Analysis of Novel Porosity–Water-to-Binder Index for Prediction of Strength, Stiffness and Durability for Cemented Soils

Abstract

:1. Introduction

2. Methodology

2.1. Theoretical Derivation of Porosity-to-Cement Index

2.2. Semi-Empirical Derivation of the Novel Porosity–Water-to-Cement Index

3. Results

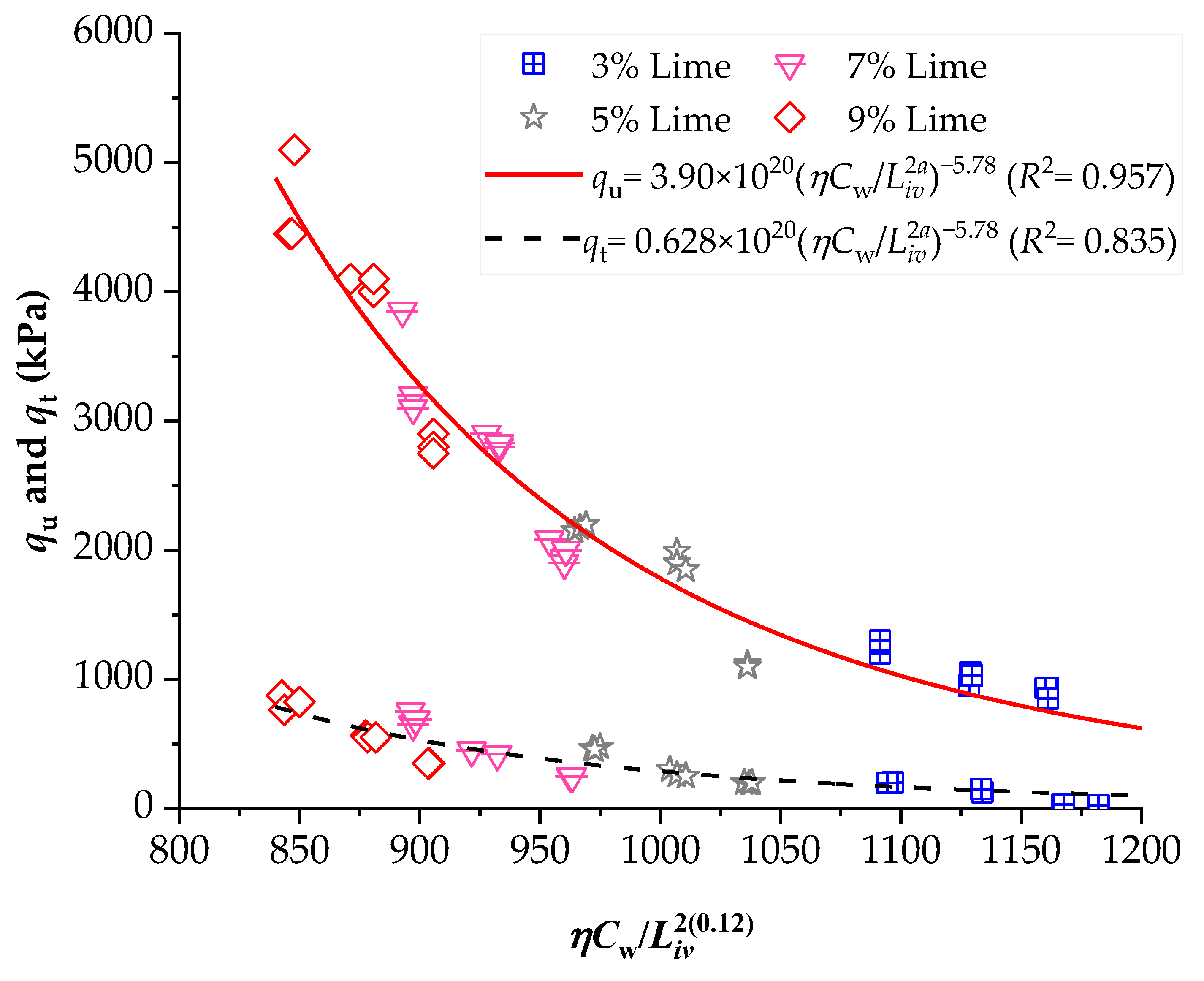

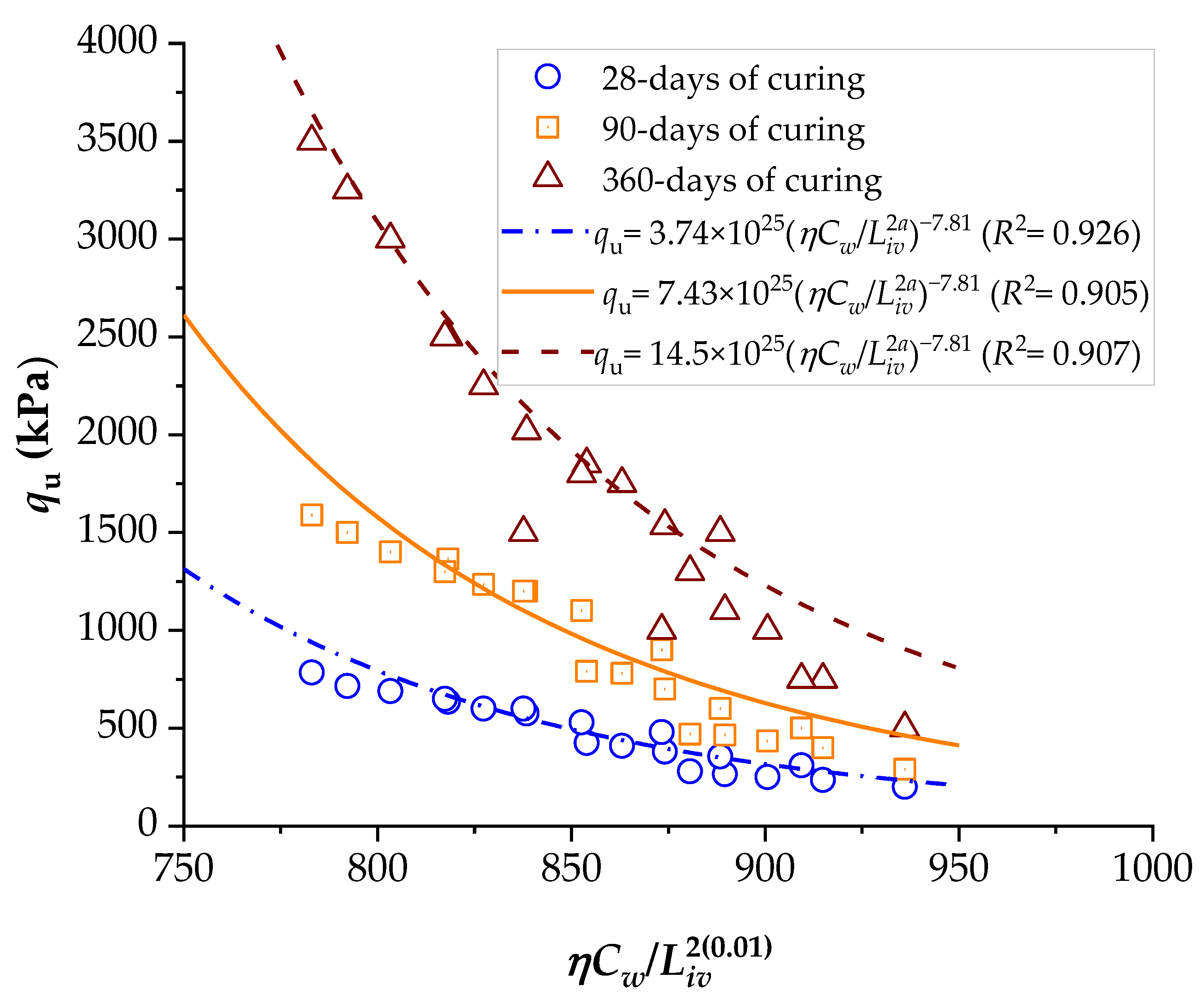

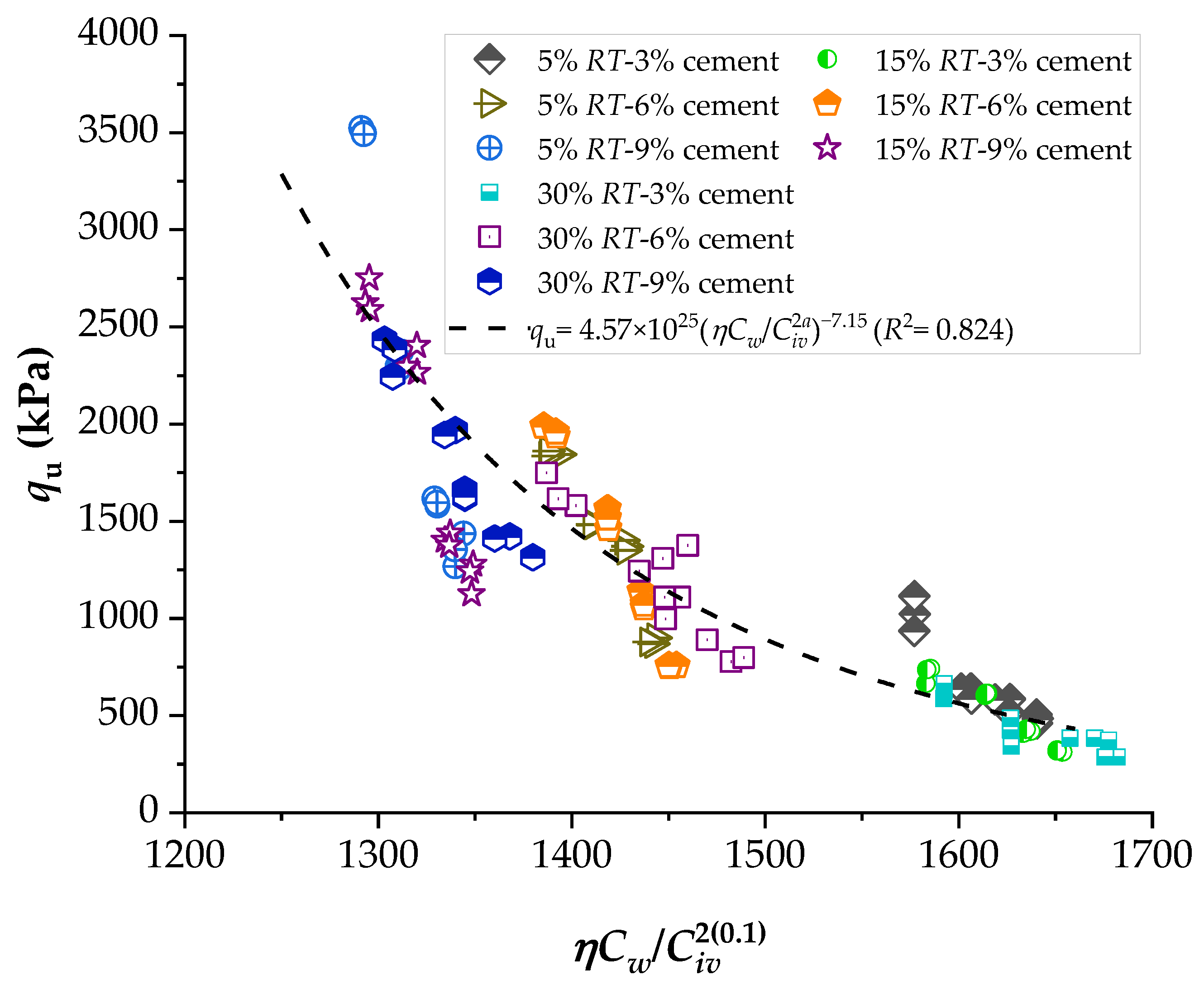

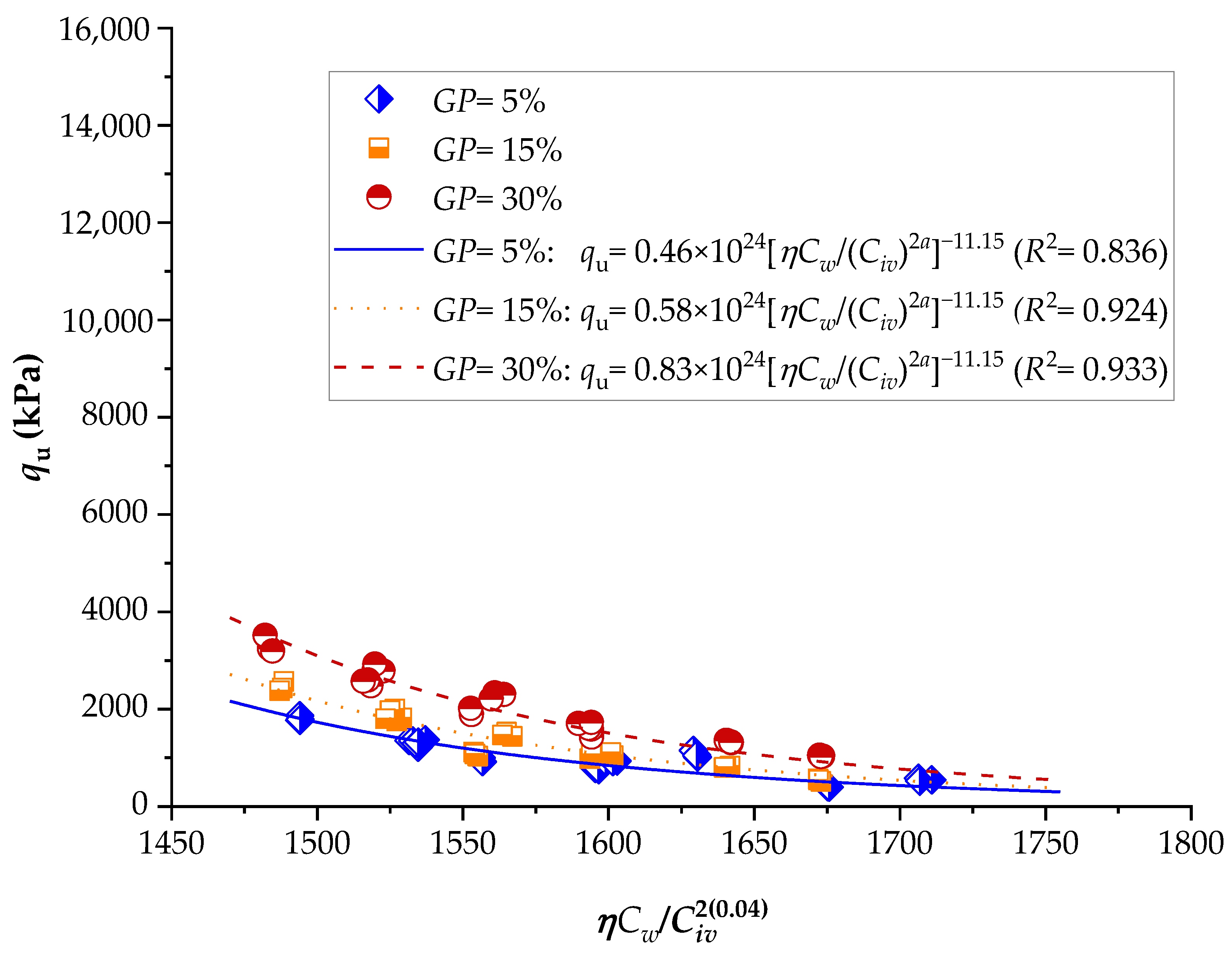

3.1. Application of the Porosity–Water/Binder Index to Predict the Strength of Compacted Blends

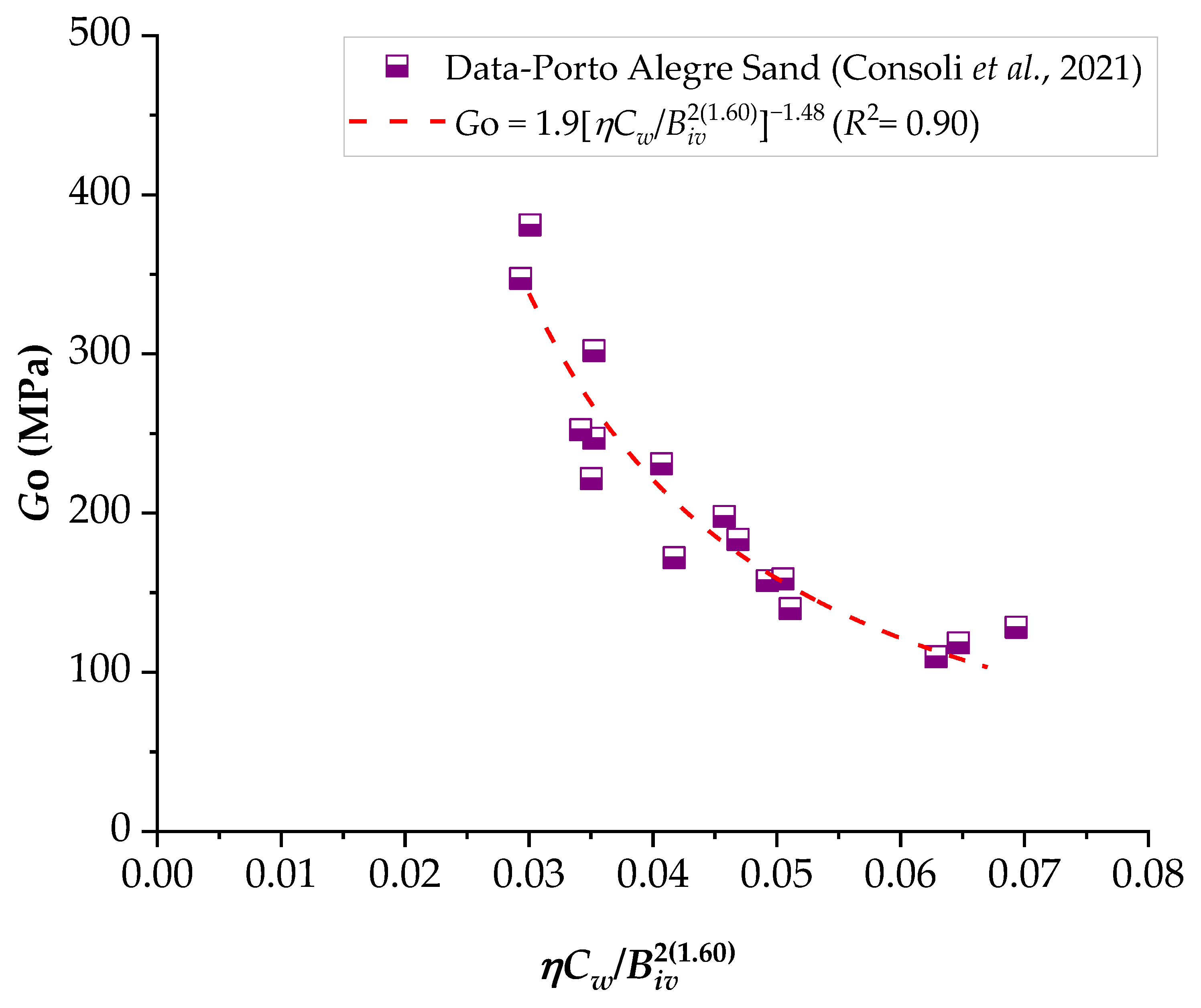

3.2. Application of the Porosity–Water/Binder Index to Predict the Stiffness of Compacted Blends

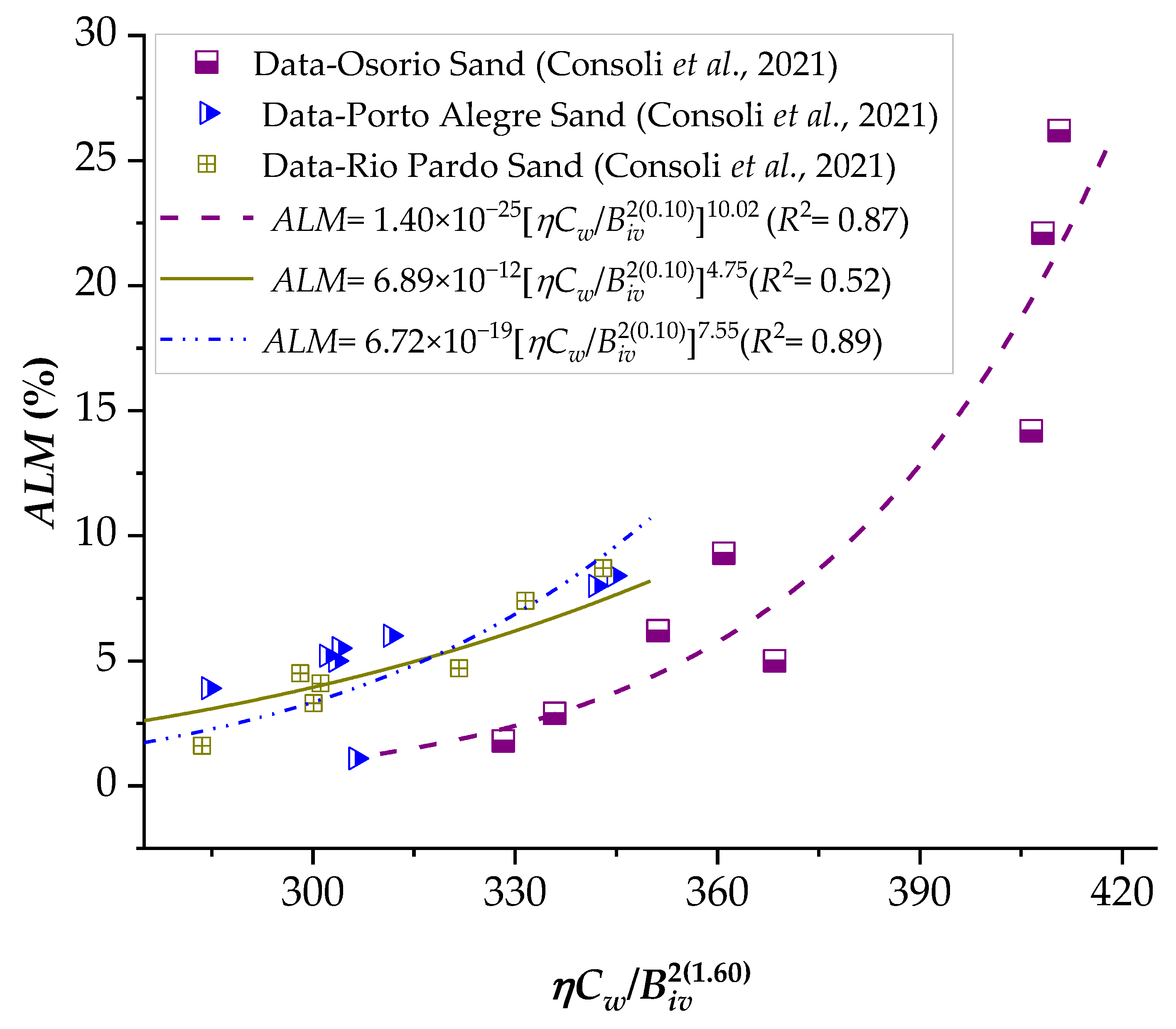

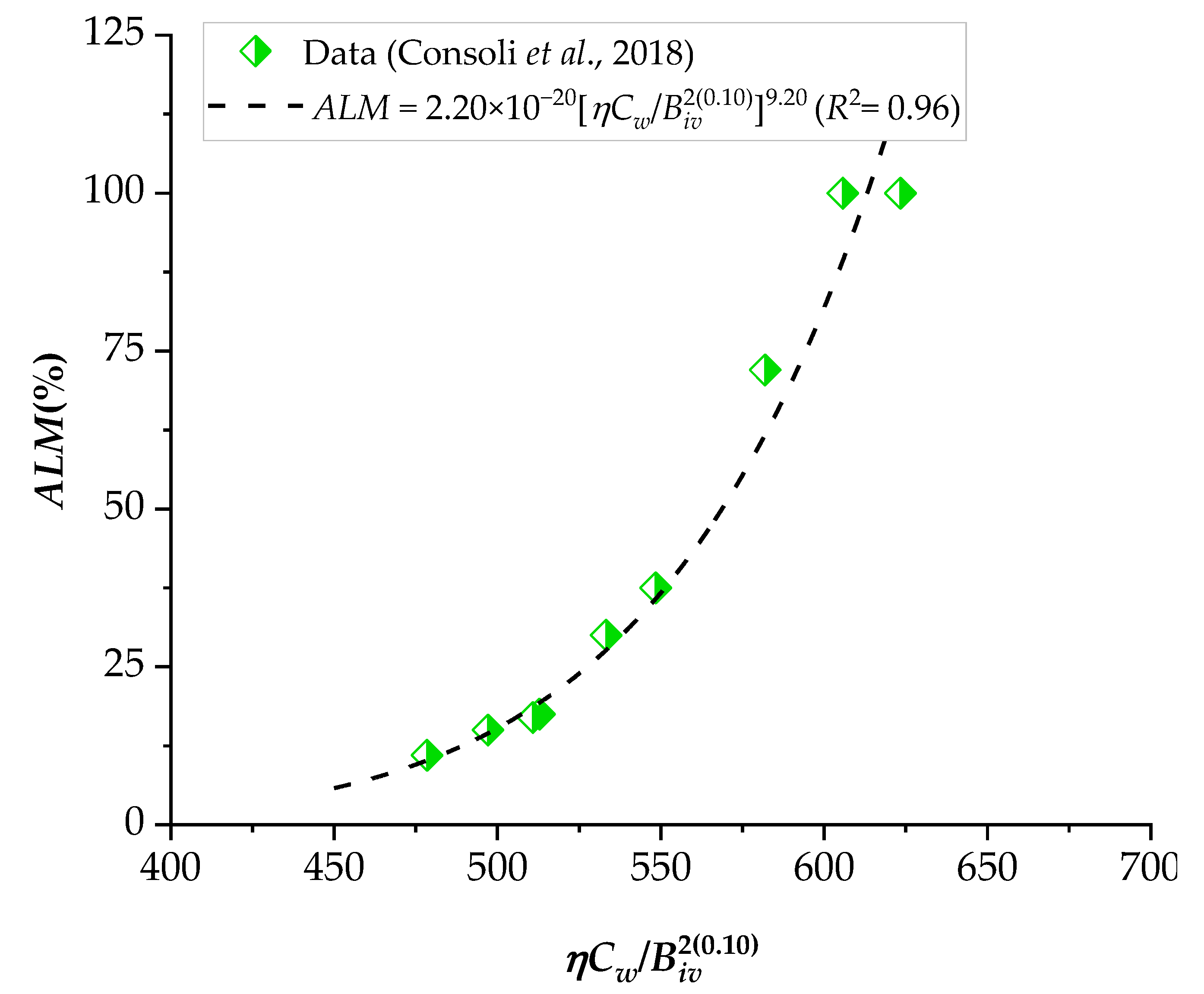

3.3. Application of the Porosity–Water/Binder Index to Predict the Durability against Wetting–Drying Cycles (Accumulated Loss of Mass, ALM)

4. Discussion

5. Conclusions

