Pervious Concrete Made with Recycled Coarse Aggregate and Reinforced with Date Palm Leaves Fibers

Abstract

1. Introduction

2. Literature Review

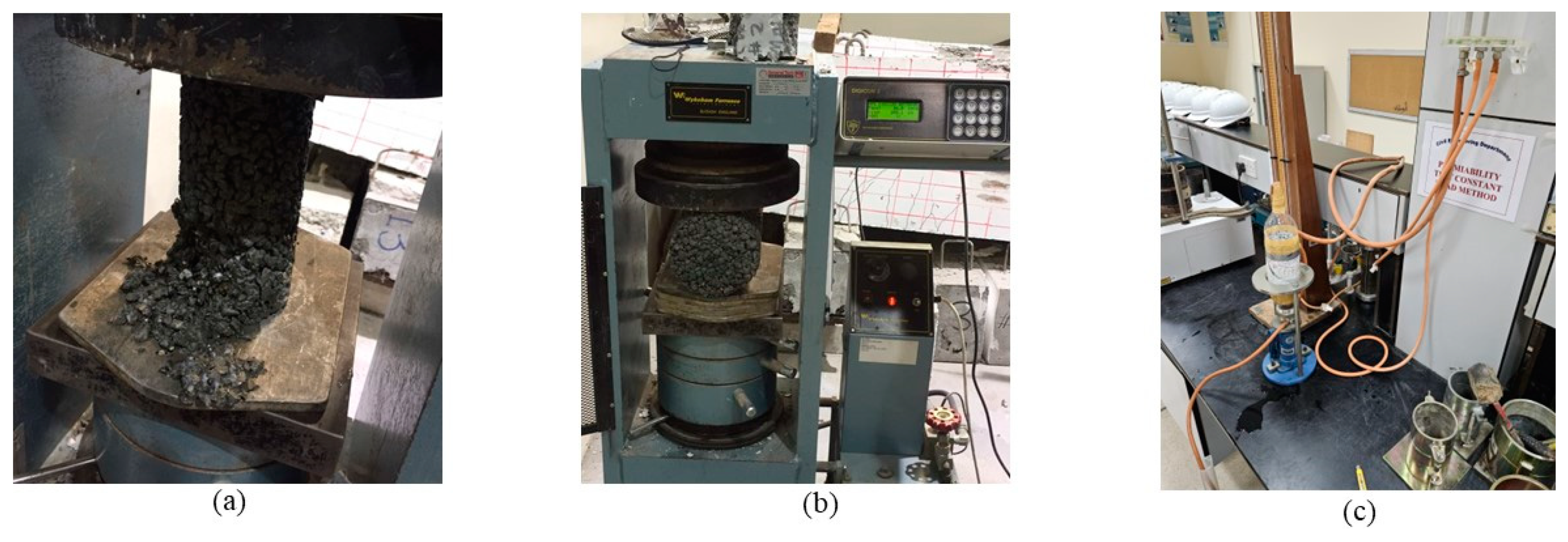

3. Materials and Methods

4. Results

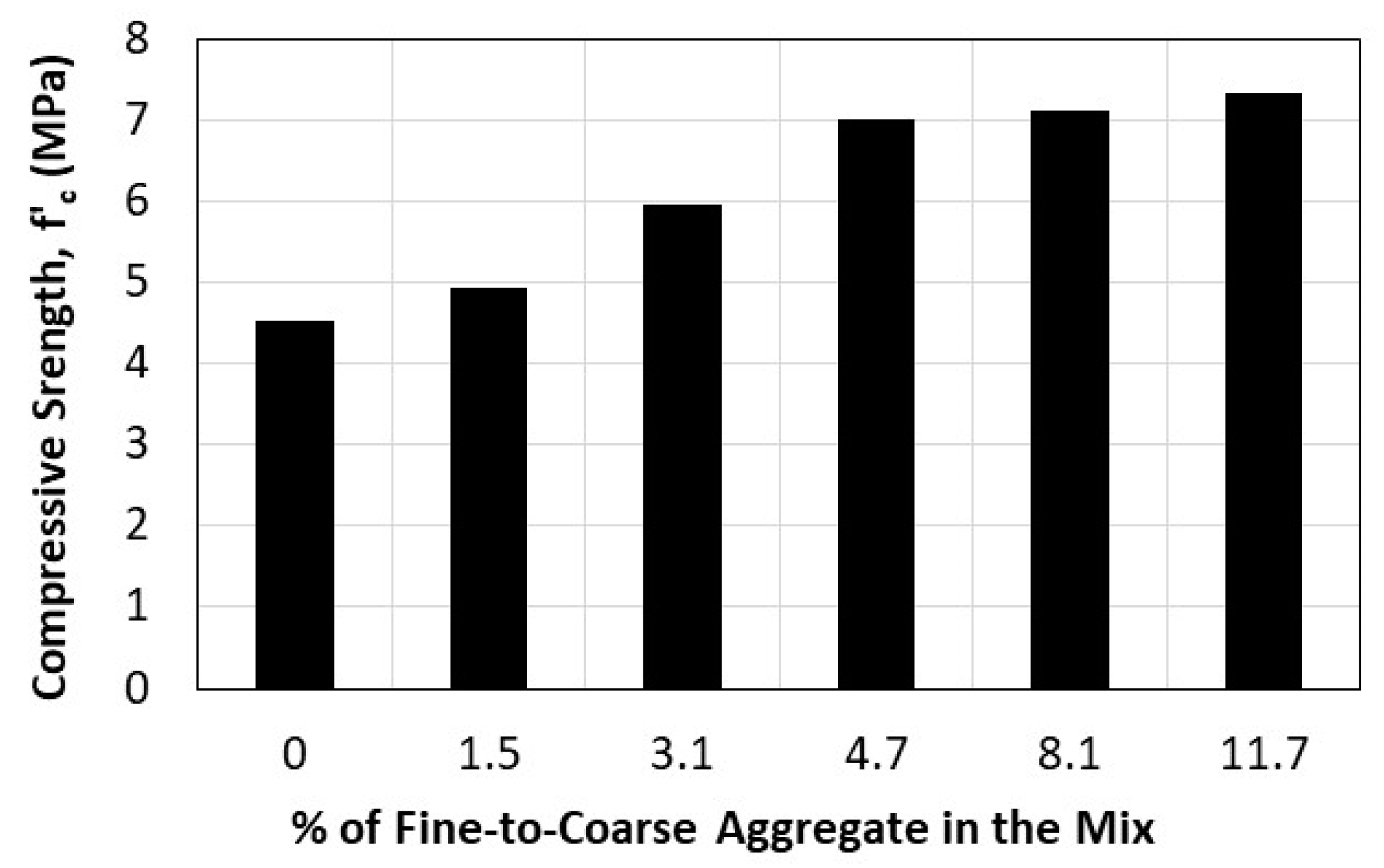

4.1. Compressive Strength

