Determination of Saturation Conditions of the Aluminum Metal Matrix Composites Reinforced with Al2O3 Sinter

Abstract

:1. Introduction

- σ—the value of the liquid surface tension [N/m],

- dmin—substitute diameter [m], and

- θ—the contact angle [°].

- –

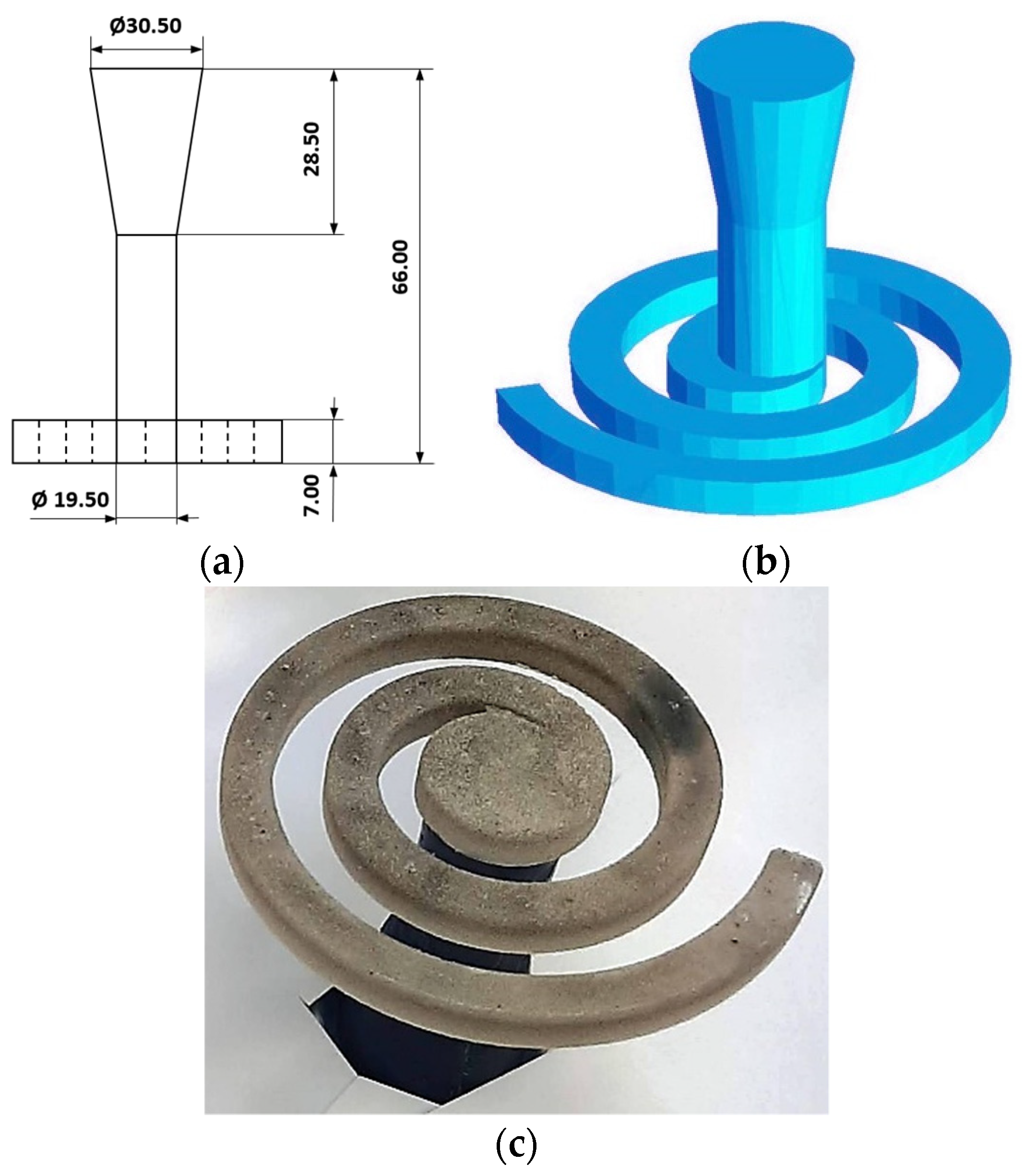

- Creating a 3D model of a fitting in the form of a spiral with HIPS.

- –

- Ceramic coating of printed HIPS fittings.

- –

- Firing ceramic shapes (creating a spiral-shaped reinforcing structure–ceramic sinter).

