Study on the Mechanical Properties and Mechanism of a Nickel-Iron Slag Cement-Based Composite under the Action of Sodium Sulfate

Abstract

:1. Introduction

2. Preparation and Testing of Materials

2.1. Testing of Raw Materials

2.1.1. Nickel–Iron Slag

2.1.2. Silty Clay

2.1.3. Cement

2.1.4. Sodium Sulfate

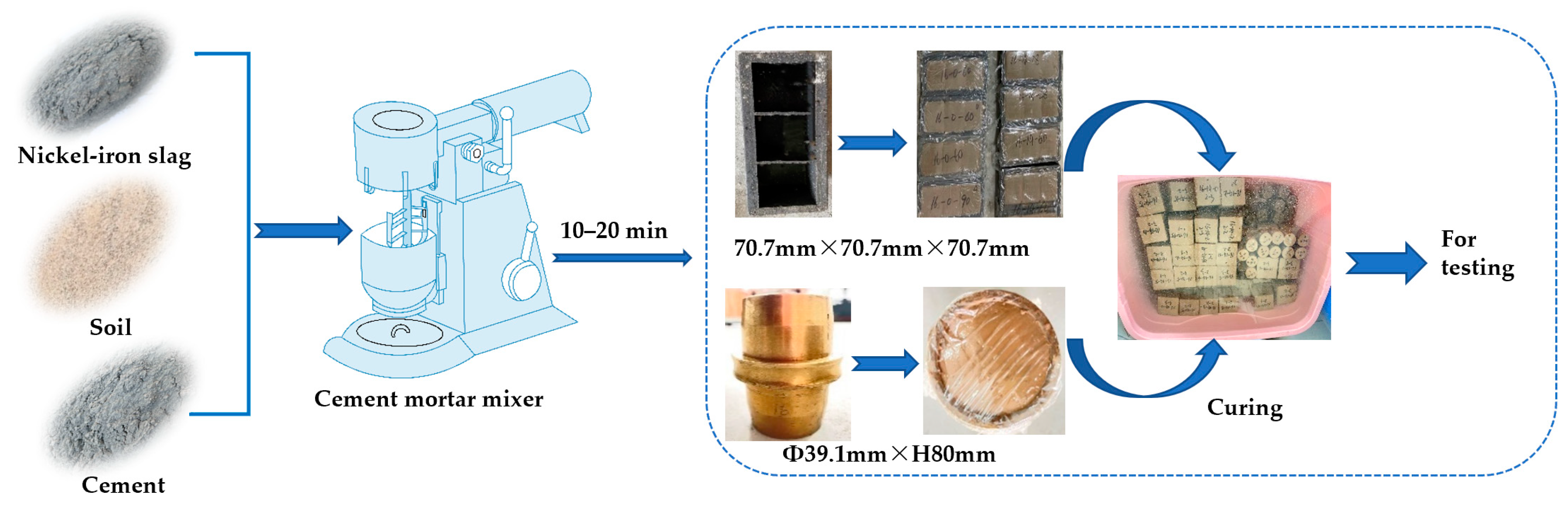

2.2. Sample Preparation

2.3. Test Scheme

2.3.1. Erosion Test

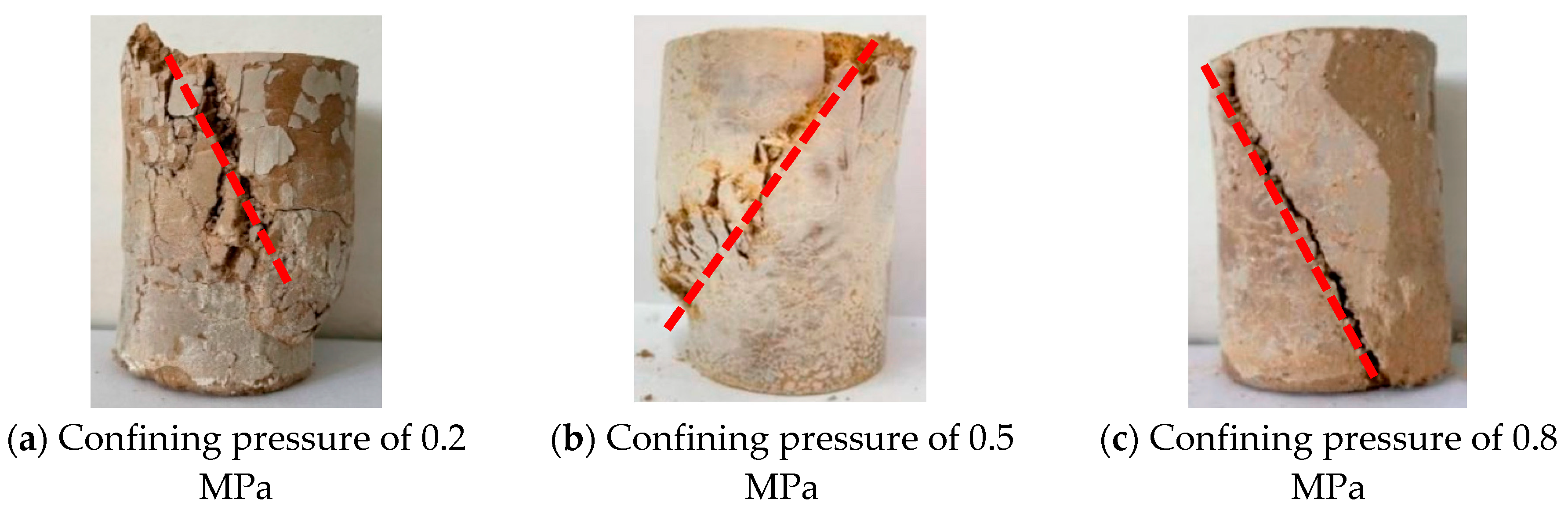

2.3.2. Triaxial Compression Test

2.3.3. Scanning Electron Microscopy

3. Test Results and Analysis

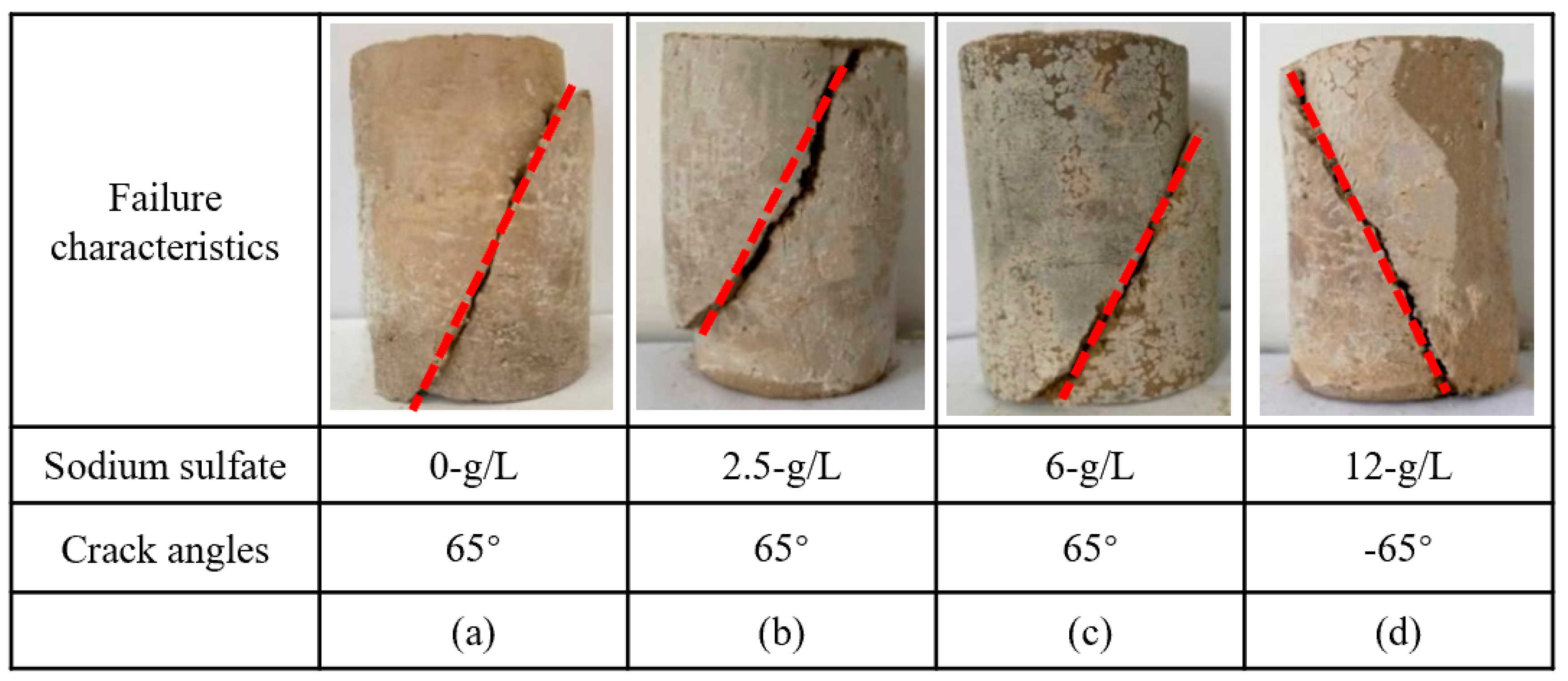

3.1. Failure Characteristics of the Nickel–Iron Slag Cement–Based Composite Materials

