Effect of Particle Size and Morphology of Siliceous Supplementary Cementitious Material on the Hydration and Autogenous Shrinkage of Blended Cement

Abstract

1. Introduction

2. Materials and Methods

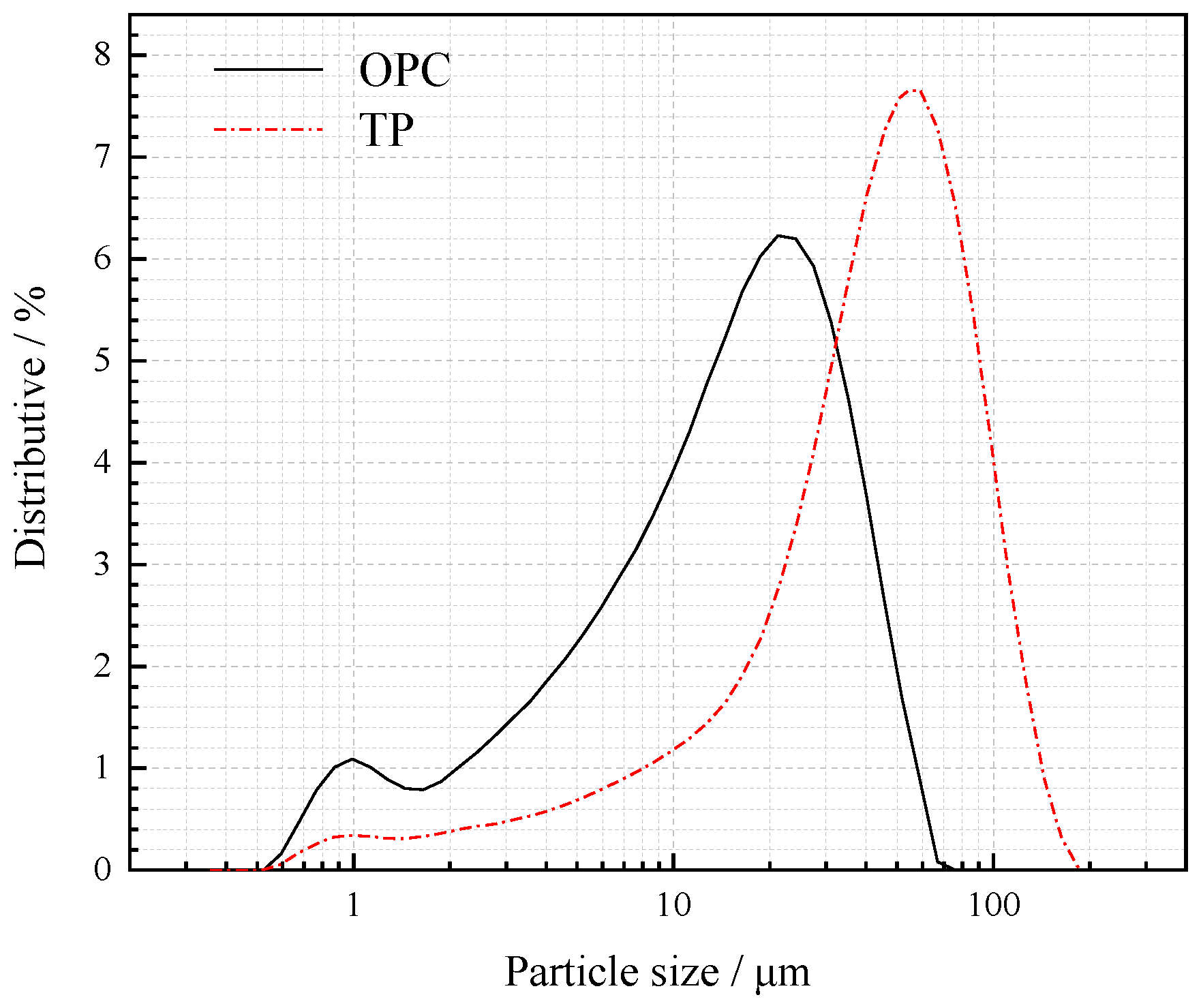

2.1. Materials

2.2. Procedure Used for the Mechanical Activation of TP

2.3. Mix Design

2.4. Mixing Procedure and Sample Preparation

2.5. Testing Methods

2.5.1. Air Content

2.5.2. Setting Time

