The Microstructures and Deformation Mechanism of Hetero-Structured Pure Ti under High Strain Rates

Abstract

:1. Introduction

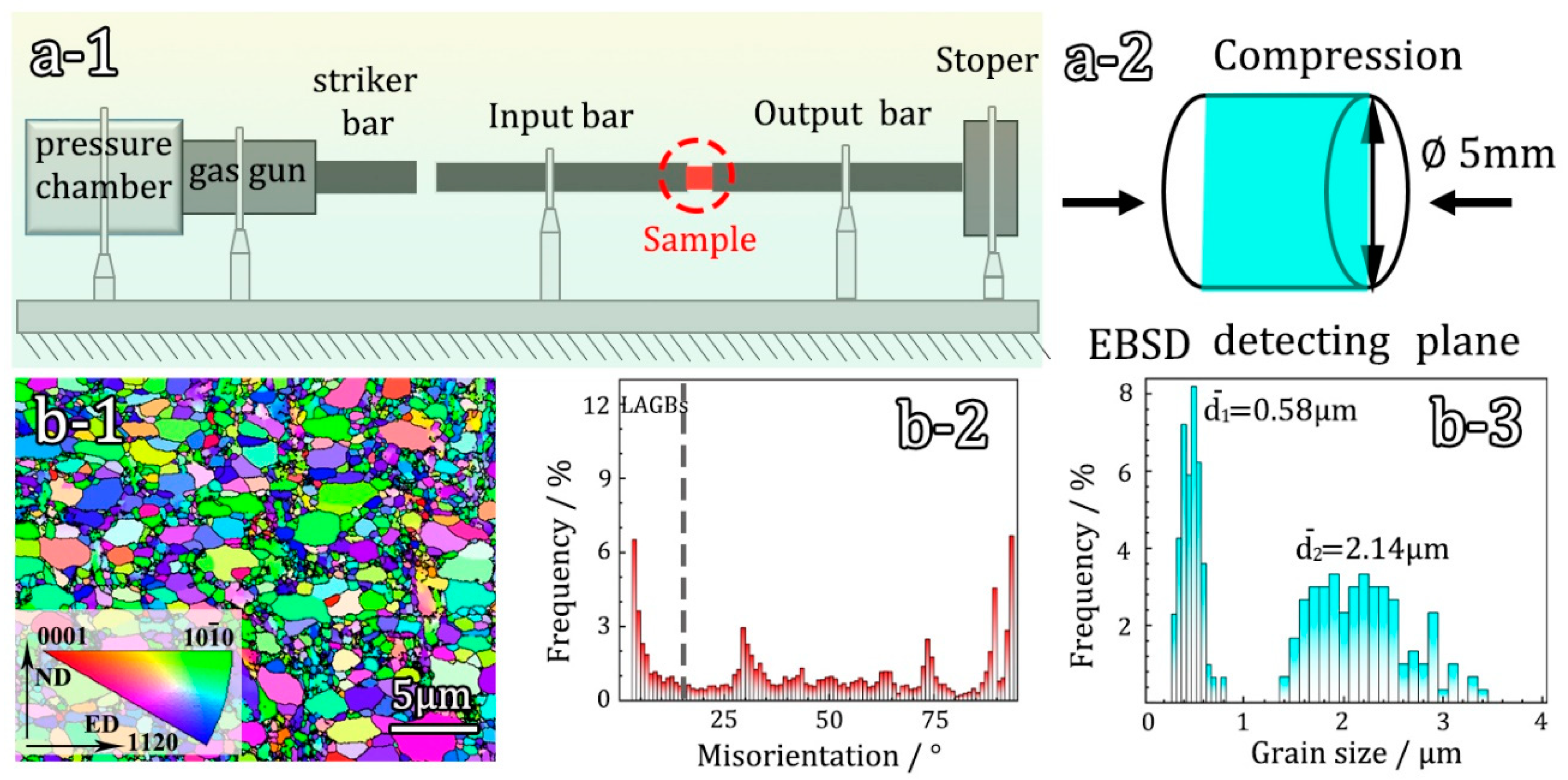

2. Experiment

3. Results and Discussion

4. Conclusions

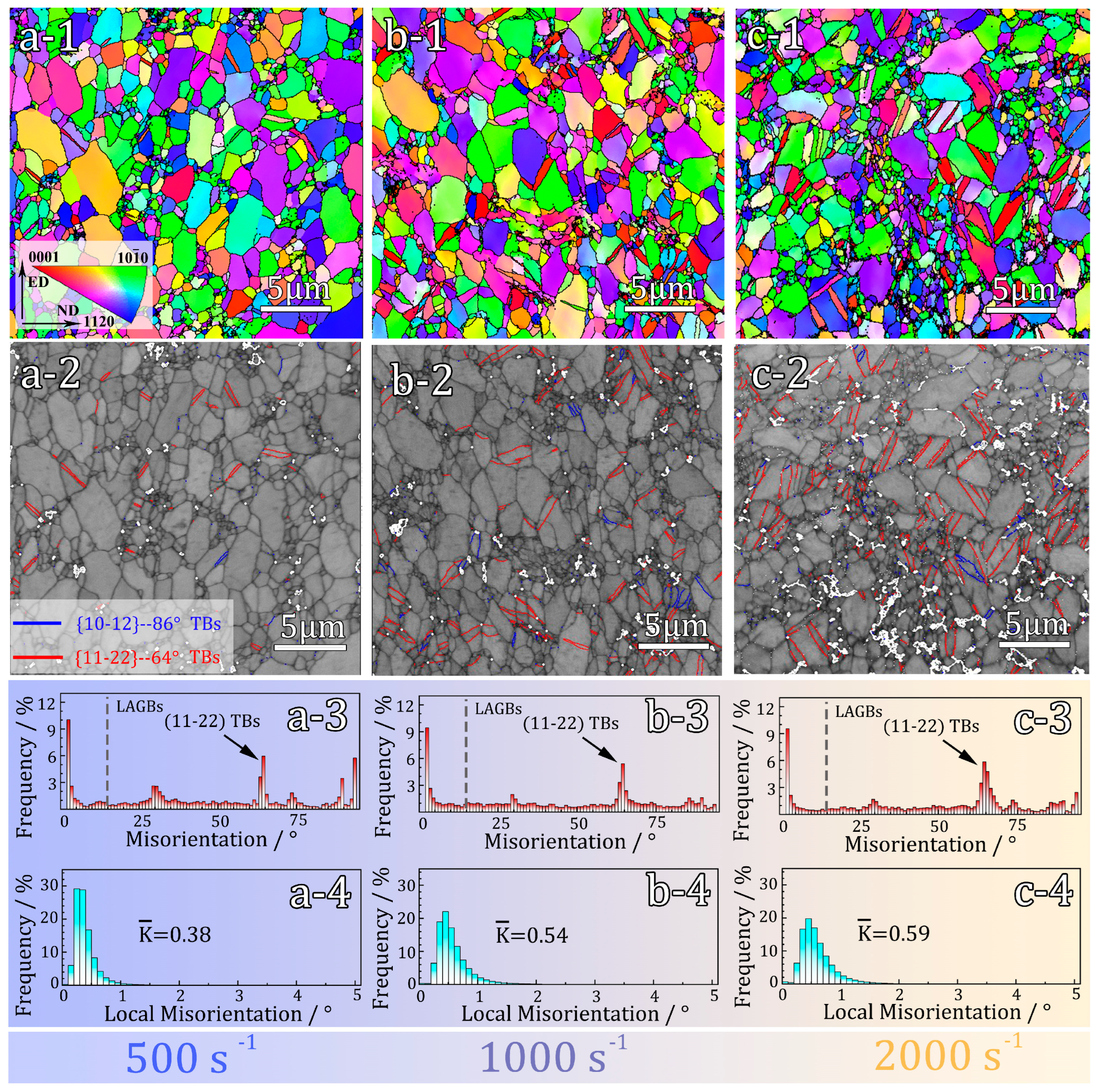