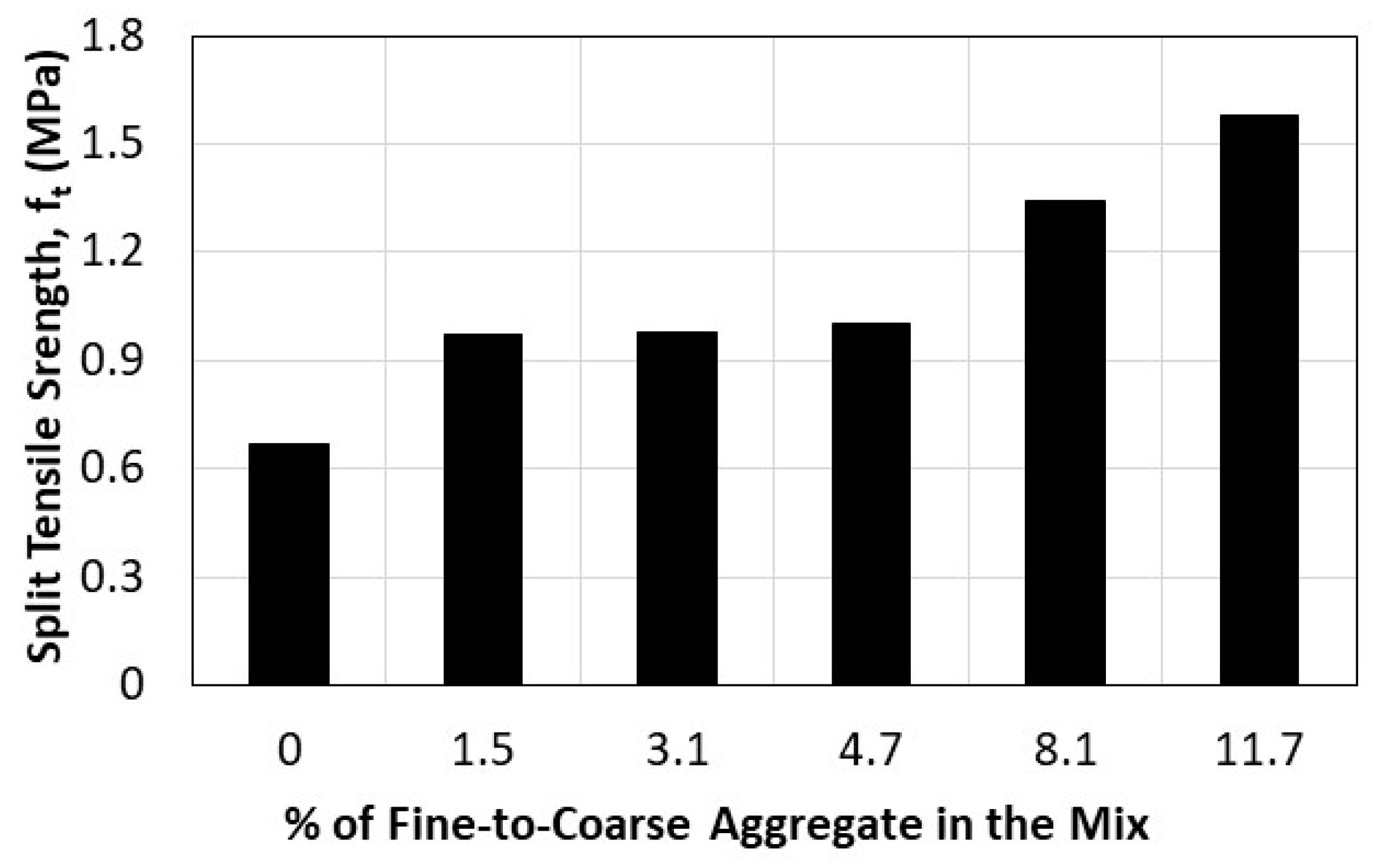

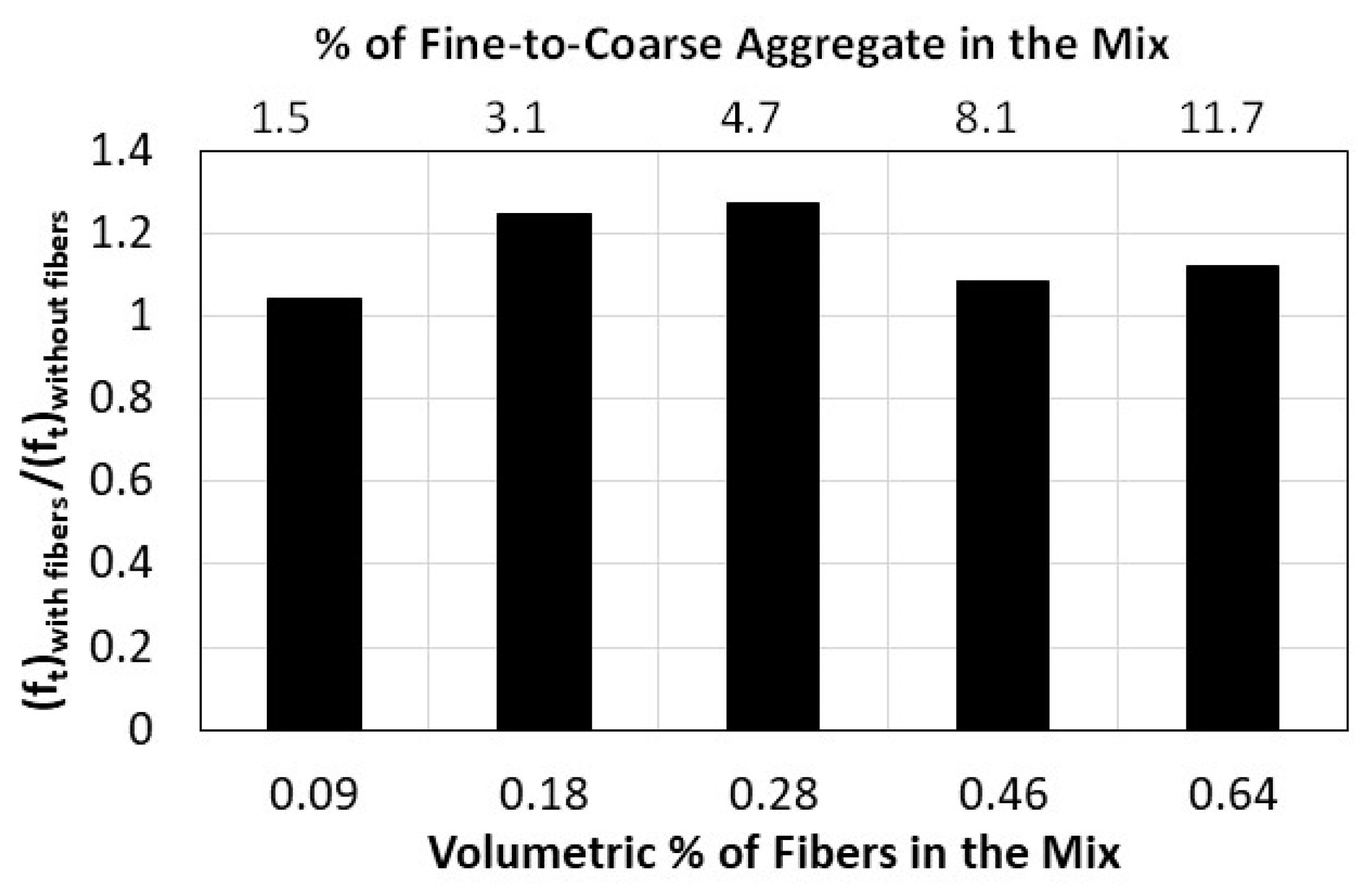

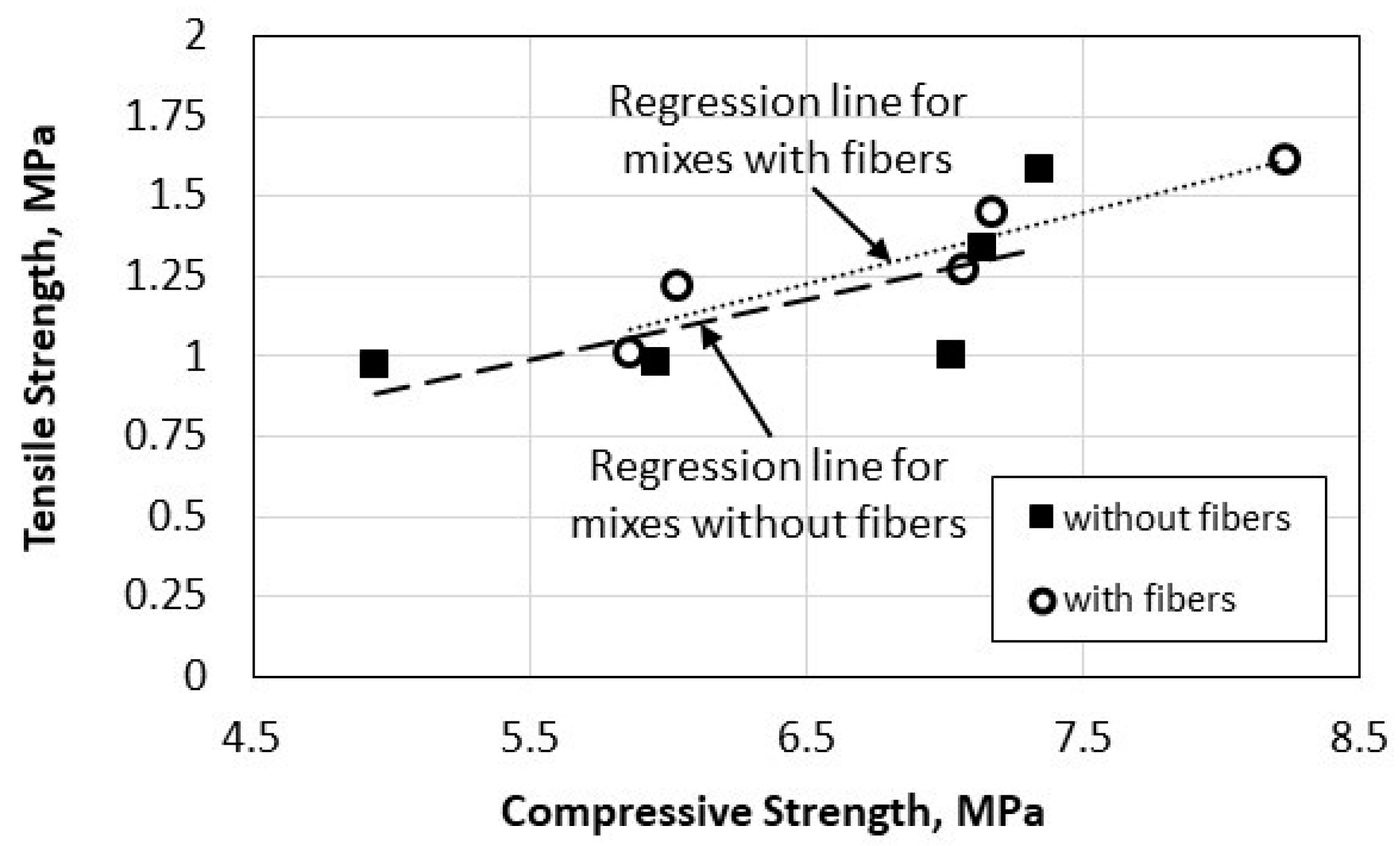

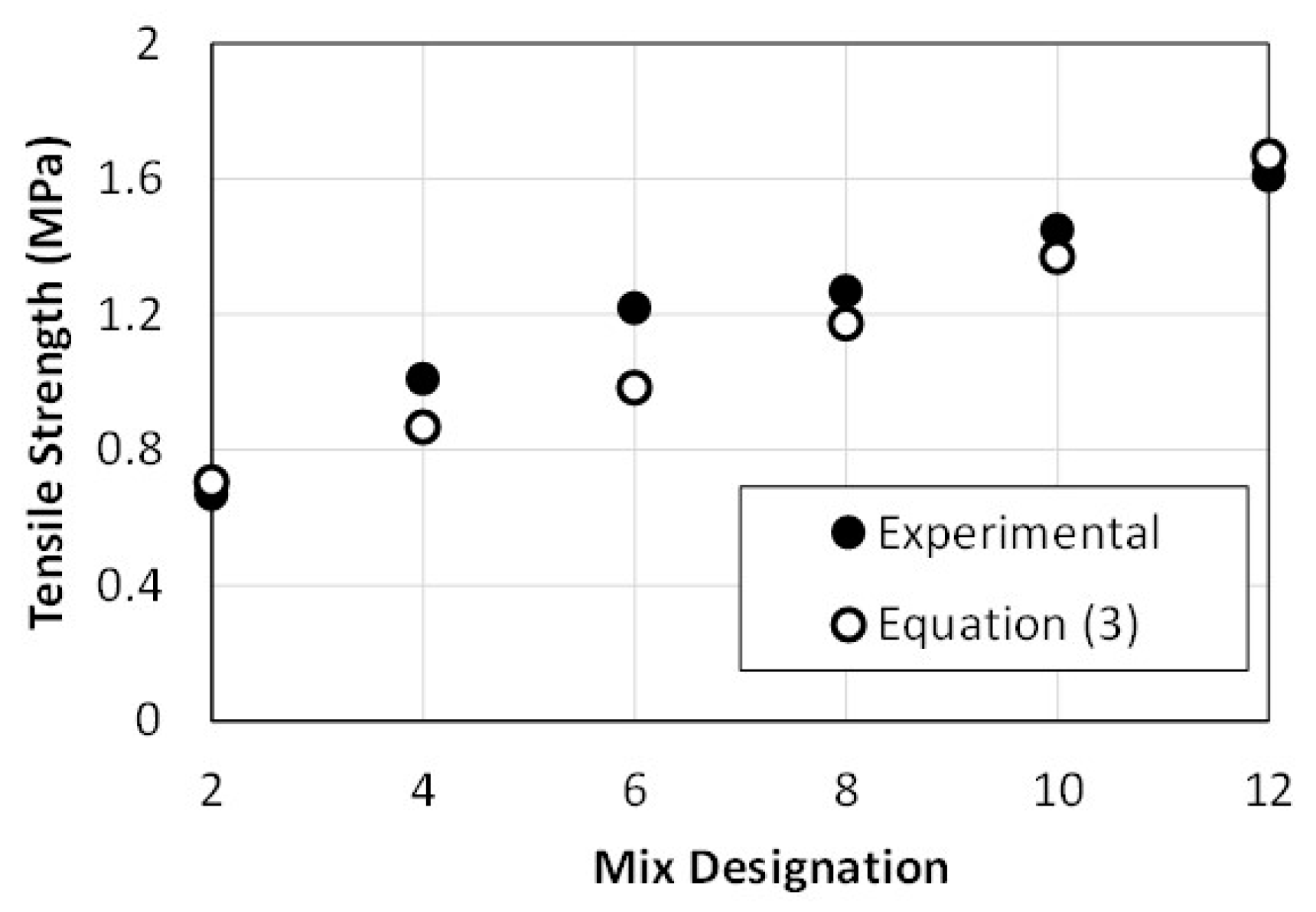

4.2. Split Tensile Strength

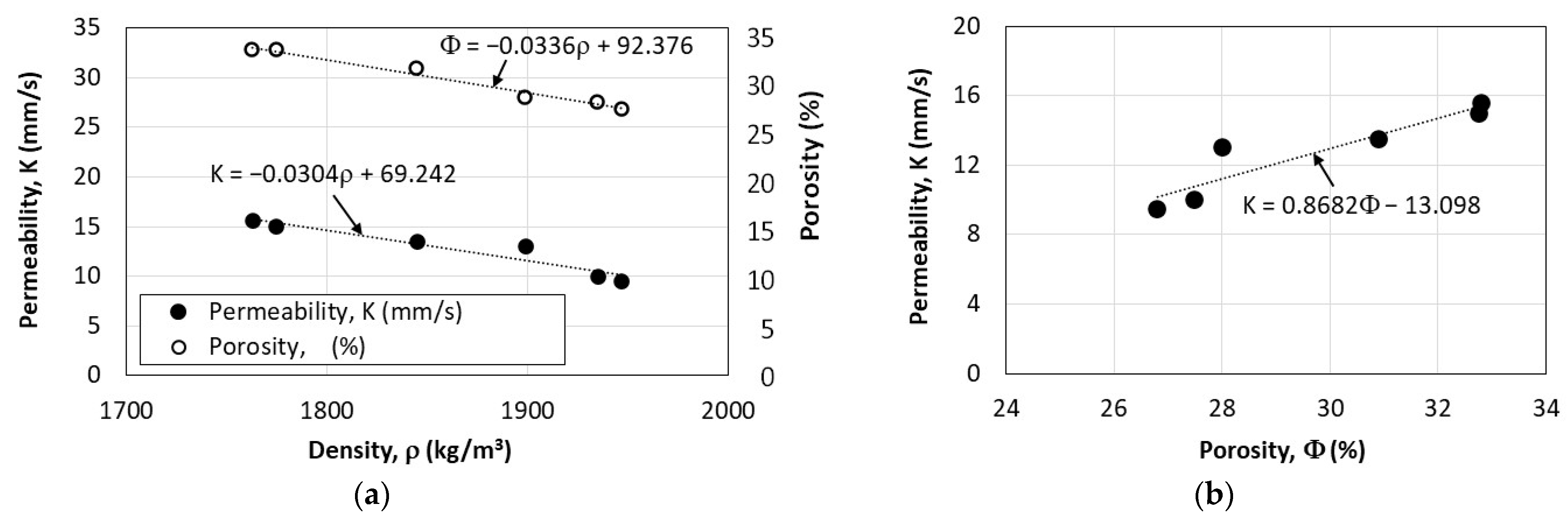

4.3. Density, Permeability and Porosity

5. Analysis of Results

6. Conclusions

- 100% replacement of natural coarse aggregate with recycled coarse aggregate from concrete demolition waste in pervious concrete mixes can reduce the compressive strength by 36% and the tensile strength by 57%.

- The addition of natural fine aggregate can help increase the density and enhance compressive and tensile strengths of pervious concrete. Adding fine aggregate equivalent to 11.7% of the recycled coarse aggregate in pervious concrete mixes can help restore the compressive and tensile strengths of the pervious concrete to the same level of pervious concrete made with 100% natural aggregate and without fine aggregate.

