Application of Composts’ Biochar as Potential Sorbent to Reduce VOCs Emission during Kitchen Waste Storage

Abstract

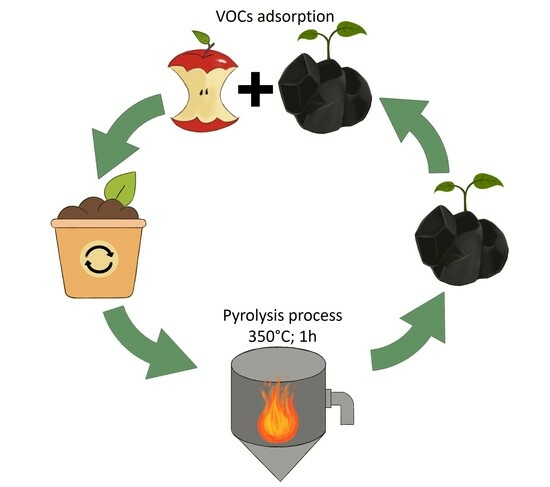

:1. Introduction

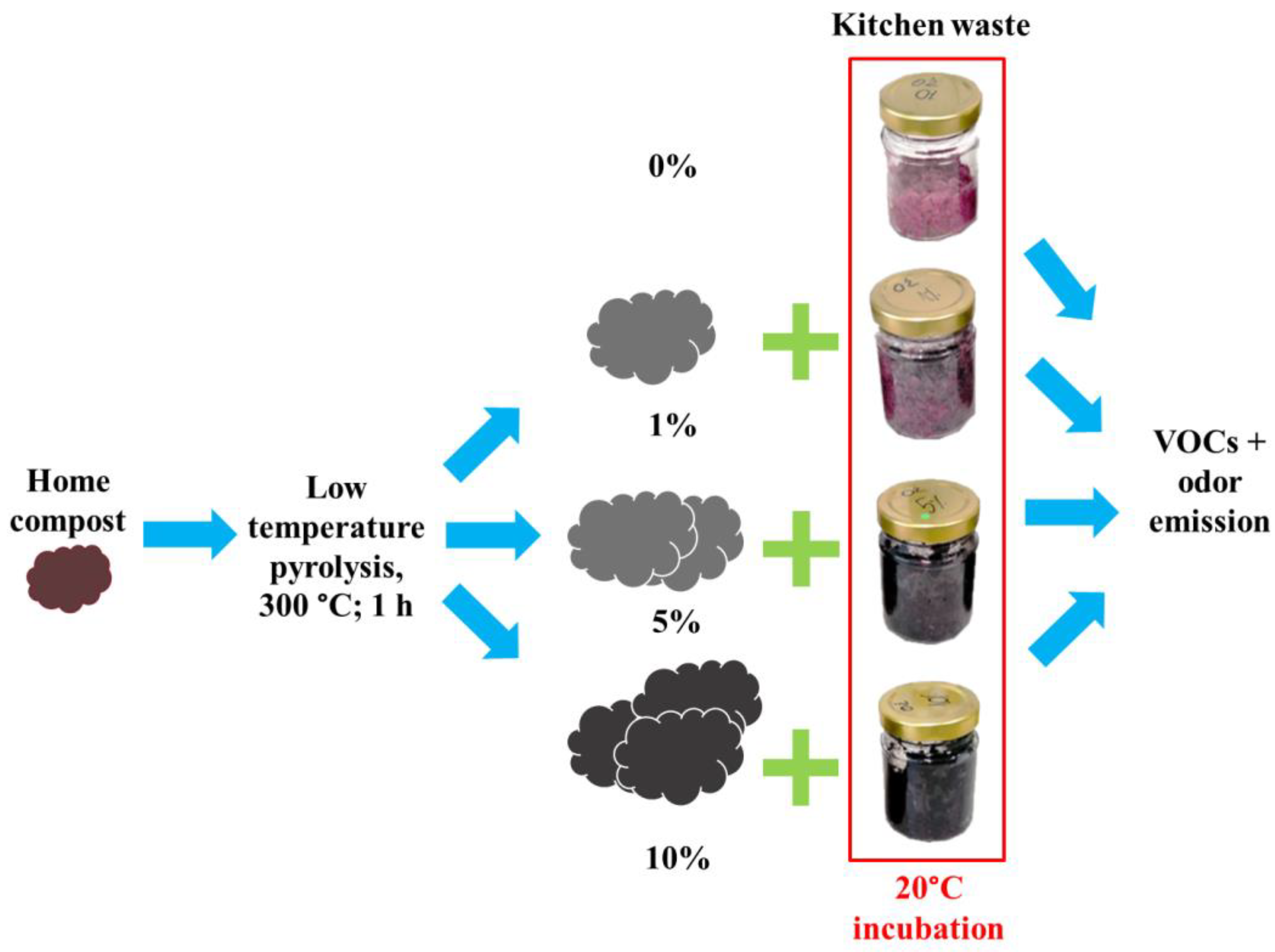

2. Materials and Methods

2.1. Materials

- vegetable and fruit waste, 65% by weight;

- pasta, rice, and bread waste, 20% by weight;

- meat and dairy waste, 15% by weight.

