Calibration of Yld2000-2D Anisotropy Yield Criterion with Traditional Testing and Inverse Identification Strategies

Abstract

:1. Introduction

2. Yld2000-2D Anisotropy Yield Criterion

3. Parameter Identification with Traditional Testing Strategy

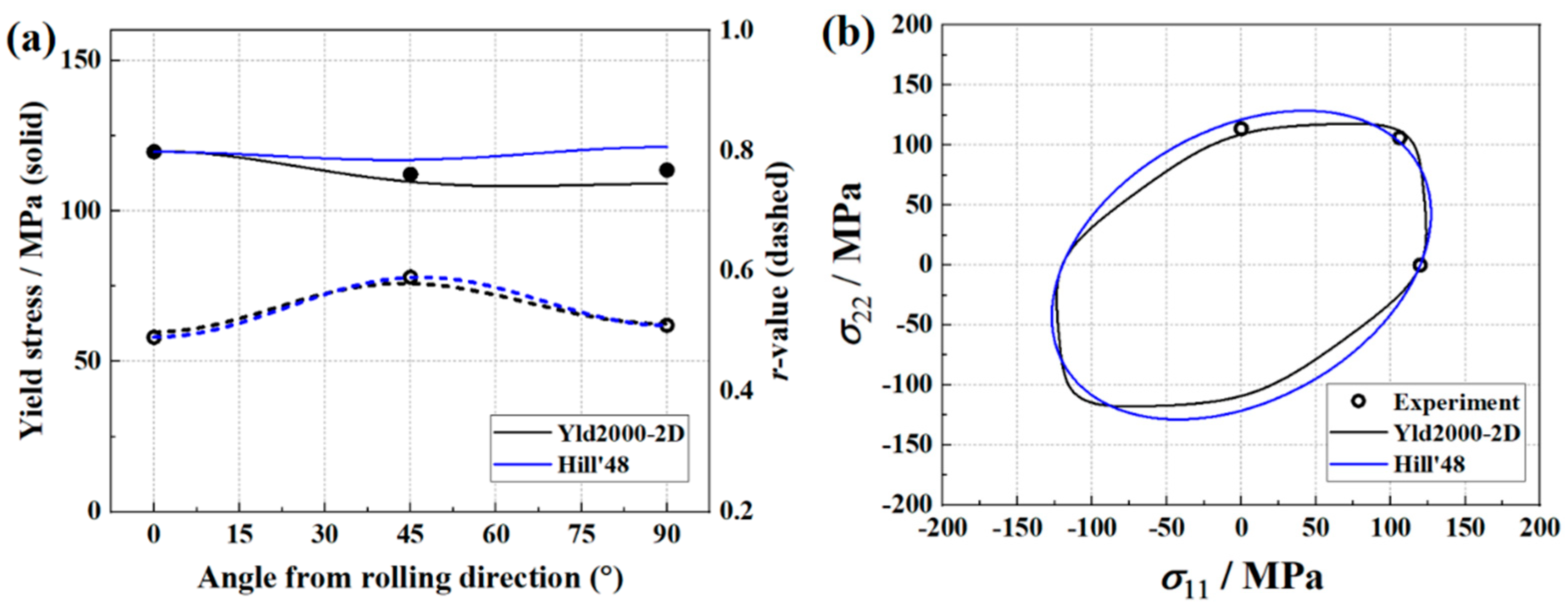

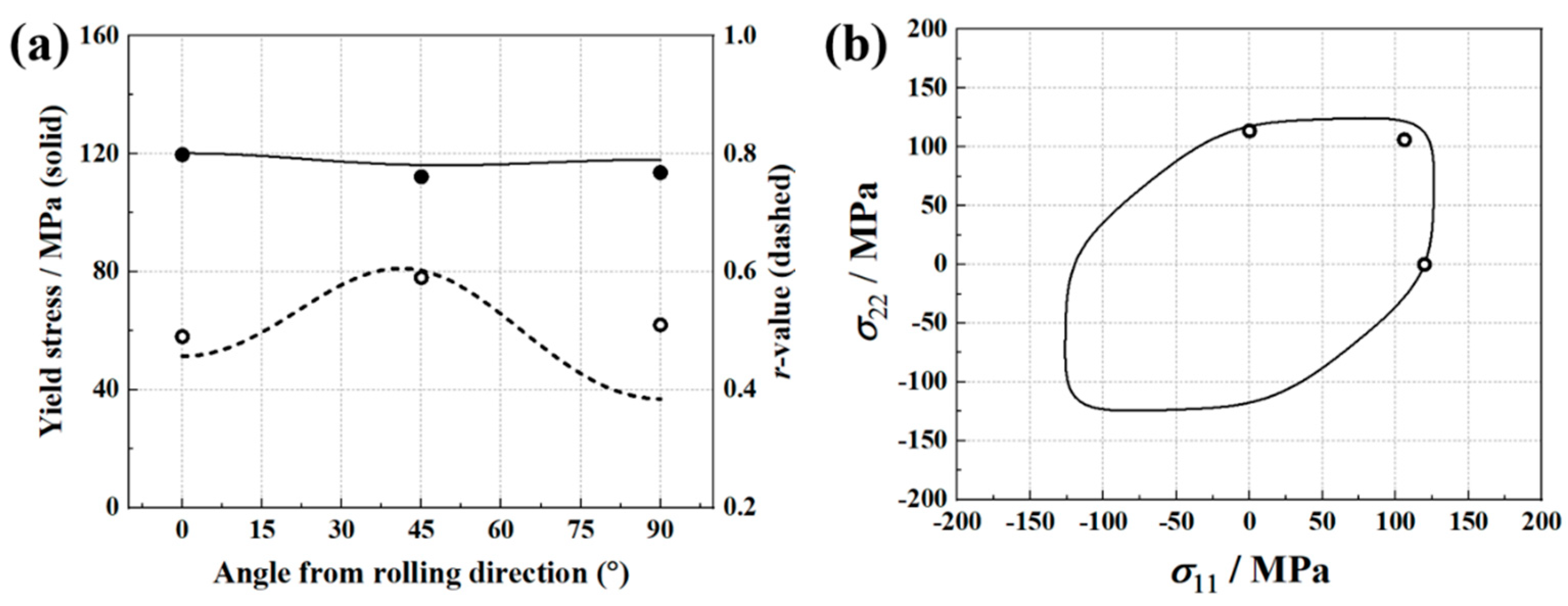

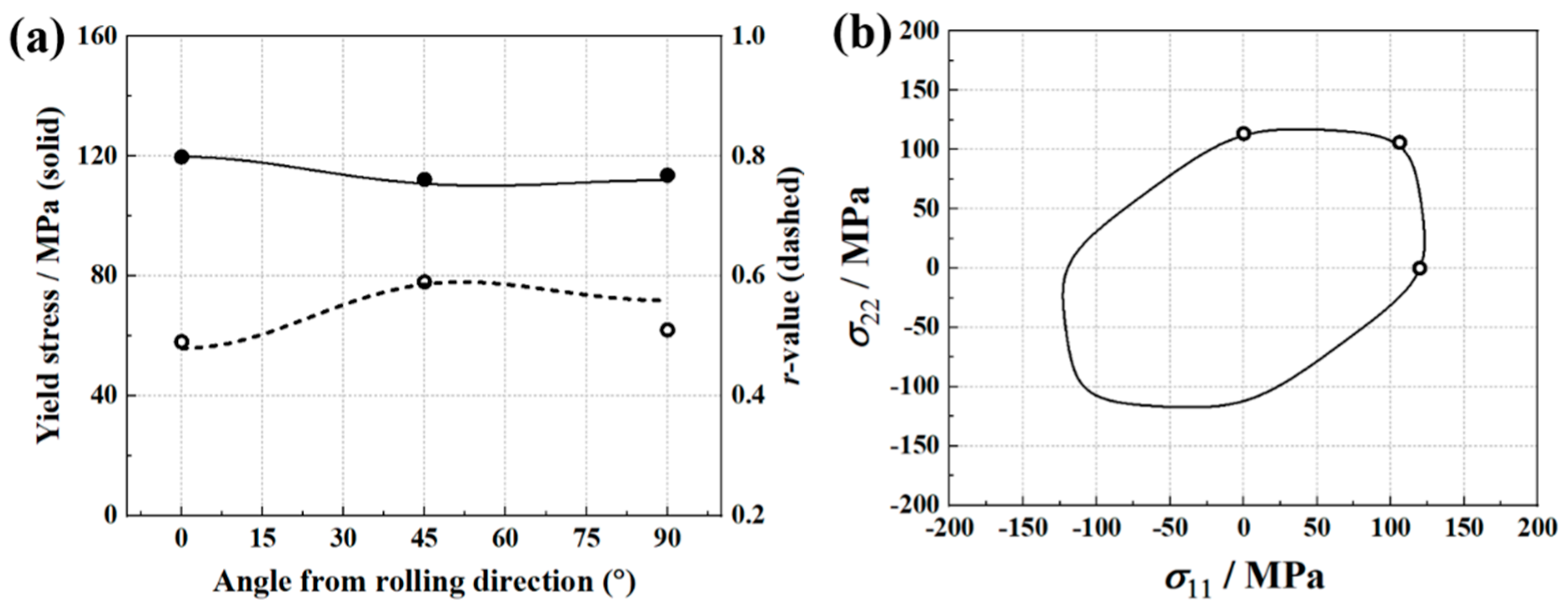

3.1. Uniaxial and Biaxial Tensile Tests

3.2. Parameter Identification of Yld2000-2D Yield Criterion

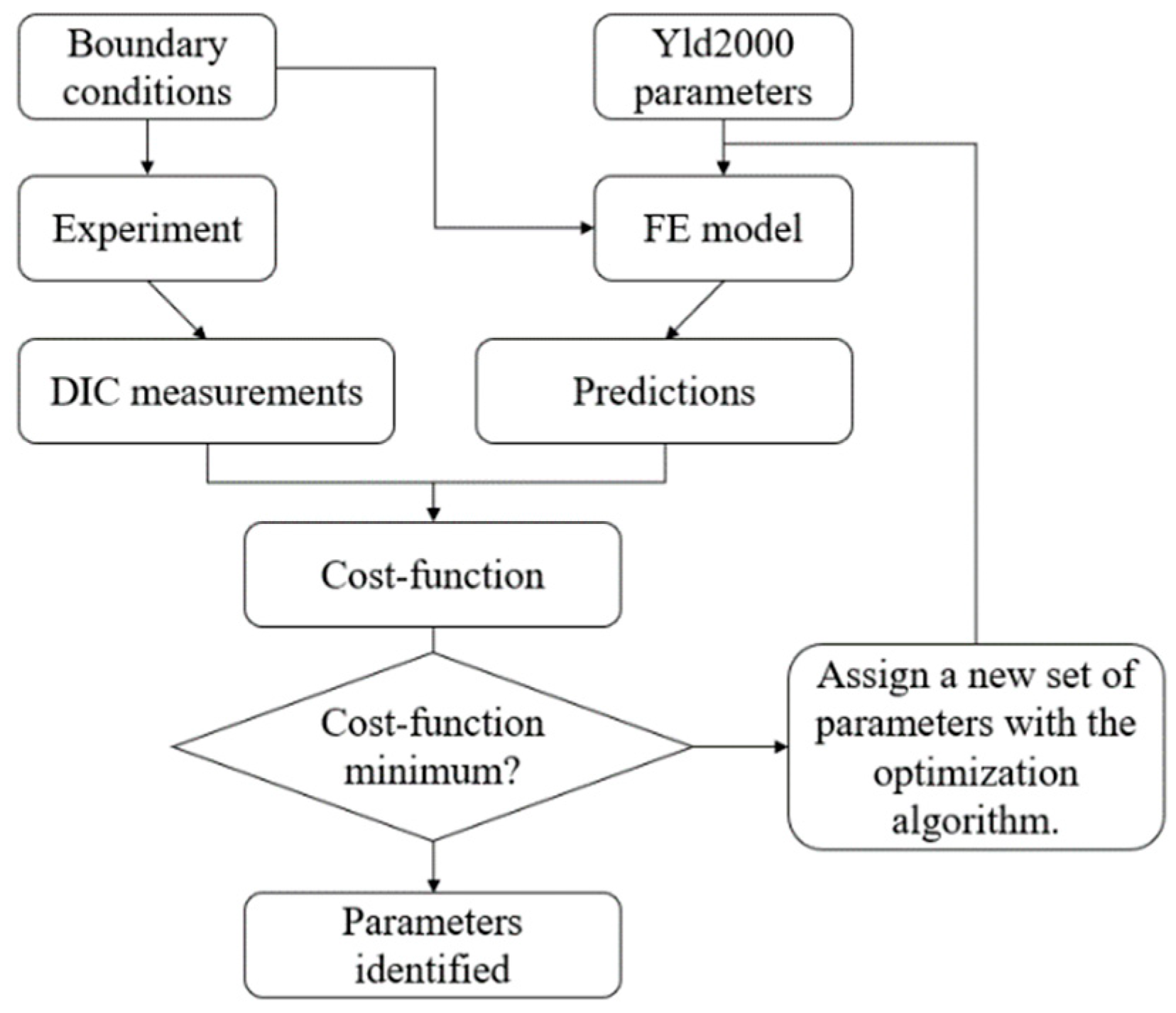

4. Parameter Identification with Inverse Identification Strategy

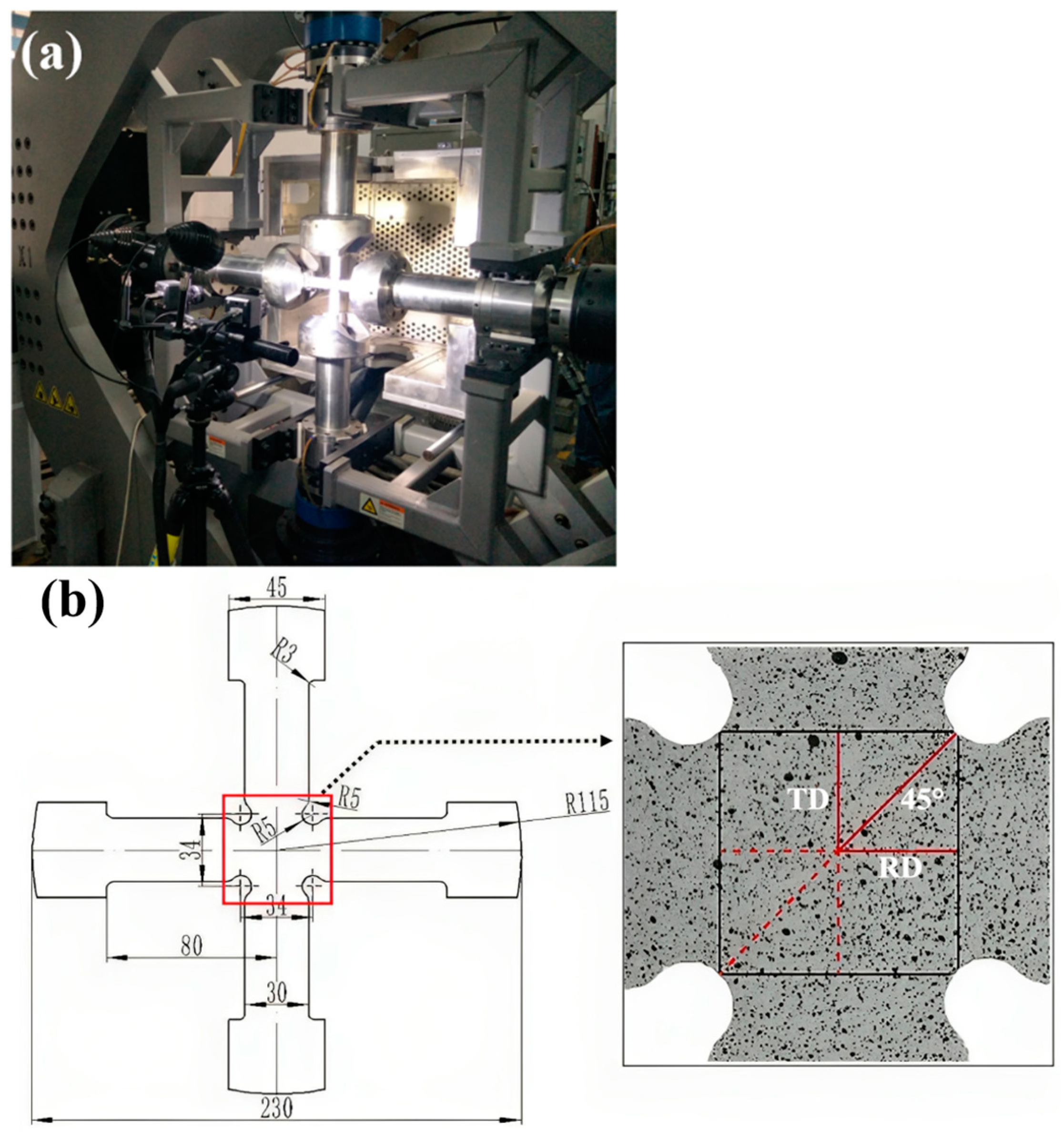

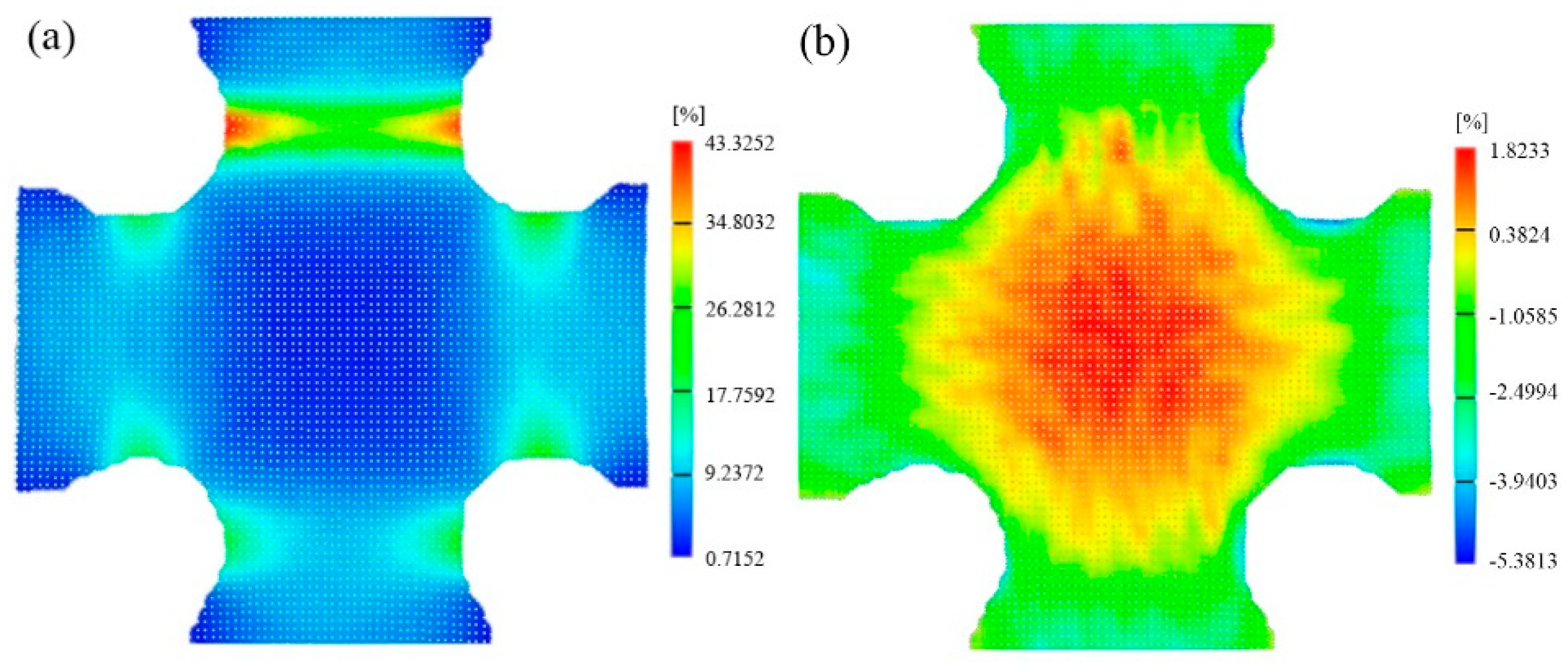

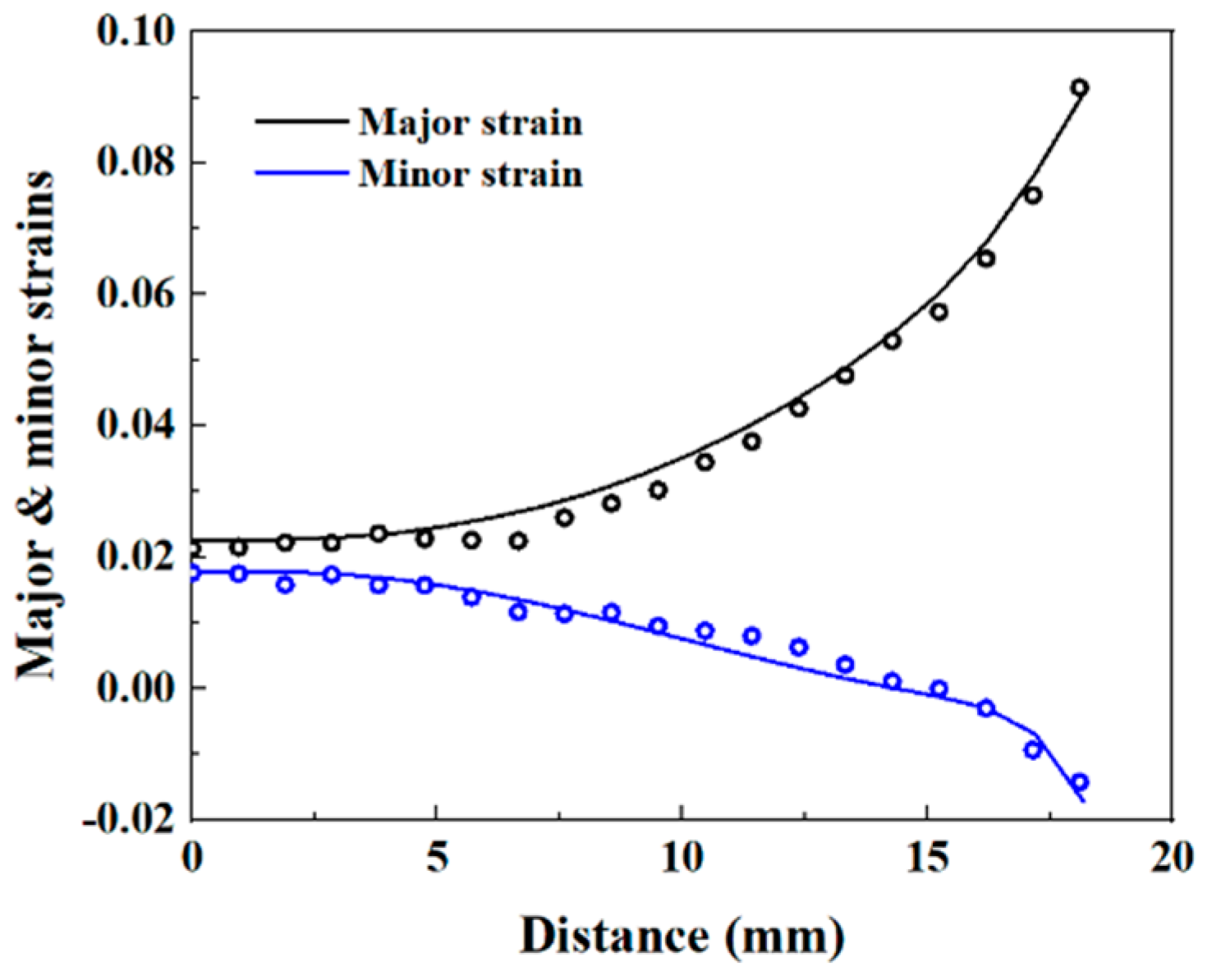

