Research on Temperature Field of Controllable Bonded Prestressed Structure Based on Electrothermal Method

Abstract

:1. Introduction

2. Temperature Testing of Controllable Bonded Prestressed Members

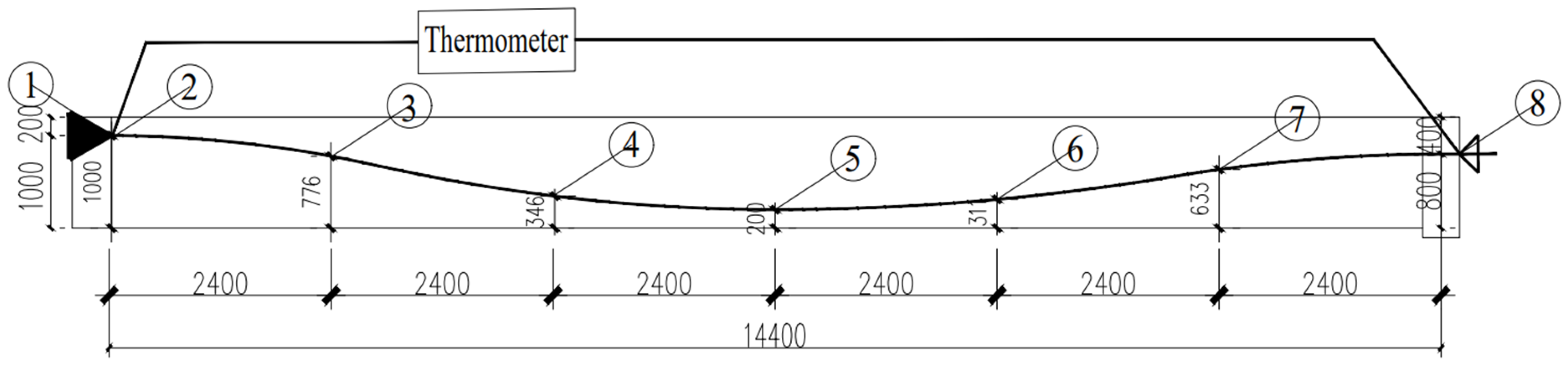

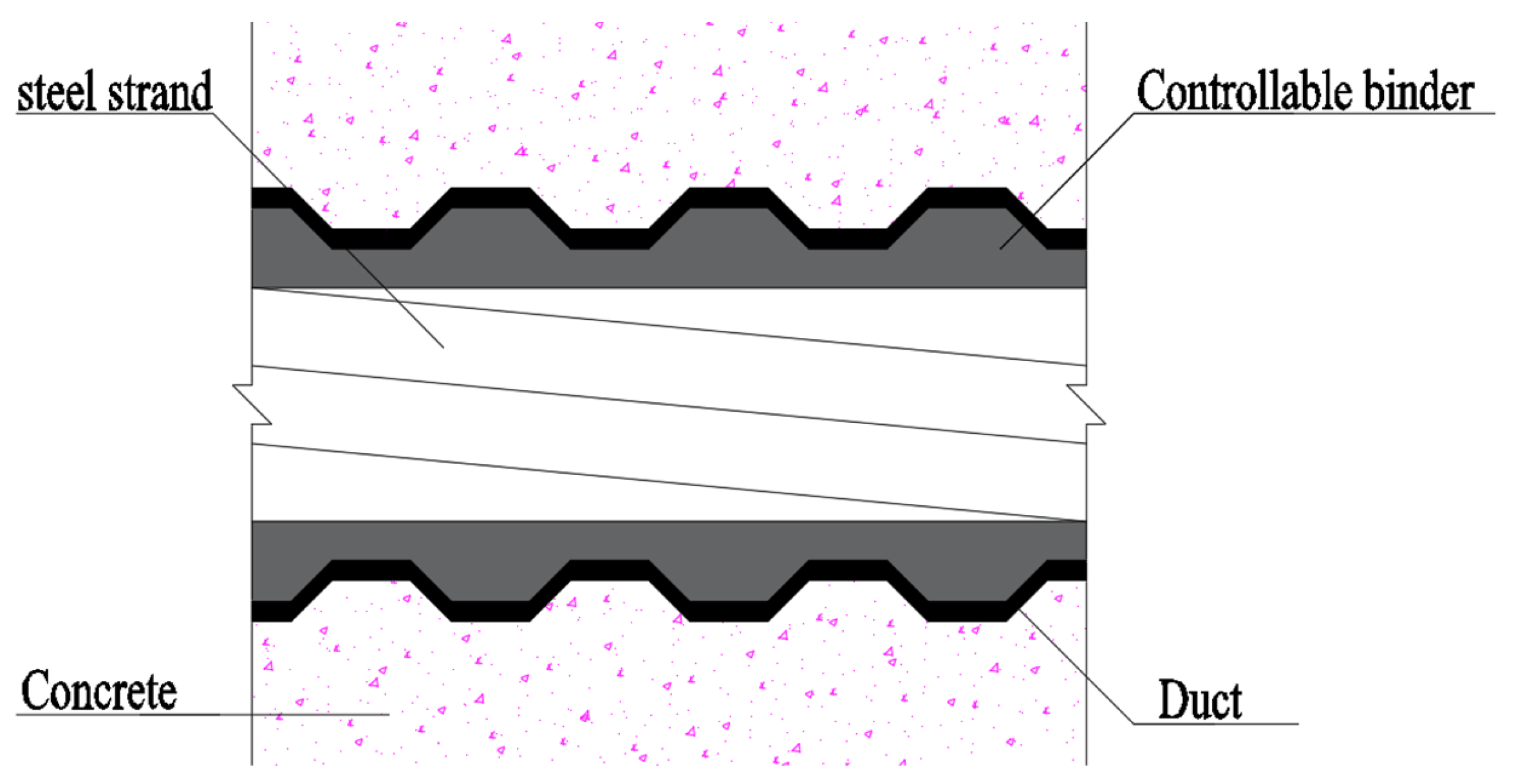

2.1. Test Profile

25 longitudinal reinforcements, while the lower segment featured 7

25 longitudinal reinforcements, while the lower segment featured 7  25 longitudinal reinforcements and

25 longitudinal reinforcements and  8 stirrups. In addition, there is a bundle of four 15.2 mm pre-tensioned prestressed steel strands before hoisting with a strength level of 1860 MPa.

