Evaluation of the Superiority of Lightweight-Aggregate-Concrete Prestressed Box Girders in Terms of Durability and Prestress Loss

Abstract

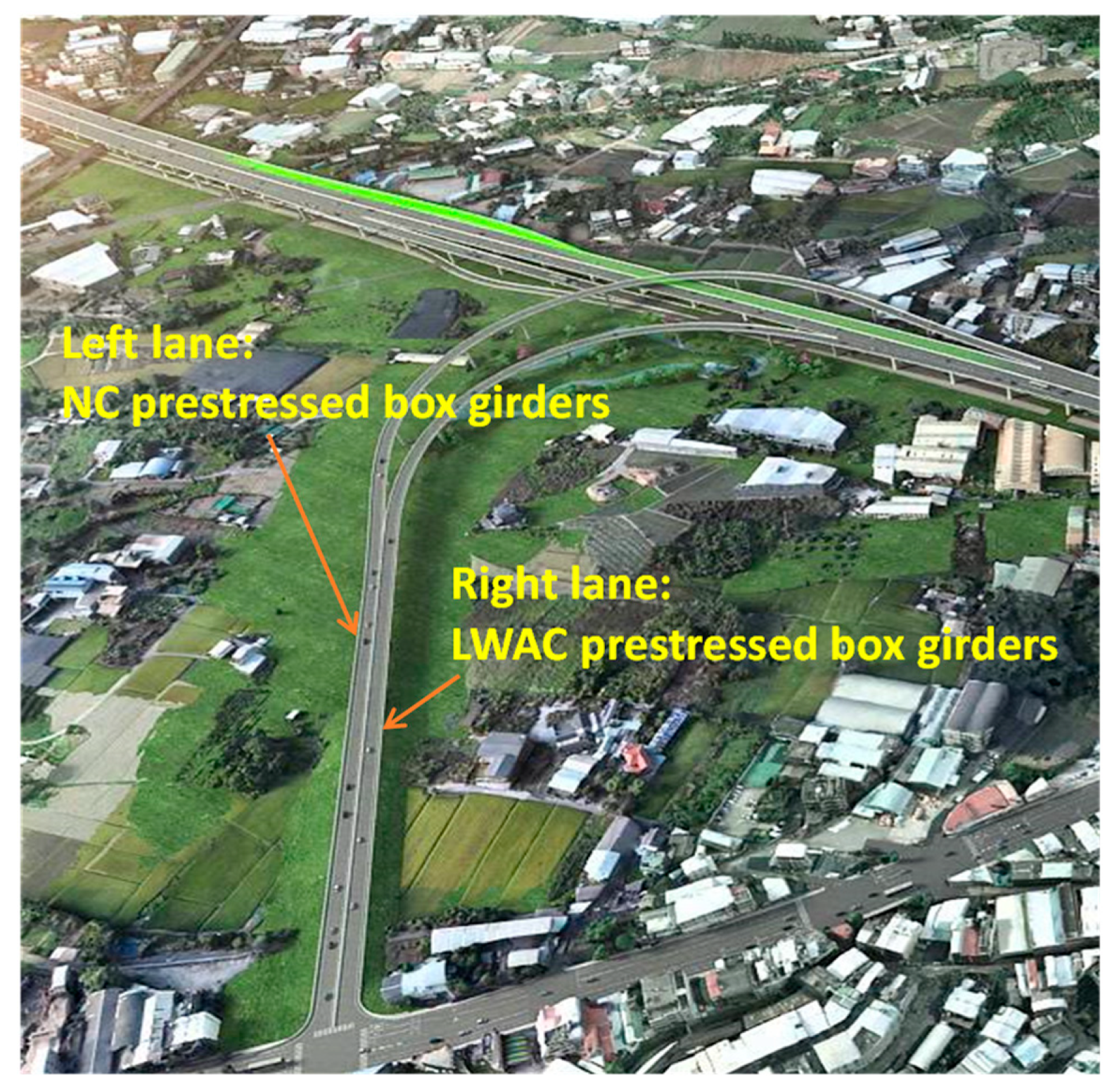

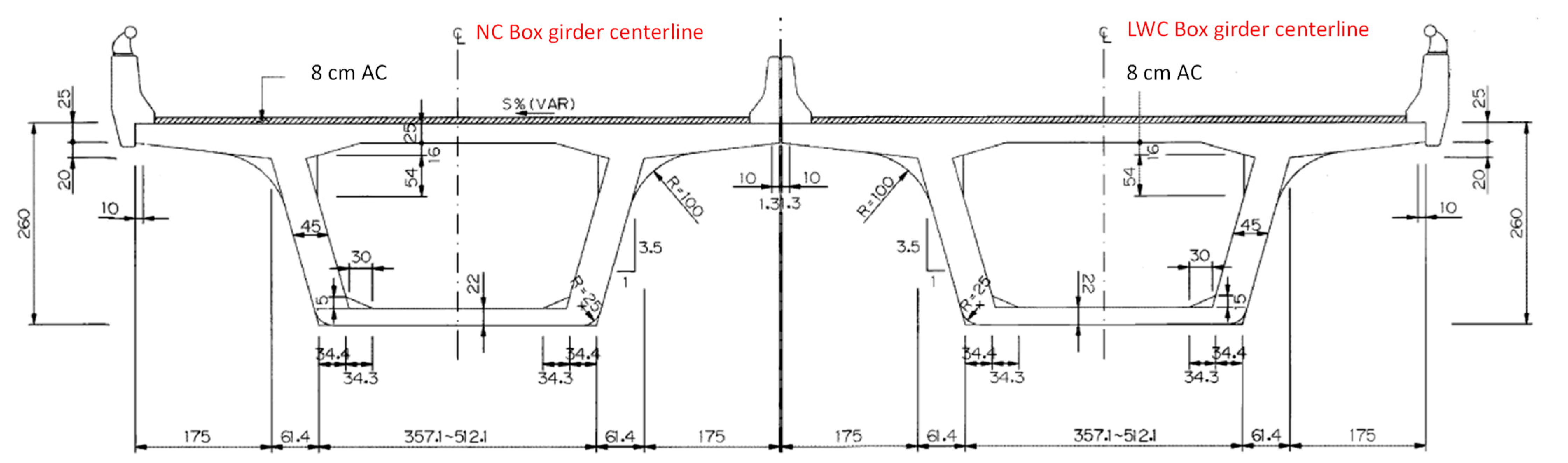

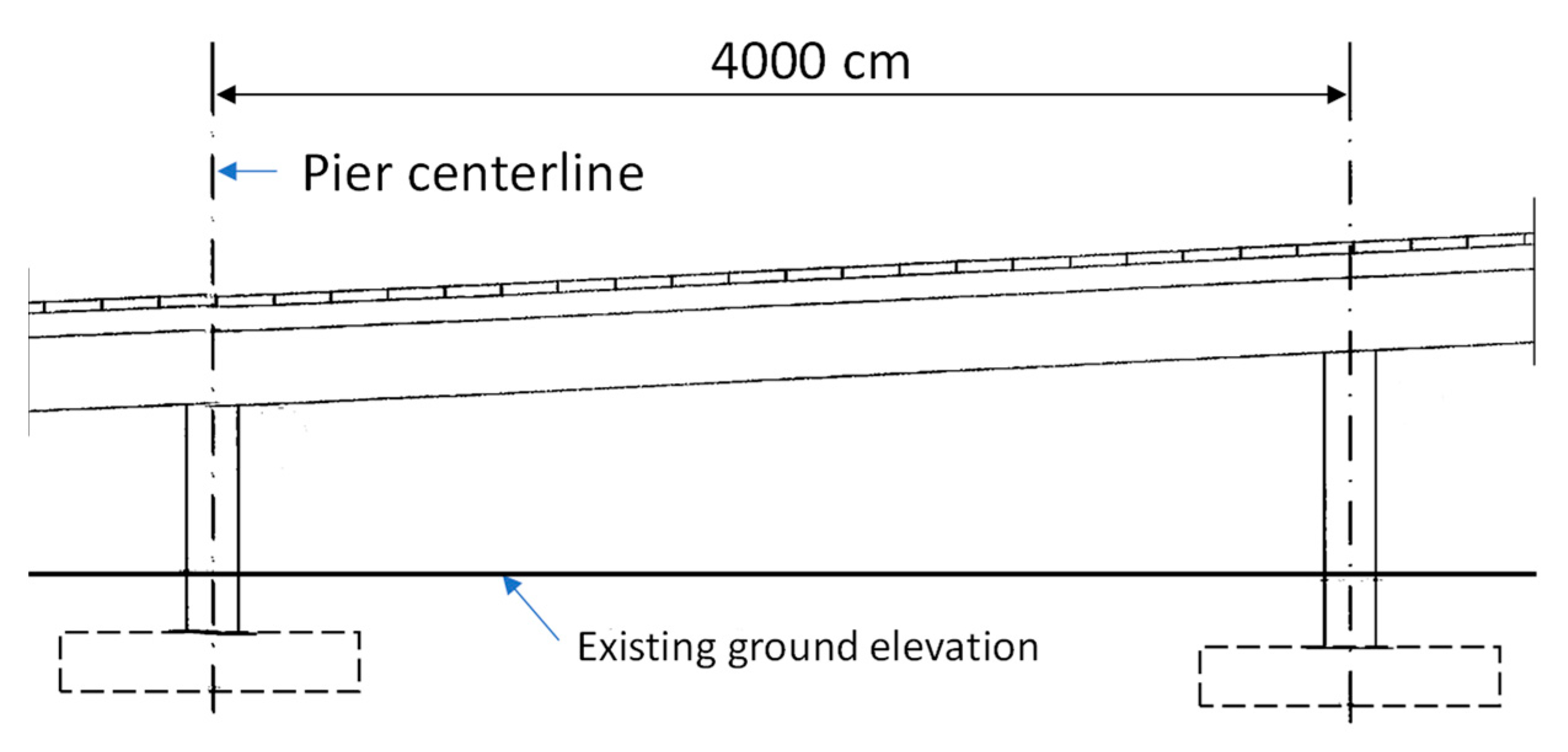

:1. Introduction

2. Materials and Methods

2.1. Materials

- Cement: a locally produced Type I Portland cement, with a specific gravity of 3.15 and a fineness of 3550 cm2/g; its chemical composition is shown in Table 1;

