Effect of Sintering Temperature and Solution Treatment on Phase Changes and Mechanical Properties of High-Nitrogen Stainless Steel Prepared by MIM

Abstract

1. Introduction

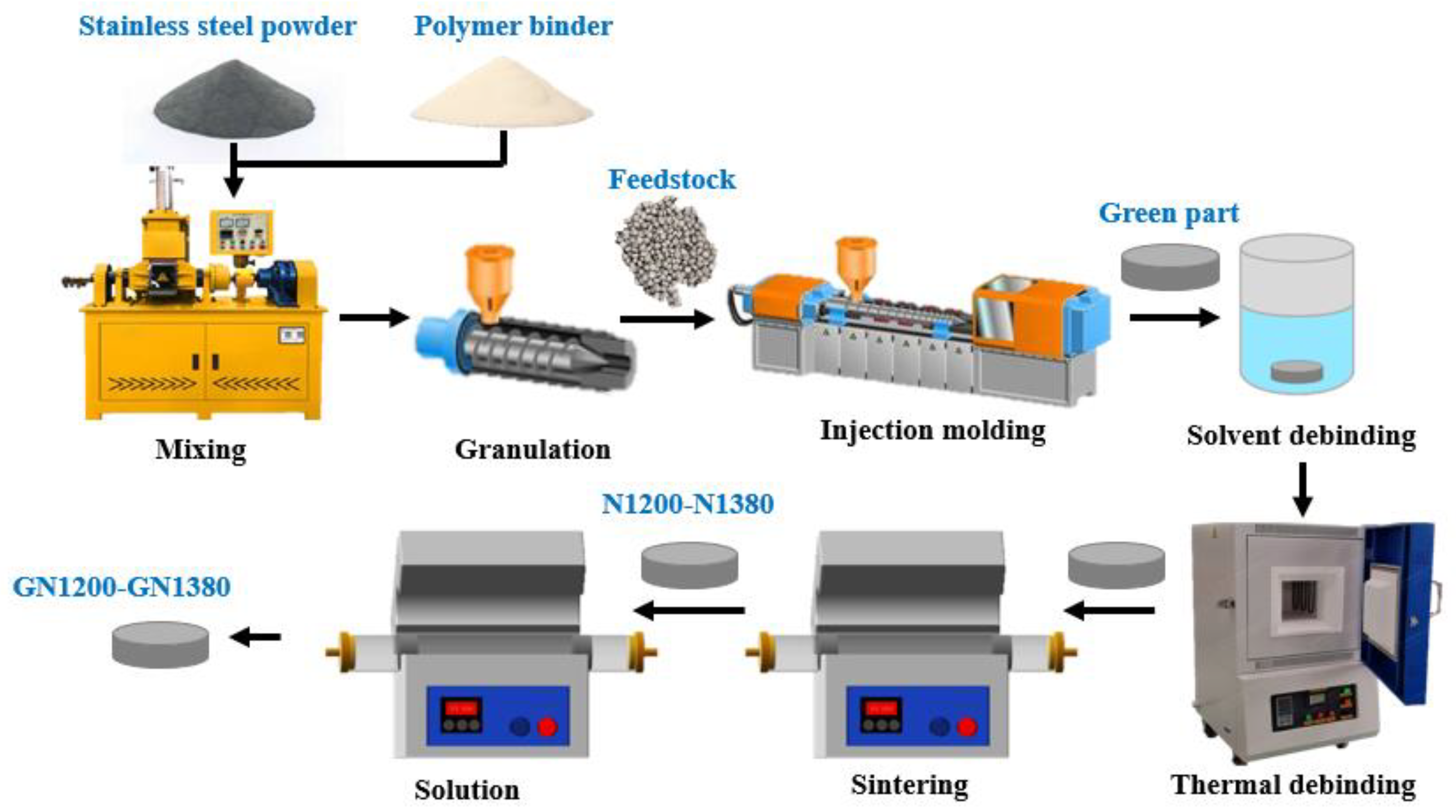

2. Materials and Methods

2.1. Specimen Preparation

2.2. Characterization of Sintered Specimens

3. Results

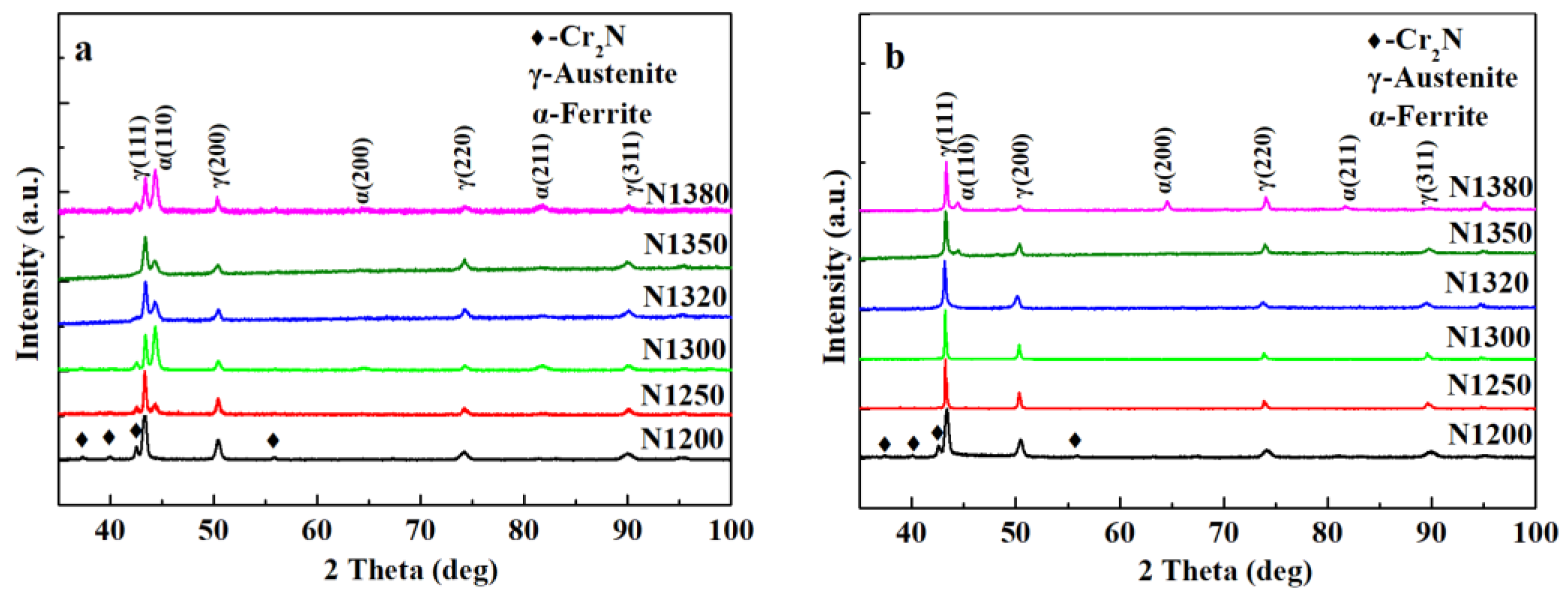

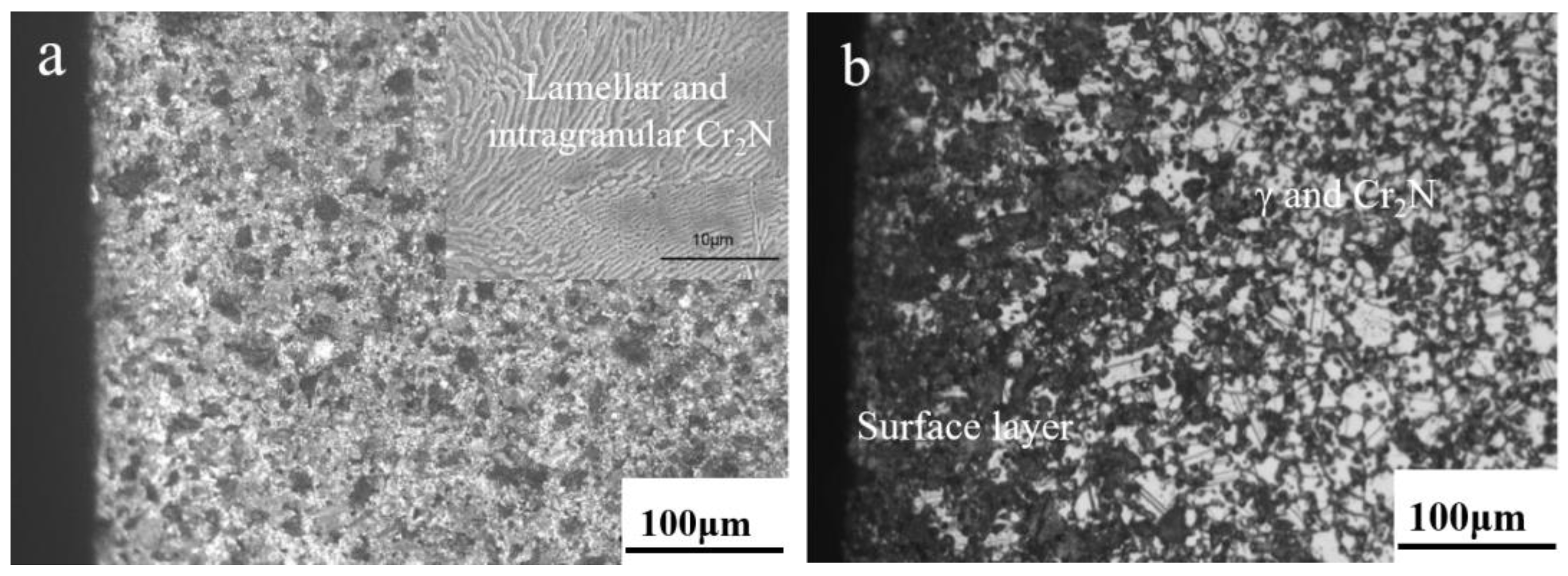

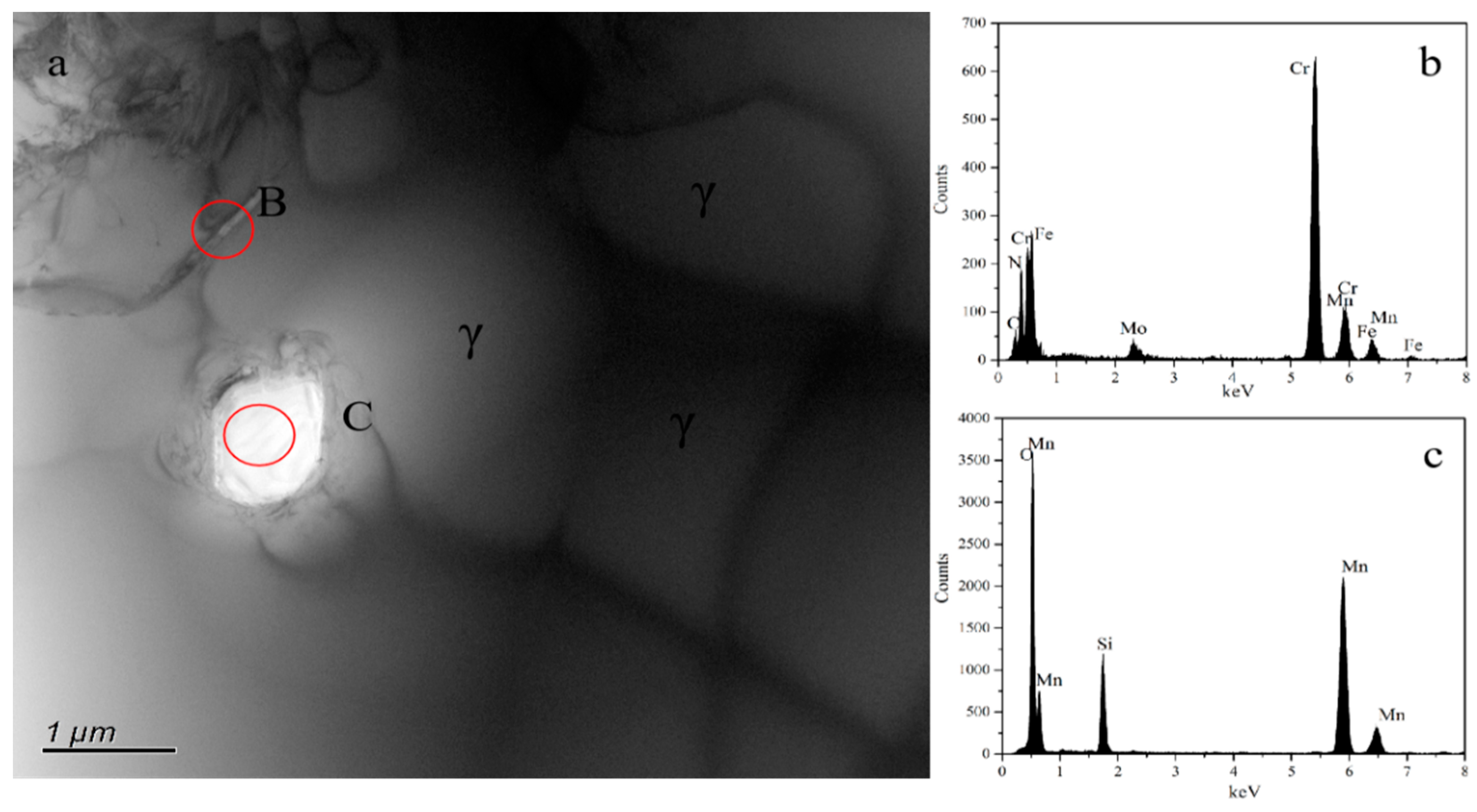

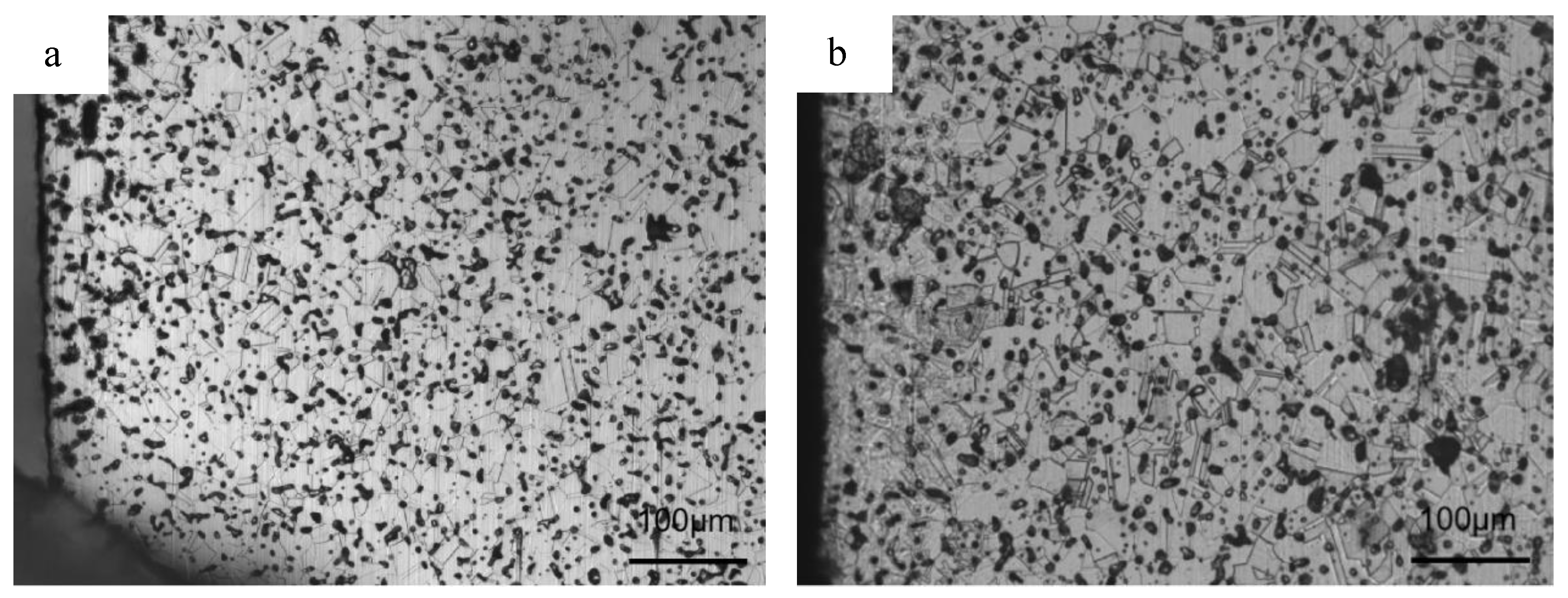

3.1. Phase Constituent and Microstructure of the Sintered Samples

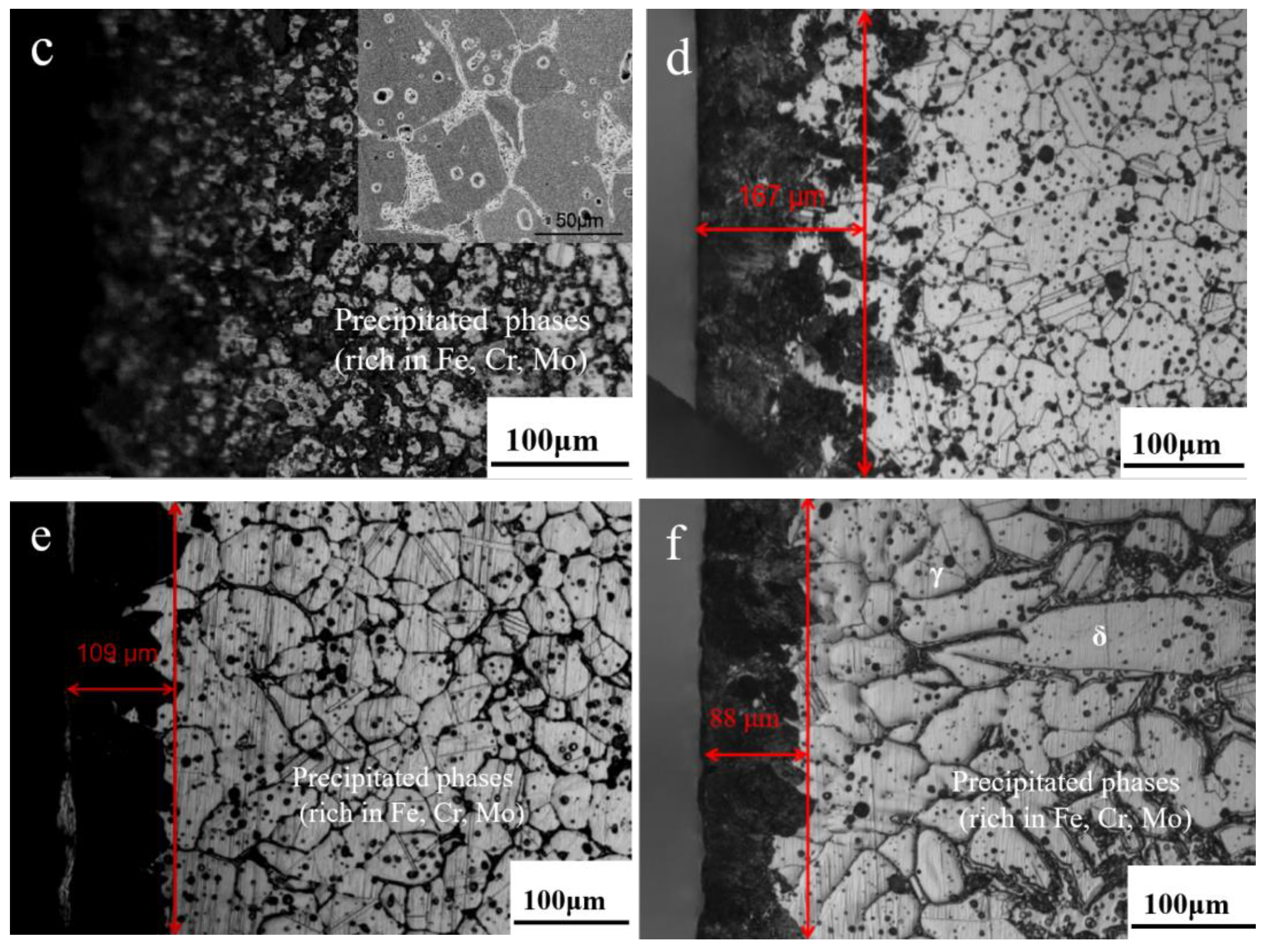

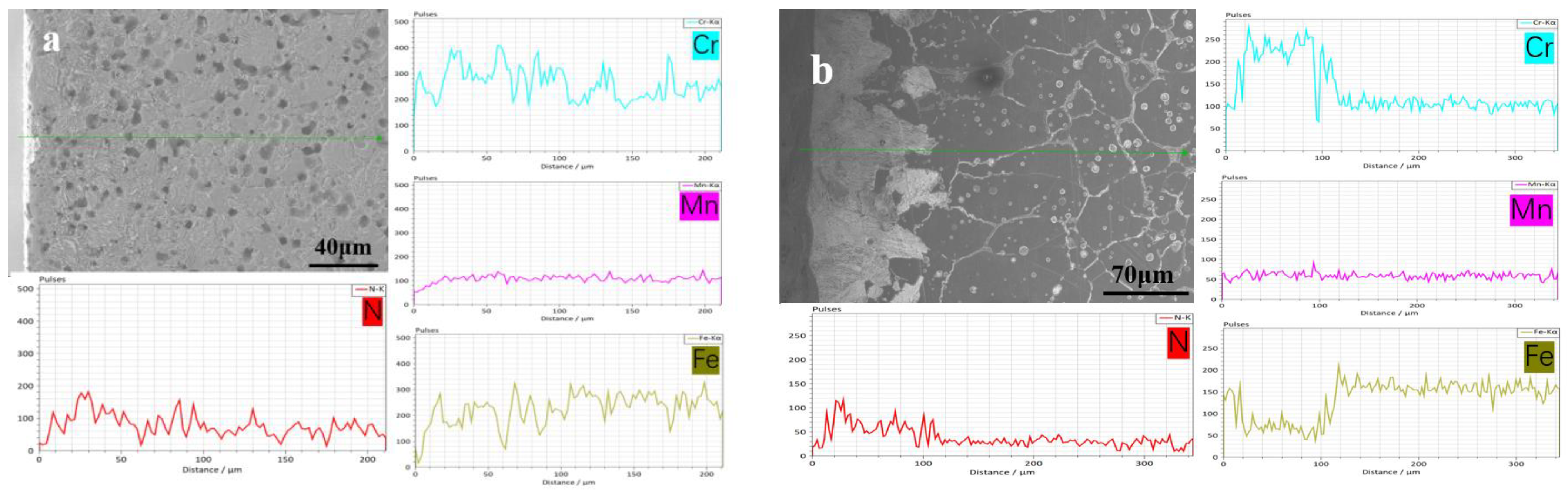

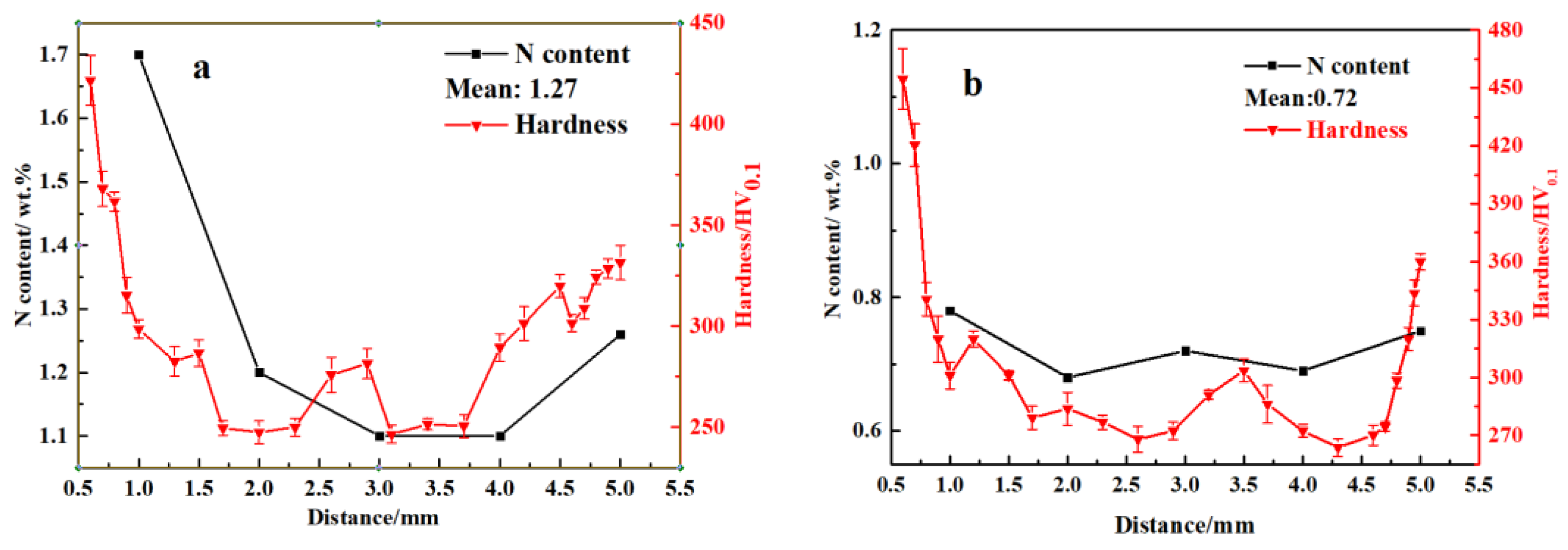

