Influence of Fumed Nanosilica on Ballistic Performance of UHPCs

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Composites

2.2. The Evaluation of the Specific Gravity

2.3. Testing of Mechanical Properties

2.4. Isothermal Calorimetry

2.5. BSEM Imaging of Fracture Surfaces

2.6. Fabrication of Composites for Testing of Ballistic Properties

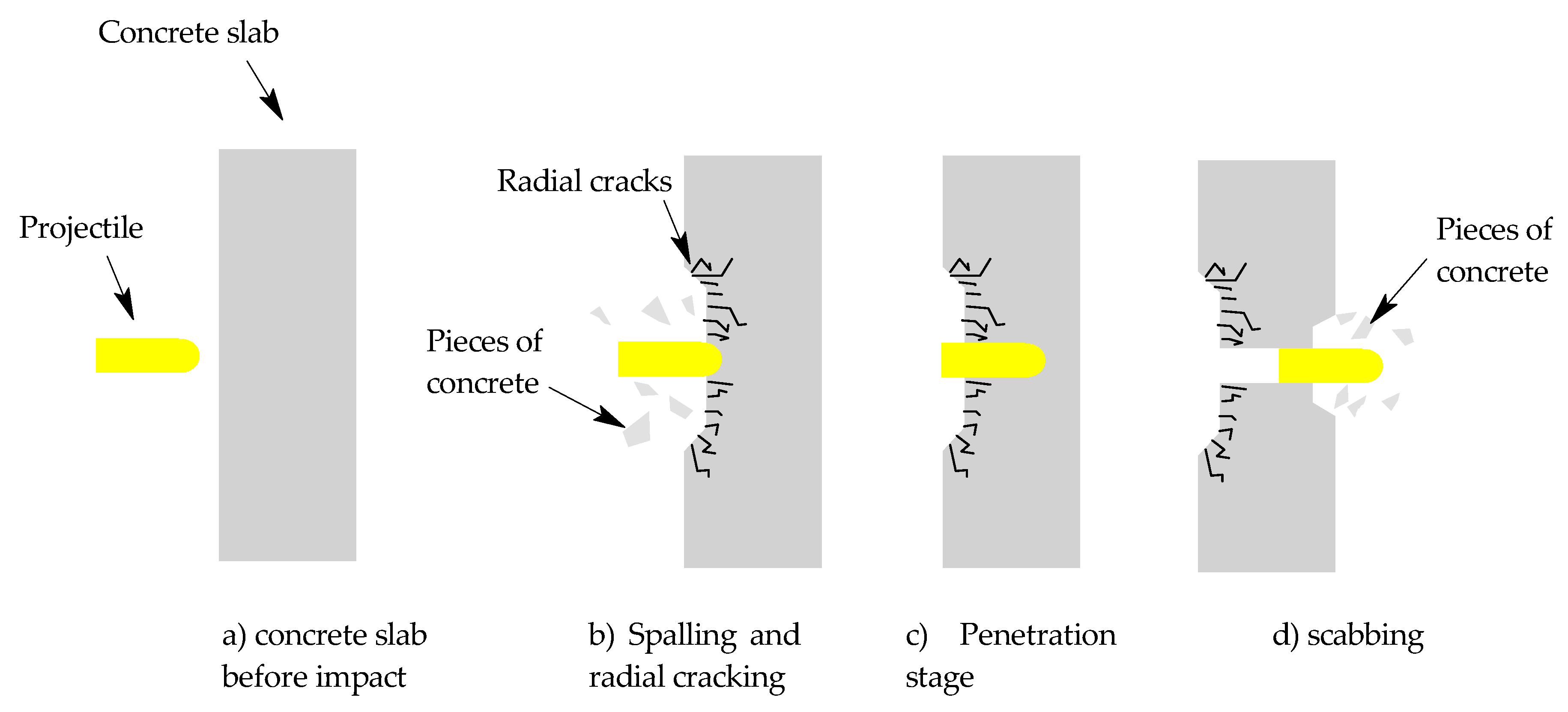

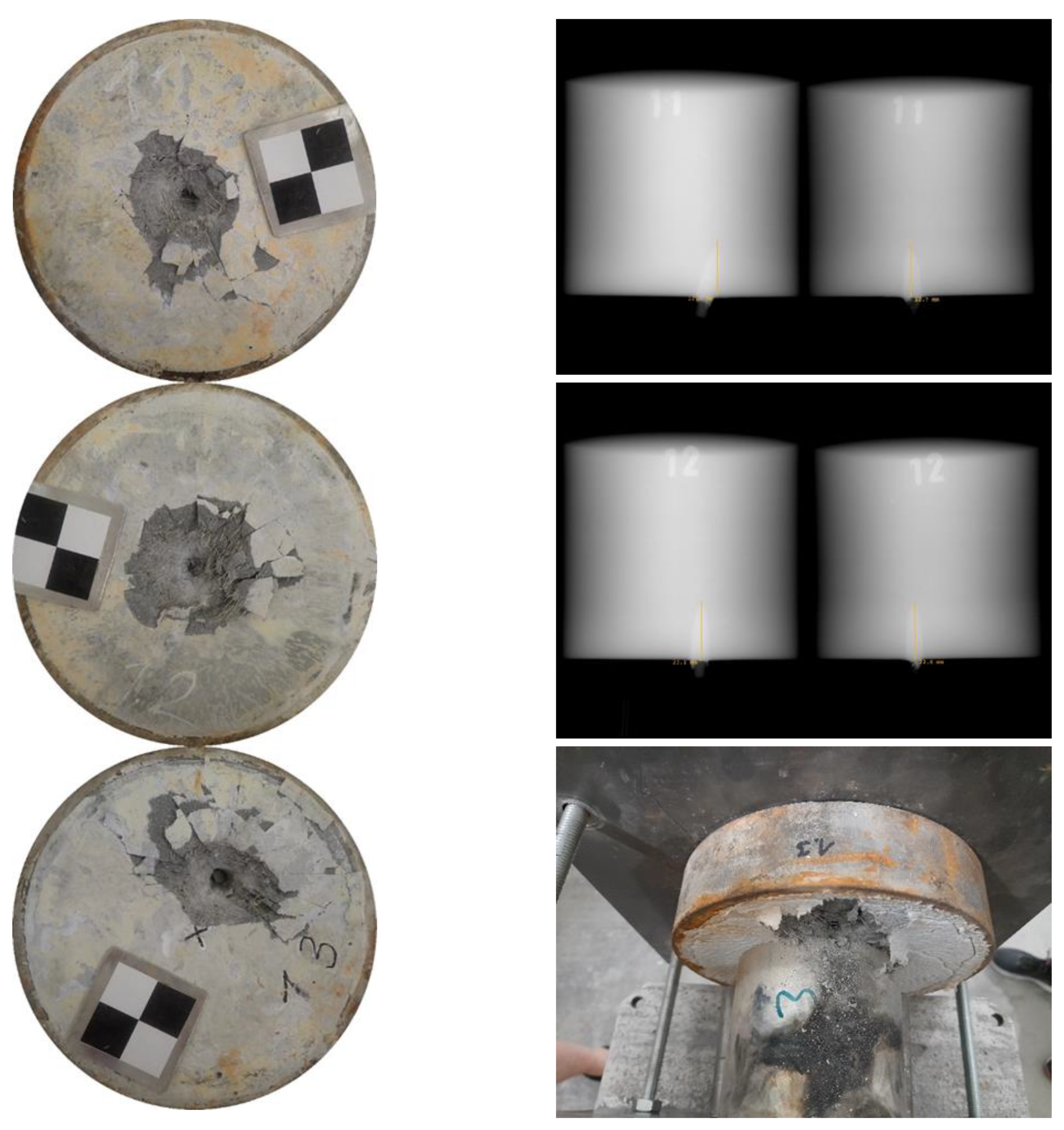

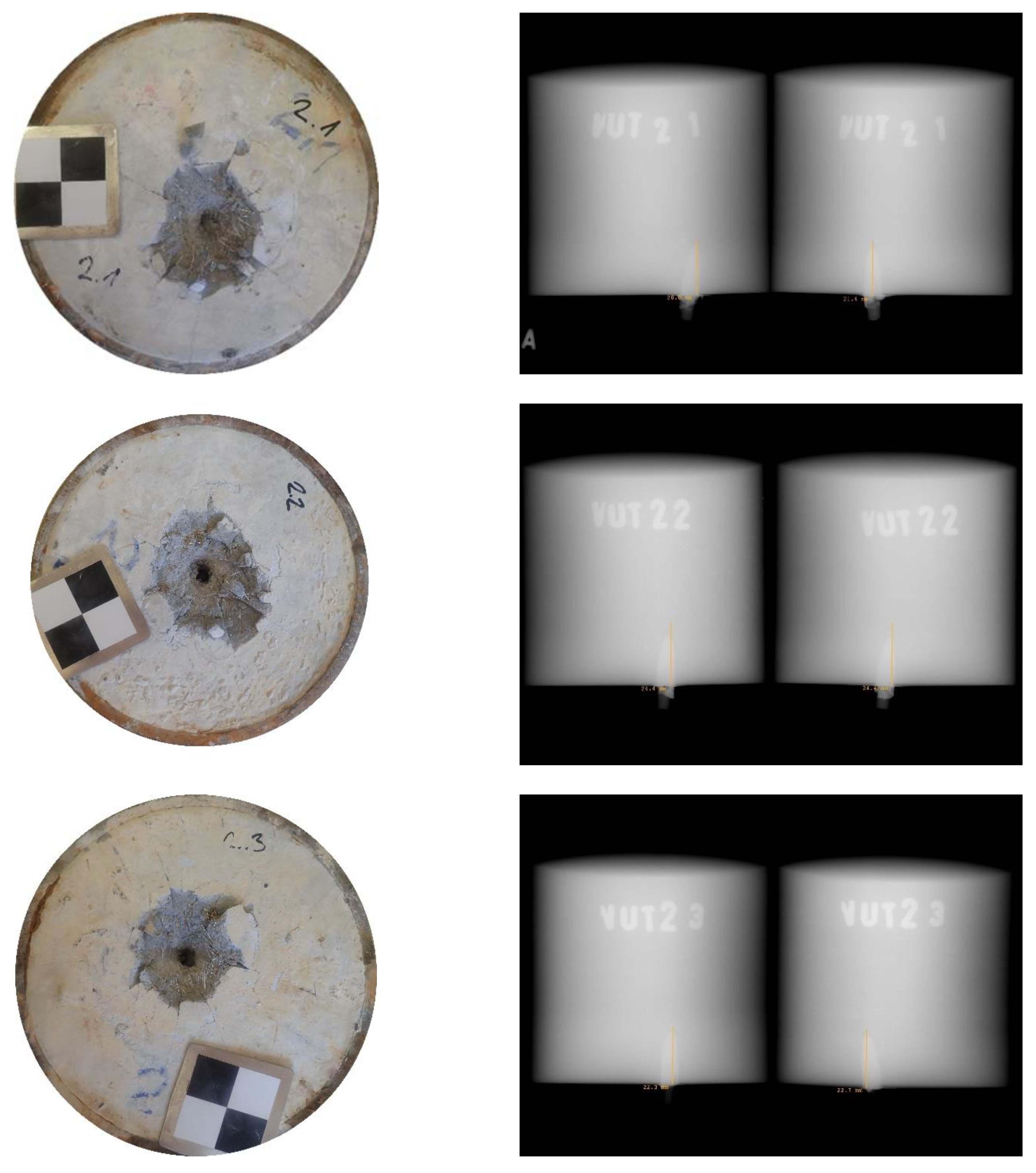

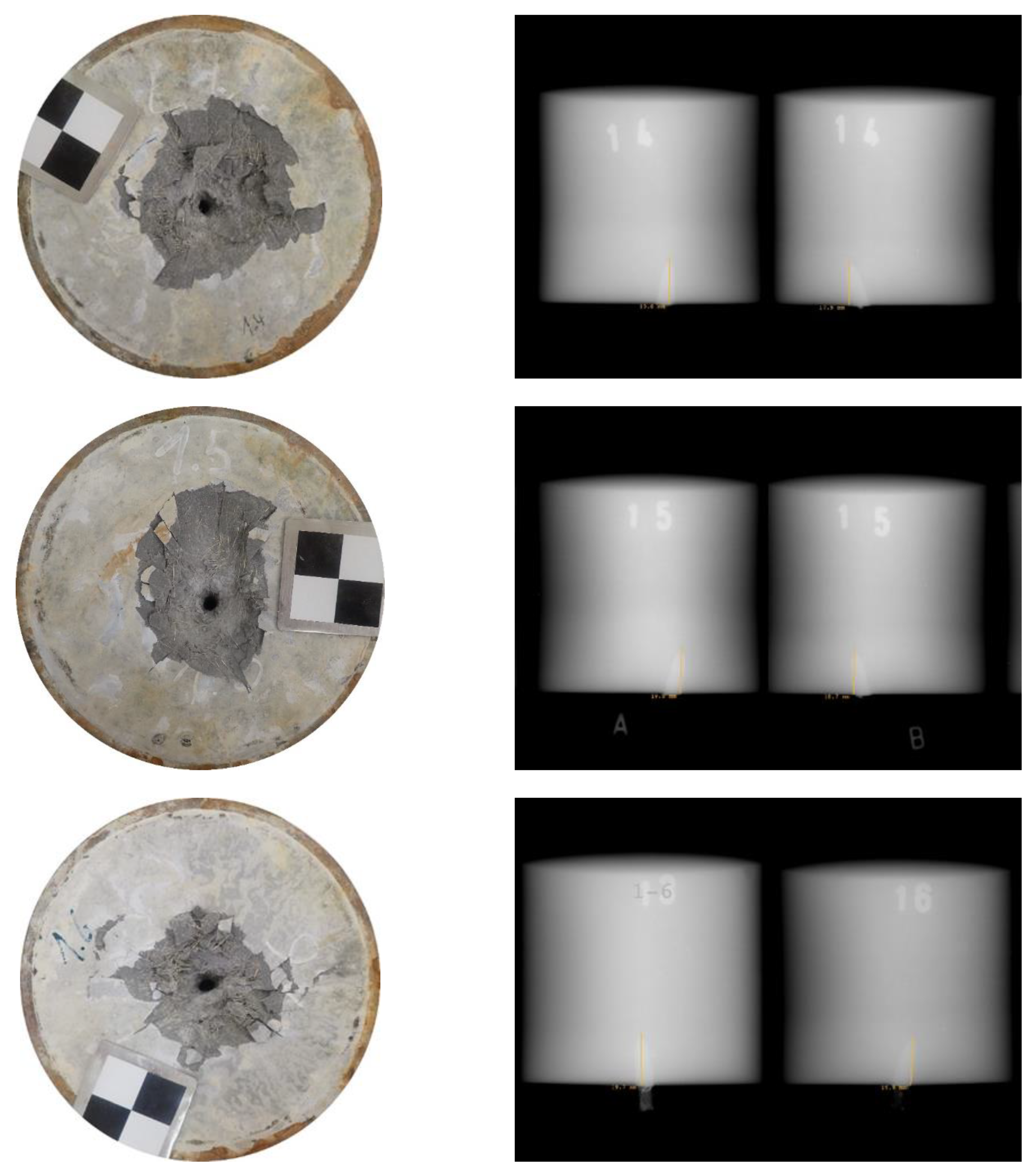

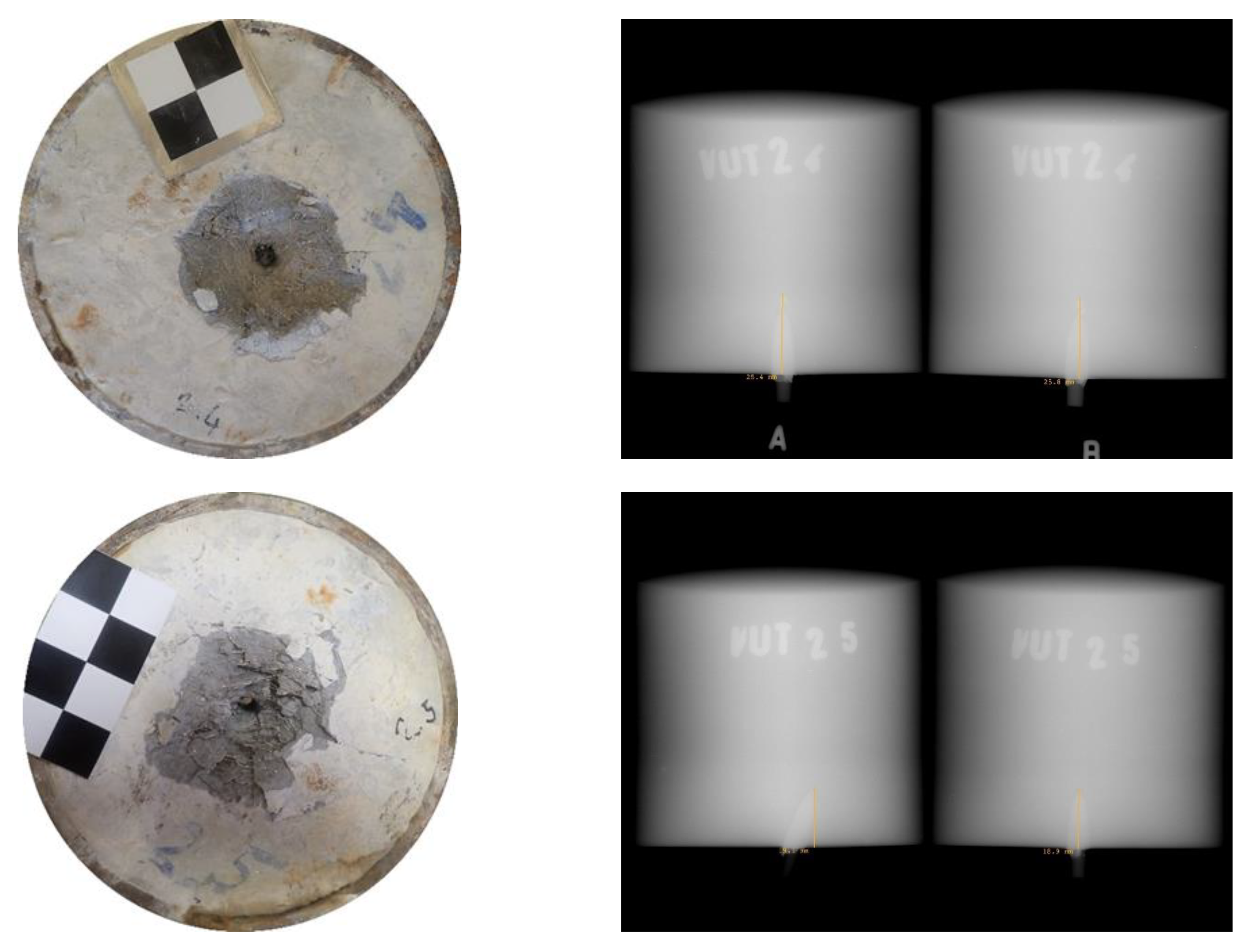

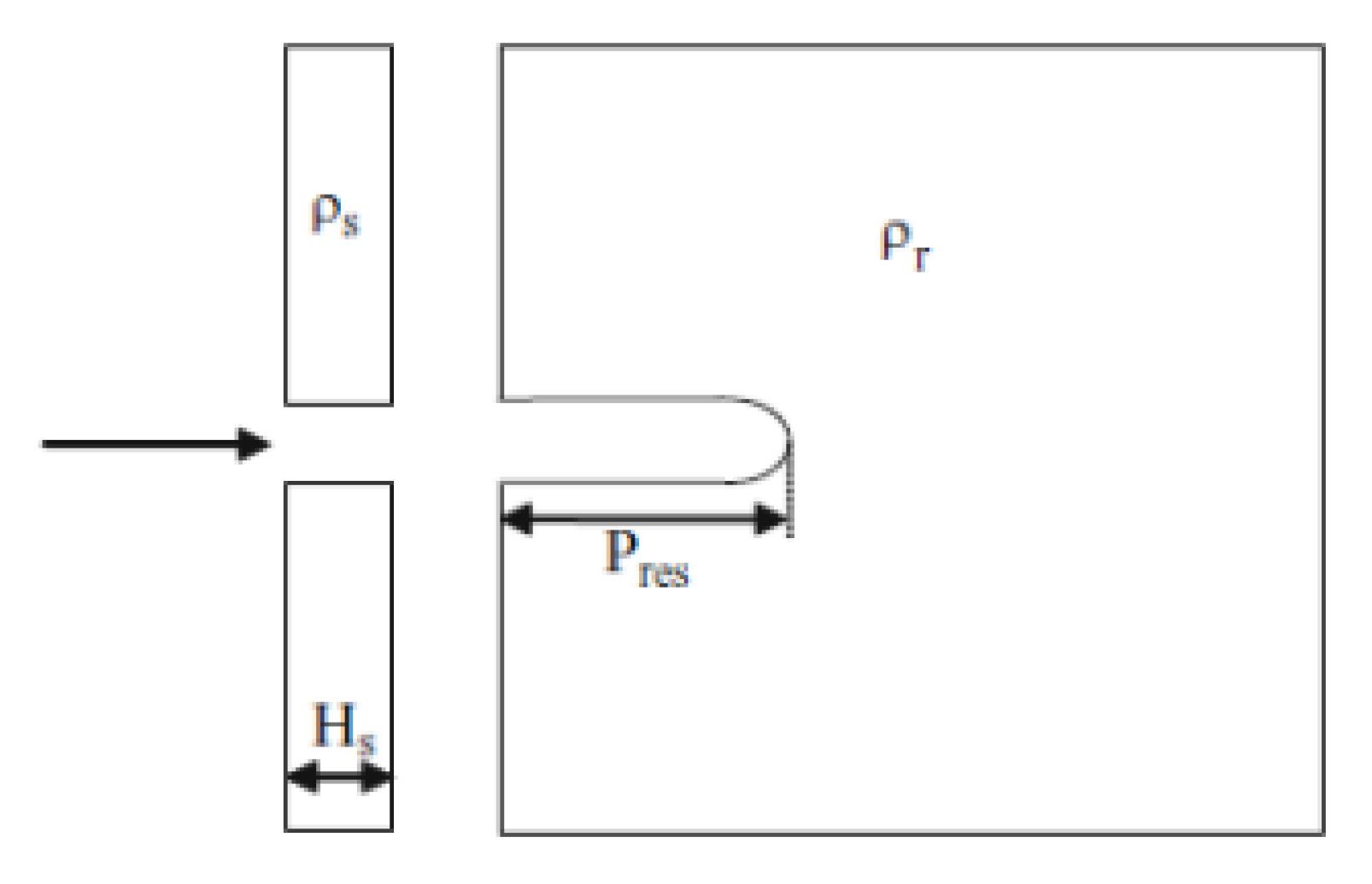

2.7. Depth of Penetration Test

3. Results and Discussion

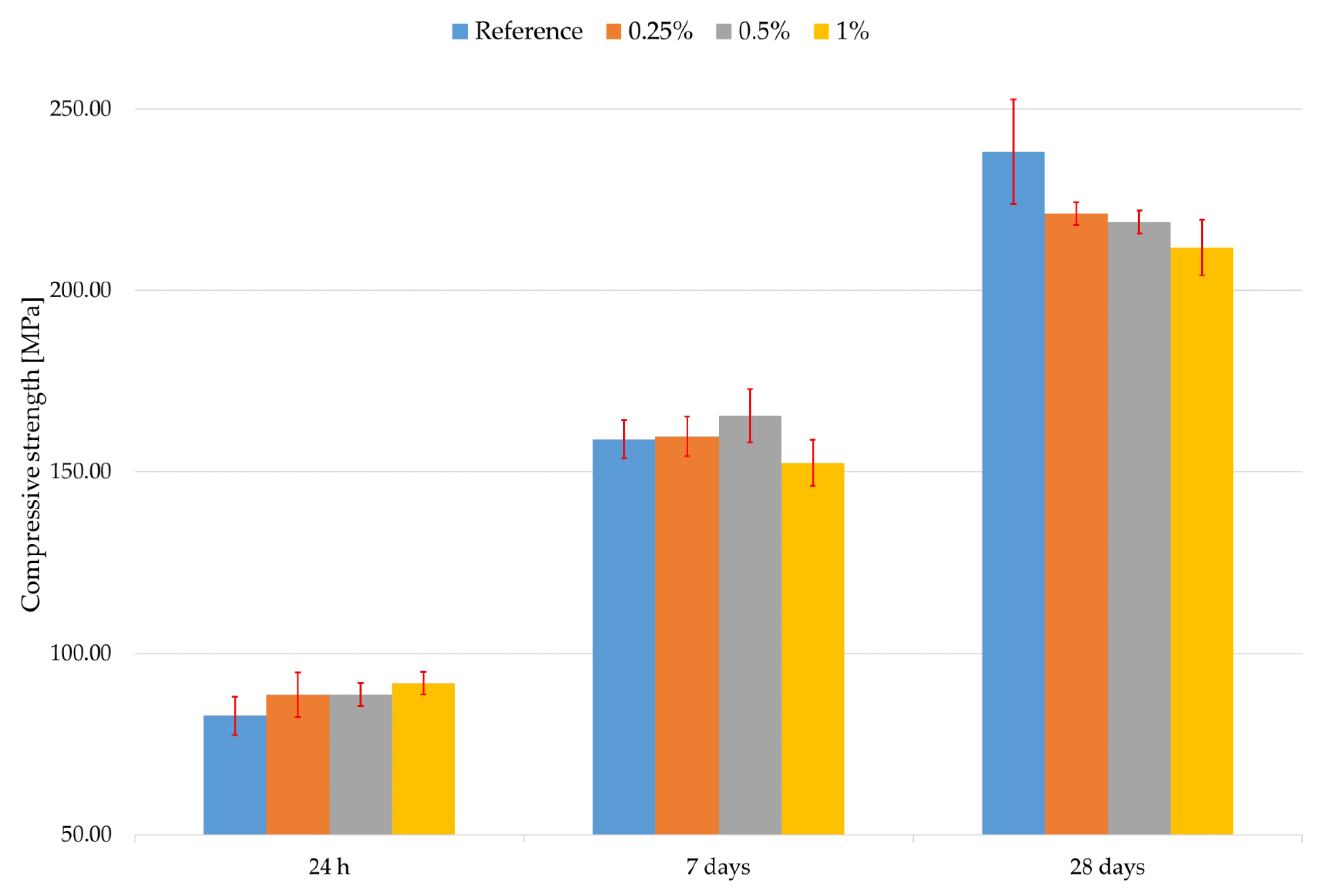

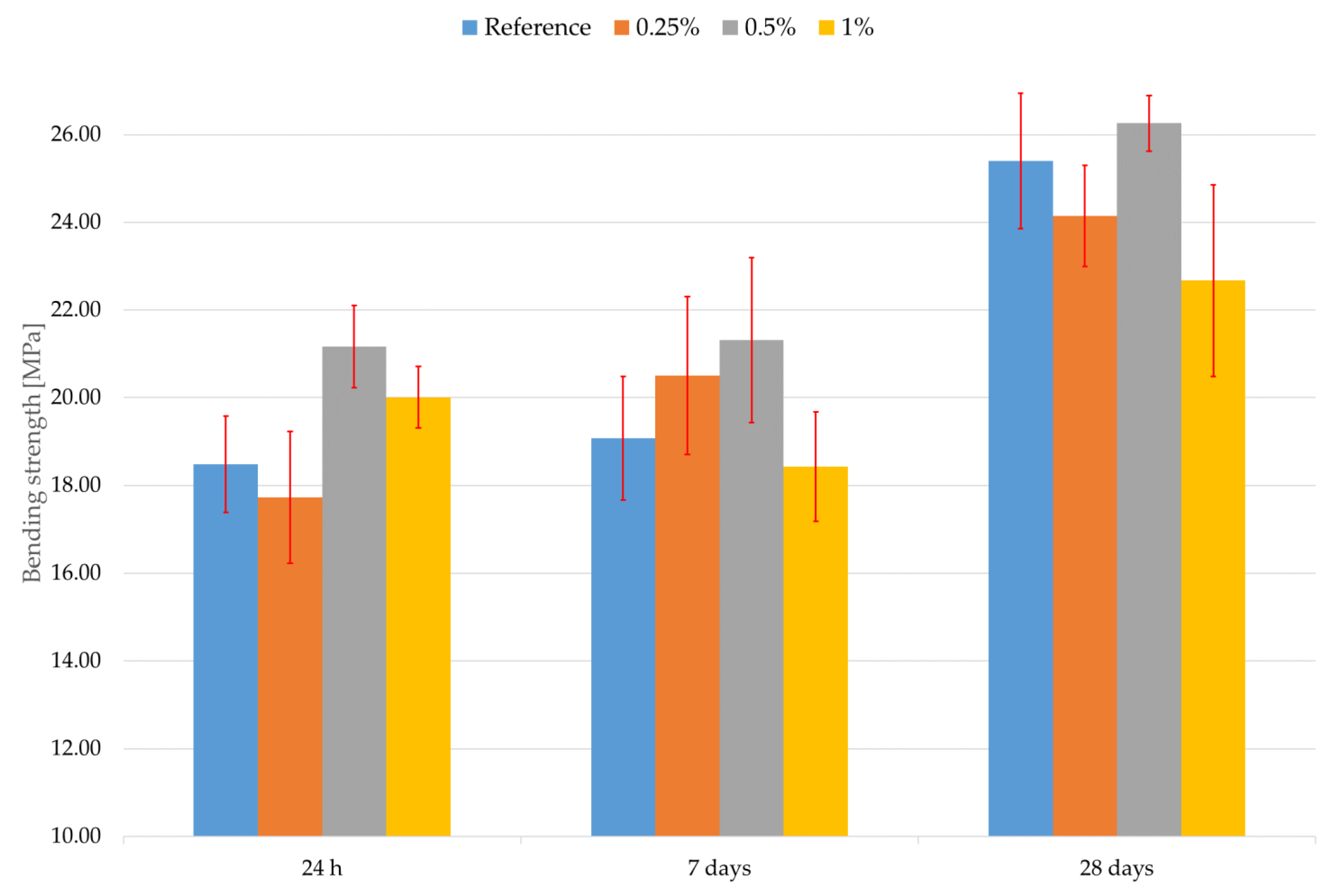

3.1. Mechanical Properties, Slump Flow, and Specific Gravity

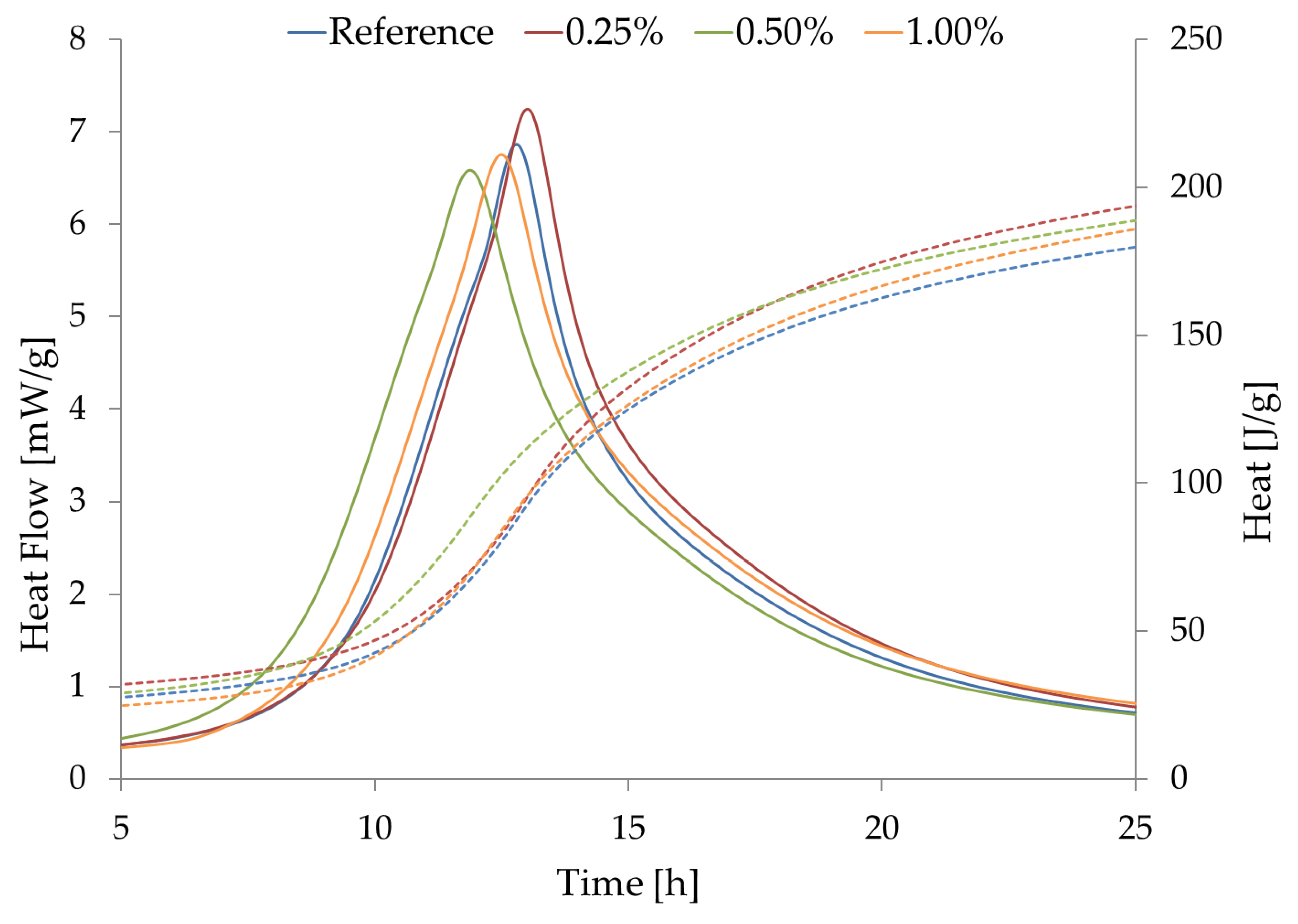

