Improvement of Warm-Mix Asphalt Concrete Performance with Lignin Obtained from Bioethanol Production from Forest Biomass Waste

Abstract

:1. Introduction

1.1. Background

1.2. Previous Findings on the Use of Lignin in Asphalt and Contributions of This Study

2. Materials and Methods

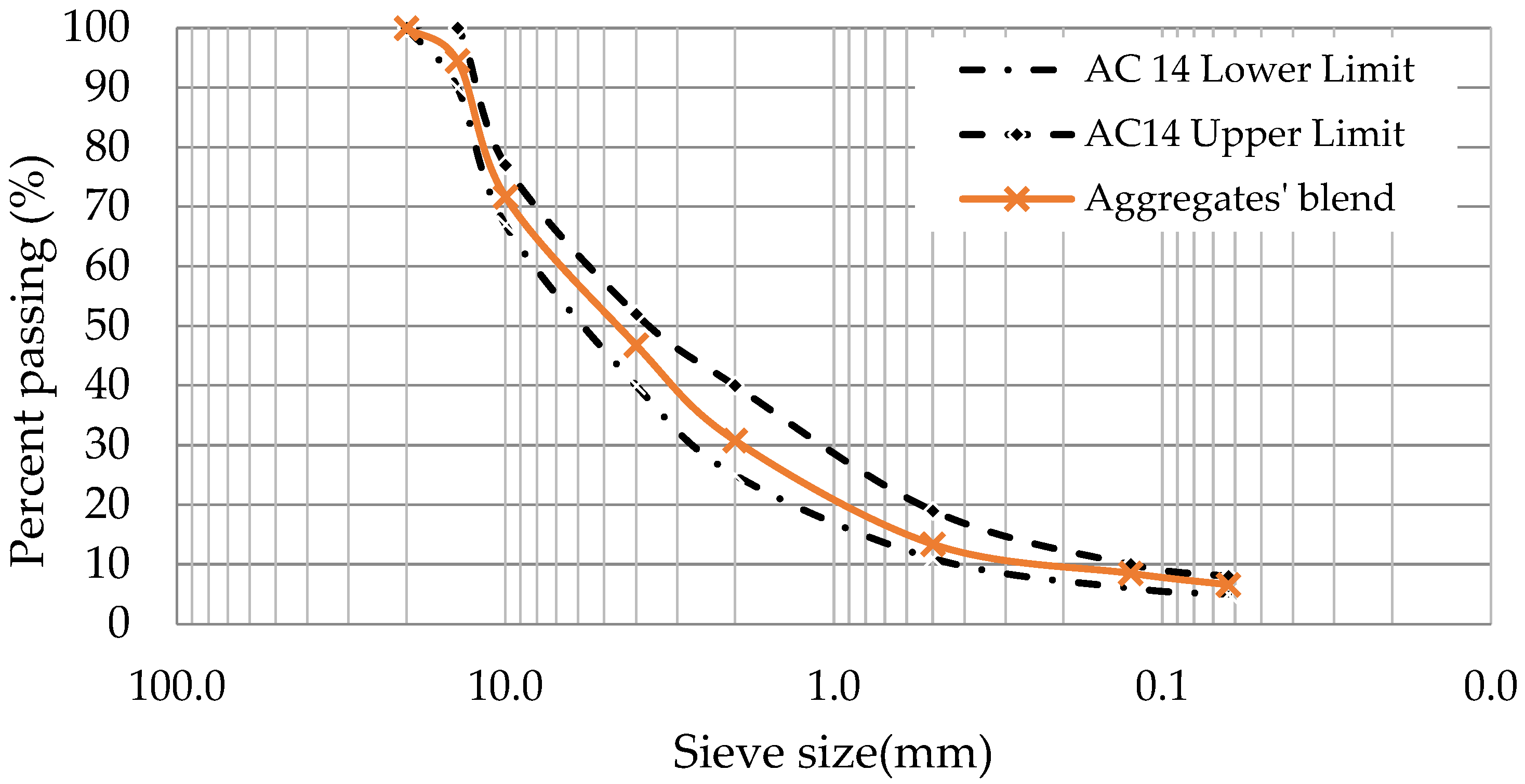

2.1. Aggregates, Bitumen, and Organic Wax

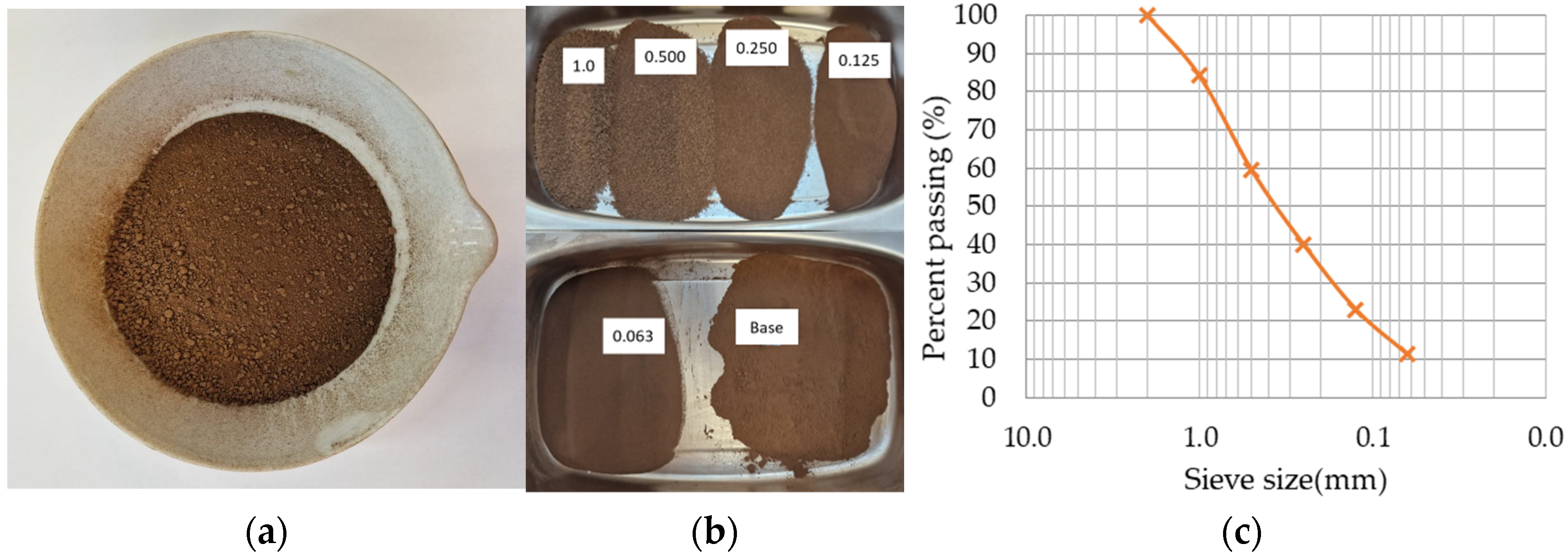

2.2. Lignin

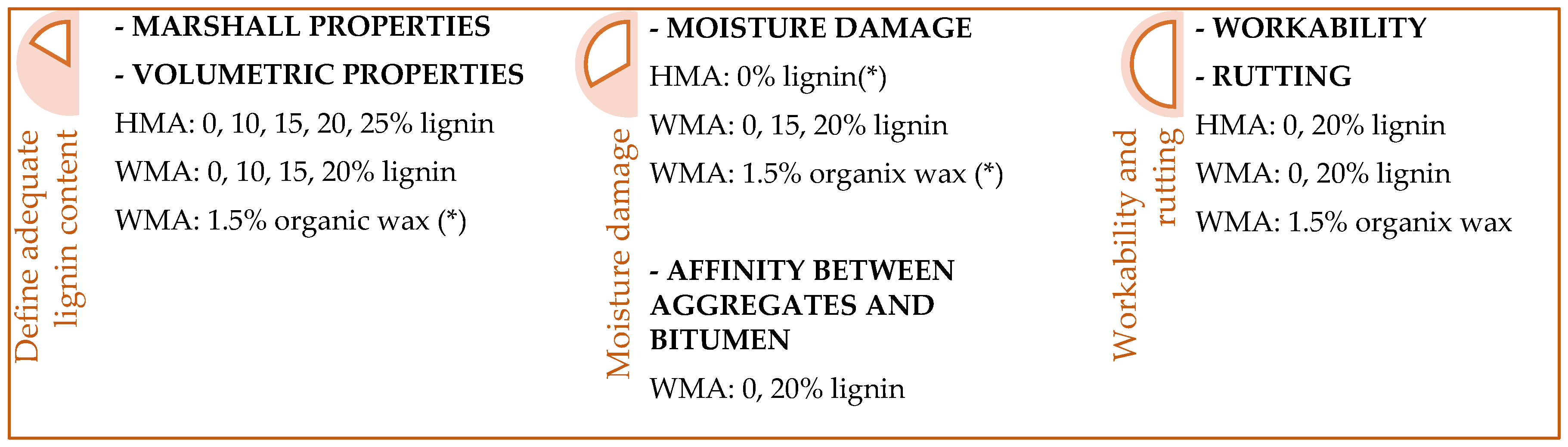

2.3. Blends Compositions

2.4. Methods

2.4.1. Marshall and Volumetric Properties

2.4.2. Moisture Damage

2.4.3. Workability

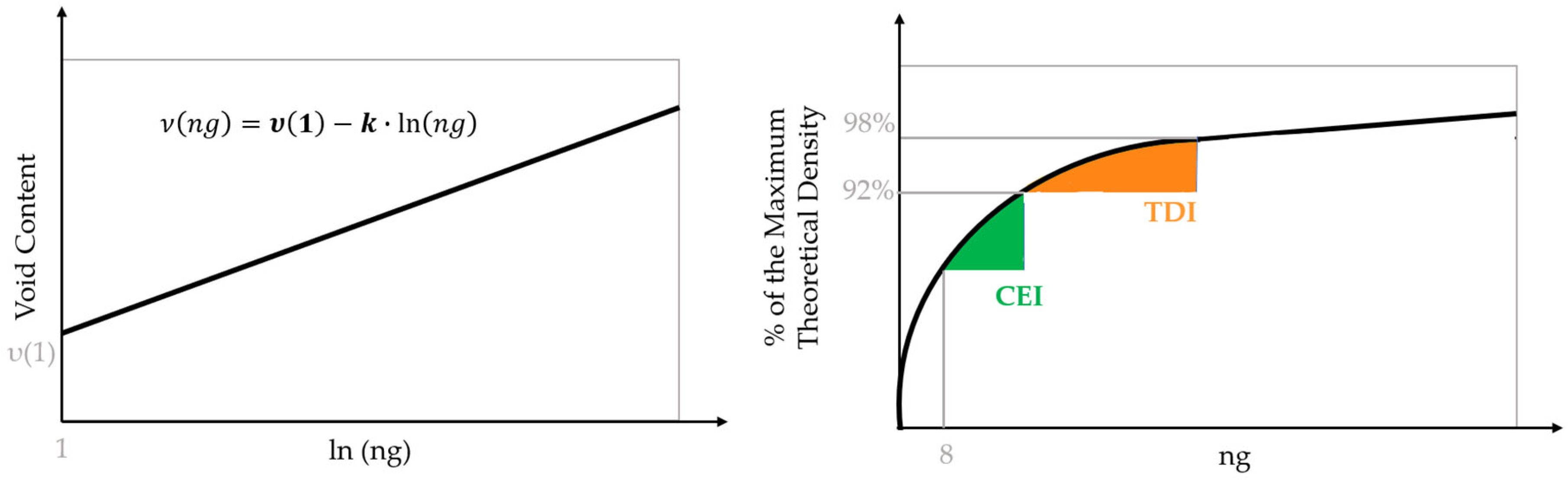

2.4.4. Rutting

3. Results and Discussion

3.1. Marshall and Volumetric Properties

3.2. Moisture Damage

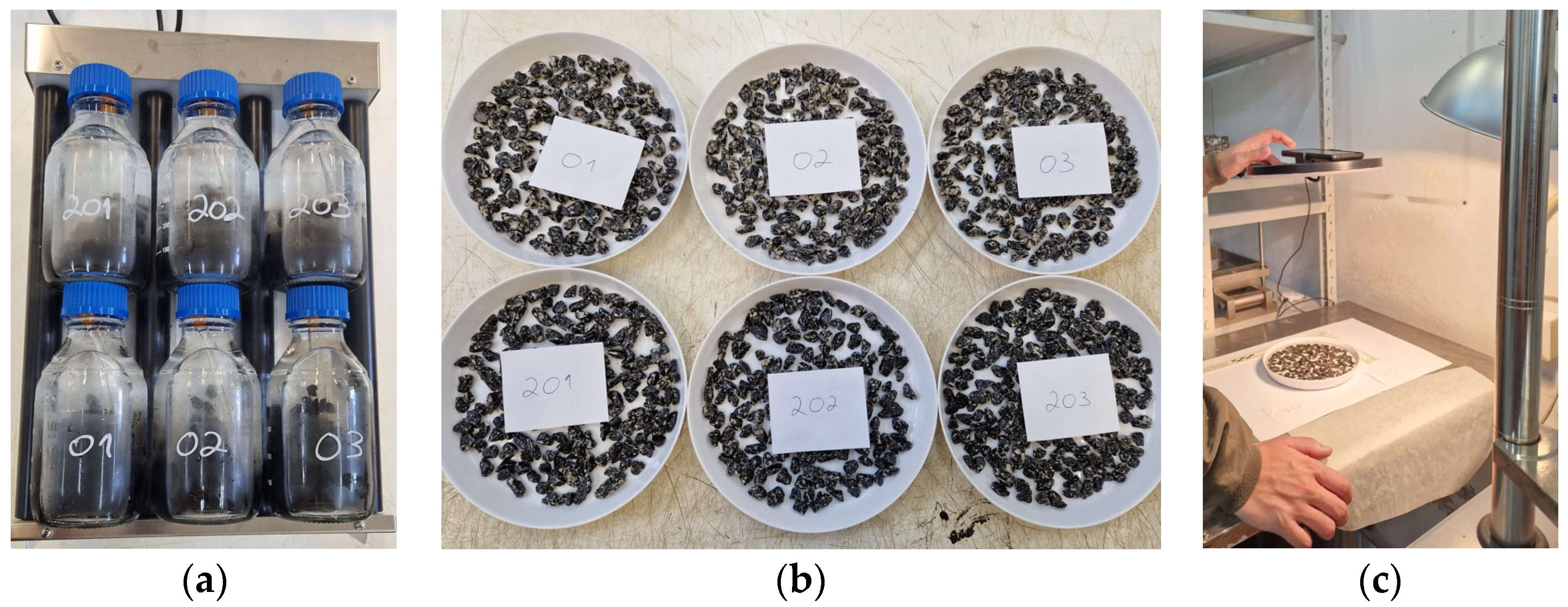

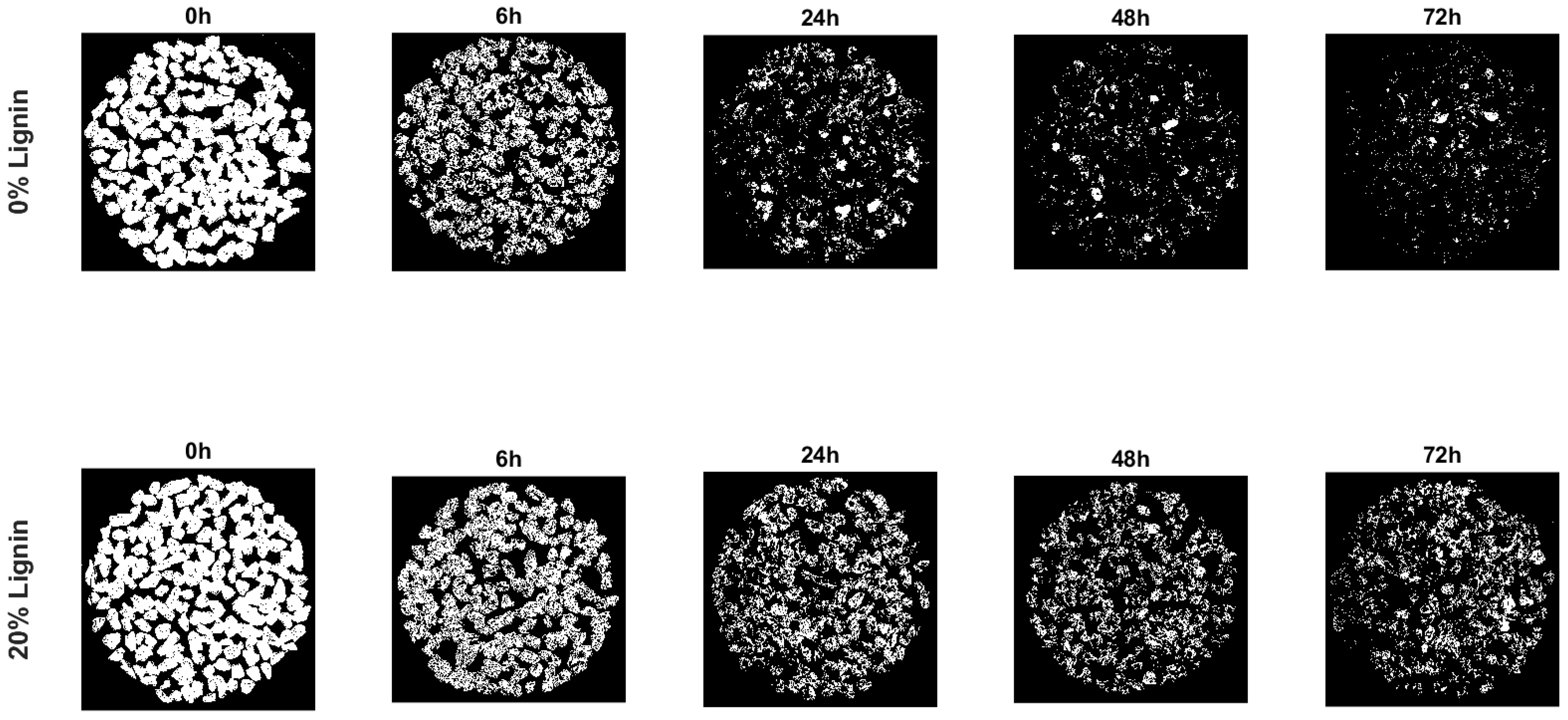