3.2. N Concentration Gradient and Microstructure Evolution of Sintered Samples

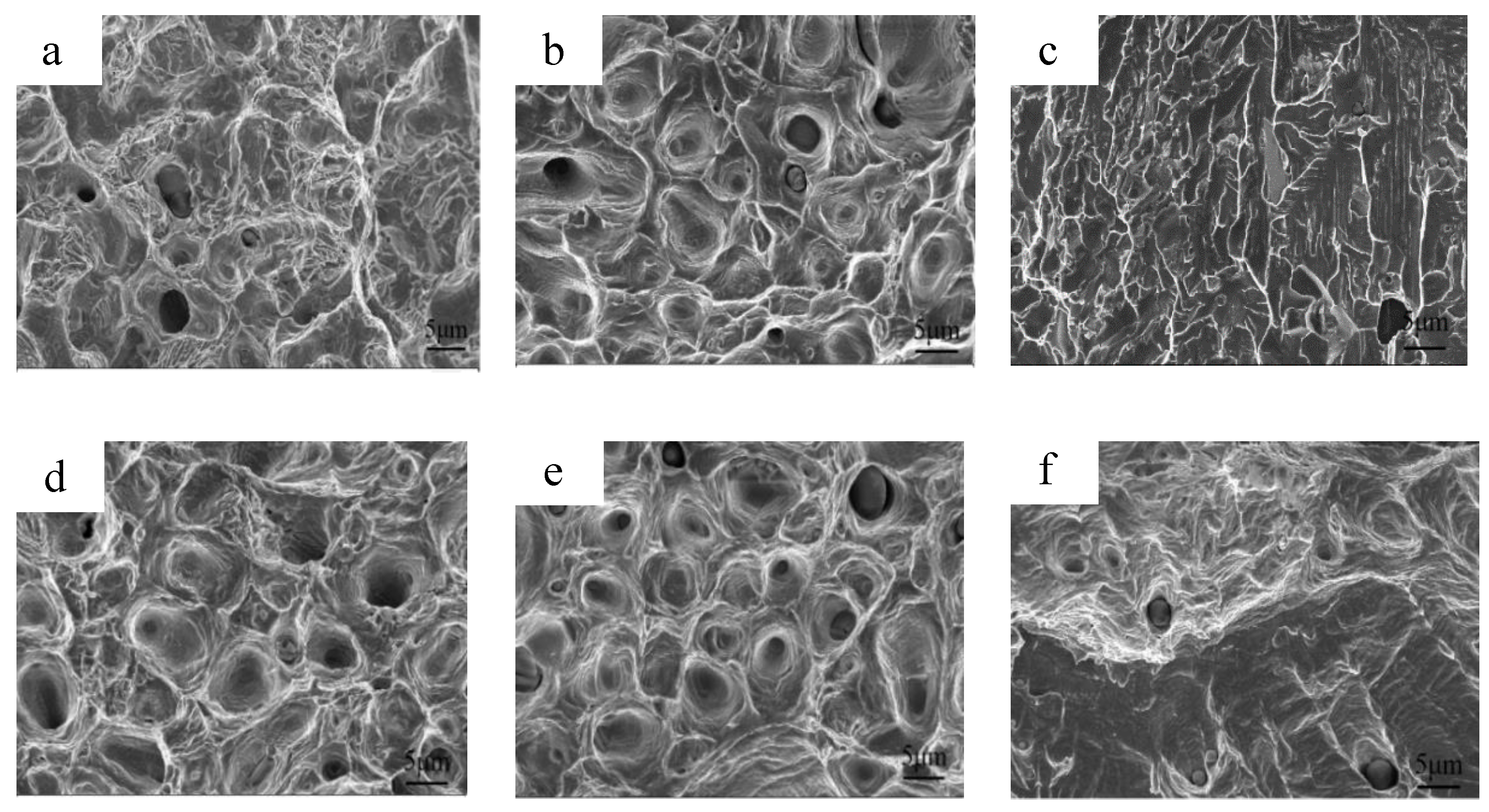

3.3. Mechanical Properties after Sintering

3.4. Microstructure after Solution Treatment

3.5. Mechanical Properties of Solution-Treated Samples

4. Discussion

5. Conclusions

- With increasing sintering temperature from 1200 °C to 1380 °C, the sample density increases, but the nitrogen content gradually decreases.

- Nitrogen content and distribution along the cross-section of as-sintered samples are not homogeneous. After sintering under the N2 atmosphere, the subsequent furnace cooling causes continuous nitriding and Cr2N precipitation, resulting in a sample surface layer rich in N and Cr elements.