- Slag: purchased from Yu Qingtang Enterprise, Taichung, Taiwan; its specific gravity was 2.89, and its chemical composition is shown in Table 1;

- Fly ash: taken from Taichung Thermal Power Plant, Taichung, Taiwan; its specific gravity was 2.32, and its chemical composition is shown in Table 1;

- Silica fume: purchased from Elkem Taiwan, Taichung, Taiwan; its specific gravity was 2.1, and its chemical composition is shown in Table 1;

- Water: general tap water, which was in line with the general quality requirements of concrete mixing water;

- Fine aggregate: a natural river sand with an FM value of 2.67, a specific gravity of 2.63, and a 24 h water absorption rate of 1.3%;

- Coarse aggregate: a natural crushed stone with a specific gravity of 2.64 and a 24 h water absorption rate of 0.7%;

- Superplasticizer: purchased from An-Yao Company; it met the requirements of ASTM C494-81 [61] Type F.

2.2. Mix Proportions of Concrete

2.3. Casting and Curing of Specimens and Test Methods

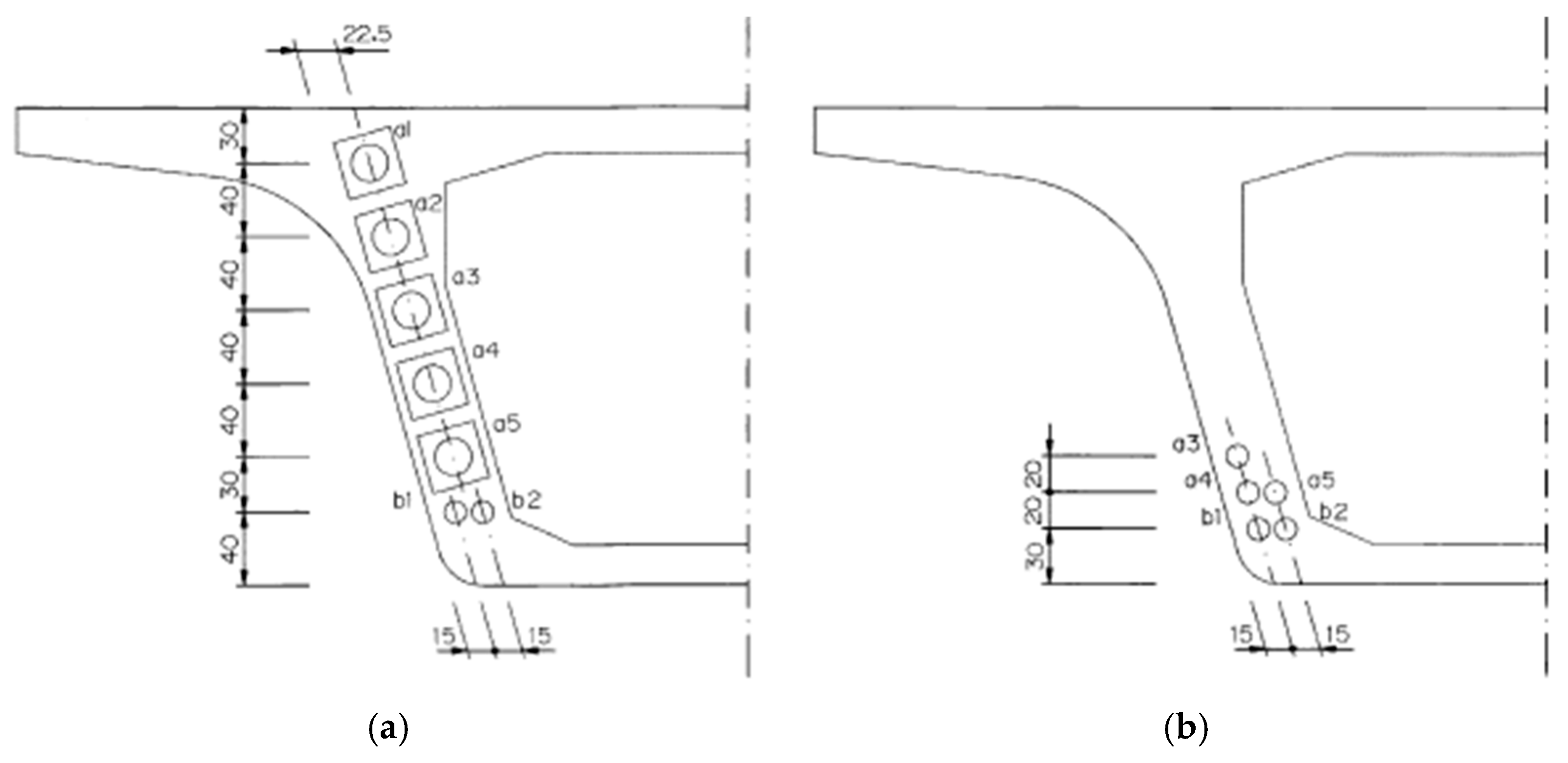

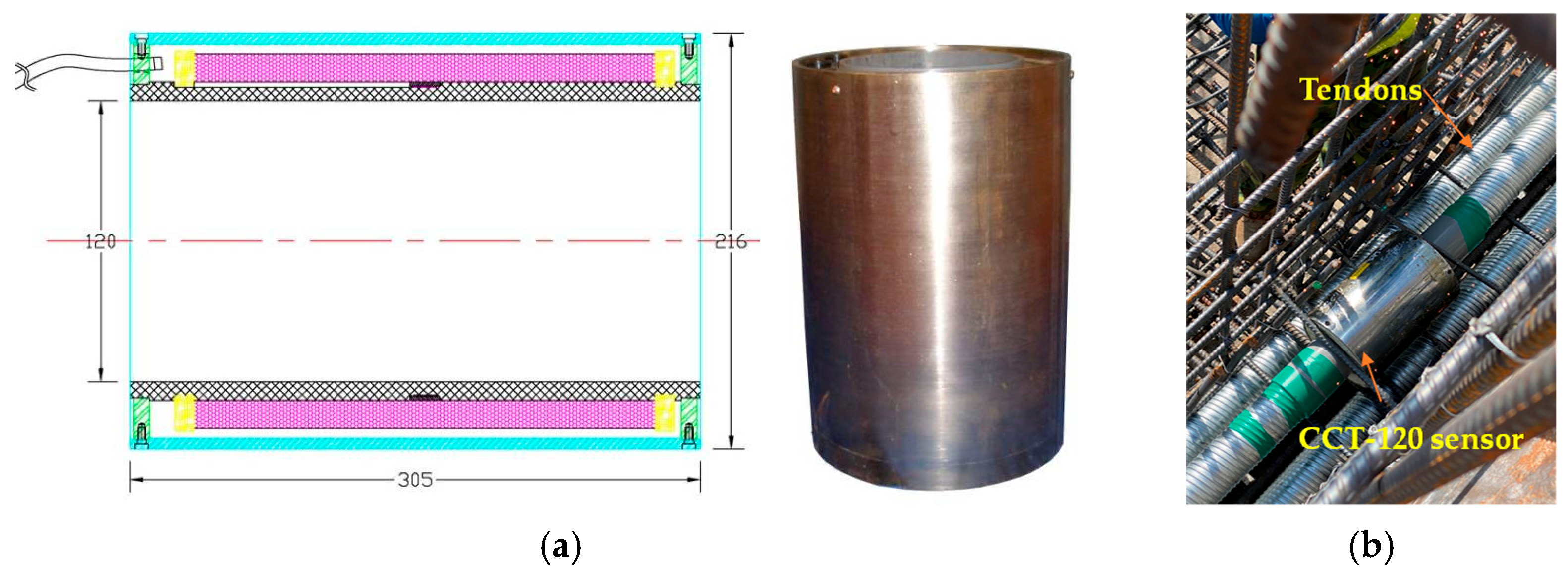

2.4. Prestress-Loss Monitoring of Prestressed Tendons

3. Results and Discussion

3.1. Test Results of the Basic Properties and Time-Dependent Deformation of Concrete

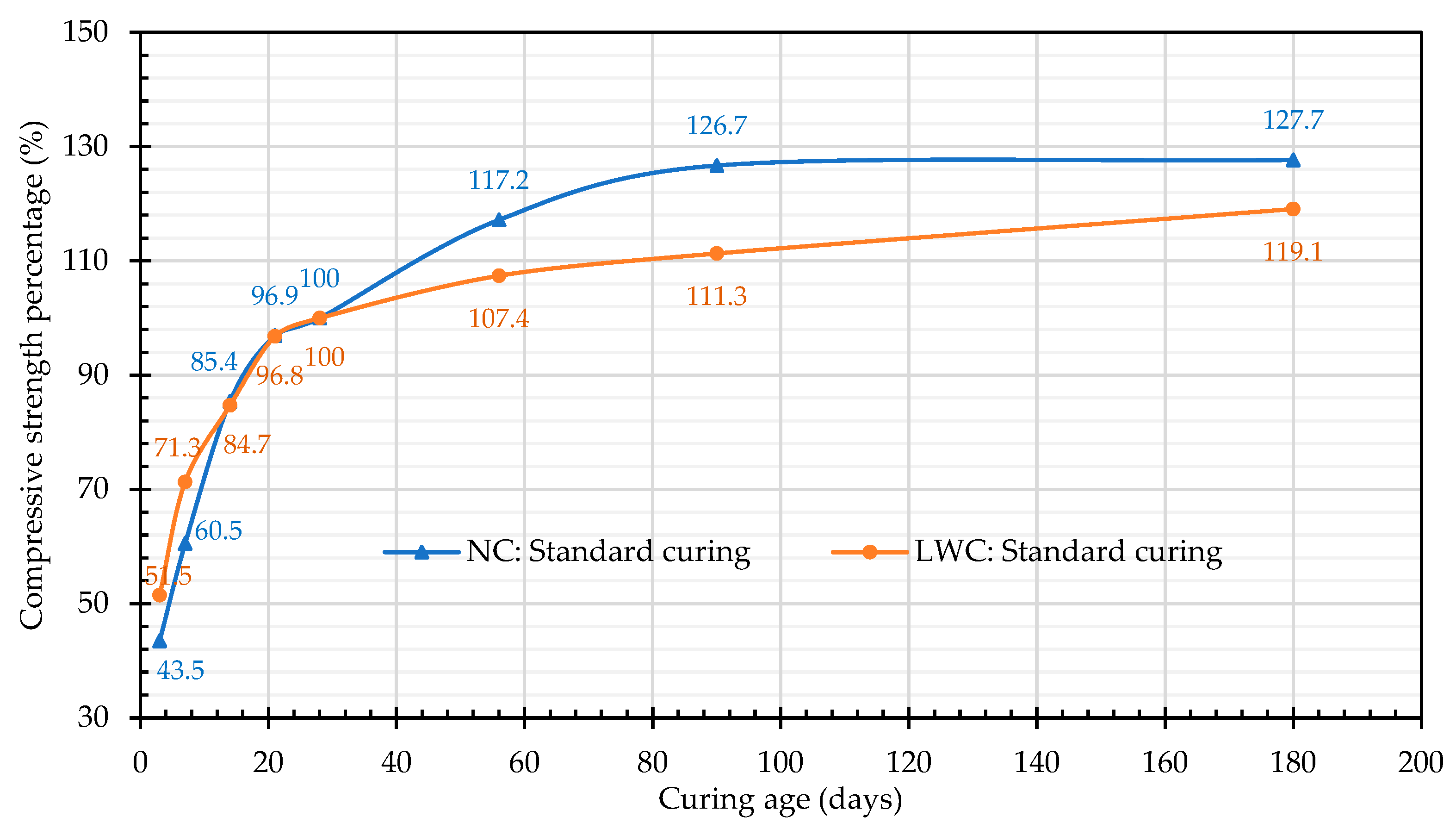

3.1.1. Results of the Air-Dried Unit Weight and Compressive-Strength Tests

3.1.2. Results of the Flexural-Strength and Splitting-Tensile-Strength Tests

3.1.3. Results of Elastic-Modulus Test

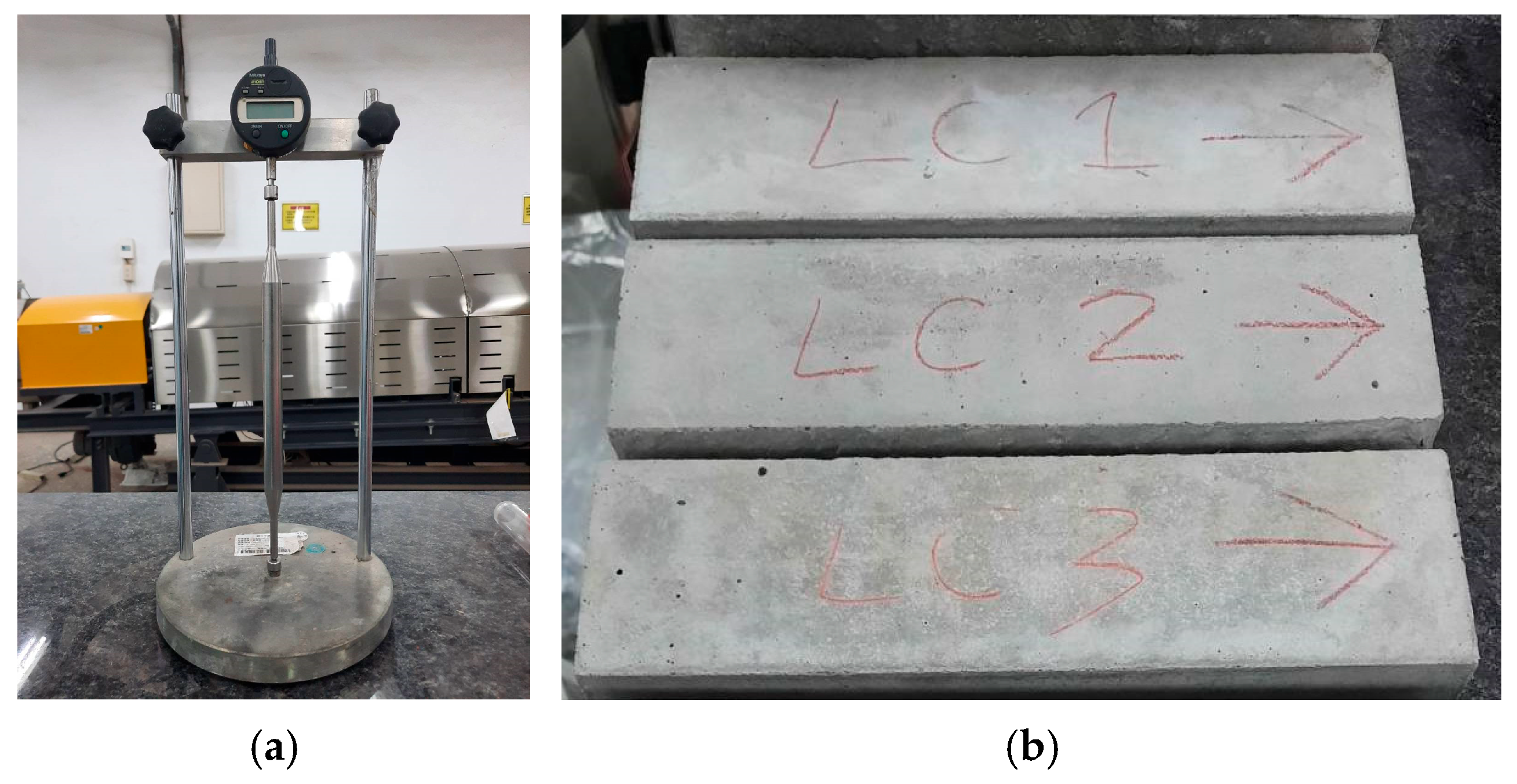

