. Laser Eng. 1993, 2, 163–167. [Google Scholar]

- Gupta, D.; Sharma, A.K.; Bhovi, P.M.; Dutta, S. Development andcharacterization of microwave composite cladding. J. Manuf. Process 2012, 14, 243–249. [Google Scholar] [CrossRef]

- Badigera, R.I.; Narendranath, S.; Srinath, M.S. Joining ofInconel-625 alloy through microwave hybrid heating and itscharacterization. J. Manuf. Process 2015, 18, 117–123. [Google Scholar] [CrossRef]

- Toozandehjani, M.; Ostovan, F.; Jamaludin, K.R.; Amrin, A.; Matori, K.A.; Shafiei, E. Process−microstructure−properties relationship in Al−CNTs−Al2O3 nanocomposites manufactured by hybrid powder metallurgy and microwave sintering process. Trans. Nonferrous Met. Soc. China 2020, 30, 2339–2354. [Google Scholar] [CrossRef]

- Amiri, E.; Ostovan, F.; Toozandehjani, M.; Shafiei, E.; Mohamed, I.F. Study and selection of most appropriate filler rod for GTAW of S32750 super duplex steel joints: A comprehensive study on microstructural, mechanical and corrosion properties. Mater. Chem. Phys. 2021, 270, 124839. [Google Scholar] [CrossRef]

- Ostovan, F.; Shafiei, E.; Toozandehjani, M.; Mohamed, I.F.; Soltani, M. On the role of molybdenum on the microstructural, mechanical and corrosion properties of the GTAW AISI 316 stainless steel welds. J. Mater. Res. Technol. 2021, 13, 2115–2125. [Google Scholar] [CrossRef]

- Singh, S.K.; Chattopadhyaya, S.; Pramanik, A.; Kumar, S.; Pandey, S.M.; Walia, R.; Sharma, S.; Khan, A.M.; Dwivedi, S.P.; Singh, S.; et al. Effect of alumina oxide nano-powder on the wear behaviour of CrN coating against cylinder liner using response surface methodology: Processing and characterizations. J. Mater. Res. Technol. 2022, 16, 1102–1113. [Google Scholar] [CrossRef]

- Singh, G.; Sharma, S.; Mittal, M.; Singh, G.; Singh, J.; Changhe, L.; Khan, A.M.; Dwivedi, S.P.; Mushtaq, R.T.; Singh, S. Impact of post-heat-treatment on the surface-roughness, residual stresses, and micromorphology characteristics of plasma-sprayed pure hydroxyapatite and 7%-Aloxite reinforced hydroxyapatite coatings deposited on titanium alloy-based biomedical implants. J. Mater. Res. Technol. 2022, 18, 1358–1380. [Google Scholar] [CrossRef]

- Singh, B.; Zafar, S. Microwave cladding for slurry erosion resistance applications: A review. Mater. Today Proc. 2021, 46, 2686–2690. [Google Scholar] [CrossRef]

- Prasad, C.D.; Lingappa, M.S.; Joladarashi, S.; Ramesh, M.; Sachin, B. Characterization and sliding wear behavior of CoMoCrSi + Flyash composite cladding processed by microwave irradiation. Mater. Today Proc. 2021, 46, 2387–2391. [Google Scholar] [CrossRef]

- Singh, B.; Zafar, S. Understanding time-temperature characteristics in microwave cladding. Manuf. Lett. 2020, 25, 75–80. [Google Scholar] [CrossRef]

- Vishwanatha, J.; Hebbale, A.M.; Kumar, N.; Srinath, M.; Badiger, R.I. ANOVA studies and control factors effect analysis of cobalt based microwave clad. Mater. Today Proc. 2021, 46, 2409–2413. [Google Scholar] [CrossRef]

- Kumar, K.P.; Mohanty, A.; Lingappa, M.S.; Srinath, M.; Panigrahi, S. Enhancement of surface properties of austenitic stainless steel by nickel based alloy cladding developed using microwave energy technique. Mater. Chem. Phys. 2020, 256, 123657. [Google Scholar] [CrossRef]