4.1. Identification with Equi-Biaxial Tensile Test

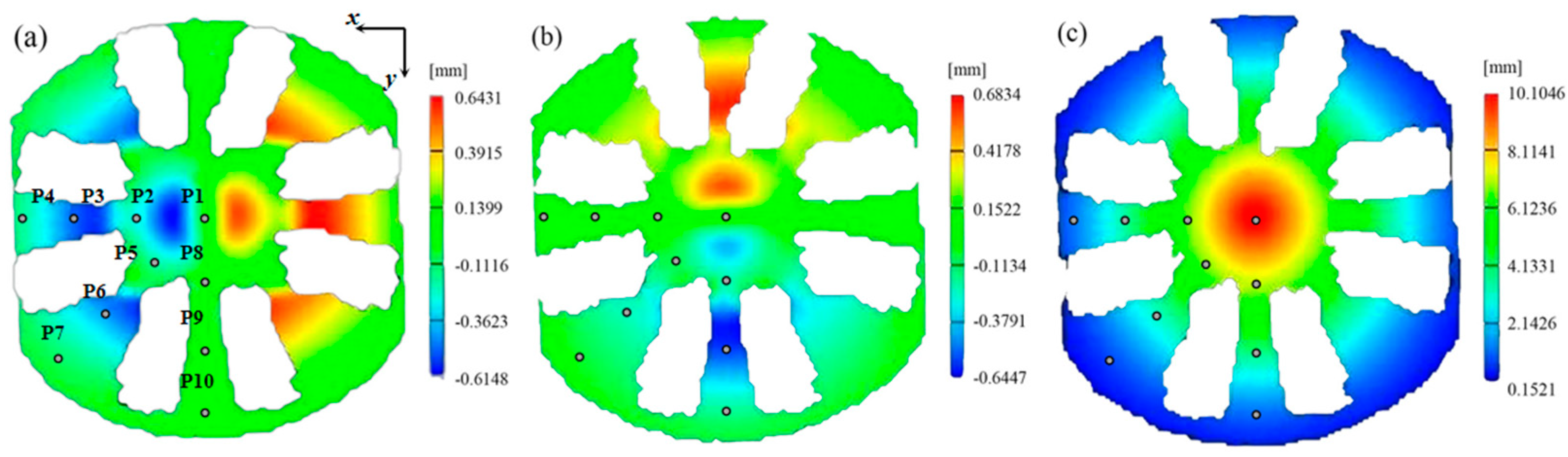

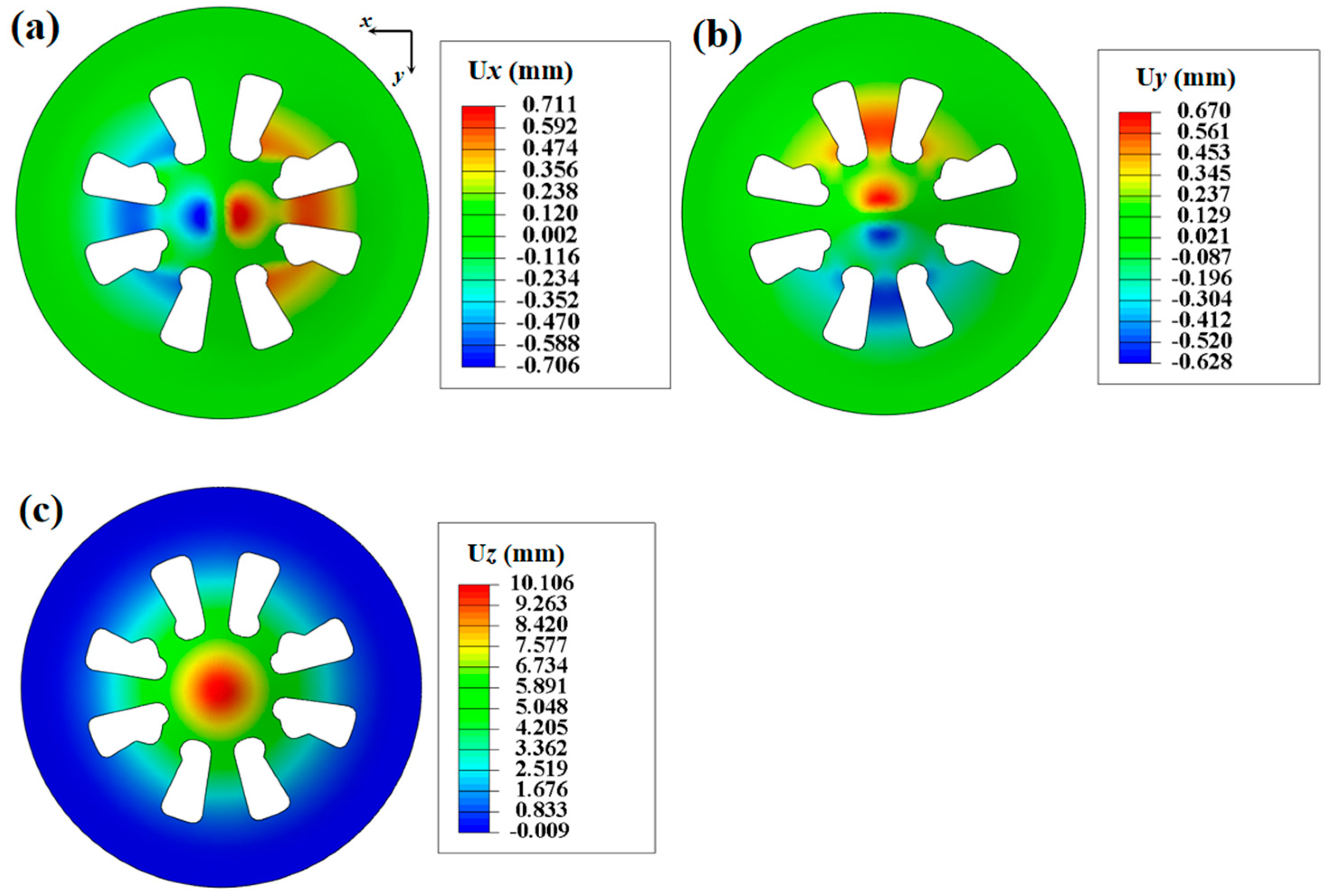

4.2. Identification with Pottier Bulging Test

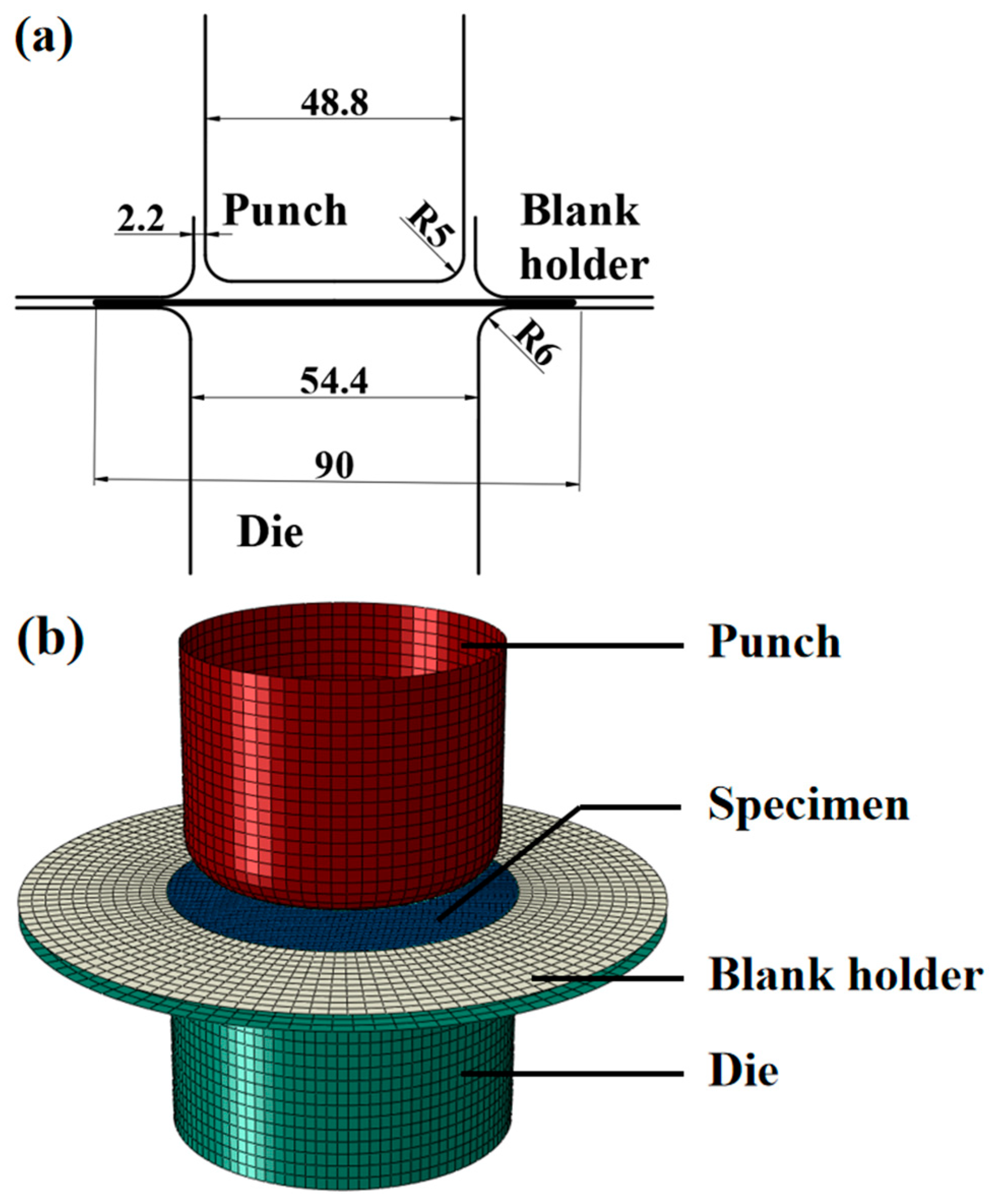

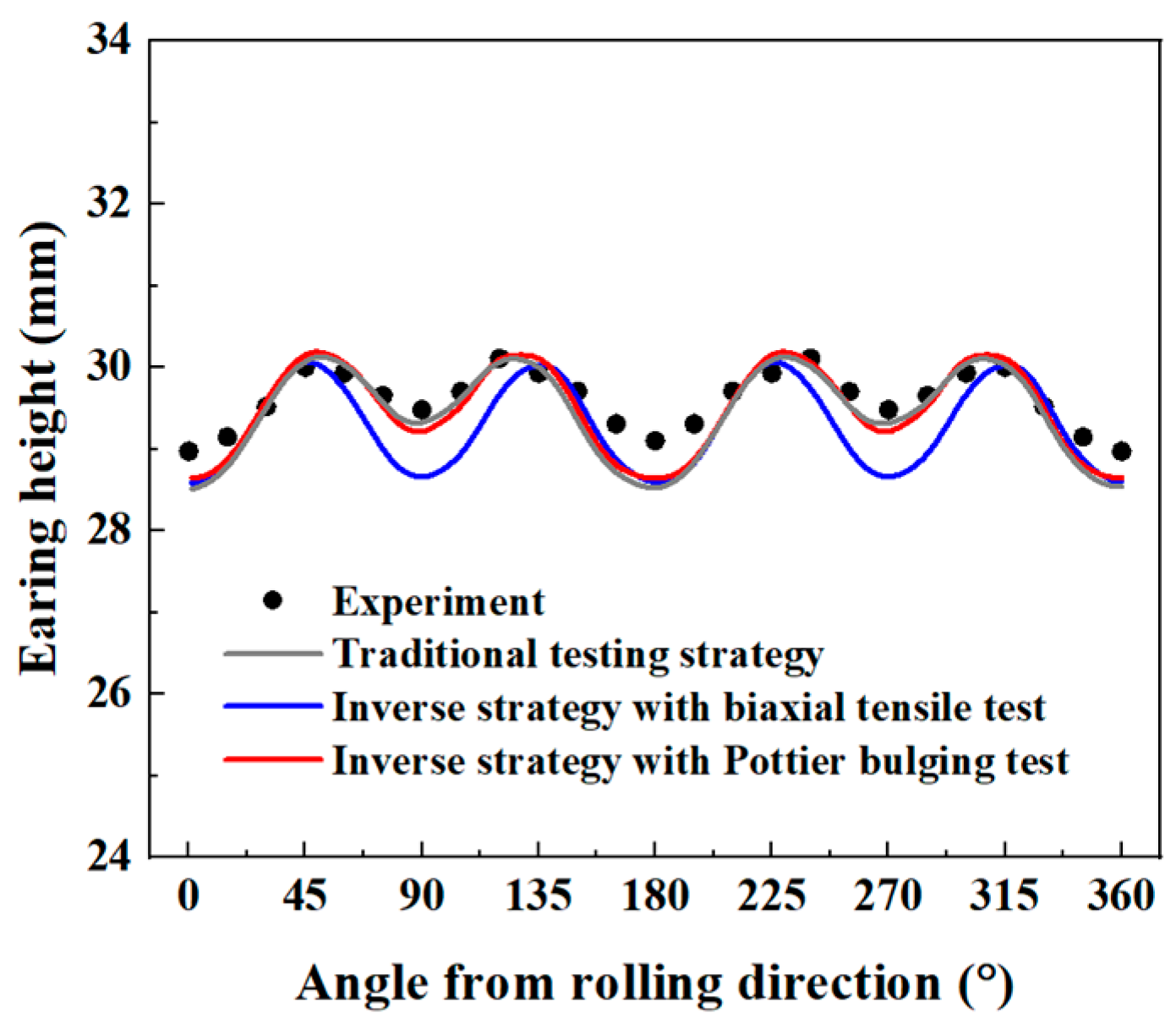

5. Verification of Yield Criterion Parameters

6. Conclusions

- The traditional testing strategy can accurately identify the parameters of Yld2000-2D anisotropy yield criterion. The identified Yld2000-2D accurately describes the yield stresses and r-values of AA5086 sheets. The prediction of the earing height is also in good agreement with the experimental result.