2.5.3. Heat of Hydration

2.5.4. Compressive Strength

2.5.5. Hydration Product Analysis

2.5.6. Mercury Intrusion Porosimetry (MIP)

2.5.7. Autogenous Shrinkage

2.5.8. Scanning Electron Microscope (SEM) Test

3. Result and Discussion

3.1. Properties of Wet-Ground TPs

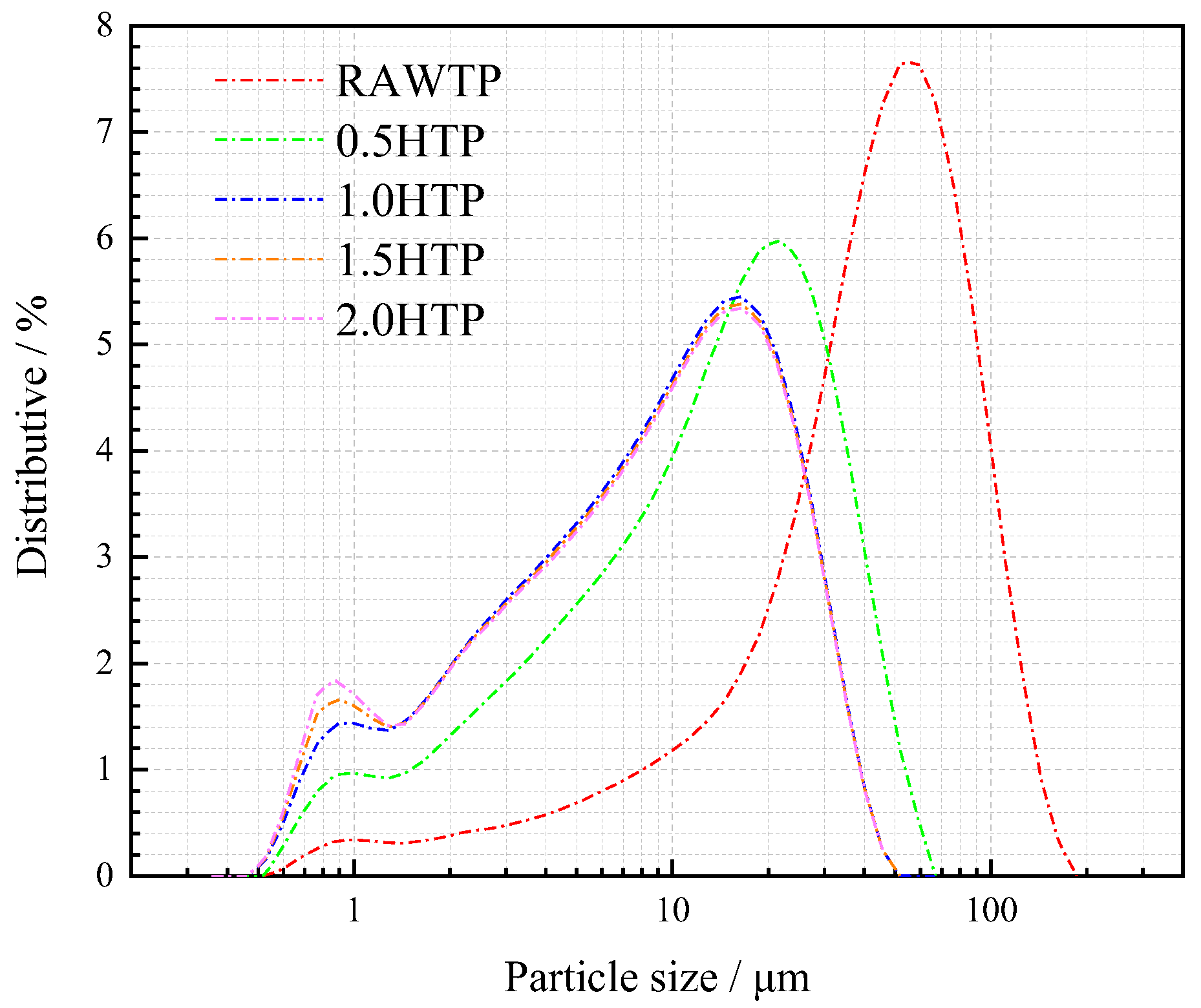

3.1.1. Particle Size and Specific Surface Area

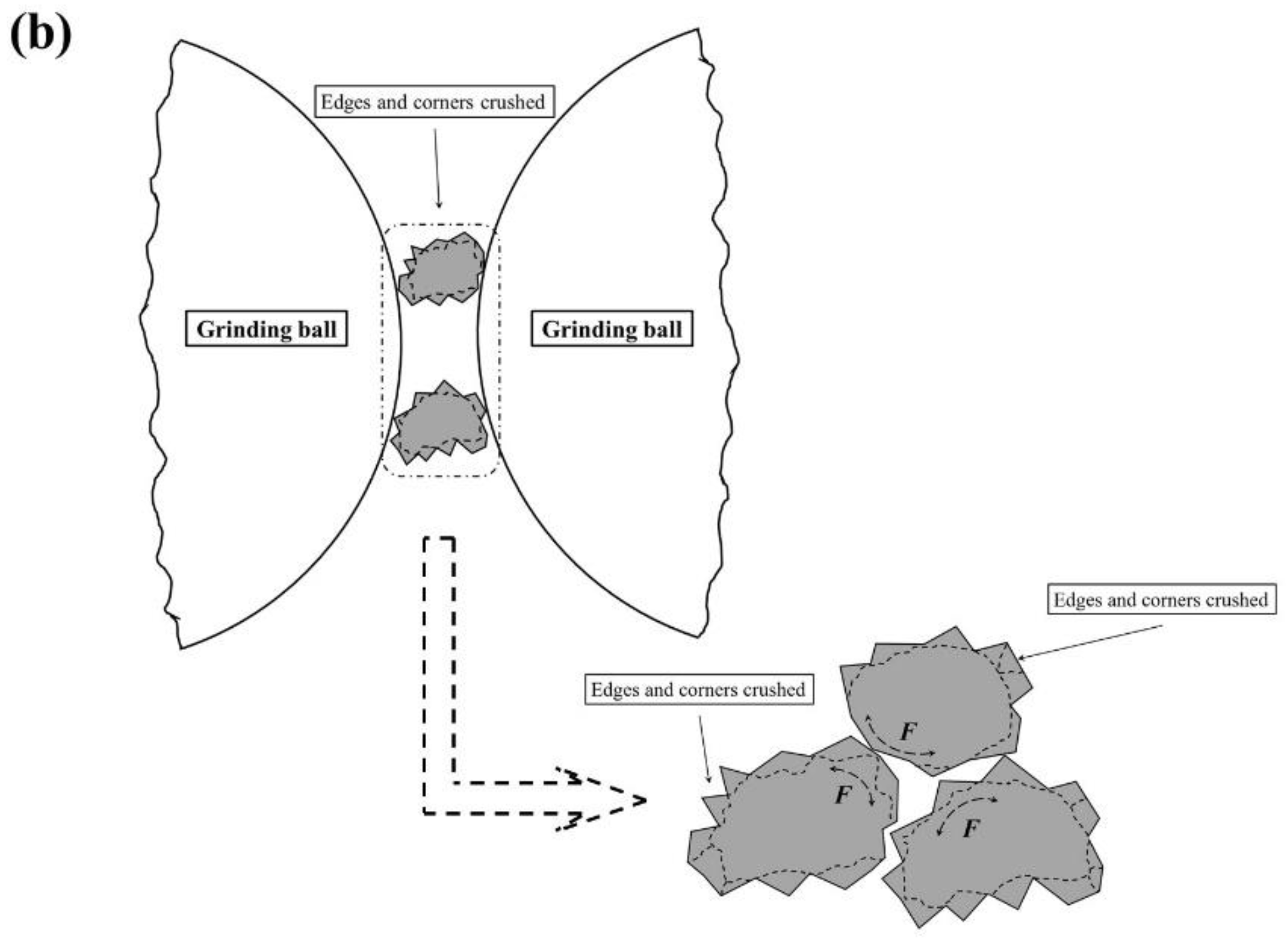

3.1.2. Grinding Mechanism

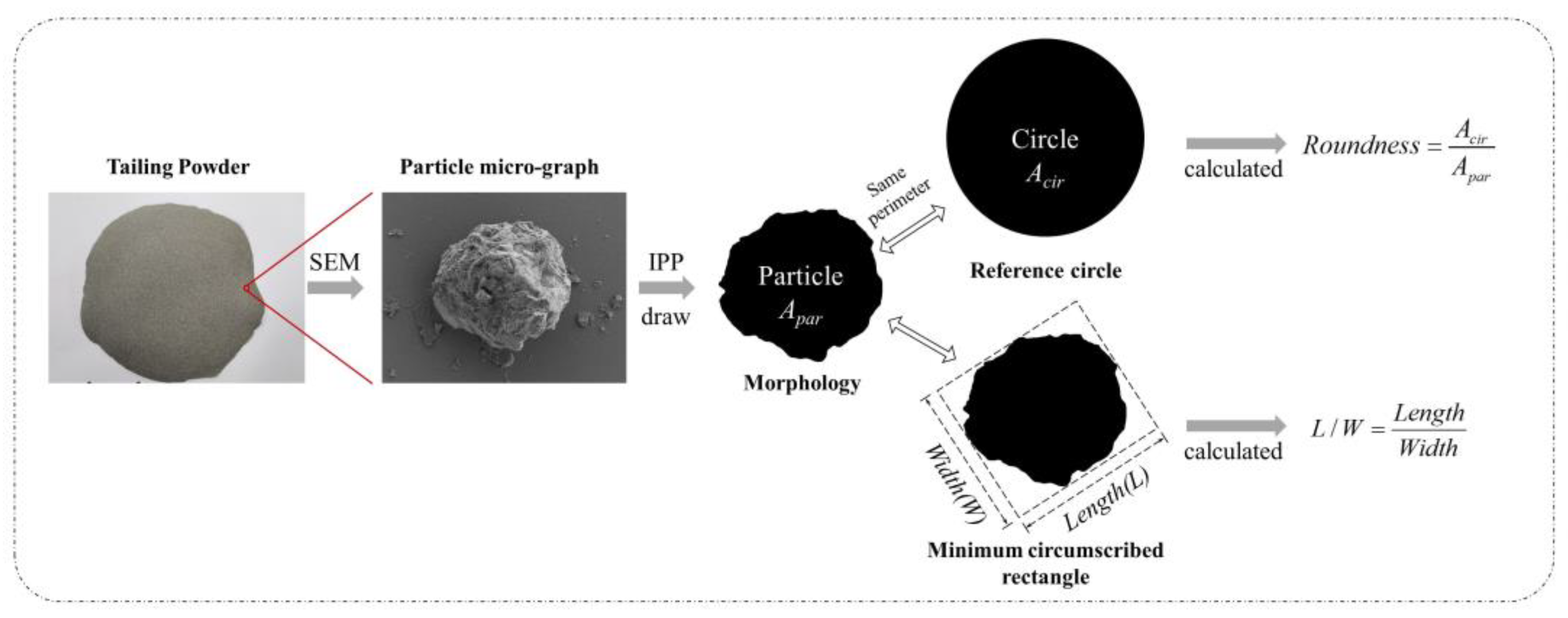