- Singh, G.; Mittal, M.; Singh, J.; Sharma, S.; Chohan, J.; Kumar, R. Effect of post coating processing on the morphological and mechanical properties of plasma Spray-reinforced hydroxyapatite coating. Mater. Today: Proc. 2022, 68, 1180–1186. [Google Scholar] [CrossRef]

- Janney, M.A.; Calhoun, C.L.; Kimrey, H.D. Microwave sintering ofsolid oxide fuel cell materials. J. Am. Ceram. Soc. 1992, 75, 341–346. [Google Scholar] [CrossRef]

- Rocha, O.L.; Siqueira, C.A.; Garcia, A. Cellular spacing’s inunsteady-state directionally solidified Sn–Pb alloys. MaterSci. Eng. A 2003, 361, 111–118. [Google Scholar] [CrossRef]

- Kunlin, W.; Qingbo, Z.; Xingguo, W.; Yunming, Z. Rare-earthLa2O3modification of laser-clad coatings. J. Mater Sci. 1998, 33, 3573–3577. [Google Scholar] [CrossRef]

- Tlotleng, M.; Akinlabi, E.; Shukla, M.; Pityana, S. Microstructure, hardness and bioactivity of hydroxyapatite coatingsdeposited by direct laser melting process. Mater. Sci. Eng. C 2014, 43, 189–198. [Google Scholar] [CrossRef]

- Yang, J.; Chen, G.; Chen, Z.; Mu, X.; Yu, Y.; Zhang, L.; Li, X.; Qu, X.; Qin, X. Effects of doping route on microstructure and mechanical properties of W−1.0wt.%La2O3 alloys. Trans. Nonferrous Met. Soc. China 2020, 30, 3296–3306. [Google Scholar] [CrossRef]

- Dwivedi, S.P.; Sharma, S.; Sharma, S. Identification of Microwave Radiation Effect on Copper Welded Joint with Brass as Filler Material Using Response Surface Methodology. Mater. Perform. Charact. 2020, 9, 267–276. [Google Scholar] [CrossRef]

- Dwivedi, S.P.; Sharma, S.; Singh, T.; Kumar, N. Mechanical and Metallurgical Characterization of Copper-Based Welded Joint Using Brass as Filler Metal Developed by Microwave Technique. Ann. De Chim.-Sci. Des. Matériaux. 2020, 44, 281–286. [Google Scholar] [CrossRef]

- Singh, G.; Mittal, M.; Singh, J.; Sharma, S.; Gill, A.; Chohan, J.; Kumar, R.; Joshi, A. Study on the morphological and mechanical properties of TaC reinforced plasma spray coating deposited on titanium alloy. Mater. Today Proc. 2022, 68, A22–A26. [Google Scholar] [CrossRef]

- Ganeshkumar, S.; Singh, B.K.; Kumar, S.D.; Gokulkumar, S.; Sharma, S.; Mausam, K.; Li, C.; Zhang, Y.; Tag Eldin, E.M. Study of Wear, Stress and Vibration Characteristics of Silicon Carbide Tool Inserts and Nano Multi-Layered Titanium Nitride-CoatedCutting Tool Inserts in Turning of SS304 Steels. Materials 2022, 15, 7994. [Google Scholar] [CrossRef]

- Amer, A.; Abdelsalam, A.; Aryanfar, Y.; Assad, M.E.H.; Sharma, S.; Alayi, R. Reducing PV soiling and condensation using hydrophobic coating with brush and controllable curtains. Int. J. Low-Carbon Technol. 2022, 17, 919–930. [Google Scholar] [CrossRef]

- Singh, Y.; Sharma, S.; Singh, G.; Singh, G.; Singh, J.; Dwivedi, S.P.; Singh, S.; Kumar, R.; Chattopadhyaya, S.; Li, C. Studies on Physical, Micro-structural, and Slurry Erosion behaviour of Cold Sprayed Ni-20Cr+TiC+Re Coatings on SA516 steel for high-temperature applications. Surf. Rev. Lett. 2023. [Google Scholar] [CrossRef]