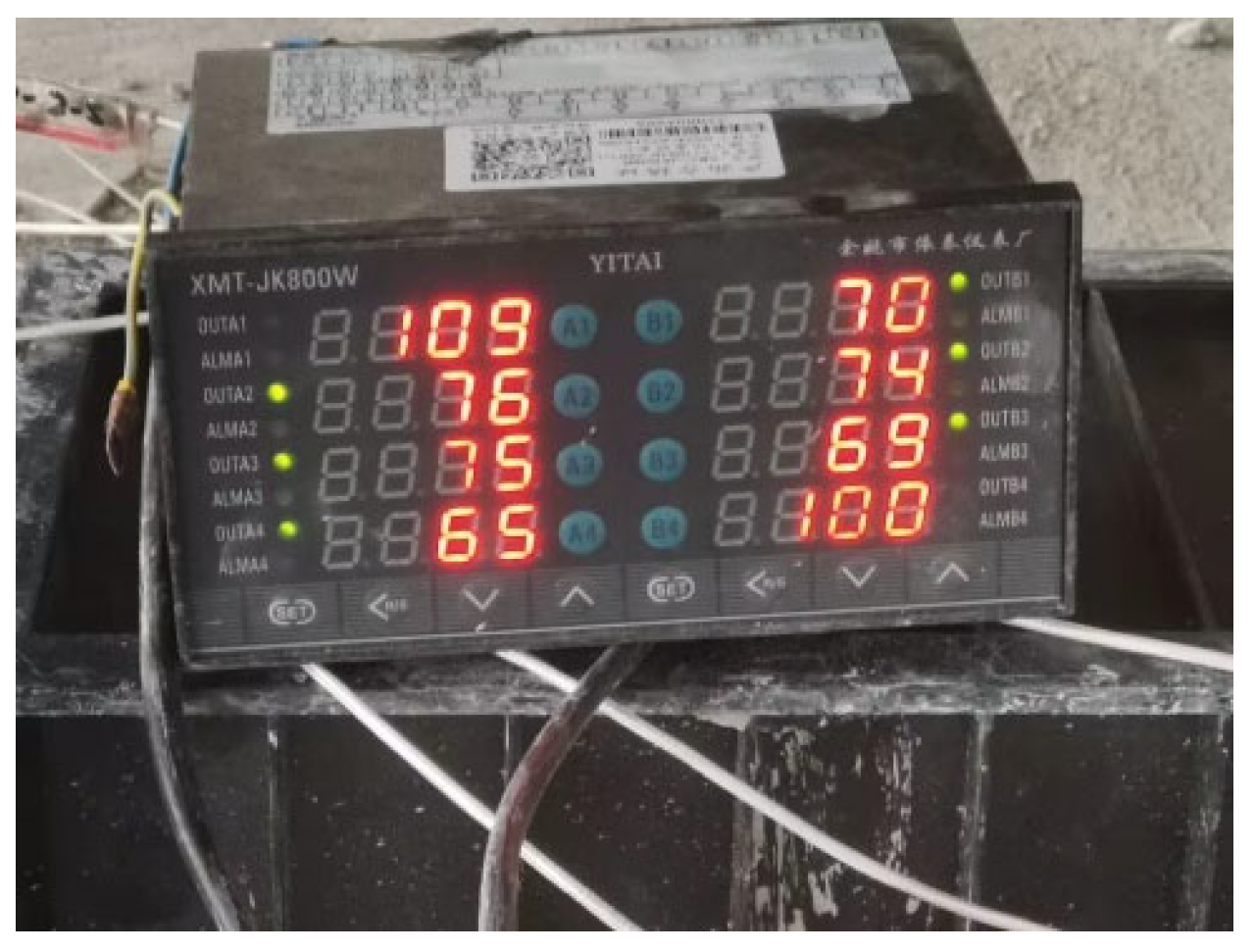

8 stirrups. In addition, there is a bundle of four 15.2 mm pre-tensioned prestressed steel strands before hoisting with a strength level of 1860 MPa.2.2. Experimental Setup