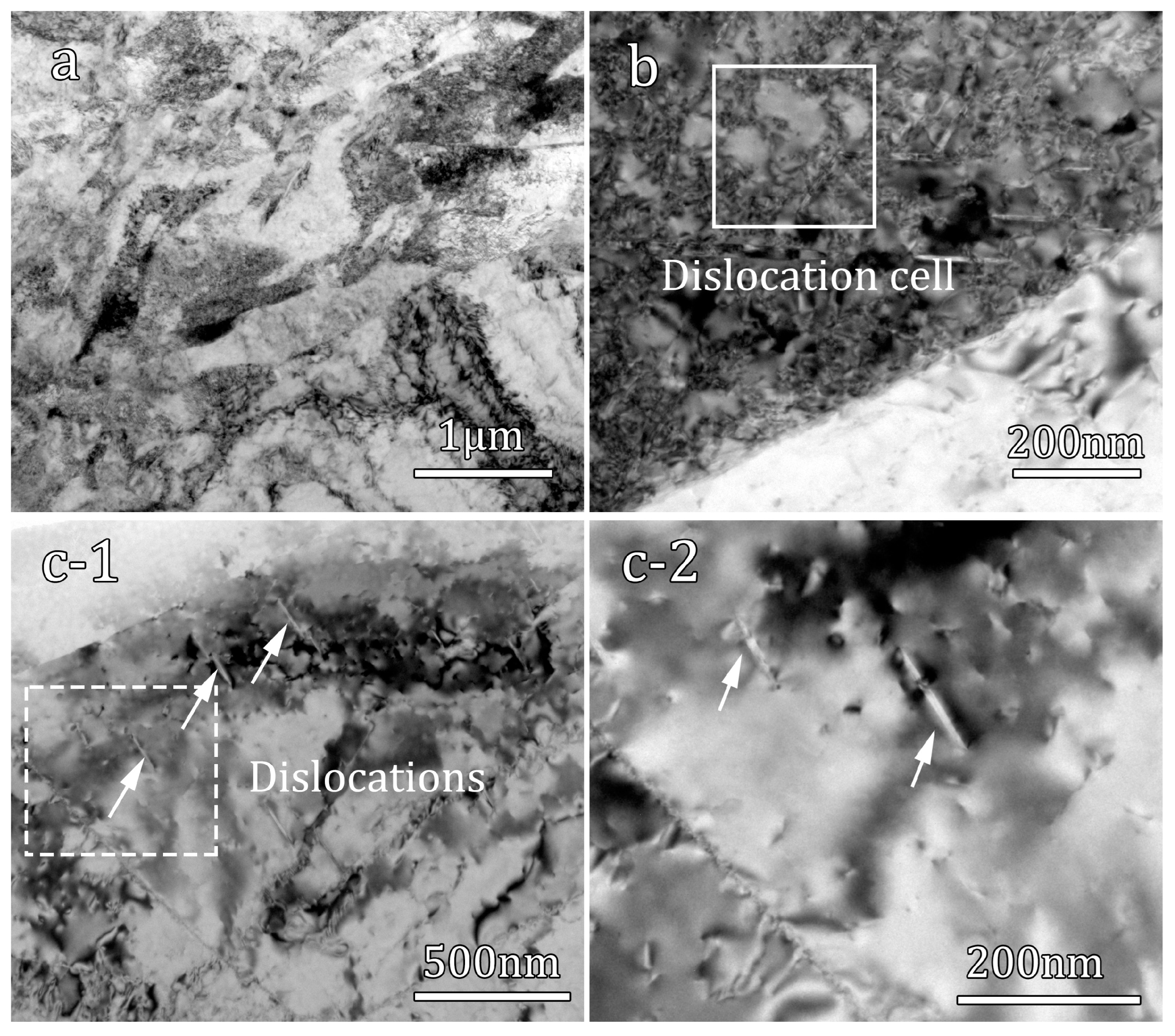

- The mechanical responses and deformation mechanism of hetero-structured pure Ti samples are closely related to the strain rate. As the strain rate increases from 500 s−1 to 2000 s−1, dislocation activities are the primary deformation carrier, but the dominance of dislocation slipping reduces and the dislocation configurations undergo changes. Conversely, there is an increase in the percentage of deformation twinning with higher strain rates.

