Application of Sunflower Husk Pellet as a Reducer in Metallurgical Processes

Abstract

:1. Introduction

2. The Present Study

- Determination of copper slag melting temperature;

- Sunflower pellet degasification tests using the thermogravimetric method;

- Copper slag reduction tests using sunflower pellet.

2.1. Research Materials

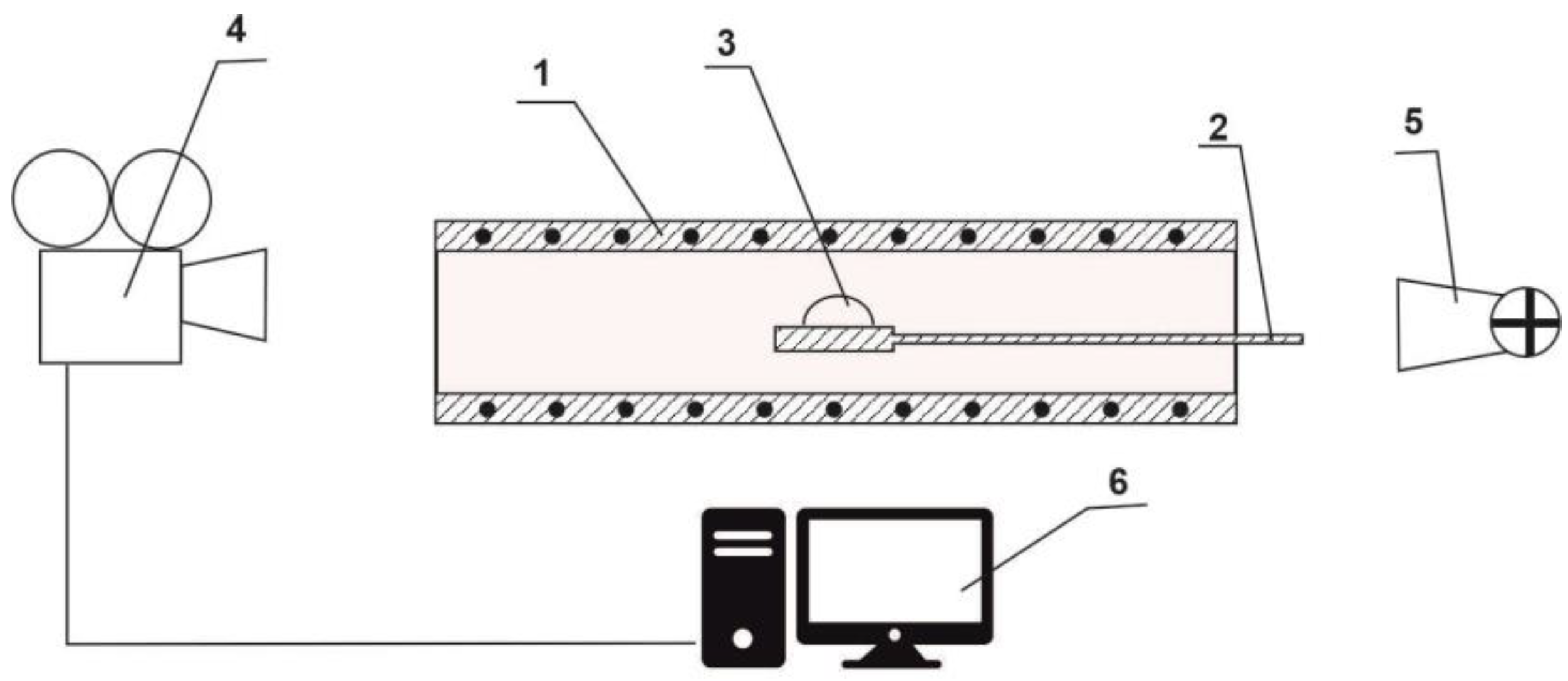

2.2. Equipment and Research Methods

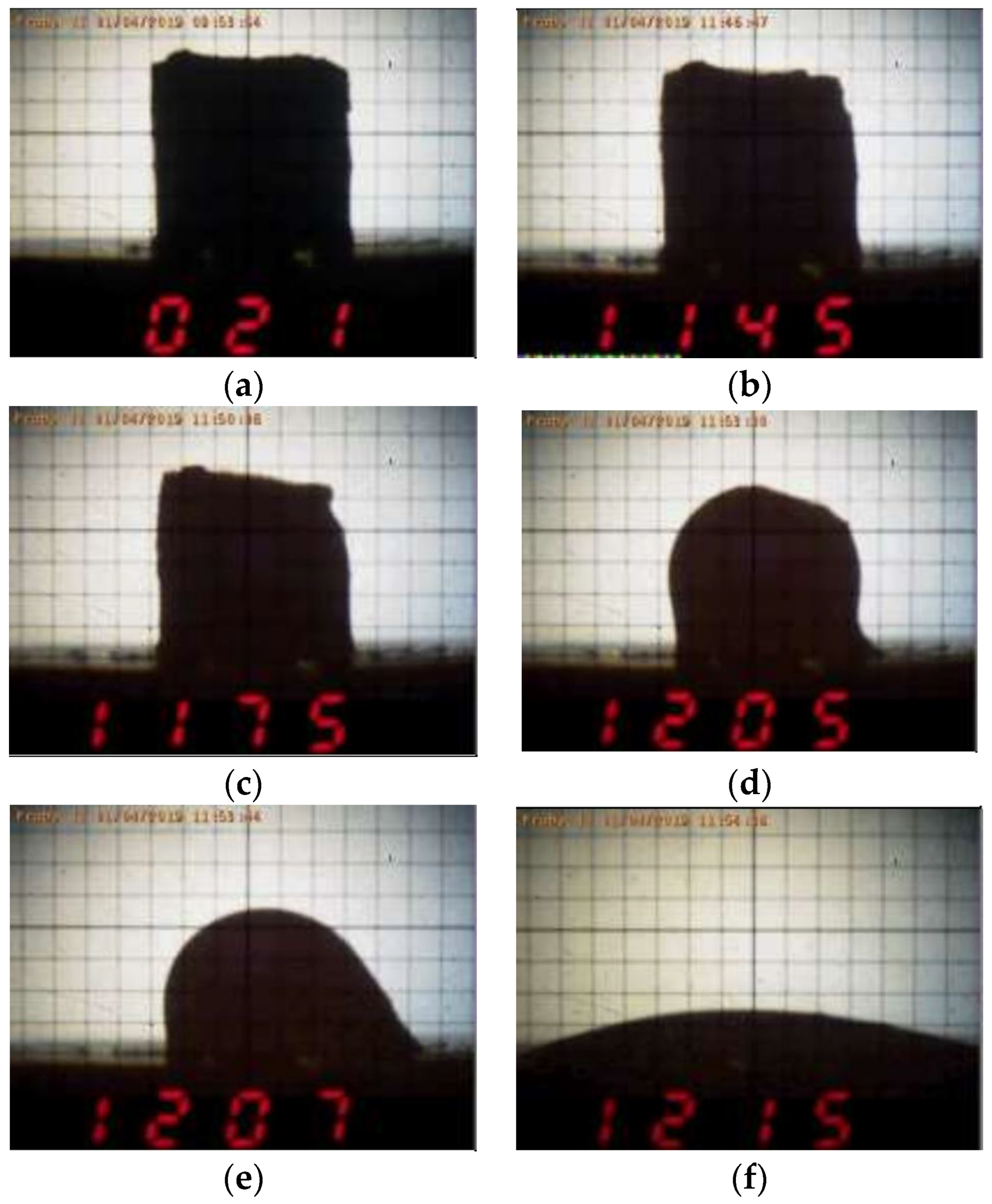

- (a)

