Effect of Dispersing Carbon Nanotube in Aqueous Solution by Poly-Carboxylic-Based Surfactants on Mechanical and Microstructural Properties as Cementitious Composites

Abstract

1. Introduction

2. Experimental Design and Methods

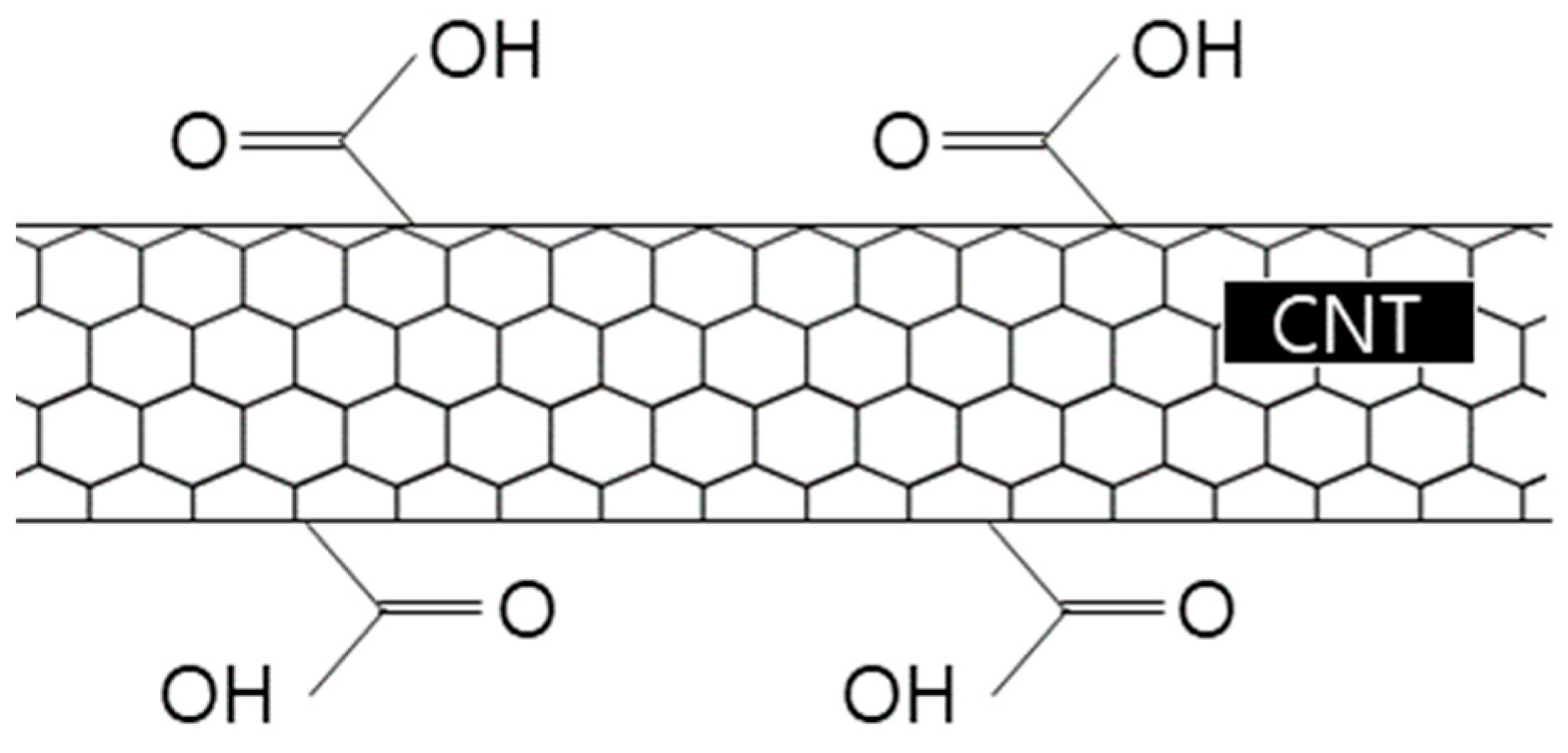

2.1. Preparation of CNT Aqueous Dispersions

2.2. Materials and Methods of Cement Paste Mixing

3. Experimental Method

3.1. Vicat Needle Test for Penetration Resistance Measurement