- High N content promotes austenite decomposition: γsaturated translated to γ and Cr2N. Meanwhile, Mn is easily effused on the surface of the sample surface and is oxidized, resulting in the decomposition of γ: γ translated to α and Cr2N.

- Samples with a homogeneous γ microstructure can be obtained after solution treatment at 1150 °C for 1.5 h under an N2 atmosphere for samples sintered at 1320 °C or lower. For solution-treated austenitic samples sintered at 1320 °C, its tensile strength is 988.76 MPa; yield strength is 615.61 MPa, and elongation is 42.58%.

- Solution-treated samples with a dual-phase structure (γ and δ) that sintered at 1350 °C have a tensile strength of 1036.12 MPa, a yield strength of 636.14 MPa, and an elongation of 40.08%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wan, P.; Ren, Y.; Zhang, B.; Yang, K. Analysis of Magnetism in High Nitrogen Austenitic Stainless Steel and Its Elimination by High Temperature Gas Nitriding. J. Mater. Sci. Technol. 2011, 27, 1139–1142. [Google Scholar] [CrossRef]

- Lang, Y.; Qu, H.; Chen, H.; Weng, Y. Research Progress and Development Tendency of Nitrogen-alloyed Austenitic Stainless Steels. J. Iron Steel Res. Int. 2015, 22, 91–98. [Google Scholar] [CrossRef]

- Mohammadzadeh, R.; Akbari, A.; Mohammadzadeh, M. Impact Toughness Properties of Nickel- and Manganese-Free High Nitrogen Austenitic Stainless Steels. Metall. Mater. Trans. A 2016, 47, 6032–6041. [Google Scholar] [CrossRef]