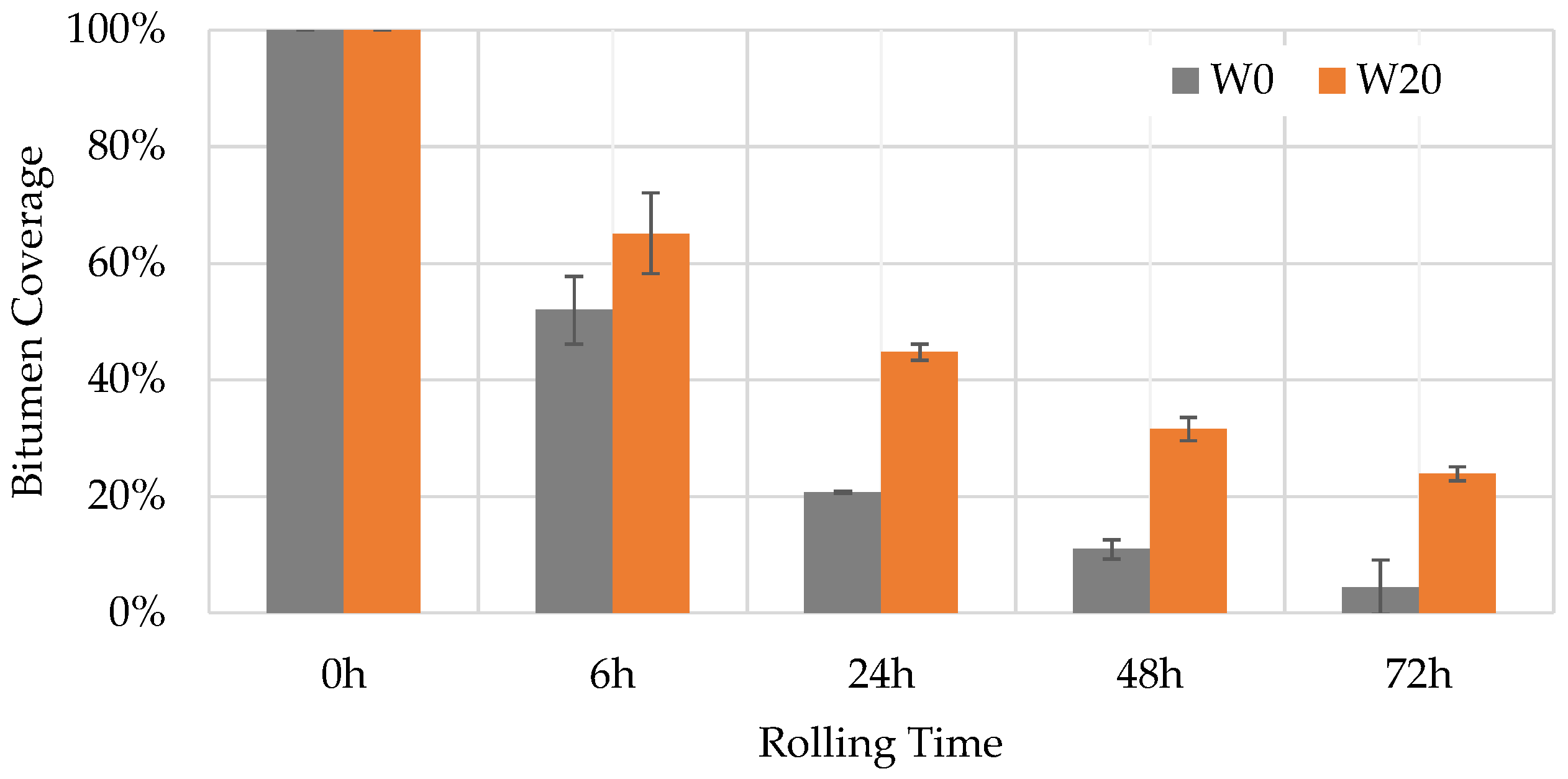

3.2.1. Rolling Bottle Test

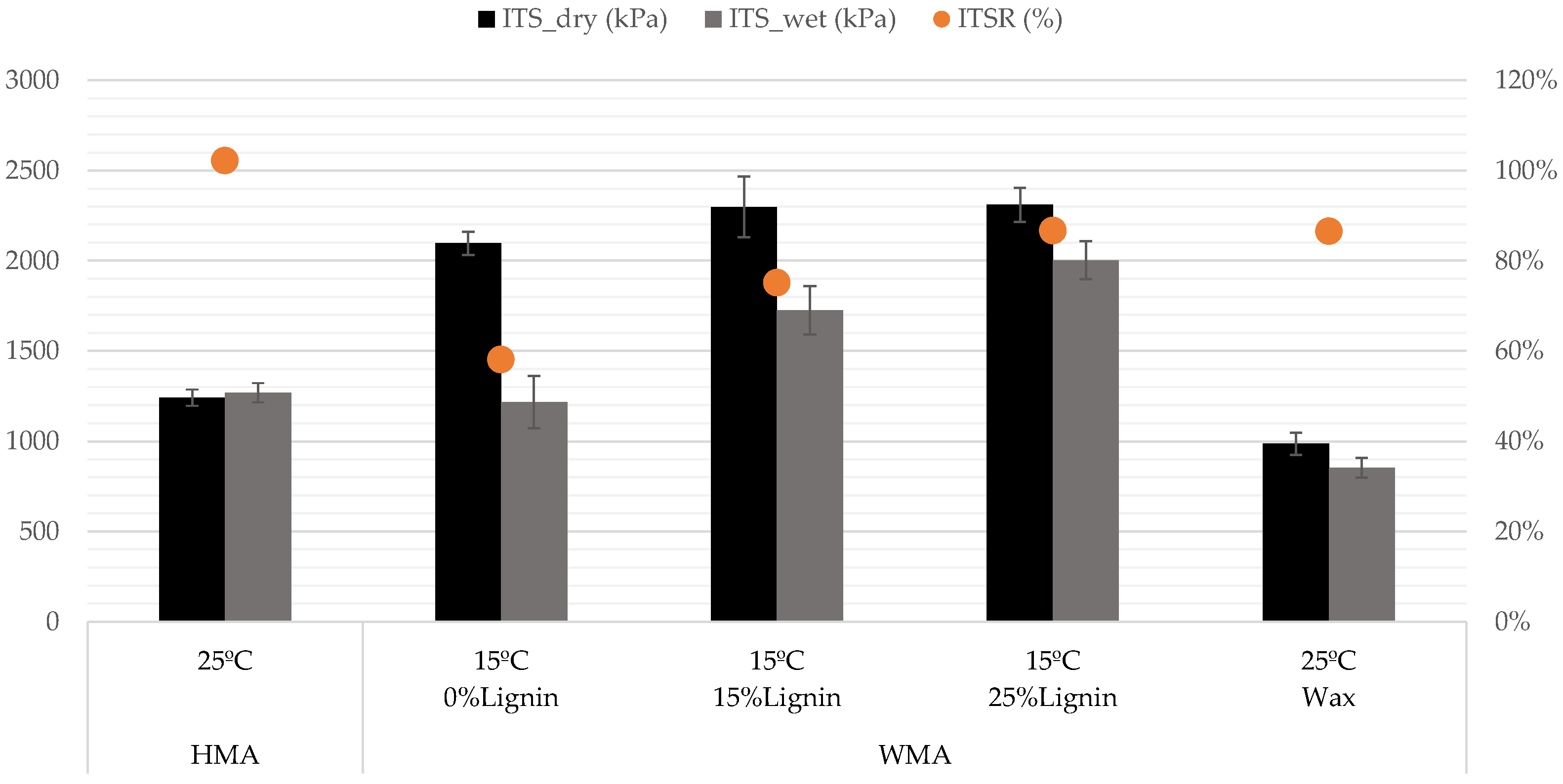

3.2.2. Indirect Tensile Strength Ratio (ITSR)

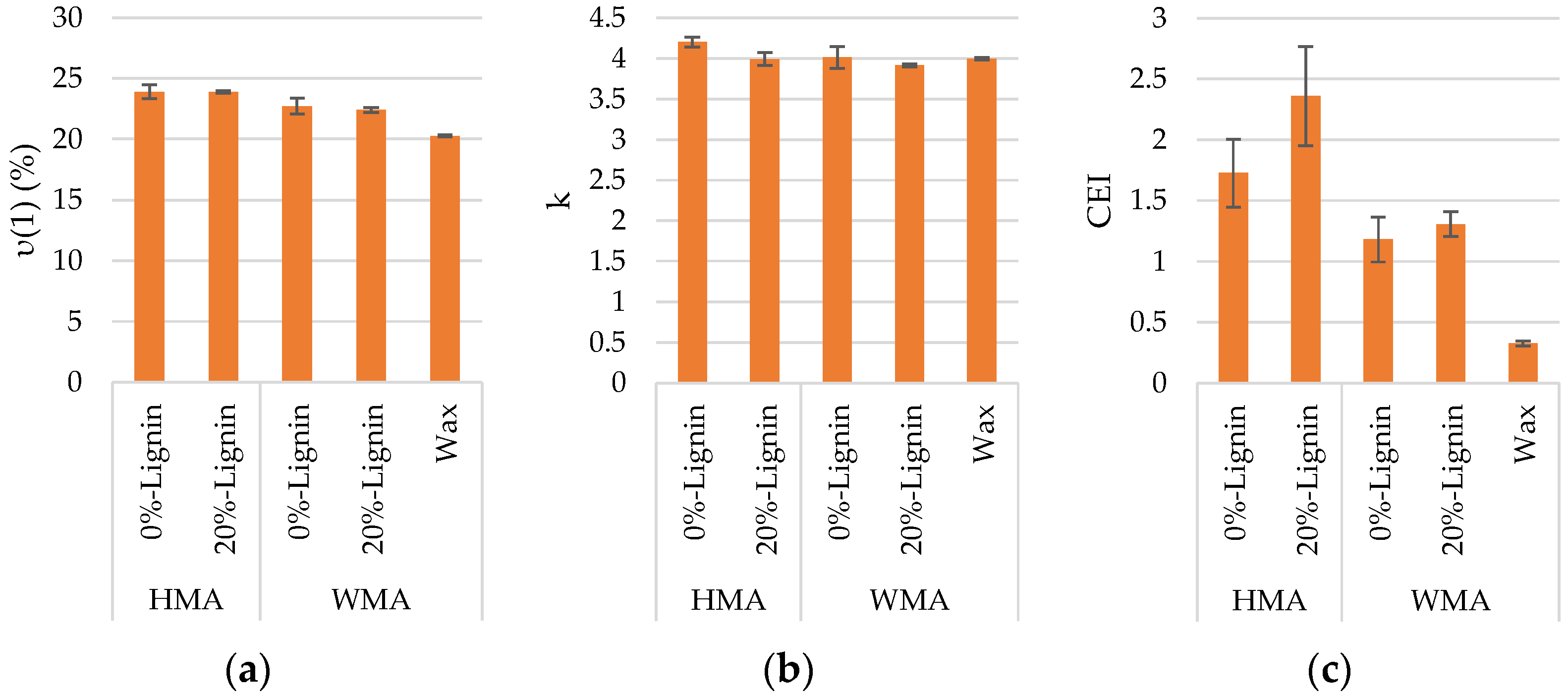

3.3. Workability

3.4. Rutting Resistance

3.5. Direct Cost Analysis

4. Conclusions

- -

- Marshall stability increased as lignin content increased up to 20% for HMA, but the influence was not visible for the WMA, and 15 or 20% lignin reduced Marshall flow for HMA and slightly increased it for WMA.

- -

- The void content seems not to be considerably influenced by adding lignin and reducing bitumen contents for WMA.

- -

- Adding lignin by the dry process enhanced the affinity between the bitumen and aggregates, comparing traditional WMA with wax and WMA with lignin.

- -