3.2. Thermogravimetric Analysis (TGA)

3.3. Measurement of Compressive Strength and Flexural Strength

3.4. SEM Analysis

3.5. BET Analysis

4. Experimental Results and Analysis

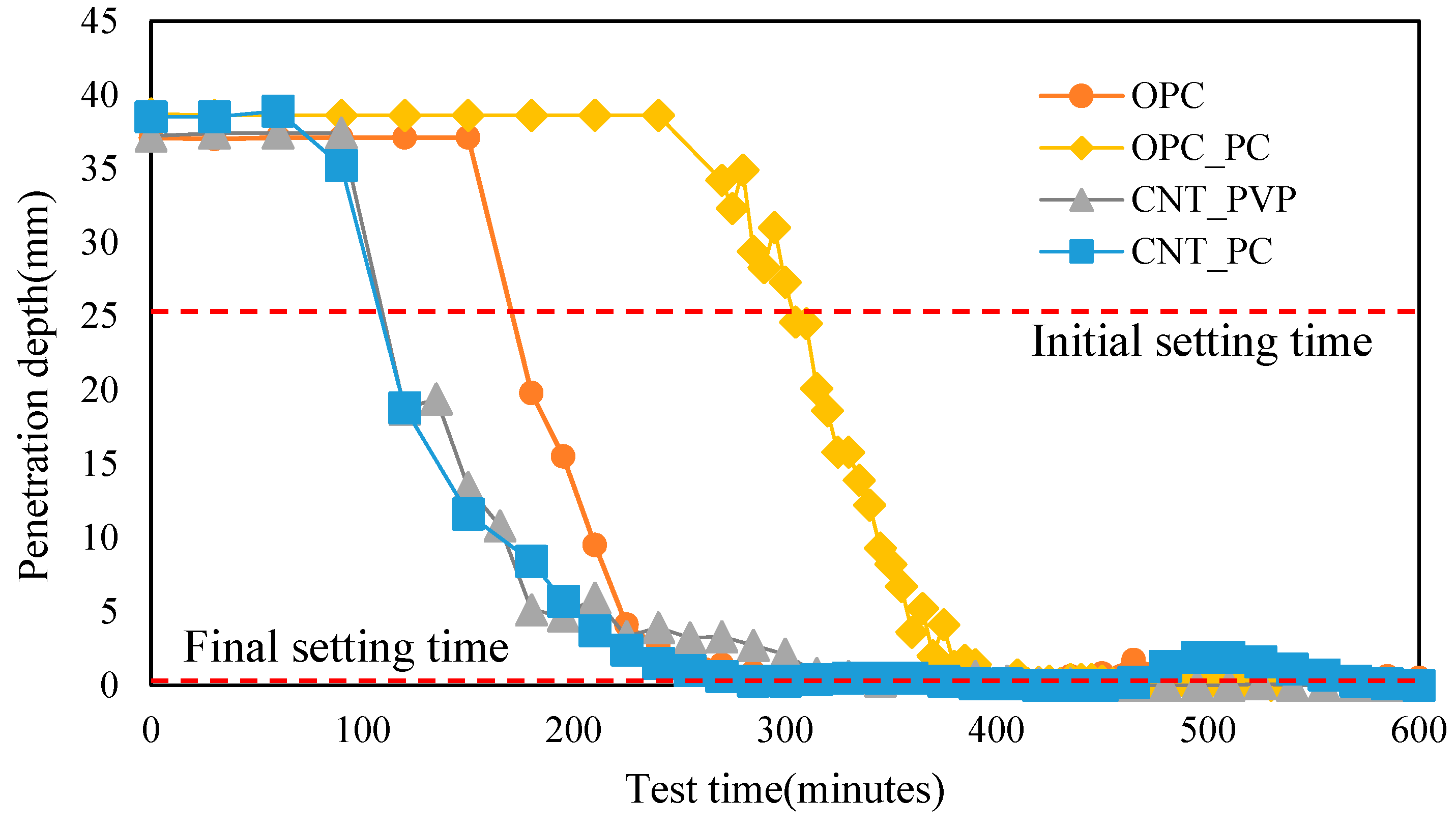

4.1. Results of Vicat Needle Test

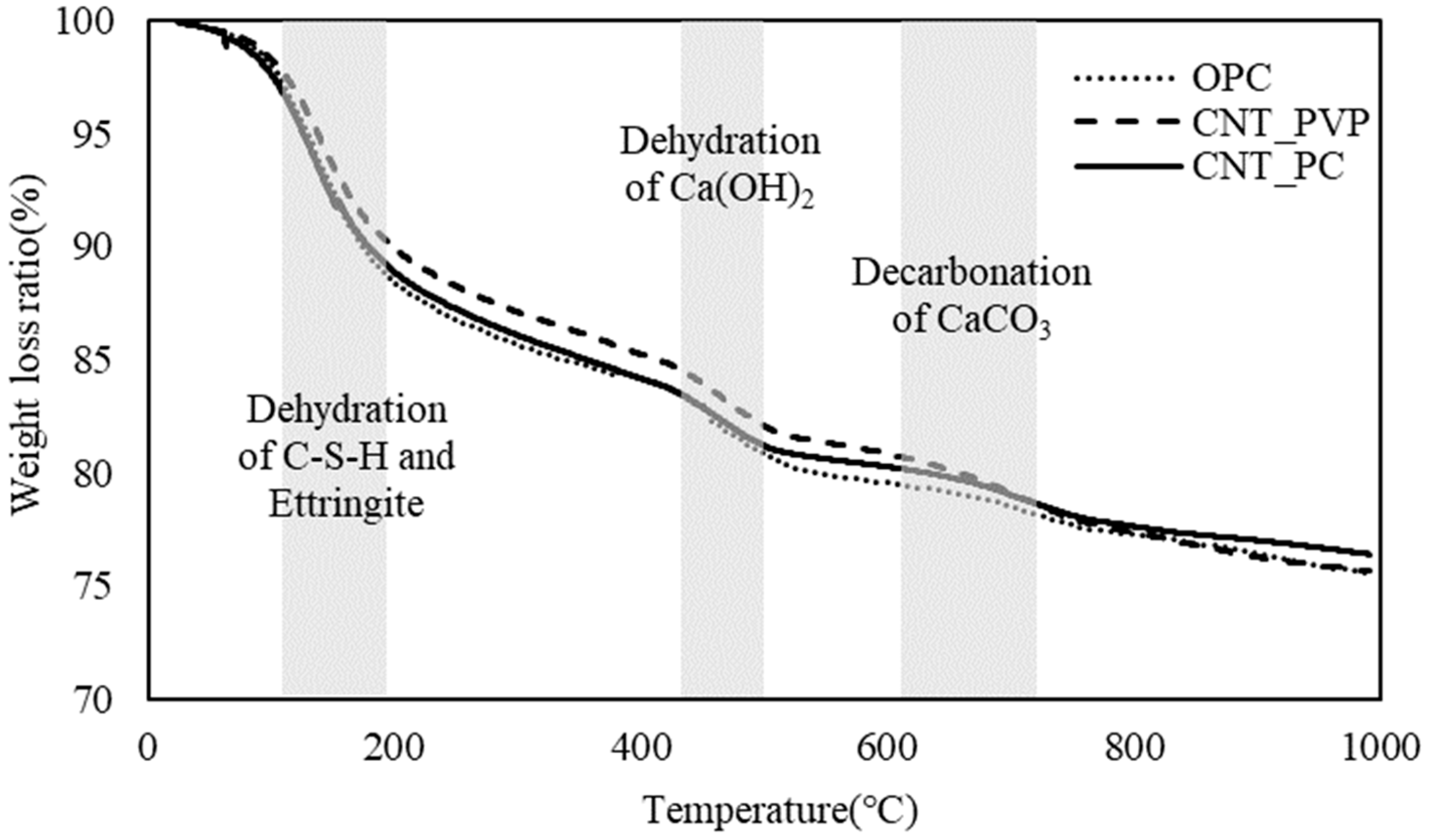

4.2. Results of Thermogravimetric Analysis

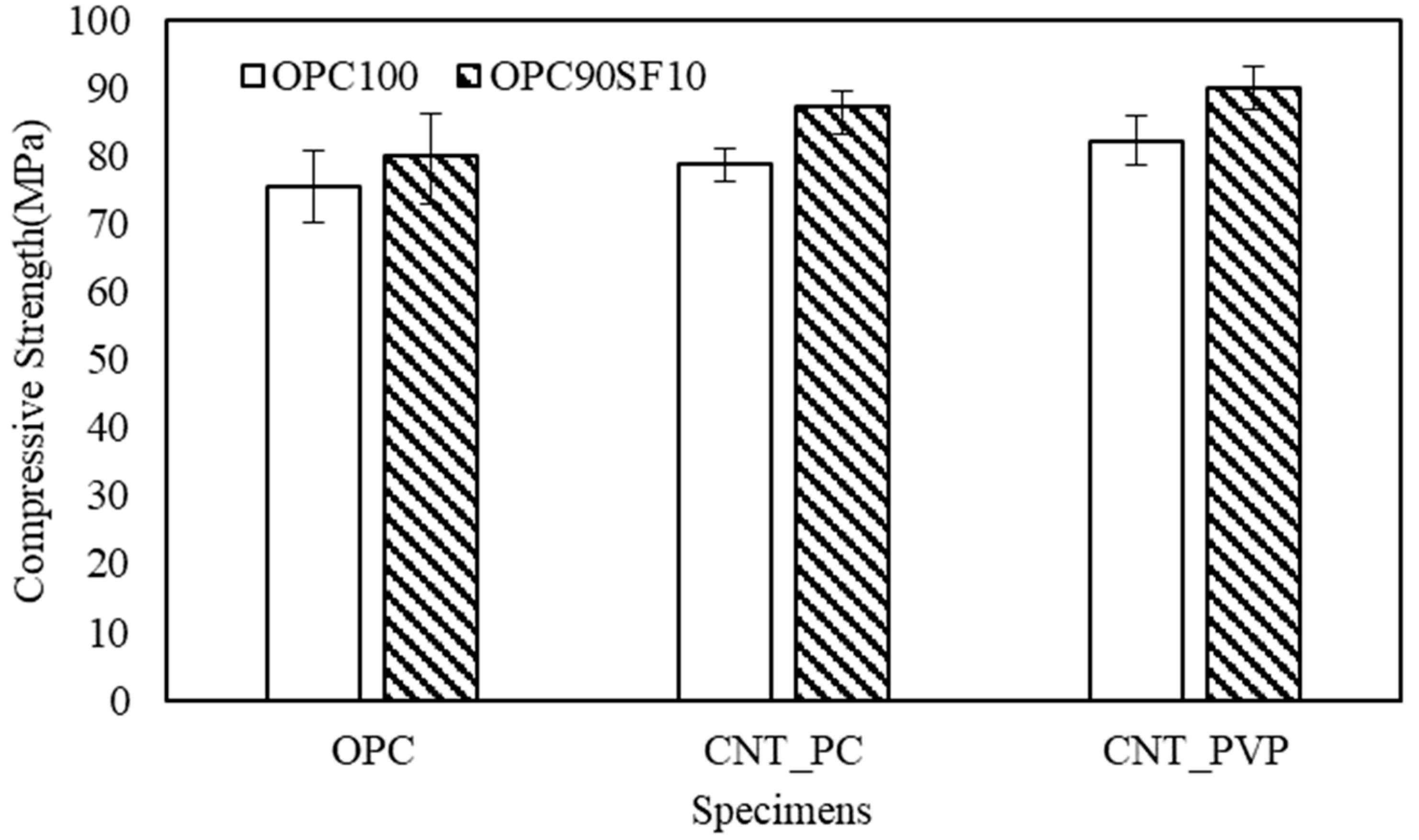

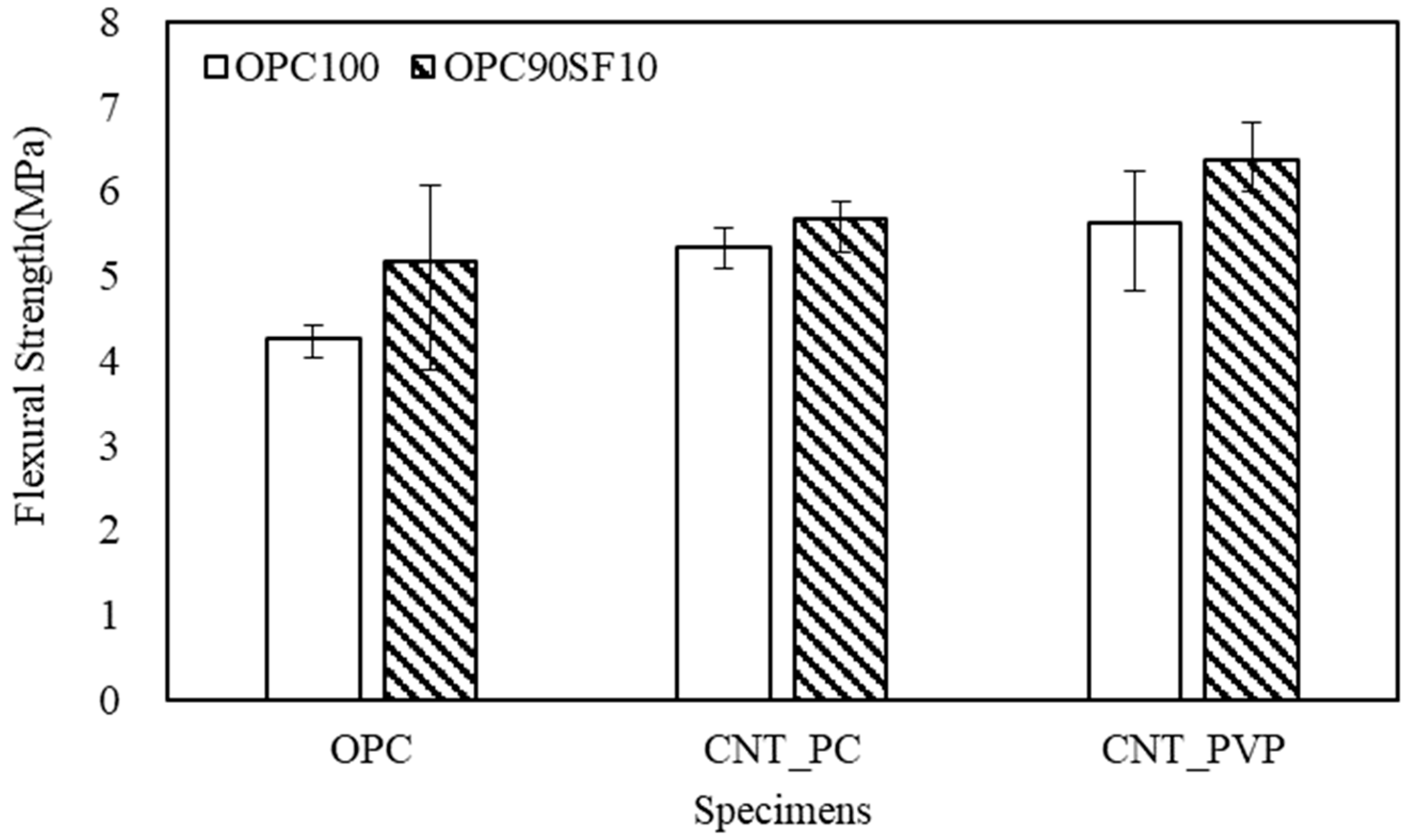