- Deformation temperature (DT)—the first signs of the sample edge rounding define the start of material softening;

- (b)

- Spherical shape temperature (ST)—the softening temperature is defined by the shape of the sample with completely rounded edges (sphere), without a change in its height;

- (c)

- Hemispherical shape temperature (HT)—the melting temperature is defined approximately by the hemispherical shape of the sample, where the height is equal to the half of the diameter of the base;

- (d)

- Flow temperature (FT)—the temperature is defined by a flowing sample with 1/3 of the height of the tested sample at the melting temperature (HT).

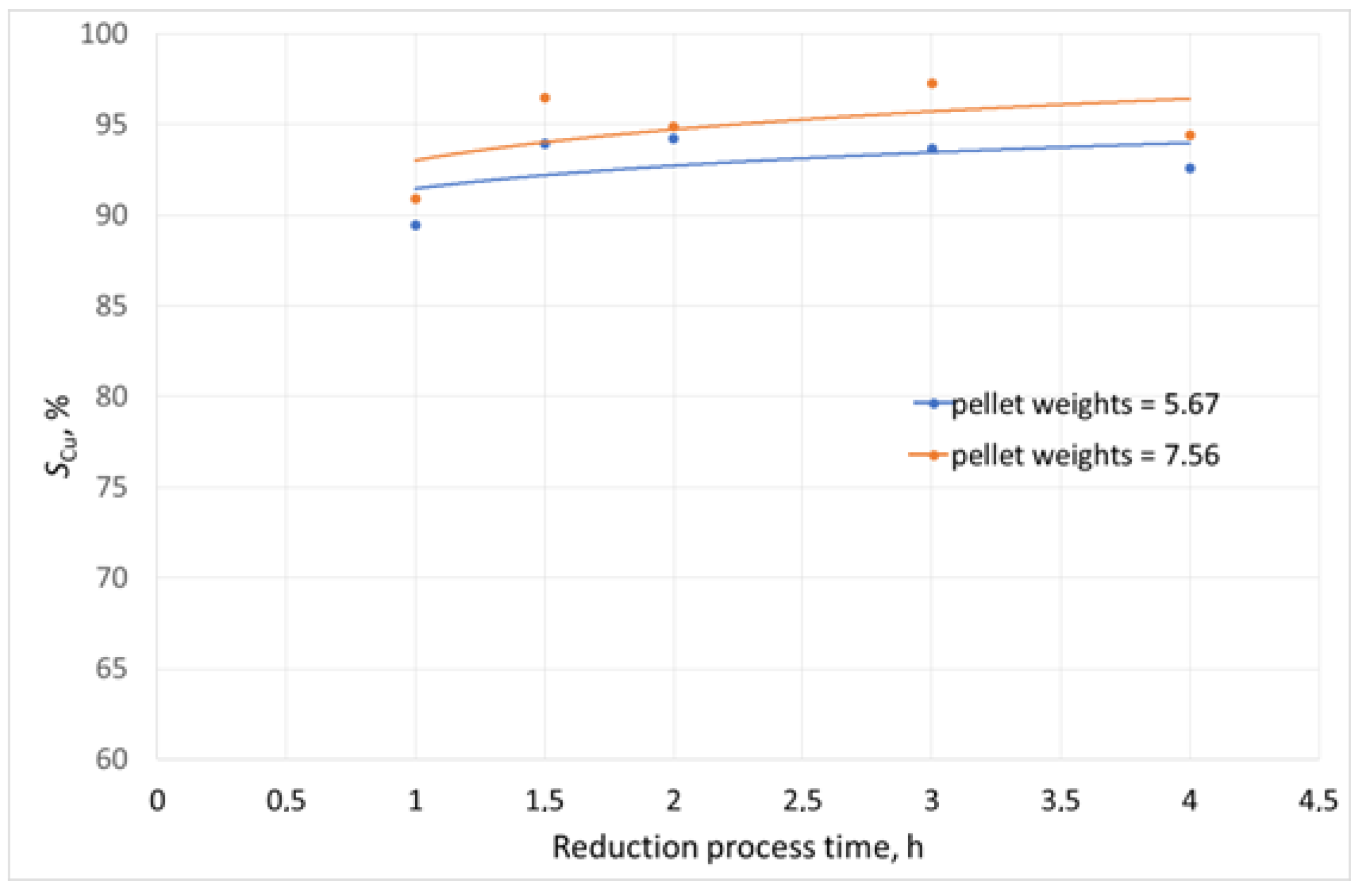

- The reducer (pellet) weights: 5.67 g and 7.56 g, respectively;

- Duration of the reduction process (1 h to 4 h).

