X-ray Tomographic Method to Study the Internal Structure of a TiNi–TiB2 Metal Matrix Composite Obtained by Direct Laser Deposition

Abstract

1. Introduction

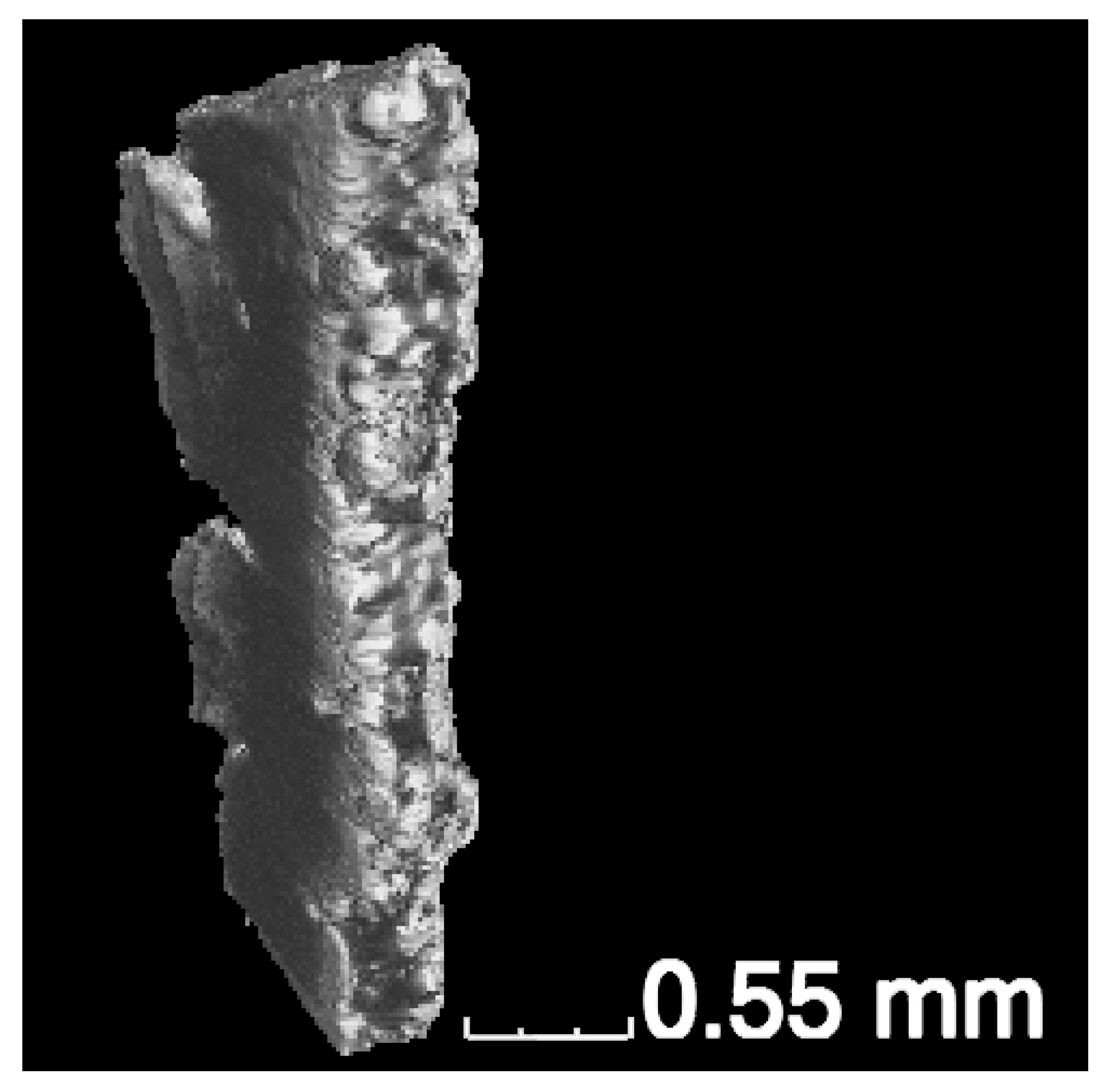

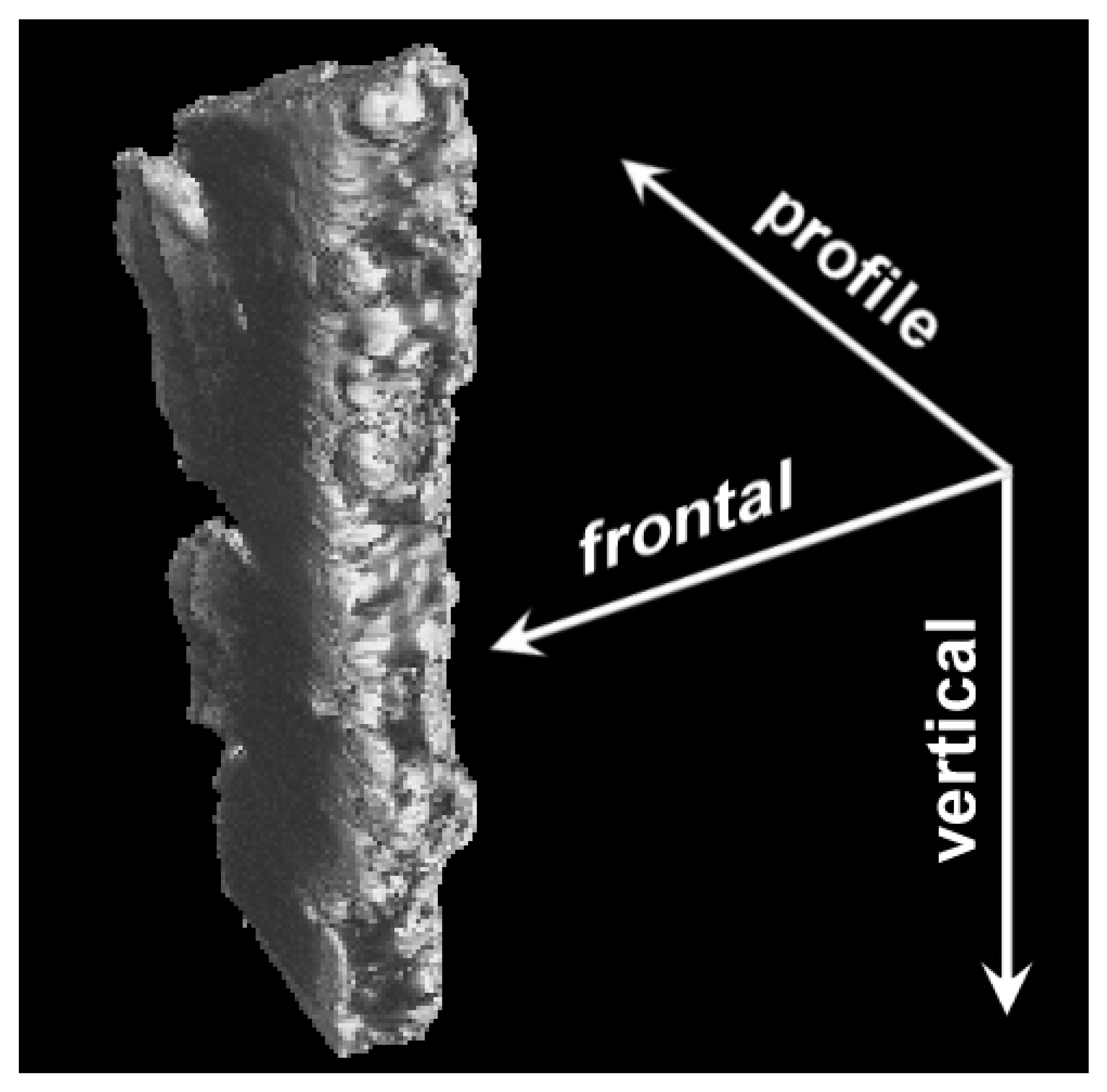