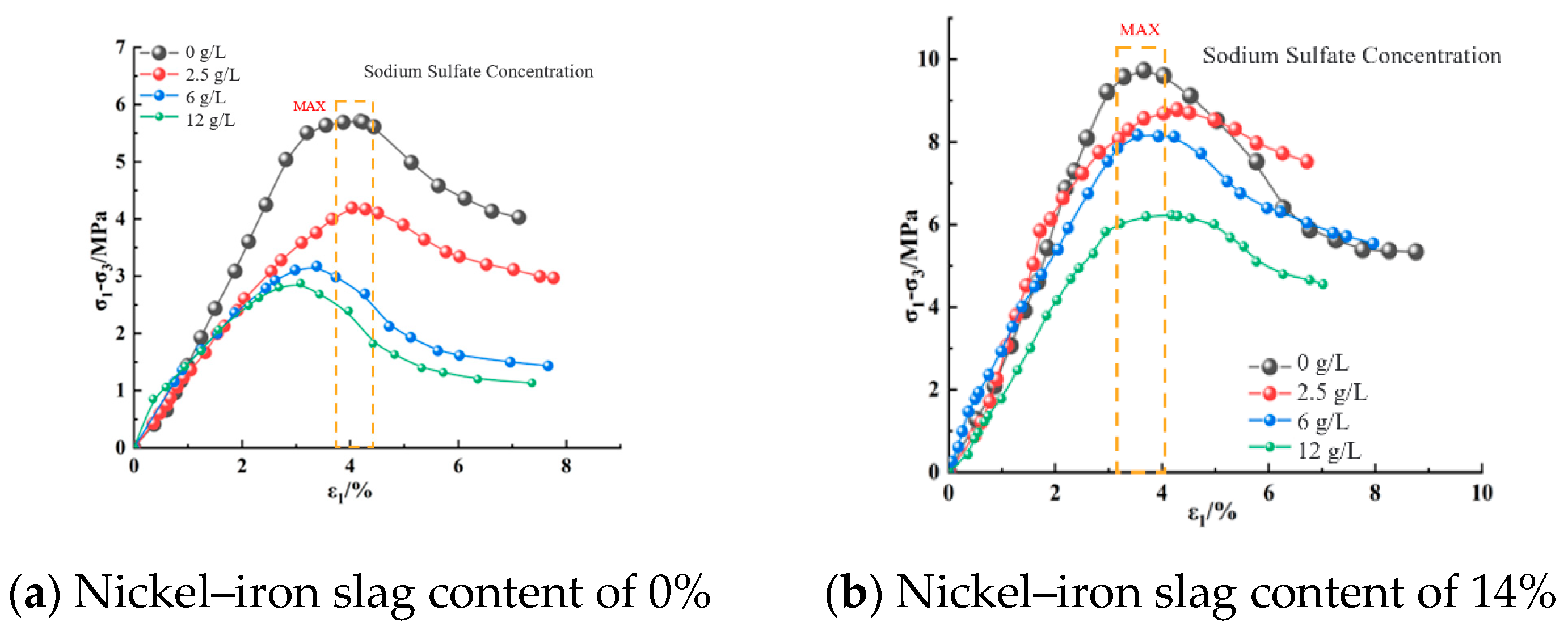

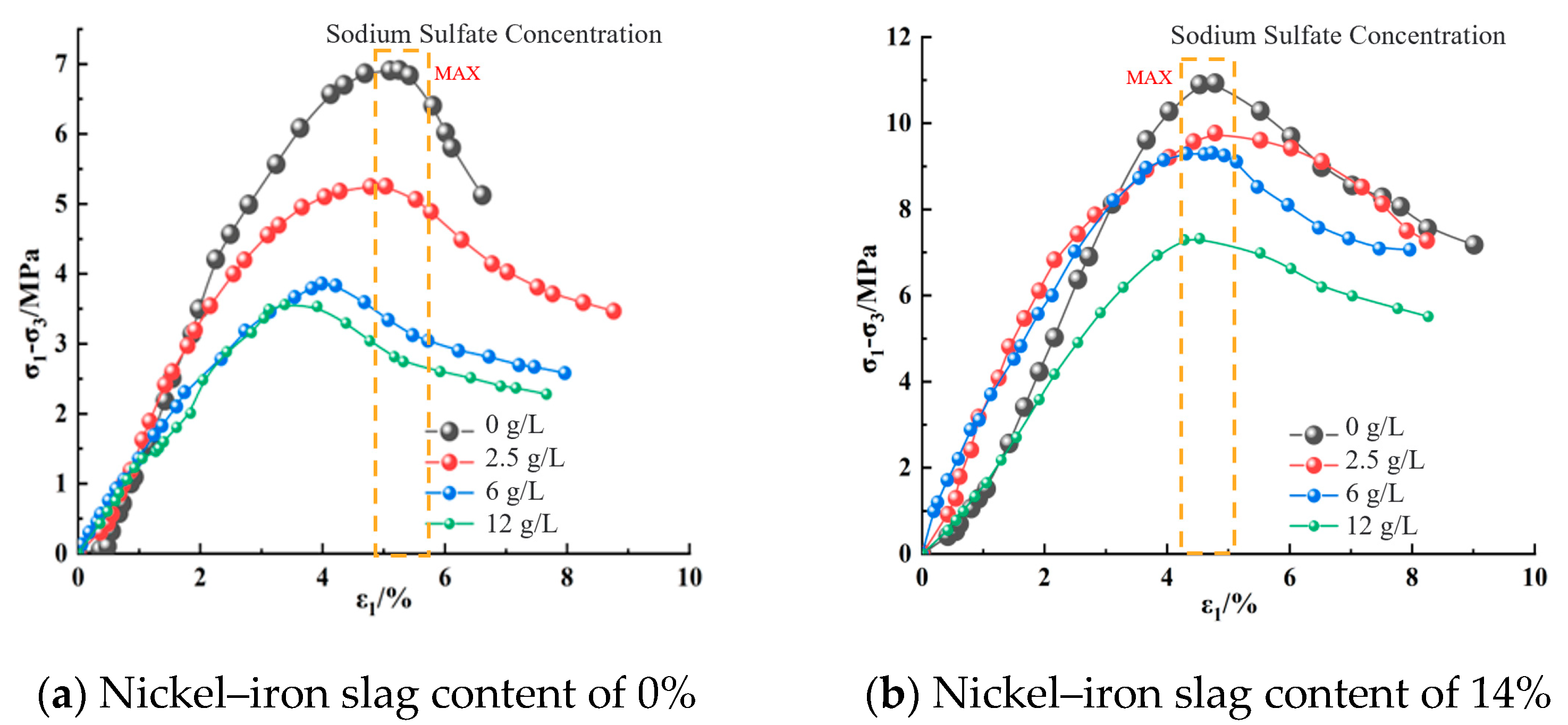

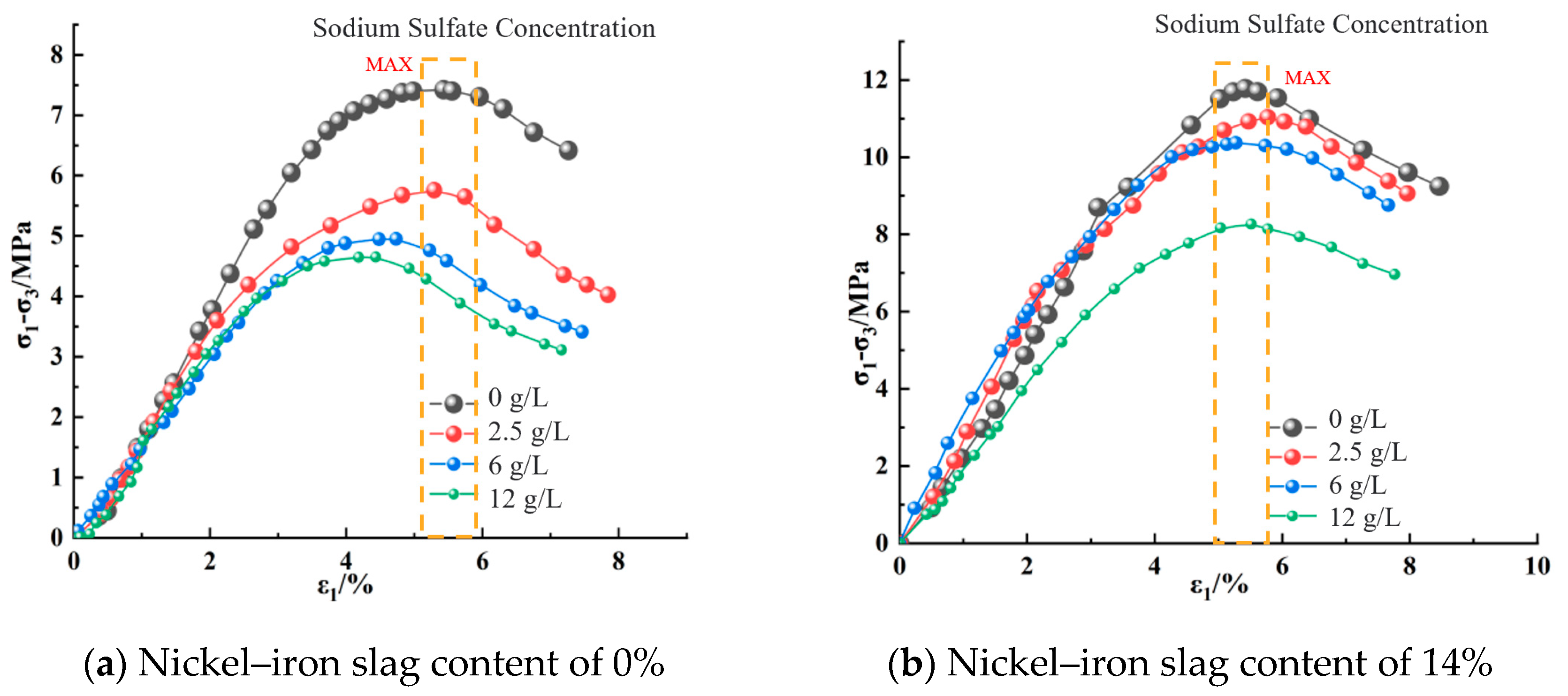

3.2. Influence of Sodium Sulfate Concentration on the Stress–Strain Relation of Nickel–Iron Slag Cement-Based Composites

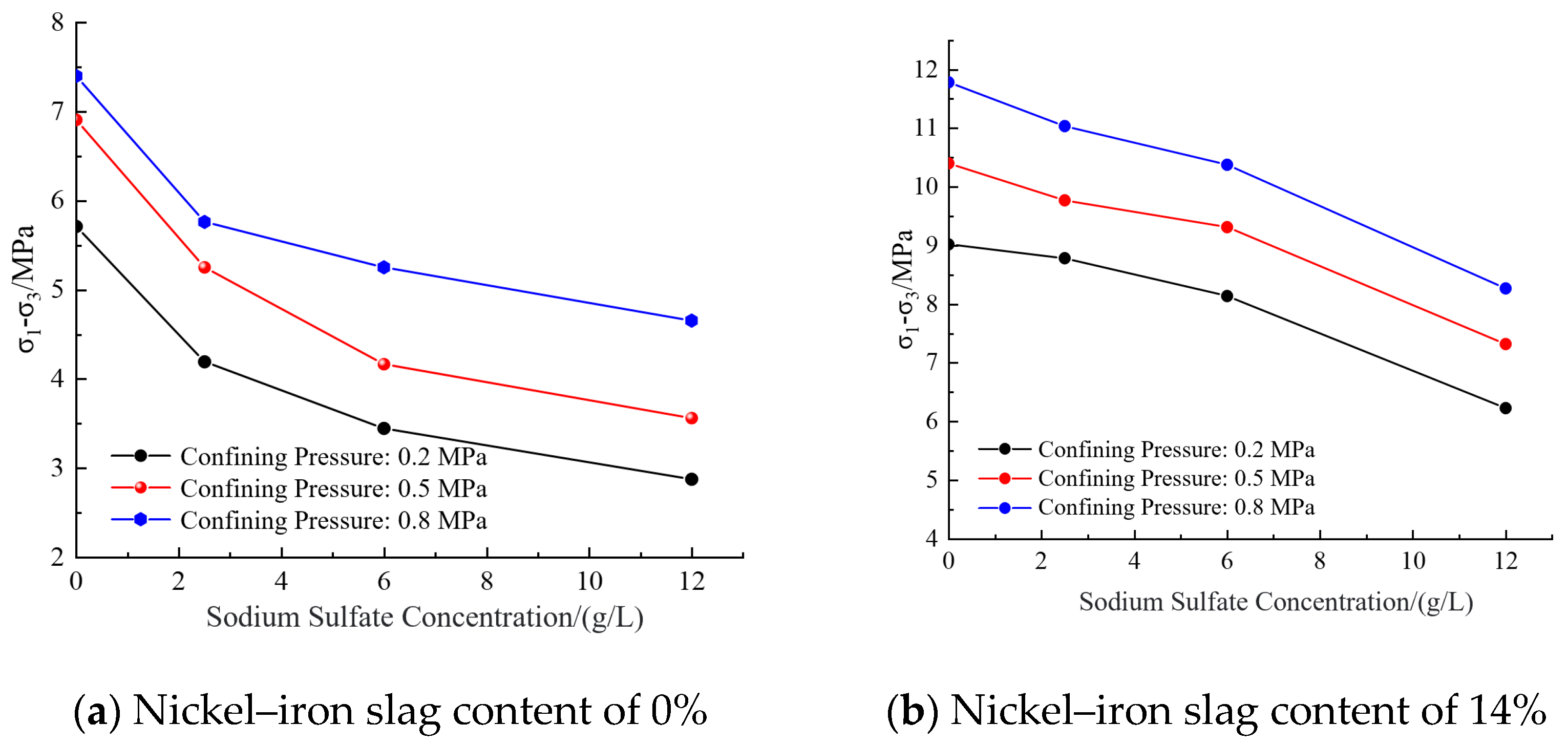