- The equi-biaxial tensile test using a dedicated cruciform specimen for producing heterogeneous strain fields has been investigated. The inverse identification of Yld2000-2D parameters is performed by minimizing the gap between the experimental and numerical principal strains along a diagonal direction of the specimen’s ROI. The identified Yld2000-2D parameters provide a correct prediction of the material yield stresses. But for the r-values at the 90° direction, the predicted values are significantly lower than the experiment. This results in predicted earing heights for the deep drawing test being lower than the experimental measurements in the 90° and 270° directions.

- The Pottier bulging test for producing heterogeneous displacement fields has also been investigated. The inverse identification procedure of Yld2000-2D parameters is performed based on displacement data extracted from 10 material points covering the expansion, shear, and tension regions of the Pottier specimen. The identified Yld2000-2D parameters accurately describe the material anisotropic behaviors (yield stresses and r-values), and the predicted earing height distribution is close to the experimental one.

- The inverse identification strategy based on the FEMU method can be an effective alternative to identify the parameters of Yld2000-2D yield criterion. A well-designed heterogeneous test could lead to a better identification result.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, Z.; Xiao, A.; Cui, X.; Lin, Y.; Yu, H.; Chen, B. Fracture behavior of 7075-T6 aluminum alloy under electromagnetic forming and traditional stamping. Arch. Civ. Mech. Eng. 2021, 21, 134. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Tang, Z.H.; Pan, S.P.; Liu, W.H.; Song, Y.F.; Zhu, B.W.; Liu, Y.; Wen, Z.L. The fatigue crack behavior of 7N01-T6 aluminum alloy in different particle environments. Arch. Civ. Mech. Eng. 2020, 20, 129. [Google Scholar] [CrossRef]

- Hill, R. A theory of the yielding and plastic flow of anisotropic metals. Proc. R. Soc. Lond. Ser. A 1948, 193, 281–297. [Google Scholar]

