Anisotropic Deformation Behavior and Indentation Size Effect of Monocrystalline BaF2 Using Nanoindentation

Abstract

:1. Introduction

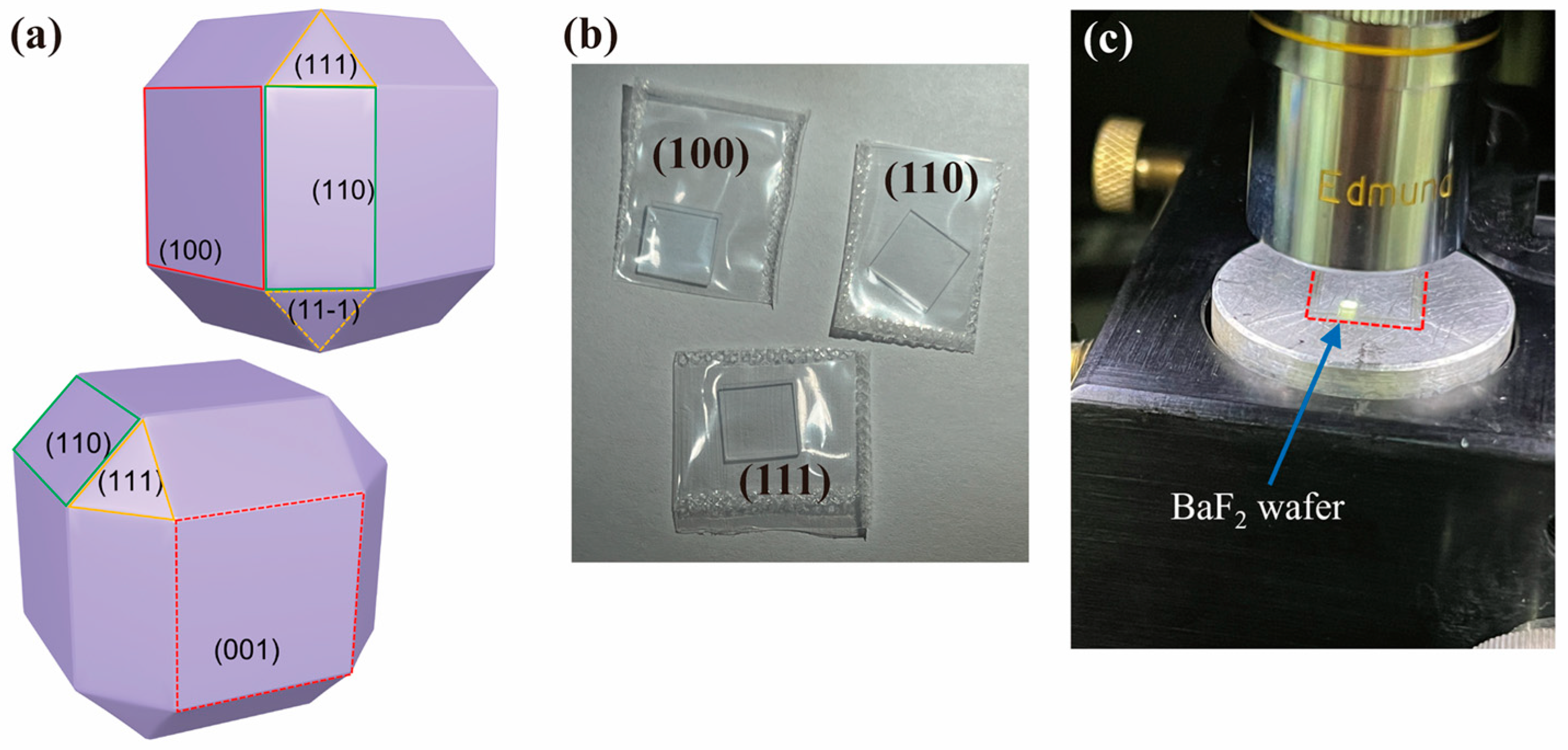

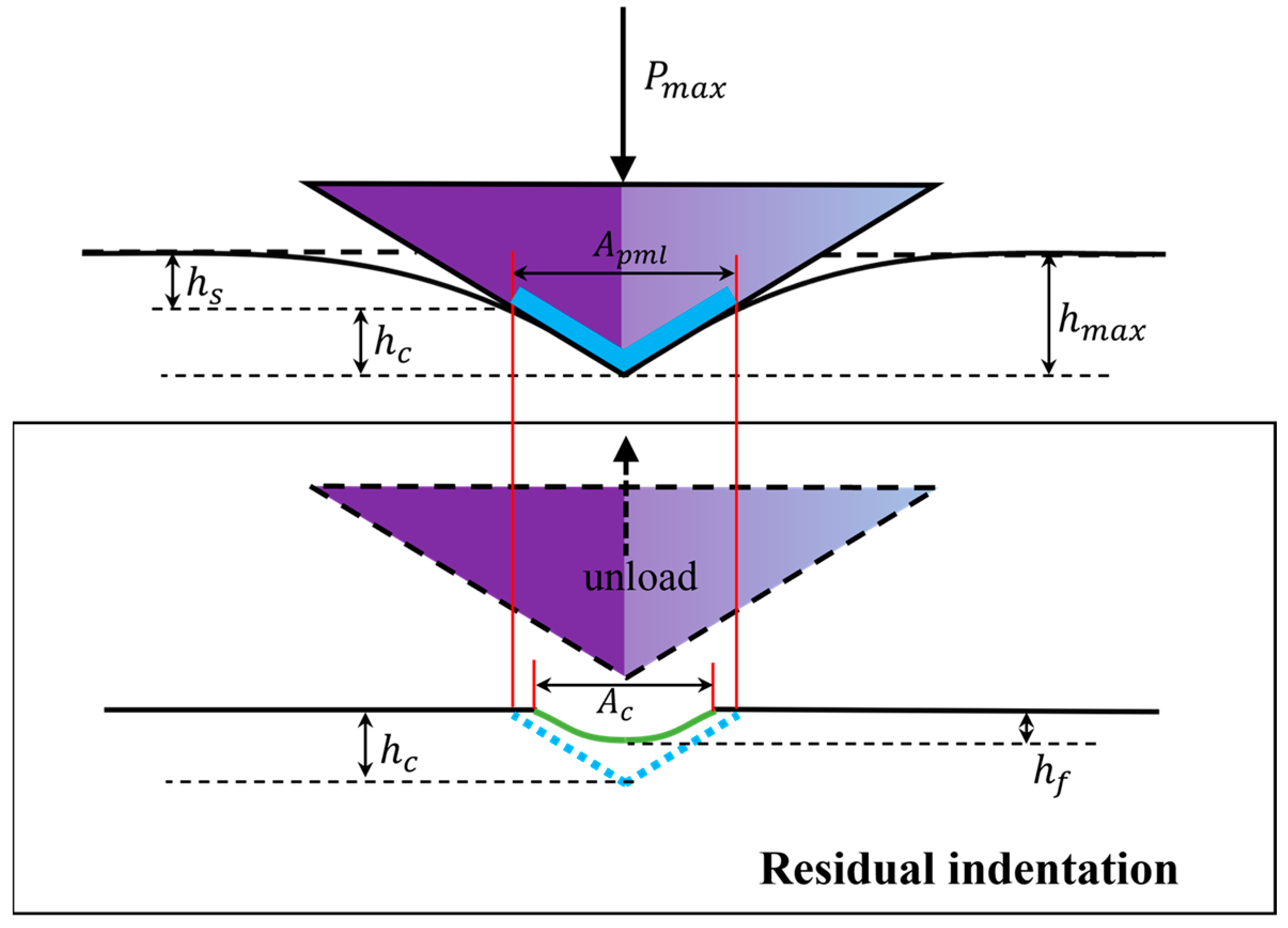

2. Experimental Procedures

3. Results and Discussion

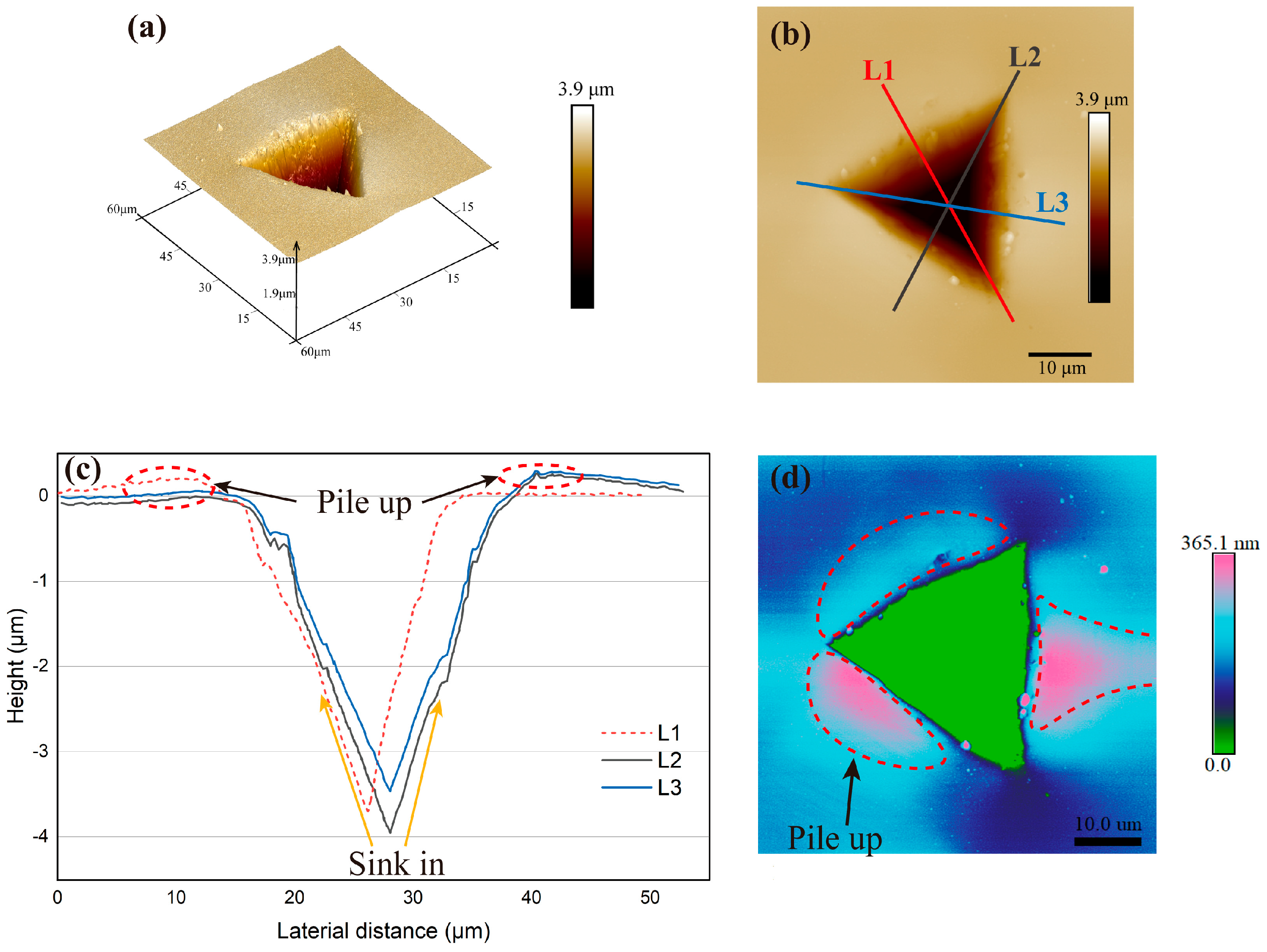

3.1. Indentation Morphology

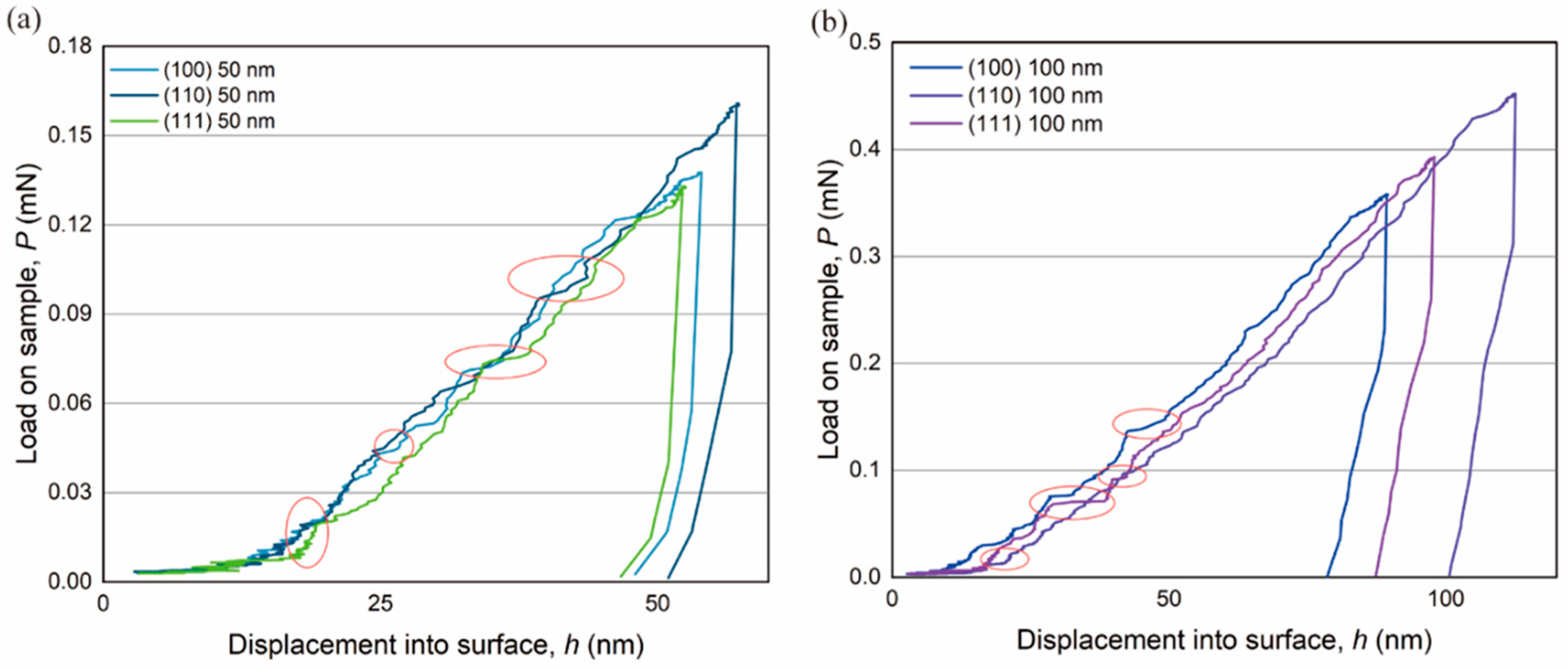

3.2. Indentation Load vs. Displacement Curves and Plastic Deformation

3.2.1. Pop-In Events

3.2.2. Elastic–Plastic Transmission

3.3. Anisotropy ISE of Monocrystalline BaF2

3.3.1. Mechanical Properties

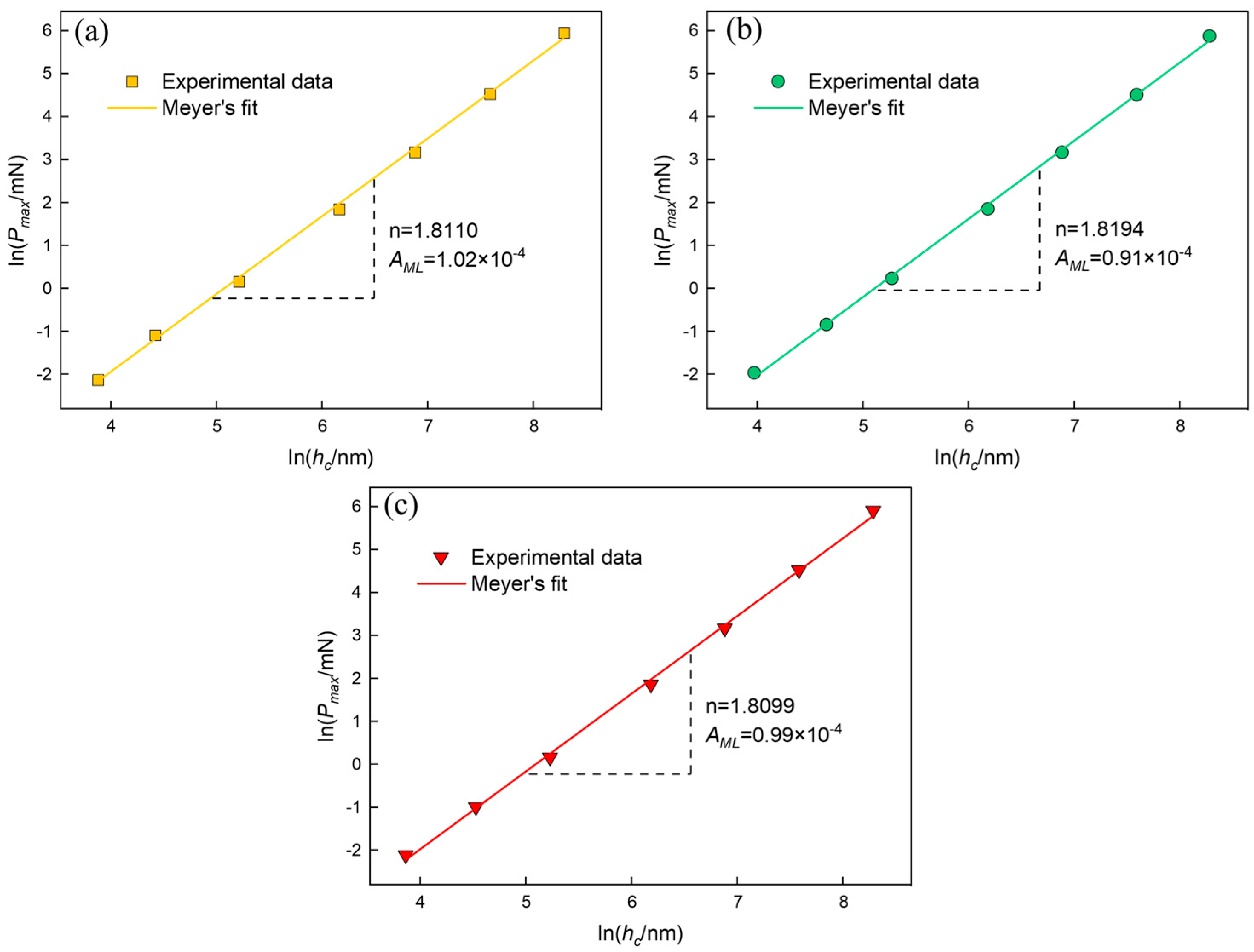

3.3.2. Meyer’s Law (ML)

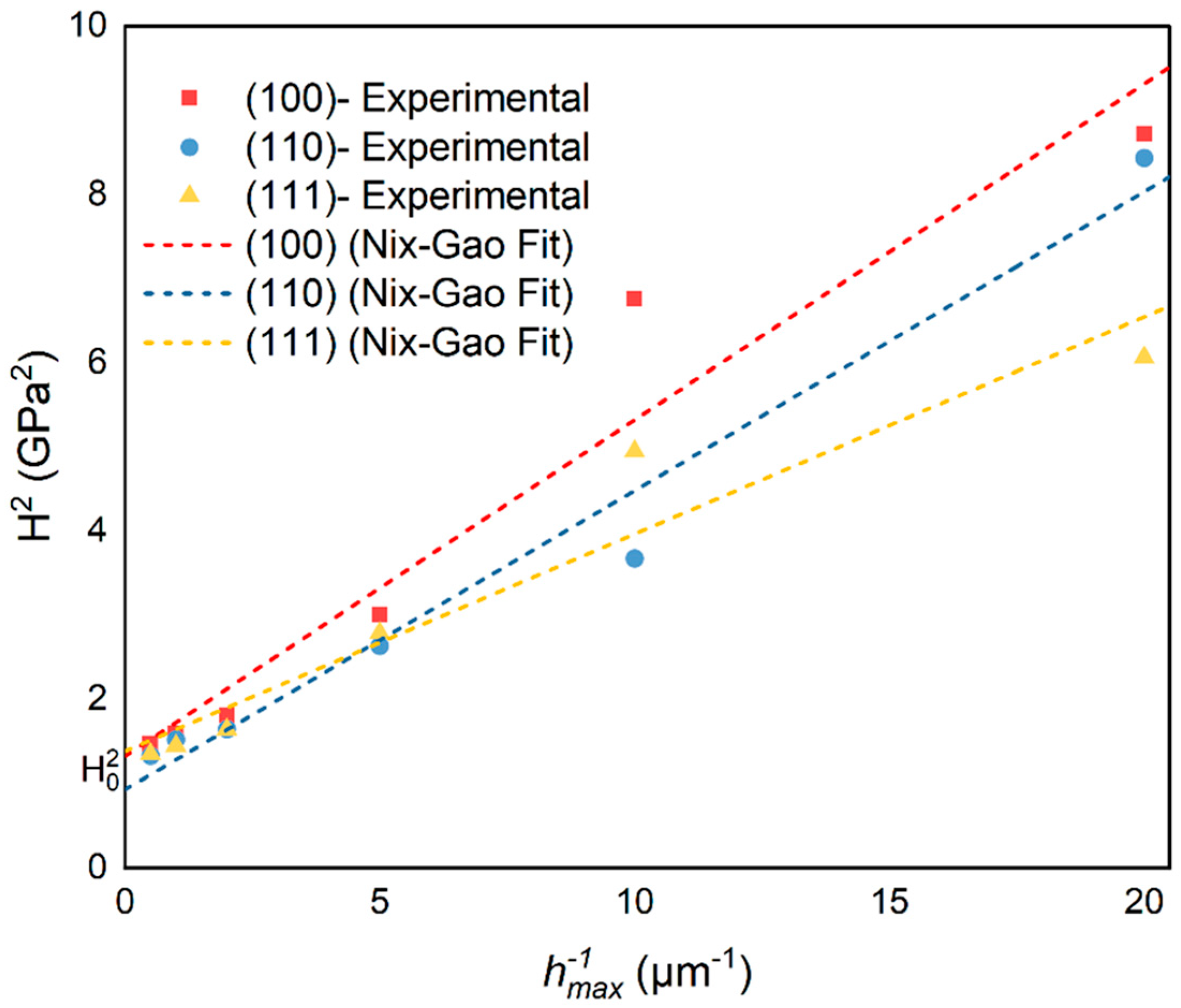

3.3.3. Nix–Gao (N-G) Model