2.2. Experimental Procedure

2.3. Methods

2.3.1. Materials Analysis

2.3.2. Sample Preparation for VOC Analysis

2.3.3. VOC Analysis—GC–MS, SPME Arrow Extraction

2.4. Statistical Analysis

3. Results and Discussion

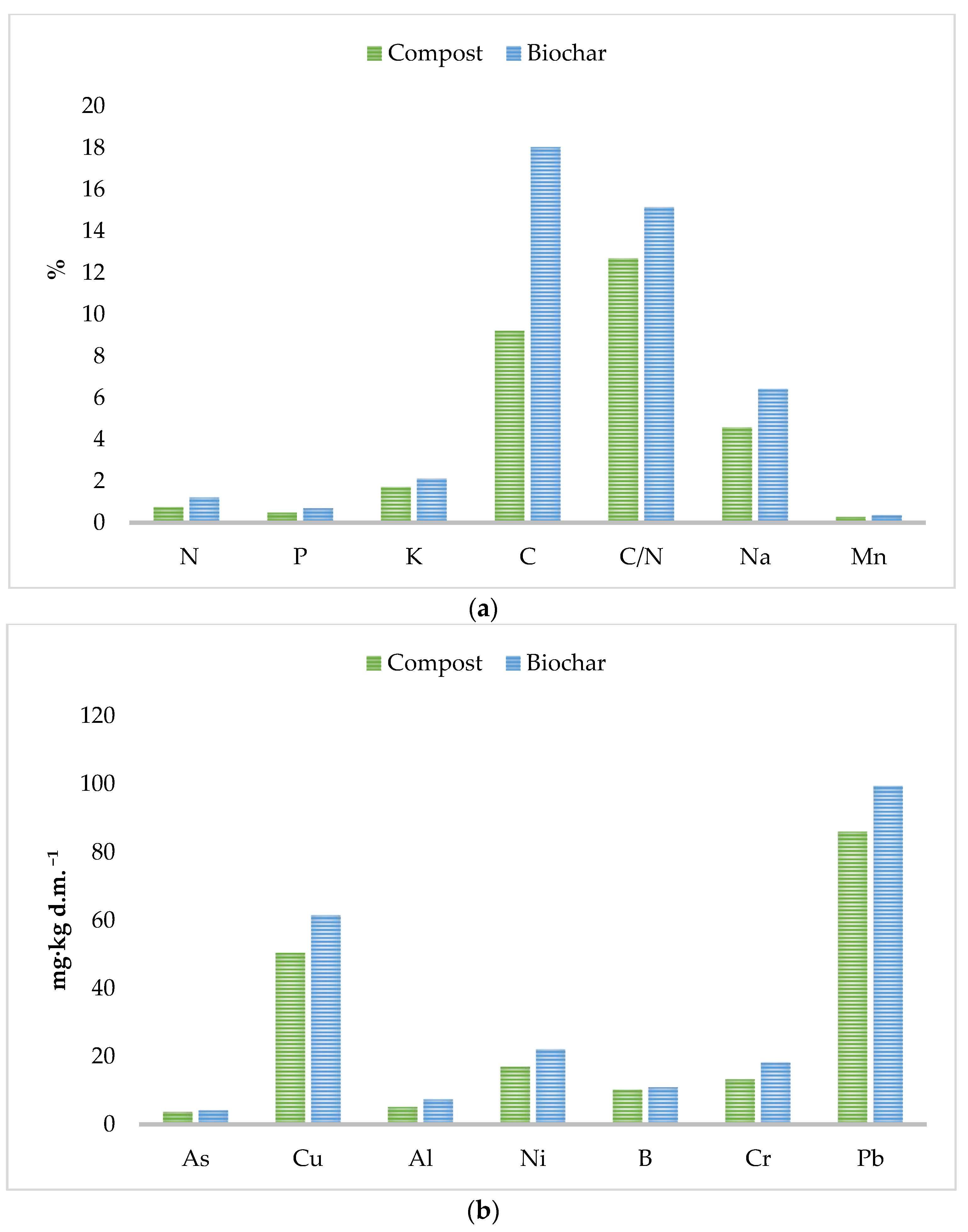

3.1. Properties of Compost, Biochar, and Kitchen Waste

Infrared Spectroscopy Analysis of Compost and Biochar

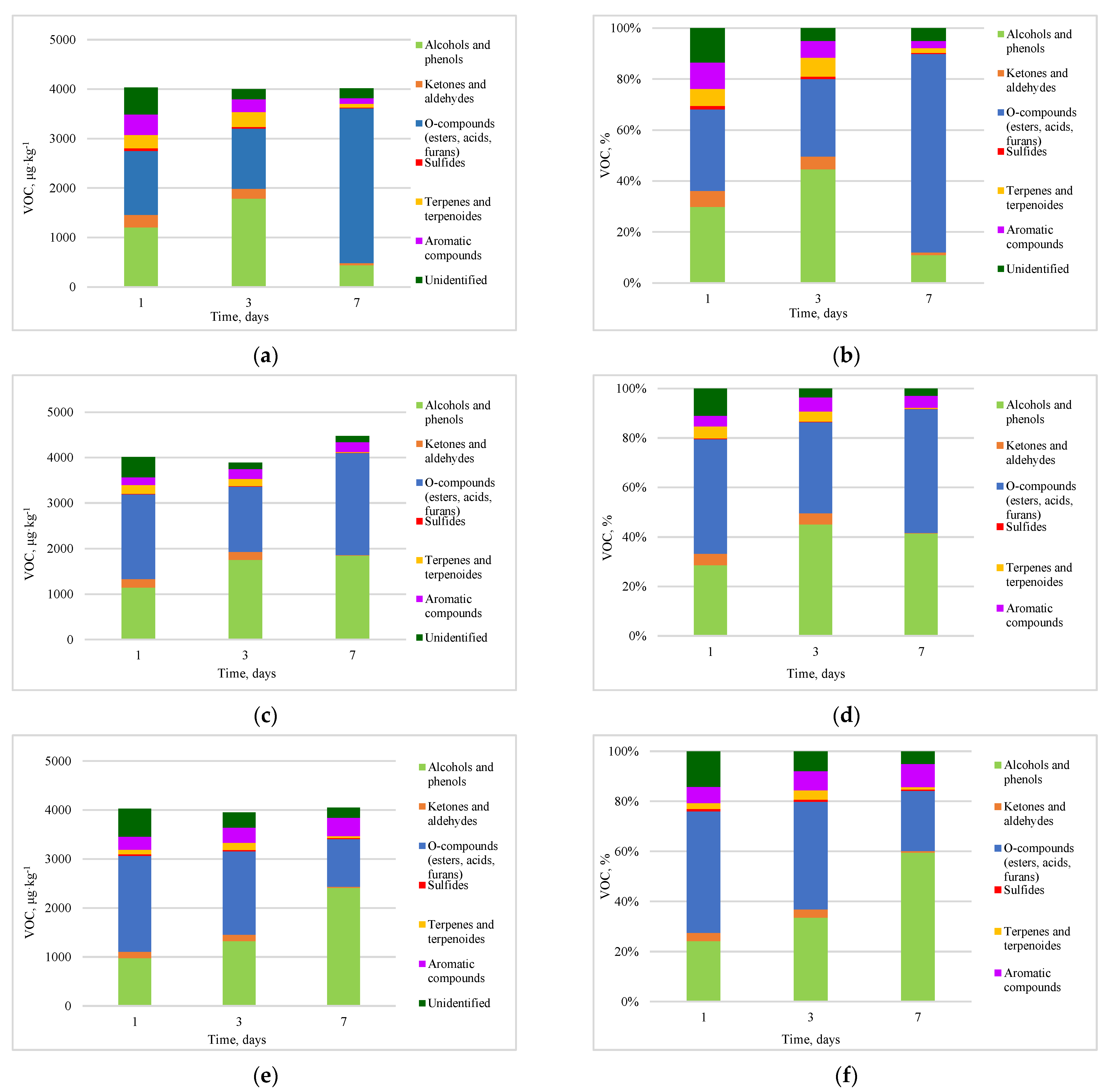

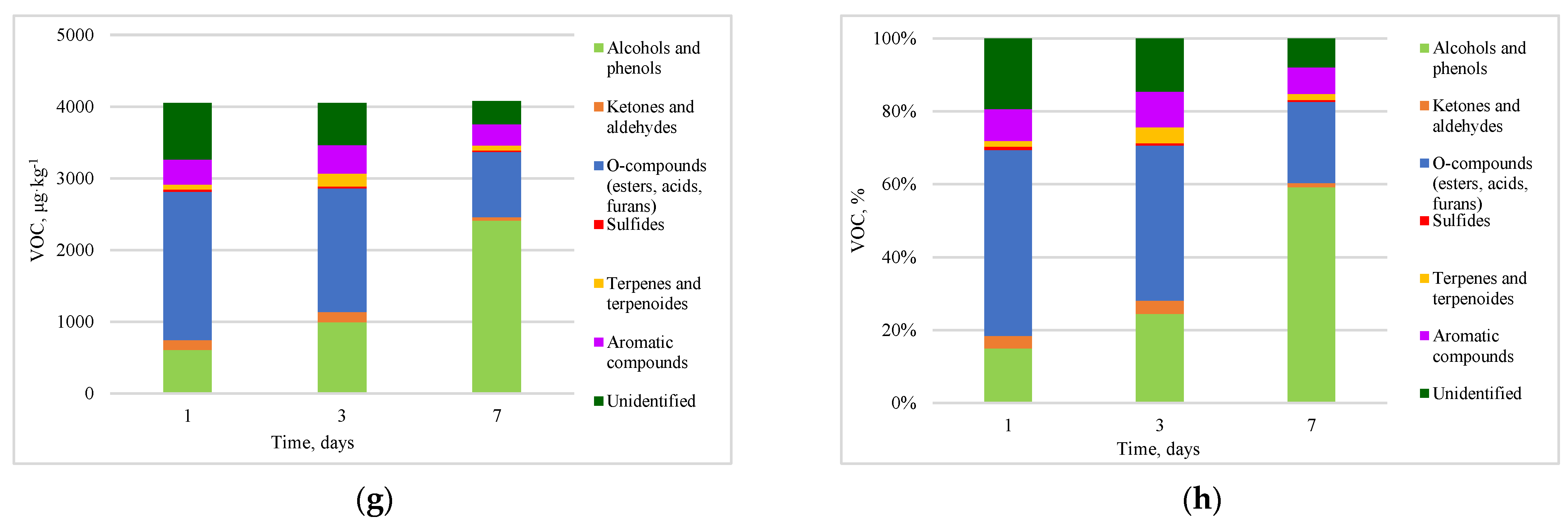

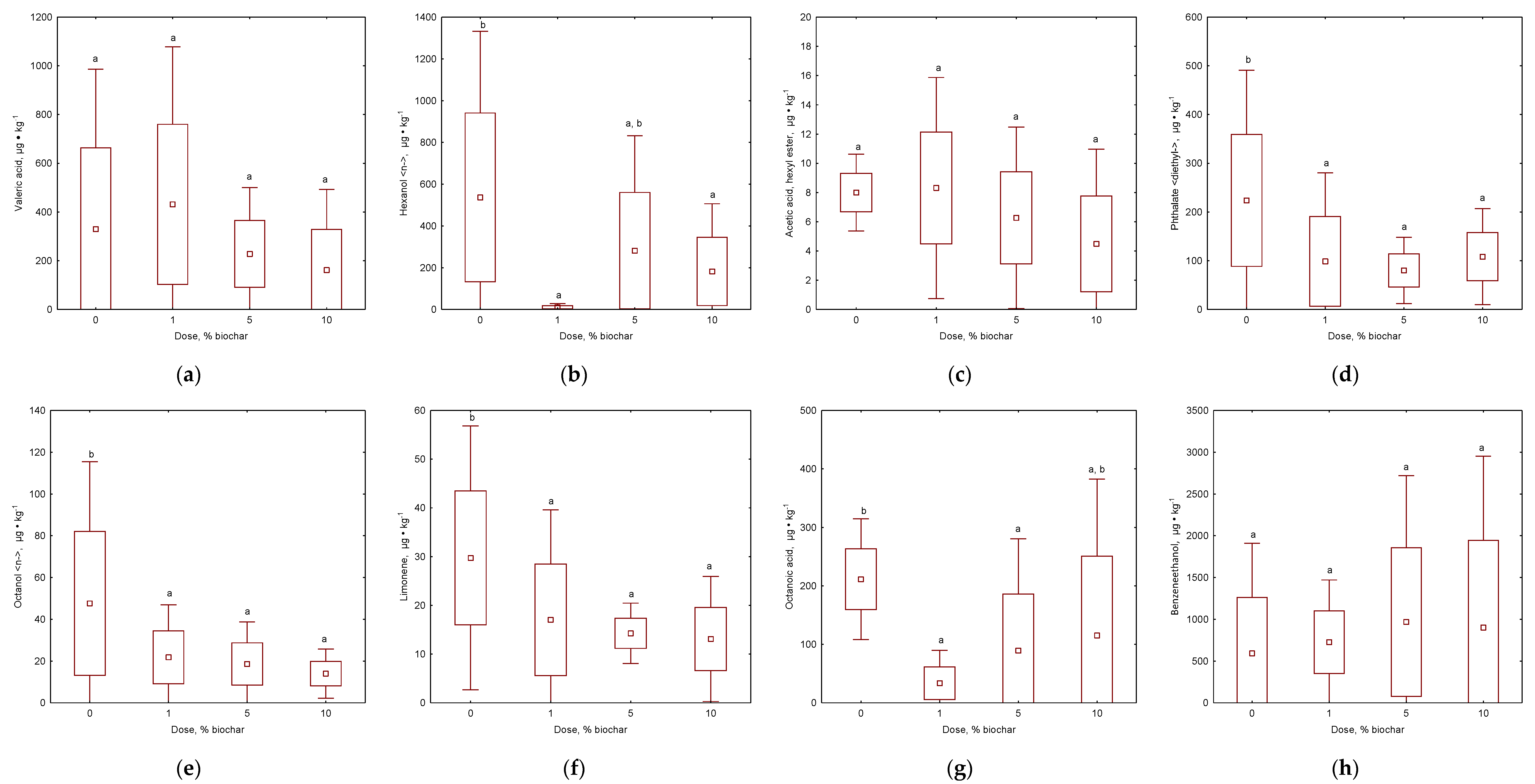

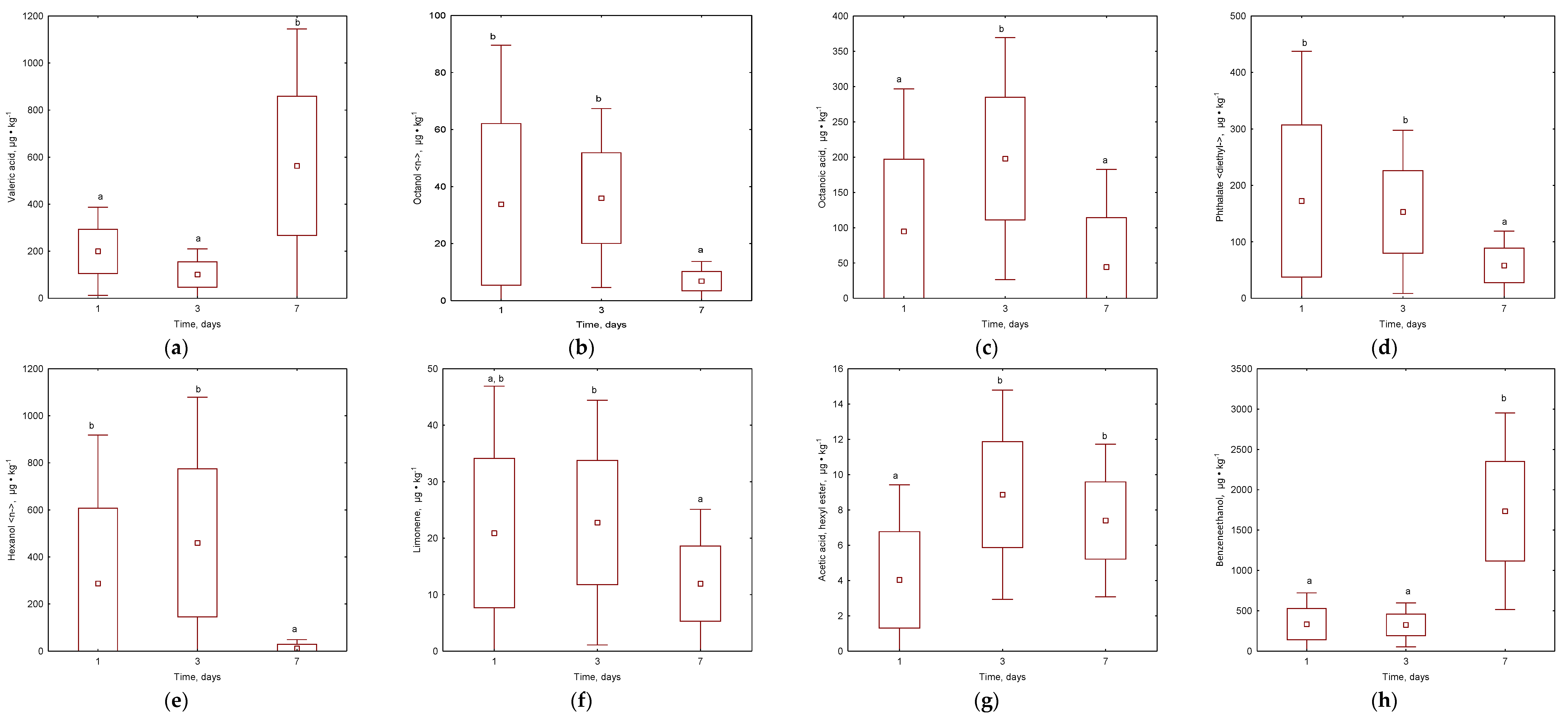

3.2. Emissions of VOC during the Incubation of Kitchen Waste at 20 °C

4. Conclusions

- The addition of composts’ biochar to kitchen waste demonstrated the significant removal of VOCs, with an over 70% reduction in VOCs emissions when 5–10% biochar was added.

- The most effective reduction was observed for unpleasant odours such as hexanol <-n> acetic acid, hexyl ester, and diethyl-phthalate, while no effect was observed for pleasant odours such as octanol <n->, limonene, octanoic acid, and benzene-ethanol.