4.3. Analysis of Mechanical Properties

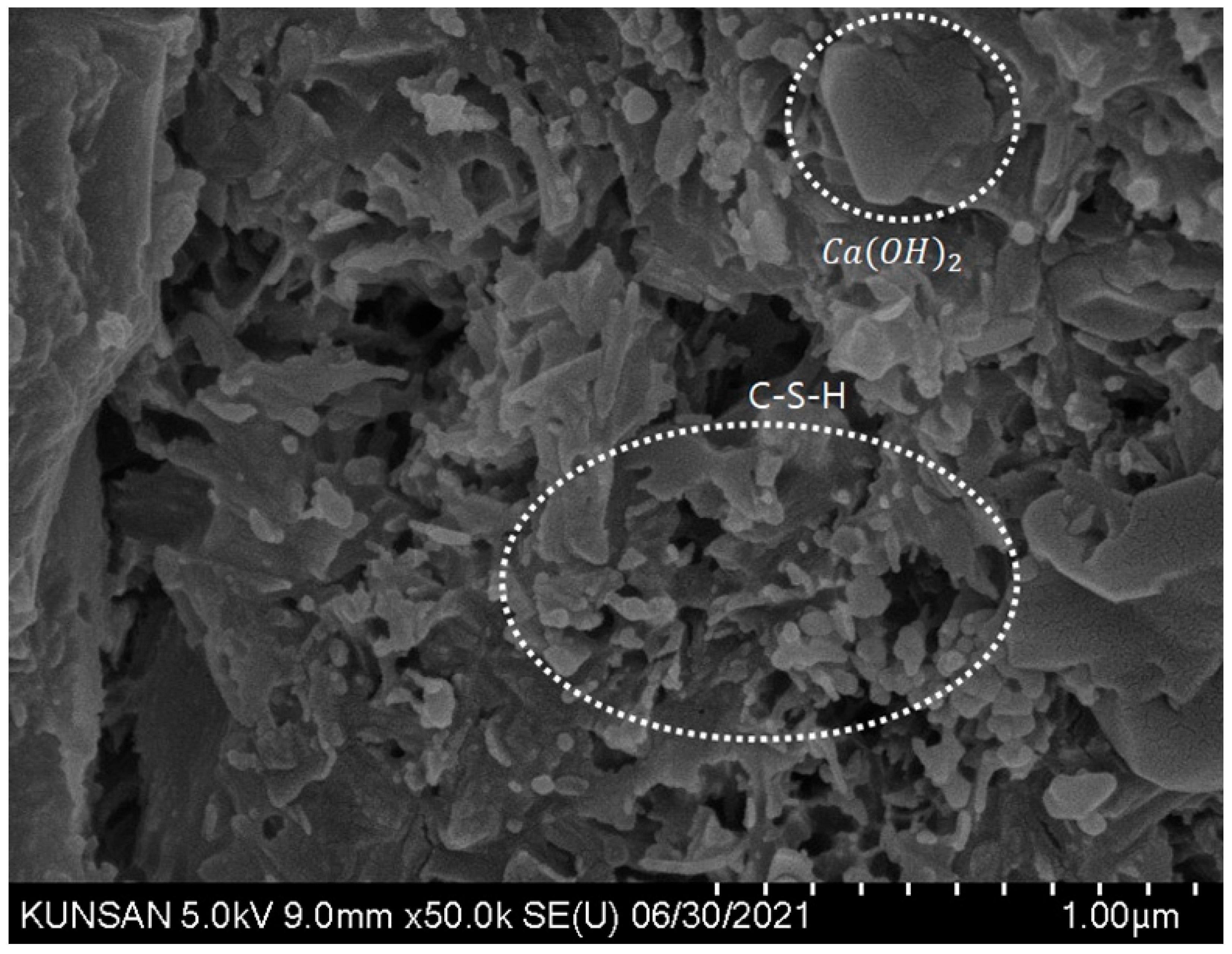

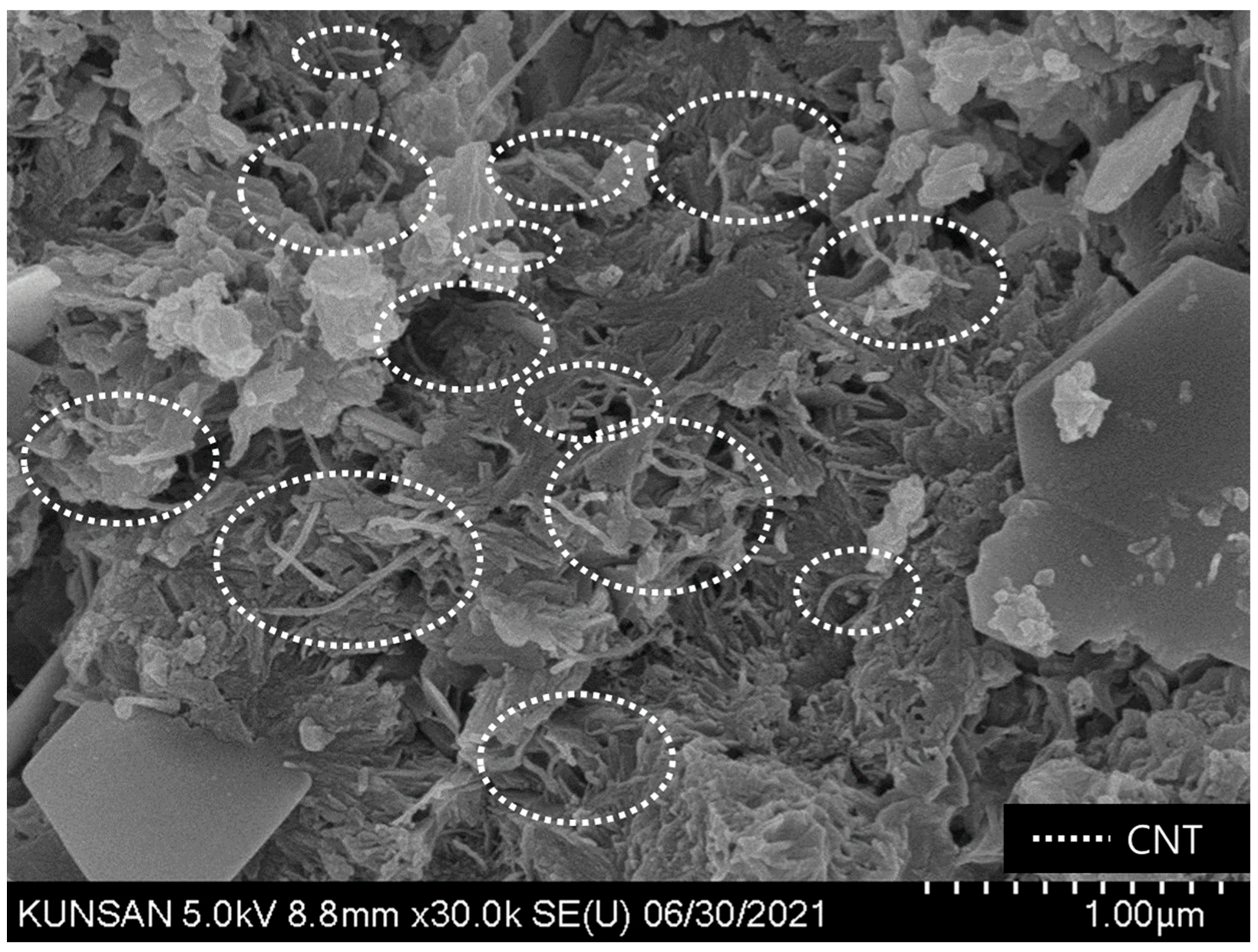

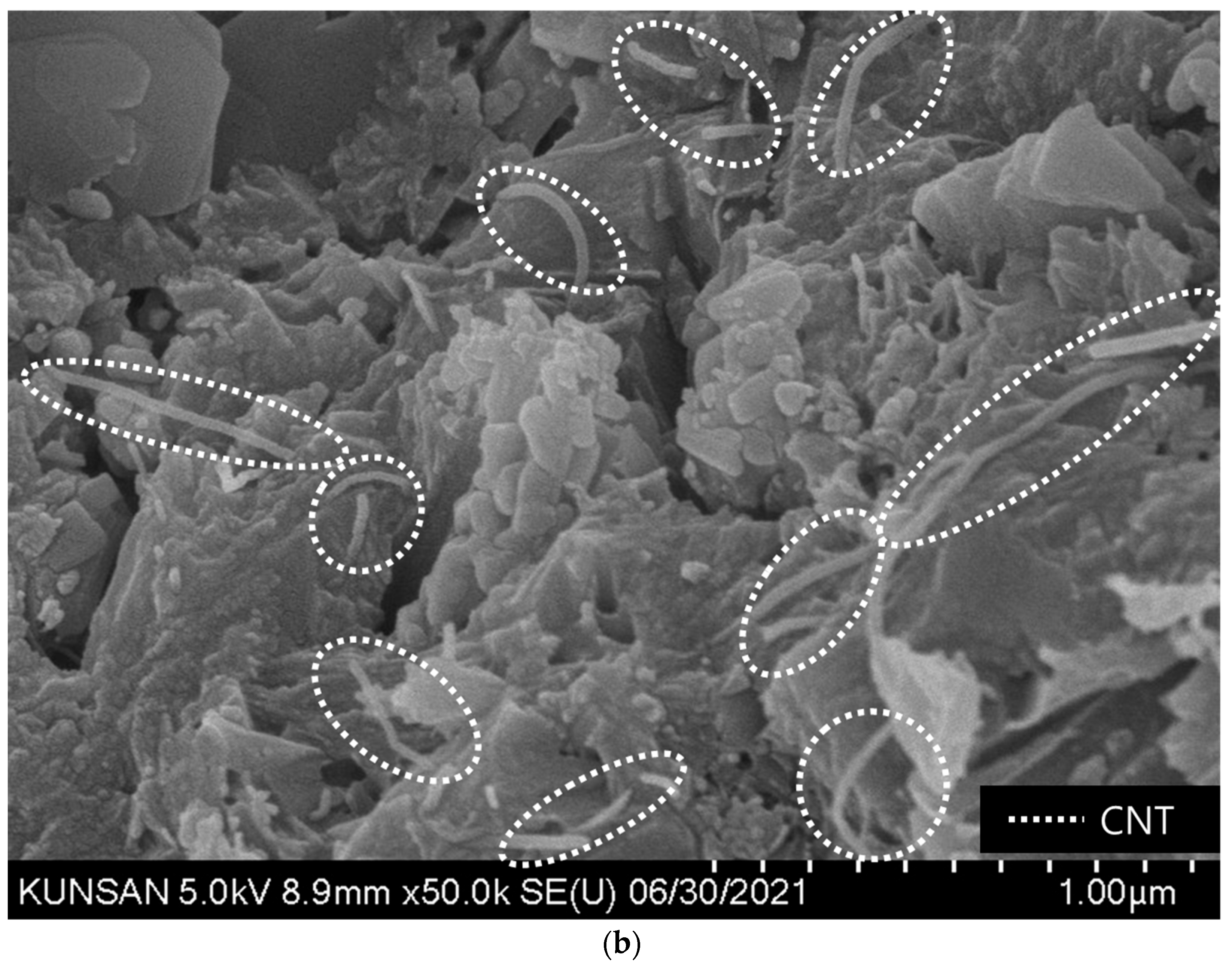

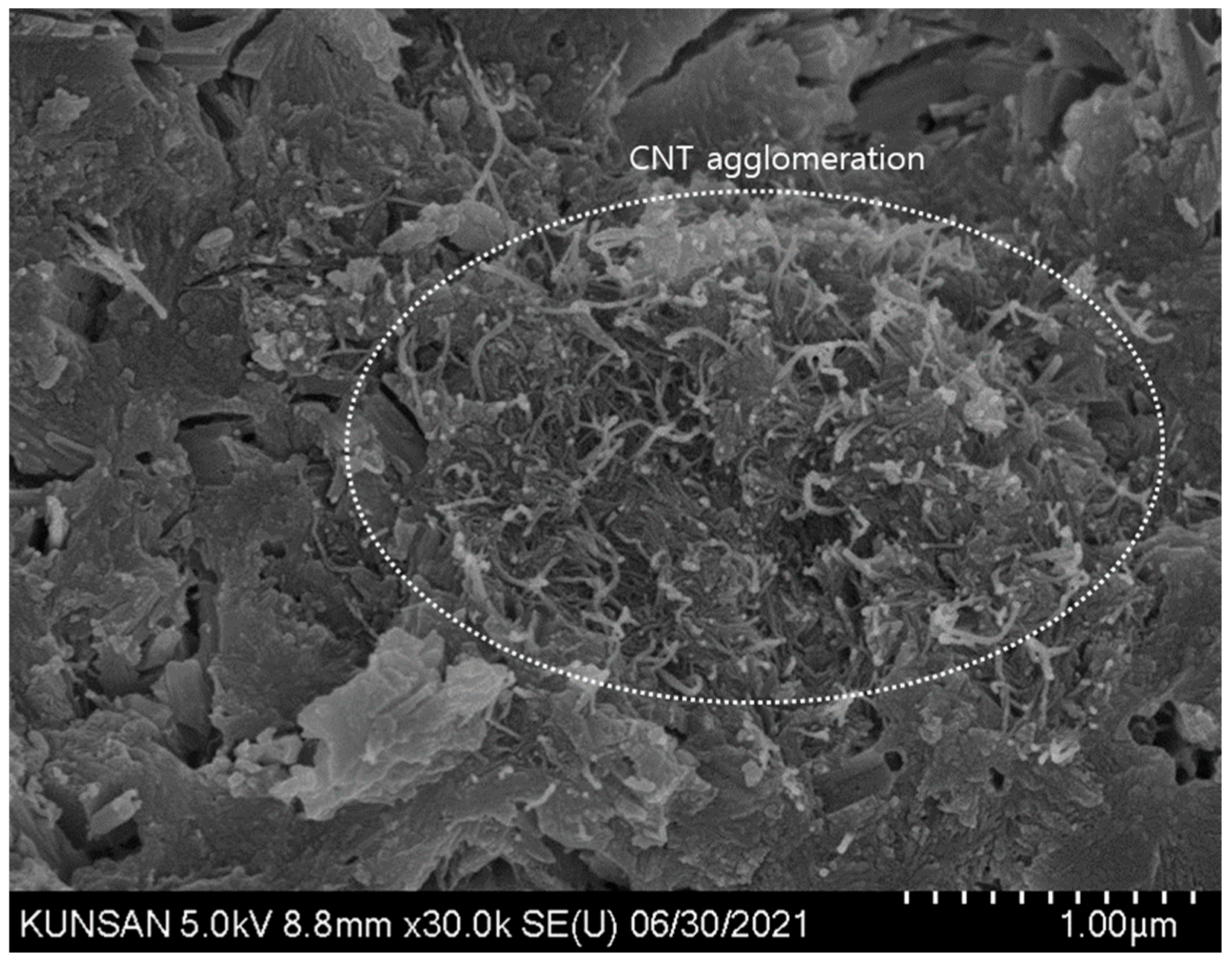

4.4. Results of SEM Analysis

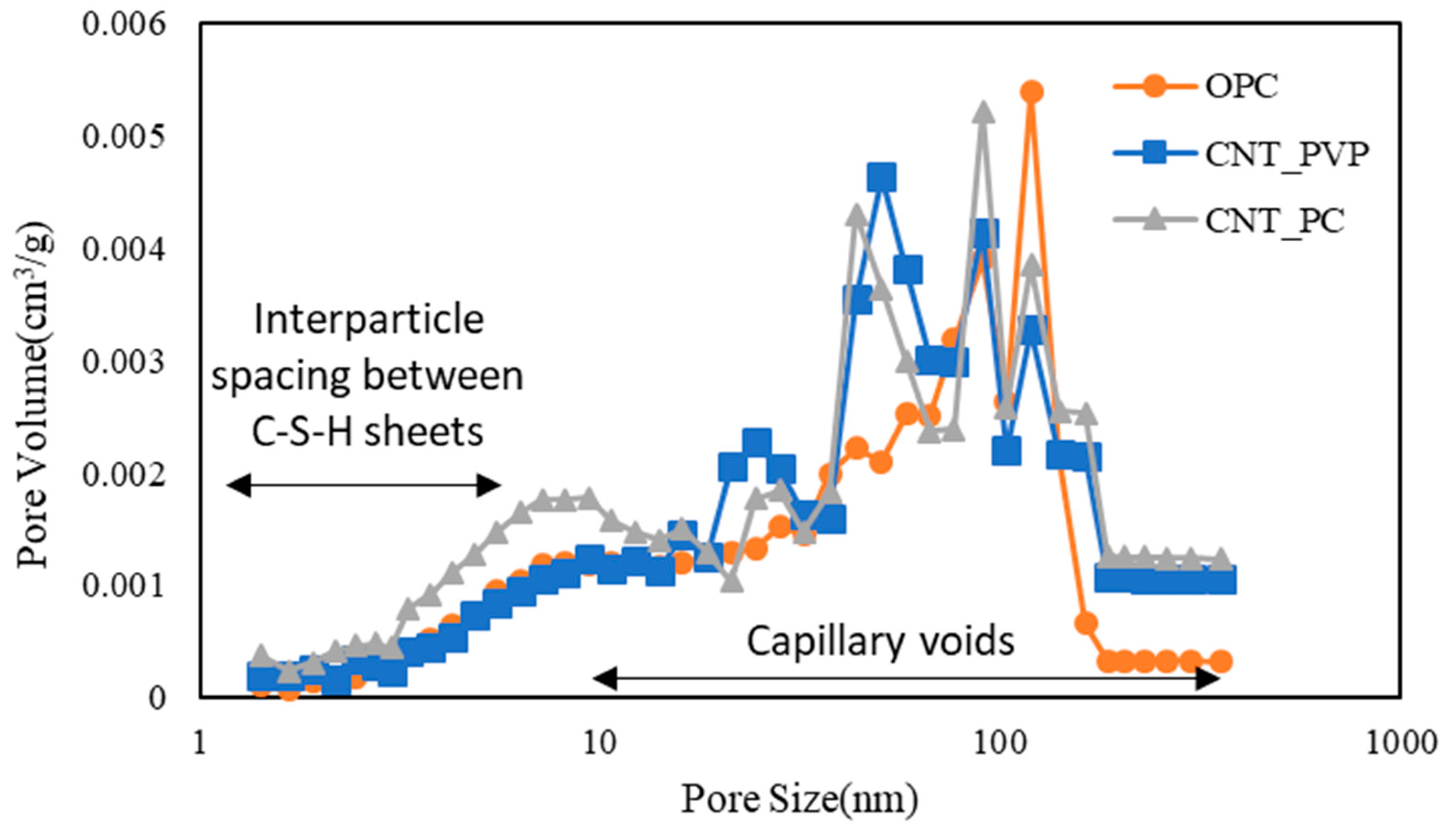

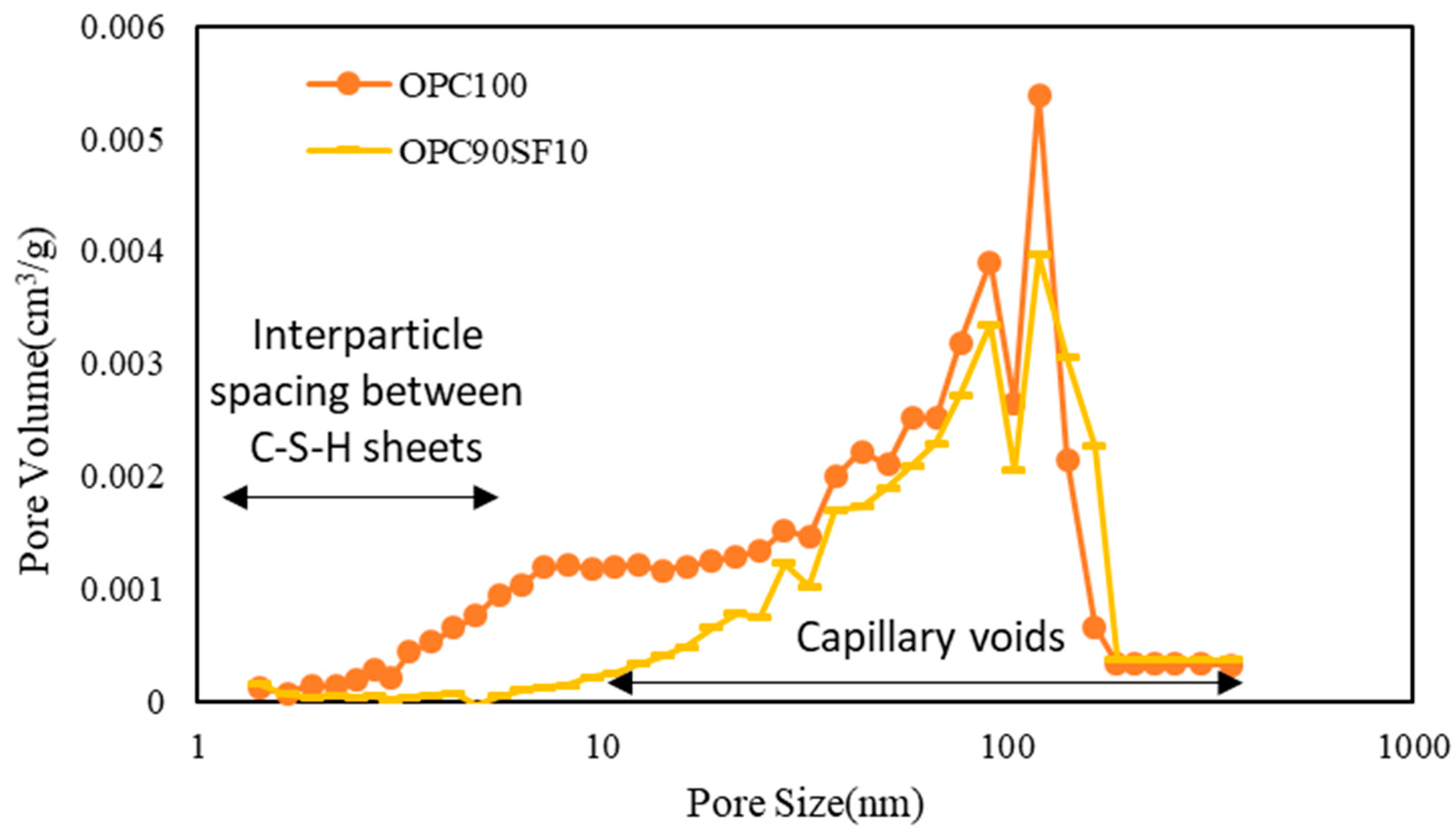

4.5. Results of BET Analysis

5. Conclusions

- (1)

- Based on the results of the Vicat needle test for the measurement of the penetration