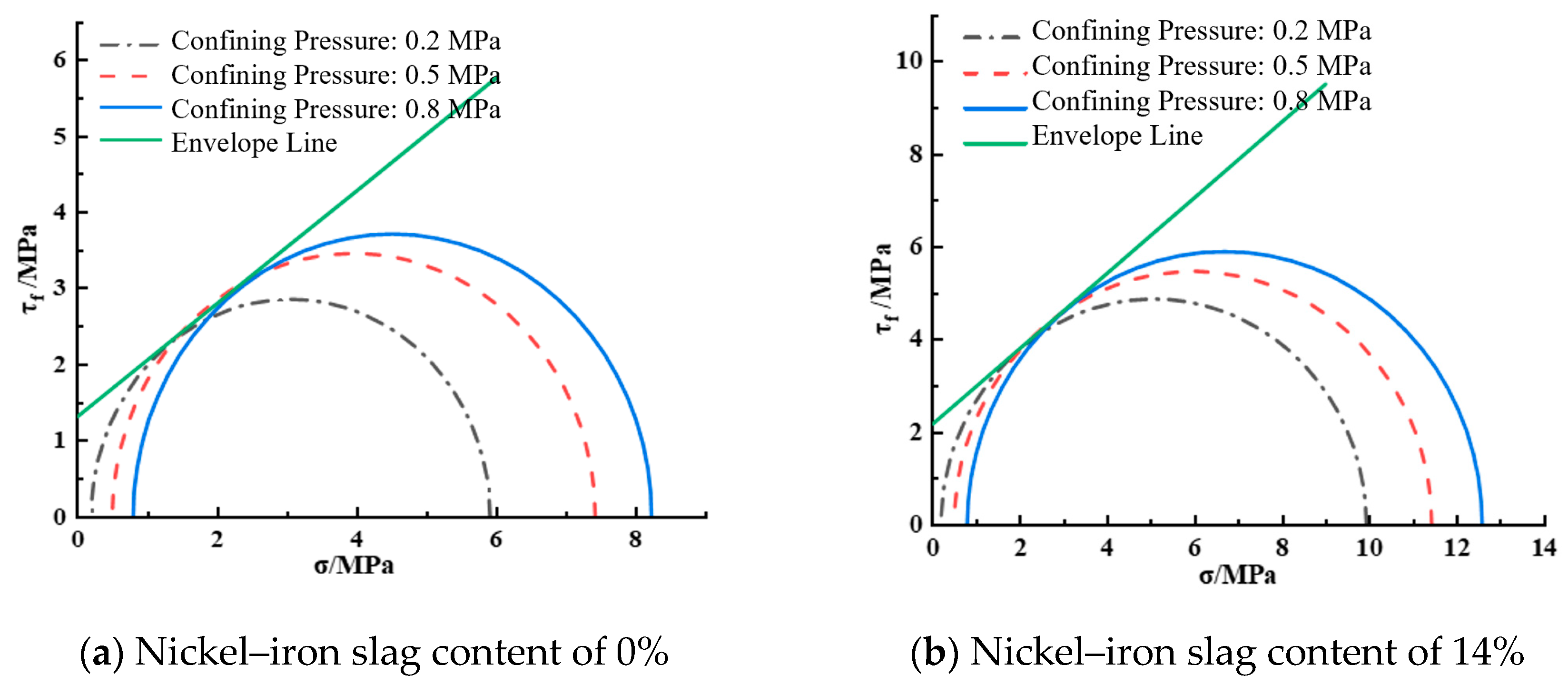

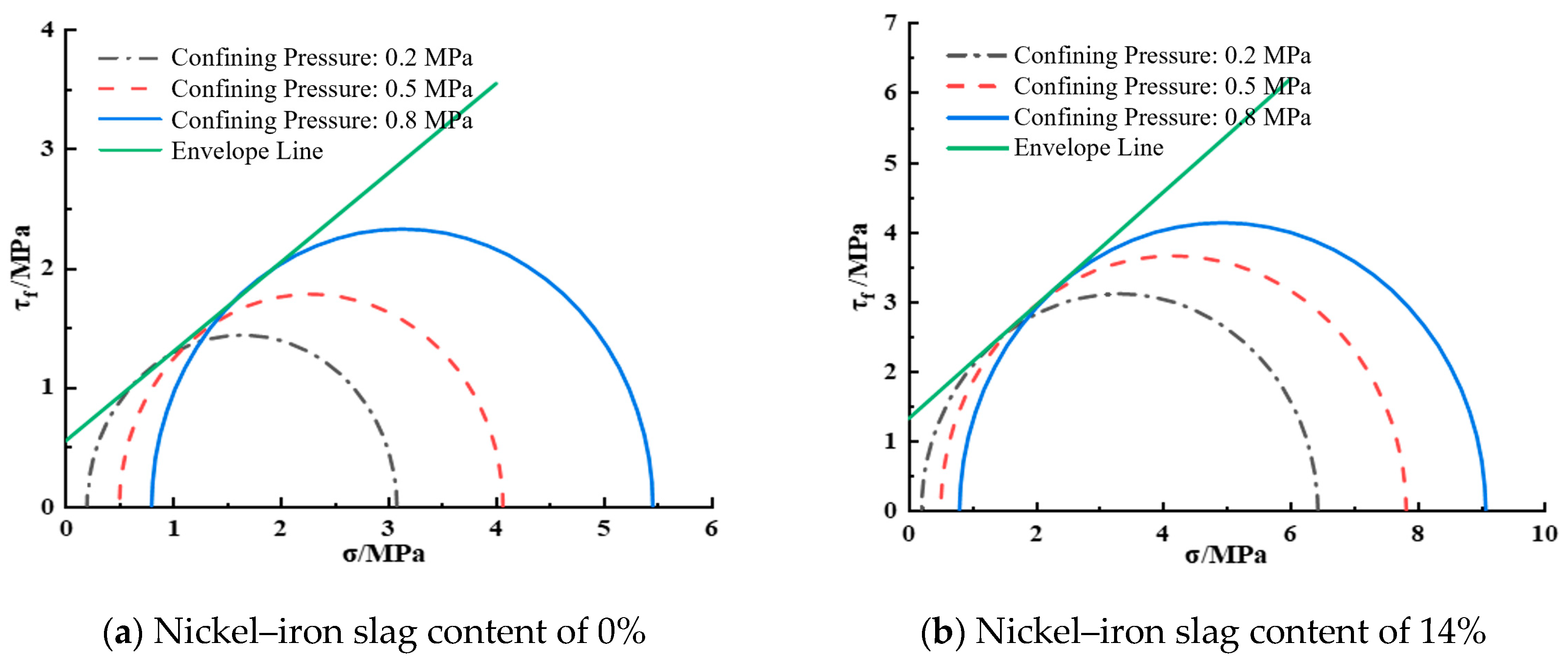

3.3. Influence of Sodium Sulfate Concentration on the Shear Strength of Nickel–Iron Slag Cement-Based Composite Materials

3.4. Influence of Sodium Sulfate Concentration on the Cohesion and Internal Friction Angle of the Nickel–Iron Slag Cement-Based Composites