- The high mineral fraction content of composts’ biochar suggests that the gaseous sorption of VOCs was more controlled by the non-carbonised organic matter content than physical adsorption.

- In total, 25% of the detected VOC compounds played a role in the plant, microorganism, and human metabolism, suggesting that composts’ biochar has a positive impact on overall metabolism and accelerates biodegradation.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, G.; Liu, J.; Shao, Z.; Chen, T. Emission Characteristics and Health Risk Assessment of VOCs from a Food Waste Anaerobic Digestion Plant: A Case Study of Suzhou, China. Environ. Pollut. 2020, 257, 113546. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Gao, Y.; Tan, L.; Wang, Q.; Li, Q.; Wei, X.; Liu, F.; Li, Y.; Zheng, X. Exploration of Bacterial Communities in Products after Composting Rural Wastes with Different Components: Core Microbiome and Potential Pathogenicity. Environ. Technol. Innov. 2022, 25, 102222. [Google Scholar] [CrossRef]

- Chai, F.; Li, P.; Li, L.; Qiu, Z.; Han, Y.; Yang, K. Dispersion, Olfactory Effect, and Health Risks of VOCs and Odors in a Rural Domestic Waste Transfer Station. Environ. Res. 2022, 209, 112879. [Google Scholar] [CrossRef] [PubMed]

- Chung, W.J.; Chang, S.W.; Chaudhary, D.K.; Shin, J.D.; Kim, H.; Karmegam, N.; Govarthanan, M.; Chandrasekaran, M.; Ravindran, B. Effect of Biochar Amendment on Compost Quality, Gaseous Emissions and Pathogen Reduction during in-Vessel Composting of Chicken Manure. Chemosphere 2021, 283, 131129. [Google Scholar] [CrossRef]

- Yang, K.; Wang, C.; Xue, S.; Li, W.; Liu, J.; Li, L. The Identification, Health Risks and Olfactory Effects Assessment of VOCs Released from the Wastewater Storage Tank in a Pesticide Plant. Ecotoxicol. Environ. Saf. 2019, 184, 109665. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Gao, X.; Qin, J.; Guo, Q.; Zhou, H.; Jin, W. Microporous Polyimide VOC-Rejective Membrane for the Separation of Nitrogen/VOC Mixture. J. Hazard. Mater. 2021, 402, 123817. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhao, S.; Cui, L.; Bi, F.; Zhang, Y.; Liu, N.; Wang, Y.; Liu, F.; He, C.; Zhang, X. Recent Advancement and Future Challenges of Photothermal Catalysis for VOCs Elimination: From Catalyst Design to Applications. Green Energy Environ. 2023, 8, 654–672. [Google Scholar] [CrossRef]

- Adelodun, A.A. Influence of Operation Conditions on the Performance of Non-Thermal Plasma Technology for VOC Pollution Control. J. Ind. Eng. Chem. 2020, 92, 41–55. [Google Scholar] [CrossRef]

- Vikrant, K.; Kim, K.H.; Peng, W.; Ge, S.; Sik Ok, Y. Adsorption Performance of Standard Biochar Materials against Volatile Organic Compounds in Air: A Case Study Using Benzene and Methyl Ethyl Ketone. Chem. Eng. J. 2020, 387, 123943. [Google Scholar] [CrossRef]

- Huang, H.; Chen, C.; Yang, R.; Yu, Y.; Albilali, R.; He, C. Remarkable Promotion Effect of Lauric Acid on Mn-MIL-100 for Non-Thermal Plasma-Catalytic Decomposition of Toluene. Appl. Surf. Sci. 2020, 503, 144290. [Google Scholar] [CrossRef]