3. Test Results and Discussion

3.1. Determination of the Copper Slag Melting Temperature

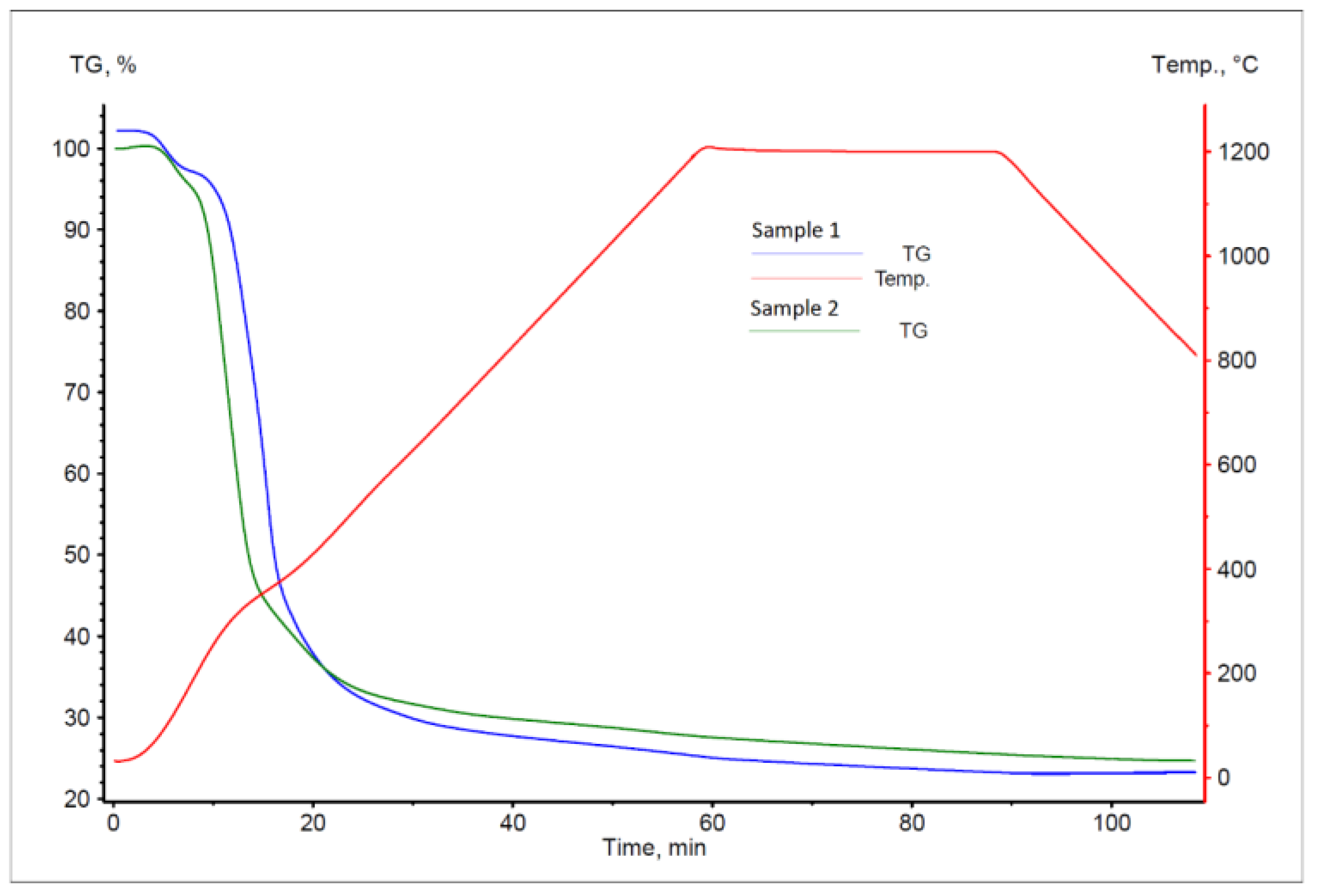

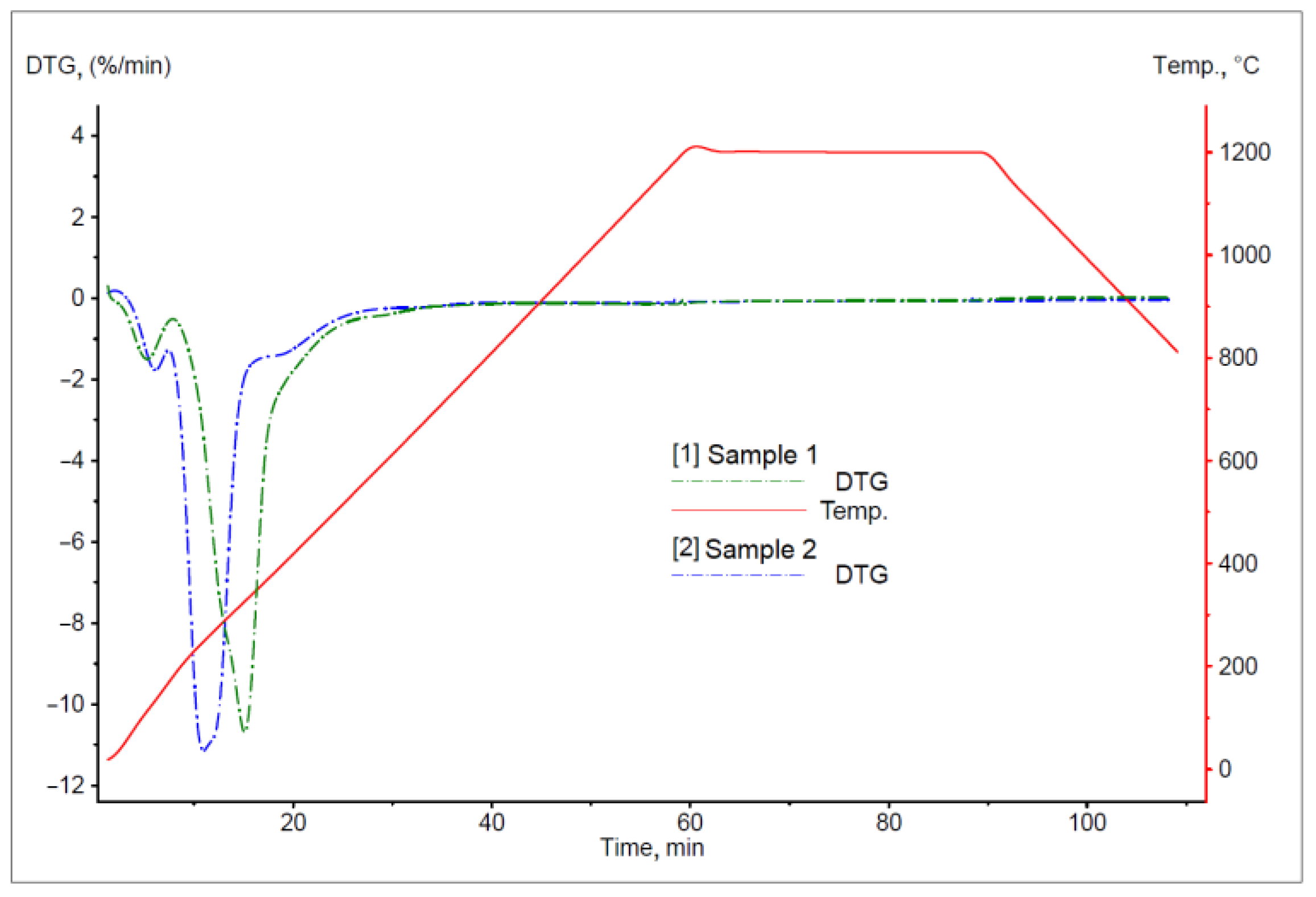

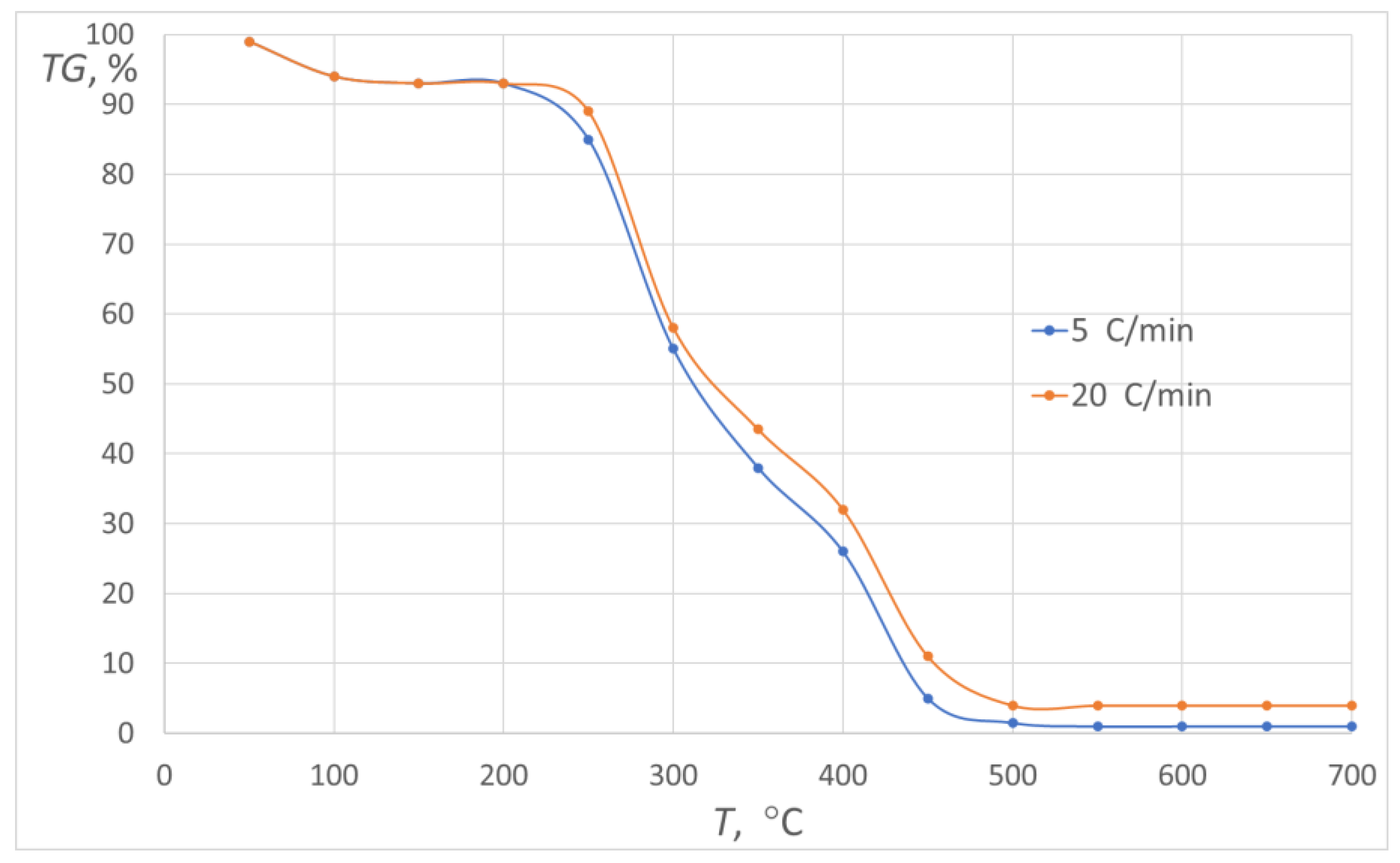

3.2. Tests of Sunflower Pellet Degasification

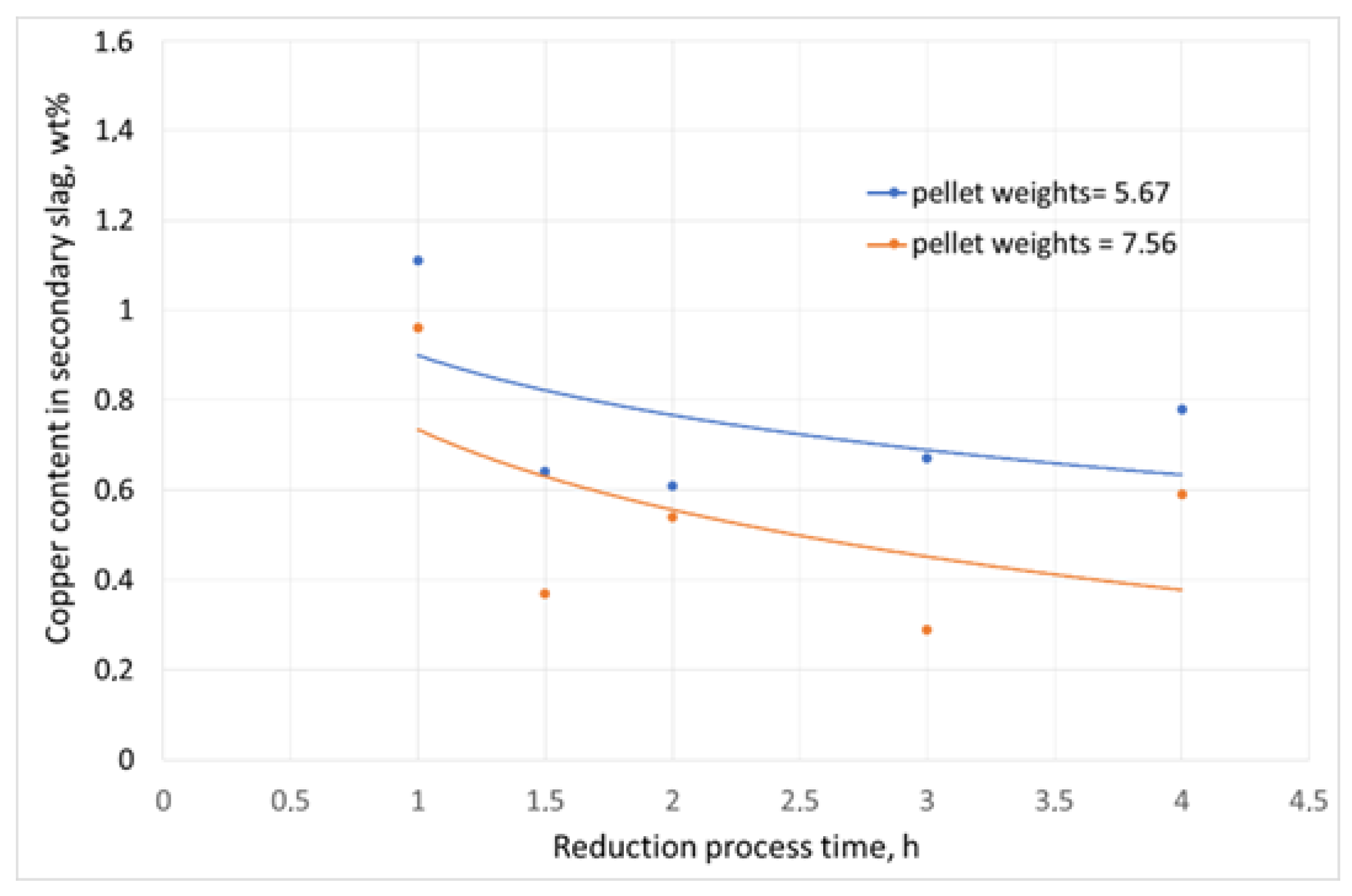

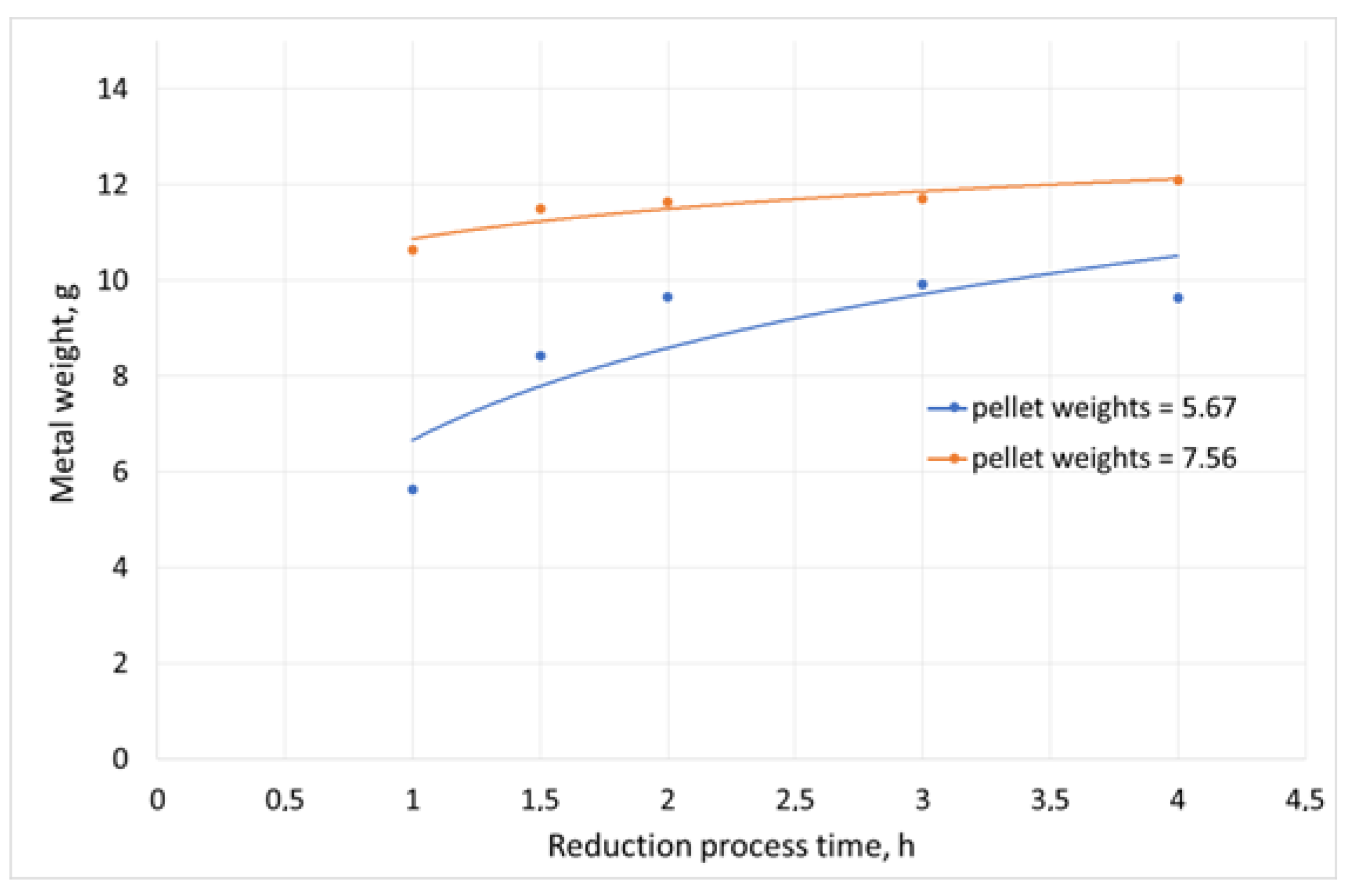

3.3. Slag Reduction Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zuo, Z.; Yu, Q.; Wei, M.; Xie, H.; Duan, W.; Wang, K.; Qin, Q. Thermogravimetric study of the reduction of copper slag by biomass. J. Therm. Anal. Calorim. 2016, 126, 481–491. [Google Scholar] [CrossRef]

- Zhou, S.; Wei, Y.; Zhang, S.; Li, B.; Wang, H.; Yang, Y.; Barati, M. Reduction of copper smelting slag using waste cooking oil. J. Clean. Prod. 2019, 236, 117668. [Google Scholar] [CrossRef]