- This study introduces a novel perspective on the application of the porosity/binder relationship, underscoring its potential in delineating the strength evolution of artificially cemented soils.

- This research establishes the porosity–water/binder index as a multifaceted instrument, adept at assessing the strengths of varied artificially cemented soils, highlighting its pivotal role in subsequent geotechnical research.

- These findings corroborate the consistent impact of water content on the qt/qu values across different soil blends, bolstering the credibility of antecedent research insights.

- The efficacy of the porosity–water/binder ratio in addressing a spectrum of soil types, especially those inherently challenging from a geotechnical standpoint, accentuates its indispensability in a multitude of stabilization methodologies.

- To further this avenue of investigation, it is imperative to explore the intricacies of this ratio’s influence on the durability and resilience of cemented soils.

- The expansive applicability scope of the porosity–water/binder index, spanning an array of geological contexts, manifests its prospective capacity to instigate transformative shifts in modern geotechnical engineering practices.

- The analysis of the influence of water content on the ratio of splitting tensile strength to compressive strength (qt/qu) for stabilized soils revealed consistent results across soil–cement and lime–soil blends. The qt/qu values of 0.15 and 0.16 for soil–cement and lime–soil blends, respectively, aligned well with the values reported in previous studies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Consoli, N.C.; Scheuermann Filho, H.C.; Leon, H.B.; da Silva Carretta, M.; Corte, M.B.; Cordeiro, R.E.; Caballero, R.D.; Lourenço, D.E. General Relationships Controlling Loss of Mass, Stiffness and Strength of Sustainable Binders Amended Sand. Transp. Geotech. 2021, 27, 100473. [Google Scholar] [CrossRef]

- Ekinci, A.; Hanafi, M.; Aydin, E. Strength, Stiffness, and Microstructure of Wood-Ash Stabilized Marine Clay. Minerals 2020, 10, 796. [Google Scholar] [CrossRef]

