Investigation into Rheological Behavior of Warm-Mix Recycled Asphalt Binders with High Percentages of RAP Binder

Abstract

:1. Introduction

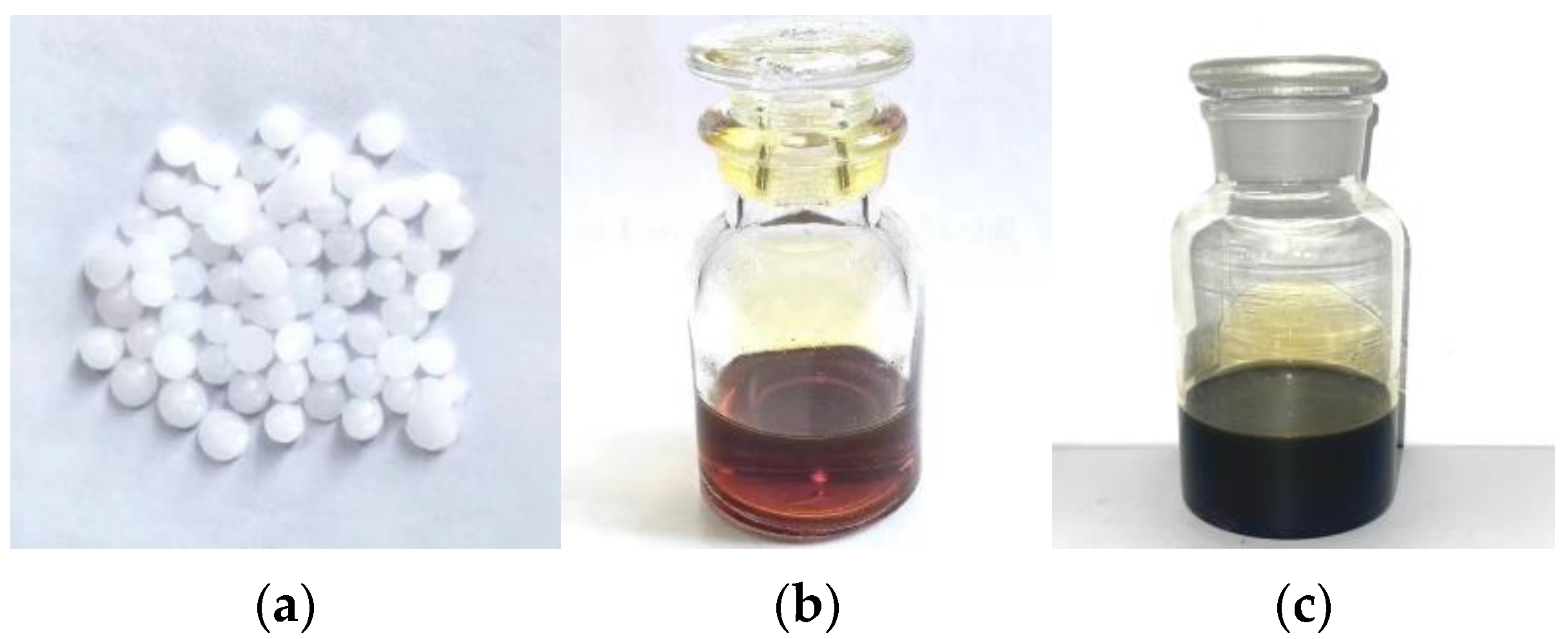

2. Materials

3. Methodology

3.1. Conventional Performance Tests

3.2. Apparent Viscosity Test by Brookfield Rotational Viscometer

3.3. High- and Intermediate-Temperature Performance Test

3.4. Low-Temperature Performance Test

3.5. Frequency Sweep Test

3.6. Experimental Procedure

4. Results and Discussion

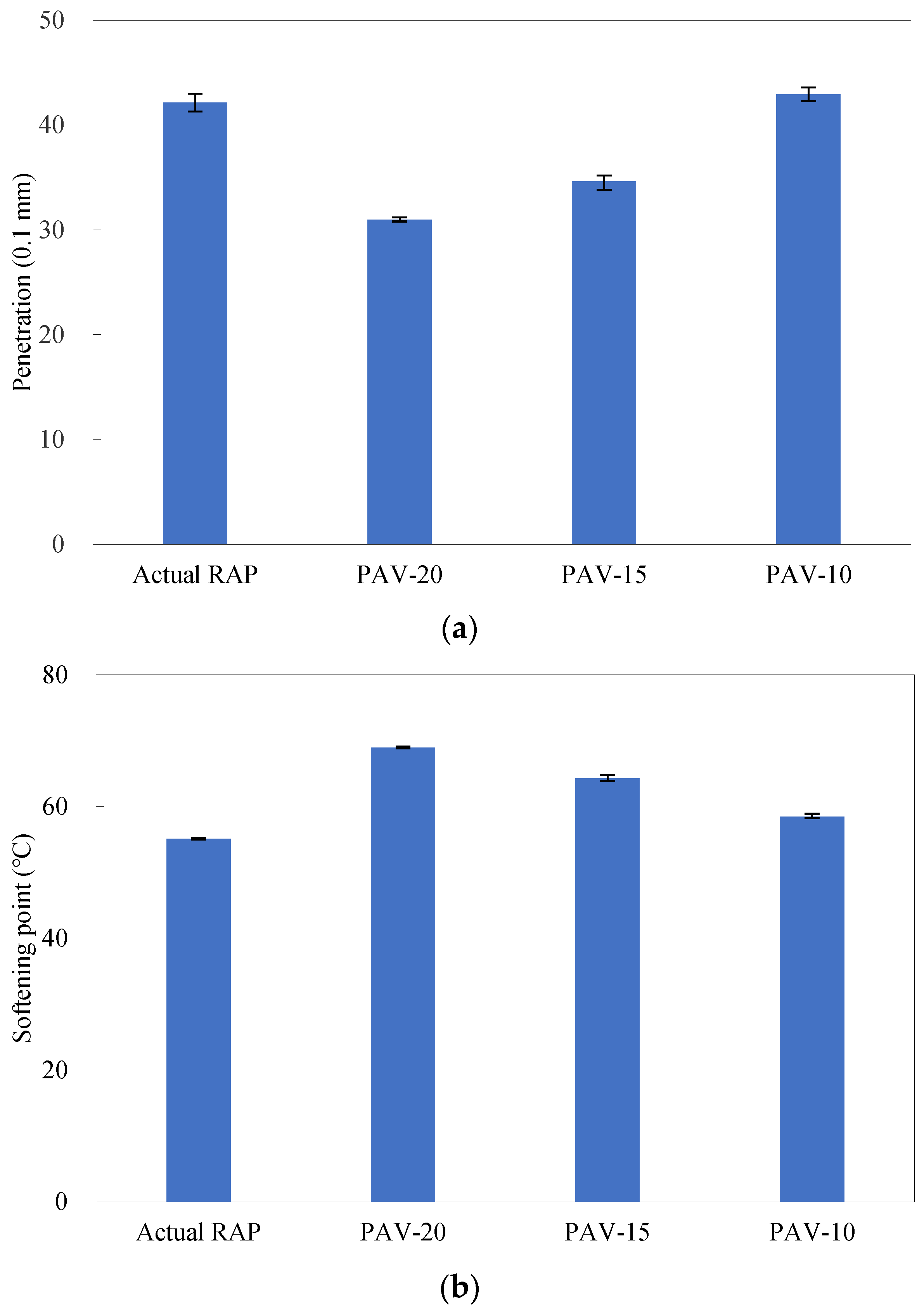

4.1. Determination of PAV Aging Time for Artificial RAP Binder

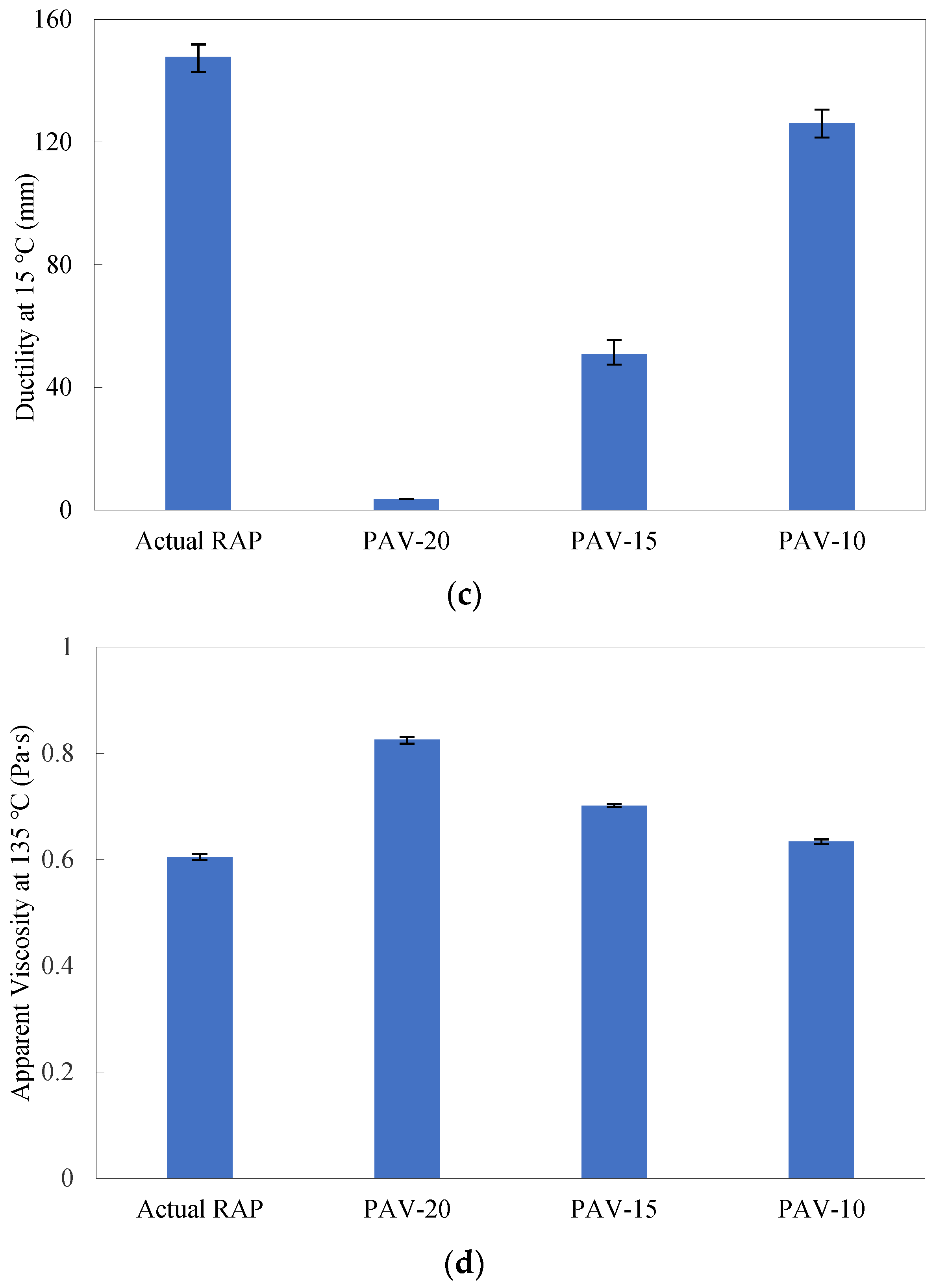

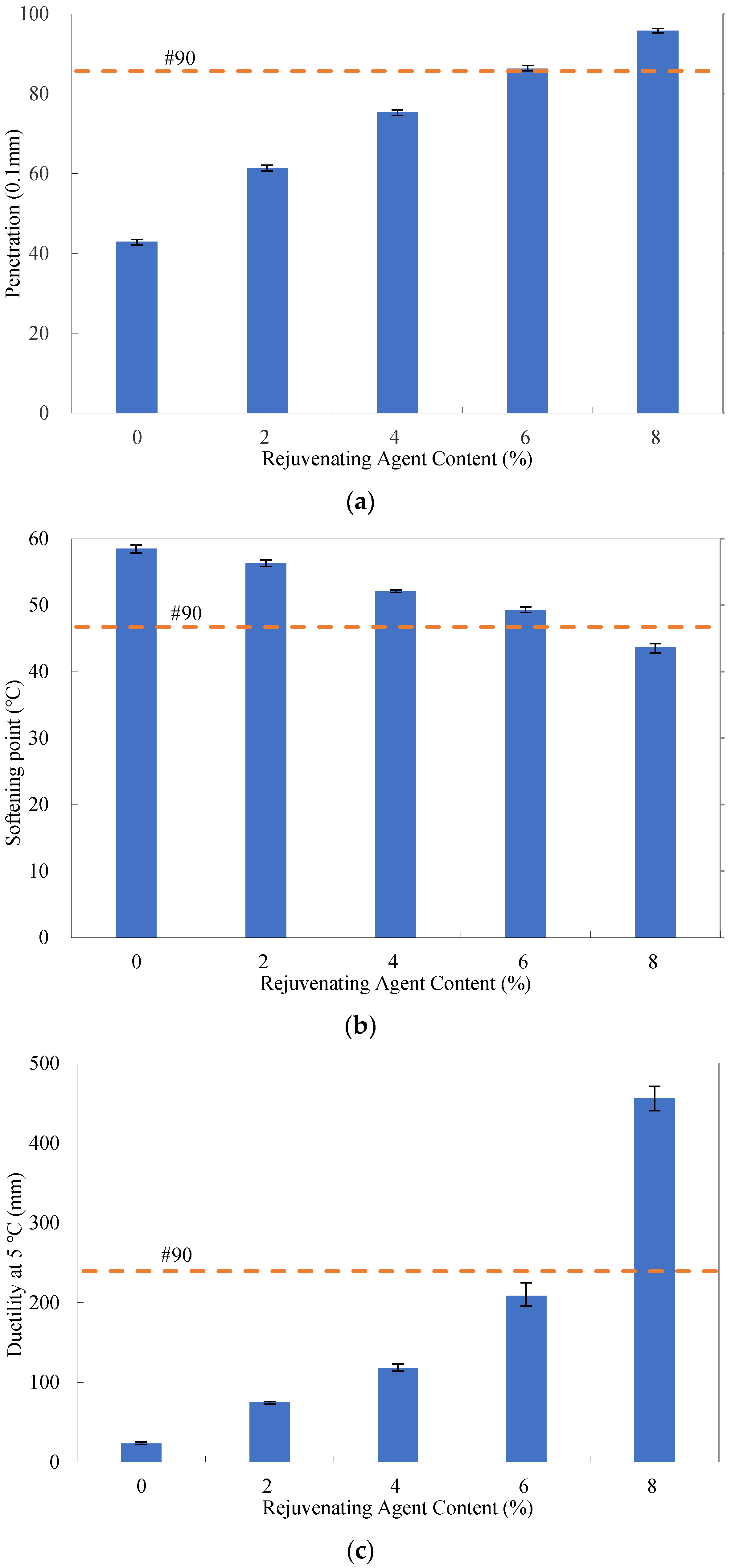

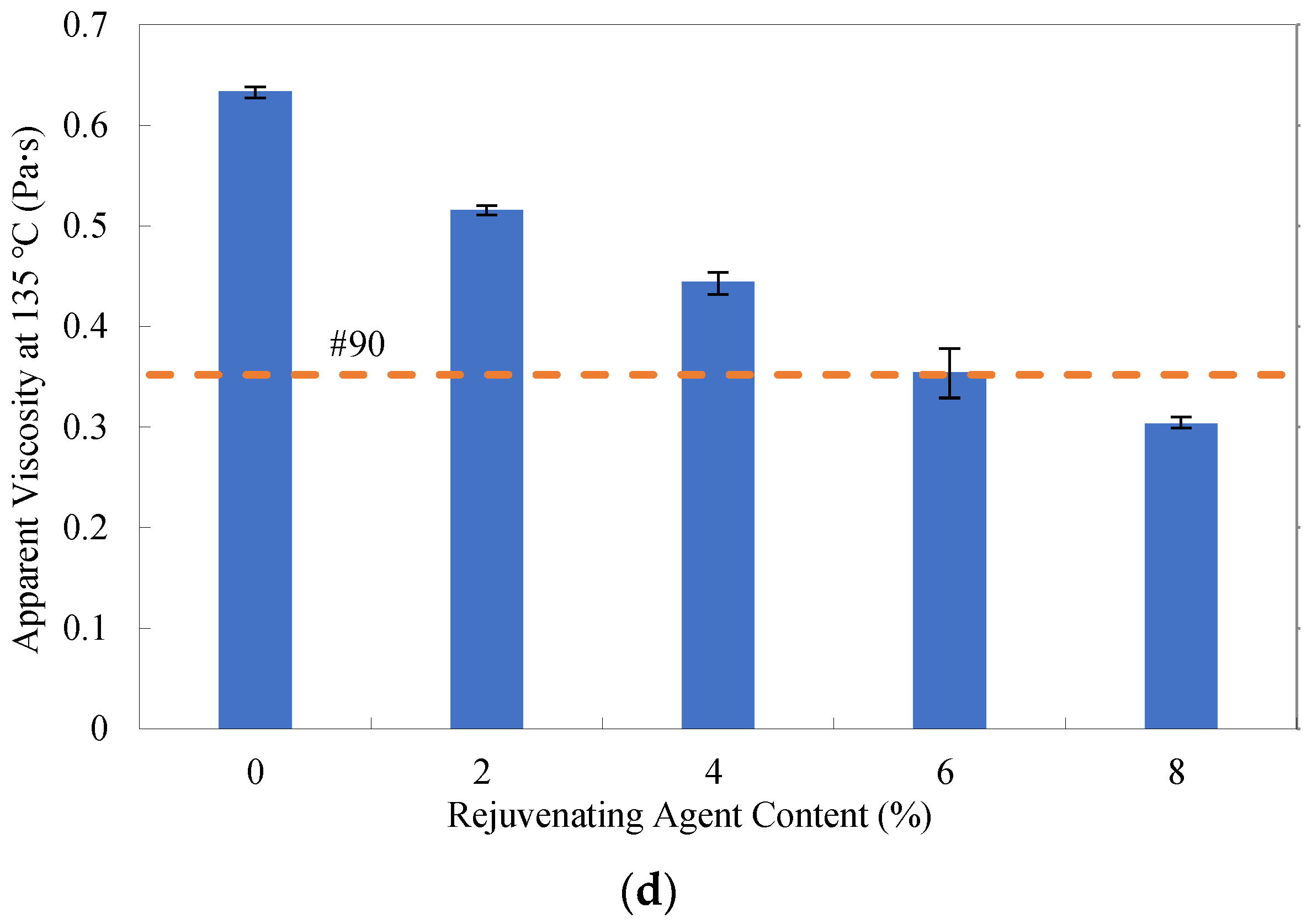

4.2. Determination of Rejuvenating Agent Content

4.3. Analysis of Apparent Viscosity Test Results

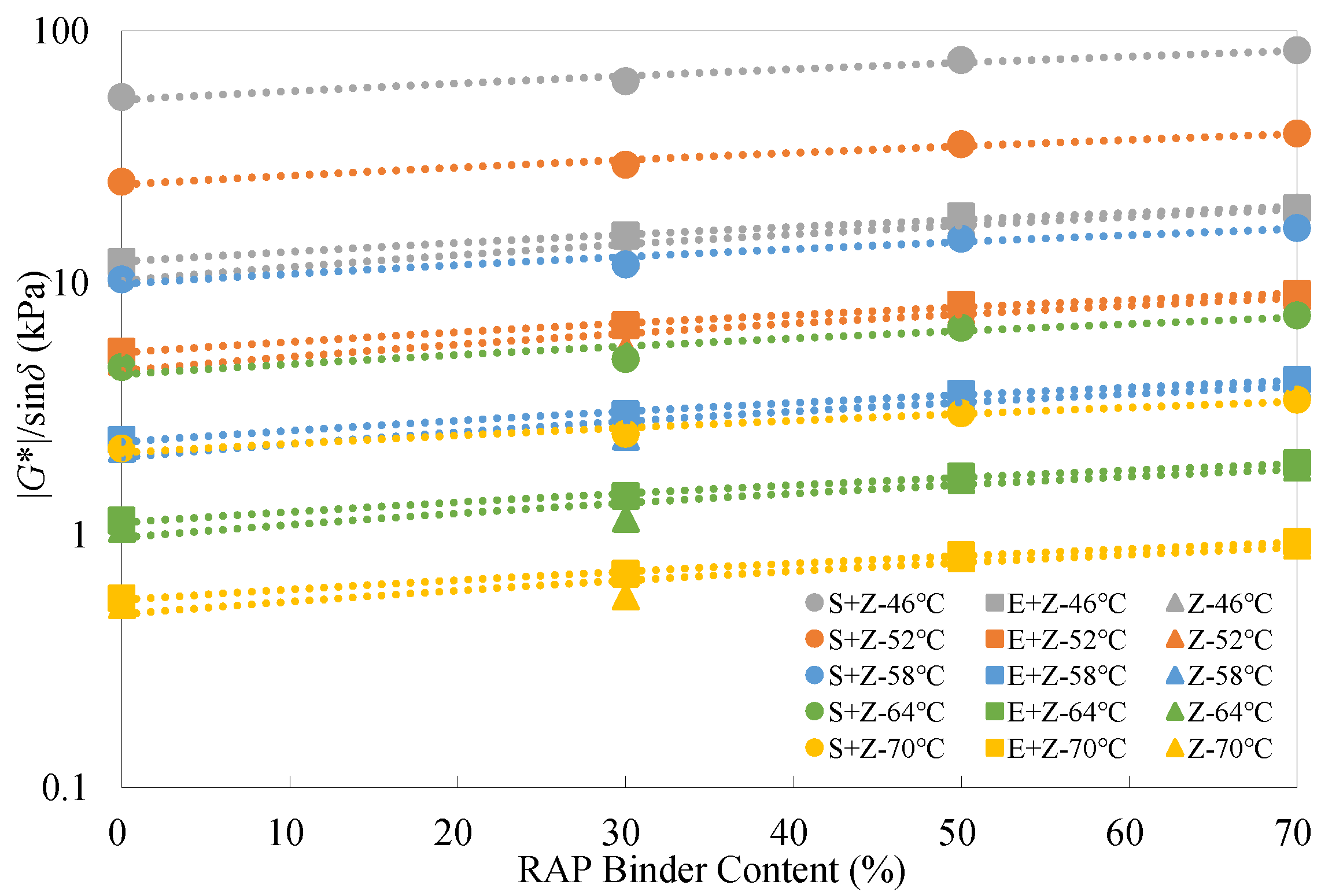

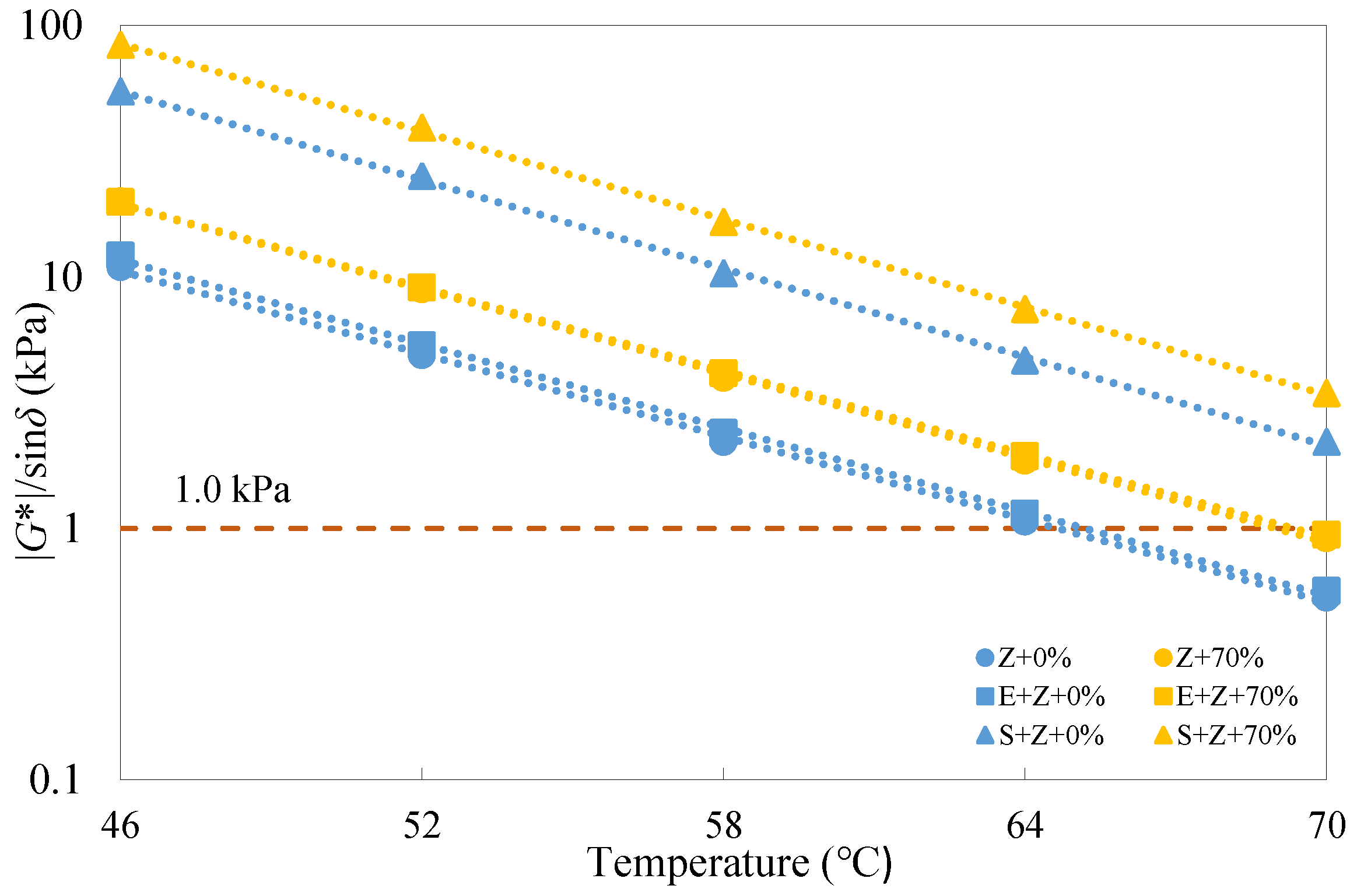

4.4. Analysis of High-Temperature Performance Test Results

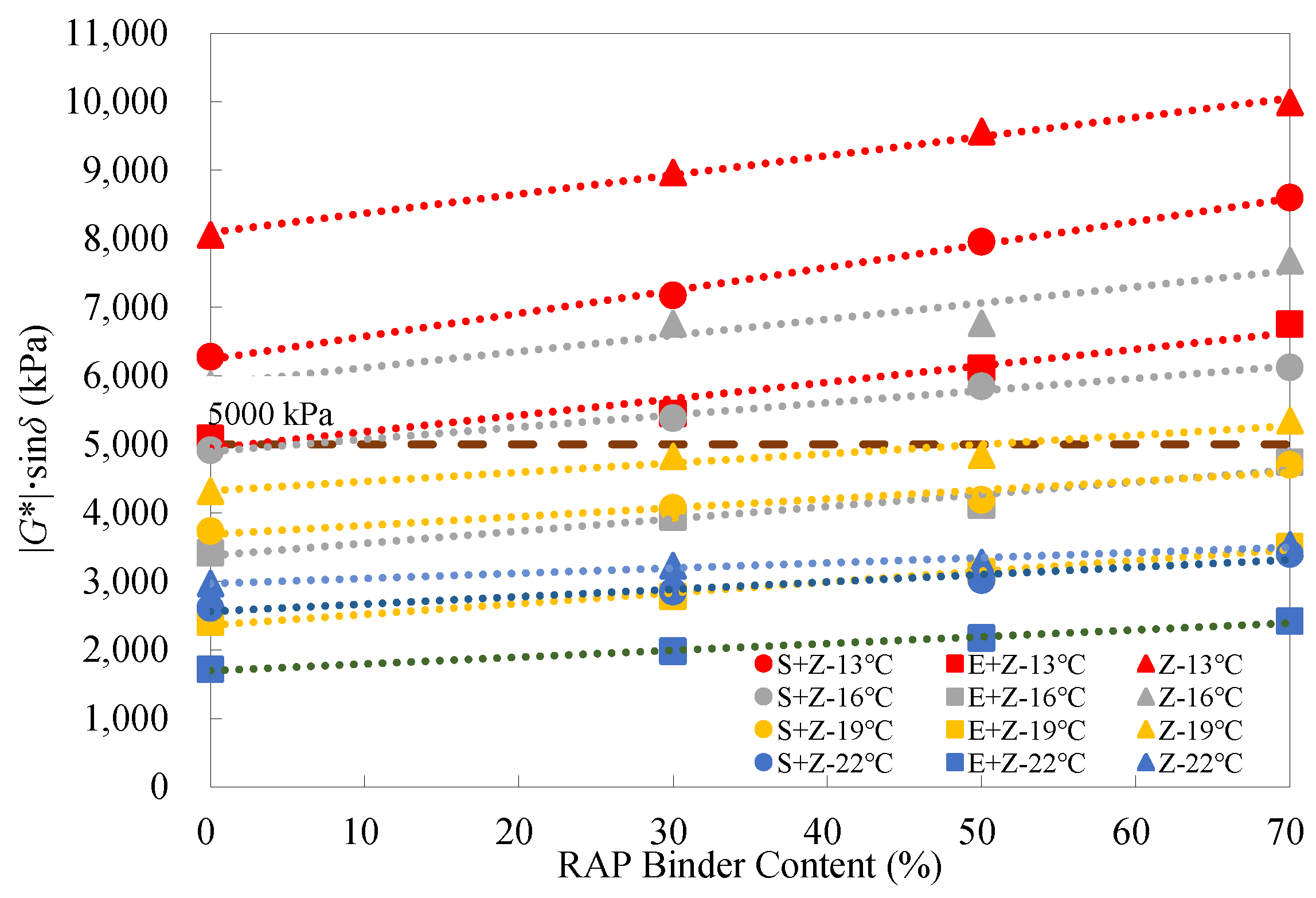

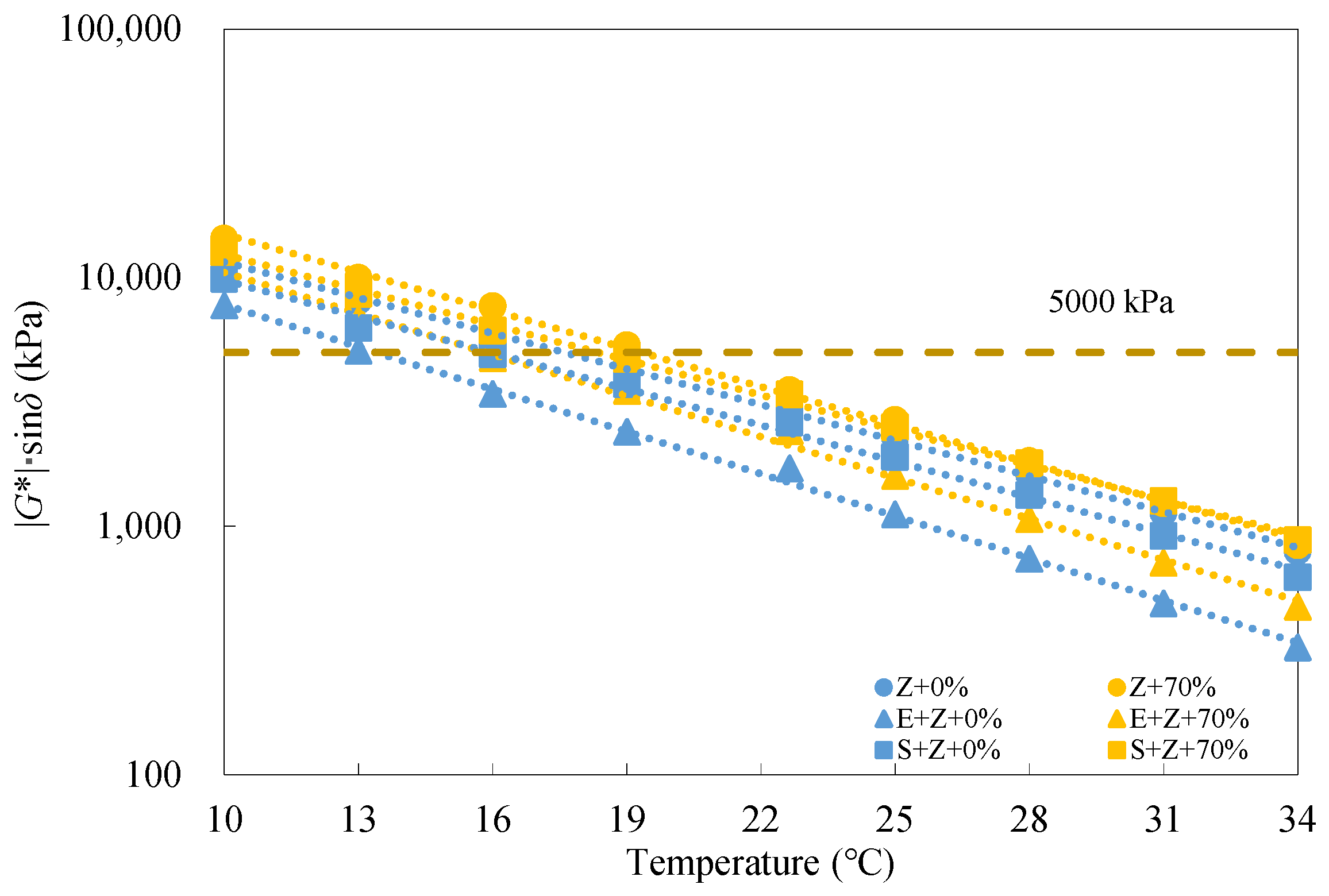

4.5. Analysis of Intermediate-Temperature Performance Test Results

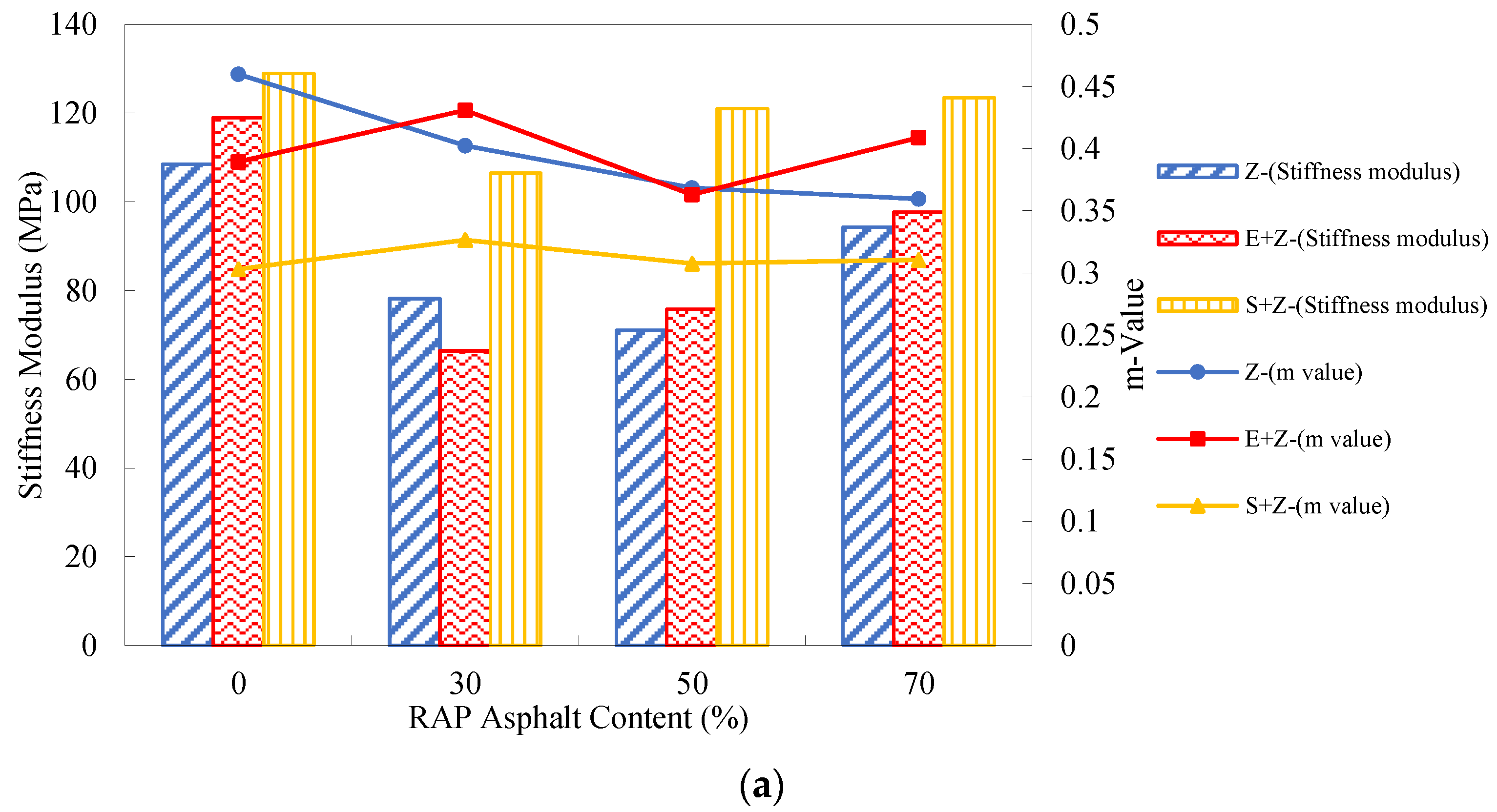

4.6. Analysis of Low-Temperature Performance Test Results

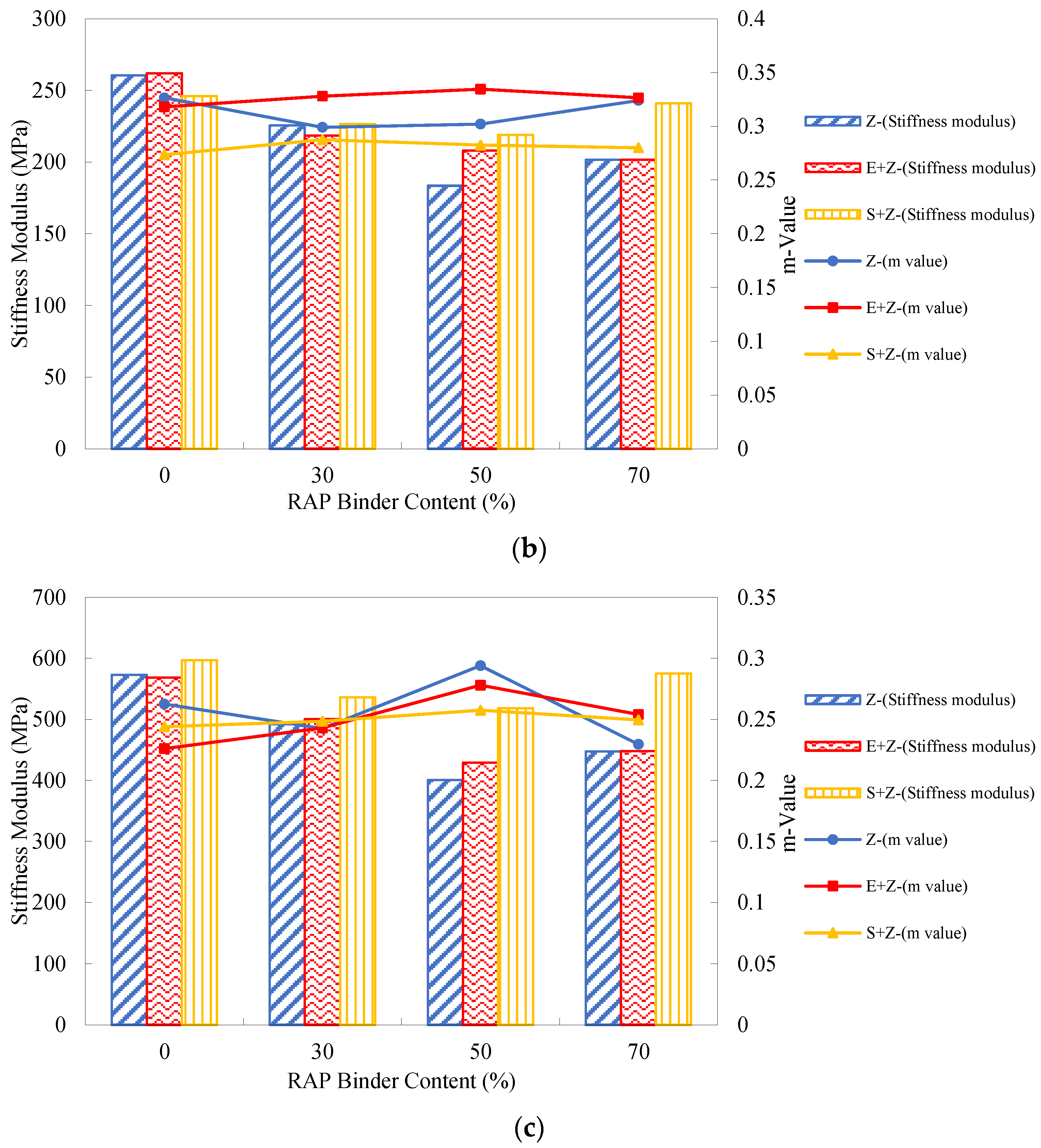

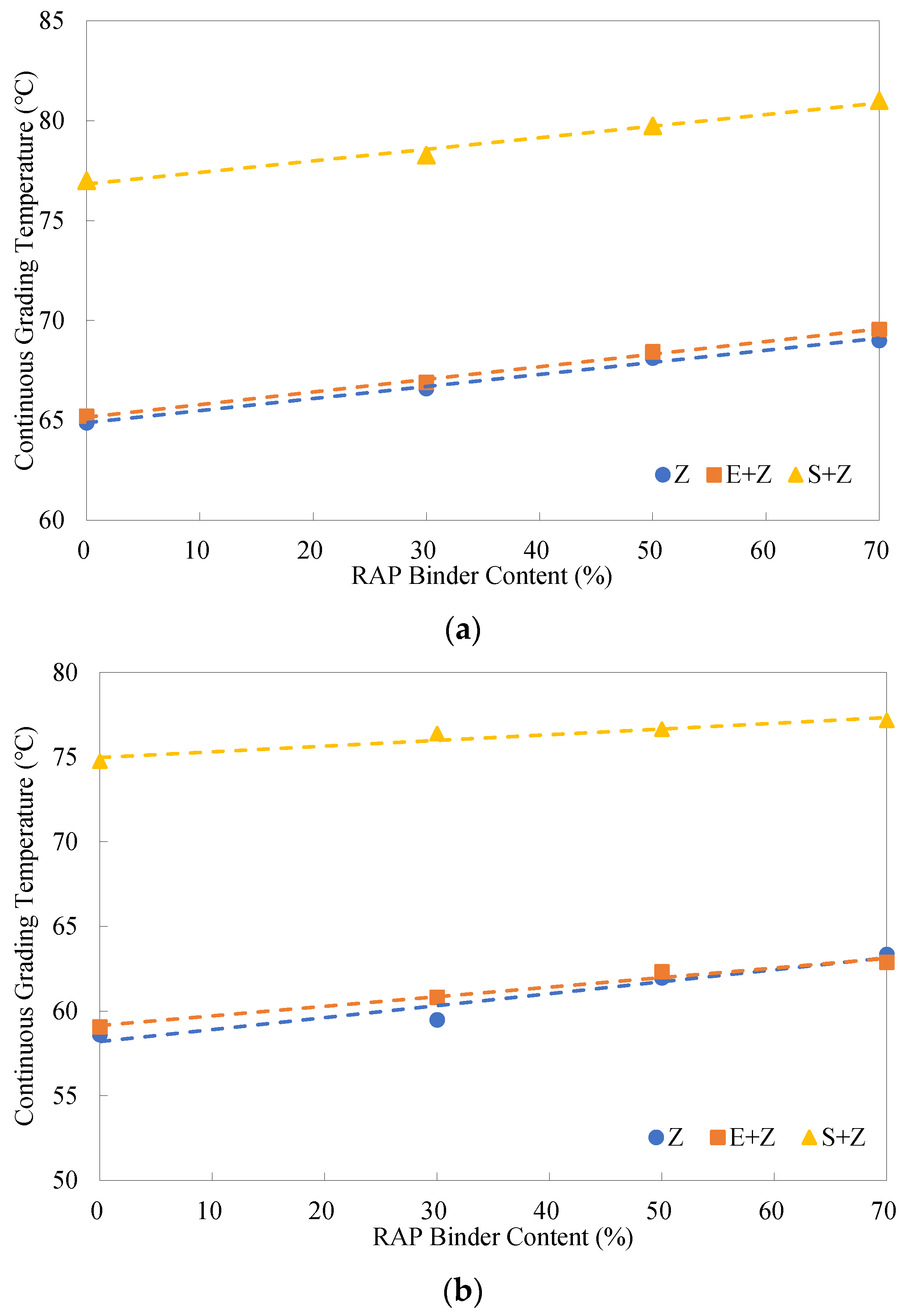

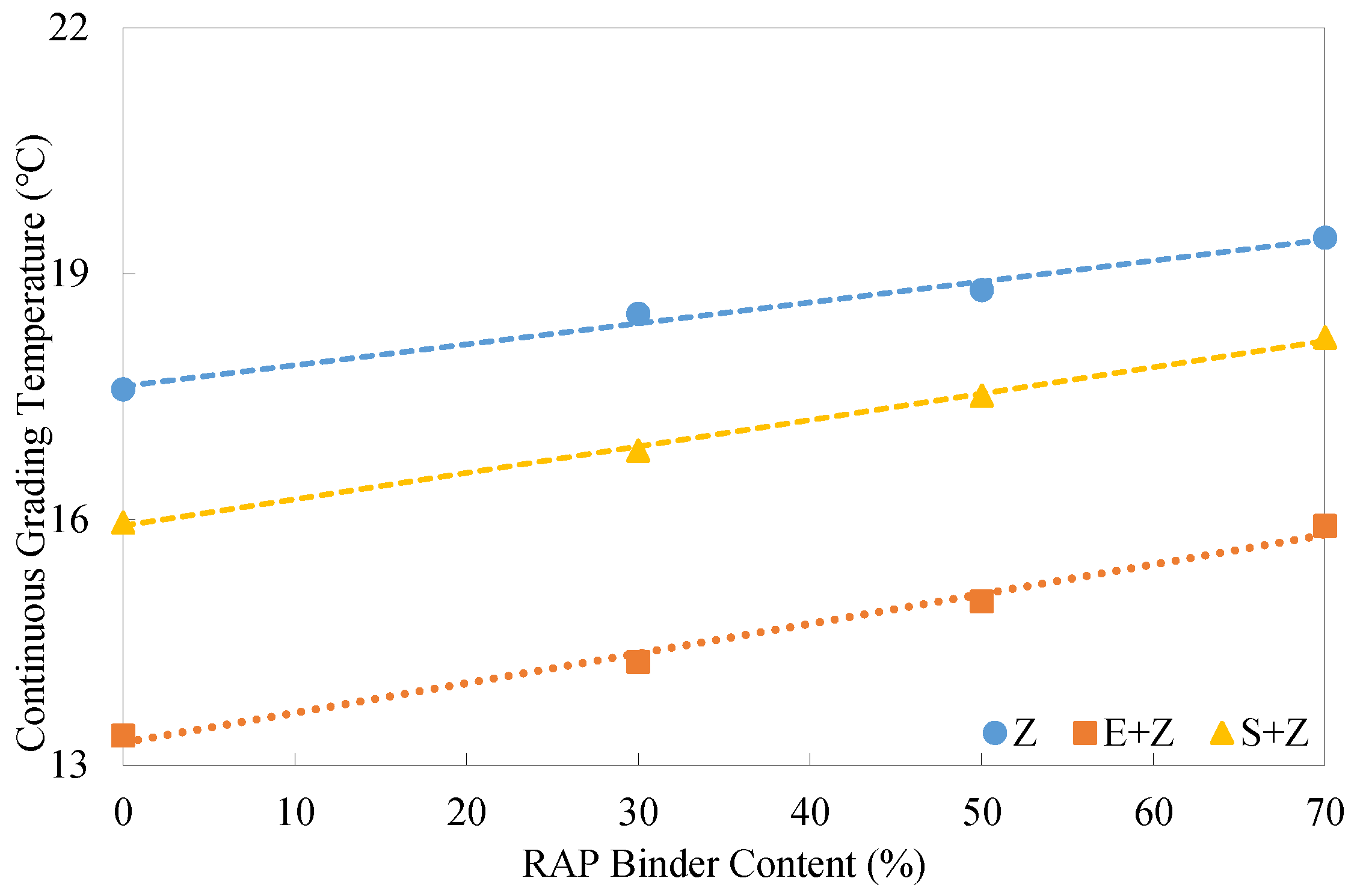

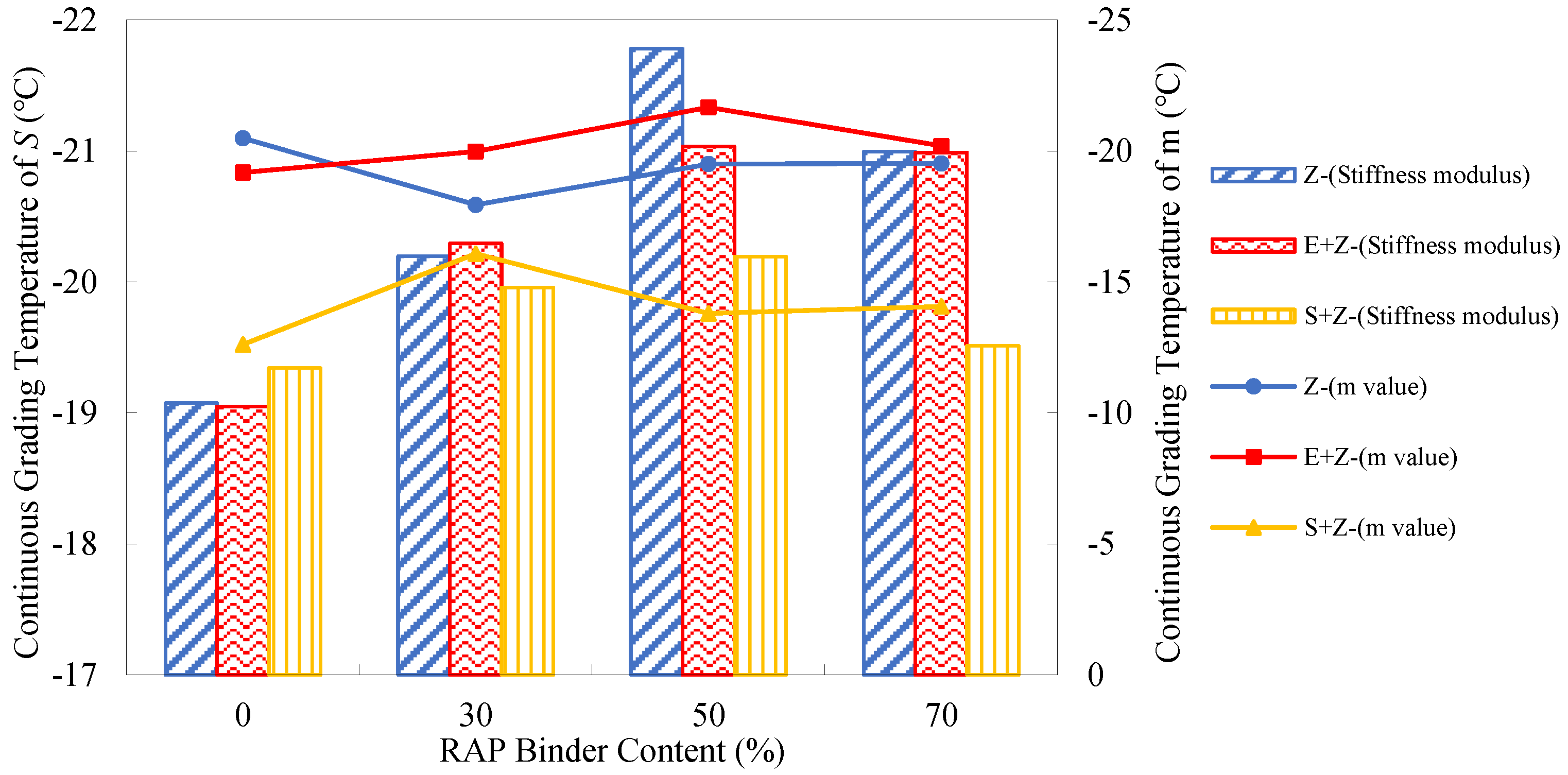