2.3. Operating Conditions

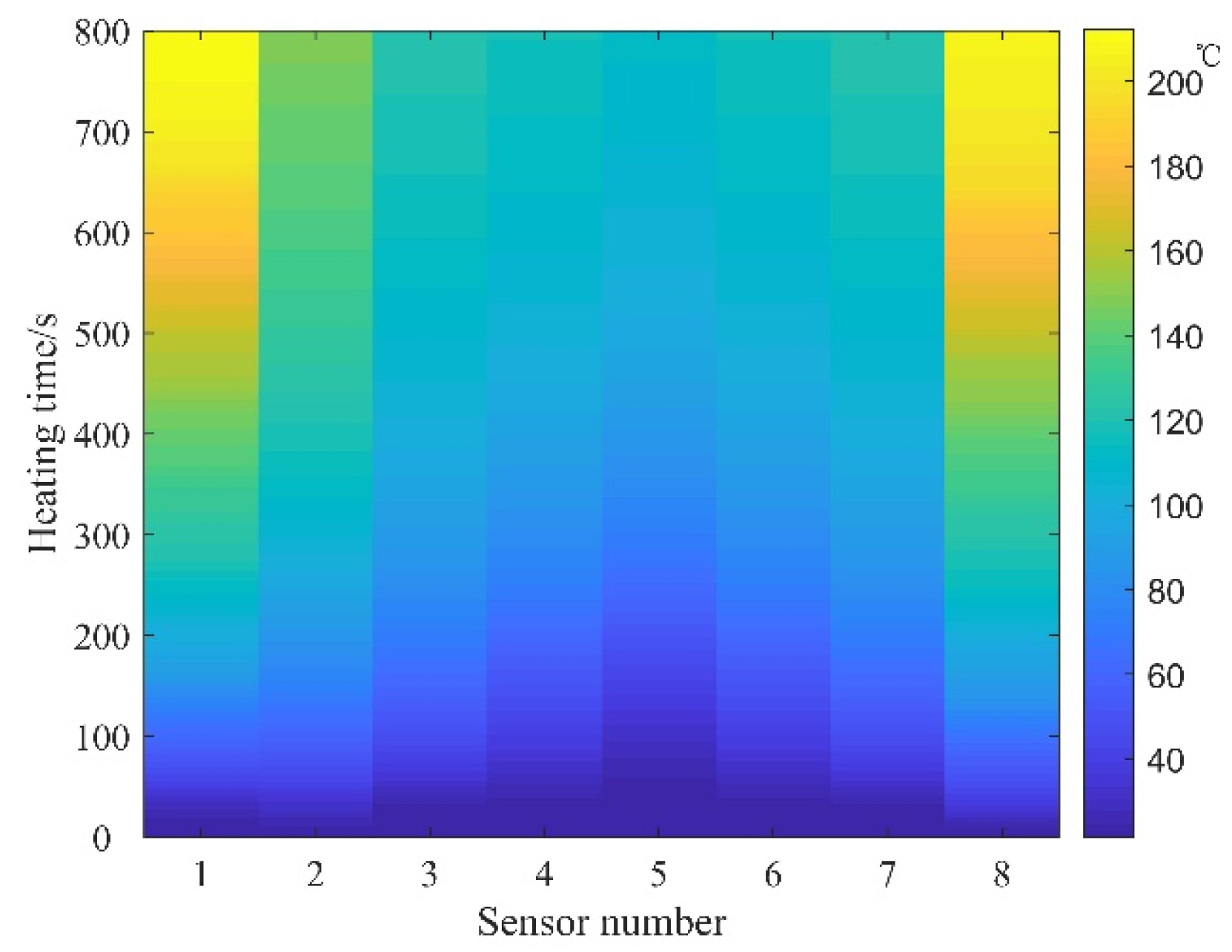

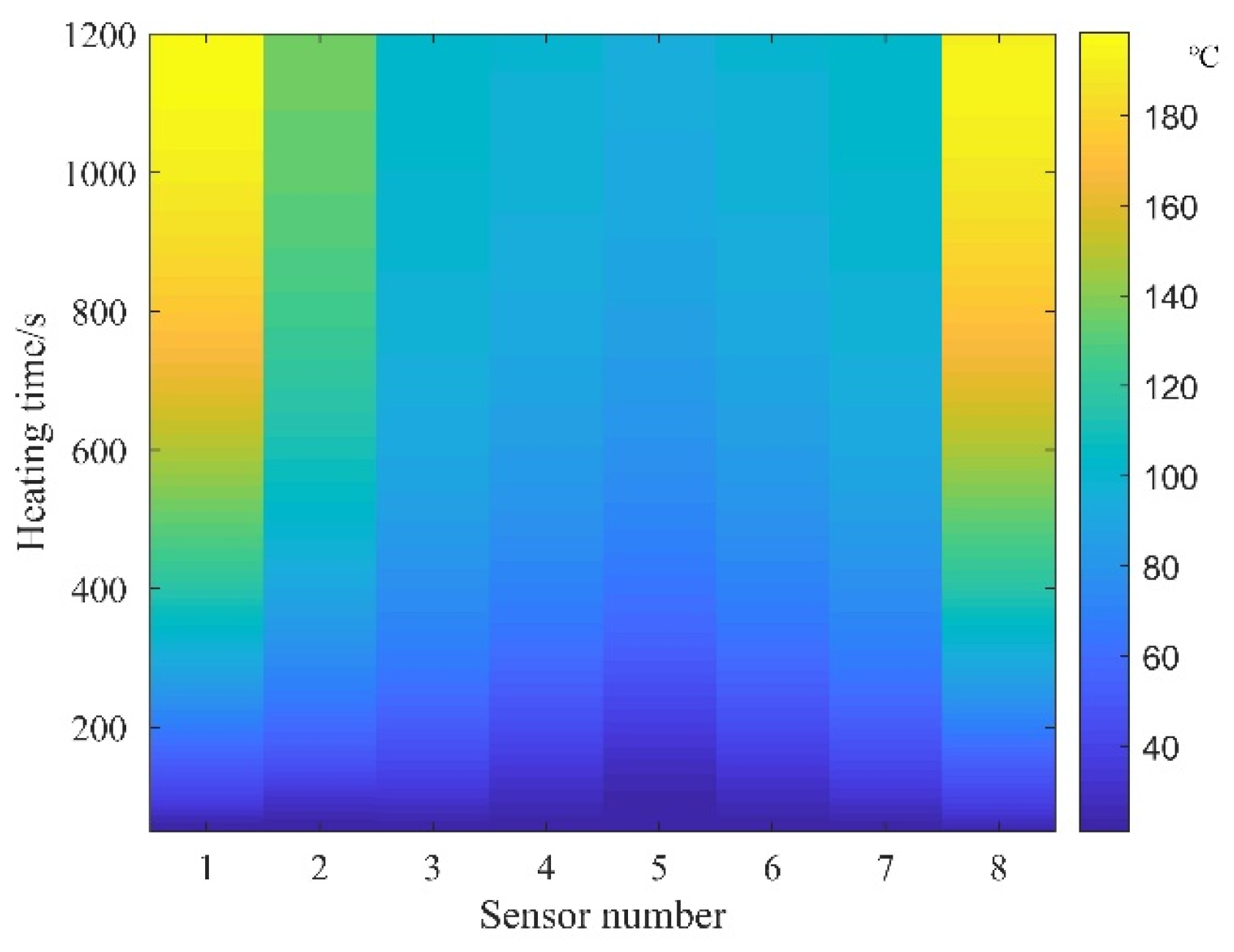

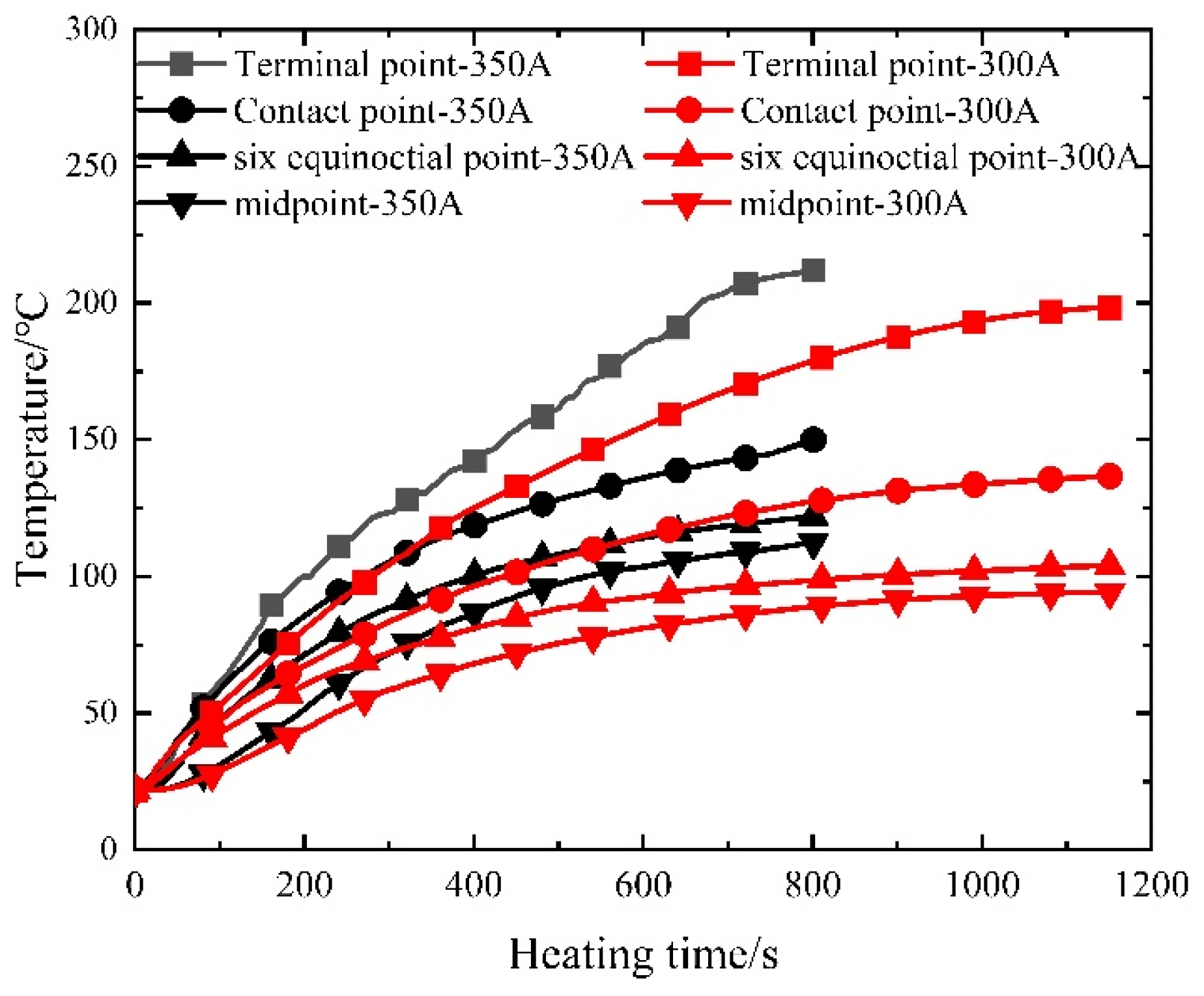

3. Test Results and Discussions

- The temperature field within prestressed concrete showcases symmetry, yielding a more uniform temperature distribution. Despite the concrete’s poor thermal conductivity, measuring points nearer the concrete surface exhibit lower temperatures, indicative of higher heat loss.

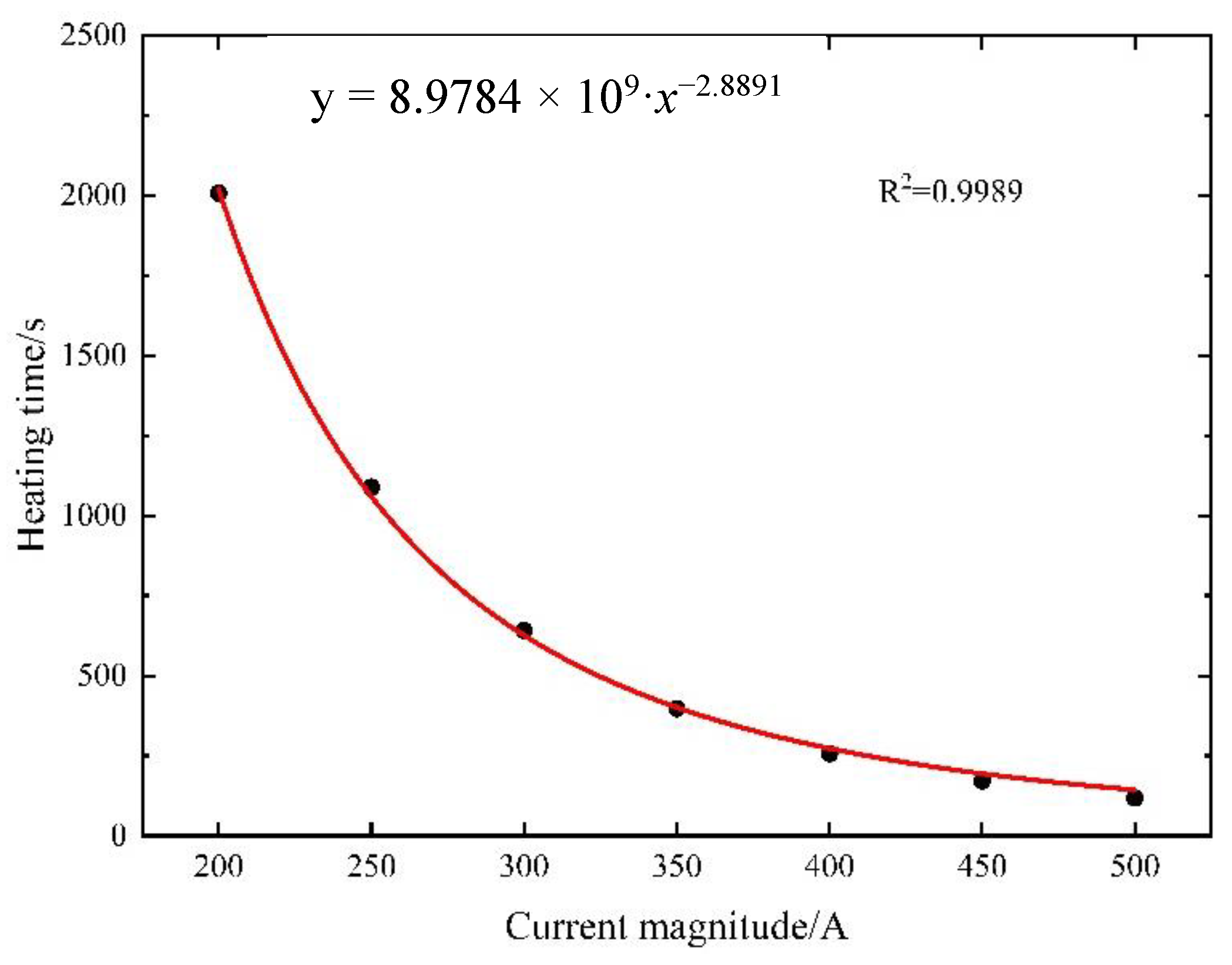

- Larger currents lead to swifter temperature elevation in controllable bonded prestressed reinforcement upon power activation. However, with smaller currents, the heating power deficiency intensifies the heat transfer between the controllable bonded prestressed reinforcement and its surroundings as the temperature rises. In the later stages, the prestressed reinforcement attains a balance between the temperature rise and heat dissipation, resulting in a quicker approach to stable temperature conditions. During this phase, despite ongoing electric heating, the temperature remains nearly constant at a certain level, fostering favorable conditions for the curing reaction of the controllable bonded binder within this environment. The comparison of stable temperatures under different current sizes is tabulated in Table 3. By evaluating the ratio of stable temperature to current size, a positive correlation between the stable temperature and current size becomes apparent. Notably, changes in current size exert a significant influence on the endpoint temperature while impacting the prestressed reinforcement within the concrete to a relatively lesser extent.