- Speidel, M.O. New Nitrogen-Bearing Austenitic Stainless Steels with High Strength and Ductility. Met. Sci. Heat Treat. 2005, 47, 489–493. [Google Scholar] [CrossRef]

- Kuroda, D.; Hiromoto, S.; Hanawa, T.; Katada, Y. Corrosion Behavior of Nickel-Free High Nitrogen Austenitic Stainless Steel in Simulated Biological Environments. Mater. Trans. 2002, 43, 3100–3104. [Google Scholar] [CrossRef]

- Talha, M.; Behera, C.K.; Sinha, O.P. A Review on Nickel-Free Nitrogen Containing Austenitic Stainless Steels for Biomedical Applications. Mater. Sci. Eng. C 2013, 33, 3563–3575. [Google Scholar] [CrossRef] [PubMed]

- Simmons, J.W. Overview: High-Nitrogen Alloying of Stainless Steels. Mater. Sci. Eng. A 1996, 207, 159–169. [Google Scholar] [CrossRef]

- Yuan, Z.Z.; Dai, Q.X.; Cheng, X.N.; Chen, K.M. Microstructural Thermostability of High Nitrogen Austenitic Stainless Steel. Mater. Charact. 2007, 58, 87–91. [Google Scholar] [CrossRef]

- Li, H.; Jiang, Z.; Zhang, Z.; Xu, B.; Liu, F. Mechanical Properties of Nickel Free High Nitrogen Austenitic Stainless Steels. J. Iron Steel Res. Int. 2007, 14, 330–334. [Google Scholar] [CrossRef]

- Pujar, M.G.; Kamachi Mudali, U.; Singh, S.S. Electrochemical Noise Studies of the Effect of Nitrogen on Pitting Corrosion Resistance of High Nitrogen Austenitic Stainless Steels. Corros. Sci. 2011, 53, 4178–4186. [Google Scholar] [CrossRef]