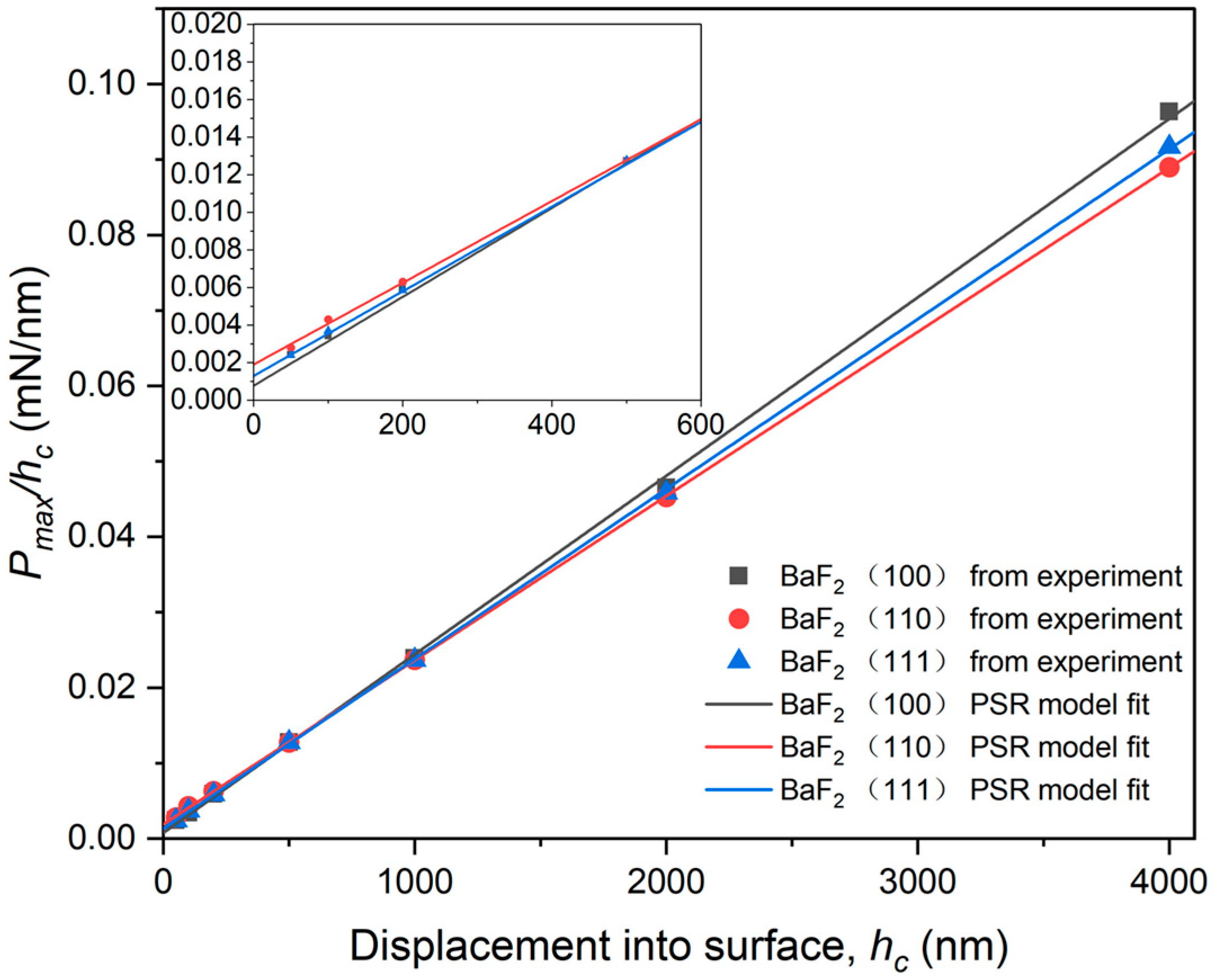

3.3.4. Proportional Specimen Resistance (PSR) Model

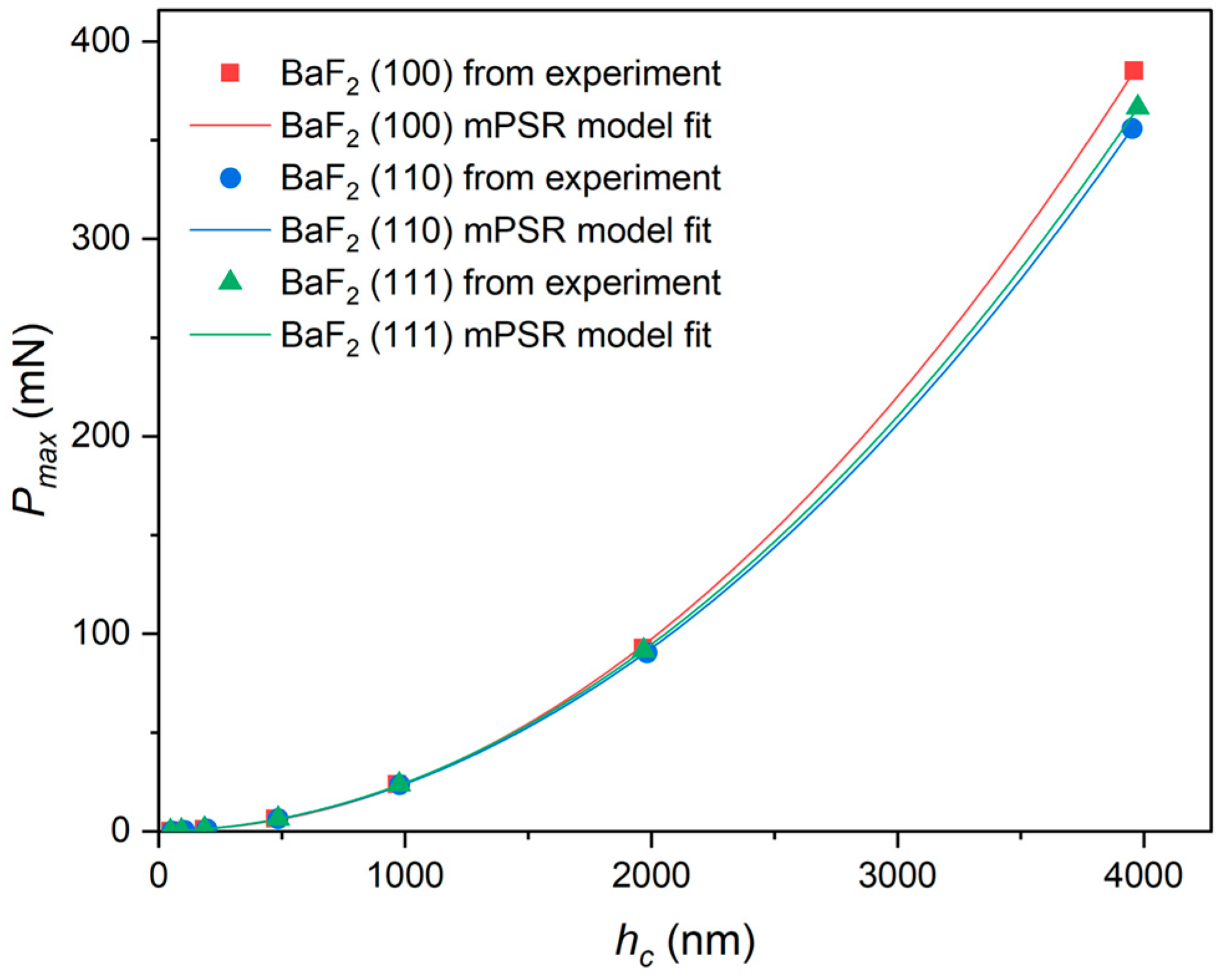

3.3.5. The Modified PSR Model

3.3.6. Quantification of Size Effects

4. Conclusions

- Successive pop-in events were observed on the load-depth curves, and a pile-up phenomenon was observed based on AFM images. The onset loads for the first pop-in were found to be 11.0 μN, 19.0 μN, and 7.0 μN for the (100), (110), and (111) crystallographic planes, respectively. Among these planes, the (100) plane required BaF2 (110) and BaF2 (111), BaF2 (100) necessitates the highest load at a given indentation depth. The critical depth of elastic-plastic deformation for monocrystalline