- Hanafi, M.; Ekinci, A.; Aydin, E. Triple-Binder-Stabilized Marine Deposit Clay for Better Sustainability. Sustainability 2020, 12, 4633. [Google Scholar] [CrossRef]

- Henzinger, C.; Schuhmacher, S.A.; Festugato, L. Applicability of the Porosity/Binder Index to Nonhomogeneous Mixtures of Fine-Grained Soil with Lignite Fly Ash. J. Mater. Civ. Eng. 2018, 30, 06018013. [Google Scholar] [CrossRef]

- Ermolovich, E.A.; Ivannikov, A.L.; Khayrutdinov, M.M.; Kongar-Syuryun, C.B.; Tyulyaeva, Y.S. Creation of a Nanomodified Backfill Based on the Waste from Enrichment of Water-Soluble Ores. Materials 2022, 15, 3689. [Google Scholar] [CrossRef]

- Kanty, P.; Rybak, J.; Stefaniuk, D. Some Remarks on Practical Aspects of Laboratory Testing of Deep Soil Mixing Composites Achieved in Organic Soils. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022018. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Silva Lopes, L.; Foppa, D.; Heineck, K.S. Key Parameters Dictating Strength of Lime/Cement-Treated Soils. Proc. Inst. Civ. Eng.-Geotech. Eng. 2009, 162, 111–118. [Google Scholar] [CrossRef]