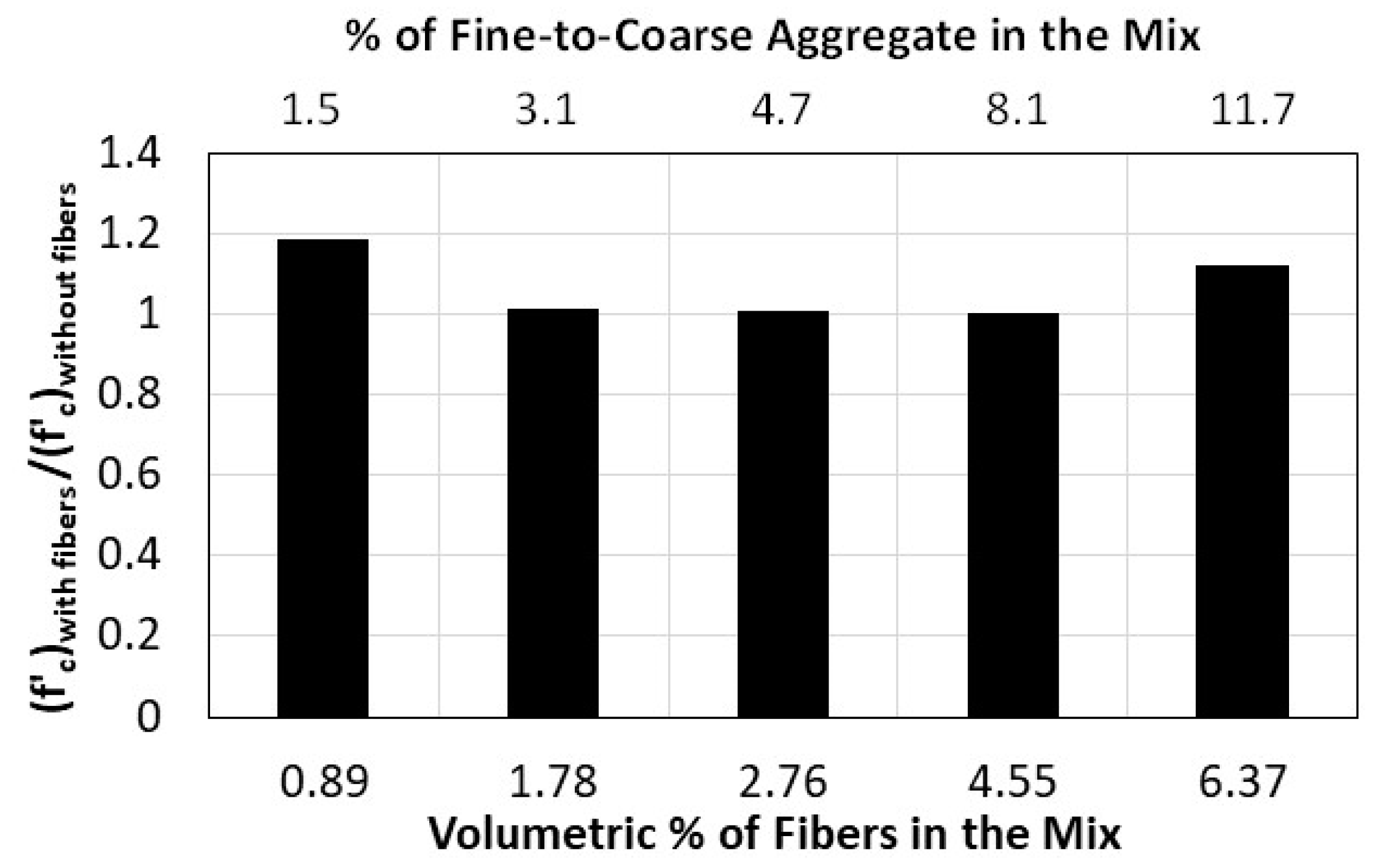

- While the influence of adding date palm leaves fibers to pervious concrete made with recycled coarse aggregate is minimal on the compressive strength, its effect on the tensile strength is reasonably high.

- The addition of fine natural aggregate and date palm leaves fibers in uniform amounts to pervious concrete mixtures that incorporate recycled coarse aggregate reduces the permeability and porosity of the hardened product.

- The tensile strength of pervious concrete utilizing recycled aggregate and natural aggregate and reinforced with date palm leaves fibers can be predicted from the compressive strength.

- There is a strong relationship between permeability and porosity since both parameters are approximately linearly correlated with the density of the concrete material.