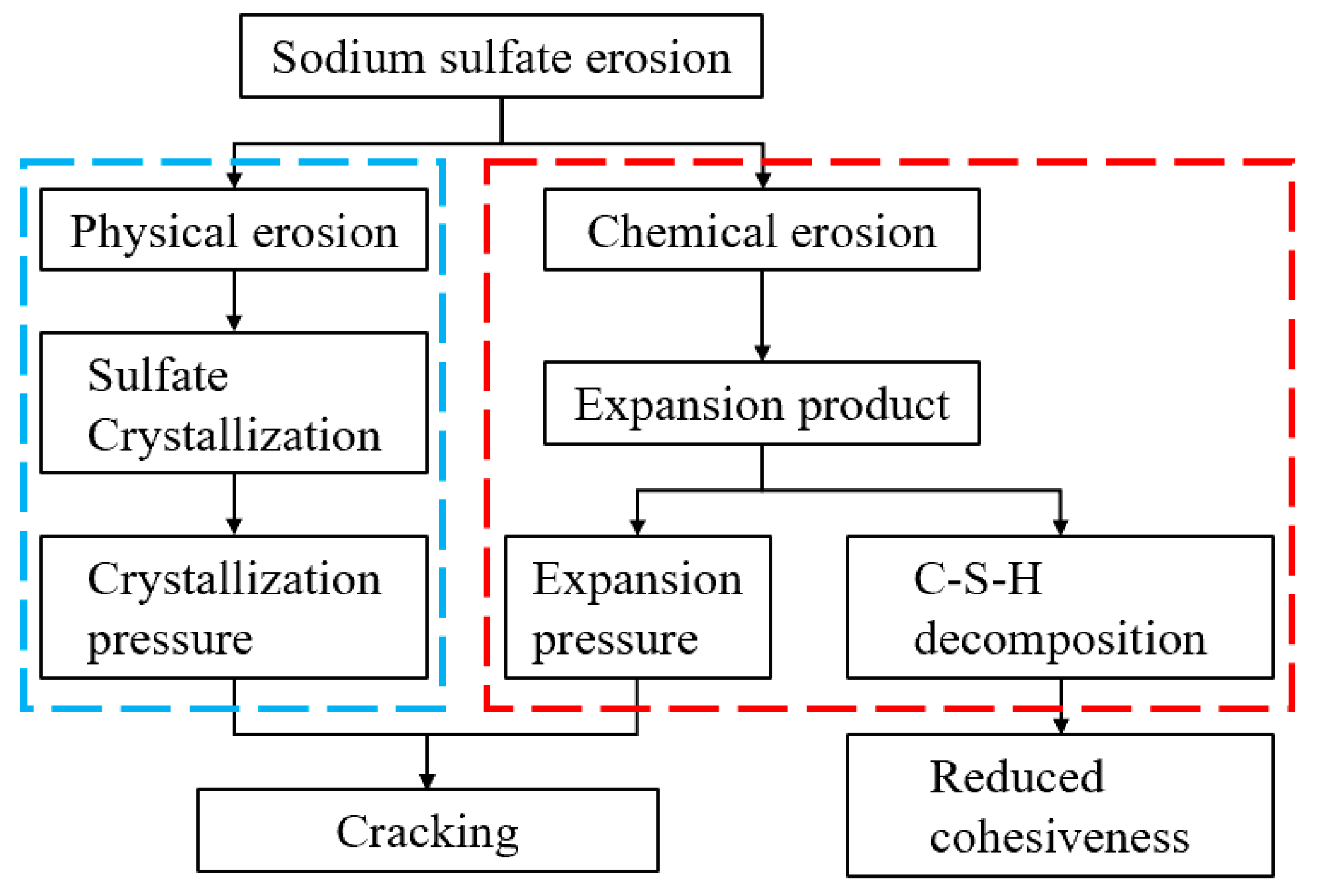

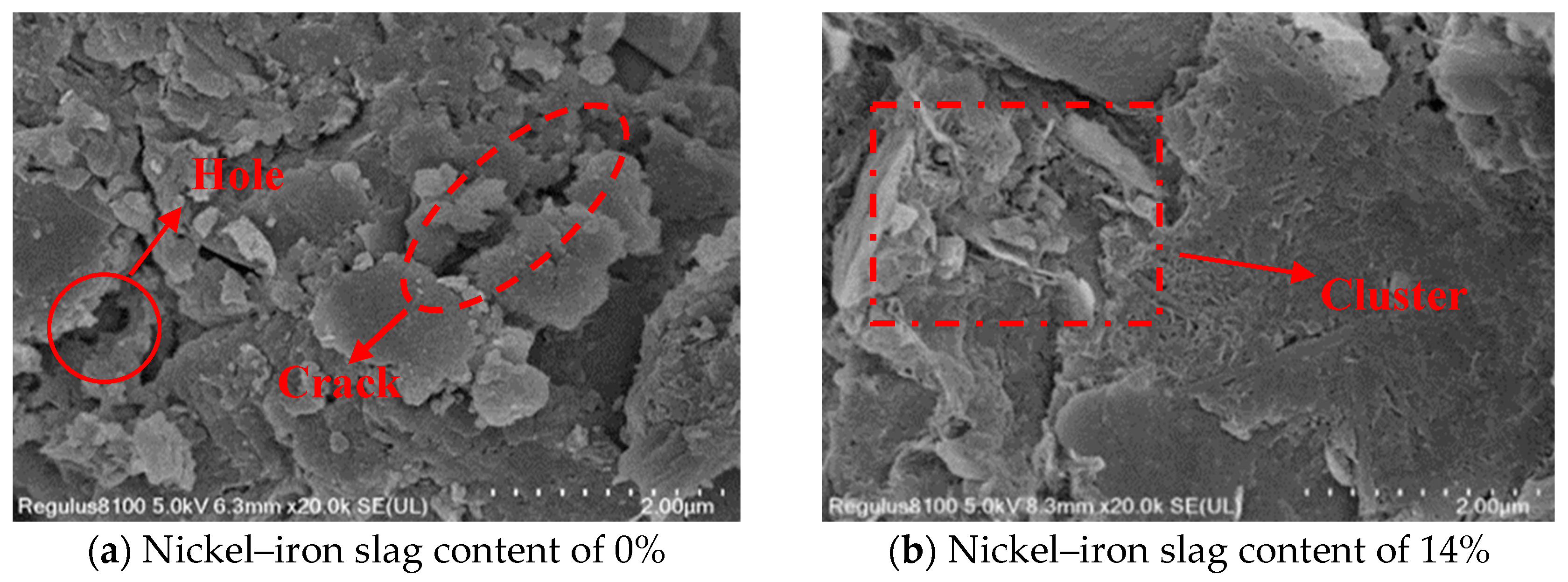

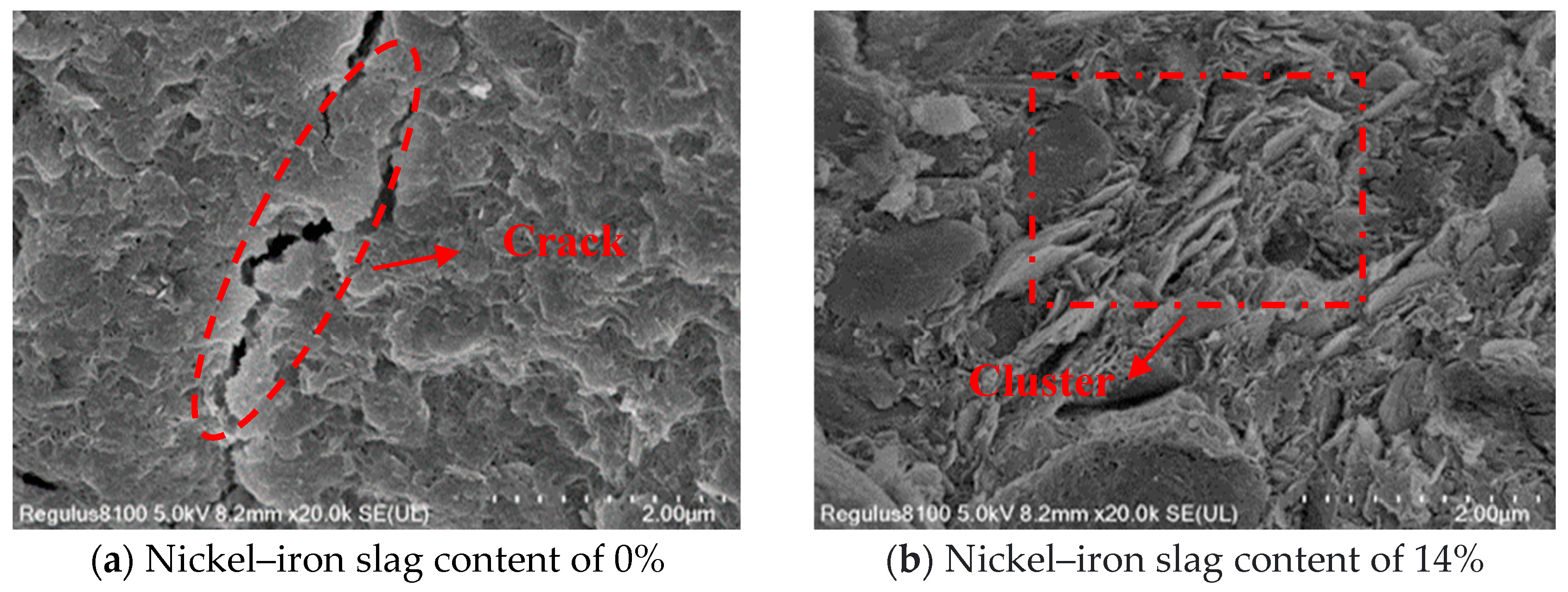

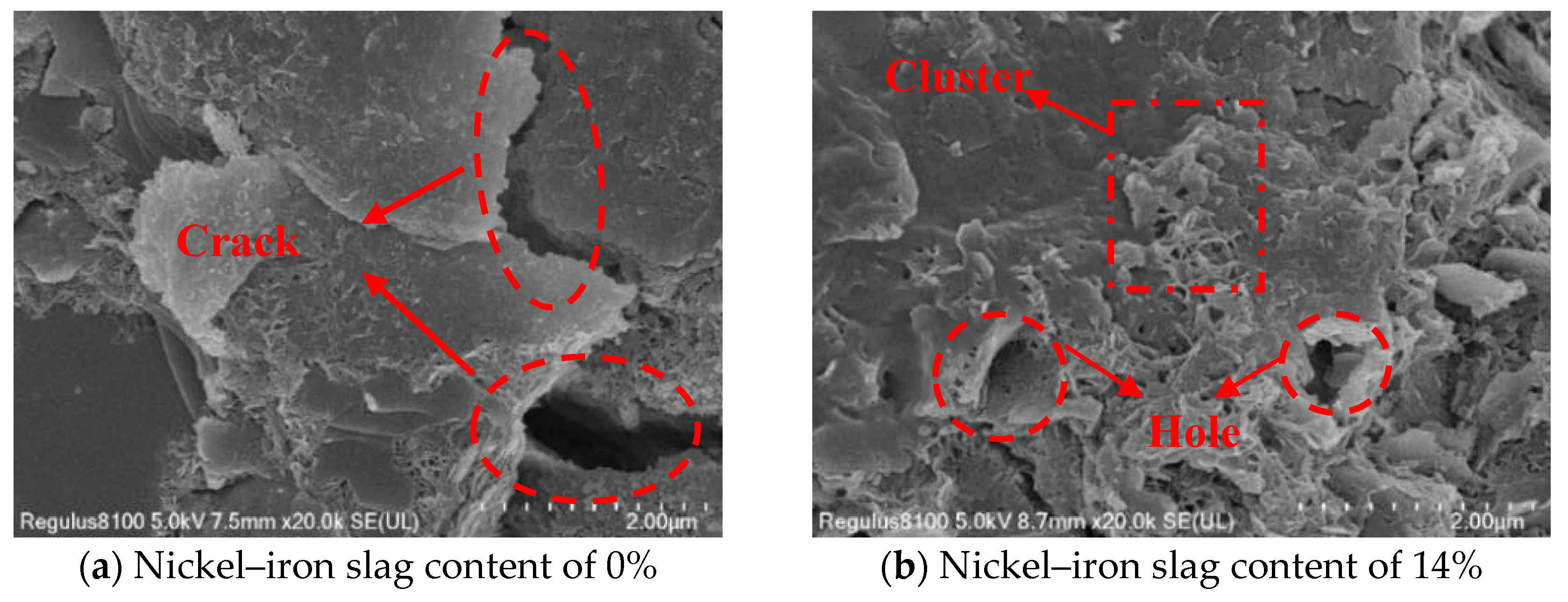

3.5. Microscopic Mechanism of the Nickel–Iron Slag Cement-Based Composites under the Action of Sodium Sulfate

4. Conclusions

- (1)

- Under the action of sodium sulfate, the stress–strain curve of the nickel–iron slag cement-based composite reflects softening, and the shear strength of the nickel–iron slag cement-based composite gradually decreases with the increasing sodium sulfate concentration. The optimum 14% nickel–iron slag addition leads to the increase in its plasticity and decrease in its brittleness.

- (2)

- With the increase in the sodium sulfate concentration, the cohesion and internal friction angle of the cement-based composite decrease. The decrease in the cohesion and internal friction angle of the cement-based composite derived from the nickel–iron slag is low in the case of a nickel–iron slag content of 14%. The addition of nickel–iron slag can delay the reduction in the cohesion and internal friction angle; hence, the corrosion resistance of the cement-based composite can be improved.

- (3)

- SEM images under 20,000× magnification reveal that with the increase in the sodium sulfate concentration and under a nickel–iron slag content of 14%, no clear cracks are observed inside the cement-based composite material. Adequate synergetic reaction occurs between SiO2 and cement in the nickel–iron slag structure, resulting in a large number of gel granule structures inside the cement-based composite material. Thus, with increasing nickel–iron slag content, the internal pores are filled tightly, the degree of cementation is increased, the corrosion of the cement–soil composite by sulfate ions is effectively inhibited, and the corrosion resistance of the nickel–iron slag