- Berns, H.; Bouwman, J.W.; Eul, U.; Izagirre, J.; Juse, R.L.; Niederau, H.J.; Tavernier, G.; Zieschang, R. Solution Nitriding of Stainless Steels for Process Engineering. Materwiss. Werksttech. 2000, 31, 152–161. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of Metal Matrix Composites by Metal Injection Molding—A review. J. Mater. Process. Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Khalil, K.A. Effect of Powder Loading on Metal Injection Molding Stainless Steels. J. Mater. Process. Technol. 2007, 183, 432–439. [Google Scholar] [CrossRef]

- Uggowitzer, P.J.; Bähre, W.F.; Wohlfromm, H.; Speidel, M.O. Nickel-Free High Nitrogen Austenitic Stainless Steels Produced by Metal Injection Molding. Mater. Sci. Forum. 1999, 318, 663–672. [Google Scholar] [CrossRef]

- Knutsen, R.D.; Lang, C.I.; Basson, J.A. Discontinuous cellular precipitation in a Cr-Mn-N steel with niobium and vanadium additions. Acta Mater. 2004, 52, 2407–2417. [Google Scholar] [CrossRef]

- Simmons, J.W.; Atteridge, D.G.; Rawers, J.C. Sensitization of high-nitrogen austenitic stainless steels by dichromium nitride precipitation. Corrosion 1994, 50, 491–501. [Google Scholar] [CrossRef]

- Chao, K.L.; Liao, H.Y.; Shyue, J.J.; Lian, S.S. Corrosion behavior of high nitrogen nickel-free Fe-16Cr-Mn-Mo-N stainless steels. Metall. Mater. Trans. B 2014, 45, 381–391. [Google Scholar] [CrossRef]

- Feng, H.; Jiang, Z.; Li, H.; Lu, P.; Zhang, S.; Zhu, H.; Zhang, B.; Zhang, T.; Xu, D.; Chen, Z. Influence of Nitrogen on Corrosion Behaviour of High Nitrogen Martensitic Stainless Steels Manufactured by Pressurized Metallurgy. Corros. Sci. 2018, 144, 288–300. [Google Scholar] [CrossRef]

- Mohammadzadeh, R.; Akbari, A. Effect of Pressurized Solution Nitriding on Phase Changes and Mechanical Properties of Ferritic Fe-22.7Cr-2.4Mo Stainless Steel. Mater. Sci. Eng. A 2014, 592, 153–163. [Google Scholar] [CrossRef]

- Tsuchiyama, T.; Takaki, S.; Ito, H.; Kataoka, K. Fabrication of ultrahigh nitrogen austenitic steels by nitrogen gas absorption into solid solution. Metall. Mater. Trans. A 2003, 34, 2591–2599. [Google Scholar] [CrossRef]

- Xu, Z.W.; Jia, C.C.; Kuang, C.J.; Qu, X.H. Fabrication and Sintering Behavior of High-Nitrogen Nickel-Free Stainless Steels by Metal Injection Molding. Int. J. Miner. Metall. Mater. 2010, 17, 423–428. [Google Scholar] [CrossRef]

- Kuroda, Y.; Komada, M.; Murakami, R.; Fukumoto, S.; Tsuchida, N.; Harada, Y.; Fukaura, K. Metal Injection Molding of Nickel-Free Austenitic Stainless-Steels I-Manufacturing Process. Adv. Mater. Res. 2007, 26–28, 15–18. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Zhang, Z.R.; Li, H.B.; Li, Z.; Ma, Q.F. Microstructural Evolution and Mechanical Properties of Aging High Nitrogen Austenitic Stainless Steels. Int. J. Miner. Metall. Mater. 2010, 17, 729–736. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, Y.; Yao, C.; Yang, K.; Misra, R.D.K. Residual Ferrite and Relationship Between Composition and Microstructure in High-Nitrogen Austenitic Stainless Steels. Metall. Mater. Trans. A 2015, 46, 5537–5545. [Google Scholar] [CrossRef]

- Cui, D.; Jiang, J.; Cao, G.; Xiao, E.; Qu, X. Preparation of High Nitrogen and Nickel-Free Austenitic Stainless Steel by Powder Injection Molding. J. Univ. Sci. Technol. Beijing Miner. Metall. Mater. 2008, 15, 150–154. [Google Scholar] [CrossRef]

- Cui, D.; Qu, X.; Guo, P.; Li, K. Sintering Optimization and Solution Annealing of High Nitrogen Nickel Free Austenitic Stainless Steels Prepared by PIM. Powder Metall. 2010, 53, 91–95. [Google Scholar] [CrossRef]

- NIST Data Base. Available online: https://srdata.nist.gov/xps/ (accessed on 3 January 2023).

- Major, G.H.; Farley, N.; Sherwood, P.M.A.; Linford, M.R.; Terry, J.; Fernandez, V.; Artyushkova, K. Practical guide for curve fitting in X-ray photoelectron spectroscopy. J. Vac. Sci. Technol. A 2020, 38, 061203. [Google Scholar] [CrossRef]

- Cojocaru, V.D.; Şerban, N.; Angelescu, M.L.; Cojocaru, E.M.; Cinca, I.; Răducanu, D.; Vintilă, A.N. Effect of Short Duration Solution Treatment at Temperatures Below 1000 °C on σ-Phase Precipitation in a Super Duplex Stainless Steel Alloy. Materwiss. Werksttech. 2018, 49, 530–537. [Google Scholar] [CrossRef]

- Fukumoto, S.; Okane, T.; Umeda, T.; Kurz, W. Crystallographic Relationships between δ-Ferrite and γ-Austenite during Unidirectional Solidification of Fe-Cr-Ni Alloys. ISIJ Int. 2000, 40, 677–684. [Google Scholar] [CrossRef]