- The temperature variation trend within the exposed concrete of controllable adhesive tendons mirrors that of the interior, albeit with higher actual temperatures. In practical applications where internal temperature sensing is unfeasible, estimating internal temperature can be approximated by measuring the contact point between prestressed tendons and concrete.

- The measured temperature-induced stress aligns remarkably well with theoretical values, indicating that during electric heating of prestressed strands, steel strands undergo uninhibited elongation within the controllable bonded binder. This observation implies that temperature-induced stress can be leveraged to impart lower prestress, thus fostering a more even distribution of effective prestress throughout the prestressed strands.

4. Temperature Field Simulation and Analysis

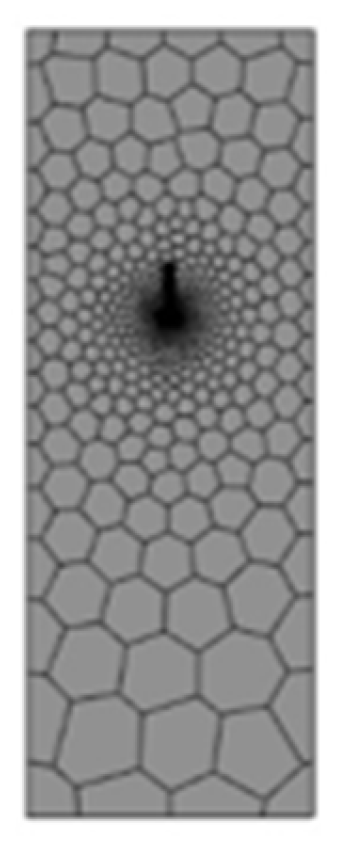

4.1. Model Development

4.1.1. Model Overview and Description

4.1.2. Mesh Generation

4.1.3. Applied Loads and Boundary Conditions

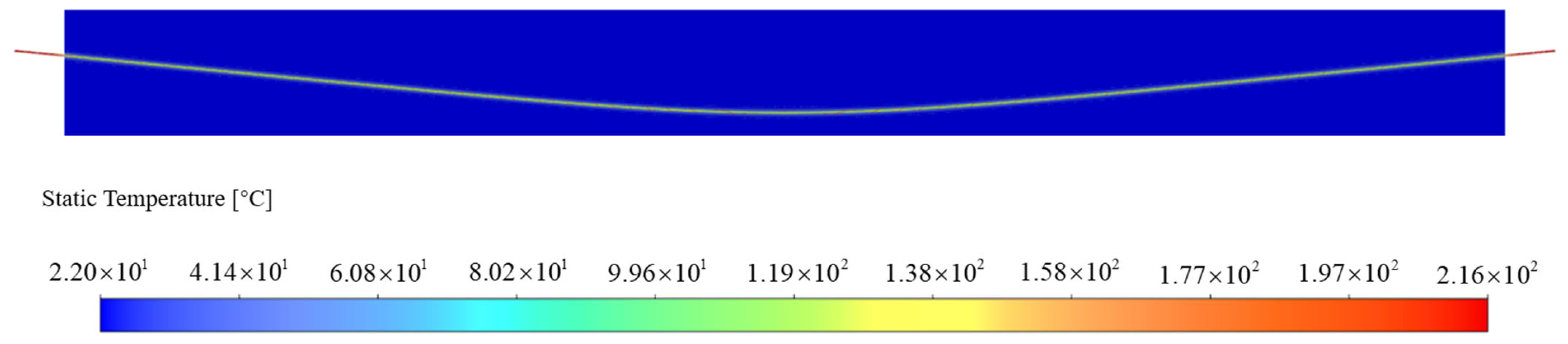

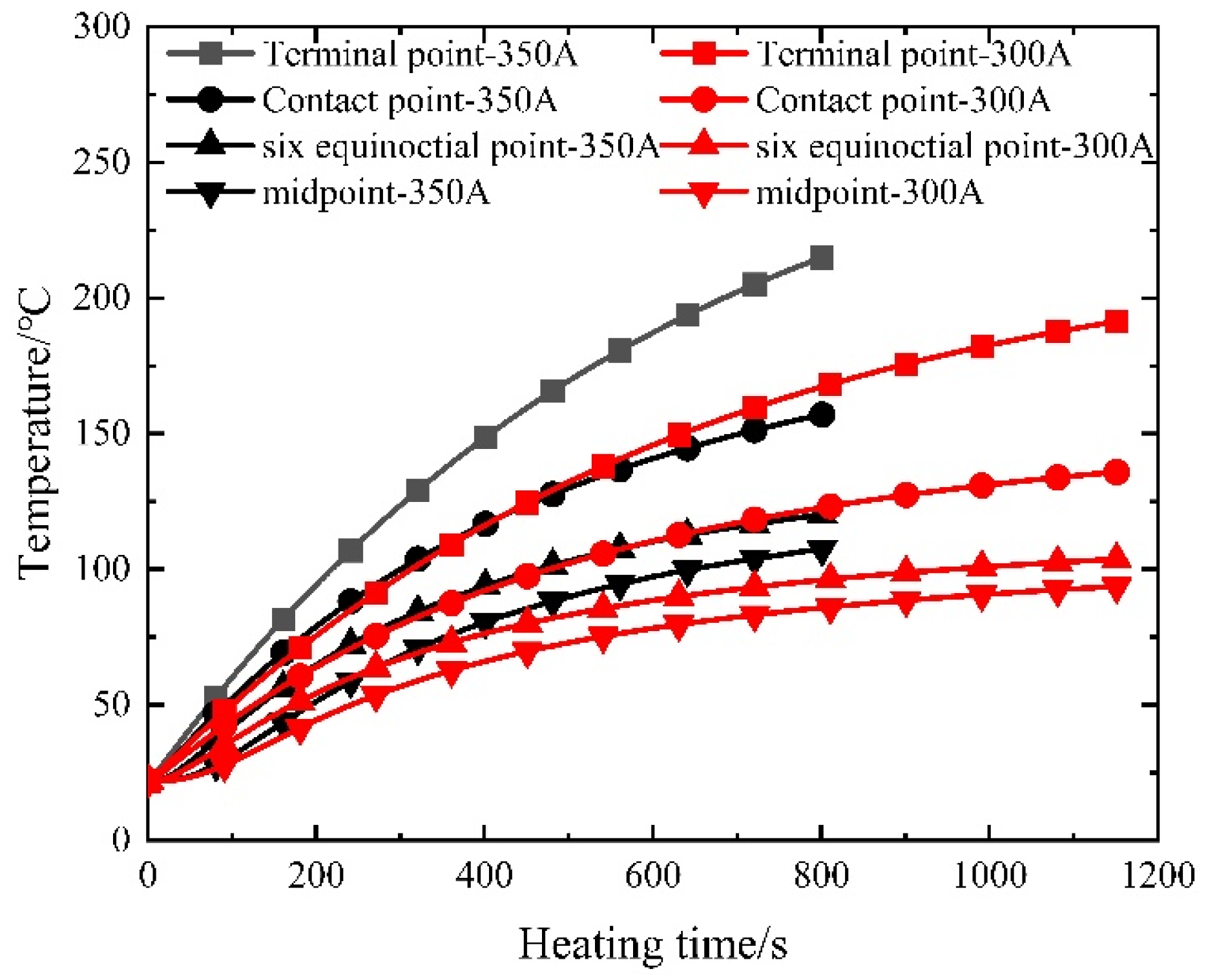

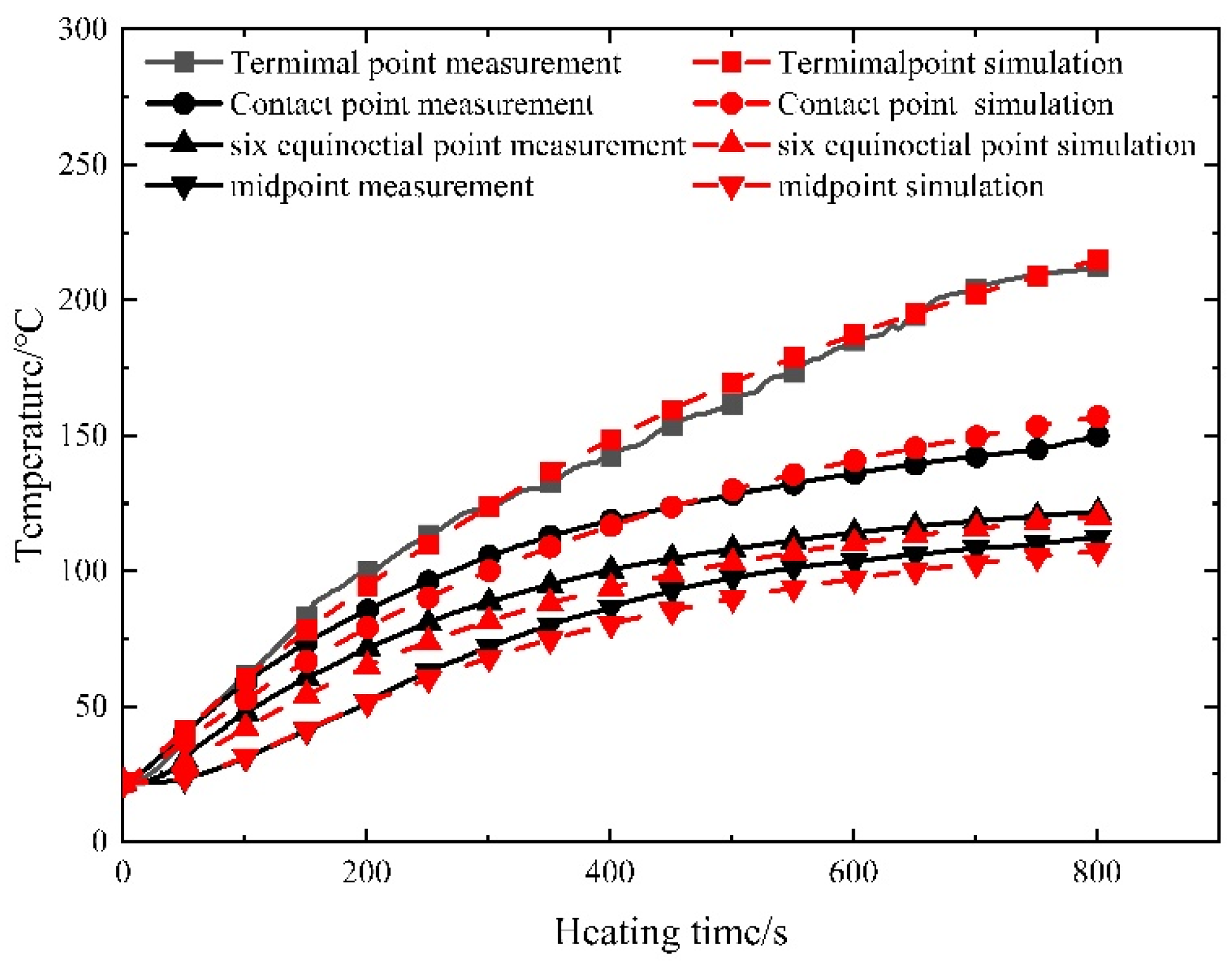

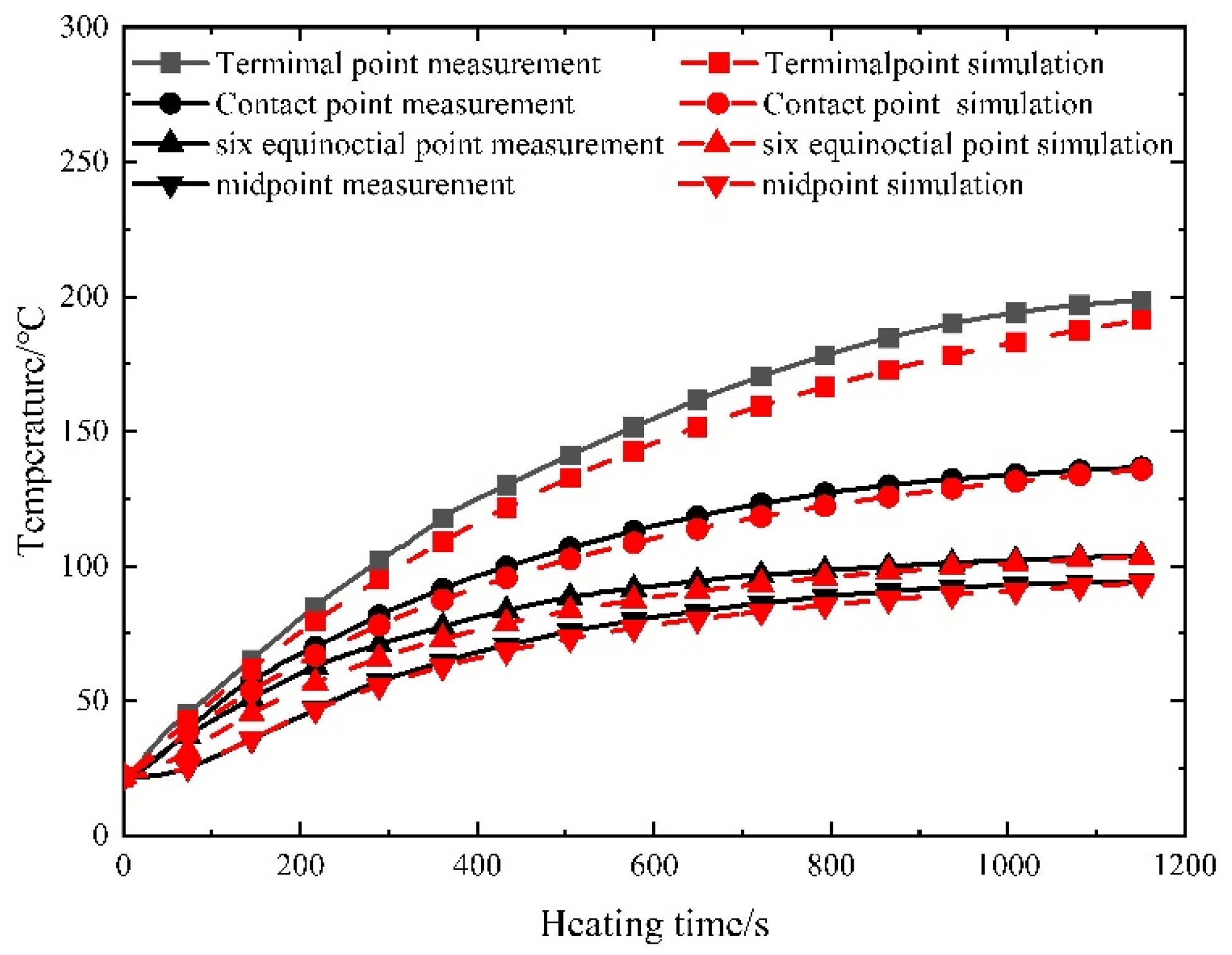

4.2. Simulation Results and Experimental Validation

- (1)

- The steel strand’s endpoint experiences high temperatures, with the maximum temperature reaching 216 °C.

- (2)

- The temperature decreases rapidly along the steel strand from its endpoint to the contact point with the concrete. At the contact point, the temperature registers at 150 °C.

- (3)

- The temperature distribution within the steel strand inside the concrete manifests symmetry. Notably, the temperature slightly diminishes towards the middle of the span. For instance, the sixth point reflects a temperature of 121.9 °C, while the lowest temperature of 112.3 °C occurs at the midpoint.