3.1.3. Morphology

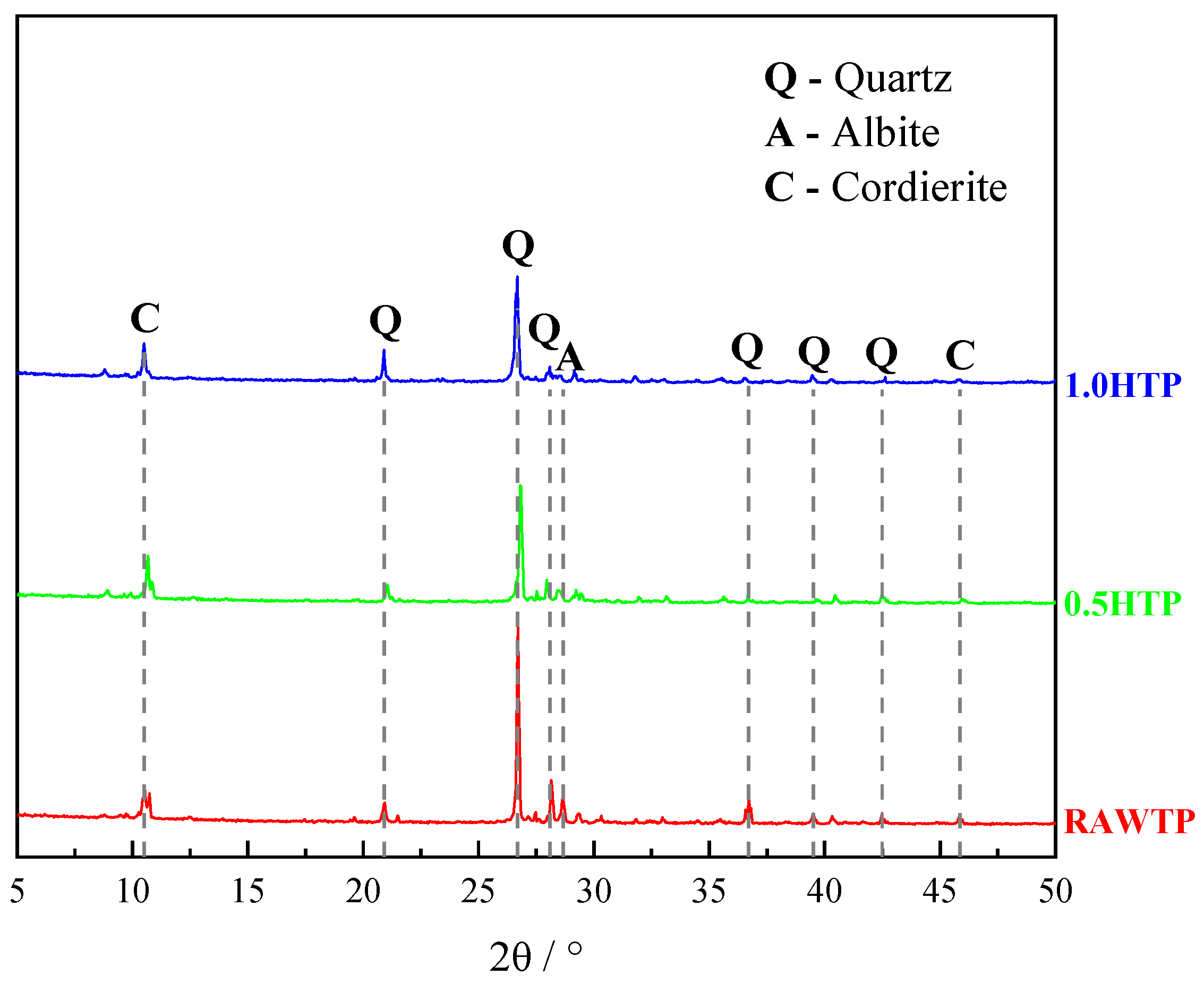

3.1.4. Phase Assemblages

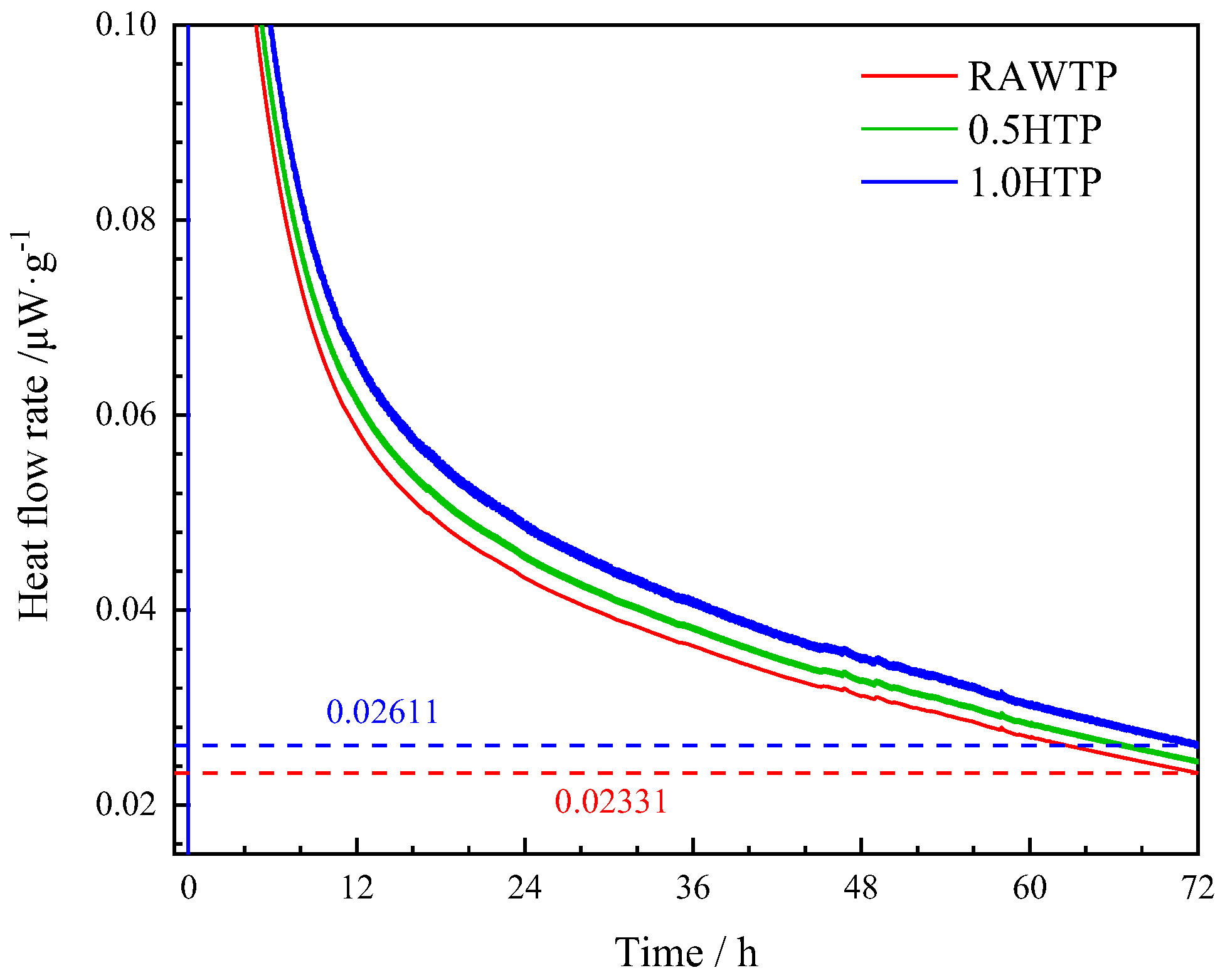

3.1.5. Calorimetry Test of Hydration Reactivity

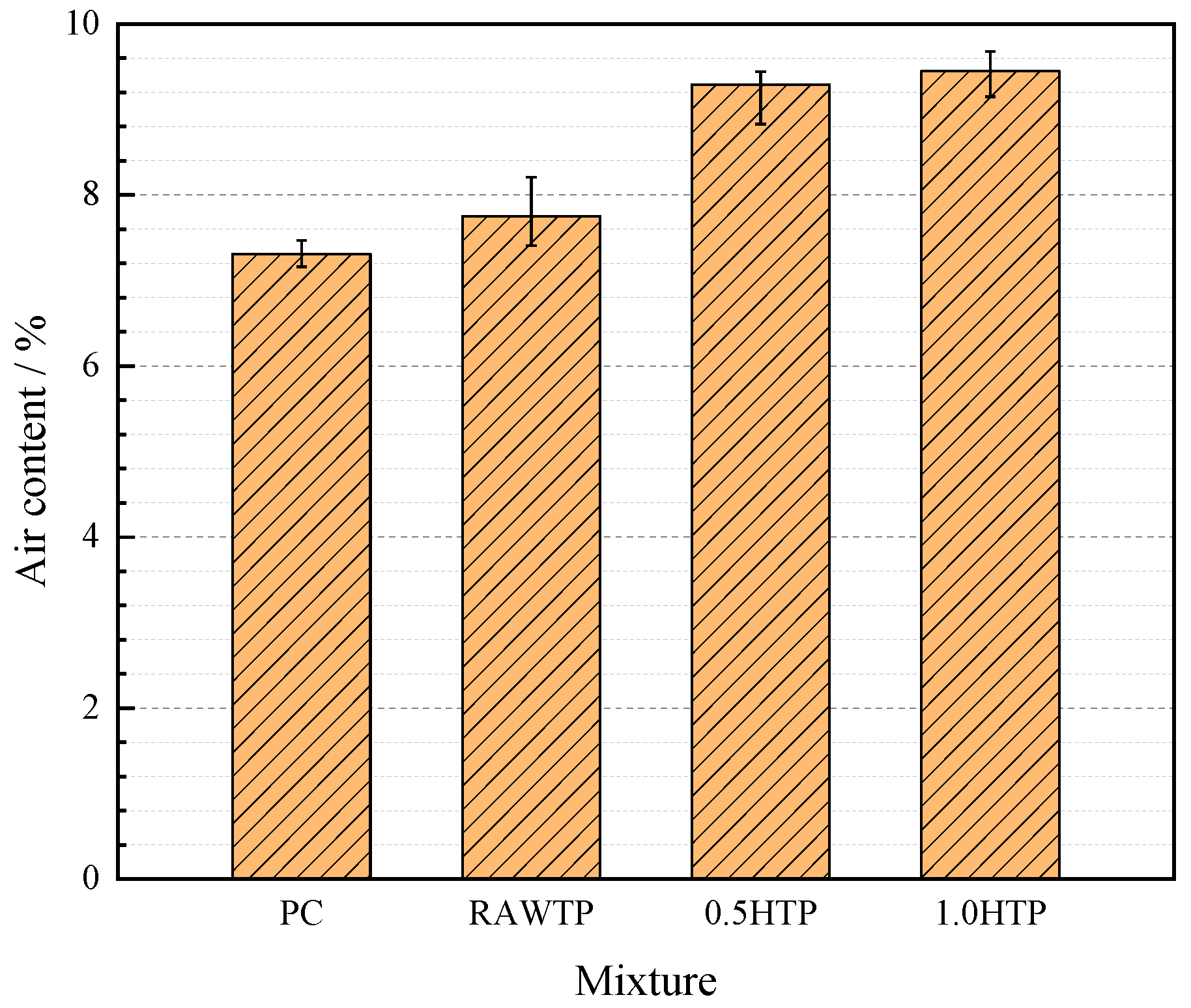

3.2. Air Content

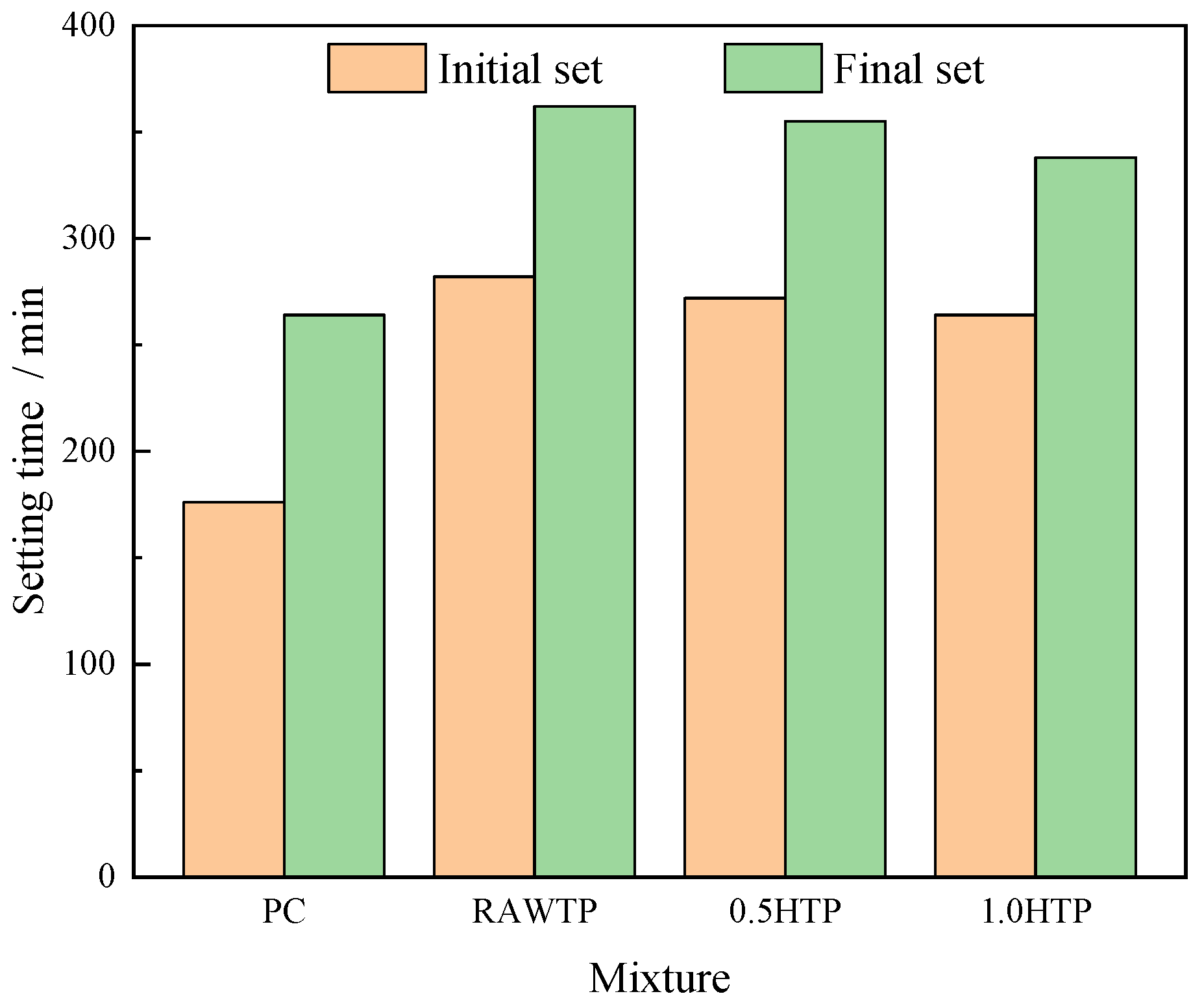

3.3. Setting Time

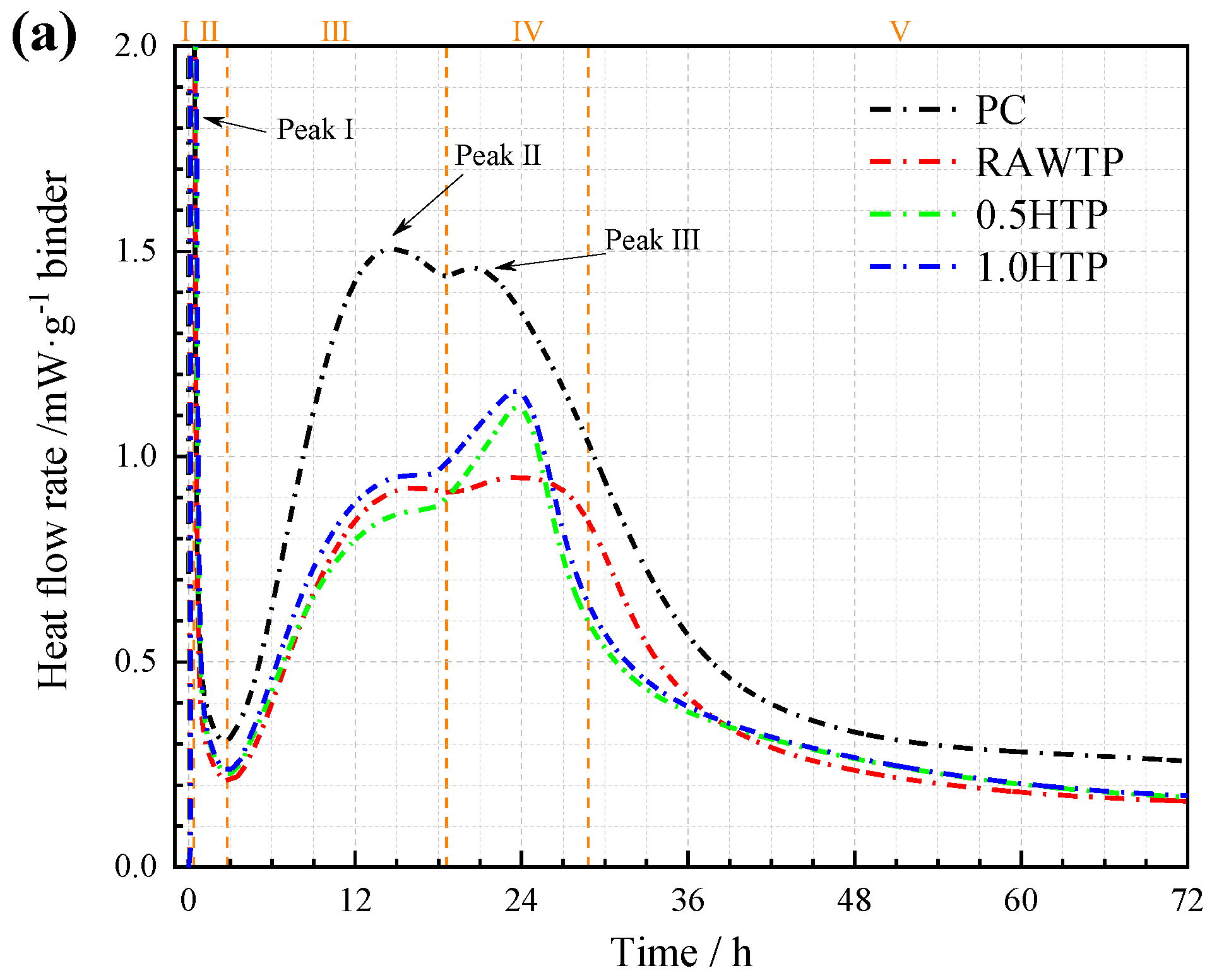

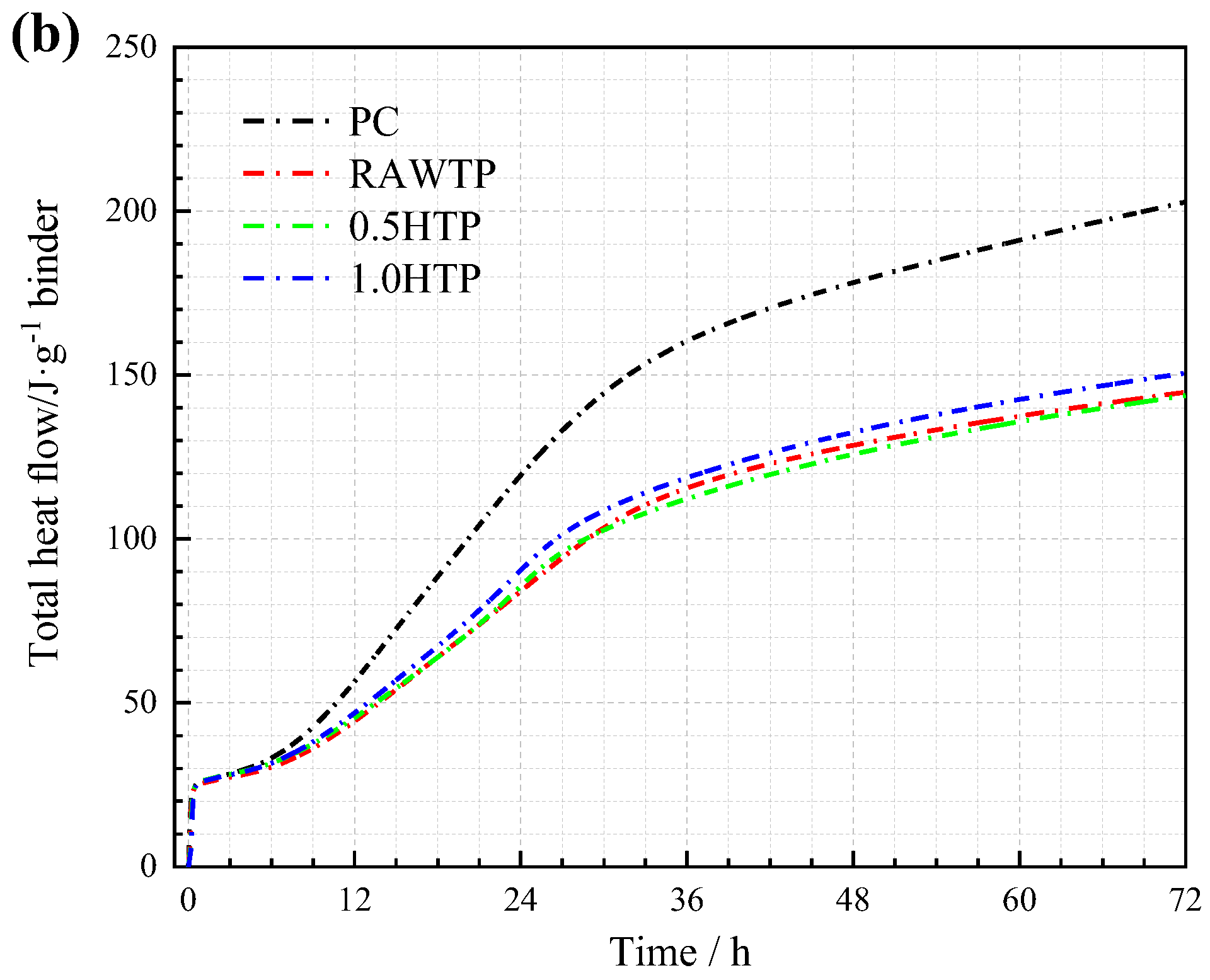

3.4. Hydration Reaction Kinetics

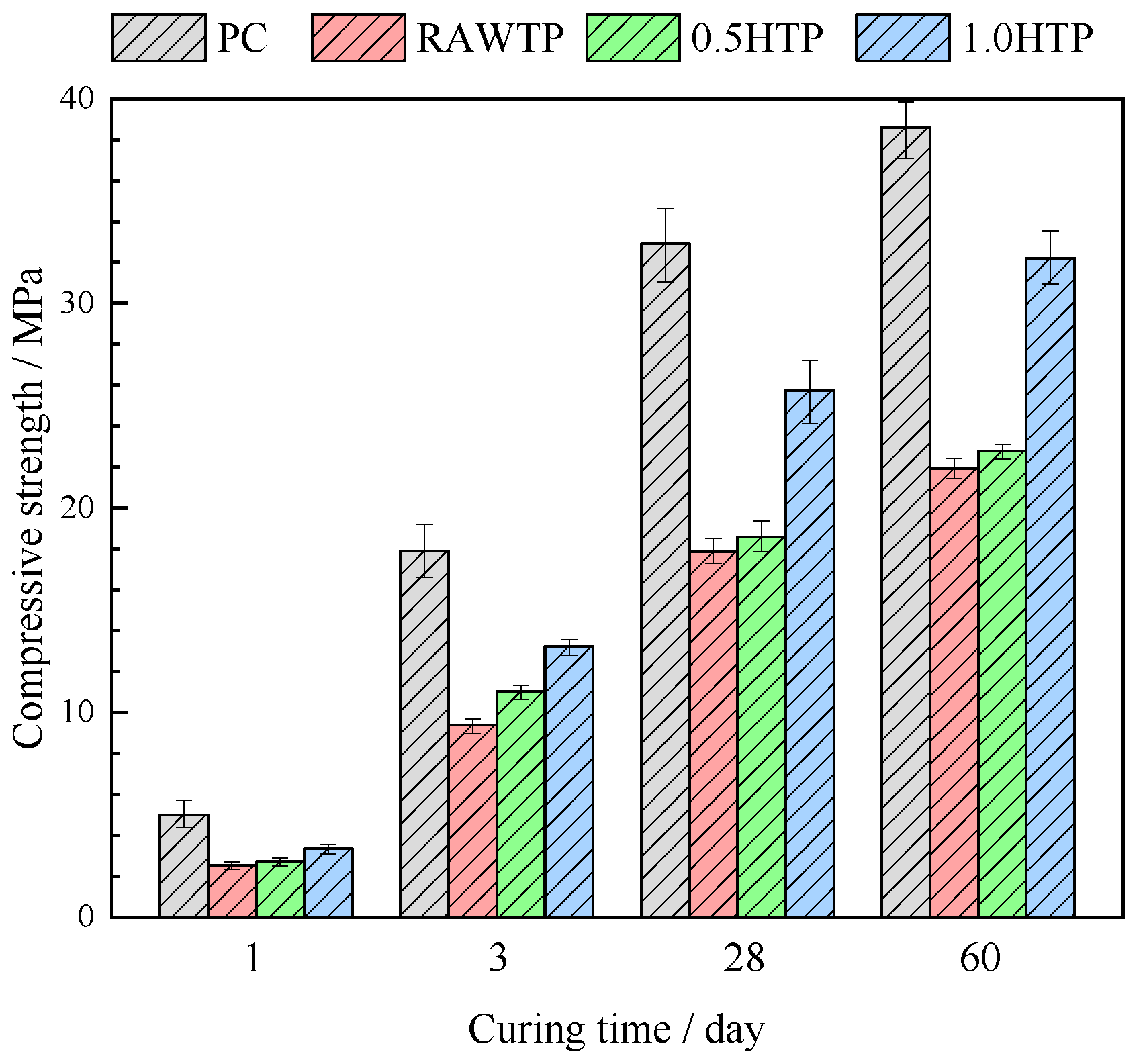