- Al-Tameemi, H.A.; Al-Dulaimi, T.; Awe, M.O.; Sharma, S.; Pimenov, D.Y.; Koklu, U.; Giasin, K. Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy. Materials 2021, 14, 1783. [Google Scholar] [CrossRef]

- Sharma, S.; Dong, X.N.; Wei, P.; Long, C. Electro-Chemical Deposited Cu-Ni Binary and Cu-Ni-Mn Ternary Alloys from Sulphate Bath for Anti-Corrosive Coating Applications in Brine Environment: Effect of Corrosion Behaviour, Polarization Studies, Morphological and Structural Characterizations. Key Eng. Mater. 2020, 837, 102–108. [Google Scholar] [CrossRef]

- Sheng, C.; He, G.; Hu, Z.; Chou, C.; Shi, J.; Li, J.; Meng, Q.; Ning, X.; Wang, L.; Ning, F. Yarn on yarn abrasion failure mechanism of ultrahigh molecular weight polyethylene fiber. J. Eng. Fibers Fabr. 2021, 16, 1925832385. [Google Scholar] [CrossRef]

- Ning, F.; He, G.; Sheng, C.; He, H.; Wang, J.; Zhou, R.; Ning, X. Yarn on yarn abrasion performance of high modulus polyethylene fiber improved by graphene/polyurethane composites coating. J. Eng. Fibers Fabr. 2021, 16. [Google Scholar] [CrossRef]

- Yuhua, C.; Yuqing, M.; Weiwei, L.; Peng, H. Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints. Opt. Laser Technol. 2017, 91, 197–202. [Google Scholar] [CrossRef]

- Deng, H.; Chen, Y.; Jia, Y.; Pang, Y.; Zhang, T.; Wang, S.; Yin, L. Microstructure and mechanical properties of dissimilar NiTi/Ti6Al4V joints via back-heating assisted friction stir welding. J. Manuf. Process. 2021, 64, 379–391. [Google Scholar] [CrossRef]

- Long, X.; Guo, Y.; Su, Y.; Siow, K.S.; Chen, C. Unveiling the damage evolution of SAC305 during fatigue by entropy generation. Int. J. Mech. Sci. 2023, 244, 108087. [Google Scholar] [CrossRef]

- Zhu, H.; Zhao, R. Isolated Ni atoms induced edge stabilities and equilibrium shapes of CVD-prepared hexagonal boron nitride on Ni(111) surface. New J. Chem. 2022, 46, 17496–17504. [Google Scholar] [CrossRef]

- Fan, B.; Zhao, X.; Liu, Z.; Xiang, Y.; Zheng, X. Inter-component synergetic corrosion inhibition mechanism of Passiflora edulia Sims shell extract for mild steel in pickling solution: Experimental, DFT and reactive dynamics investigations. Sustain. Chem. Pharm. 2022, 29, 100821. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, B.; He, T.; Tu, L.; Lu, X.; Xu, H. Tribology and dynamic characteristics of textured journal-thrust coupled bearing considering thermal and pressure coupled effects. Tribol. Int. 2023, 180, 108292. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z.; Yue, X.; Wang, P.; Zhai, Y. Water jet impact damage mechanism and dynamic penetration energy absorption of 2A12 aluminum alloy. Vacuum 2022, 206, 111532. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z.; Liu, J.; Yu, J.; Mai, Q.; Yue, X. Effect of aging plus cryogenic treatment on the machinability of 7075 aluminum alloy. Vacuum 2023, 208, 111692. [Google Scholar] [CrossRef]

- Fan, X.; Wei, G.; Lin, X.; Wang, X.; Si, Z.; Zhang, X.; Shao, Q.; Mangin, S.; Fullerton, E.; Jiang, L.; et al. Reversible Switching of Interlayer Exchange Coupling through Atomically Thin VO2 via Electronic State Modulation. Matter 2020, 2, 1582–1593. [Google Scholar] [CrossRef]

- Guo, K.; Gou, G.; Lv, H.; Shan, M. Jointing of CFRP/5083 Aluminum Alloy by Induction Brazing: Processing, Connecting Mechanism, and Fatigue Performance. Coatings 2022, 12, 1559. [Google Scholar] [CrossRef]