cement-based composite material is improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abathar, A.H.; Murat, K.; Wael, A.; Elsadig, M.; Nuri, C.O. Green Concrete for a Circular Economy: A Review on Sustainability, Durability, and Structural Properties. Materials 2021, 14, 351. [Google Scholar] [CrossRef]

- Chen, S.L.; Ning, B.K. Environmental Effects of Geotechnical Materials; Metallurgical Industry Press: Beijing, China, 2010. [Google Scholar]

- Pacheco-Torgal, F.; Jalali, S. Reusing ceramic wastes in concrete. Constr. Build. Mater. 2010, 24, 832–838. [Google Scholar] [CrossRef]

- Watabe, Y.; Noguchi, T. Site-Investigation and Geotechnical Design of D-Runway Construction in Tokyo Haneda Airport. Soils Found. 2011, 51, 1003–1018. [Google Scholar]

- Kim, T.-H.; Kim, T.-H.; Kang, G.-C. Performance Evaluation of Road Embankment Constructed Using Lightweight Soils on an Unimproved Soft Soil Layer. Eng. Geol. 2013, 160, 34–43. [Google Scholar]

- Xu, L.N.; Zhang, R.Z.; Niu, L.; Song, D.H.; Jin, Y.J. Coupling effect of saline solution and freezing-thawing cycles on performance of basalt fiber reinforced cemented soil. Bull. Chin. Ceram. Soc. 2021, 40, 3572–3583. [Google Scholar]

- Dana, A.; Iluti, V.; Claudiu, A. Metallurgical Wastes as Resources for Sustainability of the Steel Industry. Materials 2022, 14, 5488. [Google Scholar] [CrossRef]

- Long, Y. Comprehensive Utilization of Laterite Nickel Ore Smelting Nickel-Iron Slag. Master’s Thesis, Northeastern University, Shenyang, China, 2017. [Google Scholar]

- Abdelli, K.; Tahlaiti, M.; Belarbi, R.; Oudjit, M.N. Influence of the pozzolanic reactivity of the Blast Furnace Slag (BFS) and metakaolin on mortars. Energy Procedia 2017, 139, 224–229. [Google Scholar]

- Manjunath, R.; Narasimhan, M.C. Alkali-activated concrete systems: A state of art. In New Materials in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 459–491. [Google Scholar]