resistance, by mixing CNT aqueous dispersions, the effect of reducing the initial setting time was observed, and the type of surfactant for CNT dispersions had an insignificant effect. After the initial setting, the setting rate gradually decreased, and the final setting time was measured at values similar to those of the OPC.

- (2)

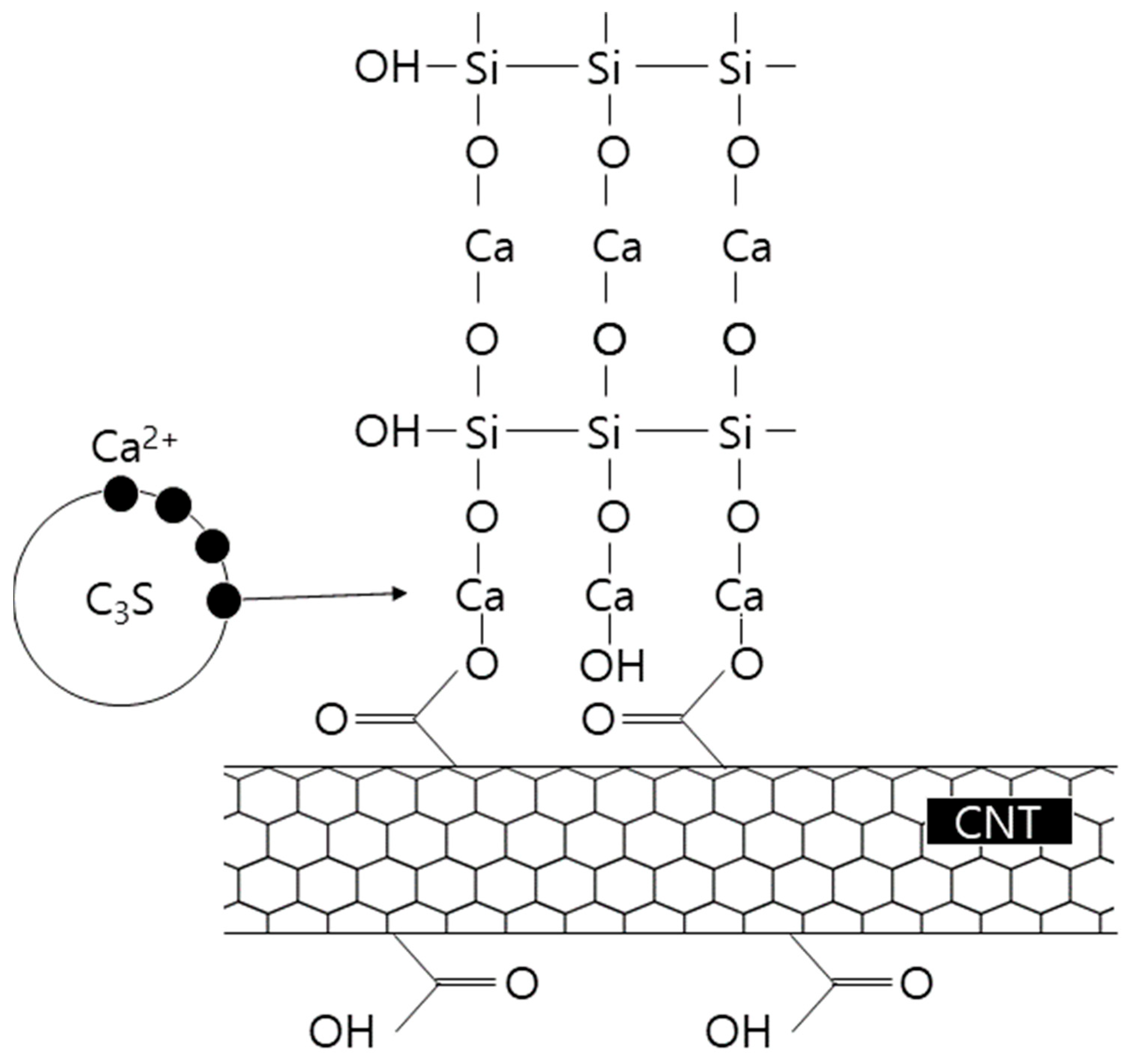

- Based on the TGA results, the weight loss curves of the specimens with CNT aqueous dispersions showed a similar result to that of the OPC specimen. This indicates that, when considering the result of the Vicat needle test, in the formation of hydrates, there is no chemical reaction between the CNT and cement, but CNTs only affected nucleation and physical bridging.

- (3)

- From the analyses of the mechanical properties, when the CNT aqueous dispersion was added, the compressive strength increased to be 9.6–10.8% higher than that of OPC. A similar compressive strength was measured when PVP surfactants were used as compared to PC-based surfactants. The PVP surfactants wrapping the CNT are superior to the PC-based surfactants, which was also confirmed by the SEM image analysis. However, using PC-based surfactants, the strength improvement effect was confirmed to be similar, indicating a sufficient level of usability of the PC-based surfactants.