- –

- Composite casting, consisting of preparing the mold, placing reinforcement in it, pouring liquid metal into the mold, and solidifying, cooling, and removing the casting from the mold. The casting operation was performed eight times with different process parameters.

- –

- Assessment of the degree of saturation of the fitting by measuring the distance from the face of the spiral using microscopic methods.

- –

- Performance of the energy balance of the composite casting manufacturing process.

- –

- Verification of the casting process by the finite difference method (FDM).

2. Methods

2.1. Optical Microscopy

2.2. Energy Balance of the Process of Producing Composite Castings

- V—the composite volume,

- P—the porosity of the ceramic preform,

- cmet—the specific heat of infiltrating metal matrix,

- czbr—the specific heat of the reinforcement material,

- ρmet—the density of the infiltrating metal matrix,

- ρzbr—the reinforcement density,

- ΔTmet—the temperature decrease in the liquid matrix, and

- ΔTzbr—the temperature increase in the reinforcement material.

- Tmet—the initial temperature of the liquid matrix,

- Tzbr—the initial temperature of the reinforcement, and

- Tk—the temperature of the infiltrated composite.

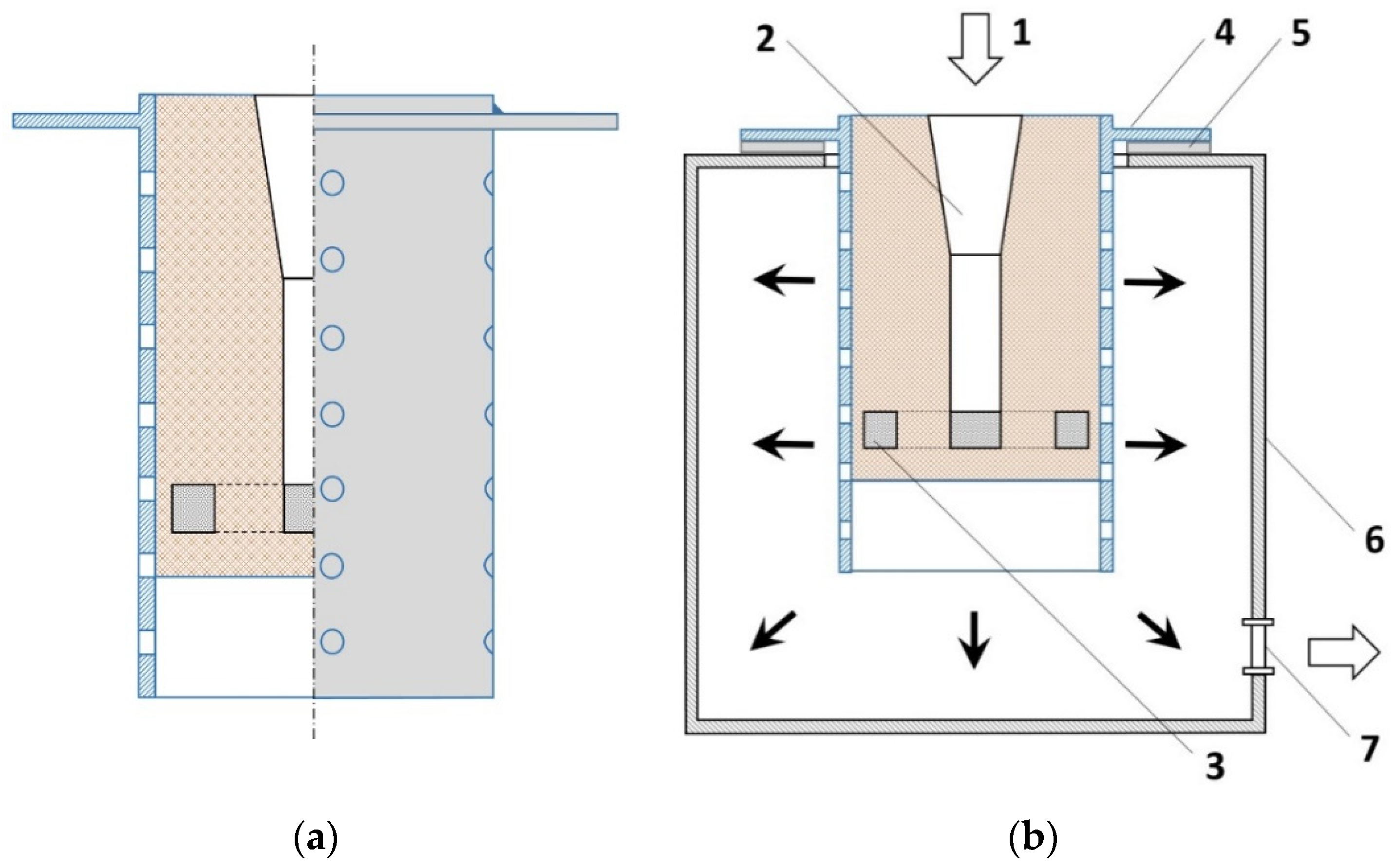

3. Materials and Samples Preparation

- -

- Placing the mold on the stand,

- -

- Connecting the measuring elements to the recorder,

- -

- Starting the vacuum pump,

- -

- Pouring liquid alloy into the mold,

- -

- Turning off the pump, after the alloy solidifies in the gating system, and

- -

- Knocking the casting out of the mold.