3.1.4. Results of the Drying Shrinkage Test

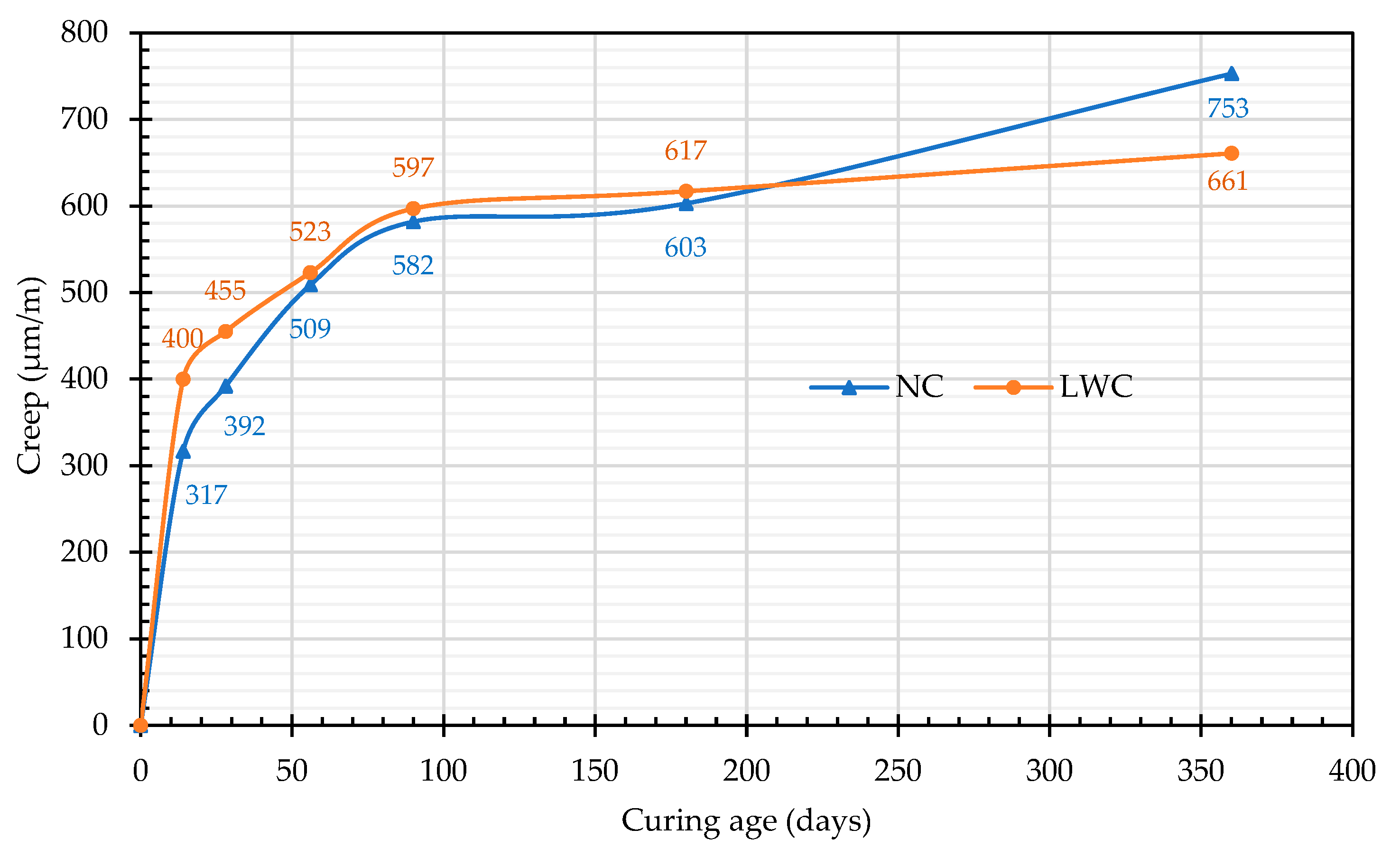

3.1.5. Results of Creep Test

3.2. Test Results of Concrete Durability

3.2.1. Results of the Ultrasonic Pulse Velocity Test

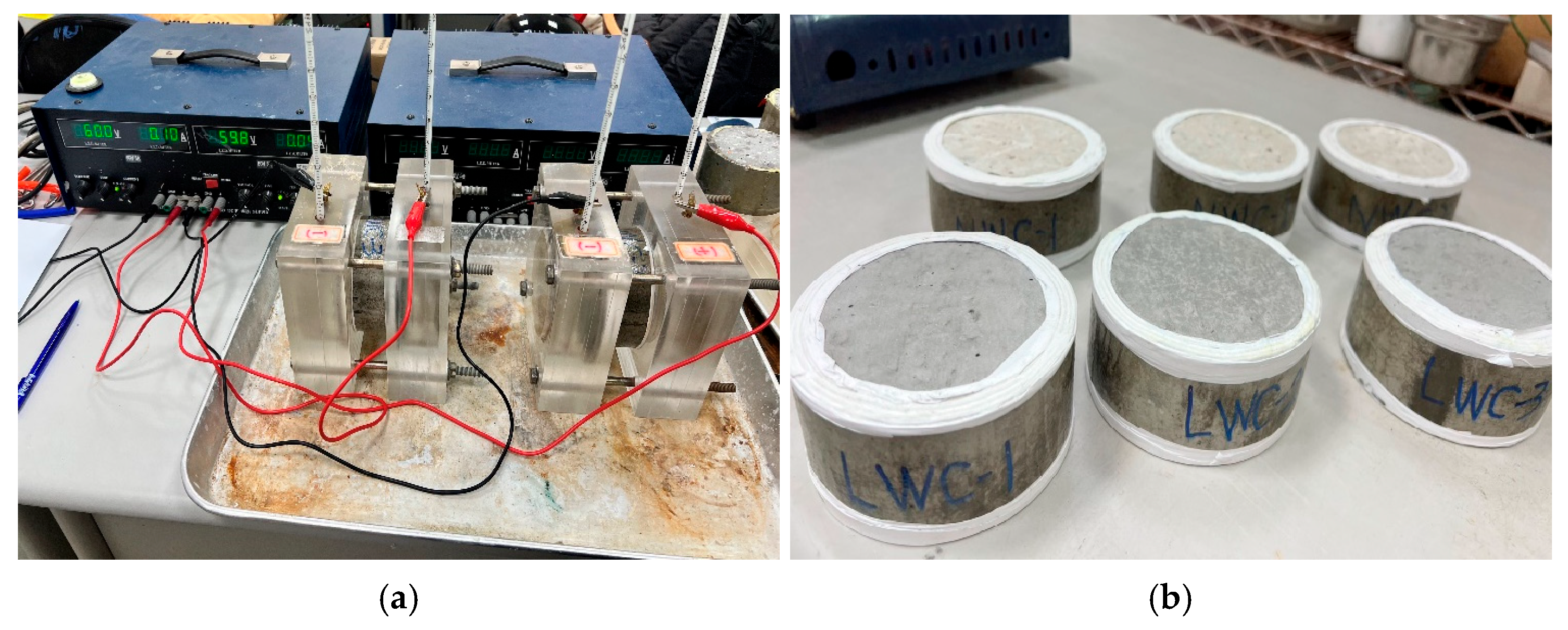

3.2.2. Results for the Electrical Indication of the Concrete’s Ability to Resist the Chloride Ion Penetration Test

3.2.3. Results of the Chloride Ion Penetration Test

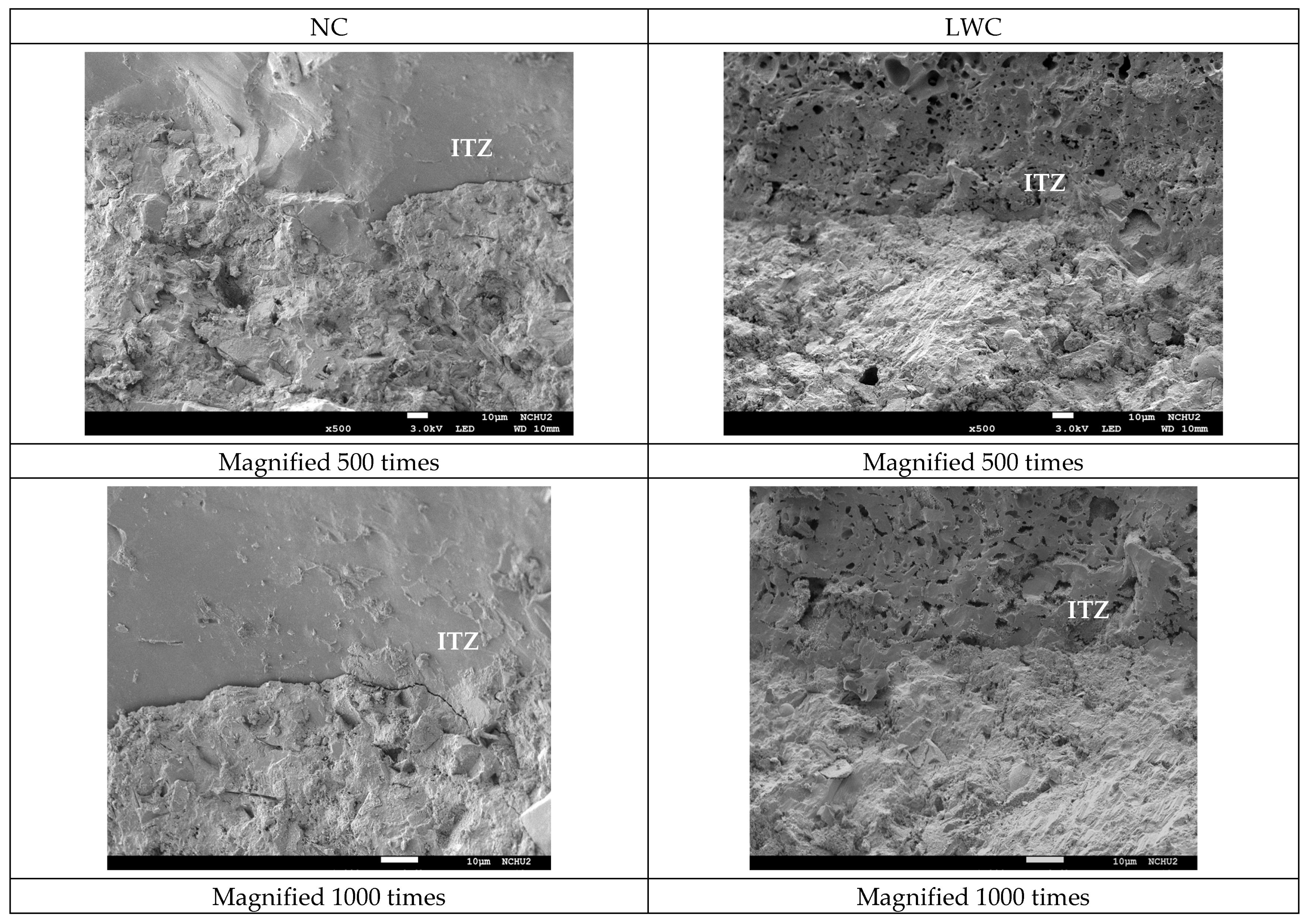

3.2.4. Results of the Scanning Electron Microscope Observation

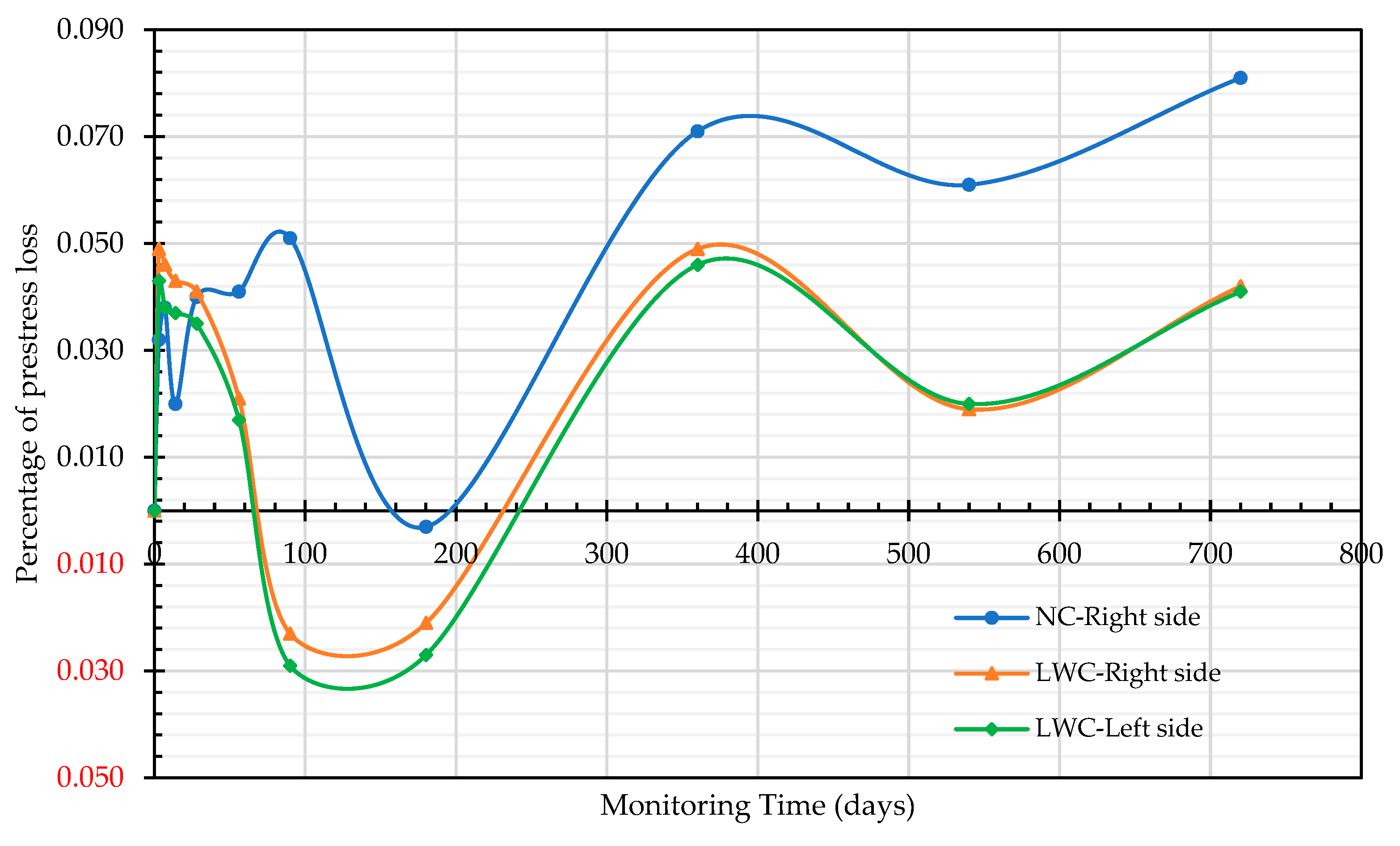

3.3. Results of Prestress-Loss Monitoring of Prestressed Tendons

3.4. Summary of Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2006. [Google Scholar]

- Mindess, S.; Young, J.F. Concrete; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 1981; pp. 521–532. [Google Scholar]

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete; NJ Noyes Publications: Norwich, UK, 2003. [Google Scholar]

- DIN EN 13055; Leichte Gesteinskörnungen (Lightweight Aggregates). Beuth-Verlag: Berlin, Germany, 2016; p. 58.

- Cheeseman, C.R.; Virdi, G.S. Properties and microstructure of lightweight aggregate produced from sintered sewage sludge ash. Resour. Conserv. Recycl. 2005, 45, 18–30. [Google Scholar] [CrossRef]

- Mun, K.J. Development and tests of lightweight aggregate using sewage sludge for nonstructural concrete. Constr. Build. Mater. 2007, 21, 1583–1588. [Google Scholar] [CrossRef]