4.7. Analysis of Continuous Grading Temperatures and PG Grades

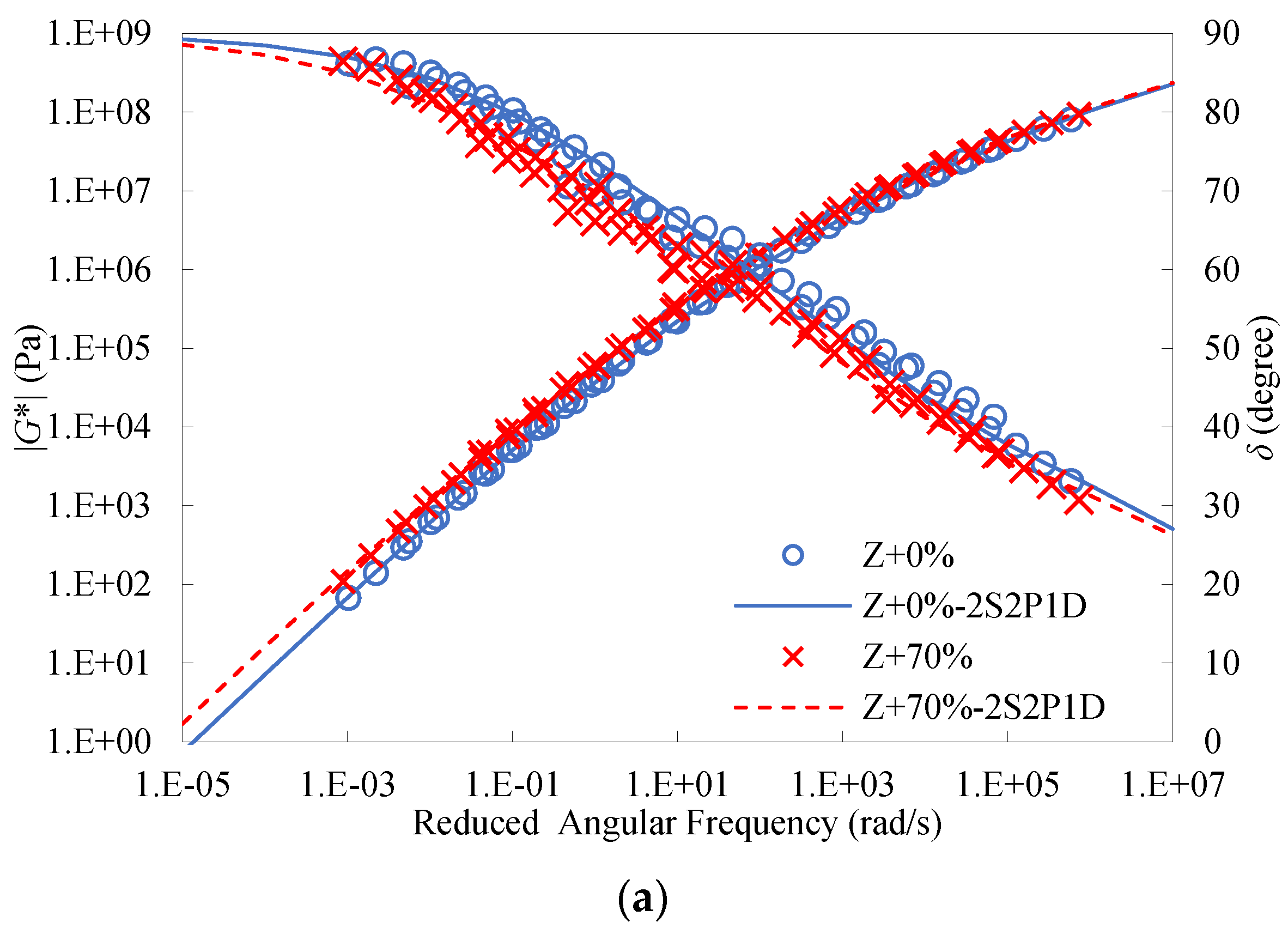

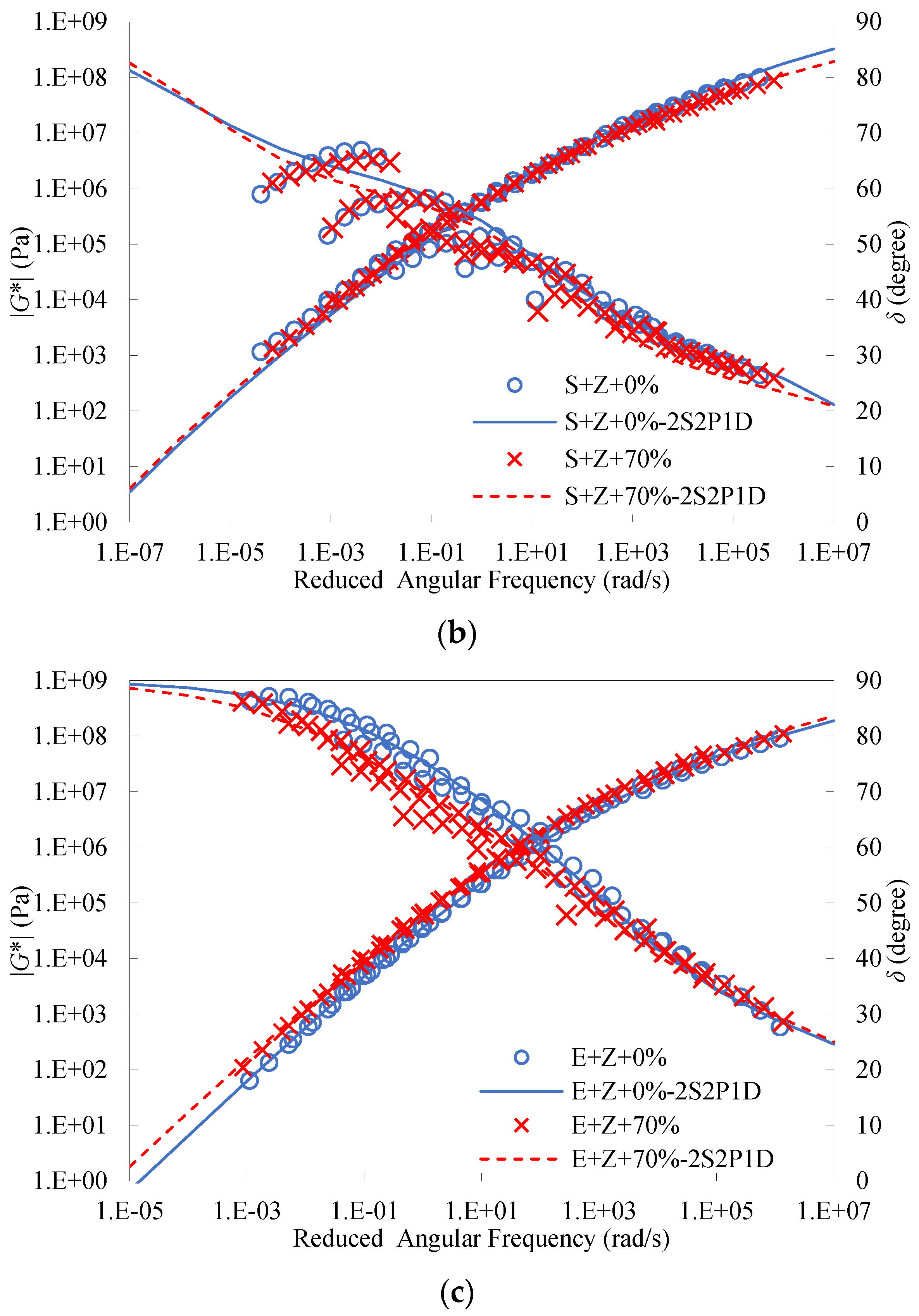

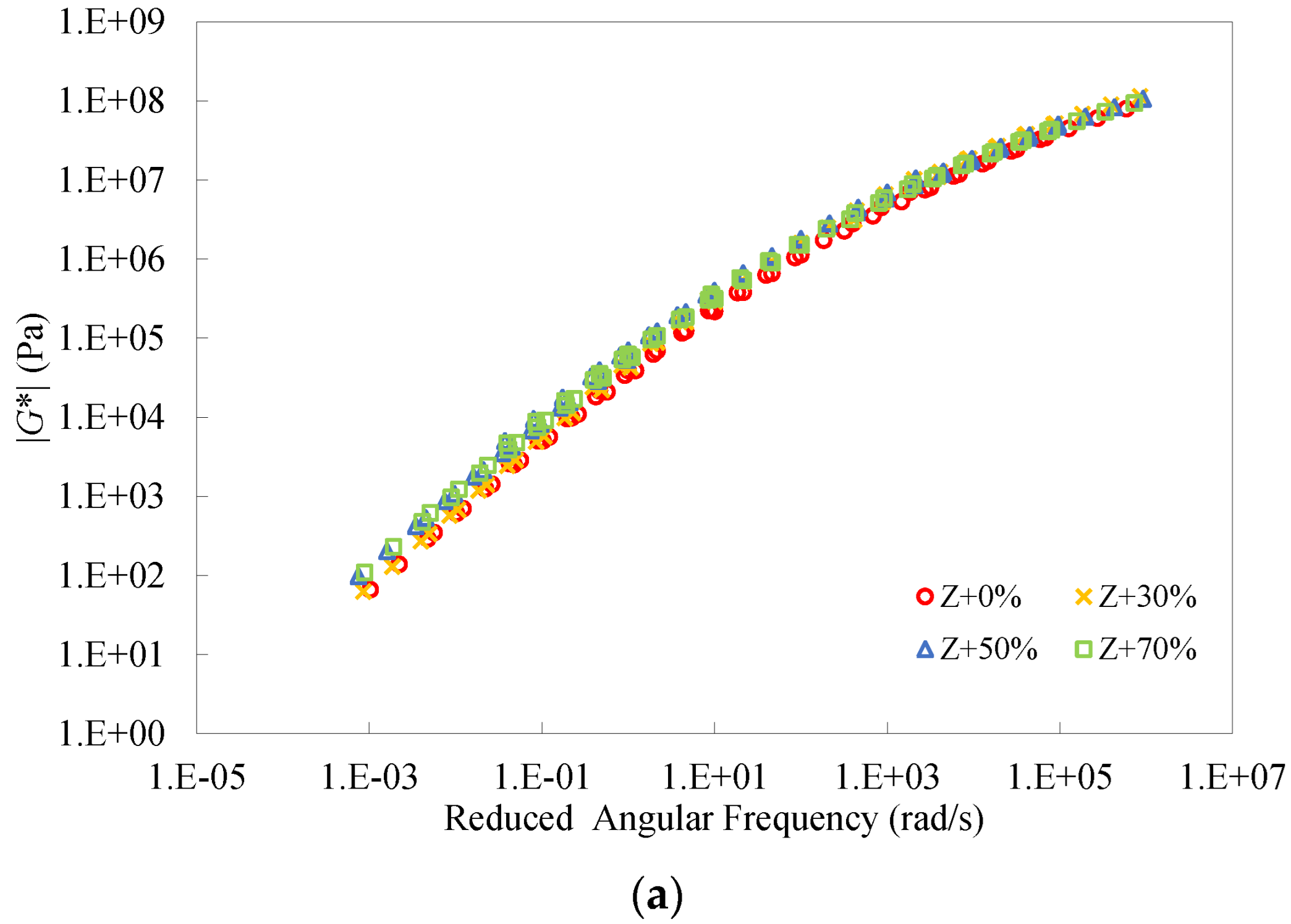

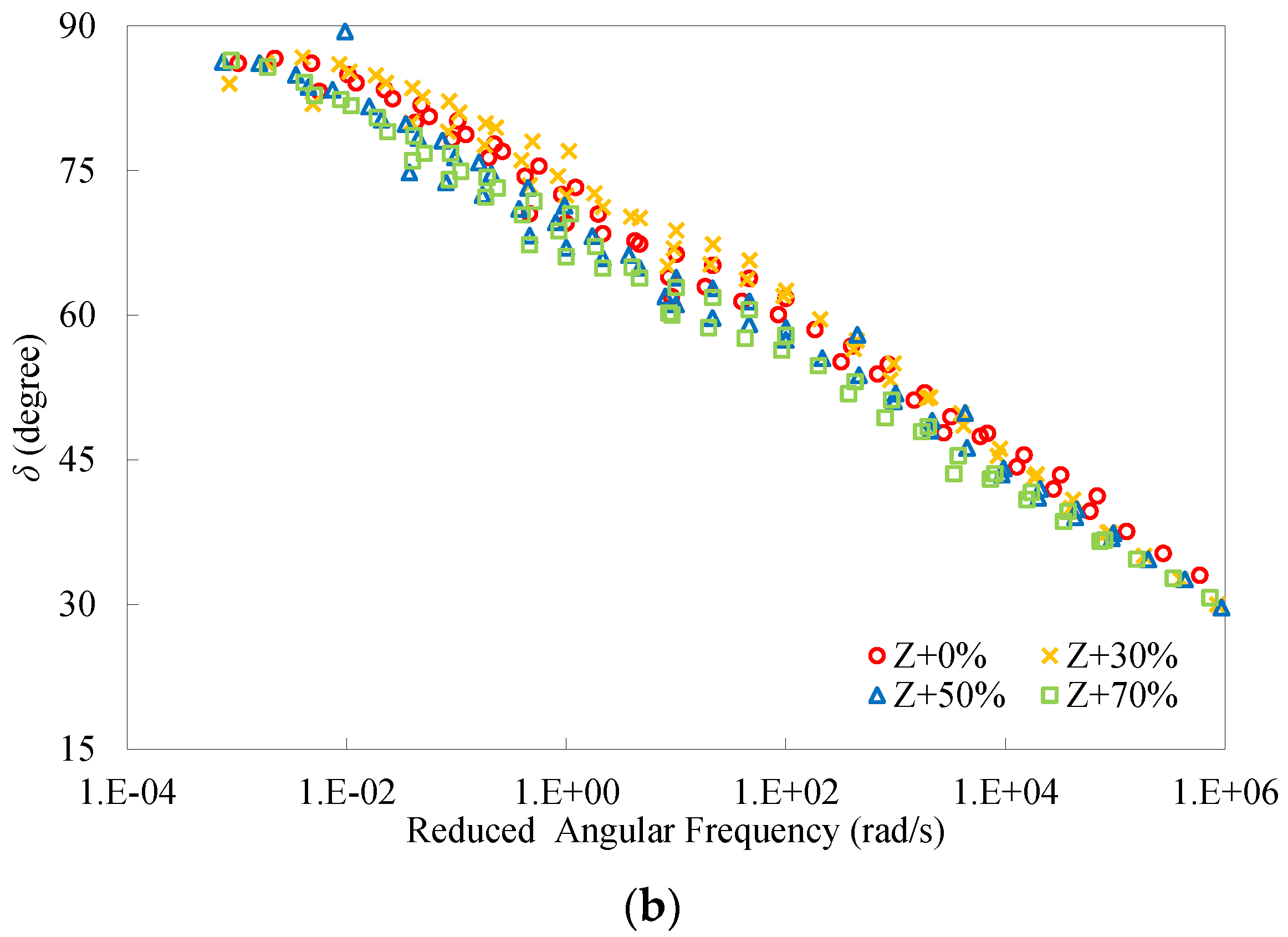

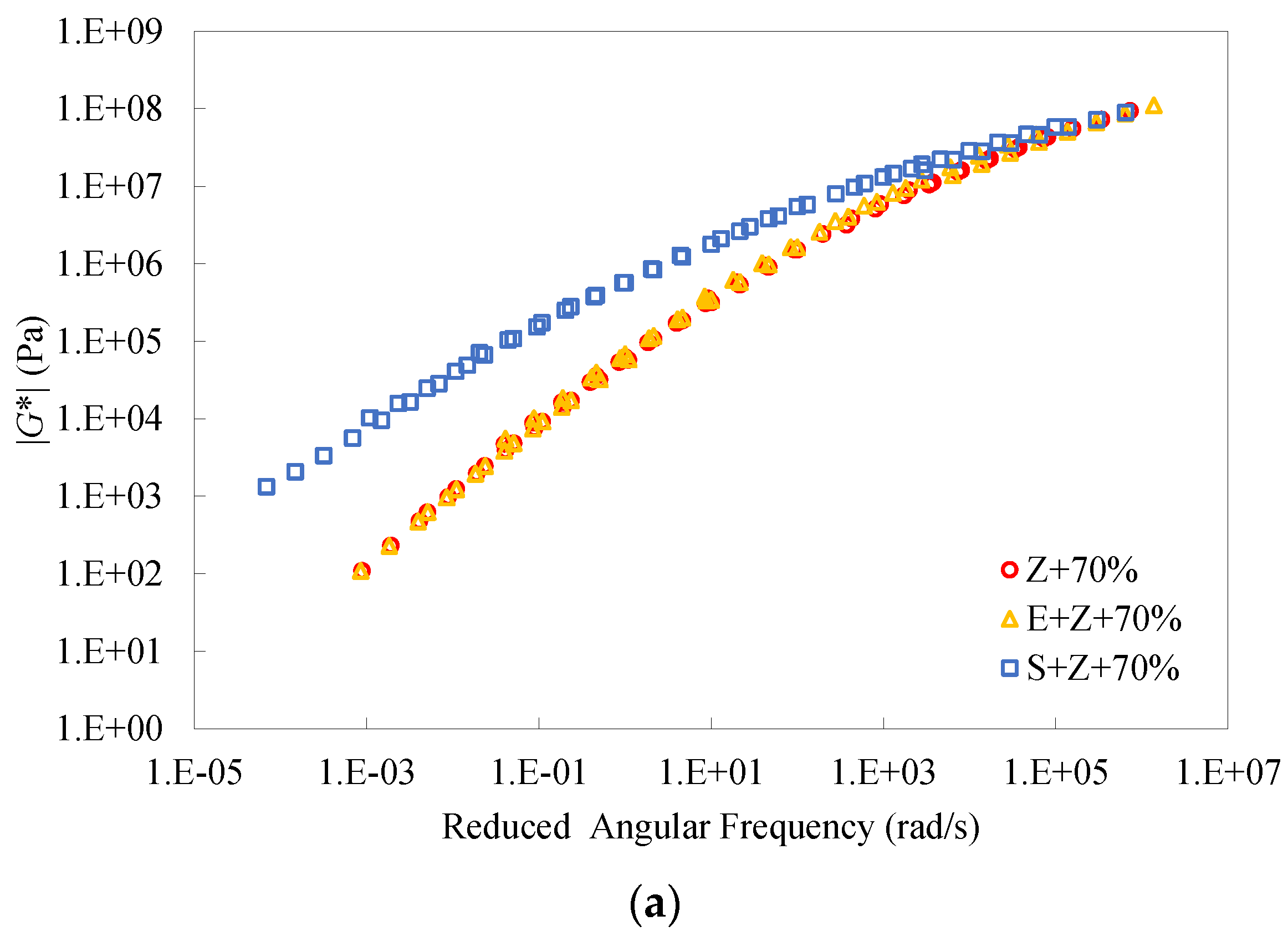

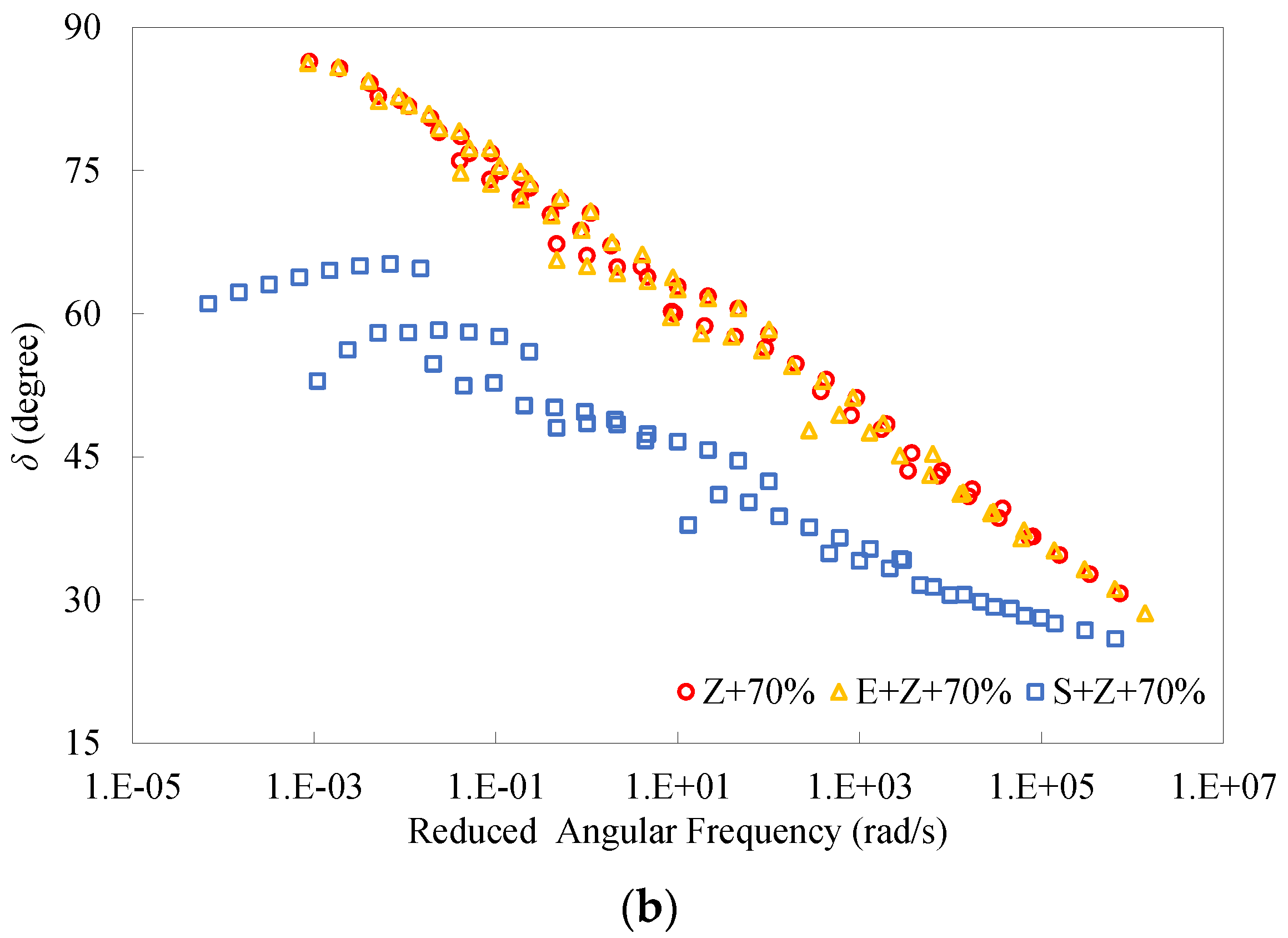

4.8. Analysis of Linear Viscoelastic Master Curves

5. Conclusions

- In terms of the conventional performance tests and the apparent viscosity test, the artificial RAP binder that was obtained by subjecting the virgin binder to successive RTFO aging and PAV aging with a specific exposure duration could achieve similar performance and aging degree to those of the actual one;

- The rejuvenating agent Z could effectively alleviate the aging effect of the RAP binder; however, it was still difficult to completely eliminate this negative impact, in particular at higher RAP binder contents, despite a relatively accurate rejuvenating agent dosage by weight of the RAP binder (6%) used;

- The addition of S remarkably lowered the apparent viscosity of the warm-mix recycled binders (by up to 35.0%), and with the decreasing temperature, this effect of viscosity reduction became more significant (within the range of 115 °C to 175 °C); however, the WMA additive E had little influence (with the reduction of only up to 5.2% in apparent viscosity) on the binder viscosity due to its surfactant nature;