- (4)

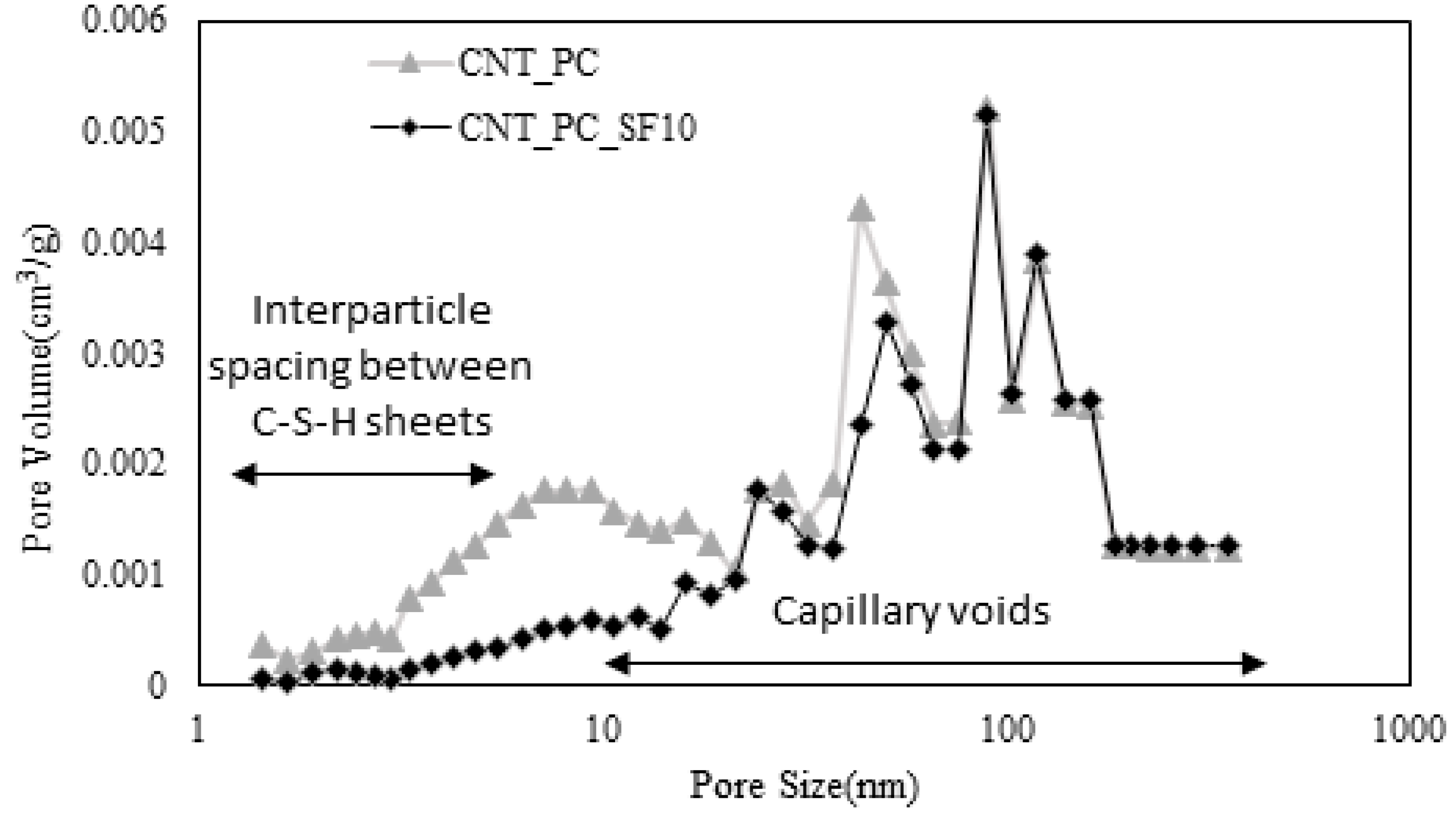

- From the results of measuring the flexural strength of CNT–cement composites, the strength improvement was confirmed, as is shown in the compressive strength test. The effect of mechanical property enhancement was higher in terms of the flexural strength compared to the effect of compressive strength improvement. Based on SEM image analysis, it was confirmed that CNTs, compared to the results of BET analysis, the space between the C-S-H hydrates, and capillary voids, were filled by silica fumes and CNTs, leading to a denser internal void structure, thereby enhancing the mechanical properties.

- (5)

- Based on the results of analyzing the microstructure, when CNT aqueous dispersions were mixed, the pore volume per unit weight increased. Both of the CNT aqueous dispersions dispersed with PC-based surfactants, and PVP surfactants played a role in dispersing the size of capillary voids, which led to an improvement in the mechanical properties. Therefore, based on the findings of this study, the use of the PC-based surfactant as a CNT dispersant requires additional improvement, but it is considered to have sufficient potential for usability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thostenson, E.T. Advances in the Science and Technology of Carbon Nanotubes and their Composites: A Review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Zoua, B.; Chen, S.J.; Korayem, A.H.; Collins, F.; Wang, C.M.; Duan, W.H. Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon 2015, 85, 212–220. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem. Concr. Compos. 2011, 34, 201–207. [Google Scholar] [CrossRef]

- Kim, S.W.; Kim Th Kim, Y.S.; Choi, H.S.; Lim, H.J.; Yang, S.J.; Park, C.R. Surface modifications for the effective dispersion of carbon nanotubes in solvents and polymers. Carbon 2012, 50, 3–33. [Google Scholar] [CrossRef]

- Park, S.S.; Park, Y.C.; Kim, N.J. A Comparative Study on the Characteristics of the MWCNTs and PVP Added Nanofluids. Korean J. Air-Cond. Refrig. Eng. 2011, 23, 47–53. [Google Scholar] [CrossRef]

- O’Connell, M.J.; Boul, P.; Ericson, L.M.; Huffman, C.; Wang, Y.; Haroz, E.; Kuperm, C.; Tour, J.; Ausman, K.D.; Smalley, R.E. Reversible water-solubilization of single-walled carbon nanotubes by polymer wrapping. Chem. Phys. Lett. 2001, 342, 265–271. [Google Scholar] [CrossRef]

- Yousef, S.; Kalpokaitė-Dičkuvienė, R.; Baltušnikas, A.; Pitak, I.; Lukošiūtė, S.I. A new strategy for functionalization of char derived from pyrolysis of textile waste and its application as hybrid fillers (CNTs/char and graphene/char) in cement industry. J. Cleaner Prod. 2021, 314, 128058. [Google Scholar] [CrossRef]

- Rocha, V.V.; Ludvig, P. Influence of Carbon Nanotubes on the Mechanical Behavior and Porosity of Cement Pastes Prepared by A Dispersion on Cement Particles in Isopropanol Suspension. Materials 2020, 13, 3164. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.; Guedes, M.; Pereira, M.F.C. Dispersion and reinforcement efficiency of carbon nanotubes in cementitious composites. Mag. Concr. Res. 2019, 71, 408–423. [Google Scholar] [CrossRef]

- Micheli, D.; Pastore, R.; Vricela, A.; Morles, R.B.; Marcheti, M.; Delfini, A.; Moglie, F.; Mariani Primiani, V. Electromagnetic Characterization and Shielding Effectiveness of Concrete Composite Reinforced with Carbon Nanotubes in the Mobile Phones Frequency Band. Mater. Sci. Eng. B 2014, 188, 119–129. [Google Scholar] [CrossRef]

- Vesmawala, G.R.; Vaghela, A.R.; Yadav, K.D.; Patil, Y. Effectiveness of polycarboxylate as a dispersant of carbon nanotubes in concrete. Mater. Today Proc. 2020, 28, 1170–1174. [Google Scholar] [CrossRef]

- Liebscher, M.; Lange, A.; Schroefl, C.; Fuge, R. Impact of the molecular architecture of polycarboxylate superplasticizers on the dispersion of multi-walled carbon nanotubes in aqueous phase. J. Mater. Sci. 2017, 52, 2296–2307. [Google Scholar] [CrossRef]