- Salahinejad, E.; Amini, R.; Marasi, M.; Hadianfard, M.J. The Effect of Sintering Time on the Densification and Mechanical Properties of a Mechanically Alloyed Cr-Mn-N Stainless Steel. Mater. Des. 2010, 31, 527–532. [Google Scholar] [CrossRef]

- Ali, S.; Abdul Rani, A.M.; Mufti, R.A.; Hastuty, S.; Hussain, M.; Shehzad, N.; Baig, Z.; Abdu Aliyu, A.A. An Efficient Approach for Nitrogen Diffusion and Surface Nitriding of Boron-Titanium Modified Stainless Steel Alloy for Biomedical Applications. Metals 2019, 9, 755. [Google Scholar] [CrossRef]

- Peng, H.; Baker, I.; Yi, Y.; Hu, L.; Fang, W.; Li, L.; Luo, B.; Luo, Z. Dissimilar electron beam welding of the medium-entropy alloy (NiCoCr)94Al3Ti3 to 304 stainless steel. Scr. Mater. 2022, 214, 114659. [Google Scholar] [CrossRef]

- Wang, L.J.; Sheng, L.Y.; Hong, C.M. Influence of Grain Boundary Carbides on Mechanical Properties of High Nitrogen Austenitic Stainless Steel. Mater. Des. 2012, 37, 349–355. [Google Scholar] [CrossRef]

- Lefor, K.; Walter, M.; Weddeling, A.; Hryha, E.; Huth, S.; Weber, S.; Nyborg, L.; Theisen, W. Influence of the PM-Processing Route and Nitrogen Content on the Properties of Ni-Free Austenitic Stainless Steel, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 1154–1167. [Google Scholar] [CrossRef]

- Hu, L.; Peng, H.; Baker, I.; Li, L.; Zhang, W.; Ngai, T. Characterization of High-Strength High Nitrogen Austenitic Stainless Steel Synthesized from Nitrided Powders by Spark Plasma Sintering. Mater. Charact. 2019, 152, 76–84. [Google Scholar] [CrossRef]

| Sample | N1200 | N1250 | N1300 | N1320 | N1350 | N1380 |

|---|---|---|---|---|---|---|

| Surface/wt.% | 0.68 | 0.72 | 0.67 | 0.62 | 0.57 | 0.43 |

| Interior/wt.% | 0.83 | 1.01 | 1.05 | 1.11 | 0.92 | 0.83 |

| Sample Code | Relative Density | Hardness | σb | σ0.2 | Elongation |

|---|---|---|---|---|---|

| (%) | (HV) | (MPa) | (MPa) | (%) | |

| N1200 | 88.71 ± 0.8 | 271.76 ± 30 | 1113.8 ± 30 | 1087.3 ± 50 | 3.4 ± 1 |

| N1250 | 92.82 ± 0.5 | 296.23 ± 35 | 804.7 ± 50 | 689.5 ± 30 | 9.5 ± 2.3 |

| N1300 | 94.41 ± 0.3 | 272.38 ± 28 | 835.6 ± 42 | 613.8 ± 25 | 18.4 ± 1.6 |

| N1320 | 95.87 ± 0.5 | 239.54 ± 32 | 842.5 ± 28 | 588.1 ± 26 | 25.8 ± 3.2 |

| N1350 | 97.61 ± 0.6 | 291.39 ± 38 | 916.3 ± 38 | 690.7 ± 23 | 19.4 ± 1.8 |

| N1380 | 98.18 ± 0.9 | 309.26 ± 40 | 804.7 ± 46 | 709.2 ± 18 | 5.1 ± 1 |

| GN1200 | --- | --- | 958.1 ± 50 | 671.5 ± 30 | 17.5 ± 1 |

| GN1250 | --- | --- | 1006.9 ± 80 | 635.4 ± 40 | 25.5 ± 1 |

| GN1300 | --- | --- | 1033.7 ± 30 | 615.5 ± 10 | 37.1 ± 2 |

| GN1320 | --- | --- | 988.8 ± 30 | 615.6 ± 40 | 42.6 ± 3.5 |

| GN1350 | --- | --- | 1036.1 ± 30 | 636.2 ± 60 | 40.1 ± 3.2 |

| GN1380 | --- | --- | 1021.2 ± 50 | 810.1 ± 10 | 12.1 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Li, L.; Huang, C.; Ngai, T.; Hu, L. Effect of Sintering Temperature and Solution Treatment on Phase Changes and Mechanical Properties of High-Nitrogen Stainless Steel Prepared by MIM. Materials 2023, 16, 2135. https://doi.org/10.3390/ma16062135

Zhang W, Li L, Huang C, Ngai T, Hu L. Effect of Sintering Temperature and Solution Treatment on Phase Changes and Mechanical Properties of High-Nitrogen Stainless Steel Prepared by MIM. Materials. 2023; 16(6):2135. https://doi.org/10.3390/ma16062135

Chicago/Turabian StyleZhang, Weipeng, Liejun Li, Chengcheng Huang, Tungwai Ngai, and Ling Hu. 2023. "Effect of Sintering Temperature and Solution Treatment on Phase Changes and Mechanical Properties of High-Nitrogen Stainless Steel Prepared by MIM" Materials 16, no. 6: 2135. https://doi.org/10.3390/ma16062135

APA StyleZhang, W., Li, L., Huang, C., Ngai, T., & Hu, L. (2023). Effect of Sintering Temperature and Solution Treatment on Phase Changes and Mechanical Properties of High-Nitrogen Stainless Steel Prepared by MIM. Materials, 16(6), 2135. https://doi.org/10.3390/ma16062135