- Barlat, F.; Brem, J.C.; Yoon, J.W.; Chung, K.; Dick, R.E.; Lege, D.J.; Pourboghrat, F.; Choi, S.H.; Chu, E. Plane stress yield function for aluminum alloy sheets—Part 1: Theory. Int. J. Plast. 2003, 19, 1297–1319. [Google Scholar] [CrossRef]

- Yoon, J.W.; Barlat, F.; Dick, R.E.; Chung, K.; Kang, T.J. Plane stress yield function for aluminum alloy sheets—Part II: FE formulation and its implementation. Int. J. Plast. 2004, 20, 495–522. [Google Scholar] [CrossRef]

- Barlat, F.; Aretz, H.; Yoon, J.W.; Karabin, M.E.; Brem, J.C.; Dick, R.E. Linear transfomation-based anisotropic yield functions. Int. J. Plast. 2005, 21, 1009–1039. [Google Scholar] [CrossRef]

- Bron, F.; Besson, J. A yield function for anisotropic materials Application to aluminum alloys. Int. J. Plast. 2004, 20, 937–963. [Google Scholar] [CrossRef]

- Zang, S.L.; Thuillier, S.; Le Port, A.; Manach, P.Y. Prediction of anisotropy and hardening for metallic sheets in tension, simple shear and biaxial tension. Int. J. Mech. Sci. 2011, 53, 338–347. [Google Scholar] [CrossRef]

- Zhang, S.; Leotoing, L.; Guines, D.; Thuillier, S.; Zang, S.L. Calibration of anisotropic yield criterion with conventional tests or biaxial test. Int. J. Mech. Sci. 2014, 85, 142–151. [Google Scholar] [CrossRef]

- Tian, H.; Brownell, B.; Baral, M.; Korkolis, Y.P. Earing in cup-drawing of anisotropic Al-6022-T4 sheets. Int. J. Mater. Form. 2017, 10, 329–343. [Google Scholar] [CrossRef]