- Zuo, Z.; Yu, Q.; Luo, S.; Zhang, J.; Zhou, E. Effect of Two-Step Reduction Characteristics of Copper Slag Using Biochar as Reducer-Thermodynamic and Kinetics. Energy Fuels 2020, 34, 491–500. [Google Scholar] [CrossRef]

- Qu, G.; Wei, Y.; Li, B.; Wang, H.; Yang, Y.; Mclean, A. Recovery of Copper Smelting Slag Using a Green Reductant. In 11th International Symposium on High-Temperature Metallurgical Processing; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2020; pp. 417–429. [Google Scholar] [CrossRef]

- Tawil, E.; Ahmed, H.; Sundqvist Ökvist, L.; Björkman, B. Self-reduction behavior of bio-coal containing iron ore composites. Metals 2020, 10, 133. [Google Scholar] [CrossRef]

- Frohlichova, M.; Legemza, J.; Findorak, R.; Maslejova, A. Biomass as a source of energy in iron ore agglomerate production process. Arch. Metall. Mater. 2014, 52, 815–820. [Google Scholar] [CrossRef]

- Suopajarvi, H.; Kemppainen, A.; Haapakangas, J.; Fabritius, T. Extensive review of the opportunities to use bio-mass-based fuels in iron and steelmaking processes. J. Clean. Prod. 2017, 148, 709–734. [Google Scholar] [CrossRef]

- Bai, X.; Wang, G.; Gong, C.; Yu, Y.; Liu, W.; Wang, D. Co-pelletizing characteristics of torrefied wheat straw with peanut shell. Bioresour. Technol. 2017, 233, 373–381. [Google Scholar] [CrossRef] [PubMed]

- Lai, Z.Y.; Goh, S.M. Mechanical strength of binary oil palm kernel shell and HZSM-5 zeolite fuel pellets. Fuel 2015, 150, 378–385. [Google Scholar] [CrossRef]

- Lisowski, A.; Pajor, M.; Swietochowski, A.; Dabrowska, M.; Klonowski, J.; Mieszkalski, L.; Ekielski, A.; Stasiak, M.; Piatek, M. Effects of moisture content, temperature, and die thickness on the compaction process, and the density and strength of walnut shell pellets. Renew. Energy 2019, 141, 770–781. [Google Scholar] [CrossRef]