4.3. Parameter Analysis

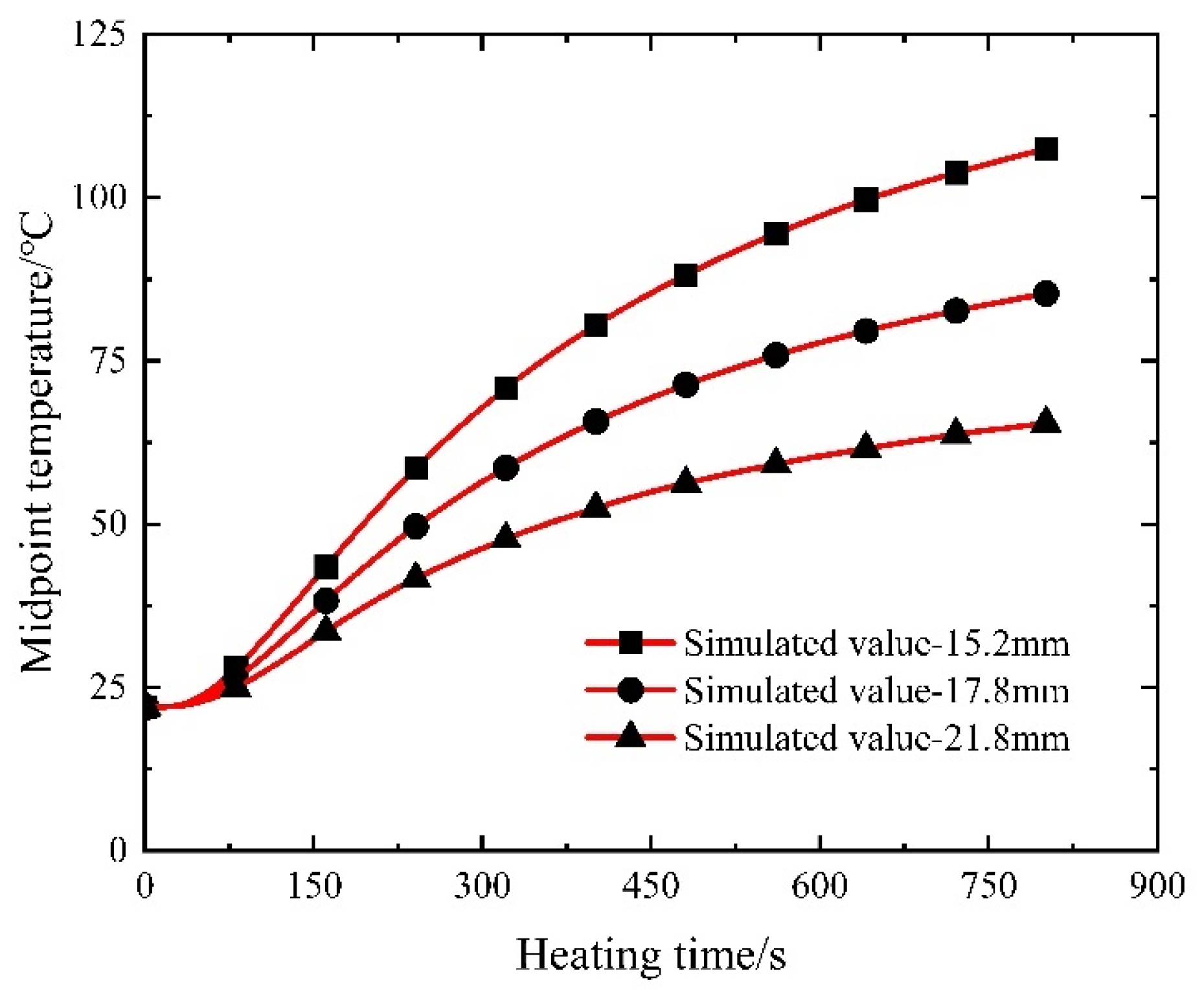

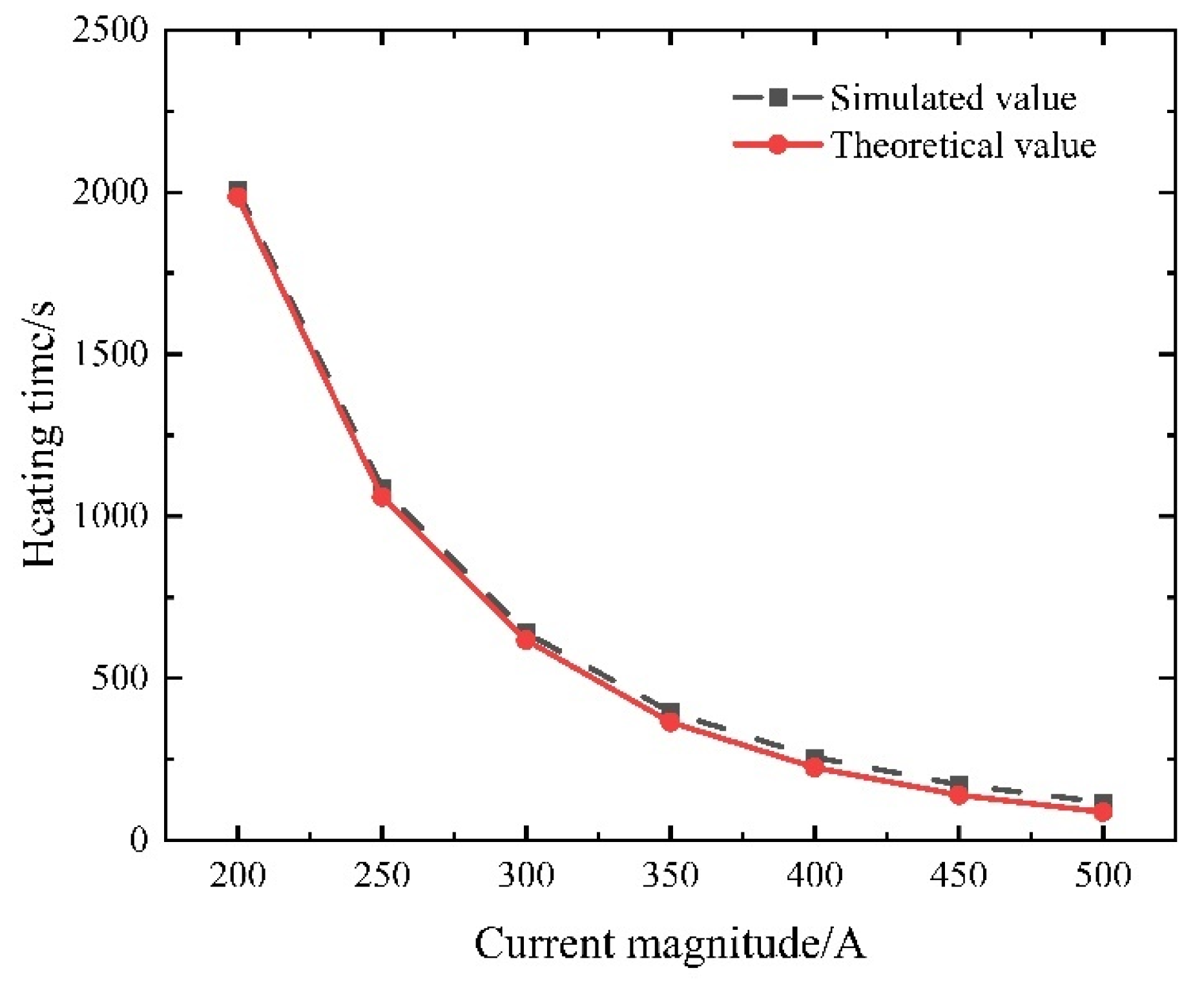

4.3.1. Current Size

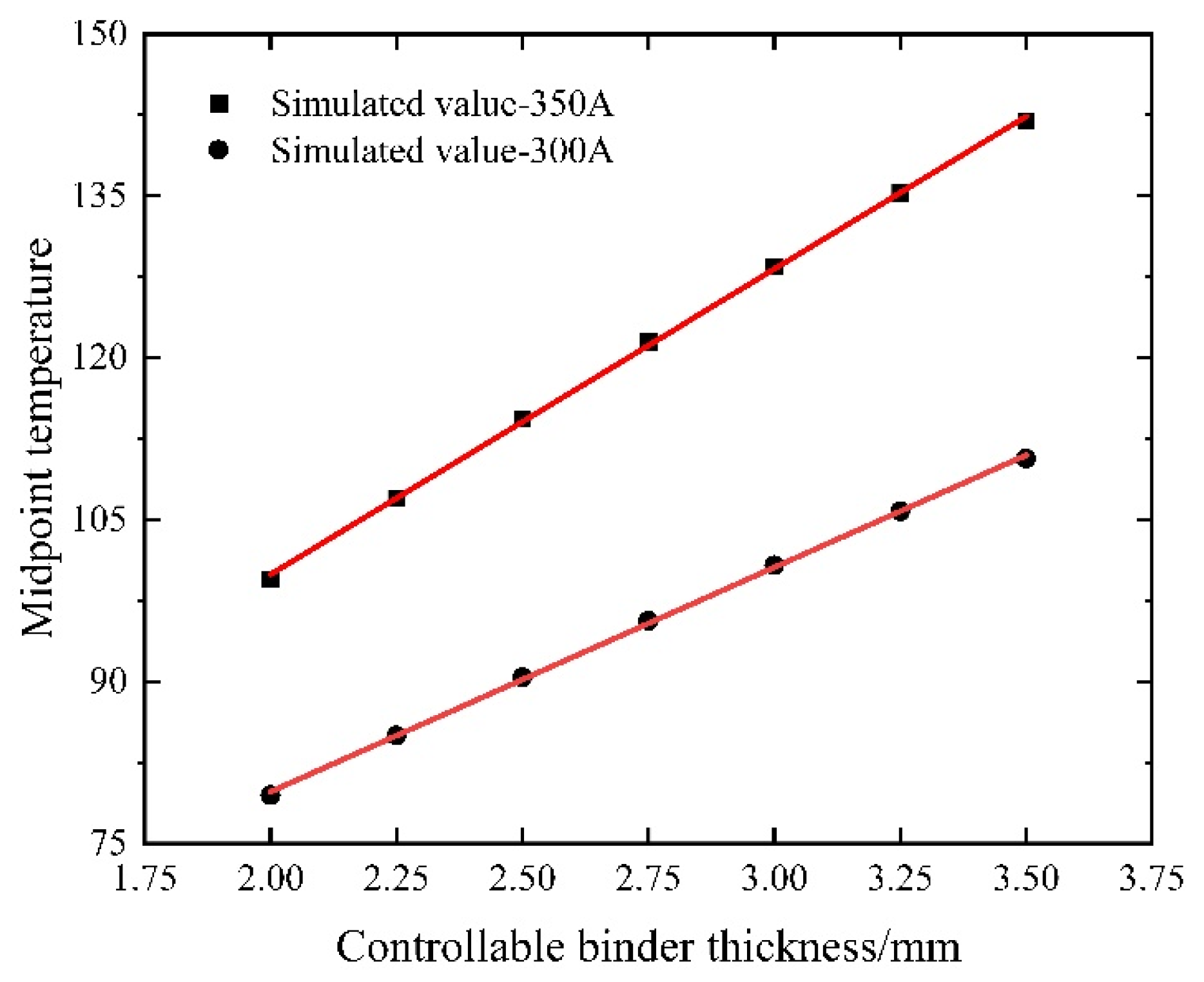

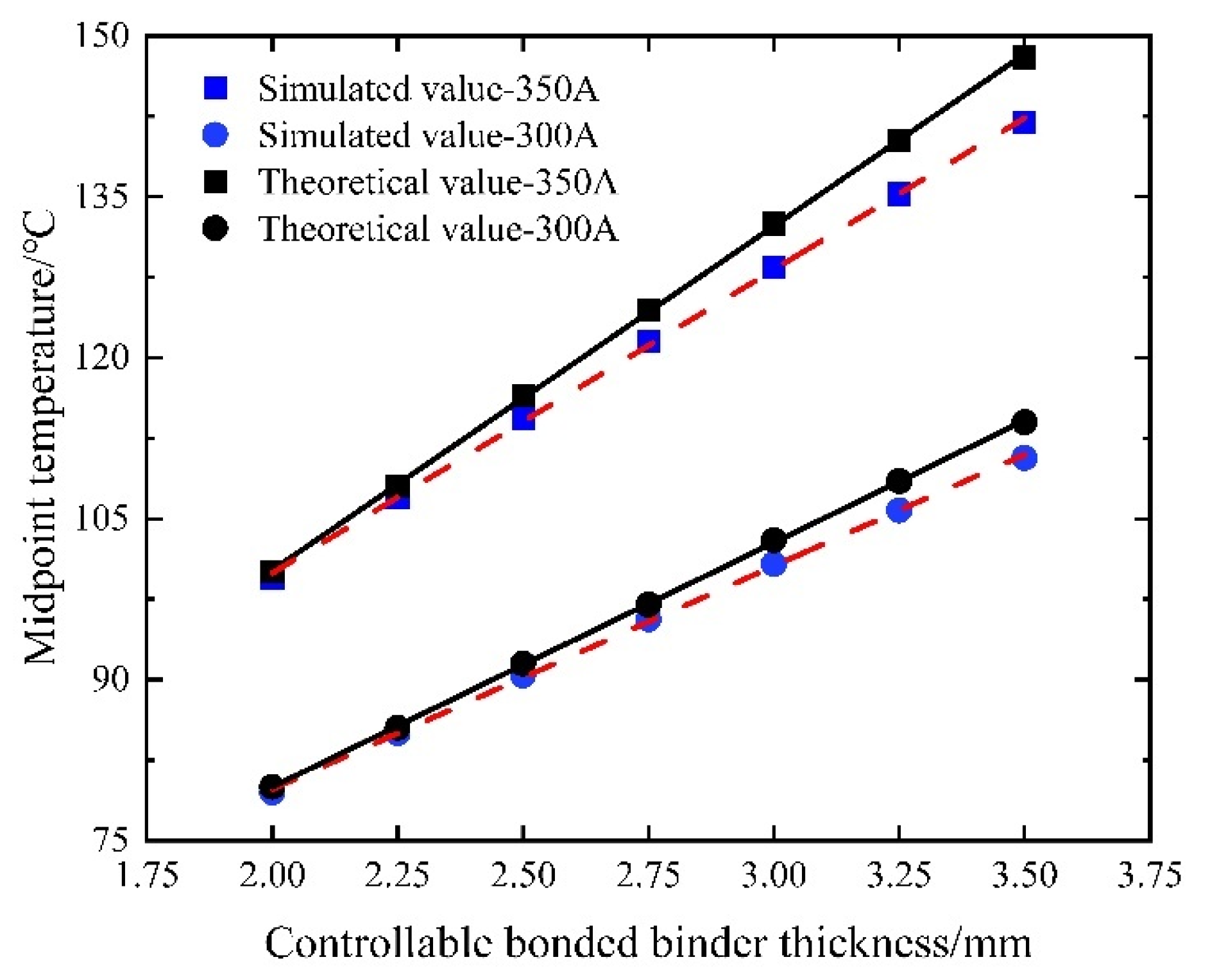

4.3.2. Controllable Bonded Binder Thickness

4.3.3. Diameter of Steel Strand

5. Theoretical Temperature Field Calculation for Controllable Bonded Prestressed Members

5.1. Stehfest Numerical Algorithm

5.2. Mathematical Formulation of Controllable Bonded Prestressing Electrothermal Method

5.3. Analysis and Comparative Results

5.3.1. Current Size

5.3.2. Controllable Bonded Binder Thickness

5.3.3. Diameter of Steel Strand

6. Conclusions

- (1)

- Feasibility and control of electric heating: The utilization of electric heating to regulate the temperature within controllable bonded prestressed reinforcement proves to be a viable and effective technique in terms of energy consumption, efficiency, and safety. However, precise control of the heating current is crucial to prevent the adverse effects caused by excessively high temperatures resulting from inadequate current, prolonged heating durations, or excessive current flow. This ensures the preservation of both the structural integrity and mechanical properties of the steel strand and concrete.

- (2)

- Agreement between theoretical model and experimental data: The developed theoretical model for electric heating of controllable bonded prestressed reinforcement demonstrates remarkable agreement with the observed distribution of the temperature field. The maximum relative error of 1.73% highlights the accuracy achieved by this proposed theoretical framework.

- (3)

- Optimization through current size and binder thickness: The analysis reveals that increasing the current size while judiciously augmenting the thickness of controllable bonded binder contributes to a reduction in heating time. Selecting an appropriate current size is pivotal in establishing a stable temperature environment conducive to the curing process.

- (4)