- Barquilha, C.E.R.; Braga, M.C.B. Adsorption of Organic and Inorganic Pollutants onto Biochars: Challenges, Operating Conditions, and Mechanisms. Bioresour. Technol. Rep. 2021, 15, 100728. [Google Scholar] [CrossRef]

- Zhang, X.; Gao, B.; Zheng, Y.; Hu, X.; Creamer, A.E.; Annable, M.D.; Li, Y. Biochar for Volatile Organic Compound (VOC) Removal: Sorption Performance and Governing Mechanisms. Bioresour. Technol. 2017, 245, 606–614. [Google Scholar] [CrossRef] [PubMed]

- Nie, E.; Zheng, G.; Shao, Z.; Yang, J.; Chen, T. Emission Characteristics and Health Risk Assessment of Volatile Organic Compounds Produced during Municipal Solid Waste Composting. Waste Manag. 2018, 79, 188–195. [Google Scholar] [CrossRef]

- Duan, Y.; Awasthi, S.K.; Liu, T.; Zhang, Z.; Awasthi, M.K. Response of Bamboo Biochar Amendment on Volatile Fatty Acids Accumulation Reduction and Humification during Chicken Manure Composting. Bioresour. Technol. 2019, 291, 121845. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Monedero, M.A.; Sánchez-García, M.; Alburquerque, J.A.; Cayuela, M.L. Biochar Reduces Volatile Organic Compounds Generated during Chicken Manure Composting. Bioresour. Technol. 2019, 288, 121584. [Google Scholar] [CrossRef]

- Hwang, O.; Lee, S.R.; Cho, S.; Ro, K.S.; Spiehs, M.; Woodbury, B.; Silva, P.J.; Han, D.W.; Choi, H.; Kim, K.Y.; et al. Efficacy of Different Biochars in Removing Odorous Volatile Organic Compounds (VOCs) Emitted from Swine Manure. ACS Sustain. Chem. Eng. 2018, 6, 14239–14247. [Google Scholar] [CrossRef]

- Awasthi, M.K.; Awasthi, S.K.; Wang, Q.; Wang, Z.; Lahori, A.H.; Ren, X.; Chen, H.; Wang, M.; Zhao, J.; Zhang, Z. Influence of Biochar on Volatile Fatty Acids Accumulation and Microbial Community Succession during Biosolids Composting. Bioresour. Technol. 2018, 251, 158–164. [Google Scholar] [CrossRef]

- Czekała, W.; Malińska, K.; Cáceres, R.; Janczak, D.; Dach, J.; Lewicki, A. Co-Composting of Poultry Manure Mixtures Amended with Biochar—The Effect of Biochar on Temperature and C-CO2 Emission. Bioresour. Technol. 2016, 200, 921–927. [Google Scholar] [CrossRef]

- Zhang, X.; Miao, X.; Xiang, W.; Zhang, J.; Cao, C.; Wang, H.; Hu, X.; Gao, B. Ball Milling Biochar with Ammonia Hydroxide or Hydrogen Peroxide Enhances Its Adsorption of Phenyl Volatile Organic Compounds (VOCs). J. Hazard. Mater. 2021, 403, 123540. [Google Scholar] [CrossRef]

- Antunes, E.; Vuppaladadiyam, A.K.; Kumar, R.; Vuppaladadiyam, V.S.S.; Sarmah, A.; Anwarul Islam, M.; Dada, T. A Circular Economy Approach for Phosphorus Removal Using Algae Biochar. Clean. Circ. Bioecon. 2022, 1, 100005. [Google Scholar] [CrossRef]

- Bolognesi, S.; Bernardi, G.; Callegari, A.; Dondi, D.; Capodaglio, A.G. Biochar Production from Sewage Sludge and Microalgae Mixtures: Properties, Sustainability and Possible Role in Circular Economy. Biomass Convers. Biorefin. 2021, 11, 289–299. [Google Scholar] [CrossRef]

- Hu, Q.; Jung, J.; Chen, D.; Leong, K.; Song, S.; Li, F.; Mohan, B.C.; Yao, Z.; Prabhakar, A.K.; Lin, X.H.; et al. Biochar Industry to Circular Economy. Sci. Total Environ. 2021, 757, 143820. [Google Scholar] [CrossRef] [PubMed]

- Danish, A.; Ali Mosaberpanah, M.; Usama Salim, M.; Ahmad, N.; Ahmad, F.; Ahmad, A. Reusing Biochar as a Filler or Cement Replacement Material in Cementitious Composites: A Review. Constr. Build. Mater. 2021, 300, 124295. [Google Scholar] [CrossRef]

- Wang, C.; Luo, D.; Zhang, X.; Huang, R.; Cao, Y.; Liu, G.; Zhang, Y.; Wang, H. Biochar-Based Slow-Release of Fertilizers for Sustainable Agriculture: A Mini Review. Environ. Sci. Ecotechnol. 2022, 10, 100167. [Google Scholar] [CrossRef]

- Lateef, A.; Nazir, R.; Jamil, N.; Alam, S.; Shah, R.; Khan, M.N.; Saleem, M.; Rehman, S. ur Synthesis and Characterization of Environmental Friendly Corncob Biochar Based Nano-Composite—A Potential Slow Release Nano-Fertilizer for Sustainable Agriculture. Environ. Nanotechnol. Monit. Manag. 2019, 11, 100212. [Google Scholar] [CrossRef]