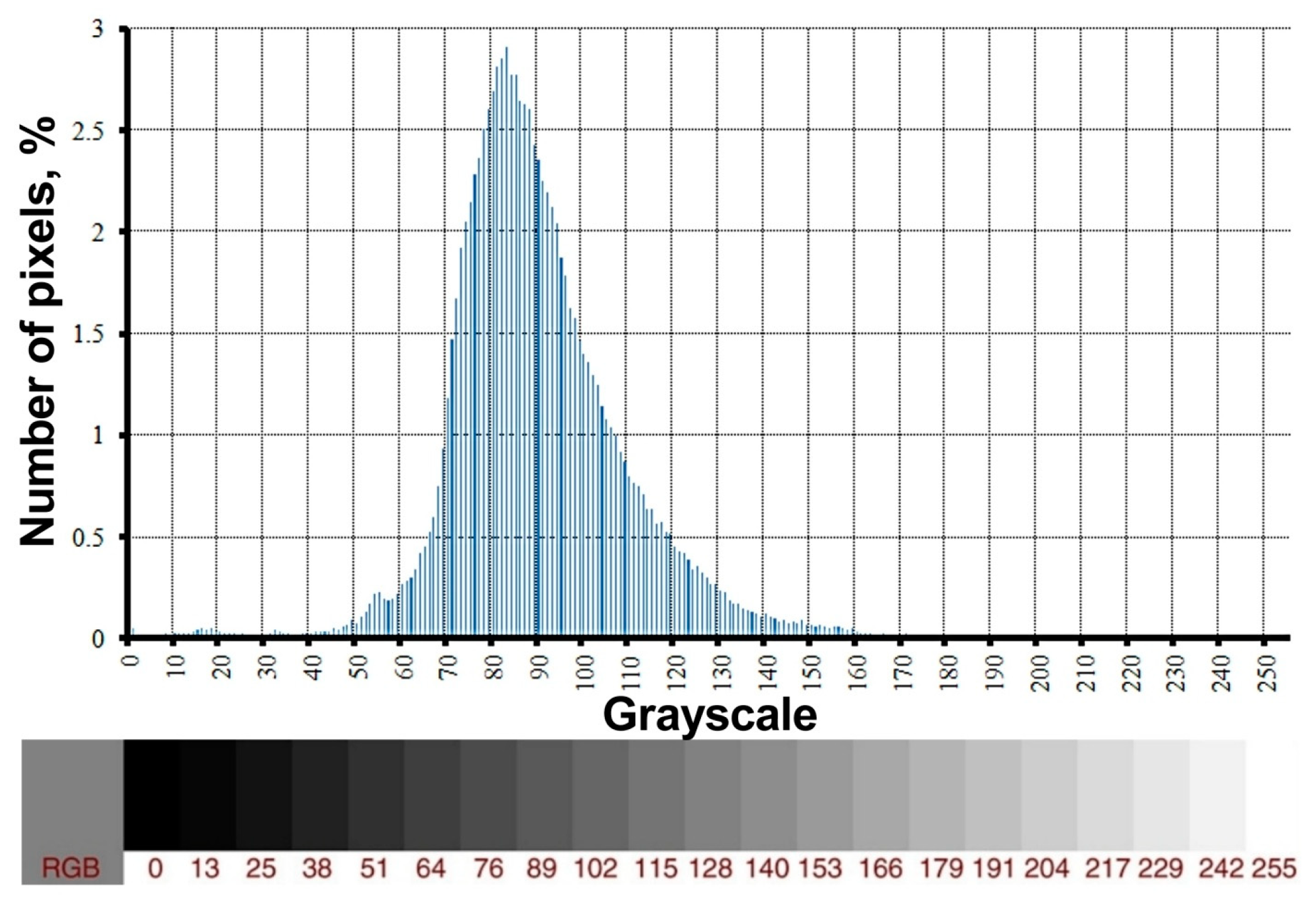

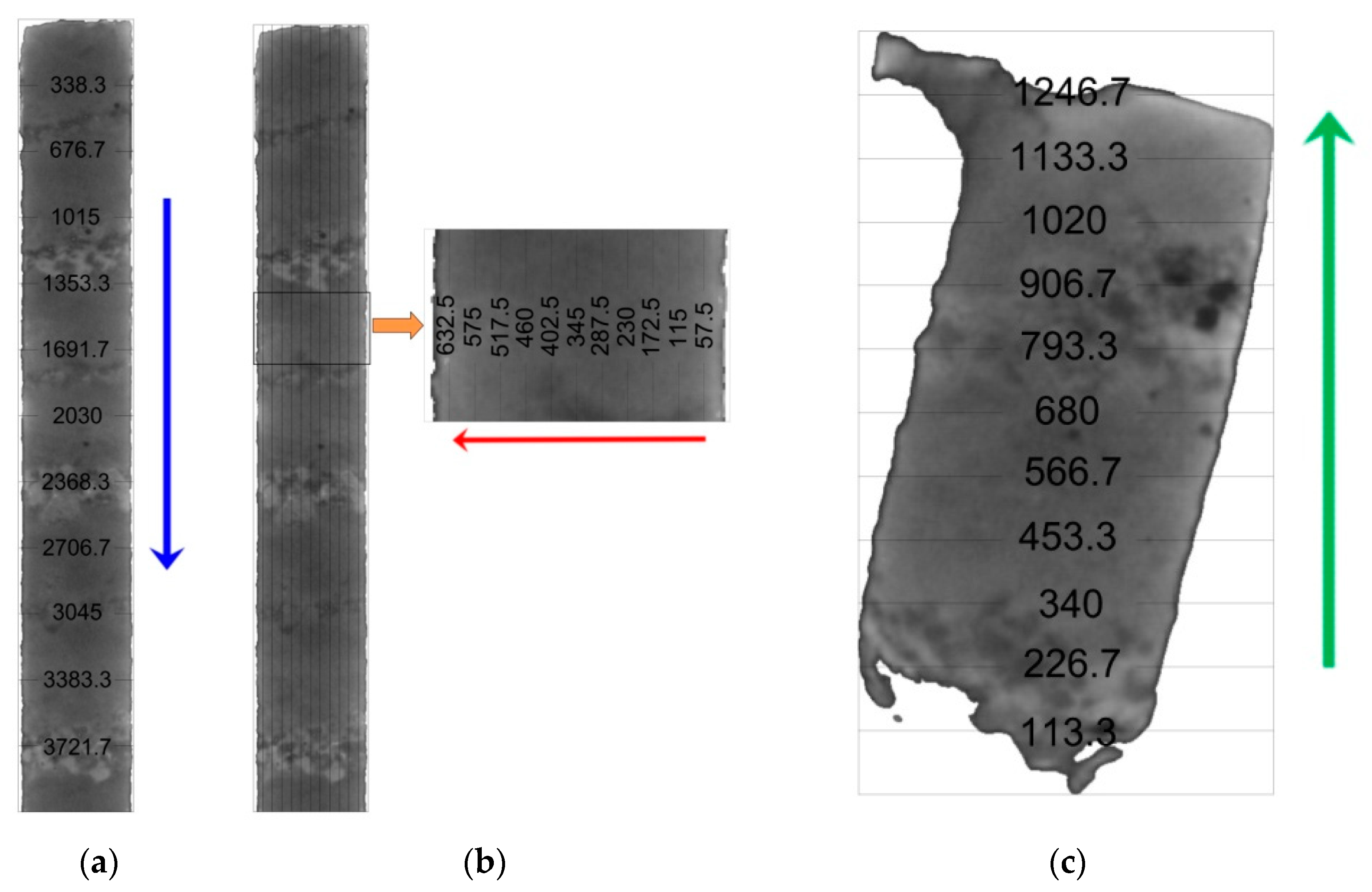

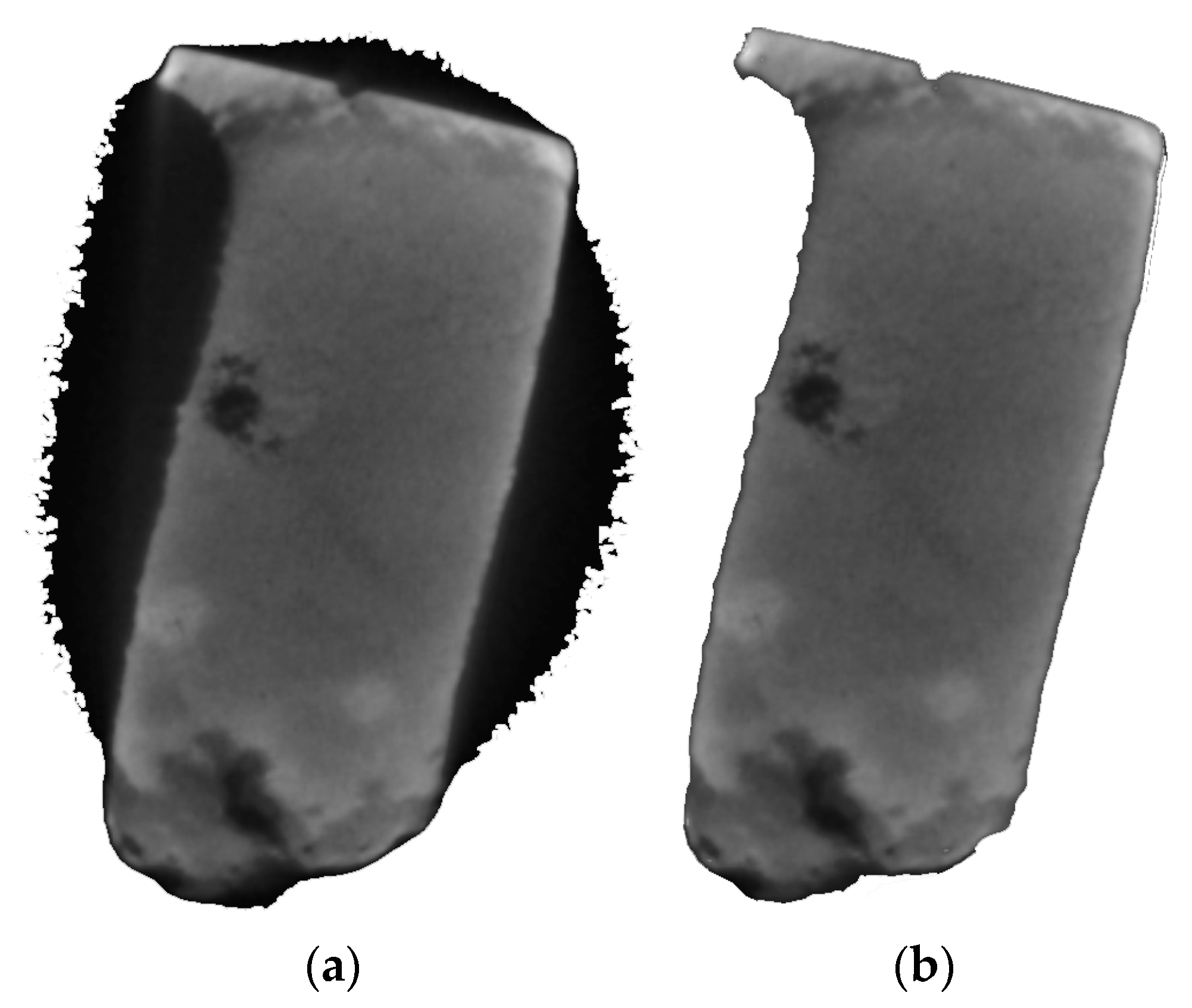

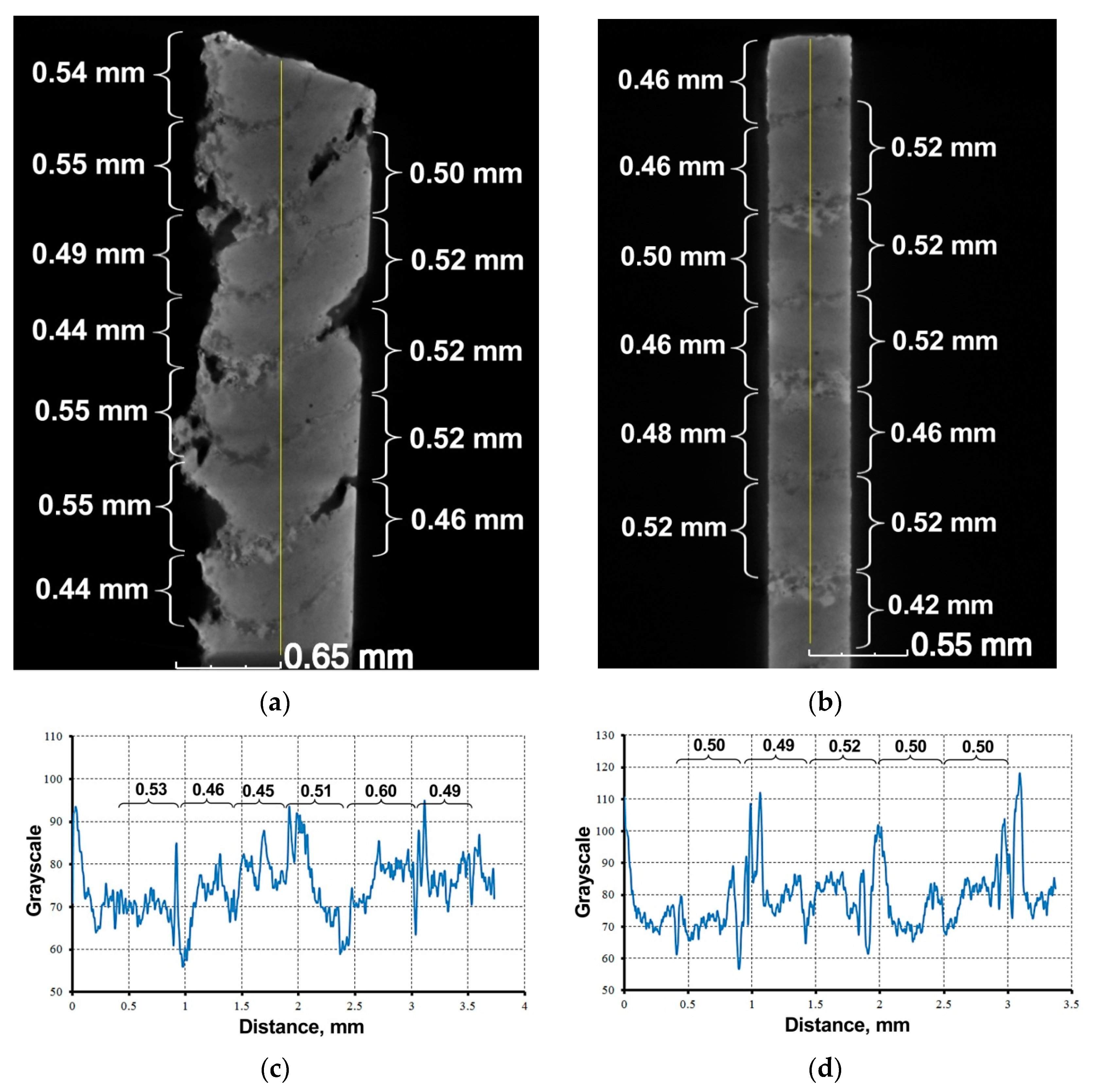

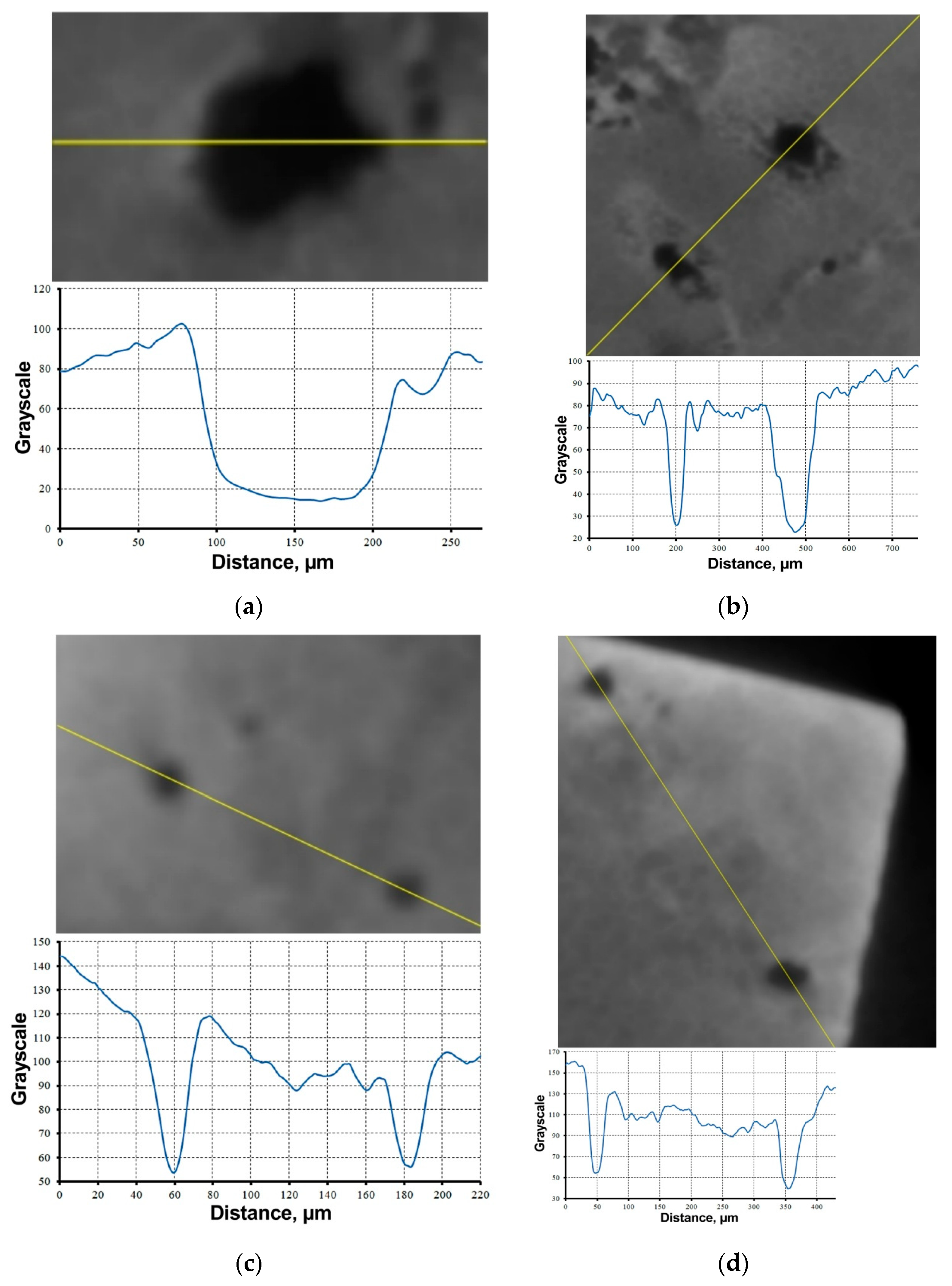

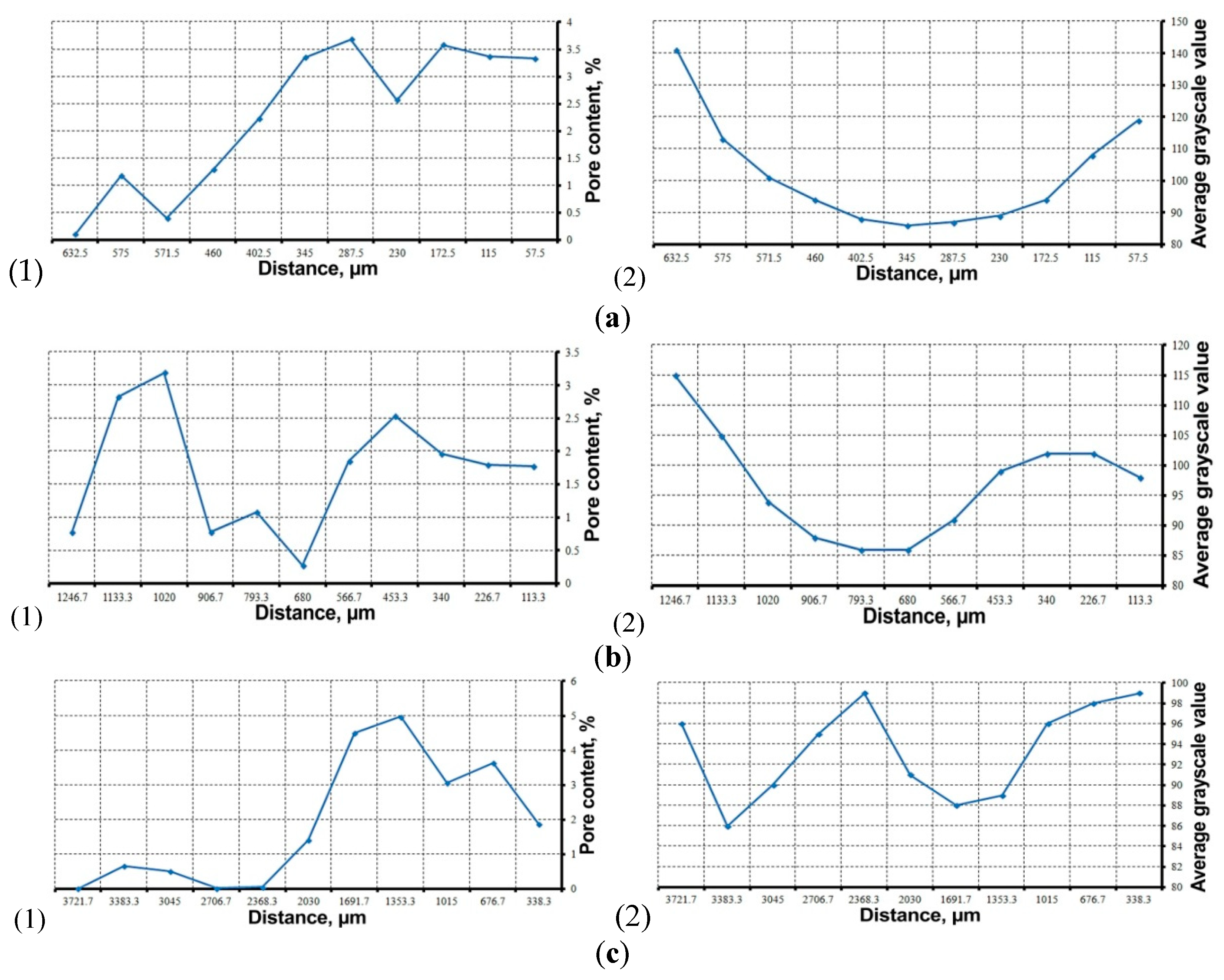

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- du Plessis, A. X-ray tomography for the advancement of laser powder bed fusion additive manufacturing. J. Microsc. 2020, 285, 121–130. [Google Scholar] [CrossRef]

- Croteau, J.R.; Griffiths, S.; Rossell, M.D.; Leinenbach, C.; Kenel, C.; Jansen, V.; Seidman, D.N.; Dunand, D.C.; Vo, N.Q. Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting. Acta Mater. 2018, 153, 35–44. [Google Scholar] [CrossRef]

- McNeil, J.L.; Sisco, K.; Frederick, C.; Massey, M.; Carver, K.; List, F.; Qiu, C.; Mader, M.; Sundarraj, S.; Babu, S.S. In Situ Monitoring for Defect Identification in Nickel Alloy Complex Geometries Fabricated by L-PBF Additive Manufacturing. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2020, 51, 6528–6545. [Google Scholar] [CrossRef]

- Saâdaoui, M.; Khaldoun, F.; Adrien, J.; Reveron, H.; Chevalier, J. X-ray tomography of additive-manufactured zirconia: Processing defects—Strength relations. J. Eur. Ceram. Soc. 2020, 40, 3200–3207. [Google Scholar] [CrossRef]