3.2. Isothermal Calorimetry

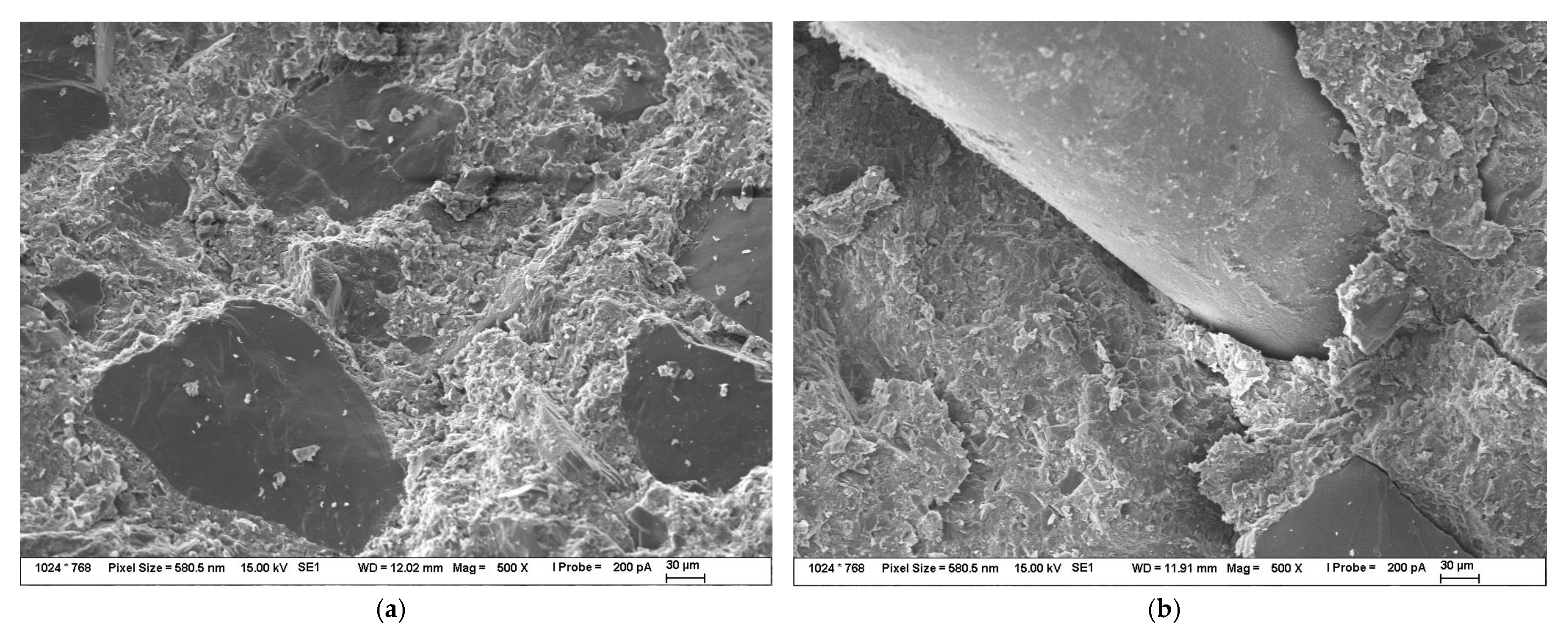

3.3. BSEM Imaging

3.4. Differential Efficiency Factor and Average Spalling Area Results

4. Conclusions

- Slump flow is negatively affected by the addition of FNS, but the relation between the size, number of agglomerates, and the homogenization of mixture on the slump flow of UHPC should be the subject of future research. It was also found out that the addition of FNS did not lead to the significant increase in specific gravity, albeit the specific gravity of composites with the addition of 0.5% of the Aerosil 200 was always higher than specific gravity of any other composite.

- The addition of FNS can affect mechanical properties both positively and negatively. The slightly reduced compressive strength in our case can be mainly attributed to the poor