- Fu, Z.; Yang, B.; Shan, M.; Li, T.; Zhu, Z.; Ma, C.; Zhang, X.; Gou, G.; Wang, Z.; Gao, W. Hydrogen embrittlement behavior of SUS301L-MT stainless steel laser-arc hybrid welded joint localized zones. Corros. Sci. 2020, 164, 108337. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Liu, Y.L.; Gou, G.Q.; Gao, W.; Chen, J. Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser + CMT. Sci. Rep. 2021, 11, 10020. [Google Scholar] [CrossRef]

- Zhu, Q.; Chen, J.; Gou, G.; Chen, H.; Li, P. Ameliorated longitudinal critically refracted—Attenuation velocity method for welding residual stress measurement. J. Mater. Process. Technol. 2017, 246, 267–275. [Google Scholar] [CrossRef]

- Niu, X.; Zhu, S.-P.; He, J.-C.; Liao, D.; Correia, J.A.; Berto, F.; Wang, Q. Defect tolerant fatigue assessment of AM materials: Size effect and probabilistic prospects. Int. J. Fatigue 2022, 160, 106884. [Google Scholar] [CrossRef]

- He, J.; Zhu, S.; Luo, C.; Niu, X.; Wang, Q. Size effect in fatigue modelling of defective materials: Application of the calibrated weakest-link theory. Int. J. Fatigue 2022, 165, 107213. [Google Scholar] [CrossRef]

- Li, X.-K.; Zhu, S.-P.; Liao, D.; Correia, J.A.; Berto, F.; Wang, Q. Probabilistic fatigue modelling of metallic materials under notch and size effect using the weakest link theory. Int. J. Fatigue 2022, 159, 106788. [Google Scholar] [CrossRef]

- Xu, H.; He, T.; Zhong, N.; Zhao, B.; Liu, Z. Transient thermomechanical analysis of micro cylindrical asperity sliding contact of SnSbCu alloy. Tribol. Int. 2022, 167, 107362. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, Y.; Wang, Y.; Zhang, T.; Jia, H. Hybrid Dynamic Modeling and Analysis of High-Speed Thin-Rimmed Gears. ASME. J. Mech. Des. 2021, 143, 123401. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, T.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar] [CrossRef]

- Liu, J.; Mao, S.; Song, S.; Huang, L.; Belfiore, L.A.; Tang, J. Towards applicable photoacoustic micro-fluidic pumps: Tunable excitation wavelength and improved stability by fabrication of Ag-Au alloying nanoparticles. J. Alloys Compd. 2021, 884, 161091. [Google Scholar] [CrossRef]

- Zhao, J.; Gao, J.; Li, W.; Qian, Y.; Shen, X.; Wang, X.; Shen, X.; Hu, Z.; Dong, C.; Huang, Q.; et al. A combinatory ferroelectric compound bridging simple ABO3 and A-site-ordered quadruple perovskite. Nat. Commun. 2021, 12, 747. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, F.; Zhang, H.; Zhang, T.; Wang, H.; Xu, Y.; Ma, Q. Influence of CeO2 addition on forming quality and microstructure of TiCx-reinforced CrTi4-based laser cladding composite coating. Mater. Charact. 2021, 171, 110732. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Q.; Yu, Z.; Wang, H.; Zhang, T. Influence of Y2O3 addition on the microstructure of TiC reinforced Ti-based composite coating prepared by laser cladding. Mater. Charact. 2022, 189, 111962. [Google Scholar] [CrossRef]

- Dong, P.; Zhang, Y.; Zhu, S.; Nie, Z.; Ma, H.; Liu, Q.; Li, J. First-Principles Study on the Adsorption Characteristics of Corrosive Species on Passive Film TiO2 in a NaCl Solution Containing H2S and CO2. Metals 2022, 12, 1160. [Google Scholar] [CrossRef]

- Singh, G.; Vasudev, H.; Bansal, A.; Vardhan, S.; Sharma, S. Microwave cladding of Inconel-625 on mild steel substrate for corrosion protection. Mater. Res. Express 2020, 7, 026512. [Google Scholar] [CrossRef]