- Consoli, N.C.; Bellaver Corte, M.; Festugato, L. Key Parameter for Tensile and Compressive Strength of Fibre-Reinforced Soil–Lime Mixtures. Geosynth. Int. 2012, 19, 409–414. [Google Scholar] [CrossRef]

- Diambra, A.; Ibraim, E.; Peccin, A.; Consoli, N.C.; Festugato, L. Theoretical Derivation of Artificially Cemented Granular Soil Strength. J. Geotech. Geoenviron. Eng. 2017, 143, 04017003. [Google Scholar] [CrossRef]

- Diambra, A.; Festugato, L.; Ibraim, E.; Peccin da Silva, A.; Consoli, N.C. Modelling Tensile/Compressive Strength Ratio of Artificially Cemented Clean Sand. Soils Found. 2018, 58, 199–211. [Google Scholar] [CrossRef]

- Festugato, L.; Peccin da Silva, A.; Diambra, A.; Consoli, N.C.; Ibraim, E. Modelling Tensile/Compressive Strength Ratio of Fibre Reinforced Cemented Soils. Geotext. Geomembr. 2018, 46, 155–165. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Silva Carretta, M.; Festugato, L.; Leon, H.B.; Tomasi, L.F.; Heineck, K.S. Ground Waste Glass–Carbide Lime as a Sustainable Binder Stabilising Three Different Silica Sands. Géotechnique 2021, 71, 480–493. [Google Scholar] [CrossRef]

- Ekinci, A.; Abki, A.; Mirzababaei, M. Parameters Controlling Strength, Stiffness and Durability of a Fibre-Reinforced Clay. Int. J. Geosynth. Ground Eng. 2022, 8, 6. [Google Scholar] [CrossRef]

- Hanafi, M.; Ekinci, A.; Aydin, E. Engineering and Microstructural Properties of Alluvium Clay Stabilized with Portland Cement and Coal Bottom Ash for Sustainable Future. KSCE J. Civ. Eng. 2022, 26, 5049–5066. [Google Scholar] [CrossRef]

- Lade, P.V.; Trads, N. The Role of Cementation in the Behaviour of Cemented Soils. Geotech. Res. 2014, 1, 111–132. [Google Scholar] [CrossRef]

- Baldovino, J.d.J.; dos Santos Izzo, R.L.; da Silva, É.R.; Lundgren Rose, J. Sustainable Use of Recycled-Glass Powder in Soil Stabilization. J. Mater. Civ. Eng. 2020, 32, 04020080. [Google Scholar] [CrossRef]

- Baldovino, J.; Izzo, R.; Rose, J.L.; Avanci, M.A. Geopolymers Based on Recycled Glass Powder for Soil Stabilization. Geotech. Geol. Eng. 2020, 38, 4013–4031. [Google Scholar] [CrossRef]

- Baldovino, J.d.J.A.; Izzo, R.L.d.S.; Feltrim, F.; da Silva, É.R. Experimental Study on Guabirotuba’s Soil Stabilization Using Extreme Molding Conditions. Geotech. Geol. Eng. 2020, 38, 2591–2607. [Google Scholar] [CrossRef]

- Baldovino, J.A.; Moreira, E.B.; Izzo, R.L.d.S.; Rose, J.L. Empirical Relationships with Unconfined Compressive Strength and Split Tensile Strength for the Long Term of a Lime-Treated Silty Soil. J. Mater. Civ. Eng. 2018, 30, 06018008. [Google Scholar] [CrossRef]

- Consoli, N.C.; Tomasi, L.F. The Impact of Dry Unit Weight and Cement Content on the Durability of Sand–Cement Blends. Proc. Inst. Civ. Eng.-Ground Improv. 2018, 171, 96–102. [Google Scholar] [CrossRef]

- Rios, S.; Viana da Fonseca, A.; Baudet, B.A. Effect of the Porosity/Cement Ratio on the Compression of Cemented Soil. J. Geotech. Geoenviron. Eng. 2012, 138, 1422–1426. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T.S. Assessment of Strength Development in Cement-Admixed High Water Content Clays with Abrams’ Law as a Basis. Géotechnique 2003, 53, 439–444. [Google Scholar] [CrossRef]

- Consoli, N.C.; Cruz, R.C.; Floss, M.F.; Festugato, L. Parameters Controlling Tensile and Compressive Strength of Artificially Cemented Sand. J. Geotech. Geoenviron. Eng. 2010, 136, 759–763. [Google Scholar] [CrossRef]

- Consoli, N.C.; Dalla Rosa Johann, A.; Gauer, E.A.; Dos Santos, V.R.; Moretto, R.L.; Corte, M.B. Key Parameters for Tensile and Compressive Strength of Silt-Lime Mixtures. Geotech. Lett. 2012, 2, 81–85. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.M.; da Silva Lopes, L.; Winter, D. Control Factors for the Long Term Compressive Strength of Lime Treated Sandy Clay Soil. Transp. Geotech. 2014, 1, 129–136. [Google Scholar] [CrossRef]

- Moreira, E.B.; Baldovino, J.A.; Rose, J.L.; Luis dos Santos Izzo, R. Effects of Porosity, Dry Unit Weight, Cement Content and Void/Cement Ratio on Unconfined Compressive Strength of Roof Tile Waste-Silty Soil Mixtures. J. Rock Mech. Geotech. Eng. 2019, 11, 369–378. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Fonseca, A.V.; Cruz, R.C.; Silva, S.R. Voids/Cement Ratio Controlling Tensile Strength of Cement-Treated Soils. J. Geotech. Geoenviron. Eng. 2011, 137, 1126–1131. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, A.; Deng, Y.; Cui, Y.; Yu, Z.; Yu, C. Strength Performance of Cement/Slag-Based Stabilized Soft Clays. Constr. Build. Mater. 2019, 211, 909–918. [Google Scholar] [CrossRef]

- Long, G.; Li, L.; Li, W.; Ma, K.; Dong, W.; Bai, C.; Zhou, J.L. Enhanced Mechanical Properties and Durability of Coal Gangue Reinforced Cement-Soil Mixture for Foundation Treatments. J Clean. Prod. 2019, 231, 468–482. [Google Scholar] [CrossRef]

- Wu, M.; Huang, R.; Wang, J. DEM Simulations of Cemented Sands with a Statistical Representation of Micro-Bond Parameters. Powder Technol. 2021, 379, 96–107. [Google Scholar] [CrossRef]

- Pham, T.A.; Kyokawa, H.; Koseki, J.; Dias, D. A New Index for the Strength Analysis and Prediction of Cement-Mixed Soils. Eur. J. Environ. Civ. Eng. 2023, 27, 1512–1534. [Google Scholar] [CrossRef]

- Pham, T.A.; Koseki, J.; Dias, D. Optimum Material Ratio for Improving the Performance of Cement-Mixed Soils. Transp. Geotech. 2021, 28, 100544. [Google Scholar] [CrossRef]

- Sukmak, G.; Sukmak, P.; Horpibulsuk, S.; Arulrajah, A.; Horpibulsuk, J. Generalized Strength Prediction Equation for Cement Stabilized Clayey Soils. Appl. Clay. Sci. 2023, 231, 106761. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Fonseca, A.V.; Silva, S.R.; Cruz, R.C.; Fonini, A. Parameters Controlling Stiffness and Strength of Artificially Cemented Soils. Geotechnique 2012, 62, 177–183. [Google Scholar] [CrossRef]