- Under both unaged and RTFO short-term aged conditions, the WMA additive S could considerably enhance the rutting performance (respectively with the increases of up to 399.5% and 411.3% in |G*|/sinδ) due to the wax crystallization in S, whereas E only enhanced the rutting resistance very slightly (respectively with the increases of up to 23.0% and 29.9% in |G*|/sinδ);

- Both S and E were capable of improving the fatigue performance of the recycled binders, but E performed better than S in this aspect (respectively with the reductions of up to 42.3% and 22.1% in|G*|·sinδ);

- The use of S had an adverse impact on the thermal cracking resistance (with an increase of up to 70.2% in Sa and a decrease of up to 34.1% in m-value between −24 °C and −12 °C), but the inclusion of E had a very mild influence on the low-temperature performance of the recycled binders;

- The addition of S broadened the ranges of pavement service temperature by about two PG grades, 12 °C though S lowered the low-temperature performance of the binders (about one PG grade, 6 °C), whereas the use of E almost did not change the PG grades of the binders. Moreover, S could enhance the short-term aging resistance of the binders;

- The inclusion of S considerably improved the dynamic modulus and lowered the phase angle of the binders over a wide range of frequencies and temperatures, indicating the reinforcement effect on the stiffness and the enhancement effect on the elasticity, but E had a very slight influence on the two master curves of the warm-mix recycled binders;

- Due to the thermorheologically complex nature of S, the phase angle test data of the S + Z binders measured at different temperatures were incapable of forming single curves by horizontal shift, which led to the failure of the time-temperature superposition principle and unsatisfactory fitting of the 2S2P1D model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gong, H.; Huang, B.; Shu, X. Field performance evaluation of asphalt mixtures containing high percentage of RAP using LTPP data. Constr. Build. Mater. 2018, 176, 118–128. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, T.; Fan, J.; Fang, Z.; Chen, T.; Zhou, Y. Experimental study of high modulus asphalt mixture containing reclaimed asphalt pavement. J. Clean. Prod. 2020, 263, 121447. [Google Scholar] [CrossRef]

- Behnood, A. Application of rejuvenators to improve the rheological and mechanical properties of asphalt binders and mixtures: A review. J. Clean. Prod. 2019, 231, 171–182. [Google Scholar] [CrossRef]

- Song, W.; Xu, Z.; Xu, F.; Wu, H.; Yin, J. Fracture investigation of asphalt mixtures containing reclaimed asphalt pavement using an equivalent energy approach. Eng. Fract. Mech. 2021, 253, 107892. [Google Scholar] [CrossRef]