- Konsta-Gdoutos, M.S.; Zoi, S.M.; Surendra, P.S. Highly-dispersed carbon nanotube-reinforced cement-based materials. Cem. Concr. Res. 2010, 40, 1052–1059. [Google Scholar] [CrossRef]

- Alrekabi, S.; Cundy, A.; Lampropoulos, A.; Savina, I. Experimental Investigation on the Effect of Ultrasonication on Dispersion and Mechanical Performance of Multi-Wall Carbon Nanotube-Cement Mortar Composites. Int. J. Civ. 2016, 111, 268–274. [Google Scholar] [CrossRef]

- Yousefi, A.; Bunnori, N.M.; Khavarian, M.; Taksiah, A.M. Dispersion of Multi-Walled Carbon Nanotubes in Portland Cement Concrete Using Ultra-Sonication and Polycarboxylic Based Superplasticizer. Appl. Mech. Mater. 2015, 802, 112–117. [Google Scholar] [CrossRef]

- Kim, H.K.; Nam, I.W.; Lee, H.K. Enhanced effect of carbon nanotube on mechanical and electrical properties of cement composites by incorporation of silica fume. Compos. Struct. 2014, 107, 60–69. [Google Scholar] [CrossRef]

- Garg, M.; Das, C.S.; Gupta, R. Use of silica particles to improve dispersion of -COOH CNTs/carbon fibers to produce HyFRCC. Constr. Build. Mater. 2020, 250, 118777. [Google Scholar] [CrossRef]

- Toyeh, B.A.; Akeed Mh Qaidi, S.; Bakar, B.H.A. Ultra-high-performance concrete: Impacts of steel fibre shape and content on flowability, compressive strength and modulus of rupture. Case Stud. Constr. Mater. 2022, 17, e01615. [Google Scholar] [CrossRef]

- Toyeh, B.A.; Akeed Mh Qaidi, S.; Bakar, B.H.A. Influence of sand grain size distribution and supplementary cementitious materials on the compressive strength of ultrahigh-performance concrete. Case Stud. Constr. Mater. 2022, 17, e01495. [Google Scholar] [CrossRef]

- Liu, H.; Cui, S.; Wang, J.; Wang, J. Influence of chemical admixtures on the dispersion of carbon nanotubes in water and cement pastes. IOP Conf. Ser. Mater. Sci. Eng. 2017, 182, 012029. [Google Scholar] [CrossRef]

- Kang, M.H.; Na, H.Y. Comparative Study of Physical Dispersion Method on Properties of Polystyrene/Multi-walled Carbon Nanotube Nanocomposites. Polymer 2013, 37, 526–532. (In Korean) [Google Scholar] [CrossRef][Green Version]

- Li, L.J.; Nicholas, R.J.; Chen, C.Y.; Darton, R.C.; Baker, S.C. Comparative study of photoluminescence of single-walled carbon nanotubes wrapped with sodium dodecyl sulfate, surfactin and polyvinylpyrrolidone. Nanotechnology 2005, 16, S202. [Google Scholar] [CrossRef]

- Iosif, D.R.; Suong, V.H. Highly Conductive Multiwall Carbon Nanotube and Epoxy Composites Produced by Three-Roll Milling. Carbon 2009, 47, 1958–1968. [Google Scholar] [CrossRef]

- Kim, W.W. Evaluation of Hydration Characteristics and Microstructure of Cementitious Composites Using Carbon Nanotube Solutions. Ph.D. Thesis, Kyonggi University, Suwon, Republic of Korea, 2023. [Google Scholar]

- Inkyo, M.; Tahara, T.; Iwaki, T.; Iskandar, F.; Hogan, C.J.; Okuyama, K., Jr. Experimental investigation of nanoparticle dispersion by beads milling with centrifugal bead separation. J. Colloid Interface Sci. 2006, 304, 535–540. [Google Scholar] [CrossRef] [PubMed]

- Nakach, M.; Authelin, J.R.; Perrin, M.A.; Lakkireddy, H.R. Comparison of high pressure homogenization and stirred bead milling for the production of nano-crystalline suspensions. Int. J. Pharm. 2018, 547, 61–71. [Google Scholar] [CrossRef] [PubMed]

- Du, M.; Jing, H.; Gao, Y.; Su, H.; Fang, H. Carbon nanomaterials enhanced cement-based composites: Advances and challenges. J. Nanotechnol. Rev. 2020, 9, 115–135. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Kopke, U.; Fiedler, B.; Schulte, K. Carbon Nanotube-reinforced Epoxy-composites: Enhanced Stiffness and Fracture Toughness at Low Nanotube Content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Sha, W. Differential Scanning Calorimetry Study of the Hydration Products in Portland Cement Pastes with Metakaolin Replacement. In Proceedings of the International Conference on Advances in Building Technology, Hong Kong, 4–6 December 2002; Volume I, pp. 881–888. [Google Scholar] [CrossRef]

- ASTM C305-20; Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency. ASTM: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C191-21; Standard Test Method for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C109/C109M-21; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C348-21; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- Bakolas, A.; Aggelakopoulou, E.; Moropoulou, A.; Anagnostopoulou, S. Evaluation of Pozzolanic Activity and Physicomechanical Characteristics in Metakaolin-lime Pastes. J. Therm. Anal. Calorim. 2006, 84, 157–163. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

| Notation | Purity (%) | Diameter (nm) | Length (nm) | Specific Surface Area (m2/g) | True Density (g/cm3) |

|---|---|---|---|---|---|

| CNT 6A | >97.5 | 5–7 | 50–150 | 200–300 | 2.22 |

| Specimens | W/B (%) | CNT (%) | Binder (%) | CS/B (%) | Surfactant (type) | Superplasticizer (%) | |

|---|---|---|---|---|---|---|---|

| C | SF | ||||||

| OPC | 30 | 0 | 100 | 0 | 0 | - | |

| SF10 | 90 | 10 | - | ||||

| OPC_PC | 100 | 0 | 0.05 | ||||

| CNT_PVP | 30 | 0.1 | 100 | 0 | 10 | PVP | - |

| CNT_PVP_SF10 | 90 | 10 | |||||

| CNT_PC | 100 | 0 | PC | ||||

| CNT_PC_SF10 | 90 | 10 | |||||

| Composition % | Cement (OPC) | Silica Fume |

|---|---|---|

| CaO | 61.33 | 0.38 |

| Al2O3 | 6.40 | 0.25 |

| SiO2 | 21.01 | 96.00 |

| Fe2O3 | 3.12 | 0.12 |

| MgO | 3.02 | 0.10 |

| SO3 | 2.30 | - |

| Specific surface (cm2/g) | 3413 | 200,000 |

| Loss ignition (%) | 1.40 | 1.50 |

| Density (g/cm3) | 3.15 | 2.10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, W.-W.; Moon, J.-H.; Lee, S.-T. Effect of Dispersing Carbon Nanotube in Aqueous Solution by Poly-Carboxylic-Based Surfactants on Mechanical and Microstructural Properties as Cementitious Composites. Materials 2023, 16, 6880. https://doi.org/10.3390/ma16216880

Kim W-W, Moon J-H, Lee S-T. Effect of Dispersing Carbon Nanotube in Aqueous Solution by Poly-Carboxylic-Based Surfactants on Mechanical and Microstructural Properties as Cementitious Composites. Materials. 2023; 16(21):6880. https://doi.org/10.3390/ma16216880

Chicago/Turabian StyleKim, Won-Woo, Jae-Heum Moon, and Seung-Tae Lee. 2023. "Effect of Dispersing Carbon Nanotube in Aqueous Solution by Poly-Carboxylic-Based Surfactants on Mechanical and Microstructural Properties as Cementitious Composites" Materials 16, no. 21: 6880. https://doi.org/10.3390/ma16216880

APA StyleKim, W.-W., Moon, J.-H., & Lee, S.-T. (2023). Effect of Dispersing Carbon Nanotube in Aqueous Solution by Poly-Carboxylic-Based Surfactants on Mechanical and Microstructural Properties as Cementitious Composites. Materials, 16(21), 6880. https://doi.org/10.3390/ma16216880