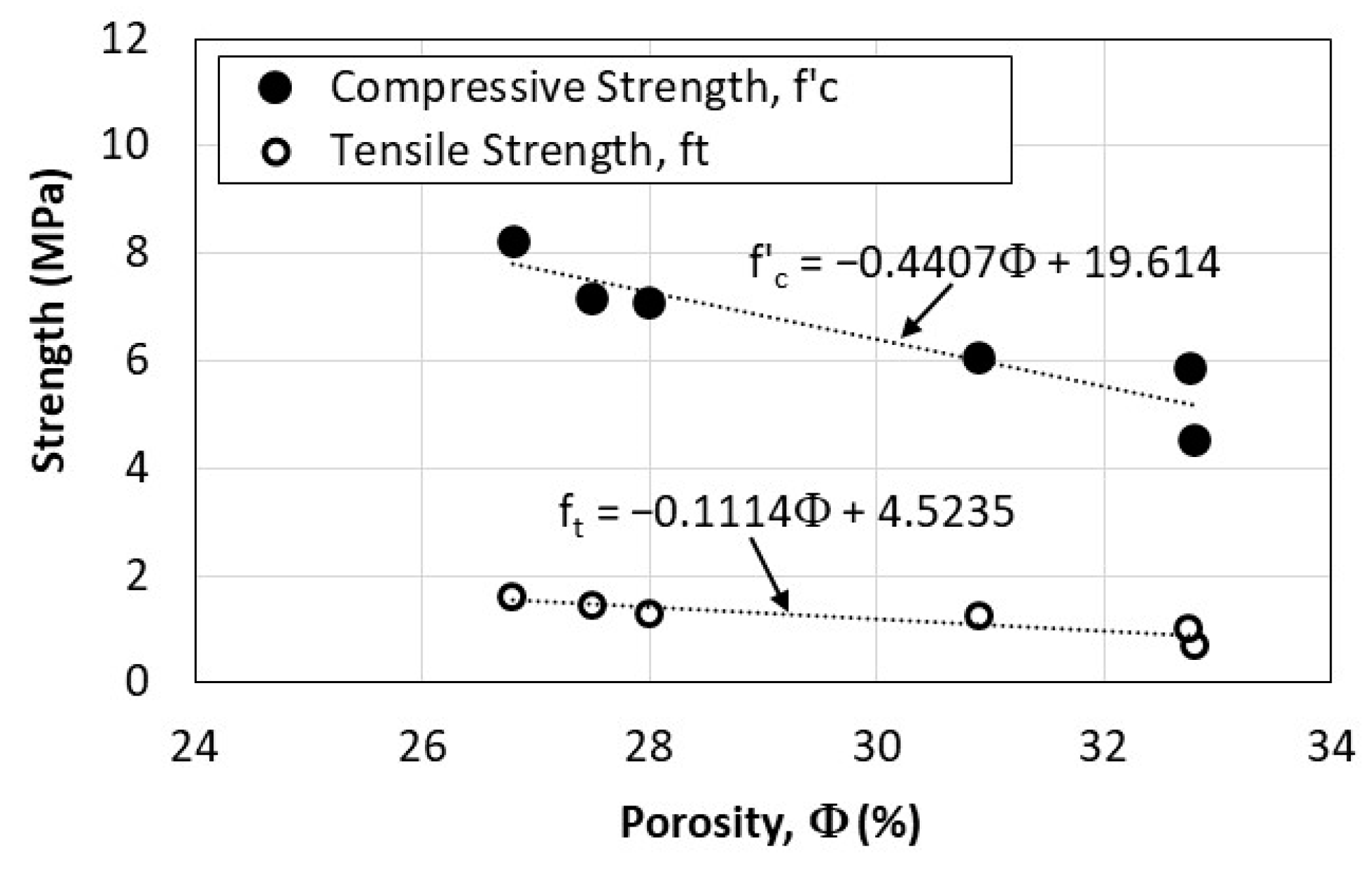

- The impact of the porosity of pervious concrete made with recycled aggregate and containing date palm leaves fibers is more pronounced on the compressive strength than it is on the tensile strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The History Of Permeable Pavers—Permeable Pavers. Available online: https://www.permeablepavers.contractors/the-history-of-permeable-pavers/ (accessed on 28 August 2023).

- ACI 522R-10; Report on Pervious Concrete. American Concrete Institute: Detroit, MI, USA, 2011.

- Cui, X.; Zhang, J.; Huang, D.; Liu, Z.; Hou, F.; Cui, S.; Zhang, L.; Wang, Z. Experimental Study on the Relationship between Permeability and Strength of Pervious Concrete. J. Mater. Civ. Eng. 2017, 29, 04017217. [Google Scholar] [CrossRef]

- Rodin, H., III; Rangelov, M.; Nassiri, S.; Englund, K. Enhancing Mechanical Properties of Pervious Concrete Using Carbon Fiber Composite Reinforcement. J. Mater. Civ. Eng. 2018, 30, 04018012. [Google Scholar] [CrossRef]

- Shi, D.; Chen, X. Flexural Tensile Fracture Behavior of Pervious Concrete under Static Preloading. J. Mater. Civ. Eng. 2018, 30, 06018015. [Google Scholar] [CrossRef]

- Kovác, M.; Sicáková, A. Pervious Concrete as an Environmental Solution for Pavements: Focus on Key Properties. Environments 2018, 5, 11. [Google Scholar] [CrossRef]

- Tang, C.-W.; Cheng, C.-K.; Tsai, C.-Y. Mix Design and Mechanical Properties of High-Performance Pervious Concrete. Materials 2019, 12, 2577. [Google Scholar] [CrossRef]

- Sahdeo, S.K.; Ransinchung R.N., G.D.; Rahul, K.L.; Debbarma, S. Effect of mix proportion on the structural and functional properties of pervious concrete paving mixtures. Constr. Build. Mater. 2020, 255, 119260. [Google Scholar] [CrossRef]

- Singh, A.; Sampath, P.V.; Biligiri, K.P. A review of sustainable pervious concrete systems: Emphasis on clogging, material characterization, and environmental aspects. Constr. Build. Mater. 2020, 261, 120491. [Google Scholar] [CrossRef]

- da Costa, F.B.P.; Haselbach, L.M.; da Silva Filho, L.C.P. Pervious concrete for desired porosity: Influence of w/c ratio and a rheology-modifying admixture. Constr. Build. Mater. 2021, 268, 121084. [Google Scholar] [CrossRef]

- Akkaya, A.; Çağatay, İ.H. Experimental investigation of the use of pervious concrete on high volume roads. Constr. Build. Mater. 2021, 279, 122430. [Google Scholar] [CrossRef]

- Akkaya, A.; Çağatay, İ.H. Investigation of the density, porosity, and permeability properties of pervious concrete with different methods. Constr. Build. Mater. 2021, 294, 123539. [Google Scholar] [CrossRef]

- Shan, J.; Zhang, Y.; Wu, S.; Lin, Z.; Li, L.; Wu, Q. Pore characteristics of pervious concrete and their influence on permeability attributes. Constr. Build. Mater. 2022, 327, 126874. [Google Scholar] [CrossRef]

- Ferić, K.; Veerappan, S.K.; Romić, A.; Gotovac, H. Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete. Sustainability 2023, 15, 1146. [Google Scholar] [CrossRef]

- Wu, S.; Wu, Q.; Shan, J.; Cai, X.; Su, X.; Sun, X. Effect of morphological characteristics of aggregate on the performance of pervious concrete. Constr. Build. Mater. 2023, 367, 130219. [Google Scholar] [CrossRef]

- Chockalingam, T.; Vijayaprabha, C.; Raj, J.L. Experimental study on size of aggregates, size and shape of specimens on strength characteristics of pervious concrete. Constr. Build. Mater. 2023, 385, 131320. [Google Scholar] [CrossRef]

- Zhou, J.; Zheng, M.; Zhan, Q.; Zhou, R.; Zhang, Y.; Wang, Y. Study on mesostructure and stress–strain characteristics of pervious concrete with different aggregate sizes. Constr. Build. Mater. 2023, 397, 132322. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P. Pervious concrete pavement incorporating GGBS to alleviate pavement runoff and improve urban sustainability. Road Mater. Pavement Des. 2018, 19, 167–181. [Google Scholar] [CrossRef]

- Huang, J.; Luo, Z.; Khan, M.B.E. Impact of aggregate type and size and mineral admixtures on the properties of pervious concrete: An experimental investigation. Constr. Build. Mater. 2020, 265, 120759. [Google Scholar] [CrossRef]

- Huang, W.; Wang, H. Geopolymer pervious concrete modified with granulated blast furnace slag: Microscale characterization and mechanical strength. J. Clean. Prod. 2021, 328, 129469. [Google Scholar] [CrossRef]

- Park, J.-H.; Jeong, S.-T.; Bui, Q.-T.; Yang, I.-H. Strength and Permeability Properties of Pervious Concrete Containing Coal Bottom Ash Aggregates. Materials 2022, 15, 7847. [Google Scholar] [CrossRef]

- Nazeer, M.; Kapoor, K.; Singh, S.P. Strength, durability and microstructural investigations on pervious concrete made with fly ash and silica fume as supplementary cementitious materials. J. Build. Eng. 2023, 69, 106275. [Google Scholar] [CrossRef]