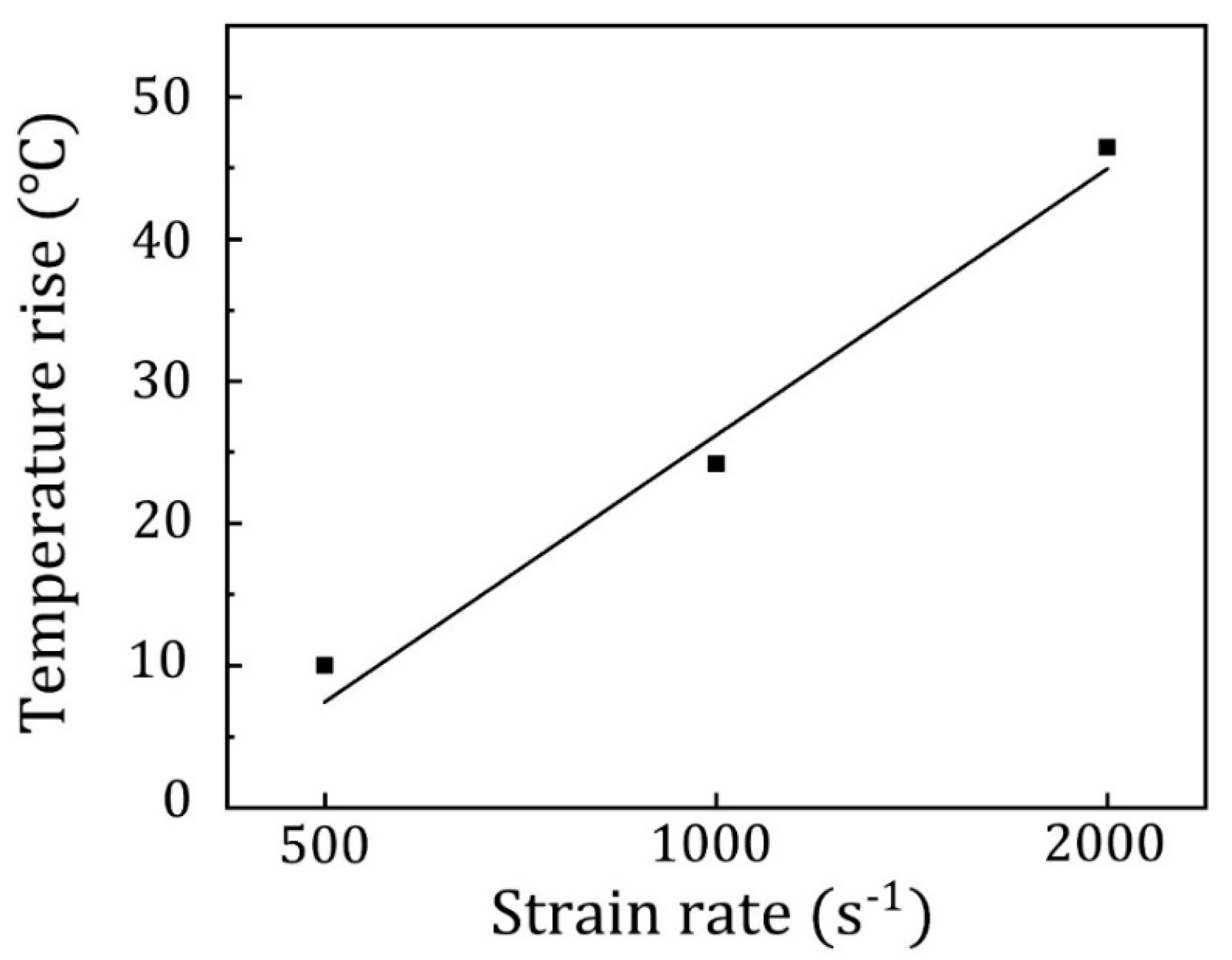

- It has been found that under different high deformation rates (500 s−1, 1000 s−1, 2000 s−1), the changes in texture are relatively minimal, and the degree of temperature rise is low (far lower than the recrystallization temperature). Consequently, the alterations in these two influential factors are insufficient to induce changes in the deformation mechanism.