- Tang, C.W.; Chen, H.J.; Wang, S.Y.; Spaulding, J. Production of synthetic lightweight aggregate using reservoir sediments for concrete and masonry. Cem. Concr. Compos. 2011, 33, 292–300. [Google Scholar] [CrossRef]

- Chen, H.J.; Yang, M.D.; Tang, C.W.; Wang, S.Y. Producing synthetic lightweight aggregates from reservoir sediments. Constr. Build. Mater. 2012, 28, 387–394. [Google Scholar] [CrossRef]

- Tang, C.W. Producing synthetic lightweight aggregates by treating waste TFT-LCD glass powder and reservoir sediments. Comput. Concr. 2014, 13, 325–342. [Google Scholar] [CrossRef]

- Liu, M.; Wang, C.; Bai, Y.; Xu, G. Effects of sintering temperature on the characteristics of lightweight aggregate made from sewage sludge and river sediment. J. Alloys Compd. 2018, 748, 522–527. [Google Scholar] [CrossRef]

- Porcino, D.D.; Mauriello, F.; Bonaccorsi, L.; Tomasello, G.; Paone, E.; Malara, A. Recovery of Biomass Fly Ash and HDPE in Innovative Synthetic Lightweight Aggregates for Sustainable Geotechnical Applications. Sustainability 2020, 12, 6552. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, K.G.; Lee, Y.S.; Wie, Y.M. Manufacturing and application of artificial lightweight aggregate from water treatment sludge. J. Clean. Prod. 2021, 307, 127260. [Google Scholar] [CrossRef]

- Nguyen, H.P.; Mueller, A.; Nguyen, V.T.; Nguyen, C.T. Development and characterization of lightweight aggregate recycled from construction and demolition waste mixed with other industrial by-products. Constr. Build. Mater. 2021, 313, 125472. [Google Scholar] [CrossRef]