- El-Hassan, H.; Kianmehr, P.; Zouaoui, S. Properties of pervious concrete incorporating recycled concrete aggregates and slag. Constr. Build. Mater. 2019, 212, 164–175. [Google Scholar] [CrossRef]

- Vieira, G.L.; Schiavon, J.Z.; Borges, P.M.; da Silva, S.R.; de Oliveira Andrade, J.J. Influence of recycled aggregate replacement and fly ash content in performance of pervious concrete mixtures. J. Clean. Prod. 2020, 271, 122665. [Google Scholar] [CrossRef]

- Zhang, Q.; Feng, X.; Chen, X.; Lu, K. Mix design for recycled aggregate pervious concrete based on response surface methodology. Constr. Build. Mater. 2020, 259, 119776. [Google Scholar] [CrossRef]

- Chaitanya, M.; Ramakrishna, G. Enhancing the mechanical properties of pervious recycled aggregate concrete using silica fumes. Mater. Today Proc. 2021, 46 Pt 1, 634–637. [Google Scholar] [CrossRef]

- Yang, L.; Kou, S.; Song, X.; Lu, M.; Wang, Q. Analysis of properties of pervious concrete prepared with difference paste-coated recycled aggregate. Constr. Build. Mater. 2021, 269, 121244. [Google Scholar] [CrossRef]

- Strieder, H.L.; Dutra, V.F.P.; Graeff, Â.G.; Núñez, W.P.; Merten, F.R.M. Performance evaluation of pervious concrete pavements with recycled concrete aggregate. Constr. Build. Mater. 2022, 315, 125384. [Google Scholar] [CrossRef]

- Tijani, M.A.; Ajagbe, W.O.; Agbede, O.A. Combined reusing of sorghum husk ash and recycled concrete aggregate for sustainable pervious concrete production. J. Clean. Prod. 2022, 343, 131015. [Google Scholar] [CrossRef]

- Gowda, S.B.; Goudar, S.K.; Thanu, H.; Monisha, B. Performance evaluation of alkali activated slag based recycled aggregate pervious concrete. Mater. Today Proc. 2023, in press.

- El-Hassan, H.; Kianmehr, P.; Tavakoli, D.; El-Mir, A.; Dehkordi, R.S. Synergic effect of recycled aggregates, waste glass, and slag on the properties of pervious concrete. Dev. Built Environ. 2023, 15, 100189. [Google Scholar] [CrossRef]

- Meng, X.; Chi, Y.; Jiang, Q.; Liu, R.; Wu, K.; Li, S. Experimental investigation on the flexural behavior of pervious concrete beams reinforced with geogrids. Constr. Build. Mater. 2019, 215, 275–284. [Google Scholar] [CrossRef]

- Zhu, H.; Wen, C.; Wang, Z.; Li, L. Study on the Permeability of Recycled Aggregate Pervious Concrete with Fibers. Materials 2020, 13, 321. [Google Scholar] [CrossRef]

- Juradin, S.; Netinger, I.; Mrakovcic, S.; Jozić, D. Impact of fibre incorporation and compaction method on properties of pervious concrete. Mater. De Construcción 2021, 71, e245. [Google Scholar] [CrossRef]

- Wu, J.; Pang, Q.; Lv, Y.; Zhang, J.; Gao, S. Research on the Mechanical and Physical Properties of Basalt Fiber-Reinforced Pervious Concrete. Materials 2022, 15, 6527. [Google Scholar] [CrossRef]

- Ozel, B.F.; Sakalli, Ş.; Şahin, Y. The effects of aggregate and fiber characteristics on the properties of pervious concrete. Constr. Build. Mater. 2022, 356, 129294. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Elmoaty, A.E.M.A.; Fawzy, A.M. Experimental investigation on permeability indices and strength of modified pervious concrete with recycled concrete aggregate. Constr. Build. Mater. 2018, 193, 105–127. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

- Novak, J.; Kohoutkova, A.; Chylik, R.; Trtik, T. Study on pervious recycled aggregate fiber-reinforced concrete for airfield pavement. 8th Global Conference on Materials Science and Engineering (CMSE2019). IOP Conf. Ser. Mater. Sci. Eng. 2020, 770, 012040. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of pumice powder and nano-clay on the strength and permeability of fiber-reinforced pervious concrete incorporating recycled concrete aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Xiao, Q.; Feng, L.; Xia, Y.; Xu, F. Characterization of PVA Fiber-Reinforced Pervious Concrete with Blended Recycled Ceramic Aggregates and Natural Aggregate. Adv. Mater. Sci. Eng. 2022, 2022, 4375043. [Google Scholar] [CrossRef]

- Mitrosz, O.; Kurpinska, M.; Miskiewicz, M.; Brzozowski, T.; Abdelgader, H.S. Influence of the Addition of Recycled Aggregates and Polymer Fibers on the Properties of Pervious Concrete. Materials 2023, 16, 5222. [Google Scholar] [CrossRef]

- Sangthongtong, A.; Semvimol, N.; Rungratanaubon, T.; Duangmal, K.; Joyklad, P. Mechanical Properties of Pervious Recycled Aggregate Concrete Reinforced with Sackcloth Fibers (SF). Infrastructures 2023, 8, 38. [Google Scholar] [CrossRef]

- Fawzi, R.Q.; Awad, H.K. The Influence of Polypropylene Fiber and Silica Fume on the Mechanical Properties of No-Fine Concrete with Recycled Aggregate. E3S Web Conf. 2023, 427, 02002. [Google Scholar] [CrossRef]

- Hailong, L.; Chenglong, M.; Hong, Q. Influence of fly ash and basalt fibers on the properties of recycled pervious concrete. Authorea 2023, 1, 13. [Google Scholar] [CrossRef]

- Beeah Group—Recycling. Available online: https://www.beeahgroup.com/services/beeah-recycling/ (accessed on 28 August 2023).

- ASTM C136-06; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM: West Conshohocken, PA, USA, 2009.

- ASTM C29/C29M-97; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM: West Conshohocken, PA, USA, 2009.

- ASTM C131-06; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM: West Conshohocken, PA, USA, 2009.

- British Standard BS 812-110:1990; Testing Aggregates—Part 110: Methods for Determination of Aggregate Crushing Value (ACV). BSI: London, UK, 1990.

- ACI 522.1; Specification for Construction of Pervious Concrete Pavement. American Concrete Institute: Farmington Hills, MI, USA, 2020; 8p.

- Bamaga, S.O. Physical and mechanical properties of mortars containing date palm fibers. Mater. Res. Express 2022, 9, 015102. [Google Scholar] [CrossRef]

- ASTM C192/C192M-14; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM C496-96; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 1996.