4. Results

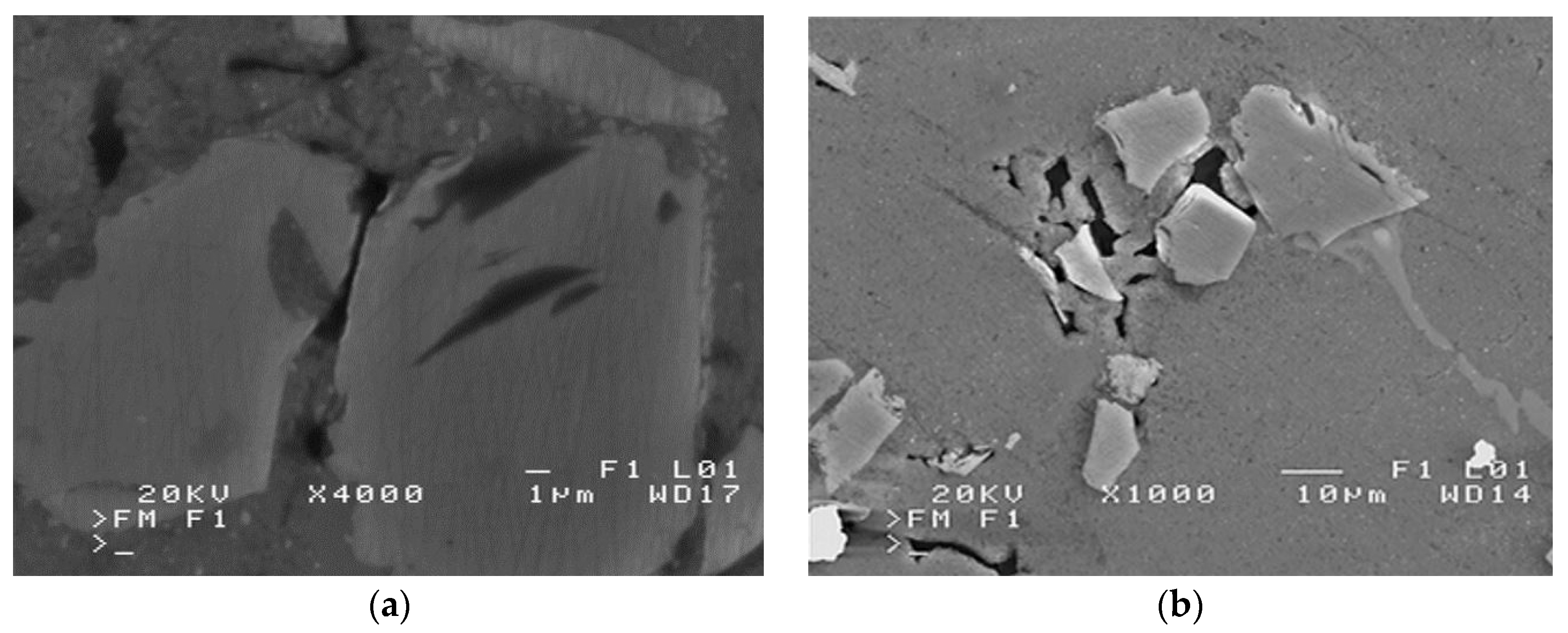

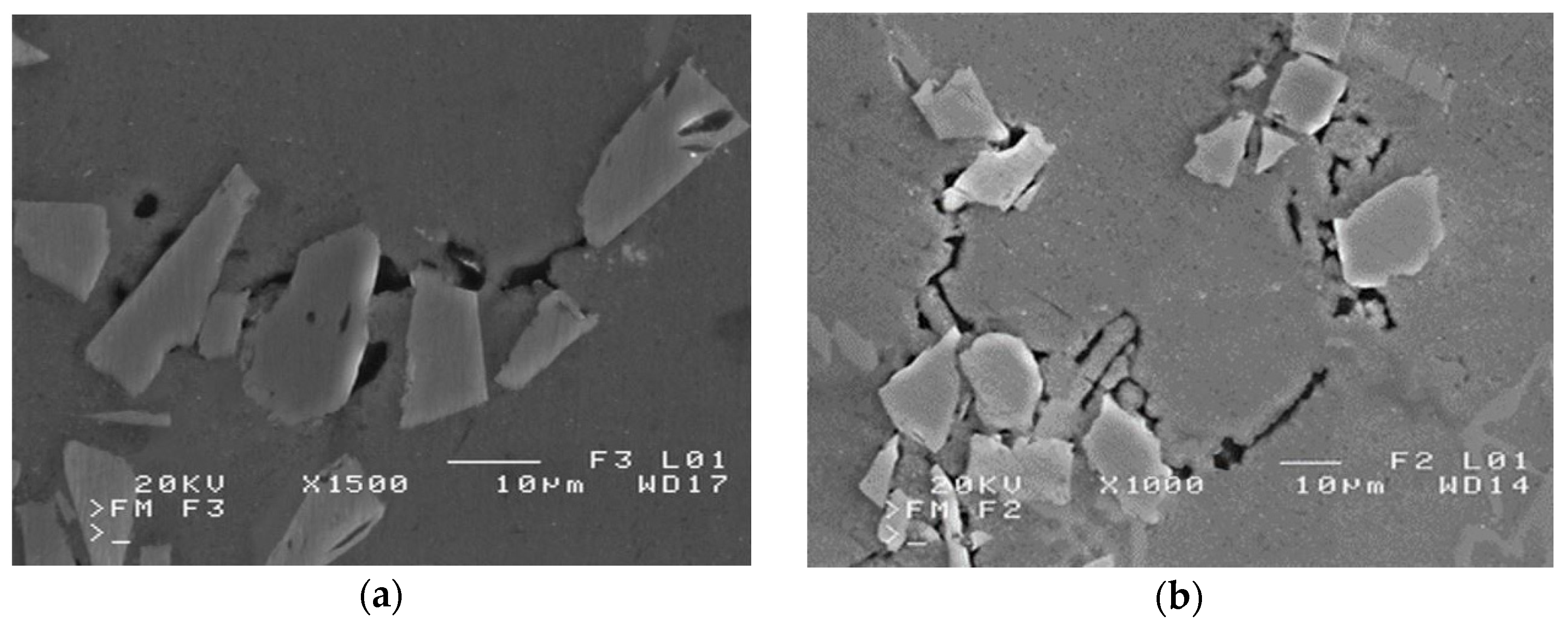