- Hettiarachchi, C.; Hou, X.; Xiang, Q.; Yong, D.; Xiao, F. A blending efficiency model for virgin and aged binders in recycled as-phalt mixtures based on blending temperature and duration. Resour. Conserv. Recycl. 2020, 161, 104957. [Google Scholar] [CrossRef]

- McDaniel, R.; Anderson, R. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Method: Technician’s Manual; Transportation Research Broad-National Research Council: Washington, DC, USA, 2001. [Google Scholar]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M. Comparative evaluation of warm mix asphalt containing high percentages of reclaimed asphalt pavement. Constr. Build. Mater. 2013, 44, 92–100. [Google Scholar] [CrossRef]

- Alsalihi, M.; Faheem, A. Compaction and Performance of Warm-Mix Asphalt with High-Reclaimed Asphalt Pavement. J. Mater. Civ. Eng. 2020, 32, 04020055. [Google Scholar] [CrossRef]

- Goli, H.; Latifi, M.; Sadeghian, M. Moisture characteristics of warm mix asphalt containing reclaimed asphalt pavement (RAP) or steel slag. Mater. Struct. 2022, 55, 53. [Google Scholar] [CrossRef]

- Xu, H.; Chen, J.; Sun, Y.; Zhu, X.; Wang, W.; Liu, J. Rheological and physico-chemical properties of warm-mix recycled asphalt mastic containing high percentage of RAP binder. J. Clean. Prod. 2020, 289, 125134. [Google Scholar] [CrossRef]