- Lam, P.S.; Lam, P.Y.; Sokhansanj, S.; Lim, C.J.; Bi, X.T.; Stephen, J.D.; Pribowo, A.; Mabee, W.E. Steam explosion of oil palm residues for the production of durable pellets. Appl. Energy 2015, 141, 160–166. [Google Scholar] [CrossRef]

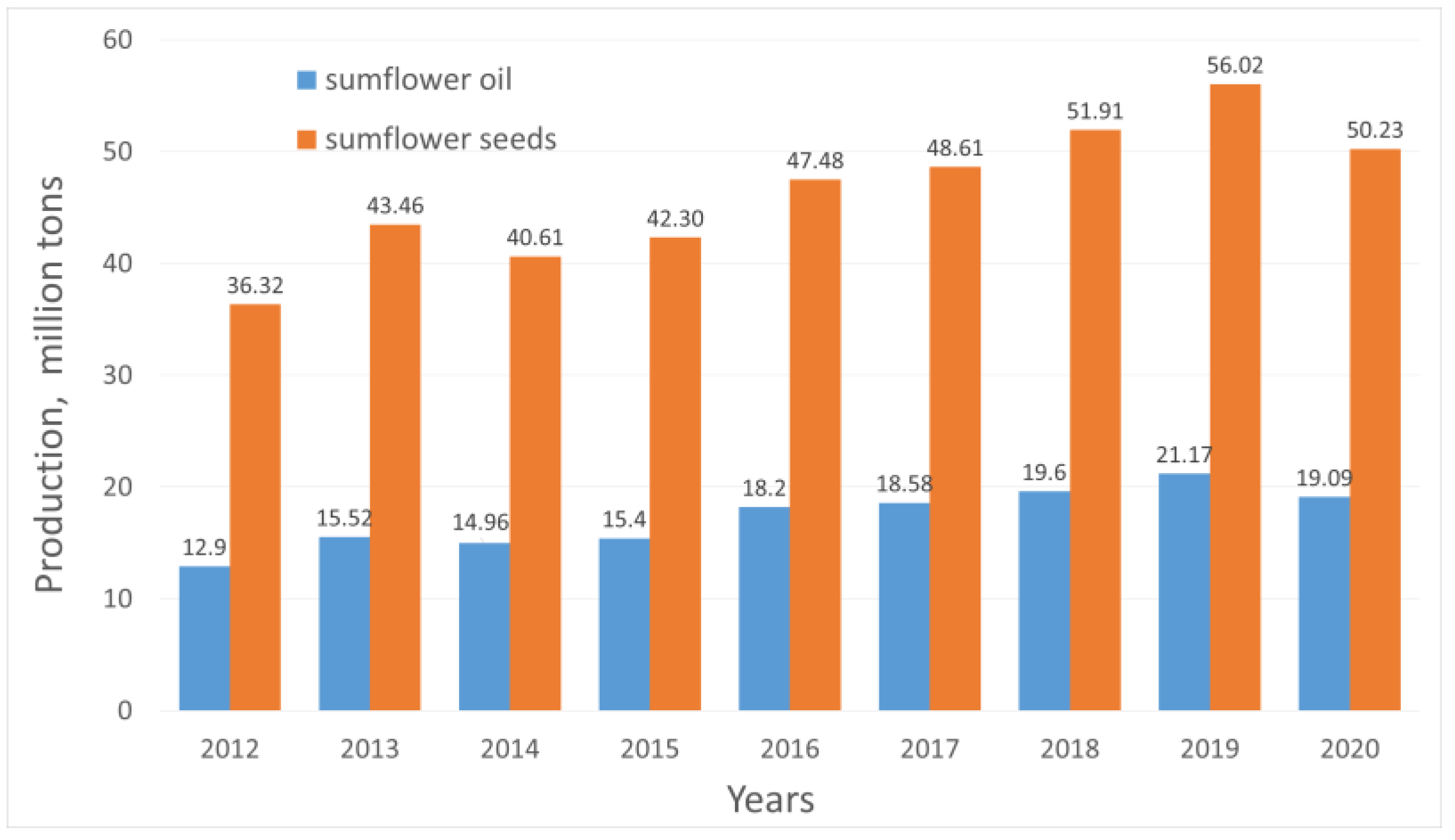

- Shahbandeh, M. Production Volume of Sunflowerseed Oil Worldwide from 2012/13 to 2022/23. Available online: https://www.statista.com/statistics/613490/sunflowerseed-oil-production-volume-worldwide/ (accessed on 8 February 2023).

- Available online: https://ourworldindata.org/grapher/sunflower-seed-production?tab=table&time=2018..latest (accessed on 2 October 2023).

- Obaidullah, M.; Bram, S.; Verma, V.; De Ruyck, J. A review on particle emissions from small scale biomass combustion. Int. J. Renew. Energy Res. 2012, 2, 147–159. [Google Scholar]

- Roy, M.M.; Corscadden, K.W. An experimental study of combustion and emissions of biomass briquettes in a domestic wood stove. Appl. Energy 2012, 99, 206–212. [Google Scholar] [CrossRef]

- Available online: https://pl.investing.com/commodities/carbon-emissions (accessed on 2 October 2023).

- Radomiak, H.; Bala-Litwiniak, A.; Zajemska, M.; Musiał, D. Numerical prediction of the chemical composition of gas products at biomass combustion and co-combustion in a domestic boiler. Energy Fuels 2016, 14, 02043. [Google Scholar] [CrossRef]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Bilgic, E.; Yaman, S.; Haykiri-Acma, H.; Kucukbayrak, S. Limits of variations on the structure and the fuel characteristics of sunflower seed shell through torrefaction. Fuel Process. Technol. 2016, 144, 197–202. [Google Scholar] [CrossRef]

- Matin, A.; Majdak, T.; Kricka, T.; Grubor, M. Valorization of sunflower husk after seeds convection drying for solid fuel production. J. Cent. Eur. Agric. 2019, 20, 389–401. [Google Scholar] [CrossRef]

- Li, H.; Jiang, L.; Li, C.; Liang, J.; Yuan, X.; Xiao, Z.; Xiao, Z.; Wang, H. Co-pelletization of sewage sludge and biomass: The energy input and properties of pellets. Fuel Process. Technol. 2015, 132, 55–61. [Google Scholar] [CrossRef]

- Shaukat, R.A.; Saqib, Q.M.; Khan, M.U.; Chougale, M.Y.; Bae, J. Bio-waste sunflower husks powder based recycled triboelectric nanogenerator for energy harvesting. Energy Rep. 2021, 7, 724–731. [Google Scholar] [CrossRef]

- Vyvan, J.R. Allelochemicals as leads for new herbicides and agrochemicals. Tetrahedron 2002, 58, 1631–1646. [Google Scholar] [CrossRef]

- Osman, N.S.; Khamil, I.A.M.; Sapawe, N. Customer Satisfaction Survey on Sunflower Shell Waste Animal Feed Pellet. Mater. Today Proc. 2019, 19, 1803–1809. [Google Scholar] [CrossRef]