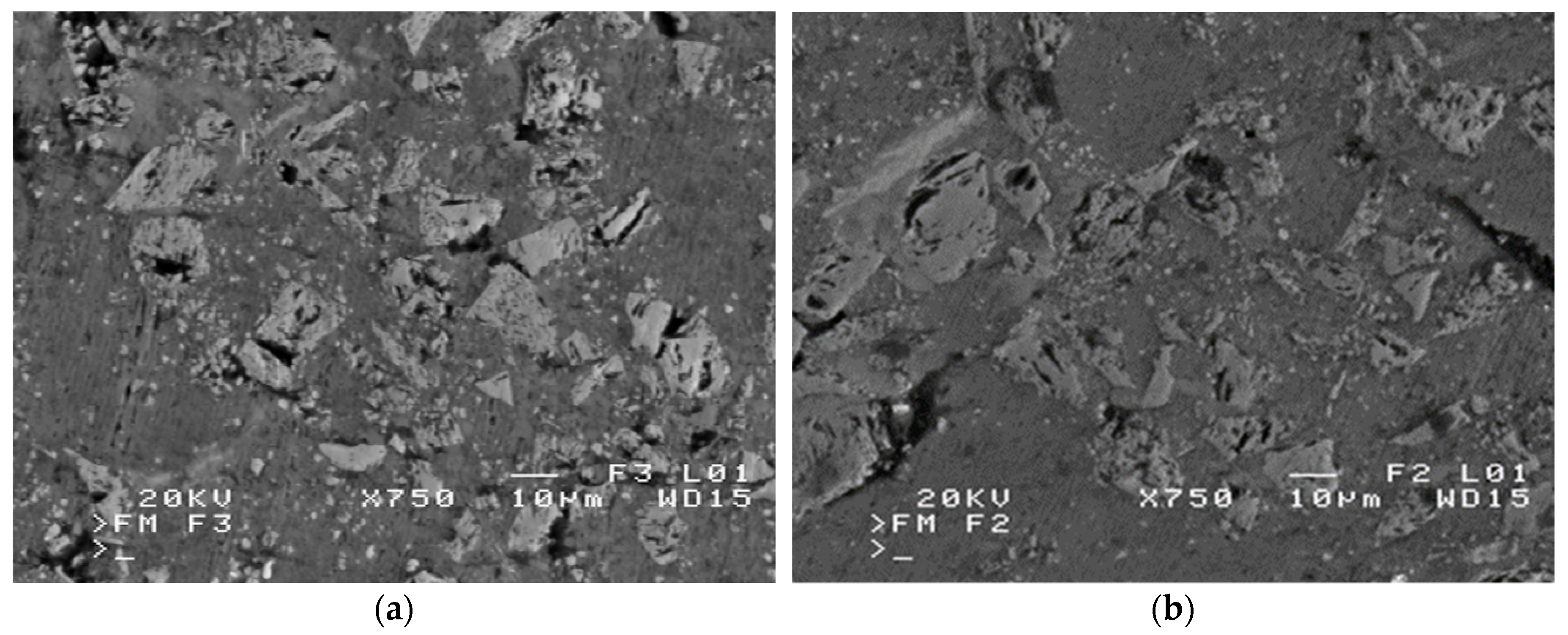

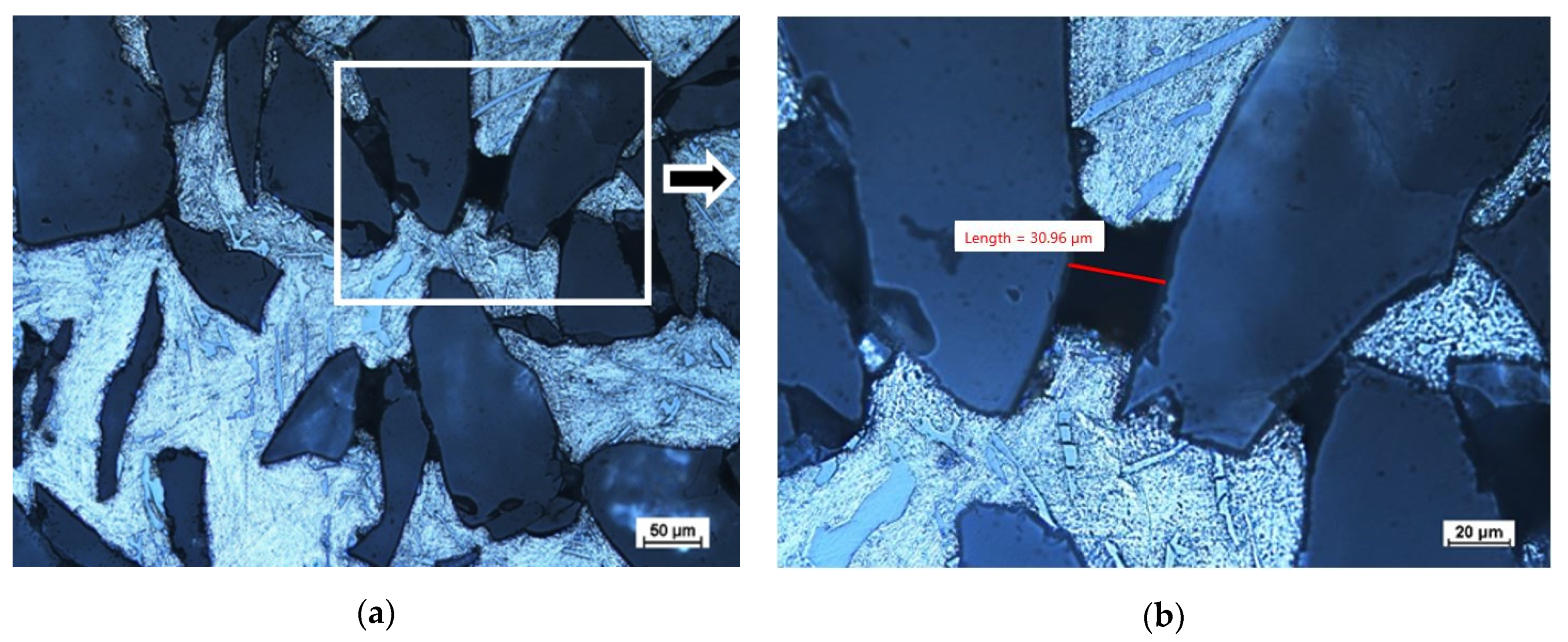