- Theoretical solution for parameter determination: The theoretical solution method proposed in this study surpasses the experimental results, providing the capability to calculate the temperature field values based on actual material parameters in real-world applications. This facilitates the identification of optimal heating parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Laura, A.; Antonio, B.; Giuseppe, D. Damage and collapse mode of existing post tensioned precast concrete bridge: The case of Petrulla viaduct. Eng. Struct. 2018, 162, 226–244. [Google Scholar]

- Takashi, K.; Akira, Y.; Kumi, H.; Kazuhiro, F.; Takeshi, Y.; Norio, T. Immobilization of flame-retardant onto silica nanoparticle surface and properties of epoxy resin filled with the flame-retardant-immobilized silica. React. Funct. Polym. 2013, 73, 613–618. [Google Scholar]

- JG/T 370-2012; Adhesive for Retard-Bonded Prestressing Steel Strand. Standardization Administration of the People’s Republic of China: Beijing, China, 2012. (In Chinese)

- JGJ 369-2016; Code for Design of Prestressed Concrete Structures. Standardization Administration of the People’s Republic of China: Beijing, China, 2016. (In Chinese)

- JG/T 387-2012; Filled Epoxy-Coated Prestressing Steel Strand. Standardization Administration of the People’s Republic of China: Beijing, China, 2012. (In Chinese)

- Xiong, X.Y.; Xiao, Q.S.; Li, X. Review of research on retard-bonded prestressed. Build. Struct. 2018, 48, 83–90. (In Chinese) [Google Scholar]

- Yin, S.; Meng, F. Research on electric heating technology for prestressed reinforcement of old concrete Bridges. Eng. Equip. Mater. 2021, 5, 145–146. (In Chinese) [Google Scholar]

- Santos, A.; Santos, P. Effect of surface preparation and bonding agent on the concrete-to-concrete interface strength. Constr. Build. Mater. 2012, 37, 102–110. [Google Scholar] [CrossRef]

- Ahmed, H.; Aziz, O. Shear behavior of dry and epoxied joints in precast concrete segmental box girder bridges under direct shear loading. Eng. Struct. 2019, 182, 89–100. [Google Scholar] [CrossRef]

- Diab, A.; Elmoaty, A.; Eldin, M. Slant shear bond strength between self compacting concrete and old concrete. Constr. Build. Mater. 2017, 130, 73–82. [Google Scholar] [CrossRef]

- Valikhani, A.; Jahromi, A.; Mantawy, A.; Azizinamini, A. Experimental evaluation of concrete-to-UHPC bond strength with correlation to surface roughness for repair application. Const. Build. Mater. 2020, 238, 117753. [Google Scholar] [CrossRef]