- Zhu, X.; Sun, Y.; Du, C.; Wang, W.; Liu, J.; Chen, J. Rutting and fatigue performance evaluation of warm mix asphalt mastic containing high percentage of artificial RAP binder. Constr. Build. Mater. 2020, 240, 117860. [Google Scholar] [CrossRef]

- Guo, N.; You, Z.; Tan, Y.; Zhao, Y. Performance evaluation of warm mix asphalt containing reclaimed asphalt mixtures. Int. J. Pavement Eng. 2016, 18, 981–989. [Google Scholar] [CrossRef]

- Behnood, A. A review of the warm mix asphalt (WMA) technologies: Effects on thermo-mechanical and rheological properties. J. Clean. Prod. 2020, 259, 120817. [Google Scholar] [CrossRef]

- Bonaquist, R. Mix Design Practices for Warm Mix Asphalt; Transportation Research Board: Washington, DC, USA, 2011. [Google Scholar]

- Mogawer, W.; Austerman, A.; Mohammad, L.; Kutay, M.E. Evaluation of high RAP-WMA asphalt rubber mixtures. Road Mater. Pavement Des. 2013, 14, 129–147. [Google Scholar] [CrossRef]

- Xiao, F.; Hou, X.; Amirkhanian, S.; Kim, K.W. Superpave evaluation of higher RAP contents using WMA technologies. Constr. Build. Mater. 2016, 112, 1080–1087. [Google Scholar] [CrossRef]

- Song, W.; Huang, B.; Shu, X. Influence of warm-mix asphalt technology and rejuvenator on performance of asphalt mixtures containing 50% reclaimed asphalt pavement. J. Clean. Prod. 2018, 192, 191–198. [Google Scholar] [CrossRef]