- Liu, L.Y.; Liu, Y.; Zhang, K.; Song, N.J.; Zhao, H.Y.; Liu, F.T. Influence of nickel-iron slag used as admixture on cement properties. Bull. Chin. Ceram. Soc. 2016, 35, 1705–1710+1715. [Google Scholar]

- Bharathi, S.H.; Sreekumaran, S. A probabilistic approach to the design of reactive powder concrete mixes modified using slag. Mater. Today Proc. 2020, 43, 1276–1282. [Google Scholar] [CrossRef]

- Li, K.Q.; Feng, L.; Gao, S.J. Preparation of cementitious materials for backfilling by using nickel slag. Chin. J. Eng. 2015, 37, 1–6. [Google Scholar] [CrossRef]

- Bao, J.; Zheng, R.; Yu, Z.; Zhang, P.; Song, Q.; Xu, J.; Gao, S. Freeze-thaw resistance of recycled aggregate concrete incorporating ferronickel slag as fine aggregate. Constr. Build. Mater. 2022, 356, 129178. [Google Scholar] [CrossRef]

- Suryaningrat, E.R.; Masykur, K.; Paula, T.I.; Bambang, P.; Asminar, A.; van den Philip, H.; de Nele, B.; Elke, G. Effect of ferronickel slag as cementitious material on strength of mortar. Key Eng. Mater. 2022, 6648, 213–218. [Google Scholar]

- Dourdounis, E.; Stivanakis, V.; Angelopoulos, G.N.; Chaniotakis, E.; Frogoudakis, E.; Papanastasiou, D.; Papamantellos, D.C. High-alumina cement production from FeNi-ERF slag, limestone and diasporic bauxite. Cem. Concr. Res. 2004, 34, 63–66. [Google Scholar] [CrossRef]

- Li, D.F.; Zhou, Y.Q.; He, W. Influence of the fineness of on the hydration activity of electric furnace nickel slag. Concrete 2019, 352, 85–89. [Google Scholar] [CrossRef]

- Yang, X.M. Microstructure and Mechanism Research on Cement Stabilized Salt-Rich Clay. Master’s Thesis, Tongji University, Shanghai, China, 2006. [Google Scholar]

- Xing, H.F.; Yang, X.M.; Xu, C. Strength characteristics and mechanisms of salt-rich soil-cement. Eng. Geol. 2009, 103, 33–38. [Google Scholar] [CrossRef]