BaF2 was determined to be 56.9 nm, 58.2 nm, and 57.8 nm for the (100), (110), and (111) planes, respectively.

- Each crystallographic plane of monocrystalline BaF2 exhibited a significant ISE and non-ISE region after indentation. The hardness () and elastic modulus () of each plane decrease as the loading depth increases, particularly for indentation depths below 200 nm, indicating a pronounced ISE. Furthermore, the loading depth had minimal effect on the elastic modulus during elastic and elastic-plastic deformation regions.

- The anisotropic ISE of monocrystalline BaF2 was effectively described by Meyer’s law, the Nix-Gao model, the PSR model, and the mPSR model. However, Meyer’s law could not accurately predict the true hardness of monocrystalline BaF2. Nanoindentation experiments showed better agreement with the Nix-Gao model and the PSR model, which effectively described the ISE of BaF2. The characteristic lengths and corresponding hardness values for the (100), (110), and (111) planes were determined to be 300.4 nm and 1.1529 ± 0.45 GPa, 381.4 nm, and 0.965 ± 0.27 GPa, and 185.8 nm and 1.1783 ± 0.32 GPa, respectively. When the indentation depth did not exceed , the monocrystalline BaF2 exhibited a significant ISE phenomenon, which weakened as the indentation depth exceeded , in accordance with the Nix-Gao model.