- Tang, C.-W.; Cheng, C.-K. Sustainable Use of Sludge from Industrial Park Wastewater Treatment Plants in Manufacturing Lightweight Aggregates. Materials 2022, 15, 1785. [Google Scholar] [CrossRef]

- Chen, H.-J.; Chang, W.-T.; Tang, C.-W.; Peng, C.-F. A Feasibility Study on Textile Sludge as a Raw Material for Sintering Lightweight Aggregates and Its Application in Concrete. Appl. Sci. 2023, 13, 6395. [Google Scholar] [CrossRef]

- Chen, H.-J.; Wu, K.-C.; Tang, C.-W.; Huang, C.-H. Engineering Properties of Self-Consolidating Lightweight Aggregate Concrete and Its Application in Prestressed Concrete Members. Sustainability 2018, 10, 142. [Google Scholar] [CrossRef]

- ACI Committee 213. ACI 213R-14 Guide for Structural Lightweight-Aggregate Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2014; p. 53. [Google Scholar]

- Ramirez, J.A.; Olek, J.; Rolle, E.J.; Manlone, B.J. Performance of Bridge Decks and Girders with Lightweight Aggregate Concrete; Publication FHWA/IN/JTRP-98/17. Joint Transportation Research Program; Indiana Department of Transportation and Purdue University: West Lafayette, IN, USA, 2000. [Google Scholar] [CrossRef]

- Holm, T.A.; Bremmer, T.W.; De Souza, H. Aggregate-Matrix Interaction in Concrete Subjected to Severe Exposure. In Proceedings of the FIP/CPCI Symposia, Calgary, AB, Canada, 25–31 August 1984. [Google Scholar]

- Holm, T.A.; Bremmer, T.W.; Newman, J.B. Lightweight Concrete Subject to Severe Weathering. Concr. Int. 1984, 6, 49–54. [Google Scholar]

- Holm, T.A.; Vaysburd, A.M. Structural Lightweight Aggregate Performance; ACI SP-136; ACI: Turin, Italy, 1992; 424p. [Google Scholar]