- Hart, K.R.; Dunn, R.M.; Sietins, J.M.; Hofmeister Mock, C.M.; Mackay, M.E.; Wetzel, E.D. Increased fracture toughness of additively manufactured amorphous thermoplastics via thermal annealing. Polymer 2018, 144, 192–204. [Google Scholar] [CrossRef]

- Perraud, J.B.; Obaton, A.F.; Bou-Sleiman, J.; Recur, B.; Balacey, H.; Darracq, F.; Guillet, J.P.; Mounaix, P. Terahertz imaging and tomography as efficient instruments for testing polymer additive manufacturing objects. Appl. Opt. 2016, 55, 3462. [Google Scholar] [CrossRef]

- Kruger, J.; du Plessis, A.; van Zijl, G. An investigation into the porosity of extrusion-based 3D printed concrete. Addit. Manuf. 2021, 37, 101740. [Google Scholar] [CrossRef]

- Pham, L.; Tran, P.; Sanjayan, J. Steel fibres reinforced 3D printed concrete: Influence of fibre sizes on mechanical performance. Constr. Build. Mater. 2020, 250, 118785. [Google Scholar] [CrossRef]

- Vlassenbroeck, J.; Dierick, M.; Masschaele, B.; Cnudde, V.; Van Hoorebeke, L.; Jacobs, P. Software tools for quantification of X-ray microtomography at the UGCT. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2007, 580, 442–445. [Google Scholar] [CrossRef]

- Wildenschild, D.; Sheppard, A.P. X-ray imaging and analysis techniques for quantifying pore-scale structure and processes in subsurface porous medium systems. Adv. Water Resour. 2013, 51, 217–246. [Google Scholar] [CrossRef]

- Liu, Y.; Kiss, A.M.; Larsson, D.H.; Yang, F.; Pianetta, P. To get the most out of high resolution X-ray tomography: A review of the post-reconstruction analysis. Spectrochim. Acta Part B At. Spectrosc. 2016, 117, 29–41. [Google Scholar] [CrossRef]

- Mees, F.; Swennen, R.; Van Geet, M.; Jacobs, P. Applications of X-ray computed tomograpy in the geosciences. Geol. Soc. Spec. Publ. 2003, 215, 1–6. [Google Scholar] [CrossRef]

- Carlson, W.D. Three-dimensional imaging of earth and planetary materials. Earth Planet. Sci. Lett. 2006, 249, 133–147. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth-Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef]

- Buffiere, J.Y.; Ferrie, E.; Proudhon, H.; Ludwig, W. Three-dimensional visualisation of fatigue cracks in metals using high resolution synchrotron X-ray micro-tomography. Mater. Sci. Technol. 2006, 22, 1019–1024. [Google Scholar] [CrossRef]

- Dinda, S.K.; Warnett, J.M.; Williams, M.A.; Roy, G.G.; Srirangam, P. 3D imaging and quantification of porosity in electron beam welded dissimilar steel to Fe-Al alloy joints by X-ray tomography. Mater. Des. 2016, 96, 224–231. [Google Scholar] [CrossRef]

- Williams, J.J.; Flom, Z.; Amell, A.A.; Chawla, N.; Xiao, X.; De Carlo, F. Damage evolution in SiC particle reinforced Al alloy matrix composites by X-ray synchrotron tomography. Acta Mater. 2010, 58, 6194–6205. [Google Scholar] [CrossRef]

- Maire, E.; Colombo, P.; Adrien, J.; Babout, L.; Biasetto, L. Characterization of the morphology of cellular ceramics by 3D image processing of X-ray tomography. J. Eur. Ceram. Soc. 2007, 27, 1973–1981. [Google Scholar] [CrossRef]

- Hsiung, C.H.H.; Pyzik, A.J.; De Carlo, F.; Xiao, X.; Stock, S.R.; Faber, K.T. Microstructure and mechanical properties of acicular mullite. J. Eur. Ceram. Soc. 2013, 33, 503–513. [Google Scholar] [CrossRef]

- Nigay, P.M.; Cutard, T.; Nzihou, A. The impact of heat treatment on the microstructure of a clay ceramic and its thermal and mechanical properties. Ceram. Int. 2017, 43, 1747–1754. [Google Scholar] [CrossRef]

- Charlet, K.; Saulnier, F.; Dubois, M.; Béakou, A. Improvement of wood polymer composite mechanical properties by direct fluorination. Mater. Des. 2015, 74, 61–66. [Google Scholar] [CrossRef]

- Wilbers, A.; Biguri, A.; Schillings, J.; Loos, J. Application of iterative reconstruction algorithms to mitigate CT-artefacts when measuring fiber reinforced polymer materials. Polymer 2019, 177, 120–130. [Google Scholar] [CrossRef]

- Gallucci, E.; Scrivener, K.; Groso, A.; Stampanoni, M.; Margaritondo, G. 3D experimental investigation of the microstructure of cement pastes using synchrotron X-ray microtomography (μCT). Cem. Concr. Res. 2007, 37, 360–368. [Google Scholar] [CrossRef]

- Cnudde, V.; Cwirzen, A.; Masschaele, B.; Jacobs, P.J.S. Porosity and microstructure characterization of building stones and concretes. Eng. Geol. 2009, 103, 76–83. [Google Scholar] [CrossRef]