- Water sensitivity was not an issue for the 20% lignin WMA blend, which achieved ITSR values above 80%. Despite the reduction in bitumen content, ITSR achieved good performance, showing that lignin compensated for the effect of the replaced bitumen.

- -

- Although the different parameters used to assess workability delivered dissimilar conclusions, the findings show that the workability of WMA is not negatively influenced by 20% lignin. CEI results indicate improvement of WMA’s resistance to compaction despite this not occurring for HMA.

- -

- Addition of 20% lignin improved the rutting resistance performances of HMA and WMA. The most significant outcome is that the resistance was better than that observed for the WMA with wax (without lignin).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. World Energy Outlook; International Energy Agency: Paris, France, 2022. [Google Scholar]

- IEA. Renewables 2022—Analysis and Forecast to 2027 (Revised Version—January 2022); International Energy Agency: Paris, France, 2023. [Google Scholar]

- EU. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. L 328/82. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L2001 (accessed on 25 September 2023).

- Saravanan, A.; Yaashikaa, P.R.; Kumar, P.S.; Thamarai, P.; Deivayanai, V.C.; Rangasamy, G. A comprehensive review on techno-economic analysis of biomass valorisation and conversional technologies of lignocellulosic residues. Ind. Crops Prod. 2023, 200, 116822. [Google Scholar] [CrossRef]

- Abbas, M.; Peszlen, I.; Shi, R.; Kim, H.; Katahira, R.; Kafle, K.; Xiang, Z.; Huang, X.; Min, D.; Mohamadamin, M.; et al. Involvement of CesA4, CesA7-A/B and CesA8-A/B in secondary wall formation in Populus trichocarpa wood. Tree Physiol. 2020, 40, 73–89. [Google Scholar] [CrossRef] [PubMed]

- Alnadish, A.M.; Singh, N.S.; Alawag, A.M. Applications of Synthetic, Natural, and Waste Fibers in Asphalt Mixtures: A Citation-Based Review. Polymers 2023, 15, 1004. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Tataranni, P.; Sangiorgi, C. The use of fibres in asphalt mixtures: A state of the art review. Constr. Build. Mater. 2023, 390, 131754. [Google Scholar] [CrossRef]

- Saha, P.; Chowdhury, S.; Roy, D.; Adhikari, B.; Kim, J.K.; Thomas, S. A brief review on the chemical modifications of lignocellulosic fibers for durable engineering composites. Polym. Bull. 2016, 73, 587–620. [Google Scholar] [CrossRef]