homogenization of the FNS in the mixture. There is also some concern regarding the kinetics of FNS hydration, but this has to be further investigated in the future. The addition of FNS can be slightly beneficial to the early-bending strength of UHPC, albeit it should be stated that it does not add almost anything in terms of bending strength at later ages.

- It was also observed that the addition of FNS accelerates hydration at the early age and that it even begins to dissolve during the induction period. Both the heat flow and heat are enhanced.

- BSEM imaging of the fracture surface revealed that the addition of FNS enhances the bond strength between the UHPC matrix and the steel fibers, but the bond strength between the aggregate and the UHPC matrix is not affected at all. The improved bond strength between steel fibers can be used to explain the ballistic performance of this composite. However, there is some concern about the brittle failure of the composite when the bond strength between the steel fiber and the UHPC matrix is enhanced.

- The addition of FNS slightly decreases the average value of DEF and increases its standard deviation. On the other hand, the average value of the spalling area and the standard deviation are both lowered, which could as a result mean that the composite with FNS is more durable in terms of ballistic protection in terms of multiple near hits. However, it is not nearly as effective in increasing the ballistic resistance of UHPC as some other means presented in the literature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Bajaber, M.A.; Hakeem, I.Y. UHPC Evolution, Development, and Utilization in Construction: A Review. J. Mater. Res. Technol. 