- Yeon, J.; Song, Y.; Kim, K.; Kang, J. Effects of Epoxy Adhesive Layer Thickness on Bond Strength of Joints in Concrete Structures. Materials 2019, 12, 2396. [Google Scholar] [CrossRef]

- Çolak, A.; Çoşgun, T.; Bakırcı, A. Effects of environmental factors on the adhesion and durability characteristics of epoxy-bonded concrete prisms. Constr. Build. Mater. 2009, 23, 758–767. [Google Scholar] [CrossRef]

- Czaderski, C.; Martinelli, E.; Michels, J.; Motavalli, M. Effect of curing conditions on strength development in an epoxy resin for structural strengthening. Compos. Part B-Eng. 2012, 43, 398–410. [Google Scholar] [CrossRef]

- Moussa, O.; Vassilopoulos, A.; Castro, J.; Keller, T. Early-age tensile properties of structural epoxy adhesives subjected to low-temperature curing. Int. J. Adhes. 2012, 35, 9–16. [Google Scholar] [CrossRef]

- Mays, G.; Hutchinson, A. Adhesives in Civil Engineering; Cambridge University Press: Cambridge, UK, 1992. [Google Scholar]

- Sancaktar, E.; Jozavi, H.; Klein, R. The Effects of Cure Temperature and Time on the Bulk Tensile Properties of a Structural Adhesive. J. Adhes. 1983, 15, 241–264. [Google Scholar] [CrossRef]

- Carbas, R.; Marques, E.; Silva, L.; Lopes, A. Effect of cure temperature on the glass transition temperature and mechanical properties of epoxy adhesives. J. Adhes. 2014, 90, 104–119. [Google Scholar] [CrossRef]

- Islam, M.; Pickering, K.; Foreman, N. Curing kinetics and effects of fibre surface treatment and curing parameters on the interfacial and tensile properties of hemp/epoxy composites. J. Adhes. Sci. Technol. 2009, 23, 2085–2107. [Google Scholar] [CrossRef]

- Cai, Y.; Gao, S.; Wang, F.; Zhang, Z.; Zhao, Z. Early hydration heat temperature field of precast concrete T-beam under steam curing: Experiment and simulation. Case Stud. Constr. Mat. 2023, 13, 8–16. [Google Scholar]

- Jiang, Y.; Zhu, Y. Temperature field simulation of electric heating prestressed concrete component. Concrete 2011, 2, 10–16. (In Chinese) [Google Scholar]

- Wei, J.; Wang, H.; Mao, J.; Zhu, Q.; Wang, F.; Xie, Y. Numerical simulation and test verification for temperature field of concrete continuous box girder bridges. J. Southeast Univ. (Nat. Sci. Ed.) 2021, 51, 378–383. (In Chinese) [Google Scholar]

- Khan, M. Factors affecting the thermal properties of concrete and applicability of its prediction models. Build. Environ. 2002, 37, 607–614. [Google Scholar] [CrossRef]

- Iman, A.; Payam, S.; Zahiruddin, F.; Norhayati, B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 201, 81–93. [Google Scholar]

- Wang, W.; Liu, B.; Venkatesh, K. Effect of Temperature on Strength and Elastic Modulus of High-Strength Steel. J. Mater. Civ. Eng. 2012, 25, 174–182. [Google Scholar] [CrossRef]

- Venkatesh, K.; Sonali, K.; Wasim, K. Effect of Temperature on Thermal and Mechanical Properties of Steel Bolts. J. Mater. Civ. Eng. 2011, 24, 765–774. [Google Scholar]

- Zhou, H.; Li, G.; Jiang, S. Experimental Studies on the Properties of Steel Strand at Elevated Temperatures. J. Sichuan Univ. 2008, 40, 106–110. (In Chinese) [Google Scholar]

- Shakya, A.; Kodur, V. Effect of temperature on the mechanical properties of low relaxation seven-wire prestressed strand. Constr. Build. Mater. 2016, 124, 74–84. [Google Scholar] [CrossRef]

- Hou, X.; Zheng, W.; Kodur, V.; Sun, H. Effect of temperature on mechanical properties of prestressing strands. Constr. Build. Mater. 2014, 61, 24–32. [Google Scholar] [CrossRef]

- Kim, K.; Jeon, S.; Kim, J.; Yang, S. An experimental study on thermal conductivity of concrete. Cement Concrete Res. 2003, 33, 363–371. [Google Scholar] [CrossRef]

- Churchill, S.; Chu, H. Correlating equations for laminar and turbulent free convection from a vertical plate. Int. J. Heat Mass Tran. 1975, 18, 1323–1329. [Google Scholar] [CrossRef]

- Stehfest, H. Algorithm 368 numerical inversion of Laplace transforms. Commun. ACM 1970, 13, 47–49. [Google Scholar] [CrossRef]

- Wang, P.; Lin, S.; Tu, S. A survey of fractional-calculus approaches to the solutions of the Bessel differential equation of general order. Appl. Math. Comput. 2006, 187, 544–555. [Google Scholar] [CrossRef]

- Lin, S.; Ling, W. A Simple Fractional-Calculus Approach to the Solutions of the Bessel Differential Equation of General Order and Some of Its Applications. Comput. Math. Appl. 2005, 49, 1487–1498. [Google Scholar] [CrossRef]

- Özisik, M.N. Heat Conduction, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1993. [Google Scholar]

| Target Temperature | Current Magnitude | ID |

|---|---|---|

| 200 | 350 | 200-350-a |

| 200 | 350 | 200-350-b |

| 200 | 300 | 200-300-a |

| 200 | 300 | 200-300-b |

| 150 | 350 | 150-350-a |

| 150 | 350 | 150-350-b |

| 150 | 300 | 150-300-a |

| 150 | 300 | 150-300-b |

| Measuring Point | ΔT/°C | Theoretical Strain Value/με | Measured Strain Value/με | Relative Error/% |

|---|---|---|---|---|

| Six equinoctial points-350 A | 110.2 | 1322.4 | 1202.01 | −9.10 |

| Mid-point-350 A | 90.6 | 1087.2 | 1087.68 | 0.04 |

| Six equinoctial points-300 A | 82.3 | 987.6 | 995.83 | 0.83 |

| Mid-point-300 A | 72.4 | 868.8 | 866.136 | −0.31 |

| Current Magnitude | Measurement Point | Stable Temperature/°C | Temperature/Current |

|---|---|---|---|

| 350 A | Terminal point | 212.2 | 0.6057 |

| 350 A | Contact point | 150.0 | 0.4286 |

| 350 A | Six equinoctial point | 121.9 | 0.3483 |

| 350 A | Midpoint | 112.3 | 0.3286 |

| 300 A | Terminal point | 198.3 | 0.6610 |

| 300 A | Contact point | 136.6 | 0.4553 |

| 300 A | Six equinoctial point | 104.0 | 0.3366 |

| 300 A | Midpoint | 94.2 | 0.3140 |

| Materials | Thermal Conductivity/(W/(m·K)) | Specific Heat/(J/(kg·K)) | Density/(kg/m3) |

|---|---|---|---|

| Steel strand | 49 | 470 | 7800 |

| Binder | 0.2 | 1600 | 1300 |

| Duct | 0.5 | 2300 | 980 |

| Concrete | 1.74 | 920 | 2500 |

| Current | Measurement Point | Root Mean Square Error/°C | Average Absolute Error/°C | Maximum Relative Error |

|---|---|---|---|---|

| 350 A | Terminal point | 4.11 | 3.54 | 1.38% |

| 350 A | Contact point | 4.29 | 3.72 | 0.91% |

| 350 A | Six equinoctial point | 4.19 | 3.79 | 1.39% |

| 350 A | Midpoint | 3.97 | 3.18 | 1.18% |

| 300 A | Terminal point | 8.89 | 8.37 | 1.73% |

| 300 A | Contact point | 3.71 | 3.51 | 0.68% |

| 300 A | Six equinoctial point | 4.00 | 3.59 | 1.19% |

| 300 A | Midpoint | 2.17 | 1.90 | 0.82% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, X.; Jiang, N. Research on Temperature Field of Controllable Bonded Prestressed Structure Based on Electrothermal Method. Materials 2023, 16, 7108. https://doi.org/10.3390/ma16227108

Xiong X, Jiang N. Research on Temperature Field of Controllable Bonded Prestressed Structure Based on Electrothermal Method. Materials. 2023; 16(22):7108. https://doi.org/10.3390/ma16227108

Chicago/Turabian StyleXiong, Xueyu, and Nan Jiang. 2023. "Research on Temperature Field of Controllable Bonded Prestressed Structure Based on Electrothermal Method" Materials 16, no. 22: 7108. https://doi.org/10.3390/ma16227108

APA StyleXiong, X., & Jiang, N. (2023). Research on Temperature Field of Controllable Bonded Prestressed Structure Based on Electrothermal Method. Materials, 16(22), 7108. https://doi.org/10.3390/ma16227108