3.5. Compressive Strengths

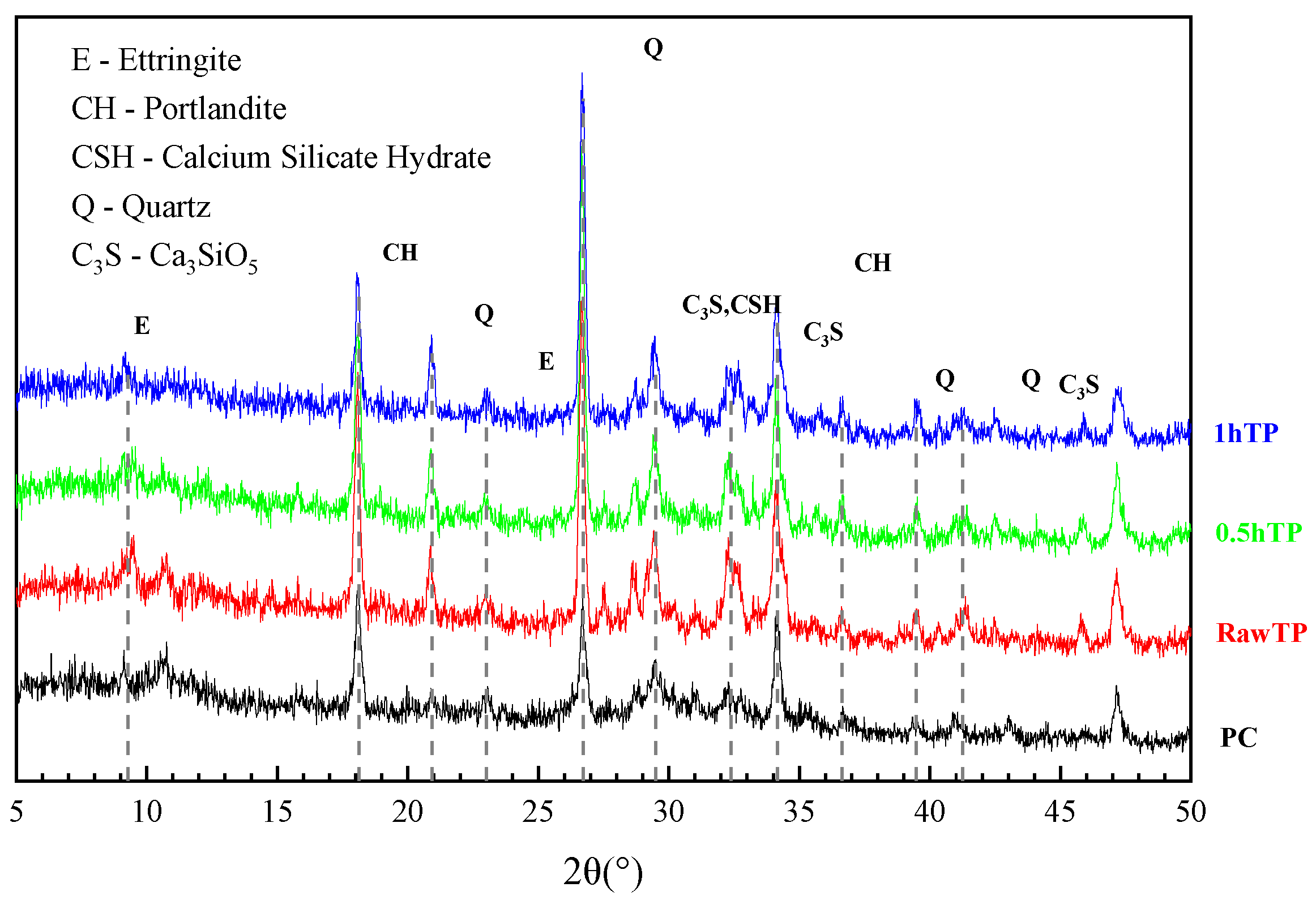

3.6. Hydration Products

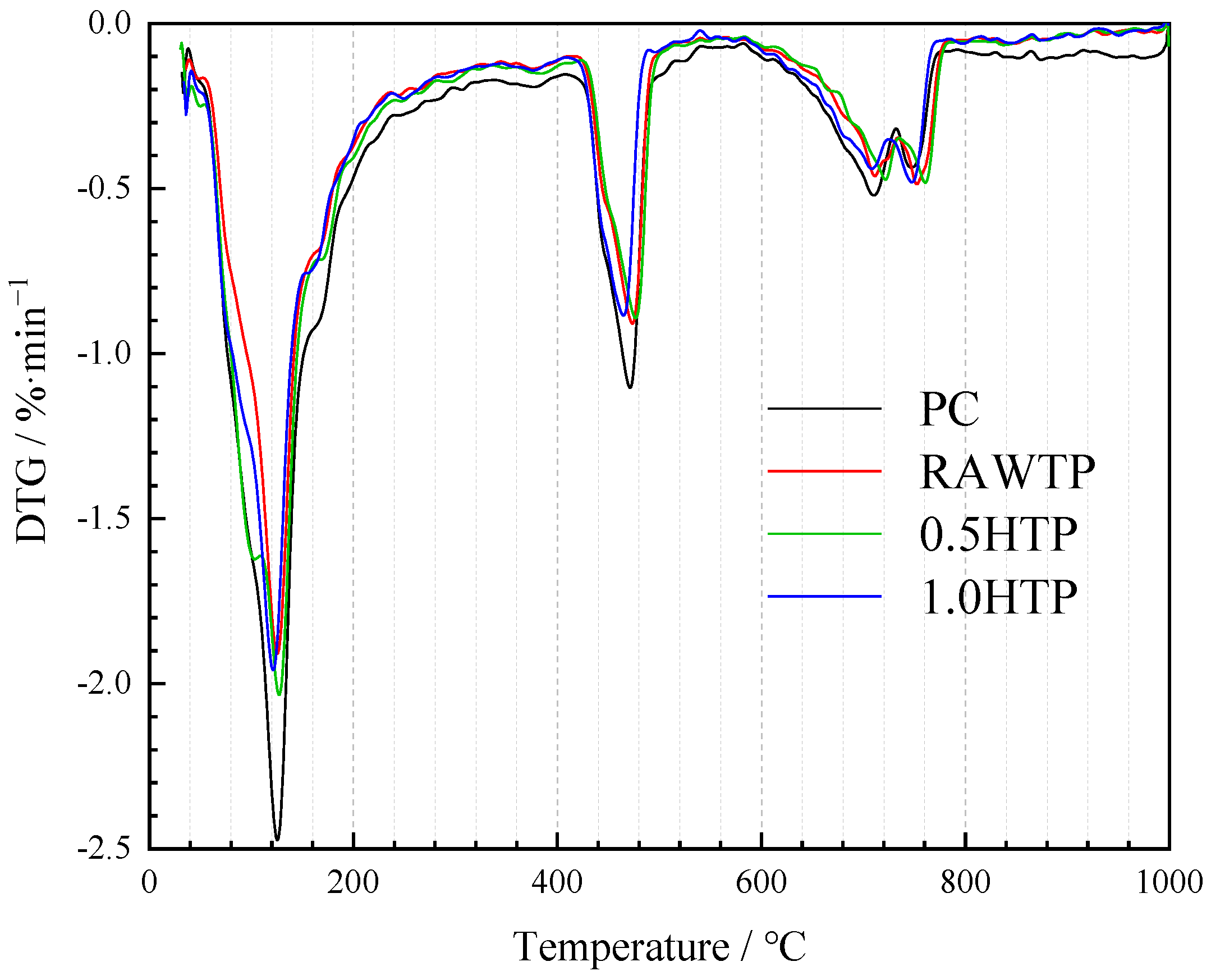

3.7. Thermogravimetric Analysis

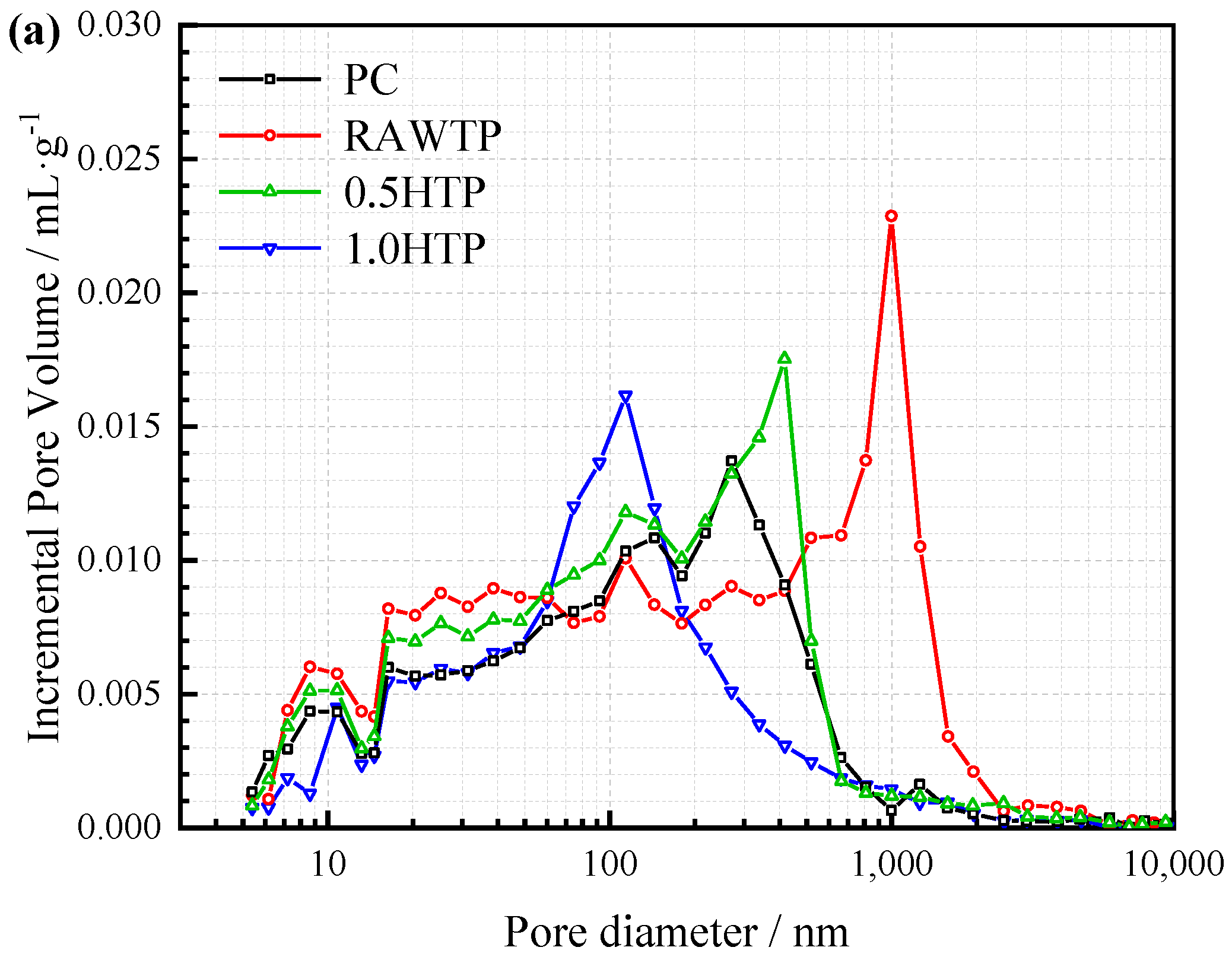

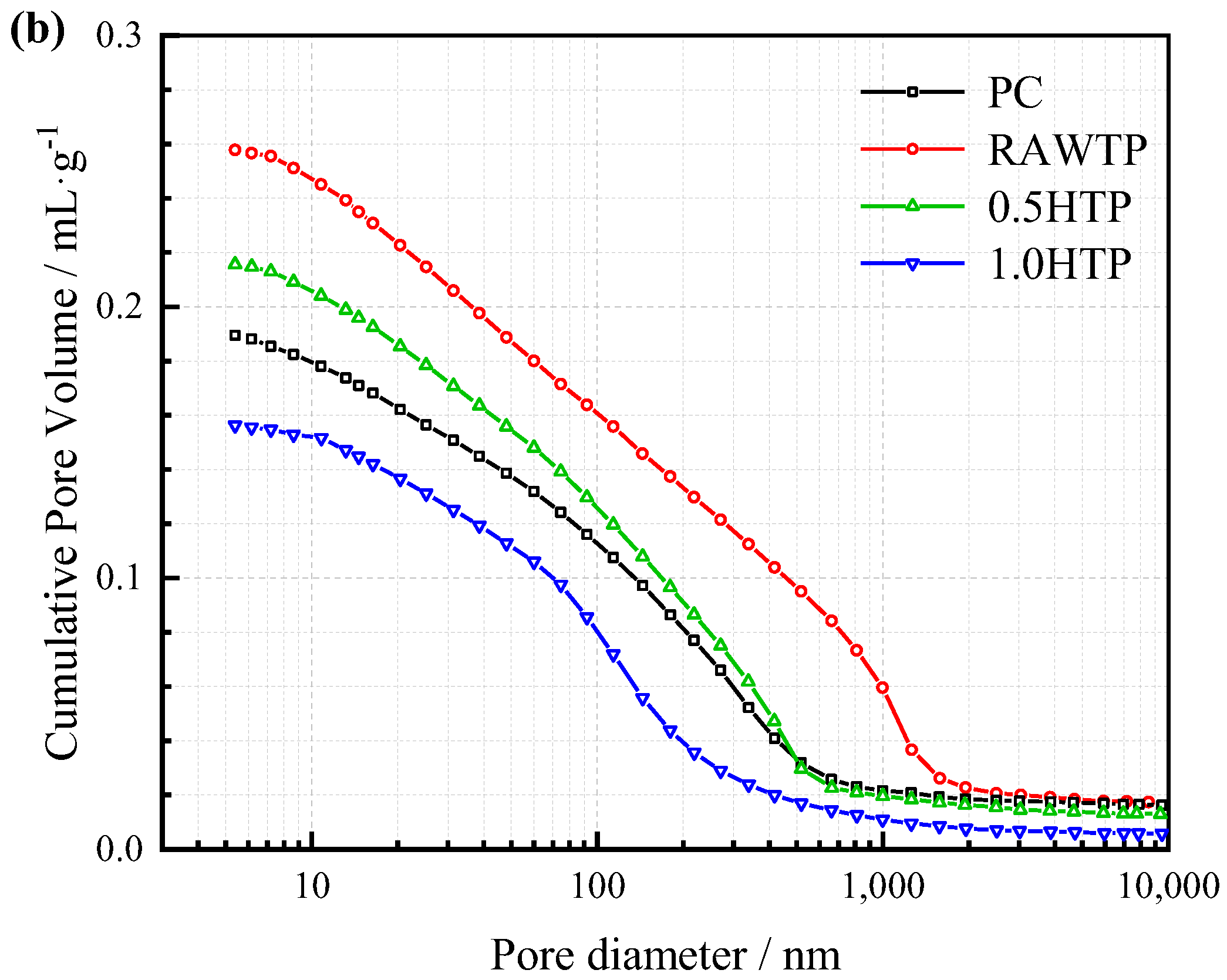

3.8. Pore Structure

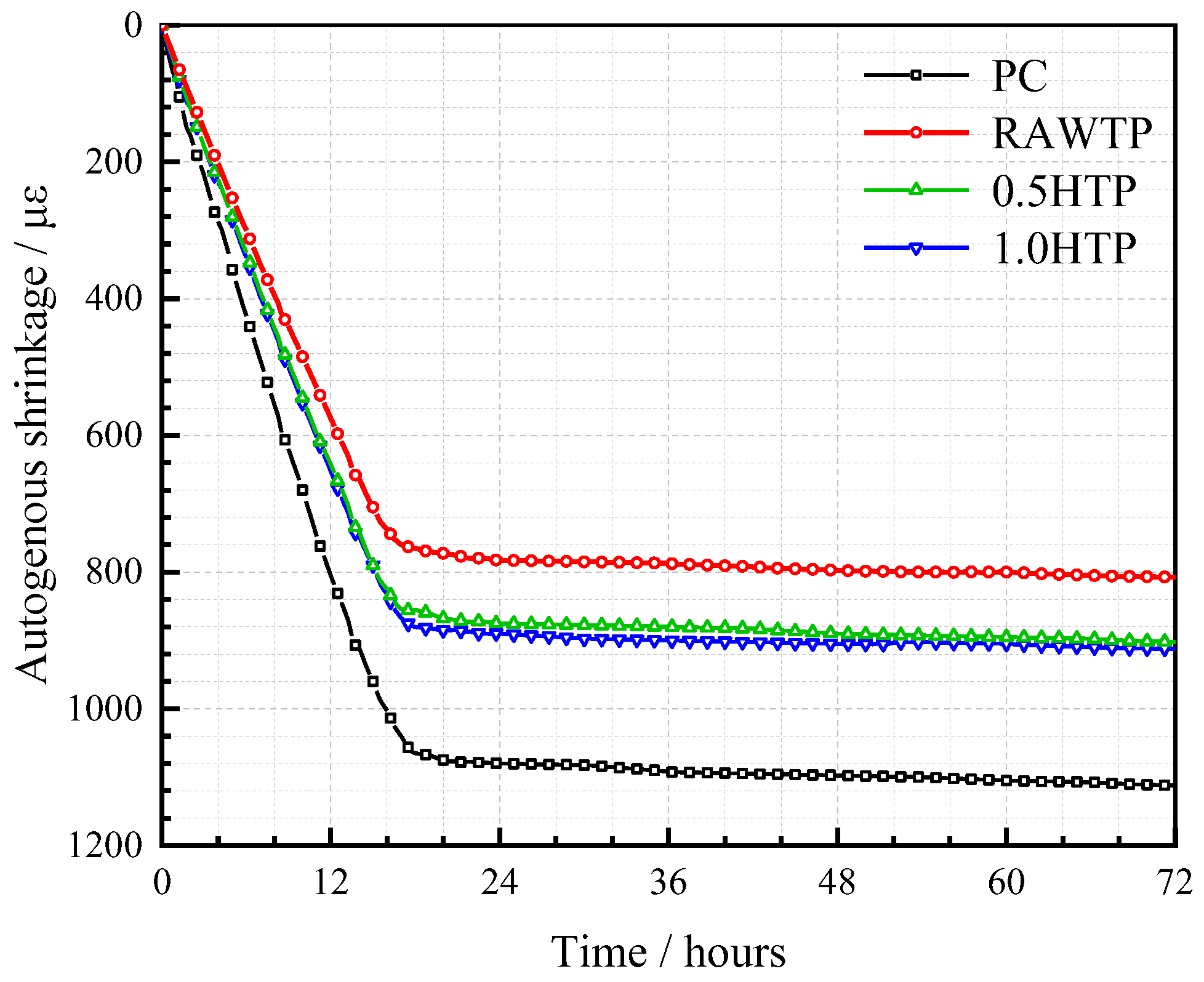

3.9. Autogenous Shrinkage

4. Conclusions

- (1)

- Throughout the grinding period, the particle size of TP gradually declines, and the decline range also decreases. The shapes of powder particles turn from sub-circular to clavate and then back to sub-circular, indicating that the grinding time significantly affects the morphology of particles.

- (2)

- The incorporation of TP delays the setting and hydration behavior of blended cement, and reduces the hydration product content. However, the further mechanically activated particles can play a role in nucleation and accelerate the hydration of cement particles. The mechanical activation of TP could significantly increase the compressive strength of blended cement pastes using TP, but these values are still lower than that of cement.

- (3)

- Autogenous shrinkage decreases with the addition of TP but increases with more grinding time. This indicates that the addition of TP has a positive effect on the early autogenous shrinkage of paste and relieves the growth of micro-crack.