- Wang, W.; Cheng, H.; Sun, L.; Sun, Y.; Liu, N. Multi-performance evaluation of recycled warm-mix asphalt mixtures with high reclaimed asphalt pavement contents. J. Clean. Prod. 2022, 377, 134209. [Google Scholar] [CrossRef]

- Xiao, F.; Putman, B.; Amirkhanian, S. Rheological characteristics investigation of high percentage RAP binders with WMA technology at various aging states. Constr. Build. Mater. 2015, 98, 315–324. [Google Scholar] [CrossRef]

- Yu, X.; Dong, F.; Xu, B.; Ding, G.; Ding, P. RAP Binder Influences on the Rheological Characteristics of Foamed Warm-Mix Recy-cled Asphalt. J. Mater. Civ. Eng. 2017, 29, 04017145. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, W.; Chen, J. Investigating impacts of warm-mix asphalt technologies and high reclaimed asphalt pavement binder content on rutting and fatigue performance of asphalt binder through MSCR and LAS tests. J. Clean. Prod. 2019, 219, 879–893. [Google Scholar] [CrossRef]

- ASTM D2872; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D6521; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). ASTM International: West Conshohocken, PA, USA, 2022.

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of Warm Mix Asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D7175; Standard Test Method for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D6648; Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). ASTM International: West Conshohocken, PA, USA, 2016.