- The depth-independent hardness determined using the mPSR model and the predicted values from the Nix-Gao model show adequate agreement and the mPSR model has the best correlation coefficient (). Higher values are attributed to the creation of pile-ups at comparatively higher indentation depths. Moreover, for BaF2 (100), BaF2, (110), and BaF2 (111), the size impact indexes are 0.198, 0.211, and 0.228, respectively. BaF2 (100) exhibits the highest hardness and size effect index , indicating the lowest plasticity compared to BaF2 (110) and BaF2 (111).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, C.; Ma, X.; Wang, Z.; Bao, J.; Dai, C.; Guan, M.; Liu, J.; Li, Z.; Ren, J.; Ruan, X.; et al. Neutron beam test of barium fluoride crystal for dark matter direct detection. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2016, 833, 49–53. [Google Scholar]

- Kato, T.; Okada, G.; Fukuda, K.; Yanagida, T. Development of BaF2 transparent ceramics and evaluation of the scintillation properties. Radiat. Meas. 2017, 106, 140–145. [Google Scholar]

- Kawano, N.; Kato, T.; Nakauchi, D.; Takebuchi, Y.; Fukushima, H.; Shiratori, D.; Jacobsohn, L.G.; Yanagida, T. TSL, OSL and scintillation properties of Tb-doped barium fluoride translucent ceramics. Opt. Mater. 2023, 141, 113948. [Google Scholar]

- Wang, S.F.; Zhang, J.; Luo, D.W.; Gu, F.; Tang, D.Y.; Dong, Z.L.; Tan, G.E.; Que, W.X.; Zhang, T.S.; Li, S.; et al. Transparent ceramics: Processing, materials and applications. Prog. Solid State Chem. 2013, 41, 20–54. [Google Scholar]