- (4)

- This study discussed the morphological effect of TP on the performance of blended cemented paste. The result indicated that this morphological property significantly affects the hydration procedure, strength, and pore structure, but hardly influences the hydration products. However, the impact mechanism of mechanical grinding on other SCMs is still limited, and a further study is needed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, Y.; Wang, Q.; Shi, M. Characteristics and reactivity of ferronickel slag powder. Constr. Build. Mater. 2017, 156, 773–789. [Google Scholar] [CrossRef]

- Xing, J.; Zhao, Y.L.; Qiu, J.P.; Sun, X.G. Microstructural and Mechanical Properties of Alkali Activated Materials from Two Types of Blast Furnace Slags. Materials 2019, 12, 16. [Google Scholar] [CrossRef]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Qiu, J.P.; Zhao, Y.L.; Xing, J.; Sun, X.G. Fly Ash/Blast Furnace Slag-Based Geopolymer as a Potential Binder for Mine Backfilling: Effect of Binder Type and Activator Concentration. Adv. Mater. Sci. Eng. 2019, 2019, 12. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Abrão, P.C.R.A.; Cardoso, F.A.; John, V.M. Efficiency of Portland-pozzolana cements: Water demand, chemical reactivity and environmental impact. Constr. Build. Mater. 2020, 247, 118546. [Google Scholar] [CrossRef]

- Cai, R.; Tian, Z.; Ye, H.; He, Z.; Tang, S. The role of metakaolin in pore structure evolution of Portland cement pastes revealed by an impedance approach. Cem. Concr. Compos. 2021, 119, 103999. [Google Scholar] [CrossRef]

- Sharma, M.; Bishnoi, S.; Martirena, F.; Scrivener, K. Limestone calcined clay cement and concrete: A state-of-the-art review. Cem. Concr. Res. 2021, 149, 106564. [Google Scholar] [CrossRef]

- Jittin, V.; Rithuparna, R.; Bahurudeen, A.; Pachiappan, B. Synergistic use of typical agricultural and industrial by-products for ternary cement: A pathway for locally available resource utilisation. J. Clean. Prod. 2021, 279, 123448. [Google Scholar] [CrossRef]

- Chand, G. Microstructural study of sustainable cements produced from industrial by-products, natural minerals and agricultural wastes: A critical review on engineering properties. Clean. Eng. Technol. 2021, 4, 100224. [Google Scholar] [CrossRef]

- Quedou, P.G.; Wirquin, E.; Bokhoree, C. A sustainable approach in using construction and demolition waste materials in concrete. World J. Eng. 2021, 18, 826–840. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Z.; Wang, D.; Yan, P.; Luo, L.; Zhang, H.; Zhang, H.; Gu, X. Hydration superposition effect and mechanism of steel slag powder and granulated blast furnace slag powder. Constr. Build. Mater. 2023, 366, 130101. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Xing, J.; Sun, X. Chemical activation of binary slag cement with low carbon footprint. J. Clean. Prod. 2020, 267, 121455. [Google Scholar] [CrossRef]

- Zhao, Q.; Pang, L.; Wang, D. Adverse Effects of Using Metallurgical Slags as Supplementary Cementitious Materials and Aggregate: A Review. Materials 2022, 15, 3803. [Google Scholar] [CrossRef] [PubMed]

- Kinomura, K.; Ishida, T. Enhanced hydration model of fly ash in blended cement and application of extensive modeling for continuous hydration to pozzolanic micro-pore structures. Cem. Concr. Compos. 2020, 114, 103733. [Google Scholar] [CrossRef]

- Li, G.; Zhou, C.; Ahmad, W.; Usanova, K.I.; Karelina, M.; Mohamed, A.M.; Khallaf, R. Fly Ash Application as Supplementary Cementitious Material: A Review. Materials 2022, 15, 2664. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Influence of silica fume content on microstructure development and bond to steel fiber in ultra-high strength cement-based materials (UHSC). Cem. Concr. Compos. 2016, 71, 97–109. [Google Scholar] [CrossRef]

- Shanmugasundaram, N.; Praveenkumar, S. Influence of supplementary cementitious materials, curing conditions and mixing ratios on fresh and mechanical properties of engineered cementitious composites—A review. Constr. Build. Mater. 2021, 309, 125038. [Google Scholar] [CrossRef]

- Elahi, M.M.A.; Shearer, C.R.; Naser Rashid Reza, A.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Samad, S.; Shah, A. Role of binary cement including Supplementary Cementitious Material (SCM), in production of environmentally sustainable concrete: A critical review. Int. J. Sustain. Built Environ. 2017, 6, 663–674. [Google Scholar] [CrossRef]

- Nécira, B.; Abadou, Y. Properties of self-compacting mortar made with various mineralogical sources different types of sands and fillers. World J. Eng. 2021, 18, 861–869. [Google Scholar] [CrossRef]

- Wan, H.; Shui, Z.; Lin, Z. Analysis of geometric characteristics of GGBS particles and their influences on cement properties. Cem. Concr. Res. 2004, 34, 133–137. [Google Scholar] [CrossRef]

- Öner, M.; Erdoğdu, K.; Günlü, A. Effect of components fineness on strength of blast furnace slag cement. Cem. Concr. Res. 2003, 33, 463–469. [Google Scholar] [CrossRef]

- Hadji, T.; Guettala, S.; Quéneudec, M. Mix design of high performance concrete with different mineral additions. World J. Eng. 2021, 18, 767–779. [Google Scholar] [CrossRef]

- Zhang, N.; Tang, B.; Liu, X. Cementitious activity of iron ore tailing and its utilization in cementitious materials, bricks and concrete. Constr. Build. Mater. 2021, 288, 123022. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Gu, X.W.; Qiu, J.P.; Zhang, W.F.; Li, X.H. Study on the Utilization of Iron Tailings in Ultra-High-Performance Concrete: Fresh Properties and Compressive Behaviors. Materials 2021, 14, 15. [Google Scholar] [CrossRef]

- Guo, Z.B.; Qiu, J.P.; Jiang, H.Q.; Zhang, S.Y.; Ding, H.X. Improving the performance of superfine-tailings cemented paste backfill with a new blended binder. Powder Technol. 2021, 394, 149–160. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.N.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Han, F.; Li, L.; Song, S.; Liu, J. Early-age hydration characteristics of composite binder containing iron tailing powder. Powder Technol. 2017, 315, 322–331. [Google Scholar] [CrossRef]

- Han, F.; Song, S.; Liu, J.; Huang, S. Properties of steam-cured precast concrete containing iron tailing powder. Powder Technol. 2019, 345, 292–299. [Google Scholar] [CrossRef]

- Han, F.; Zhou, Y.; Zhang, Z. Effect of gypsum on the properties of composite binder containing high-volume slag and iron tailing powder. Constr. Build. Mater. 2020, 252, 119023. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Ma, Z. Temperature-dependent rheological, mechanical and hydration properties of cement paste blended with iron tailings. Powder Technol. 2021, 381, 82–91. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, L.; He, X.; Su, Y.; Li, Y.; Tan, H.; Jiang, B.; Zhu, H.; Oh, S.-K. Improving durability of heat-cured high volume fly ash cement mortar by wet-grinding activation. Constr. Build. Mater. 2021, 289, 123157. [Google Scholar] [CrossRef]

- Zhu, H.J.; Ma, M.Y.; He, X.Y.; Zheng, Z.Q.; Su, Y.; Yang, J.; Zhao, H. Effect of wet-grinding steel slag on the properties of Portland cement: An activated method and rheology analysis. Constr. Build. Mater. 2021, 286, 15. [Google Scholar] [CrossRef]

- Yao, G.; Wang, Q.; Wang, Z.; Wang, J.; Lyu, X. Activation of hydration properties of iron ore tailings and their application as supplementary cementitious materials in cement. Powder Technol. 2020, 360, 863–871. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Huang, F.; Li, W.C.; Liu, R.; Li, G.L.; Wei, J.M. Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete. Constr. Build. Mater. 2016, 118, 164–170. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Effect of particle-size distribution and specific surface area of different binder systems on packing density and flow characteristics of cement paste. Cem. Concr. Compos. 2017, 78, 120–131. [Google Scholar] [CrossRef]

- Sun, X.; Liu, J.; Zhao, Y.; Zhao, J.; Li, Z.; Sun, Y.; Qiu, J.; Zheng, P. Mechanical activation of steel slag to prepare supplementary cementitious materials: A comparative research based on the particle size distribution, hydration, toxicity assessment and carbon dioxide emission. J. Build. Eng. 2022, 60, 105200. [Google Scholar] [CrossRef]

- Kriskova, L.; Pontikes, Y.; Cizer, Ö.; Mertens, G.; Veulemans, W.; Geysen, D.; Jones, P.T.; Vandewalle, L.; Van Balen, K.; Blanpain, B. Effect of mechanical activation on the hydraulic properties of stainless steel slags. Cem. Concr. Res. 2012, 42, 778–788. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, H.; Zhang, M. Flexural fatigue behaviour of recycled tyre polymer fibre reinforced concrete. Cem. Concr. Compos. 2020, 105, 103441. [Google Scholar] [CrossRef]

- Wu, Y.; Duan, P.; Yan, C. Role of layered double hydroxides in setting, hydration degree, microstructure and compressive strength of cement paste. Appl. Clay Sci. 2018, 158, 123–131. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Shui, Z.; Zhao, Z.; Song, Q.; Yang, B.; Fan, D. Development of a novel cleaner construction product: Ultra-high performance concrete incorporating lead-zinc tailings. J. Clean. Prod. 2018, 196, 172–182. [Google Scholar] [CrossRef]

- Lyu, X.; Yao, G.; Wang, Z.; Wang, Q.; Li, L. Hydration kinetics and properties of cement blended with mechanically activated gold mine tailings. Thermochim. Acta 2020, 683, 178457. [Google Scholar] [CrossRef]

- Yao, G.; Liu, Q.; Wang, J.; Wu, P.; Lyu, X. Effect of mechanical grinding on pozzolanic activity and hydration properties of siliceous gold ore tailings. J. Clean. Prod. 2019, 217, 12–21. [Google Scholar] [CrossRef]

- Ma, G.; Zhou, W.; Regueiro, R.A.; Wang, Q.; Chang, X. Modeling the fragmentation of rock grains using computed tomography and combined FDEM. Powder Technol. 2017, 308, 388–397. [Google Scholar] [CrossRef]

- Crozier, D.; Riera-Lizarazu, O.; Rooney, W.L. Application of X-ray computed tomography to analyze the structure of sorghum grain. Plant Methods 2022, 18, 3. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, J. Generation of a realistic 3D sand assembly using X-ray micro-computed tomography and spherical harmonic-based principal component analysis: Generation of a Realistic 3D Sand Assembly. Int. J. Numer. Anal. Methods Geomech. 2017, 41, 93–109. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Shui, Z.; Song, Q.; Liu, Z.; Bao, M.; Liu, Z.; Wu, S. Optimized treatment of recycled construction and demolition waste in developing sustainable ultra-high performance concrete. J. Clean. Prod. 2019, 221, 805–816. [Google Scholar] [CrossRef]

- Yao, G.; Cui, T.; Zhang, J.; Wang, J.; Lyu, X. Effects of mechanical grinding on pozzolanic activity and hydration properties of quartz. Adv. Powder Technol. 2020, 31, 4500–4509. [Google Scholar] [CrossRef]

- Kucharczyk, S.; Zajac, M.; Stabler, C.; Thomsen, R.M.; Ben Haha, M.; Skibsted, J.; Deja, J. Structure and reactivity of synthetic CaO-Al2O3-SiO2 glasses. Cem. Concr. Res. 2019, 120, 77–91. [Google Scholar] [CrossRef]