- Tschoegl, N. The phenomenological Theory of Linear Viscoelastic Behavior: An Introduction; Springer: New York, NY, USA, 1989. [Google Scholar]

- Ferry, J. Viscoelastic Properties of Polymers; Wiley: New York, NY, USA, 1980. [Google Scholar]

- Olard, F.; Di Benedetto, H. General 2S2P1D Model and Relation Between the Linear Viscoelastic Behaviours of Bituminous Binders and Mixes. Road Mater. Pavement Des. 2003, 4, 185–224. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Y. Fast-Acquiring High-Quality Prony Series Parameters of Asphalt Concrete through Viscoelastic Continuous Spectral Models. Materials 2022, 15, 716. [Google Scholar] [CrossRef] [PubMed]

- ASTM D6373; Standard Specification for Performance Graded Asphalt Binder. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D7643; Standard Practice for Determining the Continuous Grading Temperatures and Continuous Grades for PG Graded Asphalt Binders. ASTM International: West Conshohocken, PA, USA, 2022.

| Binder | Original | RTFO | PAV | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Penetration at 25 °C (0.1 mm) | Softening Point (°C) | Ductility at 15 °C (mm) | Apparent Viscosity at 135 °C (Pa·s) | |G*|/sinδ (58 °C) (kPa) | |G*|/sinδ at 58 °C (kPa) | |G*|·sinδ at 25 °C (kPa) | Sa at −18 °C (MPa) | m-Value at −18 °C | |

| #90 | 85.7 | 46.7 | >1000 | 0.329 | 2.207 | 3.766 | 2278 | 260.5 | 0.324 |

| Actual RAP | 42.1 | 55.1 | 147.8 | 0.605 | 8.13 | − | 1456 | 288.5 | 0.325 |

| Saturates Fraction (%) | Aromatics Fraction (%) | Viscosity by Vacuum Capillary Viscometer at 60 °C (mm2/s) | Density at 15 °C (g/cm3) |

|---|---|---|---|

| 23.9 | 59.9 | 153.5 | 0.987 |

| RAP Binder Content (%) | Percentage Increase (%) | |||||

|---|---|---|---|---|---|---|

| 115 °C | 175 °C | |||||

| Z | E + Z | S + Z | Z | E + Z | S + Z | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 13.5 | 13.2 | 31.1 | 59.7 | 39.7 | 55.4 |

| 50 | 25.7 | 25.4 | 53.9 | 68.1 | 51.3 | 73.8 |

| 70 | 35.4 | 35.3 | 71.2 | 79.2 | 60.3 | 81.5 |

| Binder Type | Percentage Increase (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 115 °C | 175 °C | |||||||

| RAP-0% | RAP-30% | RAP-50% | RAP-70% | RAP-0% | RAP-30% | RAP-50% | RAP-70% | |

| Z | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| E + Z | −0.4 | −0.6 | −0.7 | −0.5 | 8.3 | −5.2 | −2.5 | −3.1 |

| S + Z | −35.0 | −24.9 | −20.4 | −17.9 | −9.7 | −12.1 | −6.6 | −8.5 |

| RAP Binder Content (%) | Percentage Increase (%) | |||||

|---|---|---|---|---|---|---|

| 46 °C | 70 °C | |||||

| Z | E + Z | S + Z | Z | E + Z | S + Z | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 16.8 | 27.2 | 15.5 | 8.1 | 25.2 | 14.3 |

| 50 | 59.4 | 46.1 | 39.8 | 53.4 | 37.7 | 37.9 |

| 70 | 82.1 | 63.7 | 53.0 | 72.3 | 67.5 | 56.2 |

| Binder Type | Percentage Increase (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 46 °C | 70 °C | |||||||

| RAP-0% | RAP-30% | RAP-50% | RAP-70% | RAP-0% | RAP-30% | RAP-50% | RAP-70% | |

| Z | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| E + Z | 10.8 | 20.6 | 1.5 | −0.4 | 6.2 | 23.0 | −4.7 | 3.3 |

| S + Z | 399.5 | 393.9 | 338.3 | 319.7 | 317.0 | 340.8 | 274.8 | 278.0 |

| RAP Binder Content (%) | Percentage Increase (%) | |||||

|---|---|---|---|---|---|---|

| 46 °C | 70 °C | |||||

| Z | E + Z | S + Z | Z | E + Z | S + Z | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 8.1 | 16.4 | 6.5 | 20.8 | 24.9 | 18.5 |

| 50 | 25.9 | 32.5 | 10.6 | 38.9 | 42.6 | 22.9 |

| 70 | 46.6 | 52.5 | 17.2 | 68.8 | 71.6 | 24.5 |

| Binder Type | Percentage Increase (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 46 °C | 70 °C | |||||||

| RAP-0% | RAP-30% | RAP-50% | RAP-70% | RAP-0% | RAP-30% | RAP-50% | RAP-70% | |

| Z | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| E + Z | 20.6 | 29.9 | 26.8 | 25.4 | 21.9 | 26.0 | 25.2 | 23.9 |

| S + Z | 411.3 | 403.8 | 349.1 | 308.9 | 335.3 | 327.1 | 285.2 | 221.0 |

| RAP Binder Content (%) | Percentage Increase (%) | |||||

|---|---|---|---|---|---|---|

| 13 °C | 22 °C | |||||

| Z | E + Z | S + Z | Z | E + Z | S + Z | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | 8.2 | 11.7 | 14.2 | 8.8 | 15.5 | 9.1 |

| 50 | 13.5 | 24.9 | 26.7 | 10.4 | 26.8 | 15.5 |

| 70 | 23.4 | 33.8 | 37.0 | 19.0 | 41.1 | 30.1 |

| Binder Type | Percentage Increase (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 13 °C | 22 °C | |||||||

| RAP-0% | RAP-30% | RAP-50% | RAP-70% | RAP-0% | RAP-30% | RAP-50% | RAP-70% | |

| Z | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| E + Z | −36.9 | −39.3 | −36.2 | −32.4 | −42.3 | −38.8 | −33.8 | −31.7 |

| S + Z | −22.1 | −20.0 | −16.9 | −13.9 | −12.1 | −11.9 | −8.0 | −3.9 |

| Quantity | RAP Binder Content (%) | Percentage Increase (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| −24 °C | −18 °C | −12 °C | ||||||||

| Z | E + Z | S + Z | Z | E + Z | S + Z | Z | E + Z | S + Z | ||

| Sa | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | −14.1 | −12 | −10.2 | −13.4 | −16.6 | −7.9 | −27.9 | −44.2 | −17.4 | |

| 50 | −30.1 | −24.5 | −13.2 | −29.6 | −20.6 | −11 | −34.5 | −36.3 | −6.2 | |

| 70 | −21.9 | −21.2 | −3.7 | −22.6 | −23.1 | −2 | −13.1 | −17.9 | −4.3 | |

| m-value | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 30 | −7.6 | 7.5 | 1.8 | −8.4 | 3.1 | 5.1 | −12.5 | 10.7 | 7.8 | |

| 50 | 12 | 23 | 5.5 | −7.5 | 5.2 | 3.3 | −19.9 | −6.8 | 1.5 | |

| 70 | −12.6 | 12.4 | 2.3 | −0.8 | 2.7 | 2.4 | −21.8 | 5 | 2.5 | |

| Quantity | Binder Type | Percentage Increase (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| −24 °C | −18 °C | −12 °C | |||||||||||

| RAP-0% | RAP-30% | RAP-50% | RAP-70% | RAP-0% | RAP-30% | RAP-50% | RAP-70% | RAP-0% | RAP-30% | RAP-50% | RAP-70% | ||

| Sa | Z | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| E + Z | −0.8 | 1.7 | 7.1 | 0.1 | 0.6 | −3.1 | 13.4 | 0 | 9.7 | −15.1 | 6.7 | 3.6 | |

| S + Z | 4.2 | 8.9 | 29.3 | 28.5 | −5.6 | 0.4 | 19.3 | 19.6 | 18.9 | 36.2 | 70.2 | 31 | |

| m-value | Z | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| E + Z | −13.9 | 0.2 | −5.4 | 10.7 | −2.6 | 9.7 | 10.8 | 0.8 | −15.3 | 7.1 | −1.5 | 13.8 | |

| S + Z | −7 | 2.5 | −12.4 | 8.7 | −16.2 | −3.8 | −6.5 | −13.6 | −34.1 | −18.9 | −16.6 | −13.6 | |

| Binder | PG High (Original) | PG High (RFTO) | PG Intermediate (RTFO + PAV) | PG Low (RTFO + PAV) | PG Grade |

|---|---|---|---|---|---|

| S + Z + 0% | 76 | 70 | 16 | −12 | 70–22 |

| S + Z + 30% | 76 | 76 | 19 | −12 | 76–22 |

| S + Z + 50% | 76 | 76 | 19 | −12 | 76–22 |

| S + Z + 70% | 76 | 76 | 19 | −12 | 76–22 |

| E + Z + 0% | 64 | 58 | 16 | −18 | 58–28 |

| E + Z + 30% | 64 | 58 | 16 | −18 | 58–28 |

| E + Z + 50% | 64 | 58 | 16 | −18 | 58–28 |

| E + Z + 70% | 64 | 58 | 19 | −18 | 58–28 |

| Z + 0% | 64 | 58 | 19 | −18 | 58–28 |

| Z + 30% | 64 | 58 | 19 | −12 | 58–22 |

| Z + 50% | 64 | 58 | 19 | −18 | 58–28 |

| Z + 70% | 64 | 58 | 22 | −18 | 58–28 |

| Sample | α | k | h | β | τ0 (s) | f (%) |

|---|---|---|---|---|---|---|

| Actual RAP | 8.22 | 0.33 | 0.68 | 9.20 × 101 | 4.18 × 10−6 | 1.92 |

| Pav-10 | 4.46 | 0.21 | 0.56 | 2.12 × 103 | 2.28 × 10−7 | 3.68 |

| Z + 0% | 7.50 | 0.36 | 0.69 | 8.37 × 101 | 8.98 × 10−7 | 1.37 |

| Z + 30% | 6.78 | 0.35 | 0.70 | 4.87 × 101 | 1.75 × 10−6 | 1.77 |

| Z + 50% | 8.87 | 0.37 | 0.71 | 6.58 × 101 | 2.63 × 10−6 | 1.63 |

| Z + 70% | 9.21 | 0.36 | 0.70 | 1.01 × 102 | 1.75 × 10−6 | 1.01 |

| E + Z + 0% | 8.69 | 0.32 | 0.69 | 6.97 × 101 | 9.76 × 10−7 | 1.31 |

| E + Z + 30% | 9.47 | 0.33 | 0.69 | 9.36 × 101 | 9.31 × 10−7 | 1.46 |

| E + Z + 50% | 9.36 | 0.35 | 0.70 | 8.70 × 101 | 1.75 × 10−6 | 1.39 |

| E + Z + 70% | 8.93 | 0.34 | 0.69 | 1.08 × 102 | 1.75 × 10−6 | 1.70 |

| S + Z + 0% | 14.19 | 0.34 | 0.69 | 1.84 × 103 | 2.68 × 10−5 | 4.00 |

| S + Z + 30% | 14.16 | 0.31 | 0.67 | 3.22 × 103 | 2.22 × 10−5 | 3.78 |

| S + Z + 50% | 23.46 | 0.31 | 0.70 | 8.36 × 102 | 3.86 × 10−5 | 3.21 |

| S + Z + 70% | 16.19 | 0.28 | 0.65 | 4.39 × 103 | 1.18 × 10−5 | 3.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Sun, Y.; Chen, J.; Li, J.; Yu, B.; Qiu, G.; Zhang, Y.; Xu, B. Investigation into Rheological Behavior of Warm-Mix Recycled Asphalt Binders with High Percentages of RAP Binder. Materials 2023, 16, 1599. https://doi.org/10.3390/ma16041599

Xu H, Sun Y, Chen J, Li J, Yu B, Qiu G, Zhang Y, Xu B. Investigation into Rheological Behavior of Warm-Mix Recycled Asphalt Binders with High Percentages of RAP Binder. Materials. 2023; 16(4):1599. https://doi.org/10.3390/ma16041599

Chicago/Turabian StyleXu, Hui, Yiren Sun, Jingyun Chen, Jiyang Li, Bowen Yu, Guoqing Qiu, Yan Zhang, and Bin Xu. 2023. "Investigation into Rheological Behavior of Warm-Mix Recycled Asphalt Binders with High Percentages of RAP Binder" Materials 16, no. 4: 1599. https://doi.org/10.3390/ma16041599

APA StyleXu, H., Sun, Y., Chen, J., Li, J., Yu, B., Qiu, G., Zhang, Y., & Xu, B. (2023). Investigation into Rheological Behavior of Warm-Mix Recycled Asphalt Binders with High Percentages of RAP Binder. Materials, 16(4), 1599. https://doi.org/10.3390/ma16041599