- Mao, W.G.; Shen, Y.G.; Lu, C. Nanoscale elastic–plastic deformation and stress distributions of the C plane of sapphire single crystal during nanoindentation. J. Eur. Ceram. Soc. 2011, 31, 1865–1871. [Google Scholar] [CrossRef]

- Ma, Y.; Cao, L.; Hang, W.; Zhang, T.; Yuan, J. Crystallographic orientation effect on the incipient plasticity and its stochastic behavior of a sapphire single crystal by spherical nanoindentation. Ceram. Int. 2020, 46, 15554–15564. [Google Scholar] [CrossRef]

- Sato, Y.; Shinzato, S.; Ohmura, T.; Hatano, T.; Ogata, S. Unique universal scaling in nanoindentation pop-ins. Nat. Commun. 2020, 11, 4177. [Google Scholar]

- Lodes, M.A.; Hartmaier, A.; Göken, M.; Durst, K. Influence of dislocation density on the pop-in behavior and indentation size effect in CaF2 single crystals: Experiments and molecular dynamics simulations. Acta Mater. 2011, 59, 4264–4273. [Google Scholar] [CrossRef]

- Tang, P.; Feng, J.; Wan, Z.; Huang, X.; Yang, S.; Lu, L.; Zhong, X. Influence of grain orientation on hardness anisotropy and dislocation behavior of AlN ceramic in nanoindentation. Ceram. Int. 2021, 47, 20298–20309. [Google Scholar] [CrossRef]

- Graça, S.; Colaço, R.; Vilar, R. Micro-to-Nano Indentation and Scratch Hardness in the Ni–Co System: Depth Dependence and Implications for Tribological Behavior. Tribol. Lett. 2008, 31, 177–185. [Google Scholar] [CrossRef]

- Chua, J.; Zhang, R.; Chaudhari, A.; Vachhani, S.J.; Kumar, A.S.; Tu, Q.; Wang, H. High-temperature nanoindentation size effect in fluorite material. Int. J. Mech. Sci. 2019, 159, 459–466. [Google Scholar] [CrossRef]

- Kathavate, V.S.; Kumar, B.P.; Singh, I.; Prasad, K.E. Analysis of indentation size effect (ISE) in nanoindentation hardness in polycrystalline PMN-PT piezoceramics with different domain configurations. Ceram. Int. 2021, 47, 11870–11877. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Ma, A.; Hartmaier, A.; Yan, Y.; Sun, T. On the crystallographic anisotropy of plastic zone size in single crystalline copper under Berkovich nanoindentation. Mater. Today Commun. 2020, 25, 101314. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, F.; Li, Y.; Wang, N.; Hu, Z.; Yan, L.; Lu, J.; Wen, Q.; Lu, X. Prediction of pop-in load for sapphires with different crystal orientations. Ceram. Int. 2020, 46, 6682–6692. [Google Scholar] [CrossRef]

- Borc, J.; Sangwal, K.; Pritula, I.; Dolzhenkova, E. Investigation of pop-in events and indentation size effect on the (001) and (100) faces of KDP crystals by nanoindentation deformation. Mater. Sci. Eng. A 2017, 708, 1–10. [Google Scholar] [CrossRef]

- Zhu, B.; Zhao, D.; Zhao, H. A study of deformation behavior and phase transformation in 4H-SiC during nanoindentation process via molecular dynamics simulation. Ceram. Int. 2019, 45, 5150–5157. [Google Scholar] [CrossRef]

- Yan, S.; Nawaz, A.; Islam, B.; Qin, Q.-H.; Mao, W.; Shen, Y.; Ahmad, I.; Hussain, I. Elastic-plastic deformation behavior of sapphire M-plane under static loading using nano-indentation. Ceram. Int. 2021, 47, 23528–23538. [Google Scholar] [CrossRef]

- Petruš, O.; Sedlák, R.; Csanádi, T.; Naughton-Duszová, A.; Vojtko, M.; Hvizdoš, P.; Dusza, J. Indentation size effect in the hardness measurements of high entropy carbides. Ceram. Int. 2023, 49, 24207–24215. [Google Scholar] [CrossRef]

- Maiti, P.; Bhattacharya, M.; Das, P.S.; Devi, P.S.; Mukhopadhyay, A.K. Indentation size effect and energy balance issues in nanomechanical behavior of ZTA ceramics. Ceram. Int. 2018, 44, 9753–9772. [Google Scholar] [CrossRef]

- Lucas, B.; Oliver, W. Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 1999, 30, 601–610. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1580. [Google Scholar] [CrossRef]

- ISO 14577-1:2015; Metallic Materials: Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method. ISO: Geneva, Switzerland, 2015.

- Eswar Prasad, K.; Ramesh, K.T. Hardness and mechanical anisotropy of hexagonal SiC single crystal polytypes. J. Alloys Compd. 2019, 770, 158–165. [Google Scholar] [CrossRef]

- Bagheripoor, M.; Klassen, R. The effect of crystal anisotropy and pre-existing defects on the incipient plasticity of FCC single crystals during nanoindentation. Mech. Mater. 2020, 143, 103311. [Google Scholar] [CrossRef]

- Bhushan, B. Principles and Applications of Tribology; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Lee, S.H. Analysis of ductile mode and brittle transition of AFM nanomachining of silicon. Int. J. Mach. Tools Manuf. 2012, 61, 71–79. [Google Scholar] [CrossRef]

- Liu, Y.; Ngan, A.H.W. Depth dependence of hardness in copper single crystals measured by nanoindentation. Scr. Mater. 2001, 44, 237–241. [Google Scholar] [CrossRef]