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled aggregate on strength properties of Concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Abdelfatah, A.; Tabsh, S.; Yehia, S. Utilization of Recycled Coarse Aggregate in Concrete Mixes. J. Civ. Eng. Archit. 2011, 5, 562–566. [Google Scholar] [CrossRef][Green Version]

- Abdelfatah, A.; Tabsh, S.W. Review of Research on and Implement of Recycled Concrete Aggregate in the GCC. Adv. Civ. Eng. J. 2011, 2011, 567924. [Google Scholar]

- Sagheer, A.M.; Tabsh, S.W. Shear Strength of Concrete Beams without Stirrups Made with Recycled Coarse Aggregate. Buildings 2022, 13, 75. [Google Scholar] [CrossRef]

- Sagheer, A.M.; Tabsh, S.W.; Yehia, S. Structural Behavior of Reinforced Concrete Beams Made with Locally Produced Recycled Aggregate in the UAE. Buildings 2023, 13, 2597. [Google Scholar] [CrossRef]

- Al Ajmani, H.; Suleiman, F.; Abuzayed, I.; Tamimi, A. Evaluation of Concrete Strength Made with Recycled Aggregate. Buildings 2019, 9, 56. [Google Scholar] [CrossRef]

| Type of Aggregate | Bulk Specific Gravity (Dry) | Saturated-Surface-Dry Bulk Specific Gravity | Apparent Specific Gravity | Water Absorption |

|---|---|---|---|---|

| RCA | 2.464 | 2.576 | 2.774 | 4.53% |

| NA | 2.440 | 2.540 | 2.700 | 3.99% |

| Weight of Ingredients (kg/m3) | Mix Number and Designation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| R0-FA/CA0-F0 | R100-FA/CA0-F0 | R100-FA/CA1.5-F0 | R100-FA/CA1.5-F0.09 | R100-FA/CA3.1-F0 | R100-FA/CA3.1-F0.18 | R100-FA/CA4.7-F0 | R100-FA/CA4.7-F0.28 | R100-FA/CA8.1-F0 | R100-FA/CA8.1-F0.46 | R100-FA/CA11.7-F0 | R100-FA/CA11.7-F0.64 | |

| Water | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 |

| Portland Cement | 356 | 356 | 356 | 356 | 356 | 356 | 356 | 356 | 356 | 356 | 356 | 356 |

| Natural Coarse Aggregate | 1599 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Recycled Coarse Aggregate | 0 | 1599 | 1575 | 1575 | 1551 | 1551 | 1527 | 1527 | 1479 | 1479 | 1431 | 1431 |

| Natural Fine Aggregate % FA/CA | 0 0 | 0 0 | 24 1.5% | 24 1.5% | 48 3.1% | 48 3.1% | 72 4.7% | 72 4.7% | 120 8.1% | 120 8.1% | 168 11.7% | 168 11.7% |

| Natural Fibers % by Vol. | 0 0% | 0 0% | 0 0% | 0.89 0.09% | 0 0% | 1.78 0.18% | 0 0% | 2.76 0.28% | 0 0% | 4.55 0.46% | 0 0% | 6.37 0.64% |

| Parameter (MPa) | Mix Number and Designation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| R0-FA/CA0-F0 | R100-FA/CA0-F0 | R100-FA/CA1.5-F0 | R100-FA/CA1.5-F0.09 | R100-FA/CA3.1-F0 | R100-FA/CA3.1-F0.18 | R100-FA/CA4.7-F0 | R100-FA/CA4.7-F0.28 | R100-FA/CA8.1-F0 | R100-FA/CA8.1-F0.46 | R100-FA/CA11.7-F0 | R100-FA/CA11.7-F0.64 | |

| Compressive Strength | 7.08 | 4.53 | 4.94 | 5.86 | 5.96 | 6.04 | 7.03 | 7.07 | 7.14 | 7.17 | 7.34 | 8.23 |

| Parameter (MPa) | Mix Number and Designation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| R0-FA/CA0-F0 | R100-FA/CA0-F0 | R100-FA/CA1.5-F0 | R100-FA/CA1.5-F0.09 | R100-FA/CA3.1-F0 | R100-FA/CA3.1-F0.18 | R100-FA/CA4.7-F0 | R100-FA/CA4.7-F0.28 | R100-FA/CA8.1-F0 | R100-FA/CA8.1-F0.46 | R100-FA/CA11.7-F0 | R100-FA/CA11.7-F0.64 | |

| Split Tensile Strength | 1.56 | 0.67 | 0.97 | 1.01 | 0.98 | 1.22 | 1.00 | 1.27 | 1.34 | 1.45 | 1.58 | 1.61 |

| Parameter | Mix Number and Designation | |||||

|---|---|---|---|---|---|---|

| 2 | 4 | 6 | 8 | 10 | 12 | |

| R100-FA/CA0-F0 | R100-FA/CA1.5-F0.09 | R100-FA/CA3.1-F0.18 | R100-FA/CA4.7-F0.28 | R100-FA/CA8.1-F0.46 | R100-FA/CA11.7-F0.64 | |

| Density (Kg/m3) | 1763 | 1775 | 1845 | 1899 | 1935 | 1947 |

| Permeability (mm/s) | 15.6 | 15.0 | 13.5 | 13.0 | 10.0 | 9.5 |

| Porosity (%) | 32.81 | 32.75 | 30.90 | 28.00 | 27.50 | 26.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tamimi, A.; Tabsh, S.W.; El-Emam, M. Pervious Concrete Made with Recycled Coarse Aggregate and Reinforced with Date Palm Leaves Fibers. Materials 2023, 16, 7496. https://doi.org/10.3390/ma16237496

Tamimi A, Tabsh SW, El-Emam M. Pervious Concrete Made with Recycled Coarse Aggregate and Reinforced with Date Palm Leaves Fibers. Materials. 2023; 16(23):7496. https://doi.org/10.3390/ma16237496

Chicago/Turabian StyleTamimi, Adil, Sami W. Tabsh, and Magdi El-Emam. 2023. "Pervious Concrete Made with Recycled Coarse Aggregate and Reinforced with Date Palm Leaves Fibers" Materials 16, no. 23: 7496. https://doi.org/10.3390/ma16237496

APA StyleTamimi, A., Tabsh, S. W., & El-Emam, M. (2023). Pervious Concrete Made with Recycled Coarse Aggregate and Reinforced with Date Palm Leaves Fibers. Materials, 16(23), 7496. https://doi.org/10.3390/ma16237496