- Consoli, N.C.; Festugato, L.; da Rocha, C.G.; Cruz, R.C. Key Parameters for Strength Control of Rammed Sand–Cement Mixtures: Influence of Types of Portland Cement. Constr. Build. Mater. 2013, 49, 591–597. [Google Scholar] [CrossRef]

- Carvalho Queiróz, L.; Dias Miguel, G.; Jordi Bruschi, G.; Deluan Sampaio de Lima, M. Macro–Micro Characterization of Green Stabilized Alkali-Activated Sand. Geotech. Geol. Eng. 2022, 40, 3763–3778. [Google Scholar] [CrossRef]

- Portland Cement Association. Soil-Cement Laboratory Handbook; Portland Cement Association: Skokie, IL, USA, 2000. [Google Scholar]

- Kluge, K.; Kirsch, A.; Budach, C. Digitale Lehre in der Geotechnik: Aktueller Stand und weitere Entwicklungen. Geotechnik 2022, 46, 48–55. [Google Scholar] [CrossRef]

- Cui, Z.-D. Land Subsidence Induced by the Engineering-Environmental Effect; Springer: Singapore, 2018; ISBN 9789811080401. [Google Scholar]

- Mickovski, S.B. Why Is the Future Ready for Environmental Geotechnics? Environ. Geotech. 2016, 3, 63–64. [Google Scholar] [CrossRef]

- Kemeny, J.; Berman, E.; Bracke, P.; Brent, W.; Budhu, M.; Coleman, A.; Dempsey, R.; Frumkin, J.; Oxnam, M.; Przybylski, L.; et al. GROW: A Digital Library for Geotechnical, Rock, and Water Aspects of Civil Engineering. In Proceedings of the 2002 ASEE Annual Conference and Exposition: Vive L’ingenieur, Montreal, QC, Canada, 16 June 2002; pp. 5523–5533. [Google Scholar]

- da Rocha, C.G.; Passuello, A.; Consoli, N.C.; Quiñónez Samaniego, R.A.; Kanazawa, N.M. Life Cycle Assessment for Soil Stabilization Dosages: A Study for the Paraguayan Chaco. J. Clean. Prod. 2016, 139, 309–318. [Google Scholar] [CrossRef]

- Consoli, N.C.; Festugato, L.; Filho, H.C.S.; Miguel, G.D.; Neto, A.T.; Andreghetto, D. Durability Assessment of Soil-Pozzolan-Lime Blends through Ultrasonic-Pulse Velocity Test. J. Mater. Civ. Eng. 2020, 32, 04020223. [Google Scholar] [CrossRef]

| Mix Design | Parameter a | Parameter 1/a | Theoretical a | p/a | Reference |

|---|---|---|---|---|---|

| Silty soil–cement–recycled glass powder | 3.87 | 0.20 | 0.26 | 0.77/β | [17] |

| Silty soil–cement–recycled glass powder | 3.92 | 0.22 | 0.26 | 0.86/β | [18] |

| Cement-treated soil | 3.30 | 0.44 | 0.30 | 1.45/β | [19] |

| Cement-treated soil | 3.30 | 0.44 | 0.30 | 1.45/β | [19] |

| Silty soil–lime | 4.39 | 0.20 | 0.23 | 0.88/β | [20] |

| Cement-treated soil–ground tile waste | 4.47 | 0.28 | 0.22 | 1.25/β | [21] |

| Osorio sand–lime–glass powder | 3.60 | 0.28 | 0.28 | 1.00/β | [13] |

| Porto Alegre sand–lime–glass powder | 3.60 | 0.28 | 0.28 | 1.00/β | [13] |

| Rio Pardo sand–lime–glass powder | 3.60 | 0.28 | 0.28 | 1.00/β | [13] |

| Soil Detail | Sand (%) | Silt (%) | Clay (%) | Limit Liquid (%) | Plasticity Index (%) | USCS Classification | Specific Gravity | Mainly Minerals | Reference |

|---|---|---|---|---|---|---|---|---|---|

| Osorio sand | 100 | - | - | - | - | SP | 2.65 | Quartz | Consoli et al. [13,24] |

| Porto Alegre sand | 100 | - | - | - | - | SP | 2.65 | Quartz | Consoli et al. [13] |

| Rio Pardo sand | 100 | - | - | - | - | SP | 2.68 | Quartz | Consoli et al. [13] |

| Silt–lime | 1.5 | 65.5 | 33 | 39 | 4 | ML | 2.64 | Kaolinite | Consoli et al. [25] |

| Porto Alegre sandy clay | 53.7 | 42 | 4.3 | 24 | 9 | CL | 2.81 | Kaolinite | Consoli et al. [26] |

| Guabirotuba silt | 33.4 | 57.6 | 9.3 | 53.1 | 21.3 | MH | 2.71 | Kaolinite | Moireira et al. [27] |

| Southern Brazil soil | 35 | 60 | 5 | 50.8 | 14.9 | MH | 2.62 | Kaolinite and quartz | Baldovino et al. [17] |

| Reference | Type of Mix | Amount of the Additives (%) | % Cement or Lime | Curing Days | Water Content w (%) | Original R2 |

|---|---|---|---|---|---|---|

| [24] | Osorio sand–cement | - | 1, 2, 3, 5, 7, 9 and 12 | 7 | 10 | 0.97–0.98 |

| [25] | Silt–lime | - | 3, 5, 7 and 9 | 28 | 20 | 0.82–0.95 |

| [26] | Silty soil–lime | - | 3, 5, 7 and 9 | 28, 90 and 360 | 23 | 0.89–0.96 |

| [27] | Soil–roof tile–cement | 5, 15 and 30 | 3, 6 and 9 | 28 | 23 | 0.97–0.98 |