- Li, L.G.; Kwan, A.K.H. Concrete mix design based on water film thickness and paste film thickness. Cem. Concr. Compos. 2013, 39, 33–42. [Google Scholar] [CrossRef]

- Dils, J.; Boel, V.; De Schutter, G. Influence of cement type and mixing pressure on air content, rheology and mechanical properties of UHPC. Constr. Build. Mater. 2013, 41, 455–463. [Google Scholar] [CrossRef]

- Chen, J.J.; Kwan, A.K.H. Superfine cement for improving packing density, rheology and strength of cement paste. Cem. Concr. Compos. 2012, 34, 1–10. [Google Scholar] [CrossRef]

- Rodríguez, J.; Frías, M.; Tobón, J.I. Eco-efficient cement based on activated coal washing rejects with low content of kaolinite. Constr. Build. Mater. 2021, 274, 122118. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, J.; Wu, P.; Sun, X.; Zhang, S.; Guo, Z. Calcined oil shale residue as a supplementary cementitious material for ordinary Portland cement. Constr. Build. Mater. 2021, 306, 124849. [Google Scholar] [CrossRef]

- Marchon, D.; Juilland, P.; Gallucci, E.; Frunz, L.; Flatt, R.J. Molecular and submolecular scale effects of comb-copolymers on tri-calcium silicate reactivity: Toward molecular design. J. Am. Ceram. Soc. 2017, 100, 817–841. [Google Scholar] [CrossRef]

- Goulart Bezerra, C.; Abelha Rocha, C.A.; Siqueira, I.S.d.; Toledo Filho, R.D. Feasibility of iron-rich ore tailing as supplementary cementitious material in cement pastes. Constr. Build. Mater. 2021, 303, 124496. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Ma, Z.; Sun, X. Eco-friendly treatment of coal gangue for its utilization as supplementary cementitious materials. J. Clean. Prod. 2021, 285, 124834. [Google Scholar] [CrossRef]

- He, X.; Zheng, Z.; Yang, J.; Su, Y.; Wang, T.; Strnadel, B. Feasibility of incorporating autoclaved aerated concrete waste for cement replacement in sustainable building materials. J. Clean. Prod. 2020, 250, 119455. [Google Scholar] [CrossRef]

- He, X.; Zheng, Z.; Ma, M.; Su, Y.; Yang, J.; Tan, H.; Wang, Y.; Strnadel, B. New treatment technology: The use of wet-milling concrete slurry waste to substitute cement. J. Clean. Prod. 2020, 242, 118347. [Google Scholar] [CrossRef]

- He, X.; Ma, M.; Su, Y.; Lan, M.; Zheng, Z.; Wang, T.; Strnadel, B.; Zeng, S. The effect of ultrahigh volume ultrafine blast furnace slag on the properties of cement pastes. Constr. Build. Mater. 2018, 189, 438–447. [Google Scholar] [CrossRef]

- He, Z.-H.; Yang, Y.; Yuan, Q.; Shi, J.-Y.; Liu, B.-J.; Liang, C.-F.; Du, S.-G. Recycling hazardous water treatment sludge in cement-based construction materials: Mechanical properties, drying shrinkage, and nano-scale characteristics. J. Clean. Prod. 2021, 290, 125832. [Google Scholar] [CrossRef]

- Furlan, A.P.; Razakamanantsoa, A.; Ranaivomanana, H.; Amiri, O.; Levacher, D.; Deneele, D. Effect of fly ash on microstructural and resistance characteristics of dredged sediment stabilized with lime and cement. Constr. Build. Mater. 2021, 272, 121637. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q. Inhibition mechanisms of steel slag on the early-age hydration of cement. Cem. Concr. Res. 2021, 140, 106283. [Google Scholar] [CrossRef]

- Hannesson, G.; Kuder, K.; Shogren, R.; Lehman, D. The influence of high volume of fly ash and slag on the compressive strength of self-consolidating concrete. Constr. Build. Mater. 2012, 30, 161–168. [Google Scholar] [CrossRef]

- Seraj, S.; Cano, R.; Ferron, R.D.; Juenger, M.C.G. The role of particle size on the performance of pumice as a supplementary cementitious material. Cem. Concr. Compos. 2017, 80, 135–142. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Liu, L.; Xin, J.; Qi, C.; Jia, H.; Song, K.-I. Experimental investigation of mechanical, hydration, microstructure and electrical properties of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120137. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.; Gan, Y.; Chang, Z.; Schlangen, E.; Šavija, B. Microstructure informed micromechanical modelling of hydrated cement paste: Techniques and challenges. Constr. Build. Mater. 2020, 251, 118983. [Google Scholar] [CrossRef]

- Chen, H.; Zhu, Z.; Lin, J.; Xu, W.; Liu, L. Numerical modeling on the influence of particle shape on ITZ’s microstructure and macro-properties of cementitious composites: A critical review. J. Sustain. Cem.-Based Mater. 2018, 7, 248–269. [Google Scholar] [CrossRef]

- Fan, Y.-F.; Luan, H.-Y. Pore structure in concrete exposed to acid deposit. Constr. Build. Mater. 2013, 49, 407–416. [Google Scholar] [CrossRef]

- Tang, S.W.; Huang, D.S.; He, Z. A review of autogenous shrinkage models of concrete. J. Build. Eng. 2021, 44, 103412. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.A.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. Effect of supplementary cementitious materials on autogenous shrinkage of ultra-high performance concrete. Constr. Build. Mater. 2016, 127, 43–48. [Google Scholar] [CrossRef]

- Li, Y.; Bao, J.; Guo, Y. The relationship between autogenous shrinkage and pore structure of cement paste with mineral admixtures. Constr. Build. Mater. 2010, 24, 1855–1860. [Google Scholar] [CrossRef]

| SiO2 | CaO | Al2O3 | MgO | Na2O | K2O | SO3 | Fe2O3 | LOI | BET Surface Area | |

|---|---|---|---|---|---|---|---|---|---|---|

| OPC | 20.19 | 63.03 | 5.11 | 1.72 | 0.10 | 0.32 | 1.19 | 2.11 | 2.14 | 1.9225 m2·g−1 |

| TP | 69.08 | 5.05 | 4.74 | 6.06 | 0.39 | 0.34 | 0.48 | 8.88 | 0.89 | 0.4437 m2·g−1 |

| d10/μm | d50/μm | d90/μm | BET Surface Area | |

|---|---|---|---|---|

| RAWTP | 15.9 | 47.2 | 98.6 | 0.4437 |

| 0.5HTP | 2.40 | 14.4 | 36.4 | 1.6595 |

| 1.0HTP | 1.67 | 9.57 | 26.4 | 2.5136 |

| 1.5HTP | 1.45 | 8.68 | 24.1 | 2.5611 |

| 2.0HTP | 1.28 | 8.68 | 24.1 | 2.5784 |

| Group | RAWTP | 0.5HTP | 1.0HTP | |||

|---|---|---|---|---|---|---|

| Roundness | L/W | Roundness | L/W | Roundness | L/W | |

| 1 | 1.242 | 1.06 | 1.4717 | 1.3 | 1.3074 | 1.2 |

| 2 | 1.276 | 1.3 | 1.4984 | 1.89 | 1.2282 | 1.14 |

| 3 | 1.389 | 1.66 | 1.4596 | 1.51 | 1.3055 | 1.22 |

| 4 | 1.327 | 1.26 | 1.3298 | 1.91 | 1.2445 | 1.16 |

| 5 | 1.326 | 1.34 | 1.3495 | 1.78 | 1.1731 | 1.23 |

| 6 | 1.364 | 1.29 | 1.6061 | 1.56 | 1.2799 | 1.18 |

| 7 | 1.326 | 1.28 | 1.4257 | 1.75 | 1.2023 | 1.19 |

| 8 | 1.373 | 1.31 | 1.4604 | 1.64 | 1.2394 | 1.14 |

| 9 | 1.353 | 1.43 | 1.6281 | 1.42 | 1.2451 | 1.19 |

| 10 | 1.309 | 1.42 | 1.6378 | 1.63 | 1.2815 | 1.26 |

| 11 | 1.286 | 1.35 | 1.6657 | 1.55 | 1.3295 | 1.16 |

| 12 | 1.315 | 1.29 | 1.4409 | 1.94 | 1.3045 | 1.16 |

| 13 | 1.307 | 1.42 | 1.4628 | 1.46 | 1.2811 | 1.21 |

| 14 | 1.317 | 1.32 | 1.4515 | 1.65 | 1.3347 | 1.16 |

| 15 | 1.275 | 1.26 | 1.4589 | 1.66 | 1.3073 | 1.25 |

| 16 | 1.262 | 1.31 | 1.5299 | 1.49 | 1.2389 | 1.16 |

| 17 | 1.331 | 1.25 | 1.4598 | 1.73 | 1.3823 | 1.17 |

| 18 | 1.342 | 1.25 | 1.3429 | 1.86 | 1.2645 | 1.24 |

| 19 | 1.397 | 1.43 | 1.3646 | 1.53 | 1.2625 | 1.26 |

| 20 | 1.318 | 1.24 | 1.474 | 1.88 | 1.3338 | 1.23 |

| Average | 1.322 | 1.32 | 1.4759 | 1.65 | 1.2773 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Zhao, Y.; Gu, X.; Zhu, Z.; Wang, F.; Zhang, Z. Effect of Particle Size and Morphology of Siliceous Supplementary Cementitious Material on the Hydration and Autogenous Shrinkage of Blended Cement. Materials 2023, 16, 1638. https://doi.org/10.3390/ma16041638

Xu X, Zhao Y, Gu X, Zhu Z, Wang F, Zhang Z. Effect of Particle Size and Morphology of Siliceous Supplementary Cementitious Material on the Hydration and Autogenous Shrinkage of Blended Cement. Materials. 2023; 16(4):1638. https://doi.org/10.3390/ma16041638

Chicago/Turabian StyleXu, Xiaochuan, Yunqi Zhao, Xiaowei Gu, Zhenguo Zhu, Fengdan Wang, and Zaolin Zhang. 2023. "Effect of Particle Size and Morphology of Siliceous Supplementary Cementitious Material on the Hydration and Autogenous Shrinkage of Blended Cement" Materials 16, no. 4: 1638. https://doi.org/10.3390/ma16041638

APA StyleXu, X., Zhao, Y., Gu, X., Zhu, Z., Wang, F., & Zhang, Z. (2023). Effect of Particle Size and Morphology of Siliceous Supplementary Cementitious Material on the Hydration and Autogenous Shrinkage of Blended Cement. Materials, 16(4), 1638. https://doi.org/10.3390/ma16041638