- Singh, G.; Sharma, S.; Singh, J.; Aggarwal, V.; Mayilswamy, S. Influence of Nickel-Based Cladding on the Hardness and Wear Behavior of Hard-Faced Mild Steel Using E-7014 Electrode Using Shielded Metal Arc Welding; CRC Press-Taylor & Francis: Boca Raton, FL, USA, 2020; ISBN 978-0-367-52106-6. [Google Scholar]

| S. No. | Properties | Values |

|---|---|---|

| 1 | “Density (g/cm3)” | 8 |

| 2 | “Tensile Strength (MPa)” | 615 |

| 3 | “Melting Temperature (Degree centigrade)” | 1450 |

| 4 | “Vickers hardness (HV)” | 210 |

| S. No. | Input Parameters | Range |

|---|---|---|

| 1 | Si (wt.%) | 15–25 |

| 2 | The skin depth (µm) | 4–5 |

| 3 | Irradiation time (s) | 90–120 |

| 4 | La2O3 (wt.%) | 10–20 |

| Standard Order | Run | A: Si (wt.%) | B: The Skin Depth of the Major Constituent of the Hard-Facing Powder (µm) | C: Irradiation Time (s) | D: La2O3 (wt.%) | Surface Hardness (HV) |

|---|---|---|---|---|---|---|

| 14 | 1 | 25 | 4 | 120 | 20 | 280 |

| 10 | 2 | 25 | 4 | 90 | 20 | 276 |

| 18 | 3 | 30 | 4.5 | 105 | 15 | 274 |

| 4 | 4 | 25 | 5 | 90 | 10 | 285 |

| 2 | 5 | 25 | 4 | 90 | 10 | 281 |

| 25 | 6 | 20 | 4.5 | 105 | 15 | 286 |

| 13 | 7 | 15 | 4 | 120 | 20 | 277 |

| 28 | 8 | 20 | 4.5 | 105 | 15 | 286 |

| 21 | 9 | 20 | 4.5 | 75 | 15 | 279 |

| 19 | 10 | 20 | 3.5 | 105 | 15 | 281 |

| 17 | 11 | 10 | 4.5 | 105 | 15 | 265 |

| 29 | 12 | 20 | 4.5 | 105 | 15 | 284 |

| 23 | 13 | 20 | 4.5 | 105 | 5 | 285 |

| 16 | 14 | 25 | 5 | 120 | 20 | 275 |

| 22 | 15 | 20 | 4.5 | 135 | 15 | 285 |

| 26 | 16 | 20 | 4.5 | 105 | 15 | 284 |

| 12 | 17 | 25 | 5 | 90 | 20 | 277 |

| 27 | 18 | 20 | 4.5 | 105 | 15 | 284 |

| 3 | 19 | 15 | 5 | 90 | 10 | 278 |

| 8 | 20 | 25 | 5 | 120 | 10 | 285 |

| 6 | 21 | 25 | 4 | 120 | 10 | 286 |

| 24 | 22 | 20 | 4.5 | 105 | 25 | 274 |

| 20 | 23 | 20 | 5.5 | 105 | 15 | 283 |

| 9 | 24 | 15 | 4 | 90 | 20 | 270 |

| 5 | 25 | 15 | 4 | 120 | 10 | 280 |

| 11 | 26 | 15 | 5 | 90 | 20 | 273 |

| 7 | 27 | 15 | 5 | 120 | 10 | 282 |

| 1 | 28 | 15 | 4 | 90 | 10 | 271 |

| 15 | 29 | 15 | 5 | 120 | 20 | 275 |

| 30 | 30 | 20 | 4.5 | 105 | 15 | 286 |

| “Source” | “Sum of Squares” | “DF” | “Mean Square” | “F Value” | “Prob > F” | |