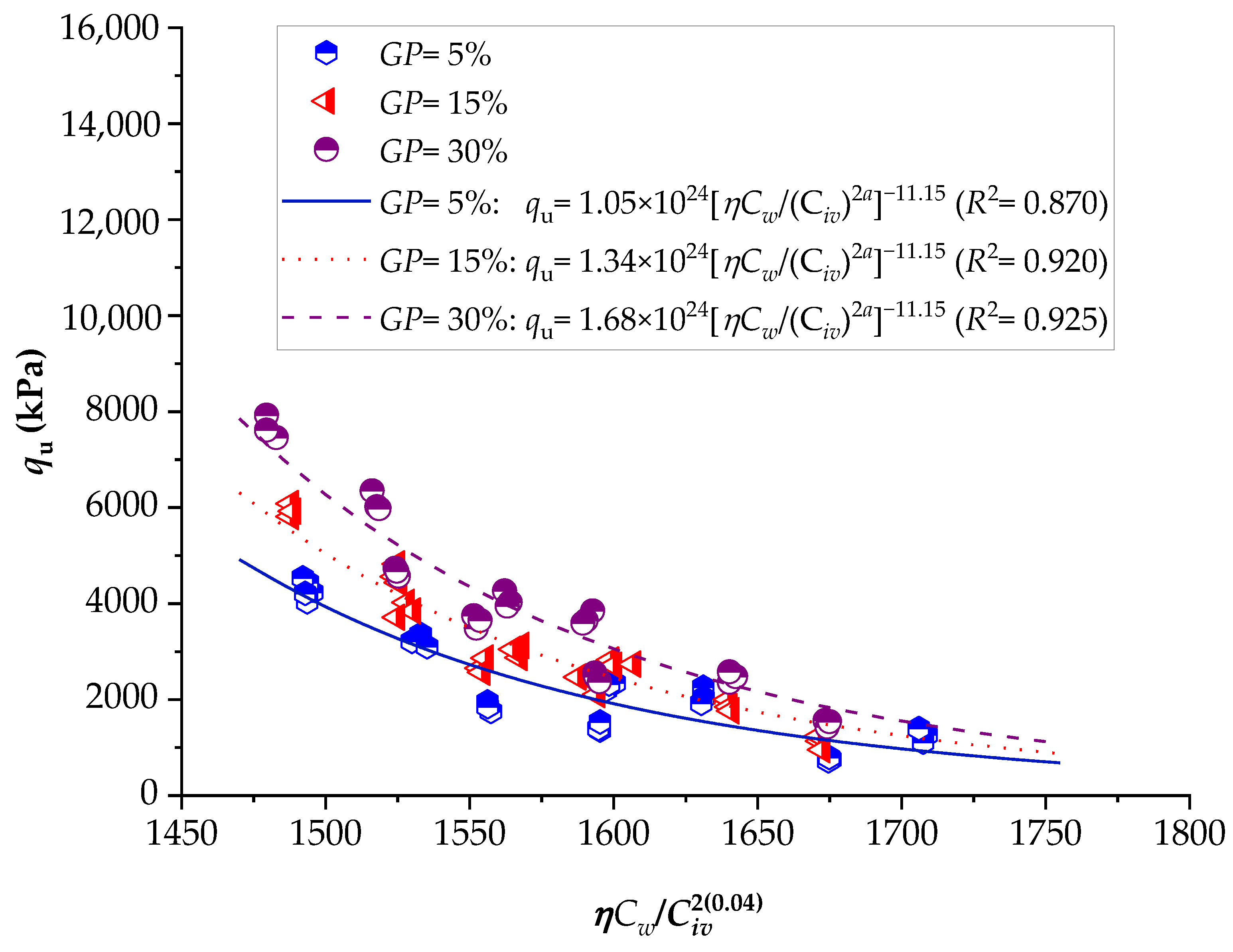

| [17] | Soil–glass powder–cement | 5, 15 and 30 | 3, 6 and 9 | 7, 28 and 90 | 26 | 0.88–0.99 |

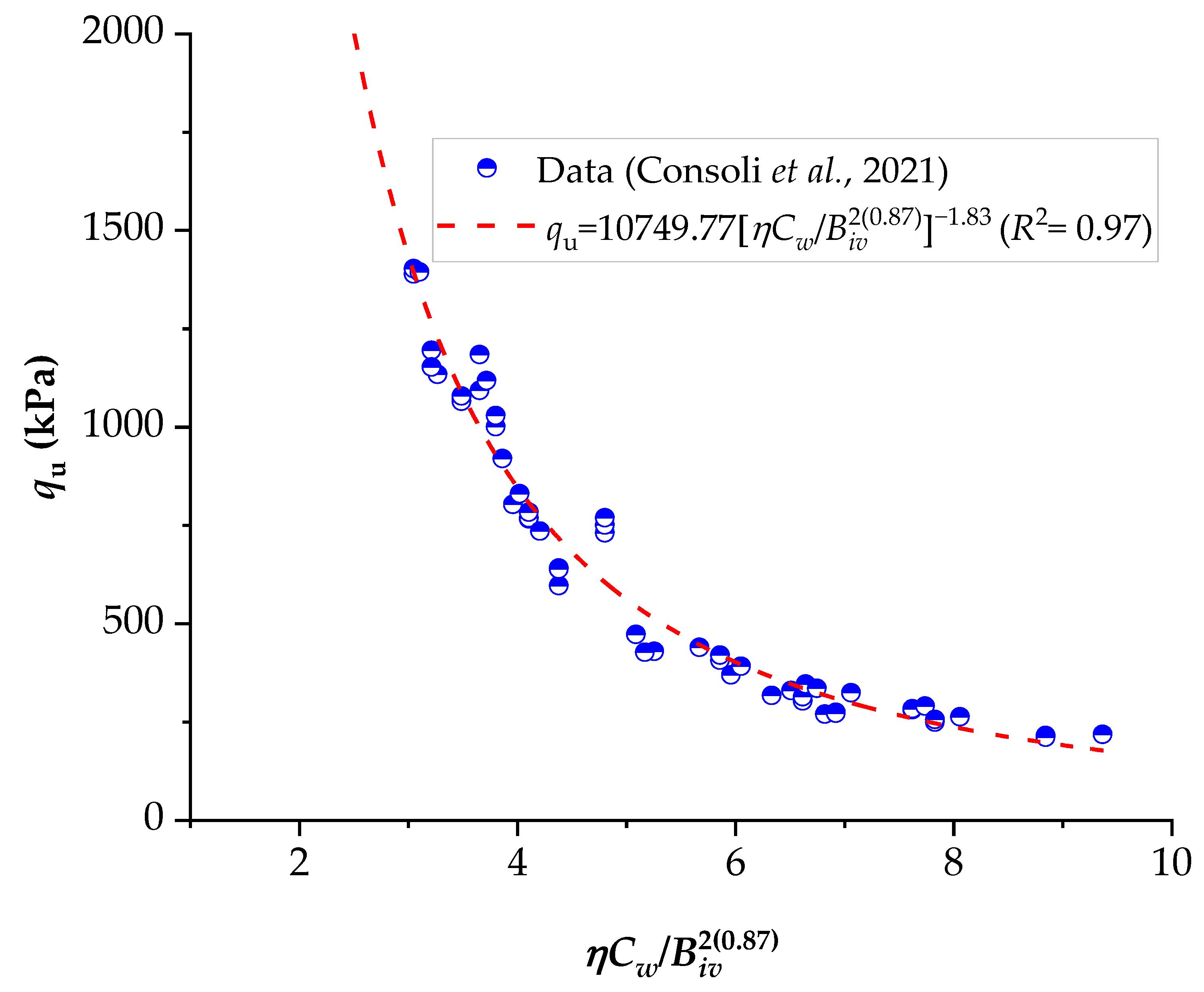

| [13] | Osorio sand–carbide lime–glass powder * | 10 and 20 | 3, 5 and 7 | 7 | 10 | 0.86 ** |