2021, 10, 1058–1074. [Google Scholar] [CrossRef]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Chen, B.; Su, J.; Xu, G.; Zhang, D.; Zhou, J. Effects of Fibers on the Mechanical Properties of UHPC: A Review. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 363–387. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Teng, L. Fiber Alignment and Its Effect on Mechanical Properties of UHPC: An Overview. Constr. Build. Mater. 2021, 296, 123741. [Google Scholar] [CrossRef]

- Bahmani, H.; Mostofinejad, D. Microstructure of Ultra-High-Performance Concrete (UHPC)–A Review Study. J. Build. Eng. 2022, 50, 104118. [Google Scholar] [CrossRef]

- Marvila, M.T.; de Azevedo, A.R.G.; de Matos, P.R.; Monteiro, S.N.; Vieira, C.M.F. Materials for Production of High and Ultra-High Performance Concrete: Review and Perspective of Possible Novel Materials. Materials 2021, 14, 4304. [Google Scholar] [CrossRef]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial Role of Nanosilica in Cement Based Materials–A Review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Mostafa, S.A.; Faried, A.S.; Farghali, A.A.; EL-Deeb, M.M.; Tawfik, T.A.; Majer, S.; Abd Elrahman, M. Influence of Nanoparticles from Waste Materials on Mechanical Properties, Durability and Microstructure of UHPC. Materials 2020, 13, 4530. [Google Scholar] [CrossRef]

- Fares, G.; Khan, M.I. Nanosilica and Its Future Prospects in Concrete. Adv. Mat. Res. 2013, 658, 50–55. [Google Scholar] [CrossRef]

- Das, N.; Nanthagopalan, P. State-of-the-Art Review on Ultra High Performance Concrete-Ballistic and Blast Perspective. Cem. Concr. Compos. 2022, 127, 104383. [Google Scholar] [CrossRef]