- Zhang, M.H.; Gjorv, O.E. Microstructure of the Interfacial Zone between Lightweight Aggregate and Cement Paste. Cem. Concr. Res. 1990, 20, 610–618. [Google Scholar] [CrossRef]

- Zhang, M.H.; Gjorv, O.E. Pozzolanic Reactivity of Lightweight Aggregates. Cem. Concr. Res. 1990, 20, 884–890. [Google Scholar] [CrossRef]

- Zhang, M.H.; Gjorv, O.E. Characteristics of Lightweight Aggregates for High-Strength Concrete. ACI Mater. J. 1991, 88, 150–158. [Google Scholar]

- Zhang, M.H.; Gjorv, O.E. Penetration of Cement Paste into Lightweight Aggregate. Cem. Concr. Res. 1992, 22, 47–55. [Google Scholar] [CrossRef]

- Swamy, R.N.; Lambert, G.H. The Microstructure of Lytag aggregate. Int. J. Cem. Compos. Lightweight Concr. 1981, 3, 273–282. [Google Scholar] [CrossRef]

- Wasserman, R.; Bentur, A. Interfacial Interactions in Lightweight Aggregate Concrete and Their Influence on the Concrete Strength. Cem. Concr. Compos. 1996, 18, 67–76. [Google Scholar] [CrossRef]

- Szydłowski, R.; Mieszczak, M. Study of application of lightweight aggregate concrete to construct posttensioned long-span slabs. Procedia Eng. 2017, 172, 1077–1085. [Google Scholar] [CrossRef]

- Thienel, K.-C.; Haller, T.; Beuntner, N. Lightweight Concrete—From Basics to Innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z. Effect of porous lightweight aggregate on strength of concrete. Mater. Lett. 2004, 58, 916–919. [Google Scholar] [CrossRef]

- Chen, H.-J.; Tsai, W.-P.; Tang, C.-W.; Liu, T.-H. Time-dependent properties of lightweight concrete using sedimentary lightweight aggregate and its application in prestressed concrete beams. Struct. Eng. Mech. 2011, 39, 833–847. [Google Scholar] [CrossRef]

- Chen, H.-J.; Liu, T.-H.; Tang, C.-W.; Tsai, W.-P. Influence of high-cycle fatigue on the tension stiffening behavior of flexural reinforced lightweight aggregate concrete beams. Struct. Eng. Mech. 2011, 40, 847–866. [Google Scholar] [CrossRef]

- Chen, H.J.; Yen, T.; Chen, K.H. Evaluating elastic modulus of lightweight aggregate. ACI Mater. J. 2003, 100, 108–113. [Google Scholar]

- Szydłowski, R.S.; Łabuzek, B. Experimental Evaluation of Shrinkage, Creep and Prestress Losses in Lightweight Aggregate Concrete with Sintered Fly Ash. Materials 2021, 14, 3895. [Google Scholar] [CrossRef]

- Bremner, T.W.; Holm, T.A. Elastic compatibility and the behavior of concrete. ACI J. 1986, 83, 244–250. [Google Scholar]

- LRFD Bridge Design Specifications, 6th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: London, UK, 2012. [Google Scholar]

- Ritthichauy, W.; Sugiyama, T.; Okamoto, T.; Tsuji, Y. Shear tests on reinforced lightweight aggregate concrete beams without web reinforcement. Concr. J. 2001, 23, 937–942. [Google Scholar]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary (ACI 318R-14); American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- Tian, Y.; Shi, S.; Jia, K.; Hu, S. Mechanical and dynamic properties of high strength concrete modified with lightweight aggregates presaturated polymer emulsion. Constr. Build. Mater. 2015, 93, 1151–1156. [Google Scholar] [CrossRef]

- Lotfy, A.; Hossain, K.M.; Lachemi, M. Durability properties of lightweight self-consolidating concrete developed with three types of aggregates. Constr. Build. Mater. 2016, 106, 43–54. [Google Scholar] [CrossRef]

- Wall, J.R. Non-traditional lightweight concrete for bridges, a lightweight aggregate manufacturers review of current practice. In Proceedings of the 2010 Concrete Bridge Conference: Achieving Safe, Smart & Sustainable Bridges National Concrete Bridge Council Federal Highway Administration Portland Cement Association, Phoenix, AZ, USA, 24–26 February 2010; p. 12. [Google Scholar]

- Kraľovanec, J.; Bahleda, F.; Prokop, J.; Moravčík, M.; Neslušan, M. Verification of Actual Prestressing in Existing Pre-Tensioned Members. Appl. Sci. 2021, 11, 5971. [Google Scholar] [CrossRef]

- Moraῠcík, M. Design of Prestressed Structures According to Eurocodes, 1st ed.; EDIS: Žilina, Slovakia, 2017. [Google Scholar]

- Hurst, M.K. Prestressed Concrete Design, 2nd ed.; E & FN SPON, An Imprint of Routledge: London, UK, 1998. [Google Scholar]

- Bymaster, J.; Dang, C.; Floyd, R.; Hale, M. Prestress losses in pretensioned concrete beams cast with lightweight self-consolidating concrete. Structures 2015, 2, 50–57. [Google Scholar] [CrossRef]

- Wendling, A.; Sadhasivam, K.; Floyd, R.W. Creep and shrinkage of lightweight self-consolidating concrete for prestressed members. Constr. Build. Mater. 2018, 167, 205–215. [Google Scholar] [CrossRef]

- Kayali, O.; Haque, M.N.; Zhu, B. Drying shrinkage of fibre-reinforced lightweight aggregate concrete containing fly ash. Cem. Concr. Res. 1999, 29, 1835–1840. [Google Scholar] [CrossRef]

- Kahn, L.F.; Lopez, M. Prestress losses in high-performance lightweight concrete pretensioned bridge girders. PCI Struct. J. 2005, 50, 84–94. [Google Scholar] [CrossRef]

- Shideler, J.J. Lightweight aggregate concrete for structural use. Proc. J. Am. Concr. Inst. 1957, 54, 298–328. [Google Scholar]

- Short, A.; Kinniburgh, W. Lightweight Concrete; John Wiley & Sons: New York, NY, USA, 1963. [Google Scholar]

- Domagała, L.; Podolska, A. Effect of Lightweight Aggregate Impregnation on Selected Concrete Properties. Materials 2021, 15, 198. [Google Scholar] [CrossRef]

- Structural LWAC. Specification and Guideline for Materials and Production; Document BE96-3942/R14, Project Funded by the European Union under the Industrial & Materials Technologies Programme (Brite-EuRam III). 2000. Available online: https://www.researchgate.net/publication/339460461_LWAC_Material_Properties_-_State-of-the-Art (accessed on 5 February 2023).

- Nilsen, U.A.; Aitcin, P.C. Properties of high-strength concrete containing light-, normal-, and heavyweight aggregate. Cem. Concr. Aggreg. 1992, 14, 8–12. [Google Scholar] [CrossRef]

- Lopez, M.; Kahn, L.F.; Kurtis, K.E. Creep and shrinkage of high performance lightweight concrete. ACI Mater. J. 2004, 101, 391–399. [Google Scholar]

- Rodacka, M.; Domagała, L.; Szydłowski, R. Assessment of Properties of Structural Lightweight Concrete with Sintered Fly Ash Aggregate in Terms of Its Suitability for Use in Prestressed Members. Materials 2023, 16, 5429. [Google Scholar] [CrossRef]

- EN 1992 Eurocode 2; Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2013.

- Lopez, M.; Kahn, L.; Kurtis, K.; Lai, J. Creep, Shrinkage, and Prestress Losses of High-Performance Lightweight Concrete; GDOT Research Project No. 2004; Office of Materials and Research Georgia Department of Transportation: Atlanta, GA, USA, 2003. [Google Scholar]

- Lopez, M.; Kurtis, K.; Kahn, L. Pre-wetted lightweight coarse aggregate reduces long-term deformations of high performance lightweight concrete. In Proceedings of the 7th CANMET/ACI International Conference on Durability of Concrete, SP-234, Montreal, QC, Canada, 28 May–3 June 2006. [Google Scholar]

- Kayali, O. Fly ash lightweight aggregates in high performance concrete. Constr. Build. Mater. 2008, 22, 2393–2399. [Google Scholar] [CrossRef]

- ASTM C494/C494M-17; Standard and Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C127/C127M-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015. Available online: https://www.astm.org/Standards/C127 (accessed on 13 March 2023).

- CNS 14779; Method of Test for the Particle Cylindrical Crushing Strength of Lightweight Coarse Aggregates. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taiwan, China, 2021.

- CNS 490; Method of Test for Resistance to Degradation of Coarse Aggregate (Smaller Then 37.5 mm) by Abrasion and Impact in the Los Angeles Machine. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taiwan, China, 2021.

- CNS 1167; Method of Test for Soundness of Aggregate by Use of Sodium Sulfate or Magnesium Sulfate. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taiwan, China, 2018.

- CNS 3691; Lightweight Aggregates for Structural Concrete. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taiwan, China, 2019.

- ASTM C567/C567M-19; Standard Test Method for Determining Density of Structural Lightweight Concrete. ASTM International: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/Standards/C567 (accessed on 12 March 2023).

- ASTM C39/C39M-18; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2018. Available online: https://www.astm.org/Standards/C39 (accessed on 12 March 2023).