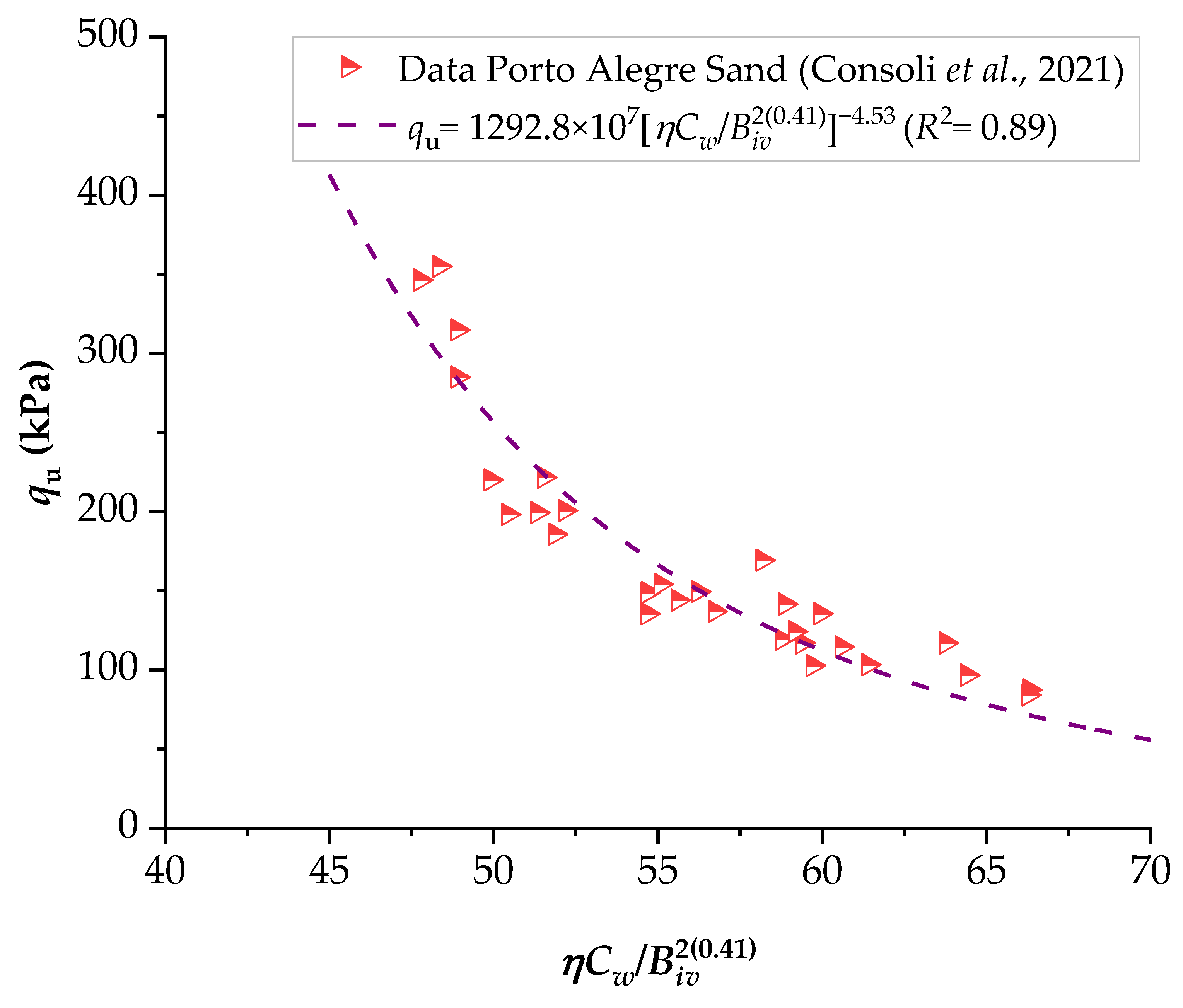

| [13] | Porto Alegre sand–carbide lime–glass powder * | 10 and 20 | 3, 5 and 7 | 7 | 10 | 0.64 ** |

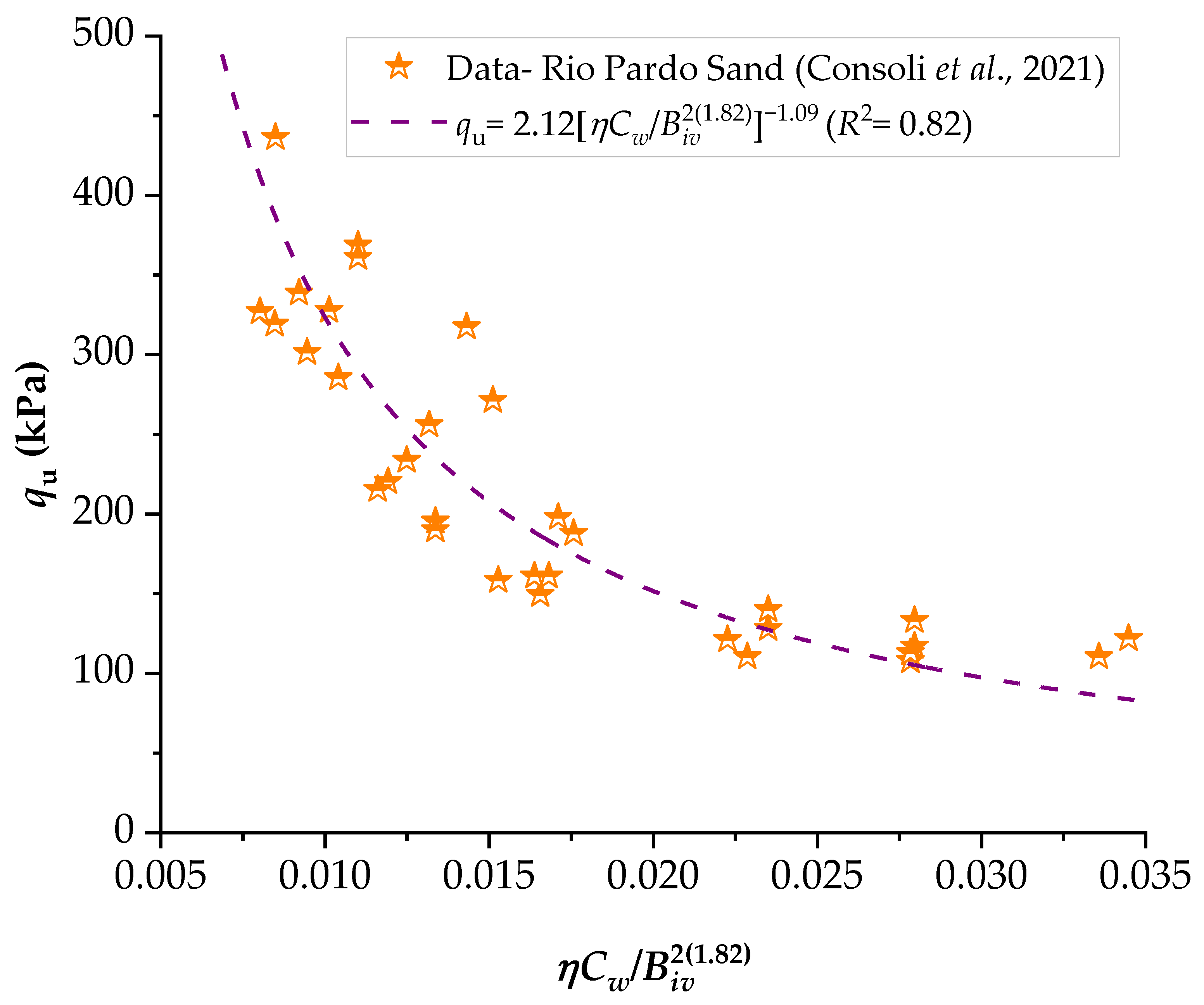

| [13] | Rio Pardo sand–carbide lime–glass powder * | 10 and 20 | 3, 5 and 7 | 7 | 10 | 0.77 ** |

| [21] | Sand–cement *** | - | 3, 6, and 9 | 7 | 10 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baldovino, J.A.; Nuñez de la Rosa, Y.E.; Palma Calabokis, O. Analysis of Novel Porosity–Water-to-Binder Index for Prediction of Strength, Stiffness and Durability for Cemented Soils. Materials 2023, 16, 6354. https://doi.org/10.3390/ma16196354

Baldovino JA, Nuñez de la Rosa YE, Palma Calabokis O. Analysis of Novel Porosity–Water-to-Binder Index for Prediction of Strength, Stiffness and Durability for Cemented Soils. Materials. 2023; 16(19):6354. https://doi.org/10.3390/ma16196354

Chicago/Turabian StyleBaldovino, Jair Arrieta, Yamid E. Nuñez de la Rosa, and Oriana Palma Calabokis. 2023. "Analysis of Novel Porosity–Water-to-Binder Index for Prediction of Strength, Stiffness and Durability for Cemented Soils" Materials 16, no. 19: 6354. https://doi.org/10.3390/ma16196354

APA StyleBaldovino, J. A., Nuñez de la Rosa, Y. E., & Palma Calabokis, O. (2023). Analysis of Novel Porosity–Water-to-Binder Index for Prediction of Strength, Stiffness and Durability for Cemented Soils. Materials, 16(19), 6354. https://doi.org/10.3390/ma16196354