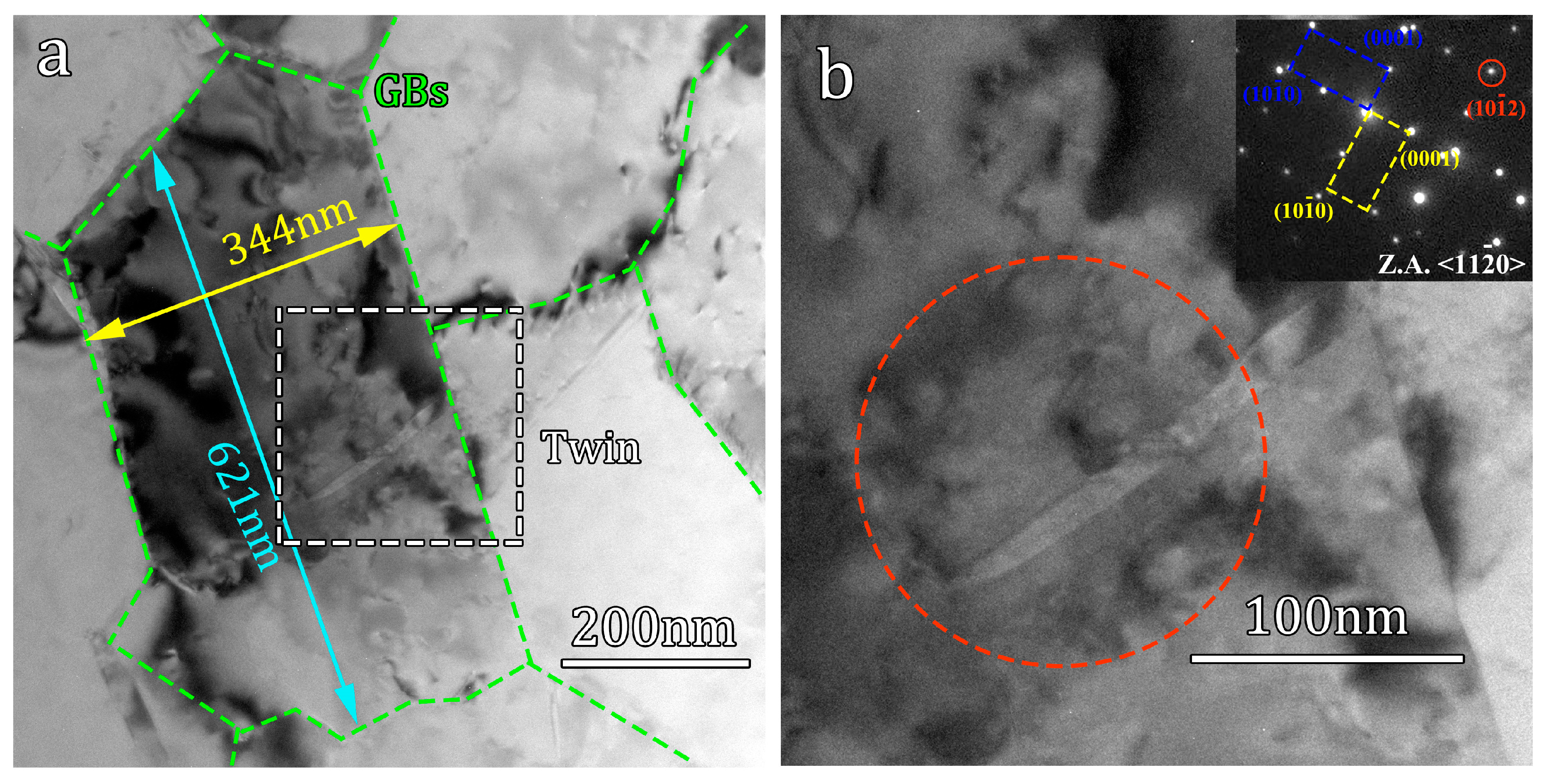

- When subjected to a strain rate of 2000 s−1, martensitic phase transformation is identified in the deformed Ti sample. Moreover, nanoscale twin lamellae are observed within the ultrafine grain, which can be attributed to the high flow stress. A modified Hall–Petch model is proposed, and the obtained can be used to effectively establish the correlation between the stress required for twinning and the grain size.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Özcan, M.; Hämmerle, C. Titanium as a Reconstruction and Implant Material in Dentistry: Advantages and Pitfalls. Materials 2012, 5, 1528–1545. [Google Scholar] [CrossRef]