- He, L.; Tao, M.; Liu, Z.; Cao, Z.; Zhu, J.; Gao, J.; Bergh, W.V.D.; Chailleux, E.; Huang, Y.; Vasconcelos, K.; et al. Biomass valorisation toward sustainable asphalt pavements: Progress and prospects. Waste Manag. 2023, 165, 159–178. [Google Scholar] [CrossRef] [PubMed]

- Ataeian, P.; Cheon, J.; Azimi Alamdary, Y.; Tam, K.C. Development of asphalt cements for road pavement using sustainable nanomaterials: A review. J. Vinyl Addit. Technol. 2023, 29, 574–588. [Google Scholar] [CrossRef]

- Nazari, M.; Mirbaha, B.; Abdi Kordani, A.; Mojabi, S.A. Laboratory Investigation of the Effect of Stone Mastic Asphalt Modified with SEBS Polymer and Cellulose Fibers on the Moisture Susceptibility. Int. J. Pavement Res. Technol. 2022, 15, 1317–1326. [Google Scholar] [CrossRef]

- Adewuyi, A. Underutilized Lignocellulosic Waste as Sources of Feedstock for Biofuel Production in Developing Countries. Front. Energy Res. 2022, 10, 741570. [Google Scholar] [CrossRef]

- Gaudenzi, E.; Cardone, F.; Lu, X.; Canestrari, F. The use of lignin for sustainable asphalt pavements: A literature review. Constr. Build. Mater. 2023, 362, 129773. [Google Scholar] [CrossRef]

- Ghabchi, R. Effect of Lignin Type as an Additive on Rheology and Adhesion Properties of Asphalt Binder. Solids 2022, 3, 603–619. [Google Scholar] [CrossRef]

- Mastrolitti, S.; Borsella, E.; Giuliano, A.; Petrone, M.; De Bari, I.; Gosselink, R.; van Erven, G.; Annevelink, E.; Traintafyllidis, K.; Stichnothe, H. Sustainable Lignin Valorisation: Technical Lignin, Processes and Market Development; IEA Bioenergy: Gela, Italy, 2021. [Google Scholar]

- Pérez, I.; Pasandín, A.R.; Pais, J.C.; Pereira, P.A.A. Feasibility of Using a Lignin-Containing Waste in Asphalt Binders. Waste Biomass Valorization 2020, 11, 3021–3034. [Google Scholar] [CrossRef]

- Faleva, A.V.; Grishanovich, I.A.; Ul’yanovskii, N.V.; Kosyakov, D.S. Application of 2D NMR Spectroscopy in Combination with Chemometric Tools for Classification of Natural Lignins. Int. J. Mol. Sci. 2023, 24, 12403. [Google Scholar] [CrossRef] [PubMed]

- Rodrigo, C.P.; James, W.H., III; Zwier, T.S. Single-Conformation Ultraviolet and Infrared Spectra of Jet-Cooled Monolignols: P-Coumaryl Alcohol, Coniferyl Alcohol, and Sinapyl Alcohol. J. Am. Chem. Soc. 2011, 133, 2632–2641. [Google Scholar] [CrossRef] [PubMed]

- Hobson, C. Evaluation of Lignin as an Antioxidant in Asphalt Binders and Bituminous Mixtures; Kansas Department of Transportation: Topeka, KS, USA, 2017. [Google Scholar]

- Vishtal, A.; Kraslawski, A. Challenges in industrial applications of technical lignins. BioResources 2011, 6, 3547–3568. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2020, 230, 117063. [Google Scholar] [CrossRef]

- Xu, C.; Wang, D.; Zhang, S.; Guo, E.; Luo, H.; Zhang, Z.; Yu, H. Effect of Lignin Modifier on Engineering Performance of Bituminous Binder and Mixture. Polymers 2021, 13, 1083. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Q.; Wang, C.; Wu, W.; Han, W. Investigation of lignin as an alternative extender of bitumen for asphalt pavements. J. Clean. Prod. 2021, 283, 124663. [Google Scholar] [CrossRef]

- Gaudenzi, E.; Cardone, F.; Lu, X.; Canestrari, F. Performance assessment of asphalt mixtures produced with a bio-binder containing 30% of lignin. Mater. Struct. 2022, 55, 221. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Zhang, Y.; Lin, P.; Apostolidis, P.; Erkens, S.; Li, M.; Xu, J. Multi-scale characterisation of lignin modified bitumen using experimental and molecular dynamics simulation methods. Constr. Build. Mater. 2021, 287, 123058. [Google Scholar] [CrossRef]

- Pan, T. A first-principles based chemophysical environment for studying lignins as an asphalt antioxidant. Constr. Build. Mater. 2012, 36, 654–664. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Apostolidis, P.; Gard, W.; van de Ven, M.; Erkens, S.; Jing, R. Chemical and Rheological Evaluation of Aged Lignin-Modified Bitumen. Materials 2019, 12, 4176. [Google Scholar] [CrossRef] [PubMed]

- Luo, D.; Khater, A.; Yue, Y.; Abdelsalam, M.; Zhang, Z.; Li, Y.; Li, J.; Iseley, D.T. The performance of asphalt mixtures modified with lignin fiber and glass fiber: A review. Constr. Build. Mater. 2019, 209, 377–387. [Google Scholar] [CrossRef]

- Norgbey, E.; Huang, J.; Hirsch, V.; Liu, W.J.; Wang, M.; Ripke, O.; Li, Y.; Takyi Annan, G.E.; Ewusi-Mensah, D.; Wang, X.; et al. Unravelling the efficient use of waste lignin as a bitumen modifier for sustainable roads. Constr. Build. Mater. 2020, 230, 116957. [Google Scholar] [CrossRef]

- Batista, K.B.; Padilha, R.P.L.; Castro, T.O.; Silva, C.F.S.C.; Araújo, M.F.A.S.; Leite, L.F.M.; Pasa, V.M.D.; Lins, V.F.C. High-temperature, low-temperature and weathering aging performance of lignin modified asphalt binders. Ind. Crops Prod. 2018, 111, 107–116. [Google Scholar] [CrossRef]

- Zahedi, M.; Zarei, A.; Zarei, M. The effect of lignin on mechanical and dynamical properties of asphalt mixtures. SN Appl. Sci. 2020, 2, 1242. [Google Scholar] [CrossRef]

- Arafat, S.; Kumar, N.; Wasiuddin, N.M.; Owhe, E.O.; Lynam, J.G. Sustainable lignin to enhance asphalt binder oxidative aging properties and mix properties. J. Clean. Prod. 2019, 217, 456–468. [Google Scholar] [CrossRef]

- NP EN 12591; Betumes e Ligantes Betuminosos—Especificações para Betumes de Pavimentação (Bitumen and Bituminous Binders—Specifications for Paving Grade Bitumens). IPQ: Caparica, Portugal, 2011.