- ASTM C78/C78M-09; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2009. Available online: https://www.astm.org/Standards/C78 (accessed on 12 March 2023).

- ASTM C496/C496M-96; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 1996. Available online: https://www.astm.org/Standards/C496 (accessed on 12 March 2023).

- ASTM C469/C469M-14; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2014. Available online: https://www.astm.org/Standards/C469 (accessed on 13 March 2023).

- ASTM C157/C157M-08; Standard Test Method for Length Change of Hardened Cement Mortar and Concrete. ASTM International: West Conshohocken, PA, USA, 2008. Available online: https://www.astm.org/Standards/C157 (accessed on 13 March 2023).

- ASTM C512/C512M-15; Standard Test Method for Creep of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2015. Available online: https://www.astm.org/Standards/C512 (accessed on 13 March 2023).

- CNS 14795; Method of Test for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taiwan, China, 2020.

- ASTM C1543-10; Standard Test Method for Determining the Penetration of Chloride Ion into Concrete by Ponding. ASTM International: West Conshohocken, PA, USA, 2010. Available online: https://www.astm.org/Standards/C1543 (accessed on 14 March 2023).

- CNS 15649; Method of Test for Resistance of Concrete to Chloride Ion Penetration. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taiwan, China, 2019.

- ASTM C597-16; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2016. Available online: https://www.astm.org/Standards/C597 (accessed on 14 March 2023).

- CNS 14702; Method of Test for Acid-Soluble Chloride in Mortar and Concrete. Bureau of Standards, Metrology and Inspection, Ministry of Economic Affairs: Taiwan, China, 2021.

- Wang, Y.; Xiao, R.; Lu, H.; Hu, W.; Jiang, X.; Huang, B. Effect of curing conditions on the strength and durability of air entrained concrete with and without fly ash. Clean. Mater. 2023, 7, 100170. [Google Scholar] [CrossRef]

- Al-Khaiat, H.; Haque, M.N. Effect of initial curing on early strength and physical properties of a lightweight concrete. Cem. Concr. Res. 1998, 28, 859–866. [Google Scholar] [CrossRef]

- Smadi, M.; Migdady, E. Properties of high strength tuff lightweight aggregate concrete. Cem. Concr. Compos. 1991, 13, 129–135. [Google Scholar] [CrossRef]

- Wu, T.; Yang, X.; Wei, H.; Liu, X. Mechanical properties and microstructure of lightweight aggregate concrete with and without fibers. Constr. Build. Mater. 2019, 199, 526–539. [Google Scholar] [CrossRef]

- Lu, J.X. Recent advances in high strength lightweight concrete: From development strategies to practical applications. Constr. Build. Mater. 2023, 400, 132905. [Google Scholar] [CrossRef]

- Nilsen, A.U.; Monteiro, P.J.M.; Gjørv, O.E. Estimation of the elastic moduli of lightweight aggregate. Cem. Concr. Res. 1995, 25, 276–280. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Özturan, T.; Güneyisi, E. Shrinkage cracking of lightweight concrete made with cold-bonded fly ash aggregates. Cem. Concr. Res. 2004, 34, 1121–1130. [Google Scholar] [CrossRef]

- Zhang, M.H.; Li, L.; Paramasivam, P. Shrinkage of high-strength lightweight aggregate concrete exposed to dry environment. ACI Mater. J. 2005, 102, 86–92. [Google Scholar]

- Kim, Y.H.; Trejo, D.; Hueste, M.B.D.; Kim, J.J. Experimental study on creep and durability of high-early-strength selfconsolidating concrete for precast elements. ACI Mater. J. 2011, 108, 128–138. [Google Scholar]

- Hong, S.-H.; Choi, J.-S.; Yuan, T.-F.; Yoon, Y.-S. A review on concrete creep characteristics and its evaluation on high-strength lightweight concrete. J. Mater. Res. Technol. 2023, 22, 230–251. [Google Scholar] [CrossRef]

- Holste, J.R.; Peterman, R.J.; Esmaeily, A. Evaluating the Time-Dependent and Bond Characteristics of Lightweight Concrete Mixes for Kansas Prestressed Concrete Bridges; Research Report KSU-08-02; Kansas State University Transportation Center: Manhattan, KS, USA, 2011. [Google Scholar]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Shen, D.; Kang, J.; Jiao, Y.; Li, M.; Li, C. Effects of different silica fume dosages on early-age behavior and cracking resistance of high strength concrete under restrained condition. Constr. Build. Mater. 2020, 263, 120218. [Google Scholar] [CrossRef]

- Kristiawan, S.A.; Nugroho, A.P. Creep behaviour of selfcompacting concrete incorporating high volume fly ash and its effect on the long-term deflection of reinforced concrete beam. Procedia Eng. 2017, 171, 715–724. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Feng, Z.; Zhu, S.; Liang, C. Influence of ground granulated blast furnace slag on the early-age anti-cracking property of internally cured concrete. Constr. Build. Mater. 2019, 223, 233–243. [Google Scholar] [CrossRef]

- Song, Y.-C.; Song, H.-W.; Byun, K.-J. Modification of creep prediction equation of concrete utilizing short-term creep test. J. Korea Concr. Inst. 2000, 12, 69–78. [Google Scholar]

- Yen, T.; Chen, H.J.; Huang, Y.L.; Liu, T.H. Application of Lightweight High-Strength Concrete in Bridge Engineering (Issue 2); National Highway New Construction Engineering Bureau, Taiwan District, Ministry of Transportation: Taipei, Taiwan, 2008. (In Chinese) [Google Scholar]

- ASTM C1202-19; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/Standards/C1202 (accessed on 15 March 2023).

- Zhutovsky, S.; Kovler, K. Effect of internal curing on durability-related properties of high performance concrete. Cem. Concr. Res. 2012, 42, 20–26. [Google Scholar] [CrossRef]

- Elsharief, A.; Cohen, M.; Olek, J. Influence of lightweight aggregate on the microstructure and durability of mortar. Cem. Concr. Res. 2005, 35, 1368–1376. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Özturan, T.; Özbay, E. Estimation of chloride permeability of concretes by empirical modeling: Considering effects of cement type, curing condition and age. Constr. Build. Mater. 2009, 23, 469–481. [Google Scholar] [CrossRef]

- Feldman, R.; Prudencio, L.R.; Chan, G. Rapid chloride permeability test on blended cement and other concretes: Correlations between charge, initial current and conductivity. Constr. Build. Mater. 1999, 13, 149–154. [Google Scholar] [CrossRef]

- Chen, H.-J.; Chen, Y.-C.; Tang, C.-W.; Lin, X.-F. The Corrosion Resistance of Reinforced Lightweight Aggregate Concrete in Strong Brine Environments. Materials 2022, 15, 7943. [Google Scholar] [CrossRef] [PubMed]

- Vaysburd, A.M. Durability of lightweight concrete bridge in severe environments. Concr. Int. 1996, 18, 33–38. [Google Scholar]

- Zhang, M.H.; Gjorv, O.E. Permeability of high strength lightweight concrete. ACI Mater. J. 1991, 88, 463–469. [Google Scholar]

- Thomas, M.D.A. Chloride diffusion in high-performance lightweight aggregate concrete. Symp. Pap. 2006, 234, 797–812. [Google Scholar]

- Liu, X.; Chia, K.S.; Zhang, M.H. Development of lightweight concrete with high resistance to water and chloride-ion penetration. Cem. Concr. Compos. 2010, 32, 757–766. [Google Scholar] [CrossRef]

- Lu, J.X.; Shen, P.; Ali, H.A.; Poon, C.S. Mix design and performance of lightweight ultra high-performance concrete. Mater. Des. 2022, 216, 110553. [Google Scholar] [CrossRef]

- Newman, J.B. Properties of structural lightweight aggregate concrete. In Structural Lightweight Aggregate Concrete; Clarke, J.L., Ed.; Chapman & Hall: London, UK, 1993; pp. 19–44. [Google Scholar]

- Mohebbi, A.; Graybeal, B. Prestress loss model for ultra-high performance concrete. Eng. Struct. 2022, 252, 113645. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; Jin, H.; Fan, X.; Liu, J.; Xing, F.; Tang, L. Research on the durability and Sustainability of an artificial lightweight aggregate concrete made from municipal solid waste incinerator bottom ash (MSWIBA). Constr. Build. Mater. 2023, 365, 129993. [Google Scholar] [CrossRef]

- Bogas, J.A.; Gomes, A. Non-steady-state accelerated chloride penetration resistance of structural lightweight aggregate concrete. Cem. Concr. Compos. 2015, 60, 111–122. [Google Scholar] [CrossRef]

- Real, S.; Bogas, J.A. Chloride ingress into structural lightweight aggregate concrete in real marine environment. Mar. Struct. 2018, 61, 170–187. [Google Scholar] [CrossRef]

- Yang, L.; Shi, C.; Liu, J.; Wu, Z. Factors affecting the effectiveness of internal curing: A review. Constr. Build. Mater. 2020, 267, 121017. [Google Scholar] [CrossRef]

- Bentz, D.P. Influence of internal curing using lightweight aggregates on interfacial transition zone percolation and chloride ingress in mortars. Cem. Concr. Compos. 2009, 31, 285–289. [Google Scholar] [CrossRef]