- Qiu, M.; Liu, L.; Ling, Q.; Cai, Y.; Yu, S.; Wang, S.; Fu, D.; Hu, B.; Wang, X. Biochar for the Removal of Contaminants from Soil and Water: A Review. Biochar 2022, 4, 19. [Google Scholar] [CrossRef]

- Dahal, R.K.; Acharya, B.; Farooque, A. Biochar: A Sustainable Solution for Solid Waste Management in Agro-Processing Industries. Biofuels 2018, 12, 237–245. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, X.; Lichtfouse, E.; Jiang, H.; Wang, C. Conversion of Waste Plastics into Value-Added Carbon Materials. Environ. Chem. Lett. 2023. [Google Scholar] [CrossRef]

- Luo, D.; Wang, L.; Nan, H.; Cao, Y.; Wang, H.; Kumar, T.V.; Wang, C. Phosphorus Adsorption by Functionalized Biochar: A Review. Environ. Chem. Lett. 2022, 21, 497–524. [Google Scholar] [CrossRef]

- Cesaro, A.; Belgiorno, V. ChemInform Abstract: Pretreatment Methods to Improve Anaerobic Biodegradability of Organic Municipal Solid Waste Fractions. ChemInform 2014, 45, 24–37. [Google Scholar] [CrossRef]

- Phares, C.A.; Akaba, S. Co-Application of Compost or Inorganic NPK Fertilizer with Biochar Influences Soil Quality, Grain Yield and Net Income of Rice. J. Integr. Agric. 2022, 21, 3600–3610. [Google Scholar] [CrossRef]

- Konaka, T.; Tadano, S.; Takahashi, T.; Suharsono, S.; Mazereku, C.; Tsujimoto, H.; Masunaga, T.; Yamamoto, S.; Akashi, K. A Diverse Range of Physicochemically-Distinct Biochars Made from a Combination of Different Feedstock Tissues and Pyrolysis Temperatures from a Biodiesel Plant Jatropha Curcas: A Comparative Study. Ind. Crops Prod. 2021, 159, 113060. [Google Scholar] [CrossRef]

- Medyńska-Juraszek, A.; Bednik, M.; Chohura, P. Assessing the Influence of Compost and Biochar Amendments on the Mobility and Uptake of Heavy Metals by Green Leafy Vegetables. Int. J. Environ. Res. Public Health 2020, 17, 7861. [Google Scholar] [CrossRef] [PubMed]

- Addai, P.; Mensah, A.K.; Sekyi-Annan, E.; Adjei, E.O. Biochar, Compost and/or NPK Fertilizer Affect the Uptake of Potentially Toxic Elements and Promote the Yield of Lettuce Grown in an Abandoned Gold Mine Tailing. J. Trace Elem. Miner. 2023, 4, 100066. [Google Scholar] [CrossRef]

- Białowiec, A.; Micuda, M.; Szumny, A.; Łyczko, J.; Koziel, J.A. The Proof-of-the-Concept of Application of Pelletization for Mitigation of Volatile Organic Compounds Emissions from Carbonized Refuse-Derived Fuel. Materials 2019, 12, 1692. [Google Scholar] [CrossRef]

- Mujtaba, G.; Hayat, R.; Hussain, Q.; Ahmed, M. Physio-Chemical Characterization of Biochar, Compost and Co-Composted Biochar Derived from Green Waste. Sustainability 2021, 13, 4628. [Google Scholar] [CrossRef]

- Silva, A.C.; Rocha, P.; Antelo, J.; Valderrama, P.; López, R.; Geraldo, D.; Proença, M.F.; Pinheiro, J.P.; Fiol, S.; Bento, F. Comparison of a Variety of Physico-Chemical Techniques in the Chronological Characterization of a Compost from Municipal Wastes. Process Saf. Environ. Prot. 2022, 164, 781–793. [Google Scholar] [CrossRef]

- Rueda, M.P.; Comino, F.; Aranda, V.; José Ayora-Cañada, M.; Domínguez-Vidal, A. Understanding the Compositional Changes of Organic Matter in Torrefied Olive Mill Pomace Compost Using Infrared Spectroscopy and Chemometrics. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2023, 293, 122450. [Google Scholar] [CrossRef]

- Maulini-Duran, C.; Puyuelo, B.; Artola, A.; Font, X.; Sánchez, A.; Gea, T. VOC Emissions from the Composting of the Organic Fraction of Municipal Solid Waste Using Standard and Advanced Aeration Strategies. J. Chem. Technol. Biotechnol. 2014, 89, 579–586. [Google Scholar] [CrossRef]

- Zhang, Y.; Yue, D.; Liu, J.; Lu, P.; Wang, Y.; Liu, J.; Nie, Y. Release of Non-Methane Organic Compounds during Simulated Landfilling of Aerobically Pretreated Municipal Solid Waste. J. Environ. Manag. 2012, 101, 54–58. [Google Scholar] [CrossRef]

- Sánchez-García, M.; Alburquerque, J.A.; Sánchez-Monedero, M.A.; Roig, A.; Cayuela, M.L. Biochar Accelerates Organic Matter Degradation and Enhances N Mineralisation during Composting of Poultry Manure without a Relevant Impact on Gas Emissions. Bioresour. Technol. 2015, 192, 272–279. [Google Scholar] [CrossRef]

- Pierucci, P.; Porazzi, E.; Martinez, M.P.; Adani, F.; Carati, C.; Rubino, F.M.; Colombi, A.; Calcaterra, E.; Benfenati, E. Volatile Organic Compounds Produced during the Aerobic Biological Processing of Municipal Solid Waste in a Pilot Plant. Chemosphere 2005, 59, 423–430. [Google Scholar] [CrossRef]