- Santhanam, M.; Cohen, M.D.; Olek, J. Sulfate attack research—Whither now? Cem. Concr. Res. 2001, 31, 845–851. [Google Scholar] [CrossRef]

- Chandra, K.J.; Kumar, S.P.; Ahmed, S.F.U. Sulphuric acid resistance of ground ferronickel slag blended fly ash geopolymer mortar. Constr. Build. Mater. 2021, 313, 125505. [Google Scholar] [CrossRef]

- Qi, T.S.; Zhou, Y.X.; Huang, Z.Y.; Gao, C.; He, Y. Hydration characteristics of blast furnace ferronickel slag powder in cement-based complex binder. Bull. Chin. Ceram. Soc. 2017, 36, 2944–2950+2957. [Google Scholar]

- Song, M.; Zhu, R.J.; Yang, L.; Jia, S.H. Research on making composite insulation block by ferronickel slag. Brick-Tile 2016, 4, 6–9. [Google Scholar]

- Li, Y.B.; Lou, G.H.; Ba, T.B.; Cao, D.S.; Xu, Y.Z. Technical analysis of autoclaved nickel-iron slag brick production line. Chin. Build. Mater. 2017, 4, 127–129. [Google Scholar]

- Zhu, G.; Peng, Z.; Yang, L.; Tang, H.; Fang, X.; Rao, M. Facile preparation of thermal insulation materials by microwave sintering of ferronickel slag and fly ash cenosphere. Ceram. Int. 2023, 49, 11978–11988. [Google Scholar] [CrossRef]

- Coto, O.; Galizia, F.; Hernández, I.; Marrero, J.; Donati, E. Cobalt and nickel recoveries from laterite tailings by organic andinorganic bio-acids. Hydrometallurgy 2008, 94, 18–22. [Google Scholar] [CrossRef]

- Wang, N.; Lu, J.; Shi, H.D. Comprehensive utilization of non-ferrous metal industrial smelting waste slag—Nickel slag. Environ. Eng. 1994, 12, 58–59. [Google Scholar]

- Wang, Z.; Ni, W.; Jia, Y.; Zhu, L.P.; Huang, X.Y. Crystallization behavior of glass ceramics prepared from the mixture of nickel slag, blast furnace slag and quartz sand. J. Non-Cryst. Solids 2010, 356, 1554–1558. [Google Scholar] [CrossRef]

- Yu, J.; Peng, Z.; Shang, W.; Chen, Q.; Zhu, G.; Tang, H.; Rao, M.; Li, G. Dual roles of Cr2O3 in preparation of glass-ceramics from ferronickel slag. Ceram. Int. 2023, 49, 15947–15958. [Google Scholar] [CrossRef]

- Liu, J.; Su, Y.; Han, Y.X.; Yin, W.X. Preparation experiment of nickel-iron slag fiber by nickel-iron slag. Met. Mine 2017, 490, 187–190. [Google Scholar]

- Al-Khafaji, R.; Dulaimi, A.; Jafer, H.; Mashaan, N.S.; Qaidi, S.; Obaid, Z.S.; Jwaida, Z. Stabilization of Soft Soil by a Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD). Recycling 2023, 8, 10. [Google Scholar] [CrossRef]

- GB/T50081-2019; Standard for Test Method of Concrete Physical and Mechanical Properties. China Architecture and Building Press: Beijing, China, 2019.

- GB-175; Common Portland Cement. Standards Press of China: Beijing, China, 2007.

- JGJ/T233-2011; Specification for Mix Proportion Design of Cement Soil. China Architecture and Building Press: Beijing, China, 2011.

- Zhou, Y.W. Experimental Study on Mechanical Properties of Nickel Iron Slag Cement Composite Soil under the Action of Sodium Sulfate. Master’s Thesis, Shenyang University of Technology, Shenyang, China, 2023. [Google Scholar]

- GB50021-2001; Code for Investigation of Geotechnical Engineering. China Architecture and Building Press: Beijing, China, 2009.

- Shi, K.J. Study on Physical and Mechanical Properties and Degradation Mechanism of Sludge Soil Solidified by Steel Slag Powder and Cement under Sulfate Chloride Erosion. Master’s Thesis, Shandong University of Science and Technology, Shandong, China, 2020. [Google Scholar]

- Sherwood, P.T. Effect of sulfates on cement and lime treated soil. In Highway Research Board Bulletin; National Research Council: Washington, DC, USA, 1962; Volume 353, pp. 98–107. [Google Scholar]

| Composition | SiO2 | Al2O3 | Na2O | K2O | Fe2O3 | CaO | TiO2 |

|---|---|---|---|---|---|---|---|

| Proportion (%) | 72.72 | 16.76 | 5.25 | 2.97 | 1.85 | 0.29 | 0.16 |

| Natural Moisture Content, w (%) | Natural Weight, γ (kN/m−3) | Natural Soil Density, ρ (g/cm−3) | Liquid Limit, wL (%) | Plastic Limit, wP (%) | Liquidity Index, IP | Plasticity Index, IL |

|---|---|---|---|---|---|---|

| 27.0 | 19.5 | 1.94 | 33.3 | 18.5 | 0.54 | 14.6 |

| Testing Content | Normal Consistency (%) | Initial Setting Time (min) | Final Setting Time (min) | Loss on Ignition (%) | Compressive Strength (MPa) | Tensile Strength (MPa) | ||

|---|---|---|---|---|---|---|---|---|

| 3 Days | 28 Days | 3 Days | 28 Days | |||||

| Measured value | 29.3 | 194 | 392 | 1.04 | 23.7 | 47.1 | 5.6 | 7.1 |

| Composition | Na2SO4 | Cl | Ca | K | SO4 | PO4 | Water-Insoluble Substance |

|---|---|---|---|---|---|---|---|

| Content (%) | ≥99.0 | ≤0.001 | ≤0.002 | ≤0.02 | ≤0.002 | ≤0.001 | ≤0.005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Zhou, Y.; Chen, S.; Meng, J.; Wang, J. Study on the Mechanical Properties and Mechanism of a Nickel-Iron Slag Cement-Based Composite under the Action of Sodium Sulfate. Materials 2023, 16, 7041. https://doi.org/10.3390/ma16217041

Zhang J, Zhou Y, Chen S, Meng J, Wang J. Study on the Mechanical Properties and Mechanism of a Nickel-Iron Slag Cement-Based Composite under the Action of Sodium Sulfate. Materials. 2023; 16(21):7041. https://doi.org/10.3390/ma16217041

Chicago/Turabian StyleZhang, Jingyu, Yuwan Zhou, Sili Chen, Jinzhu Meng, and Junxiang Wang. 2023. "Study on the Mechanical Properties and Mechanism of a Nickel-Iron Slag Cement-Based Composite under the Action of Sodium Sulfate" Materials 16, no. 21: 7041. https://doi.org/10.3390/ma16217041

APA StyleZhang, J., Zhou, Y., Chen, S., Meng, J., & Wang, J. (2023). Study on the Mechanical Properties and Mechanism of a Nickel-Iron Slag Cement-Based Composite under the Action of Sodium Sulfate. Materials, 16(21), 7041. https://doi.org/10.3390/ma16217041