- Almeida, A.; Capitão, S.; Bandeira, R.; Fonseca, M.; Picado-Santos, L. Performance of AC mixtures containing flakes of LDPE plastic film collected from urban waste considering ageing. Constr. Build. Mater. 2020, 232, 117253. [Google Scholar] [CrossRef]

- Almeida, A.; Capitão, S.; Estanqueiro, C.; Picado-Santosc, L. Possibility of incorporating waste plastic film flakes into warm-mix asphalt as a bitumen extender. Constr. Build. Mater. 2021, 291, 123384. [Google Scholar] [CrossRef]

- EN 13043; Aggregates for Bituminous Mixtures and Surface Treatments for Roads, Airfields and Other Trafficked Areas. CEN: Brussels, Belgium, 2002.

- EN 933-3; Tests for Geometrical Properties of Aggregates Determination of Particle Shape. Flakiness Index. CEN: Brussels, Belgium, 2012.

- EN 1097-2; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation. CEN: Brussels, Belgium, 2020.

- EN 1097-1; Tests for Mechanical and Physical Properties of Aggregates. Part 1: Determination of the Resistance to Wear (Micro-Deval). CEN: Brussels, Belgium, 2011.

- EN 1097-8; Tests for Mechanical and Physical Properties of Aggregates—Part 8: Determination of the Polished Stone Value. CEN: Brussels, Belgium, 2020.

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. CEN: Brussels, Belgium, 2022.

- EN 933-9; Tests for Geometrical Properties of Aggregates—Part 9: Assessment of Fines—Methylene Blue Test. CEN: Brussels, Belgium, 2022.

- EN 1097-4; Tests for Mechanical and Physical Properties of Aggregates Determination of the Voids of Dry Compacted Filler. CEN: Brussels, Belgium, 2008.

- EN 13179-1; Tests for Filler Aggregate Used in Bituminous Mixtures—Part 1: Delta Ring and Ball Test. CEN: Brussels, Belgium, 2000.

- Almeida, A.; Sergio, M. Evaluation of the Potential of Sasobit REDUX Additive to Lower Warm-Mix Asphalt Production Temperature. Materials 2019, 12, 1285. [Google Scholar] [CrossRef] [PubMed]

- EN 12697-30; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 30: Specimen Preparation by Impact Compactor. CEN: Brussels, Belgium, 2007.

- EN 12697-31; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 31: Specimen Preparation by Gyratory Compactor. CEN: Brussels, Belgium, 2004.

- EN 12697-33; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 33: Specimen Prepared by Roller Compactor. CEN: Brussels, Belgium, 2007.

- Capitão, S.D.; Picado-Santos, L.G.; Martinho, F. Pavement engineering materials: Review on the use of warm-mix asphalt. Constr. Build. Mater. 2012, 36, 1016–1024. [Google Scholar] [CrossRef]

- Roja, K.L.; Padmarekha, A.; Krishnan, J.M. Influence of warm mix additive and loading rate on rutting of warm mix asphalt pavement. Int. J. Pavement Eng. 2019, 20, 366–381. [Google Scholar] [CrossRef]

- EN 12697-6; Bituminous mixtures—Test methods for hot mix asphalt—Part 6: Determination of bulk density of bituminous specimens. CEN: Brussels, Belgium, 2007.

- EN 12697-34; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 34: Marshall Test. CEN: Brussels, Belgium, 2007.

- EN 12697-5; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 5: Determination of the Maximum Density. CEN: Brussels, Belgium, 2007.

- EN 12697-8; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 8: Determination of Void Characteristics of Bituminous Specimens. CEN: Brussels, Belgium, 2003.

- Kakar, M.R.; Hamzah, M.O.; Valentin, J. A review on moisture damages of hot and warm mix asphalt and related investigations. J. Clean. Prod. 2015, 99, 39–58. [Google Scholar] [CrossRef]

- Paliukaitė, M.; Vorobjovas, V.; Bulevičius, M.; Andrejevas, V. Evaluation of Different Test Methods for Bitumen Adhesion Properties. Transp. Res. Procedia 2016, 14, 724–731. [Google Scholar] [CrossRef]

- EN 12697-11; Bituminous Mixtures—Test Methods—Part 11: Determination of the Affinity between Aggregate and Bitumen. CEN: Brussels, Belgium, 2020.

- EN 12697-12; Bituminous Mixtures—Test Methods—Part 12: Determination of the Water Sensitivity of Bituminous Specimens. CEN: Brussels, Belgium, 2018.

- Zaidi, S.B.A.; Grenfell, J.; Airey, G.; Ahmad, N.; Ahmed, I.; Fareed, A.; Abed, A. Application of image analysis tools in Matlab to better estimate the degree of binder coverage in rolling bottles test. Road Mater. Pavement Des. 2022, 23, 601–616. [Google Scholar] [CrossRef]

- EN 12697-23; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. CEN: Brussels, Belgium, 2003.

- Tran, N.; Turner, P.; Shambley, J. Enhanced Compaction to Improve Durability and Extend Pavement Service Life: A Literature Review; NCAT Report No. 16-02R; National Center for Asphalt Technology at Auburn University: Auburn, AL, USA, 2016. [Google Scholar]

- Yan, T.; Marasteanu, M.O.; Le, J.-L. Mechanism-based evaluation of compactability of asphalt mixtures. Road Mater. Pavement Des. 2021, 22, S482–S497. [Google Scholar] [CrossRef]

- Faheem, A.; Bahia, H. Using the Gyratory Compactor to Measure Mechanical Stability of Asphalt Mixtures; Wisconsin Department of Transportation—Division of Transportation Infrastructure Development: Milwaukee, WI, USA, 2004. [Google Scholar]

- EN 12697-10; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 10: Compactability. CEN: Brussels, Belgium, 2001.

- Capitão, S.; Almeida, A.; Picado-Santos, L. 7—Volumetric properties, workability, and mechanical performance of waste plastic-modified asphalt mixtures. In Plastic Waste for Sustainable Asphalt Roads; Giustozzi, F., Nizamuddin, S., Eds.; Woodhead Publishing: Kidlington, UK, 2022; pp. 117–144. [Google Scholar]

- Ziaee, S.A.; Moghadas Nejad, F.; Dareyni, M.; Fakhri, M. Evaluation of rheological and mechanical properties of hot and warm mix asphalt mixtures containing Electric Arc Furnace Slag using gyratory compactor. Constr. Build. Mater. 2023, 378, 131042. [Google Scholar] [CrossRef]

- Gardete, D.; Picado-Santos, L.; Capitão, S.; Luzia, R. Asphalt mix design: Discussion on the bulk specific gravity procedure influence on the results obtained from empirical, volumetric, and performance-based methods. Constr. Build. Mater. 2022, 342, 127870. [Google Scholar] [CrossRef]

- EN 12697-22; Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 22: Wheel Tracking. CEN: Brussels, Belgium, 2007.