- Osman, N.S.; Sapawe, N. Petz Munchez—Sunflower Shell Waste-Based Animal Feed Pellet. Mater. Today Proc. 2019, 19, 1771–1776. [Google Scholar] [CrossRef]

- Osman, N.S.; Khamil, I.A.M.; Sapawe, N. Proximate Analysis of Animal Feed Pellet Formulated from Sunflower Shell Waste. Mater. Today Proc. 2019, 19, 1796–1802. [Google Scholar] [CrossRef]

- Quaranta, N.; Unsen, M.; López, H.; Giansiracusa, C.; Roether, J.A.; Boccaccini, A.R. Ash from sunflower husk as raw material for ceramic products. Ceram. Int. 2011, 37, 377–385. [Google Scholar] [CrossRef]

- Burbano Patiño, A.A.; Lassalle, V.L.; Horst, M.F. Magnetic hydrochar nanocomposite obtained from sunflower husk: A potential material for environmental remediation. J. Mol. Struct. 2021, 5, 130509. [Google Scholar] [CrossRef]

- Liang, C.; Yang, H.; Yu, K.; Jin, W. Sunflower seed husk-derived submicron carbon spheres and SnO2 nanoparticles composite used as an anode for high-performance lithium-ion batteries. Diam. Relat. Mater. 2021, 116, 108392. [Google Scholar] [CrossRef]

- Barczewski, M.; Sałasińska, K.; Szulc, J. Application of sunflower husk, hazelnut shell and walnut shell as waste agricultural fillers for epoxy-based composites: A study into mechanical behavior related to structural and rheological properties. Polym. Test. 2019, 75, 1–11. [Google Scholar] [CrossRef]

- Tinoco, M.P.; Gouvêa, L.; de Cássia Magalhães Martins, K.; Filho, R.D.T.; Mendoza Reales, O.A. The use of rice husk particles to adjust the rheological properties of 3D printable cementitious composites through water sorption. Constr. Build. Mater. 2023, 15, 130046. [Google Scholar] [CrossRef]

- Zuo, Z.; Yu, Q.; Xie, H.; Qin, Q.; Wei, M. Direct Reduction of Copper Slag Composite Pellets Within Lignite Using Biomass as Binder. In Energy Technology 2018; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2018; pp. 65–75. [Google Scholar] [CrossRef]

- Li, B.; Wei, Y.; Wang, H.; Yang, Y. Reduction of magnetite from copper smelting slag using petrodiesel and biodiesel. ISIJ Int. 2018, 58, 1168–1174. [Google Scholar] [CrossRef]

- Lovel, R.; Vining, K.; Dell’Amicco, M. Iron ore sintering with charcoal. Int. Miner. Process. Extr. Metall. 2007, 116, 85–92. [Google Scholar] [CrossRef]

- Kawaguchi, T.; Hara, M. Utilization of biomass for iron ore sintering. ISIJ Int. 2013, 53, 1599–1606. [Google Scholar] [CrossRef]

- Zandi, M.; Martinez-Pacheco, M.; Fray, T.A.T. Biomass for iron ore sintering. Miner. Eng. 2010, 22, 1139–1145. [Google Scholar] [CrossRef]

- Forsmo, S.P.E.; Forsmo, S.E.; Samskog, P.O.; Björkman, B.M.T. Mechanisms in oxidation and sintering of magnetite iron ore green pellets. Powder Technol. 2008, 183, 247–259. [Google Scholar] [CrossRef]

- Kieush, L.; Boyko, M.; Koveria, A.; Yaholnyk, M.; Poliakova, N. Manganese sinter production with wood biomass application. Key Eng. Mater. 2020, 844, 124–134. [Google Scholar] [CrossRef]

- Liu, Z.; Bi, X.; Gao, Z.; Liu, W. Carbothermal reduction of iron ore in its concentrate-agricultural waste pellets. Adv. Mater. Sci. Eng. 2018, 6, 2138268. [Google Scholar] [CrossRef]

- Rashid, R.Z.A.; Salleh, H.M.; Ani, M.H.; Yunus, A.; Akiyama, T.; Purwanto, H. Reduction of low grade iron ore pellet using palm kernel shell. Renew. Energy 2014, 63, 617–623. [Google Scholar] [CrossRef]

- Ooi, T.C.; Aries, E.; Ewan, B.C.R.; Thompson, D.; Anderson, D.R.; Fisher, R.; Fray, T.; Tognarelli, D. The study of sunflower seed husks as a fuel in the iron ore sintering process. Miner. Eng. 2008, 21, 167–177. [Google Scholar] [CrossRef]

- Kieush, L.; Koveria, A.; Zhu, Z.Q.; Boyko, M.; Sova, A.; Yefimenko, V. Application of Biomass Pellets for Iron Ore Sintering. MSF 2021, 1045, 17–31. [Google Scholar] [CrossRef]

- Koveria, A.; Kieush, L.; Boyko, M.; Yaholnyk, M.; Poliakova, N. Production of iron ore pellets by utilization of sunflower husks. Acta Metall. Slovaca 2021, 27, 167–171. [Google Scholar] [CrossRef]

- Perea-Moreno, M.-A.; Manzano-Agugliaro, F.; Perea-Moreno, A.-J. Sustainable Energy Based on Sunflower Seed Husk Boiler for Residential Buildings. Sustainability 2018, 10, 3407. [Google Scholar] [CrossRef]

- Kulazynski, M.; Jabłoński, S.; Kaczmarczyk, J.; Świątek, Ł.; Pstrowska, K.; Łukaszewicz, M. Technological aspects of sun flower biomass and brown coal co-firing. J. Energy Inst. 2017, 91, 668–675. [Google Scholar] [CrossRef]

- Bala-Litwiniak, A.; Zajemska, M. Computational and experimental study of pine and sunflower husk pellet combustion and co-combustion with oats in domestic boiler. Renew. Energy 2020, 162, 151–159. [Google Scholar] [CrossRef]

- Zajemska, M.; Urbańczyk, P.; Poskart, A.; Urbaniak, D.; Radomiak, H.; Musiał, D.; Golański, G.; Wyleciał, T. The impact of co-firing sunflower husk pellets with coal in a boiler on the chemical composition of flue gas. Energy Fuels 2016, 14, 02021. [Google Scholar] [CrossRef]

- Kienzl, N.; Margaritis, N.; Isemin, R.; Kienzl, N.; Strasser, C.; Isemin, R.; Sytchev, G. Applicability of Torrefied Sunflower Husk Pellets in Small and Medium Scale Furnaces. Waste Biomass Valor. 2021, 12, 2579–2596. [Google Scholar] [CrossRef]

- Smalcerz, A.; Matula, T.; Slusorz, M.; Wojtasik, J.; Chaberska, W.; Kluska, S.; Kortyka, L.; Mycka, L.; Blacha, L.; Labaj, J. The Use of PCB Scrap in the Reduction in Metallurgical Copper Slags. Materials 2023, 16, 625. [Google Scholar] [CrossRef] [PubMed]

- STN ISO 540; Coal and Coke, Determination of Ash Fusibility. ISO: Geneva, Switzerland, 2010.