- Elmustafa, A.A.; Stone, D.S. Indentation size effect in polycrystalline F.C.C. metals. Acta Mater. 2002, 50, 3641–3650. [Google Scholar] [CrossRef]

- Stelmashenko, N.; Walls, M.; Brown, L.; Milman, Y. Microindentations on W and Mo oriented single crystals: An STM study. Acta Metall. Mater. 1993, 41, 2855–2865. [Google Scholar] [CrossRef]

- Hu, J.; Sun, W.; Jiang, Z.; Zhang, W.; Lu, J.; Huo, W.; Zhang, Y.; Zhang, P. Indentation size effect on hardness in the body-centered cubic coarse-grained and nanocrystalline tantalum. Mater. Sci. Eng. A 2017, 686, 19–25. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Morris, D.J.; Myers, S.B.; Cook, R.F. Sharp probes of varying acuity: Instrumented indentation and fracture behavior. J. Mater. Res. 2004, 19, 16. [Google Scholar] [CrossRef]

- Gill, G.S.; Jones, C.; Tripathi, D.K.; Keating, A.; Putrino, G.; Silva, K.K.M.B.D.; Faraone, L.; Martyniuk, M. Mechanical properties of thermally evaporated germanium (Ge) and barium fluoride (BaF2) thin-films. MRS Commun. 2022, 12, 112–118. [Google Scholar] [CrossRef]

- Pal, T.; Kar, T. Studies of microhardness anisotropy and Young’s modulus of nonlinear optical crystal l-arginine hydrochlorobromo monohydrate. Mater. Lett. 2005, 59, 1400–1404. [Google Scholar] [CrossRef]

- Huang, H.; Wang, B.; Wang, Y.; Zou, J.; Zhou, L. Characteristics of silicon substrates fabricated using nanogrinding and chemo-mechanical-grinding. Mater. Sci. Eng. A 2008, 479, 373–379. [Google Scholar] [CrossRef]

- Zeng, D.; Jie, W.; Wang, T.; Zha, G. Residual stress and strain in CdZnTe wafer examined by X-ray diffraction methods. Appl. Phys. A 2007, 86, 257–260. [Google Scholar] [CrossRef]

- Meyer, E. Hardness testing and hardness. VDI Z. 1908, 52, 645–654. [Google Scholar]

- Peng, Z.; Gong, J.; Miao, H. On the description of indentation size effect in hardness testing for ceramics: Analysis of the nanoindentation data. J. Eur. Ceram. Soc. 2004, 24, 2193–2201. [Google Scholar] [CrossRef]

- Karuppasamy, P.; Pandian, M.S.; Ramasamy, P.; Verma, S. Crystal growth, structural, optical, thermal, mechanical, laser damage threshold and electrical properties of triphenylphosphine oxide 4-nitrophenol (TP4N) single crystals for nonlinear optical applications. Opt. Mater. 2018, 79, 152–171. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2016, 65, 23. [Google Scholar] [CrossRef]

- Li, H.; Bradt, R.C. The microhardness indentation load/size effect in rutile and cassiterite single crystals. J. Mater. Sci. 1993, 28, 917–926. [Google Scholar] [CrossRef]

- Gong, J.; Li, Y. An energy-balance analysis for the size effect in low-load hardness testing. J. Mater. Sci. 2000, 35, 209–213. [Google Scholar] [CrossRef]

- Manika, I.; Maniks, J. Size effects in micro- and nanoscale indentation. Acta Mater. 2006, 54, 2049–2056. [Google Scholar] [CrossRef]

| Sample | |||

|---|---|---|---|

| (100) | 1.1529 ± 0.45 | 0.3004 | 0.945 |

| (110) | 0.965 ± 0.27 | 0.3814 | 0.9748 |

| (111) | 1.1783 ± 0.32 | 0.1858 | 0.9336 |

| Sample | |||||

|---|---|---|---|---|---|

| (100) | 0.899 ± 0.15 | 0.967 | 0.99941 | ||

| (110) | 0.816 ± 0.16 | 0.890 | 0.99998 | ||

| (111) | 0.853 ± 0.13 | 0.918 | 0.99993 |

| Sample | ||||||

|---|---|---|---|---|---|---|

| (100) | 0.677 | 1.01 ± 0.098 | 1.012 | 0.99995 | ||

| (110) | 0.191 | 0.915 ± 0.092 | 0.914 | 0.99999 | ||

| (111) | 0.052 | 0.928 ± 0.094 | 0.927 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, G.; Yang, X.; Deng, J.; Guo, Y.; Yao, T.; Li, M.; Geng, R. Anisotropic Deformation Behavior and Indentation Size Effect of Monocrystalline BaF2 Using Nanoindentation. Materials 2023, 16, 6469. https://doi.org/10.3390/ma16196469

Du G, Yang X, Deng J, Guo Y, Yao T, Li M, Geng R. Anisotropic Deformation Behavior and Indentation Size Effect of Monocrystalline BaF2 Using Nanoindentation. Materials. 2023; 16(19):6469. https://doi.org/10.3390/ma16196469

Chicago/Turabian StyleDu, Guangyuan, Xiaojing Yang, Jiayun Deng, Yanjun Guo, Tong Yao, Maozhong Li, and Ruiwen Geng. 2023. "Anisotropic Deformation Behavior and Indentation Size Effect of Monocrystalline BaF2 Using Nanoindentation" Materials 16, no. 19: 6469. https://doi.org/10.3390/ma16196469

APA StyleDu, G., Yang, X., Deng, J., Guo, Y., Yao, T., Li, M., & Geng, R. (2023). Anisotropic Deformation Behavior and Indentation Size Effect of Monocrystalline BaF2 Using Nanoindentation. Materials, 16(19), 6469. https://doi.org/10.3390/ma16196469