- Pérez, I.P.; Rodríguez Pasandín, A.M.; Pais, J.C.; Alves Pereira, P.A. Use of lignin biopolymer from industrial waste as bitumen extender for asphalt mixtures. J. Clean. Prod. 2019, 220, 87–98. [Google Scholar] [CrossRef]

- Crucho, J.; Picado-Santos, L.; Neves, J.; Capitão, S.; Al-Qadi, I.L. Tecnico accelerated ageing (TEAGE)—A new laboratory approach for bituminous mixture ageing simulation. Int. J. Pavement Eng. 2020, 21, 753–765. [Google Scholar] [CrossRef]

| Property | Standard | Units | Gneiss 8/20 | Gneiss 4/12 | Sand 0/4 | Filler | Limit |

|---|---|---|---|---|---|---|---|

| Flakiness index (FI) | EN 933-3 [37] | % | FI15 | FI15 | --- | --- | FI20 |

| Resistance to fragmentation: Los Angeles (LA) | EN 1097-2 [38] | % | LA20 | LA20 | --- | --- | LA30 |

| Resistance to wear: micro-Deval (MDE) | EN 1097-1 [39] | % | MDE10 | MDE10 | --- | --- | MDE15 |

| Polished stone value (PSV) | EN 1097-8 [40] | % | PSV50 | PSV50 | --- | --- | PSV50 |

| Water absorption (WA) | EN 1097-6 [41] | % | 0.5 | 0.6 | 0.6 | --- | WA241 |

| Assessment of fines: methylene blue (MBF) | EN 933-9 [42] | g/kg | --- | --- | MBF10 | MBF10 | MBF10 |

| Voids of dry compacted filler (ν) | EN 1097-4 [43] | % | --- | --- | --- | 32 | ν28/38 |

| Delta ring and ball (ΔR&B) | EN 13179-1 [44] | °C | --- | --- | --- | 14 | ΔR&B |

| Components | Quantity | |

|---|---|---|

| Glucan | g/kg TS | 292 |

| Lignin (Klason lignin) | % TS | 64.6 |

| Mixture | Specimen | RDAIR (mm) | PRDAIR (%) | WTSAIR (mm/103 Cycles) | ||||

|---|---|---|---|---|---|---|---|---|

| HMA | 0% Lignin | No.1 | 3.4 | 3.5 | 8.5% | 8.7% | 0.137 | 0.130 |

| No.2 | 3.5 | 8.8% | 0.122 | |||||

| 20% Lignin | No.1 | 1.3 | 1.2 | 3.2% | 3.0% | 0.031 | 0.030 | |

| No.2 | 1.2 | 2.9% | 0.028 | |||||

| WMA | 0% Lignin | No.1 | 8.6 | 8.7 | 21.5% | 21.7% | 0.547 | 0.506 |

| No.2 | 8.8 | 21.9% | 0.465 | |||||

| 20% Lignin | No.1 | 6.3 | 6.8 | 15.7% | 16.9% | 0.322 | 0.336 | |

| No.2 | 7.2 | 18.0% | 0.350 | |||||

| Wax | No.1 | 7.4 | 7.9 | 18.4% | 19.6% | 0.382 | 0.401 | |

| No.2 | 8.3 | 20.9% | 0.421 | |||||

| Costs and Simple Resources | Average Unit Prices | HMA 1 | WMA 2 | |||

|---|---|---|---|---|---|---|

| Organic Wax | Lignin | |||||

| € | € | € | ||||

| Direct costs | Materials | Bitumen 35/50 | 565 €/t | 28.25 | 28.25 | 22.60 |

| Natural aggregates | 11 €/t | 10.45 | 10.45 | 10.45 | ||

| Lignin | 100 €/t | 1.00 | ||||

| Organic wax | 3200 €/t | 2.40 | ||||

| Equipment 3 | Asphalt plant | 400 €/h | 7.00 | 6.00 | 6.00 | |

| Loader | 60 €/h | 1.05 | 1.05 | 1.05 | ||

| Lorries 3 | 60 €/h | 4.50 | 4.50 | 4.50 | ||

| Paver | 80 €/h | 1.00 | 0.80 | 0.80 | ||

| Rollers 3 | 40 €/h | 1.00 | 0.80 | 0.80 | ||

| Labour | Skilled workers | 17 €/h | 0.89 | 0.89 | 0.89 | |

| Unskilled workers | 10 €/h | 1.40 | 1.40 | 1.40 | ||

| Other costs & contingencies (10%) | 5.55 | 5.65 | 4.95 | |||

| Overhead (10%) | 6.11 | 6.22 | 5.44 | |||

| Profit (10%) | 6.72 | 6.84 | 5.99 | |||

| TOTALS (€ per ton of mixture) | 73.9 | 75.3 | 65.9 | |||

| TOTALS (% of AC 14 surf 35/50) | 98.2% | 100.0% | 87.5% | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pascoal, A.; Almeida, A.; Capitão, S.; Picado-Santos, L. Improvement of Warm-Mix Asphalt Concrete Performance with Lignin Obtained from Bioethanol Production from Forest Biomass Waste. Materials 2023, 16, 7339. https://doi.org/10.3390/ma16237339

Pascoal A, Almeida A, Capitão S, Picado-Santos L. Improvement of Warm-Mix Asphalt Concrete Performance with Lignin Obtained from Bioethanol Production from Forest Biomass Waste. Materials. 2023; 16(23):7339. https://doi.org/10.3390/ma16237339

Chicago/Turabian StylePascoal, André, Arminda Almeida, Silvino Capitão, and Luís Picado-Santos. 2023. "Improvement of Warm-Mix Asphalt Concrete Performance with Lignin Obtained from Bioethanol Production from Forest Biomass Waste" Materials 16, no. 23: 7339. https://doi.org/10.3390/ma16237339

APA StylePascoal, A., Almeida, A., Capitão, S., & Picado-Santos, L. (2023). Improvement of Warm-Mix Asphalt Concrete Performance with Lignin Obtained from Bioethanol Production from Forest Biomass Waste. Materials, 16(23), 7339. https://doi.org/10.3390/ma16237339