- Khalfallah, A.; Oliveira, M.C.; Alves, J.L.; Menezes, L.F. Constitutive parameter identification of CB2001 yield function and its experimental verification using tube hydroforming tests. Int. J. Mech. Sci. 2020, 185, 105868. [Google Scholar] [CrossRef]

- Martins, J.M.P.; Andrade-Campos, A.; Thuillier, S. Comparison of inverse identification strategies for constitutive mechanical models using full-field measurements. Int. J. Mech. Sci. 2018, 145, 330–345. [Google Scholar] [CrossRef]

- Zhang, Y.; Van Bael, A.; Andrade-Campos, A.; Coppieters, S. Parameter identifiability analysis: Mitigating the non-uniqueness issue in the inverse identification of an anisotropic yield function. Int. J. Solids Struct. 2022, 243, 111543. [Google Scholar] [CrossRef]

- Pierron, F.; Grédiac, M. Towards Material Testing 2.0. A review of test design for identification of constitutive parameters from full-field measurements. Strain 2021, 57, e12370. [Google Scholar] [CrossRef]

- Avril, S.; Pierron, F.; Pannier, Y.; Rotinat, R. Stress reconstruction and constitutive parameter identification in plane-stress elasto-plastic problems using surface measurements of deformation fields. Exp. Mech. 2008, 48, 403–419. [Google Scholar] [CrossRef]

- Kavanagh, K.T.; Clough, R.W. Finite element applications in the characterization of elastic solids. Int. J. Solids Struct. 1971, 7, 11–23. [Google Scholar] [CrossRef]

- Borzeszkowski, B.; Lubowiecka, I.; Sauer, R.A. Nonlinear material identification of heterogeneous isogeometric Kirchhoff–Love shells. Comput. Methods Appl. Mech. Eng. 2022, 390, 114442. [Google Scholar] [CrossRef]

- Pottier, T.; Vacher, P.; Toussaint, F.; Louche, H.; Coudert, T. Out-of-plane Testing Procedure for Inverse Identification Purpose: Application in Sheet Metal Plasticity. Exp. Mech. 2012, 52, 951–963. [Google Scholar] [CrossRef]

- Wang, Z.; Zang, S.; Chu, X.; Zhang, S.; Lionel, L. Identification of 7B04 aluminum alloy anisotropy yield criteria with conventional test and Pottier test at elevated temperature. Results Phys. 2019, 15, 102655. [Google Scholar] [CrossRef]

- Zhang, S.; Léotoing, L.; Guines, D.; Thuillier, S. Potential of the Cross Biaxial Test for Anisotropy Characterization Based on Heterogeneous Strain Field. Exp. Mech. 2015, 55, 817–835. [Google Scholar] [CrossRef]

- Martins, J.M.P.; Andrade-Campos, A.; Thuillier, S. Calibration of anisotropic plasticity models using a biaxial test and the virtual fields method. Int. J. Solids Struct. 2019, 172–173, 21–37. [Google Scholar] [CrossRef]

- Voce, E. The relationship between stress and strain for homogeneous deformation. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- ISO 16842:2021; Metallic Materials: Sheet and Strip—Biaxial Tensile Testing Method Using a Cruciform Test Piece. ISO: Geneva, Switzerland, 2021.

- Neto, D.M.; Martins, J.M.P.; Cunha, P.M.; Alves, J.L.; Oliveira, M.C.; Laurent, H.; Menezes, L.F. Thermo-mechanical finite element analysis of the AA5086 alloy under warm forming conditions. Int. J. Solids Struct. 2018, 151, 99–117. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 0.32 | 0.41 | 0.06 | 0.51 | 4.12 | 0.19 | 0.16 | 0.07 | Other |

| σ0 (MPa) | σ45 (MPa) | σ90 (MPa) | σb (MPa) | r0 | r45 | r90 | rb |

|---|---|---|---|---|---|---|---|

| 119.704 | 112.215 | 113.646 | 106.067 | 0.49 | 0.59 | 0.51 | 1.101 |

| α1 | α2 | α3 | α4 | α5 | α6 | α7 | α8 |

|---|---|---|---|---|---|---|---|

| 0.862 | 1.136 | 1.029 | 1.110 | 1.069 | 1.180 | 1.042 | 1.160 |

| F | G | H | N |

|---|---|---|---|

| 0.645 | 0.671 | 0.329 | 1.434 |

| α1 | α2 | α3 | α4 | α5 | α6 | α7 | α8 |

|---|---|---|---|---|---|---|---|

| 0.945 | 0.920 | 0.986 | 1.047 | 1.030 | 1.008 | 0.986 | 1.104 |

| α1 | α2 | α3 | α4 | α5 | α6 | α7 | α8 |

|---|---|---|---|---|---|---|---|

| 0.8684 | 1.139 | 1.216 | 1.119 | 1.086 | 1.252 | 1.047 | 1.067 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Wang, Z.; Chu, X.; Yue, Z.; Zhao, C.; Zhou, Y. Calibration of Yld2000-2D Anisotropy Yield Criterion with Traditional Testing and Inverse Identification Strategies. Materials 2023, 16, 6904. https://doi.org/10.3390/ma16216904

Chen J, Wang Z, Chu X, Yue Z, Zhao C, Zhou Y. Calibration of Yld2000-2D Anisotropy Yield Criterion with Traditional Testing and Inverse Identification Strategies. Materials. 2023; 16(21):6904. https://doi.org/10.3390/ma16216904

Chicago/Turabian StyleChen, Jiaqi, Zhihao Wang, Xingrong Chu, Zhenming Yue, Chao Zhao, and Yiqi Zhou. 2023. "Calibration of Yld2000-2D Anisotropy Yield Criterion with Traditional Testing and Inverse Identification Strategies" Materials 16, no. 21: 6904. https://doi.org/10.3390/ma16216904

APA StyleChen, J., Wang, Z., Chu, X., Yue, Z., Zhao, C., & Zhou, Y. (2023). Calibration of Yld2000-2D Anisotropy Yield Criterion with Traditional Testing and Inverse Identification Strategies. Materials, 16(21), 6904. https://doi.org/10.3390/ma16216904