- Roviello, G.; Ricciotti, L.; Molino, A.J.; Menna, C.; Ferone, C.; Asprone, D.; Cioffi, R.; Ferrandiz-Mas, V.; Russo, P.; Tarallo, O. Hybrid fly ash-based geopolymeric foams: Microstructural, thermal and mechanical properties. Materials 2020, 13, 2919. [Google Scholar] [CrossRef] [PubMed]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of defects on mechanical properties inmetaladditivemanufacturing: A review focusing on X-ray tomography insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Makarov, P.V.; Bakeev, R.A.; Peryshkin, A.Y.; Zhukov, A.S.; Ziatdinov, M.K.; Promakhov, V.V. Modelling of the deformation and destruction of a TiNi-TiB2 metal-ceramic composite fabricated by direct laser deposition. Eng. Fract. Mech. 2019, 222, 106712. [Google Scholar] [CrossRef]

- Promakhov, V.; Zhukov, A.; Ziatdinov, M.; Zhukov, I.; Schulz, N.; Kovalchuk, S.; Dubkova, Y.; Korsmik, R.; Klimova-Korsmik, O.; Turichin, G.; et al. Inconel 625/TiB2 metal matrix composites by direct laser deposition. Metals 2019, 9, 141. [Google Scholar] [CrossRef]

- Makarov, P.V.; Bakeev, R.A.; Promakhov, V.V.; Zhukov, A.S. Mechanisms of mesoscopic fracture of TiNi-TiB2 metal-ceramic composite. AIP Conf. Proc. 2019, 2167, 020209. [Google Scholar] [CrossRef]

- Cai, C.; Radoslaw, C.; Zhang, J.; Yan, Q.; Wen, S.; Song, B.; Shi, Y. In-situ preparation and formation of TiB/Ti-6Al-4V nanocomposite via laser additive manufacturing: Microstructure evolution and tribological behavior. Powder Technol. 2019, 342, 73–84. [Google Scholar] [CrossRef]

- Cai, C.; Song, B.; Qiu, C.; Li, L.; Xue, P.; Wei, Q.; Zhou, J.; Nan, H.; Chen, H.; Shi, Y. Hot isostatic pressing of in-situ TiB/Ti-6Al-4V composites with novel reinforcement architecture, enhanced hardness and elevated tribological properties. J. Alloys Compd. 2017, 710, 364–374. [Google Scholar] [CrossRef]

- Thuketana, S.; Taute, C.; Möller, H.; du Plessis, A. Characterization of surface roughness and subsurface pores and their effect on corrosion in 3D-printed AlSi10Mg. J. S. Afr. Inst. Min. Metall. 2020, 120, 369–376. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.T.; Corfield, M.R.; Tuck, C.; Clare, A.T.; Leach, R.K.; Wildman, R.D.; Ashcroft, I.A.; Hague, R.J.M. Quantification and characterisation of porosity in selectively laser melted Al-Si10-Mg using X-ray computed tomography. Mater. Charact. 2016, 111, 193–204. [Google Scholar] [CrossRef]

- du Plessis, A.; Macdonald, E. Hot isostatic pressing in metal additive manufacturing: X-ray tomography reveals details of pore closure. Addit. Manuf. 2020, 34, 101191. [Google Scholar] [CrossRef]

- Drankov, A.D.; Kalugin, G.V.; Shagnev, S.Y. 3D printing in the production of rocket and space technology. Add. Manuf. Technol. 2017, 3, 30–31. [Google Scholar]

- Lathaba, S. Additive Manufacturing of Aluminium Based Alloys and Composites. In Fundamentals of AluminiumMettalurgy—Recent Advances, 1st ed.; Lumley, R.N., Ed.; Woodhead Publishing: Melbourne, Australia, 2018; pp. 47–92. [Google Scholar]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

| Projection Type | Average Value of Pore Content, % | Standard Deviation | Average Grayscale Value | Standard Deviation |

|---|---|---|---|---|

| Frontal | 2.28 | 1.33 | 102 | 17 |

| Profile | 1.71 | 0.92 | 97 | 9 |

| Horizontal | 1.89 | 1.87 | 93 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korobenkov, M.; Lebedev, M.; Promakhov, V.; Narikovich, A. X-ray Tomographic Method to Study the Internal Structure of a TiNi–TiB2 Metal Matrix Composite Obtained by Direct Laser Deposition. Materials 2023, 16, 1353. https://doi.org/10.3390/ma16041353

Korobenkov M, Lebedev M, Promakhov V, Narikovich A. X-ray Tomographic Method to Study the Internal Structure of a TiNi–TiB2 Metal Matrix Composite Obtained by Direct Laser Deposition. Materials. 2023; 16(4):1353. https://doi.org/10.3390/ma16041353

Chicago/Turabian StyleKorobenkov, Maxim, Mikhail Lebedev, Vladimir Promakhov, and Anton Narikovich. 2023. "X-ray Tomographic Method to Study the Internal Structure of a TiNi–TiB2 Metal Matrix Composite Obtained by Direct Laser Deposition" Materials 16, no. 4: 1353. https://doi.org/10.3390/ma16041353

APA StyleKorobenkov, M., Lebedev, M., Promakhov, V., & Narikovich, A. (2023). X-ray Tomographic Method to Study the Internal Structure of a TiNi–TiB2 Metal Matrix Composite Obtained by Direct Laser Deposition. Materials, 16(4), 1353. https://doi.org/10.3390/ma16041353