- Konstantinov, A.S.; Bazhin, P.M.; Stolin, A.M.; Kostitsyna, E.V.; Ignatov, A.S. Ti-B-Based Composite Materials: Properties, Basic Fabrication Methods, and Fields of Application (Review). Compos. Part A Appl. Sci. Manuf. 2018, 108, 79–88. [Google Scholar] [CrossRef]

- Zochowski, P.; Bajkowski, M.; Grygoruk, R.; Magier, M.; Burian, W.; Pyka, D.; Bocian, M.; Jamroziak, K. Ballistic Impact Resistance of Bulletproof Vest Inserts Containing Printed Titanium Structures. Metals 2021, 11, 225. [Google Scholar] [CrossRef]

- Yan, N.; Li, Z.; Xu, Y.; Meyers, M.A. Shear Localization in Metallic Materials at High Strain Rates. Prog. Mater. Sci. 2021, 199, 100755. [Google Scholar] [CrossRef]

- Lei, L.; Zhao, Q.; Zhao, Y.; Wu, C.; Huang, S.; Jia, W.; Zeng, W. Gradient nanostructure, phase transformation, amorphization and enhanced strength-plasticity synergy of pure titanium manufactured by ultrasonic surface rolling. J. Am. Acad. Dermatol. 2022, 299, 117322. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; He, Q.; Wei, W.; Guo, F.; Su, W.; Huang, C. A Strong and Ductile Pure Titanium. Mater. Sci. Eng. A 2022, 833, 142534. [Google Scholar] [CrossRef]

- Won, J.W.; Lee, S.; Kim, W.C.; Hyun, Y.-T.; Lee, D.W. Significantly increased twinning activity of pure titanium during room-temperature tensile deformation by cryogenic-deformation treatment. Mater. Sci. Eng. A 2023, 862, 144453. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, R.; Yu, Q.; Ell, J.; Ritchie, R.O.; Minor, A.M. Cryoforged Nanotwinned Titanium with Ultrahigh Strength and Ductility. Science 2021, 373, 1363–1368. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, Y.; Nie, J.; Zhou, H.; Li, Y. Microstructures and Mechanical Properties of Commercially Pure Ti Processed by Rotationally Accelerated Shot Peening. Materials 2018, 11, 366. [Google Scholar] [CrossRef]

- Zhou, P.; Xiao, D.; Jiang, C.; Sang, G.; Zou, D. Twin Interactions in Pure Ti Under High Strain Rate Compression. Met. Mater. Trans. A 2016, 48, 126–138. [Google Scholar] [CrossRef]

- Jia, H.; Marthinsen, K.; Li, Y. Revealing Abnormal {112¯1} Twins in Commercial Purity Ti Subjected to Split Hopkinson Pressure Bar. J. Alloys Compd. 2019, 783, 513–523. [Google Scholar] [CrossRef]

- Wang, T.B.; Li, B.L.; Li, M.; Li, Y.C.; Nie, Z.R. The Dynamic Mechanical Behavior and Microstructural Evolution of Commercial Pure Titanium. Adv. Mater. Res. 2014, 968, 7–11. [Google Scholar] [CrossRef]

- Gurao, N.; Kapoor, R.; Suwas, S. Deformation behaviour of commercially pure titanium at extreme strain rates. Acta Mater. 2011, 59, 3431–3446. [Google Scholar] [CrossRef]

- Deguchi, M.; Yamasaki, S.; Mitsuhara, M.; Nakashima, H.; Tsukamoto, G.; Kunieda, T. Tensile Deformation Behaviors of Pure Ti with Different Grain Sizes under Wide-Range of Strain Rate. Materials 2023, 16, 529. [Google Scholar] [CrossRef]