|---|---|---|---|---|---|---|

| Model | 910.2833333 | 14 | 65.0202381 | 137.689916 | <0.0001 | significant |

| A | 135.375 | 1 | 135.375 | 286.6764706 | <0.0001 | |

| B | 7.041666667 | 1 | 7.041666667 | 14.91176471 | 0.0015 | |

| C | 70.04166667 | 1 | 70.04166667 | 148.3235294 | <0.0001 | |

| D | 187.0416667 | 1 | 187.0416667 | 396.0882353 | <0.0001 | |

| A2 | 414.0744048 | 1 | 414.0744048 | 876.8634454 | <0.0001 | |

| B2 | 15.86011905 | 1 | 15.86011905 | 33.58613445 | <0.0001 | |

| C2 | 15.86011905 | 1 | 15.86011905 | 33.58613445 | <0.0001 | |

| D2 | 52.64583333 | 1 | 52.64583333 | 111.4852941 | <0.0001 | |

| AB | 7.5625 | 1 | 7.5625 | 16.01470588 | 0.0012 | |

| AC | 14.0625 | 1 | 14.0625 | 29.77941176 | <0.0001 | |

| AD | 10.5625 | 1 | 10.5625 | 22.36764706 | 0.0003 | |

| BC | 27.5625 | 1 | 27.5625 | 58.36764706 | <0.0001 | |

| BD | 14.0625 | 1 | 14.0625 | 29.77941176 | <0.0001 | |

| CD | 3.0625 | 1 | 3.0625 | 6.485294118 | 0.0223 | |

| “Residual” | 7.083333333 | 15 | 0.472222222 | |||

| “Lack of Fit” | 1.083333333 | 10 | 0.108333333 | 0.090277778 | 0.9992 | not significant |

| “Pure Error” | 6 | 5 | 1.2 | |||

| “Cor Total” | 917.3666667 | 29 | ||||

| “Std. Dev.” | 0.687184271 | “R-Squared” | 0.992278624 | |||

| “Mean” | 279.5666667 | “Adj R-Squared” | 0.985072006 | |||

| “C.V.” | 0.245803364 | “Pred R-Squared” | 0.983779659 | |||

| “PRESS” | 14.88 | “Adeq Precision” | 43.64638992 |

| Axial Load | Wear Rate (mm3/m) | Friction | ||

|---|---|---|---|---|

| SS-304 | The Mixture of 69.72% Ni, 19.28% Si, and 11% La2O3 Particles Cladding on SS-304 | SS-304 | The Mixture of 69.72% Ni, 19.28% Si, and 11% La2O3 Particles Cladding on SS-304 | |

| 2.5 | 0.00411 | 0.00292 | 0.091 | 0.294 |

| 5 | 0.00456 | 0.00367 | 0.0956 | 0.312 |

| 7.5 | 0.00471 | 0.00397 | 0.0987 | 0.345 |

| 10 | 0.00490 | 0.00401 | 0.0994 | 0.398 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dwivedi, S.P.; Sharma, S.; Sharma, K.P.; Kumar, A.; Agrawal, A.; Singh, R.; Eldin, S.M. The Microstructure and Properties of Ni-Si-La2O3 Coatings Deposited on 304 Stainless Steel by Microwave Cladding. Materials 2023, 16, 2209. https://doi.org/10.3390/ma16062209

Dwivedi SP, Sharma S, Sharma KP, Kumar A, Agrawal A, Singh R, Eldin SM. The Microstructure and Properties of Ni-Si-La2O3 Coatings Deposited on 304 Stainless Steel by Microwave Cladding. Materials. 2023; 16(6):2209. https://doi.org/10.3390/ma16062209

Chicago/Turabian StyleDwivedi, Shashi Prakash, Shubham Sharma, Kanta Prasad Sharma, Abhinav Kumar, Ashish Agrawal, Rajesh Singh, and Sayed M. Eldin. 2023. "The Microstructure and Properties of Ni-Si-La2O3 Coatings Deposited on 304 Stainless Steel by Microwave Cladding" Materials 16, no. 6: 2209. https://doi.org/10.3390/ma16062209

APA StyleDwivedi, S. P., Sharma, S., Sharma, K. P., Kumar, A., Agrawal, A., Singh, R., & Eldin, S. M. (2023). The Microstructure and Properties of Ni-Si-La2O3 Coatings Deposited on 304 Stainless Steel by Microwave Cladding. Materials, 16(6), 2209. https://doi.org/10.3390/ma16062209