- Hou, P.; Kawashima, S.; Kong, D.; Corr, D.J.; Qian, J.; Shah, S.P. Modification Effects of Colloidal NanoSiO2 on Cement Hydration and Its Gel Property. Compos. B Eng. 2013, 45, 440–448. [Google Scholar] [CrossRef]

- Björnström, J.; Martinelli, A.; Matic, A.; Börjesson, L.; Panas, I. Accelerating Effects of Colloidal Nano-Silica for Beneficial Calcium–Silicate–Hydrate Formation in Cement. Chem. Phys. Lett. 2004, 392, 242–248. [Google Scholar] [CrossRef]

- Kontoleontos, F.; Tsakiridis, P.E.; Marinos, A.; Kaloidas, V.; Katsioti, M. Influence of Colloidal Nanosilica on Ultrafine Cement Hydration: Physicochemical and Microstructural Characterization. Constr. Build. Mater. 2012, 35, 347–360. [Google Scholar] [CrossRef]

- Chen, Y.X.; Li, S.; Mezari, B.; Hensen, E.J.M.; Yu, R.; Schollbach, K.; Brouwers, H.J.H.; Yu, Q. Effect of Highly Dispersed Colloidal Olivine Nano-Silica on Early Age Properties of Ultra-High Performance Concrete. Cem. Concr. Compos. 2022, 131, 104564. [Google Scholar] [CrossRef]

- Li, W.; Huang, Z.; Cao, F.; Sun, Z.; Shah, S.P. Effects of Nano-Silica and Nano-Limestone on Flowability and Mechanical Properties of Ultra-High-Performance Concrete Matrix. Constr. Build. Mater. 2015, 95, 366–374. [Google Scholar] [CrossRef]

- Said, A.M.; Zeidan, M.S.; Bassuoni, M.T.; Tian, Y. Properties of Concrete Incorporating Nano-Silica. Constr. Build. Mater. 2012, 36, 838–844. [Google Scholar] [CrossRef]

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of Nano-Silica on Rheology and Fresh Properties of Cement Pastes and Mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Zapata, L.E.; Portela, G.; Suárez, O.M.; Carrasquillo, O. Rheological Performance and Compressive Strength of Superplasticized Cementitious Mixtures with Micro/Nano-SiO2 Additions. Constr. Build. Mater. 2013, 41, 708–716. [Google Scholar] [CrossRef]

- Aly, M.; Hashmi, M.S.J.; Olabi, A.G.; Messeiry, M.; Abadir, E.F.; Hussain, A.I. Effect of Colloidal Nano-Silica on the Mechanical and Physical Behaviour of Waste-Glass Cement Mortar. Mater. Des. 2012, 33, 127–135. [Google Scholar] [CrossRef]

- Jalal, M.; Mansouri, E.; Sharifipour, M.; Pouladkhan, A.R. Mechanical, Rheological, Durability and Microstructural Properties of High Performance Self-Compacting Concrete Containing SiO2 Micro and Nanoparticles. Mater. Des. 2012, 34, 389–400. [Google Scholar] [CrossRef]

- Naji Givi, A.; Abdul Rashid, S.; Aziz, F.N.A.; Salleh, M.A.M. Experimental Investigation of the Size Effects of SiO2 Nano-Particles on the Mechanical Properties of Binary Blended Concrete. Compos. B Eng. 2010, 41, 673–677. [Google Scholar] [CrossRef]

- Ji, T. Preliminary Study on the Water Permeability and Microstructure of Concrete Incorporating Nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Gaitero, J.J.; Campillo, I.; Guerrero, A. Reduction of the Calcium Leaching Rate of Cement Paste by Addition of Silica Nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef]

- Kong, D.; Du, X.; Wei, S.; Zhang, H.; Yang, Y.; Shah, S.P. Influence of Nano-Silica Agglomeration on Microstructure and Properties of the Hardened Cement-Based Materials. Constr. Build. Mater. 2012, 37, 707–715. [Google Scholar] [CrossRef]

- Zyganitidis, I.; Stefanidou, M.; Kalfagiannis, N.; Logothetidis, S. Nanomechanical Characterization of Cement-Based Pastes Enriched with SiO2 Nanoparticles. Mater. Sci. Eng. B 2011, 176, 1580–1584. [Google Scholar] [CrossRef]

- Shekari, A.H.; Razzaghi, M.S. Influence of Nano Particles on Durability and Mechanical Properties of High Performance Concrete. Procedia Eng. 2011, 14, 3036–3041. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Asaad, D.S.; Muhyaddin, G.F. Properties of Low Binder Ultra-High Performance Cementitious Composites: Comparison of Nanosilica and Microsilica. Constr. Build. Mater. 2016, 102, 706–713. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. The Effect of Nanosilica Addition on Flowability, Strength and Transport Properties of Ultra High Performance Concrete. Mater. Des. 2014, 59, 1–9. [Google Scholar] [CrossRef]

- Ramadoss, P.; Nagamani, K. Impact Characteristics of High-Performance Steel Fiber Reinforced Concrete under Repeated Dynamic Loading. Int. J. Civ. Eng. 2014, 12, 513–520. [Google Scholar]

- Yan, H.; Sun, W.; Chen, H. The Effect of Silica Fume and Steel Fiber on the Dynamic Mechanical Performance of High-Strength Concrete. Cem. Concr. Res. 1999, 29, 423–426. [Google Scholar] [CrossRef]

- Rao, G.A. Investigations on the Performance of Silica Fume-Incorporated Cement Pastes and Mortars. Cem. Concr. Res. 2003, 33, 1765–1770. [Google Scholar] [CrossRef]

- Pi, Z.; Xiao, H.; Li, H. Influence of Interfacial Microstructure on Pullout Behavior and Failure Mechanism of Steel Fibers Embedded in Cement-Based Materials. Constr. Build. Mater. 2021, 304, 124688. [Google Scholar] [CrossRef]

- Su, Y.; Li, J.; Wu, C.; Wu, P.; Li, Z.-X. Influences of Nano-Particles on Dynamic Strength of Ultra-High Performance Concrete. Compos. B Eng. 2016, 91, 595–609. [Google Scholar] [CrossRef]

- Drdlová, M.; Buchar, J.; Krátký, J.; Řídký, R. Blast Resistance Characteristics of Concrete with Different Types of Fibre Reinforcement. Struct. Concr. 2015, 16, 508–517. [Google Scholar] [CrossRef]

- Tabatabaei, Z.S.; Volz, J.S.; Baird, J.; Gliha, B.P.; Keener, D.I. Experimental and Numerical Analyses of Long Carbon Fiber Reinforced Concrete Panels Exposed to Blast Loading. Int. J. Impact. Eng. 2013, 57, 70–80. [Google Scholar] [CrossRef]

- Wu, C.; Oehlers, D.J.; Rebentrost, M.; Leach, J.; Whittaker, A.S. Blast Testing of Ultra-High Performance Fibre and FRP-Retrofitted Concrete Slabs. Eng. Struct. 2009, 31, 2060–2069. [Google Scholar] [CrossRef]