- Ovid’Ko, I.; Valiev, R.; Zhu, Y. Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater. Sci. 2018, 94, 462–540.A. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, X.; Ni, H.; Liu, Q. Deformation twinning in pure Ti during dynamic plastic deformation. Mater. Sci. Eng. A 2012, 541, 190–195. [Google Scholar] [CrossRef]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef]

- Tanaka, Y.; Kondo, M.; Miyazaki, N.; Ueji, R. Deformation Behavior of Pure Titanium at a Wide Range of Strain Rates. J. Phys. Conf. Ser. 2010, 240, 012021. [Google Scholar] [CrossRef]

- Li, Q.; Xu, Y.B.; Bassim, M.N. Dynamic Mechanical Behavior of Pure Titanium. J. Mater. Process. Technol. 2004, 155–156, 1889–1892. [Google Scholar] [CrossRef]

- Xu, S.; Wang, J. Deformation Twins Stimulated by {} Twinning in Adjacent Grain in Titanium. Acta Mater. 2022, 229, 117805. [Google Scholar] [CrossRef]

- Huang, Z.; Jin, S.; Zhou, H.; Li, Y.; Cao, Y.; Zhu, Y. Evolution of twinning systems and variants during sequential twinning in cryo-rolled titanium. Int. J. Plast. 2019, 112, 52–67. [Google Scholar] [CrossRef]

- Yu, Q.; Mishra, R.K.; Minor, A.M. The Effect of Size on the Deformation Twinning Behavior in Hexagonal Close-Packed Ti and Mg. JOM 2012, 64, 1235–1240. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Z.; Shen, G. Effect of Grain Size on the Tensile Deformation Mechanisms of Commercial Pure Titanium as Revealed by Acoustic Emission. J. Mater. Eng. Perform. 2015, 24, 1975–1986. [Google Scholar] [CrossRef]

- Yu, K.; Wang, X.; Mahajan, S.; Beyerlein, I.J.; Cao, P.; Rupert, T.J.; Schoenung, J.M.; Lavernia, E.J. Twin Nucleation from Disconnection-Dense Sites between Stacking Fault Pairs in a Random Defect Network. Materialia 2023, 30, 101835. [Google Scholar] [CrossRef]

- Mittemeijer, E.J. The Crystal Imperfection; Structure Defects. In Fundamentals of Materials Science; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Wei, K.; Hu, R.; Yin, D.; Xiao, L.; Pang, S.; Cao, Y.; Zhou, H.; Zhao, Y.; Zhu, Y. Grain size effect on tensile properties and slip systems of pure magnesium. Acta Mater. 2021, 206, 116604. [Google Scholar] [CrossRef]

- Huang, Z.; Wen, D.; Hou, X.; Li, Y.; Wang, B.; Wang, A. Grain size and temperature mediated twinning ability and strength-ductility correlation in pure titanium. Mater. Sci. Eng. A 2022, 849, 143461. [Google Scholar] [CrossRef]

- Ahmadikia, B.; Wang, L.; Kumar, M.A.; Beyerlein, I.J. Grain boundary slip—Twin transmission in titanium. Acta Mater. 2023, 244, 118556. [Google Scholar] [CrossRef]

- Zhao, H.; Ding, N.; Ren, Y.; Xie, H.; Yang, B.; Qin, G. Shear-induced hexagonal close-packed to face-centered cubic phase transition in pure titanium processed by equal channel angular drawing. J. Mater. Sci. 2019, 54, 7953–7960. [Google Scholar] [CrossRef]

- Zheng, X.; Gong, M.; Xiong, T.; Ge, H.; Yang, L.; Zhou, Y.; Zheng, S.; Wang, J.; Ma, X. Deformation Induced Fcc Lamellae and Their Interaction in Commercial Pure Ti. Scr. Mater. 2019, 162, 326–330. [Google Scholar] [CrossRef]

- Sun, J.; Trimby, P.; Yan, F.; Liao, X.; Tao, N.; Wang, J. Grain size effect on deformation twinning propensity in ultrafine-grained hexagonal close-packed titanium. Scr. Mater. 2013, 69, 428–431. [Google Scholar] [CrossRef]