- Statheropoulos, M.; Agapiou, A.; Pallis, G. A Study of Volatile Organic Compounds Evolved in Urban Waste Disposal Bins. Atmos. Environ. 2005, 39, 4639–4645. [Google Scholar] [CrossRef]

- Scaglia, B.; Orzi, V.; Artola, A.; Font, X.; Davoli, E.; Sanchez, A.; Adani, F. Odours and Volatile Organic Compounds Emitted from Municipal Solid Waste at Different Stage of Decomposition and Relationship with Biological Stability. Bioresour. Technol. 2011, 102, 4638–4645. [Google Scholar] [CrossRef] [PubMed]

- Akdeniz, N.; Koziel, J.A.; Ahn, H.K.; Glanville, T.D.; Crawford, B.P.; Raman, D.R. Laboratory Scale Evaluation of Volatile Organic Compound Emissions as Indication of Swine Carcass Degradation inside Biosecure Composting Units. Bioresour. Technol. 2010, 101, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Świechowski, K.; Matyjewicz, B.; Telega, P.; Białowiec, A. The Influence of Low-Temperature Food Waste Biochars on Anaerobic Digestion of Food Waste. Materials 2022, 15, 945. [Google Scholar] [CrossRef]

- Turan, N.G.; Akdemir, A.; Ergun, O.N. Emission of Volatile Organic Compounds during Composting of Poultry Litter. Water Air Soil Pollut. 2007, 184, 177–182. [Google Scholar] [CrossRef]

- Sun, D.; Lan, Y.; Xu, E.G.; Meng, J.; Chen, W. Biochar as a Novel Niche for Culturing Microbial Communities in Composting. Waste Manag. 2016, 54, 93–100. [Google Scholar] [CrossRef]

- Maulini-Duran, C.; Artola, A.; Font, X.; Sánchez, A. Gaseous Emissions in Municipal Wastes Composting: Effect of the Bulking Agent. Bioresour. Technol. 2014, 172, 260–268. [Google Scholar] [CrossRef]

- Staley, B.F.; Xu, F.; Cowie, S.J.; Barlaz, M.A.; Hater, G.R. Release of Trace Organic Compounds during the Decomposition of Municipal Solid Waste Components. Environ. Sci. Technol. 2006, 40, 5984–5991. [Google Scholar] [CrossRef]

- Dorado, A.D.; Husni, S.; Pascual, G.; Puigdellivol, C.; Gabriel, D. Inventory and Treatment of Compost Maturation Emissions in a Municipal Solid Waste Treatment Facility. Waste Manag. 2014, 34, 344–351. [Google Scholar] [CrossRef]

- Yang, K.; Xue, F.; Sun, Q.; Yue, R.; Lin, D. Adsorption of Volatile Organic Compounds by Metal-Organic Frameworks MOF-177. J. Environ. Chem. Eng. 2013, 1, 713–718. [Google Scholar] [CrossRef]

- Agapiou, A.; Vamvakari, J.P.; Andrianopoulos, A.; Pappa, A. Volatile Emissions during Storing of Green Food Waste under Different Aeration Conditions. Environ. Sci. Pollut. Res. 2016, 23, 8890–8901. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Gao, B.; Creamer, A.E.; Cao, C.; Li, Y. Adsorption of VOCs onto Engineered Carbon Materials: A Review. J. Hazard. Mater. 2017, 338, 102–123. [Google Scholar] [CrossRef] [PubMed]

| Substrate | CEC, cmol(+)‧kg−1 | N-NH4, mg‧kg−1 d.m. | N-NO3, mg‧kg−1 d.m. | LOI, % d.m. | pH, - | Moisture, % | EC, mS‧cm−1 |

|---|---|---|---|---|---|---|---|

| Compost | 143.28 | 125.85 | 1322.03 | 34 | 7.09 | 1.71 | 2.88 |

| Biochar | 123.92 | 55.99 | 16.03 | 19 | 6.92 | 40.20 | n.d. |

| Kitchen waste | Day 1 | 4.92 | 80.05 | 2.05 | |||

| Day 7 | 3.87 | 79.95 | 1.91 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosik, J.; Łyczko, J.; Marzec, Ł.; Stegenta-Dąbrowska, S. Application of Composts’ Biochar as Potential Sorbent to Reduce VOCs Emission during Kitchen Waste Storage. Materials 2023, 16, 6413. https://doi.org/10.3390/ma16196413

Rosik J, Łyczko J, Marzec Ł, Stegenta-Dąbrowska S. Application of Composts’ Biochar as Potential Sorbent to Reduce VOCs Emission during Kitchen Waste Storage. Materials. 2023; 16(19):6413. https://doi.org/10.3390/ma16196413

Chicago/Turabian StyleRosik, Joanna, Jacek Łyczko, Łukasz Marzec, and Sylwia Stegenta-Dąbrowska. 2023. "Application of Composts’ Biochar as Potential Sorbent to Reduce VOCs Emission during Kitchen Waste Storage" Materials 16, no. 19: 6413. https://doi.org/10.3390/ma16196413

APA StyleRosik, J., Łyczko, J., Marzec, Ł., & Stegenta-Dąbrowska, S. (2023). Application of Composts’ Biochar as Potential Sorbent to Reduce VOCs Emission during Kitchen Waste Storage. Materials, 16(19), 6413. https://doi.org/10.3390/ma16196413