- Lai, J.; Guo, X.; Zhu, Y. Repeated Penetration and Different Depth Explosion of Ultra-High Performance Concrete. Int. J. Impact. Eng. 2015, 84, 1–12. [Google Scholar] [CrossRef]

- Feng, J.; Gao, X.; Li, J.; Dong, H.; Yao, W.; Wang, X.; Sun, W. Influence of Fiber Mixture on Impact Response of Ultra-High-Performance Hybrid Fiber Reinforced Cementitious Composite. Compos. B Eng. 2019, 163, 487–496. [Google Scholar] [CrossRef]

- Dapper, P.R.; Ehrendring, H.Z.; Pacheco, F.; Christ, R.; Menegussi, G.C.; de Oliveira, M.F.; Tutikian, B.F. Ballistic Impact Resistance of UHPC Plates Made with Hybrid Fibers and Low Binder Content. Sustainability 2021, 13, 13410. [Google Scholar] [CrossRef]

- Tai, Y.S. Flat Ended Projectile Penetrating Ultra-High Strength Concrete Plate Target. Theor. Appl. Fract. Mech. 2009, 51, 117–128. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Using Particle Packing and Statistical Approach to Optimize Eco-Efficient Ultra-High-Performance Concrete. ACI Mater. J. 2017, 114, 847–858. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, H.; Fang, Q.; Huang, T.; Gong, Z.M.; Peng, Y. UHP-SFRC Panels Subjected to Aircraft Engine Impact: Experiment and Numerical Simulation. Int. J. Impact. Eng. 2017, 109, 276–292. [Google Scholar] [CrossRef]

- Sovják, R.; Vavřiník, T.; Máca, P.; Zatloukal, J.; Konvalinka, P.; Song, Y. Experimental Investigation of Ultra-High Performance Fiber Reinforced Concrete Slabs Subjected to Deformable Projectile Impact. Procedia Eng. 2013, 65, 120–125. [Google Scholar] [CrossRef]

- Kravanja, S.; Sovják, R. Ultra-High-Performance Fibre-Reinforced Concrete under High-Velocity Projectile Impact. Part I. Experiments. Acta Polytech. 2018, 58, 232. [Google Scholar] [CrossRef]

- Mára, M.; Talone, C.; Sovják, R.; Fornůsek, J.; Zatloukal, J.; Kheml, P.; Konvalinka, P. Experimental Investigation of Thin-Walled UHPFRCC Modular Barrier for Blast and Ballistic Protection. Appl. Sci. 2020, 10, 8716. [Google Scholar] [CrossRef]

- Mára, M.; Kheml, P.; Carrera, K.; Fornůsek, J.; Sovják, R. Effect of Corundum and Basalt Aggregates on the Ballistic Resistance of UHP-SFRC. Crystals 2021, 11, 1529. [Google Scholar] [CrossRef]

- Pontiroli, C.; Erzar, B.; Buzaud, E. Concrete Behaviour under Ballistic Impacts. In Computational Modelling of Concrete and Concrete Structures; CRC Press: Boca Raton, FL, USA, 2014; pp. 685–693. ISBN 978-1-138-00145-9. [Google Scholar]

- Qin, F.; Wu, H. Concrete Structures under Projectile Impact, 1st ed.; Springer: Singapore, 2017; pp. 9–31. ISBN 978-981-10-3620-0. [Google Scholar]

- Bocian, L.; Novotny, R.; Soukal, F.; Palovcik, J.; Brezina, M.; Koplik, J. Influence of Anticorrosive Surface Treatment of Steel Reinforcement Fibers on the Properties of Ultra-High Performance Cement Composite. Materials 2022, 15, 8401. [Google Scholar] [CrossRef] [PubMed]

| Ingredients | Reference | 0.25% Aerosil 200 | 0.5% Aerosil 200 | 1.0% Aerosil 200 |

|---|---|---|---|---|

| Fine sand according to ČSN EN 196-1 (Filtrační písky Chlum, Czech Republic) | 1980 g | 1980 g | 1980 g | 1980 g |

| Micronized sand ST-2 (Sklopísek Střeleč, Czech Republic) | 135 g | 135 g | 135 g | 135 g |

| Micro-dorsilit 110 (Dorfner, D) | 405 g | 405 g | 405 g | 405 g |

| CEM I 52.5 R-SR 5 white (Aalborg Portland, DE) | 864 g | 864 g | 864 g | 864 g |

| Silica fume RW Füller-Q (Elkem, D) | 216 g | 216 g | 216 g | 216 g |

| Steel fibers 12.5 × 0.2 mm (KrampeHarex, D) | 300 g | 300 g | 300 g | 300 g |

| Potassium formate (synthesized) | 34.4 g | 34.4 g | 34.4 g | 34.4 g |

| Superplasticizer MasterGlenium ACE 446 (BASF, D) | 45 mL | 45 mL | 45 mL | 45 mL |

| Aerosil 200 (Evonik, USA) | 0 g | 2.7 g | 5.4 g | 10.8 g |

| Demineralized water | 278 mL | 279 mL | 280 mL | 281 mL |

| Mixture | Slump Flow [mm] |

|---|---|

| Reference | 179 |

| 0.25% Aerosil 200 | 176 |

| 0.5% Aerosil 200 | 153 |

| 1.0% Aerosil 200 | 143 |

| Mixture | Specific Gravity [kg/m3] |

|---|---|

| Reference | 2574 |

| 0.25% Aerosil 200 | 2567 |

| 0.5% Aerosil 200 | 2580 |

| 1.0% Aerosil 200 | 2550 |

| Mixture | Specific Gravity [kg/m3] |

|---|---|

| Reference | 2540 |

| 0.25% Aerosil 200 | 2548 |

| 0.5% Aerosil 200 | 2606 |

| 1.0% Aerosil 200 | 2560 |

| Composite | DEF [-] | Average Spalling Area [mm2] |

|---|---|---|

| Reference | 0.878 ± 0.044 | 3600 ± 740 |

| 0.5% Aerosil 200 | 0.855 ± 0.056 | 2692 ± 462 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markusík, D.; Bocian, L.; Novotný, R.; Palovčík, J.; Hrbáčová, M. Influence of Fumed Nanosilica on Ballistic Performance of UHPCs. Materials 2023, 16, 2151. https://doi.org/10.3390/ma16062151

Markusík D, Bocian L, Novotný R, Palovčík J, Hrbáčová M. Influence of Fumed Nanosilica on Ballistic Performance of UHPCs. Materials. 2023; 16(6):2151. https://doi.org/10.3390/ma16062151

Chicago/Turabian StyleMarkusík, David, Luboš Bocian, Radoslav Novotný, Jakub Palovčík, and Markéta Hrbáčová. 2023. "Influence of Fumed Nanosilica on Ballistic Performance of UHPCs" Materials 16, no. 6: 2151. https://doi.org/10.3390/ma16062151

APA StyleMarkusík, D., Bocian, L., Novotný, R., Palovčík, J., & Hrbáčová, M. (2023). Influence of Fumed Nanosilica on Ballistic Performance of UHPCs. Materials, 16(6), 2151. https://doi.org/10.3390/ma16062151