- Palán, J.; Procházka, R.; Džugan, J.; Nacházel, J.; Duchek, M.; Németh, G.; Máthis, K.; Minárik, P.; Horváth, K. Comprehensive Evaluation of the Properties of Ultrafine to Nanocrystalline Grade 2 Titanium Wires. Materials 2018, 11, 2522. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured Materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Zhu, Y.; Ameyama, K.; Anderson, P.M.; Beyerlein, I.J.; Gao, H.; Kim, H.S.; Lavernia, E.; Mathaudhu, S.; Mughrabi, H.; Ritchie, R.O.; et al. Heterostructured materials: Superior properties from hetero-zone interaction. Mater. Res. Lett. 2020, 9, 1–31. [Google Scholar] [CrossRef]

- Xu, S.; Zhou, P.; Liu, G.; Xiao, D.; Gong, M.; Wang, J. Shock-Induced Two Types of {} Sequential Twinning in Titanium. Acta Mater. 2019, 165, 547–560. [Google Scholar] [CrossRef]

- He, Y.; Li, B.; Wang, C.; Mao, S.X. Direct observation of dual-step twinning nucleation in hexagonal close-packed crystals. Nat. Commun. 2020, 11, 2483. [Google Scholar] [CrossRef]

- Kou, Z.; Yang, Y.; Huang, B.; Luo, X.; Li, P.; Zhao, G.; Zhang, W. Observing the Dynamic {} twining Process in Pure Ti at Atomic Resolution. Scr. Mater. 2017, 139, 139–143. [Google Scholar] [CrossRef]

- Liao, X.; Wang, J.; Nie, J.; Jiang, Y.; Wu, P. Deformation twinning in hexagonal materials. MRS Bull. 2016, 41, 314–319. [Google Scholar] [CrossRef]

- Paudel, Y.; Giri, D.; Priddy, M.W.; Barrett, C.D.; Inal, K.; Tschopp, M.A.; Rhee, H.; El Kadiri, H. A Review on Capturing Twin Nucleation in Crystal Plasticity for Hexagonal Metals. Metals 2021, 11, 1373. [Google Scholar] [CrossRef]

- Zherebtsov, S.; Dyakonov, G.; Salem, A.; Sokolenko, V.; Salishchev, G.; Semiatin, S. Formation of nanostructures in commercial-purity titanium via cryorolling. Acta Mater. 2013, 61, 1167–1178. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Z.; Phukan, H.; Kenesei, P.; Park, J.-S.; Lind, J.; Suter, R.; Bieler, T. Direct measurement of critical resolved shear stress of prismatic and basal slip in polycrystalline Ti using high energy X-ray diffraction microscopy. Acta Mater. 2017, 132, 598–610. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.; Song, M.; Zhu, Y. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Yang, H.; Li, H.; Ma, J.; Wei, D.; Chen, J.; Fu, M. Temperature dependent evolution of anisotropy and asymmetry of α-Ti in thermomechanical working: Characterization and modeling. Int. J. Plast. 2020, 127, 102650. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Yan, H.; Zhang, D.; Hu, J.; Li, Y. The Microstructures and Deformation Mechanism of Hetero-Structured Pure Ti under High Strain Rates. Materials 2023, 16, 7059. https://doi.org/10.3390/ma16217059

Wang S, Yan H, Zhang D, Hu J, Li Y. The Microstructures and Deformation Mechanism of Hetero-Structured Pure Ti under High Strain Rates. Materials. 2023; 16(21):7059. https://doi.org/10.3390/ma16217059

Chicago/Turabian StyleWang, Shuaizhuo, Haotian Yan, Dongmei Zhang, Jiajun Hu, and Yusheng Li. 2023. "The Microstructures and Deformation Mechanism of Hetero-Structured Pure Ti under High Strain Rates" Materials 16, no. 21: 7059. https://doi.org/10.3390/ma16217059

APA StyleWang, S., Yan, H., Zhang, D., Hu, J., & Li, Y. (2023). The Microstructures and Deformation Mechanism of Hetero-Structured Pure Ti under High Strain Rates. Materials, 16(21), 7059. https://doi.org/10.3390/ma16217059