- Reynaert, C.; Sniežek, E.; Szczerba, J. Corrosion tests for refractory materials intended for steel industry—A review. Ceramics-Silikaty 2020, 64, 278–288. [Google Scholar] [CrossRef]

- Matula, T.; Labaj, J.; Nowacki, K.; Blacha, L.; Kortyka, L.; Mycka, L.; Madej, P.; Jaworek, L.; Wojtal, T. Application of Spent Coffee Grounds (SCGs) as a fuel and alternative reducer of slags from the copper industry. Energies 2023, 16, 2415. [Google Scholar] [CrossRef]

- Łabaj, J.; Blacha, L.; Jodkowski, M.; Smalcerz, A.; Fröhlichová, M.; Findorak, R. The use of waste carbonaceous material in the process of cooper slag reduction. J. Clean. Prod. 2021, 288, 125640. [Google Scholar] [CrossRef]

- Ptak, S.; Polka, M. Wpływ Biomasy na Parametry Palności i Wybuchowości Pyłu Węgla Kamiennego; Wydawnictwo Szkoly Glownej Pozarniczej: Warsow, Poland, 2018. [Google Scholar]

- He, C.; Giannis, A.; Wang, J.Y. Conversion of sewage sludge to clean solid fuel using hydrothermal carbonization: Hydrochar fuel characteristics and combustion behavior. Appl. Energy 2013, 111, 257–266. [Google Scholar] [CrossRef]

- Islamova, S.; Karaeva, J.; Timofeeva, S.; Kadyirov, A. An experimental study of sunflower husk pellets combustion. BIO Web Conf. 2021, 37, 00070. [Google Scholar] [CrossRef]

- Siwiec, G.; Sozańska, M.; Blacha, L.; Smalcerz, A. Behaviour of iron during reduction of slag obtained from copper flash smelting. Metalurgija 2015, 54, 113–115. [Google Scholar]

| Composition of the tested sunflower pellet | |||||

| Pellet component | C | H | O | N | S |

| Component content, wt% | 48.0 | 5.92 | 49.1 | 0.52 | 0.09 |

| Composition of the tested copper slag | |||||

| Slag component | Cu | Pb | Fe | SiO2 | CaO |

| Component content, wt% | 10.3 | 2.25 | 11.1 | 34.5 | 14.1 |

| Composition of the Tested Sunflower Pellet | |||||

|---|---|---|---|---|---|

| Pellet Component | C | H | O | N | S |

| Component content, wt% | 42.1–69.8 | 5.17–8.8 | 30.36–48.92 | 0.33–1.15 | 0.09–0.24 |

| Sintering Temperature | From 1145 °C |

|---|---|

| Deformation temperature | 1175 °C |

| Softening temperature | 1205 °C |

| Melting temperature | 1207 °C |

| Flow temperature | 1215 °C |

| Sample 1 | Sample 2 | |||||

|---|---|---|---|---|---|---|

| Sample mass loss | Loss I, % | Loss II, % | Loss III, % | Loss I, % | Loss II, % | Loss III, % |

| 4.47 | 68.25 | 5.54 | 4.38 | 65.33 | 5.67 | |

| Temperature range for the particular loss, °C | 20–230 | 230–890 | 890–1200 | 20–180 | 180–760 | 760–1200 |

| Mass loss rate, mg | 0.0090 | 0.0346 | 0.0021 | 0.0088 | 0.0391 | 0.0019 |

| No | Type of Reducer | Amounts of the Reducer, g | Reduction Time, h | Amounts of Carbon per 1 g of Slag, g | Metal Weight, g | Secondary Slag Weight, G | Copper Content in the Metal, wt% | Copper Content in Secondary Slag, wt% | SCu, %, |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Sunflower husk pellet | 5.67 | 1 | 0.0284 | 5.64 | 89.13 | 91.00 | 1.11 | 89.46 |

| 2 | 7.56 | 0.0378 | 10.64 | 84.01 | 88.70 | 0.96 | 90.88 | ||

| 3 | 5.67 | 1.5 | 0.0284 | 8.42 | 85.97 | 94.90 | 0.64 | 93.92 | |

| 4 | 7.56 | 0.0378 | 11.49 | 85.08 | 88.30 | 0.37 | 96.49 | ||

| 5 | 5.67 | 2 | 0.0284 | 9.65 | 86.81 | 85.40 | 0.61 | 94.21 | |

| 6 | 7.56 | 0.0378 | 11.64 | 85.69 | 92.50 | 0.54 | 94.87 | ||

| 7 | 5.67 | 3 | 0.0284 | 9.92 | 88.41 | 88.41 | 0.67 | 93.64 | |

| 8 | 7.56 | 0.0378 | 11.71 | 87.01 | 86.80 | 0.29 | 97.25 | ||

| 9 | 5.67 | 4 | 0.0284 | 9.63 | 87.66 | 86.20 | 0.78 | 92.59 | |

| 10 | 7.56 | 0.0378 | 12.09 | 86.53 | 86.30 | 0.59 | 94.40 | ||

| 11 | 10 | 3 | 0.0500 | 12.26 | 85.41 | 85.66 | 0.41 | 96.11 | |

| 12 | 12 | 0.0600 | 13.26 | 84.1 | 88.08 | 0.5 | 95.25 | ||

| 13 | Coke breeze | 5.42 | 1 | 0.0700 | 2.05 | 95.25 | 92.10 | 5.25 | 50.10 |

| 14 | 2 | 3.50 | 92.13 | 93.23 | 1.01 | 90.41 | |||

| 15 | 3 | 6.70 | 87.36 | 90.13 | 1.08 | 89.72 | |||

| 16 | 4 | 8.41 | 83.95 | 87.58 | 0.67 | 93.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matula, T.; Labaj, J.; Vadasz, P.; Plešingerová, B.; Smalcerz, A.; Blacha, L. Application of Sunflower Husk Pellet as a Reducer in Metallurgical Processes. Materials 2023, 16, 6790. https://doi.org/10.3390/ma16206790

Matula T, Labaj J, Vadasz P, Plešingerová B, Smalcerz A, Blacha L. Application of Sunflower Husk Pellet as a Reducer in Metallurgical Processes. Materials. 2023; 16(20):6790. https://doi.org/10.3390/ma16206790

Chicago/Turabian StyleMatula, Tomasz, Jerzy Labaj, Pavol Vadasz, Beatrice Plešingerová, Albert Smalcerz, and Leszek Blacha. 2023. "Application of Sunflower Husk Pellet as a Reducer in Metallurgical Processes" Materials 16, no. 20: 6790. https://doi.org/10.3390/ma16206790

APA StyleMatula, T., Labaj, J., Vadasz, P., Plešingerová, B., Smalcerz, A., & Blacha, L. (2023). Application of Sunflower Husk Pellet as a Reducer in Metallurgical Processes. Materials, 16(20), 6790. https://doi.org/10.3390/ma16206790