- Haque, M.N.; Al-Khaiat, H.; Kayali, O. Strength and durability of lightweight concrete. Cem. Concr. Compos. 2004, 26, 307–314. [Google Scholar] [CrossRef]

| Chemical Composition (%) | Cement | Slag | Fly Ash | Silica Fume |

|---|---|---|---|---|

| Silicon dioxide, SiO2 | 20.49 | 33.46 | 55.90 | 92.40 |

| Aluminum oxide, Al2O3 | 6.57 | 13.70 | 29.30 | - |

| Iron oxide, Fe2O3 | 3.27 | 0.42 | 4.05 | - |

| Calcium oxide, CaO | 62.40 | 42.69 | - | - |

| Magnesium oxide, MgO | 1.91 | 6.21 | - | - |

| Sulfur trioxide, SO3 | 2.20 | 1.48 | 0.42 | - |

| Potassium oxide, K2O | - | 0.35 | - | - |

| Free calcium oxide, f-CaO | 1.03 | - | - | - |

| Titanium dioxide, TiO2 | - | 0.46 | - | - |

| Phosphorus Pentoxide, P2O5 | - | 0.04 | - | - |

| Manganese oxide, MnO | - | 0.39 | - | - |

| Loss on ignition, LOI | 1.57 | 0.27 | 3.64 | 1.50 |

| Tricalcium silicate, C3S | 39.27 | - | - | - |

| Dicalcium silicate, C2S | 29.11 | - | - | - |

| Tricalcium aluminate, C3A | 11.75 | - | - | - |

| Tetracalcium aluminoferrite, C4AF | 9.96 | - | - | - |

| Calcium sulfate dihydrate, CSH2 | 4.73 | - | - | - |

| Item | Test Value | Test Method | |

|---|---|---|---|

| Bulk specific gravity | 1.32 | ASTM C127 [62] | |

| Crushing strength | 4.9 MPa | CNS 14779 [63] | |

| Los Angeles abrasion value of aggregate | 31.20% | CNS 490 [64] | |

| Soundness of aggregate via use of sodium sulfate or magnesium sulfate | 0.11% | CNS 1167 [65] | |

| Water absorption rate | 24 h | 10% | ASTM C127 [62] |

| 48 h | 12% | ||

| Dry unit weight | 835 kg/m3 | CNS 3691 [66] | |

| Concrete Group | W/B | W | C | SL | FA | SF | LWA | CA | FA | SP |

|---|---|---|---|---|---|---|---|---|---|---|

| Control group | 0.36 | 163 | 364 | 90 | 0 | 0 | 0 | 971 | 774 | 5.0 |

| Experimental group | 0.39 | 210 | 296 | 162 | 54 | 27 | 465 | 0 | 615 | 4.85 |

| Test Items | Specimen Ages (Day) | Specimen Size | Test Specifications |

|---|---|---|---|

| Air-dry unit weight | 90 | Cylinders (15 cm diameter × 30 cm length) | ASTM C567 [67] |

| Compressive strength | 3, 7, 14, 21, 28, 56, 90, 180 | Cylinders (15 cm diameter × 30 cm length) | ASTM C39 [68] |

| Flexural strength | 28, 56, 90, 180 | Prisms (15 cm × 15 cm × 53 cm) | ASTM C78 [69] |

| Splitting tensile strength | 28 | Cylinders (15 cm diameter × 30 cm length) | ASTM C496 [70] |

| Elastic modulus | 28, 56, 90, 180 | Cylinders (15 cm diameter × 30 cm length) | ASTM C469 [71] |

| Drying shrinkage | 0, 14, 28, 56, 90, 180, 360 | Prisms (7.5 cm × 7.5 cm × 28 cm) | ASTM C157 [72] |

| Creep | 0, 14, 28, 56, 90, 180, 360 | Cylinders (15 cm diameter × 30 cm length) | ASTM C512 [73] |

| Test Items | Specimen Ages (Day) | Specimen Size | Test Specifications |

|---|---|---|---|

| Ultrasonic pulse velocity test | 28, 90, 180 | Cylinders (10 cm diameter × 20 cm length) | ASTM C597 [77] |

| Concrete’s ability to resist chloride ion penetration test | 28, 90, 180 | Cylinders (10 cm diameter × 20 cm length) | CNS 14795 [74] |

| Chloride ion penetration test | 28, 90, 180 | Cylinders (10 cm diameter × 20 cm length) | ASTM C1543 [75] and CNS 15649 [76] |

| Scanning electron microscope observation | 28, 90, 180 | Fragments after concrete compression test | ACI 213R-14 [17] |

| Group | Curing Method | Air-Dried Unit Weight (kg/m3) |

|---|---|---|

| 90 Days | ||

| NC | Standard curing | 2391 |

| On-site curing | 2333 | |

| LWC | Standard curing | 1817 |

| On-site curing | 1820 |

| Group | Curing Method | Curing Age (Day) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 3 | 7 | 14 | 21 | 28 | 56 | 90 | 180 | ||

| NC | Standard curing | 25.6 | 35.6 | 50.2 | 57 | 58.8 | 68.9 | 74.5 | 75.1 |

| On-site curing | - | - | - | - | 61.6 | 65.4 | 64.7 | 67.1 | |

| LWC | Standard curing | 24.24 | 33.6 | 39.9 | 45.6 | 47.1 | 50.6 | 52.4 | 56.1 |

| On-site curing | - | - | - | - | 51.0 | 51.6 | 52.4 | 53.3 | |

| Group | Curing Method | Splitting Tensile Strength (MPa) |

|---|---|---|

| 28 Days | ||

| NC | Standard curing | 4.6 |

| On-site curing | 4.5 | |

| LWC | Standard curing | 3.0 |

| On-site curing | 2.3 |

| Group | Curing Age (Day) | Ultrasonic Pulse Velocity (m/s) | Average UPV (m/s) |

|---|---|---|---|

| NC | 28 | 4470.4, 4452.8, 4483.2 | 4469 |

| 90 | 4608.8, 4604.3, 4682.4 | 4632 | |

| 180 | 4724.1, 4733.6, 4701.8 | 4720 | |

| LWC | 28 | 4067.5, 4053.7, 4022.4 | 4048 |

| 90 | 4252.7, 4188.6, 4231.6 | 4224 | |

| 180 | 4332.2, 4308.2, 285.7 | 4309 |

| UPV Range (m/s) | Concrete Quality |

|---|---|

| More than 4500 | Excellent |

| From 3600 to 4500 | Good |

| From 3000 to 3600 | Questionable |

| From 2100 to 3000 | Poor |

| From 1800 to 2100 | Very poor |

| Group | Curing Age (Day) | Increase in Chloride Ion Content (kg/m3) | |||

|---|---|---|---|---|---|

| Sampling Position: 1.6–13 mm | Difference from Comparison Sample | Sampling Position: 13–25 mm | Difference from Comparison Sample | ||

| NC | 0 | 0.030 | 0.000 | 0.033 | 0.000 |

| 28 | 0.524 | 0.494 | 0.293 | 0.260 | |

| 90 | 1.270 | 1.240 | 1.210 | 1.177 | |

| 180 | 1.521 | 1.490 | 1.453 | 1.420 | |

| LWC | 0 | 0.096 | 0.000 | 0.076 | 0.000 |

| 28 | 0.680 | 0.584 | 0.097 | 0.021 | |

| 90 | 0.918 | 0.822 | 0.307 | 0.231 | |

| 180 | 1.302 | 1.206 | 0.571 | 0.495 | |

| Installation Location | Monitoring Time (Day) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 3 | 7 | 14 | 28 | 56 | 90 | 180 | 360 | 540 | 720 | ||

| NC Right side | 376 | 364 | 362 | 369 | 361 | 361 | 357 | 377 | 350 | 353 | 346 | |

| LWC | Right side | 265 | 252 | 253 | 254 | 254 | 260 | 271 | 271 | 252 | 260 | 254 |

| Left side | 268 | 257 | 258 | 258 | 259 | 264 | 276 | 276 | 256 | 263 | 257 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-J.; Kuo, C.-C.; Tang, C.-W. Evaluation of the Superiority of Lightweight-Aggregate-Concrete Prestressed Box Girders in Terms of Durability and Prestress Loss. Materials 2023, 16, 6360. https://doi.org/10.3390/ma16196360

Chen H-J, Kuo C-C, Tang C-W. Evaluation of the Superiority of Lightweight-Aggregate-Concrete Prestressed Box Girders in Terms of Durability and Prestress Loss. Materials. 2023; 16(19):6360. https://doi.org/10.3390/ma16196360

Chicago/Turabian StyleChen, How-Ji, Cheng-Chang Kuo, and Chao-Wei Tang. 2023. "Evaluation of the Superiority of Lightweight-Aggregate-Concrete Prestressed Box Girders in Terms of Durability and Prestress Loss" Materials 16, no. 19: 6360. https://doi.org/10.3390/ma16196360

APA StyleChen, H.-J., Kuo, C.-C., & Tang, C.-W. (2023). Evaluation of the Superiority of Lightweight-Aggregate-Concrete Prestressed Box Girders in Terms of Durability and Prestress Loss. Materials, 16(19), 6360. https://doi.org/10.3390/ma16196360