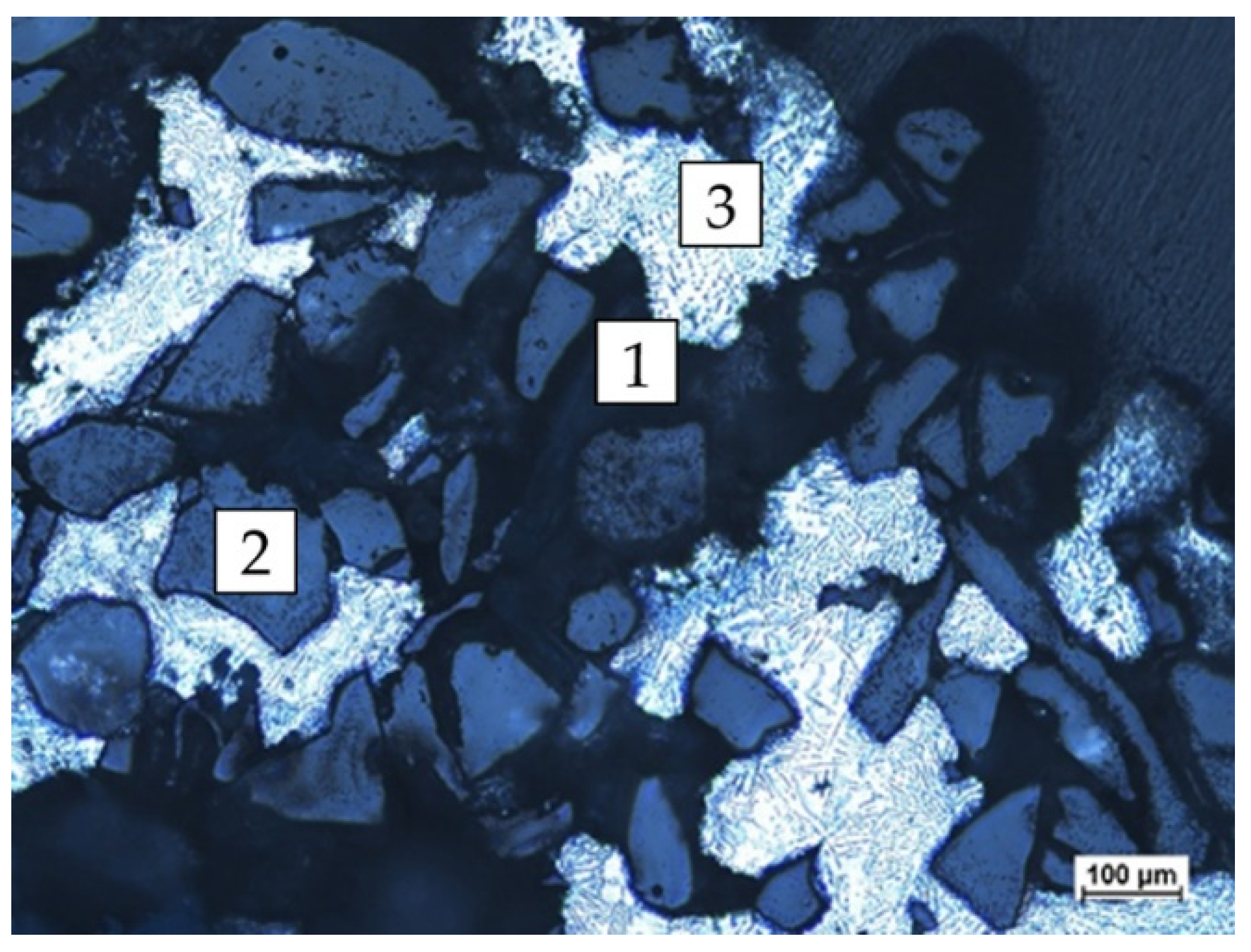

4.1. Assessment of the Infiltration Level of the Microstructure with the Use of an Optical Microscope

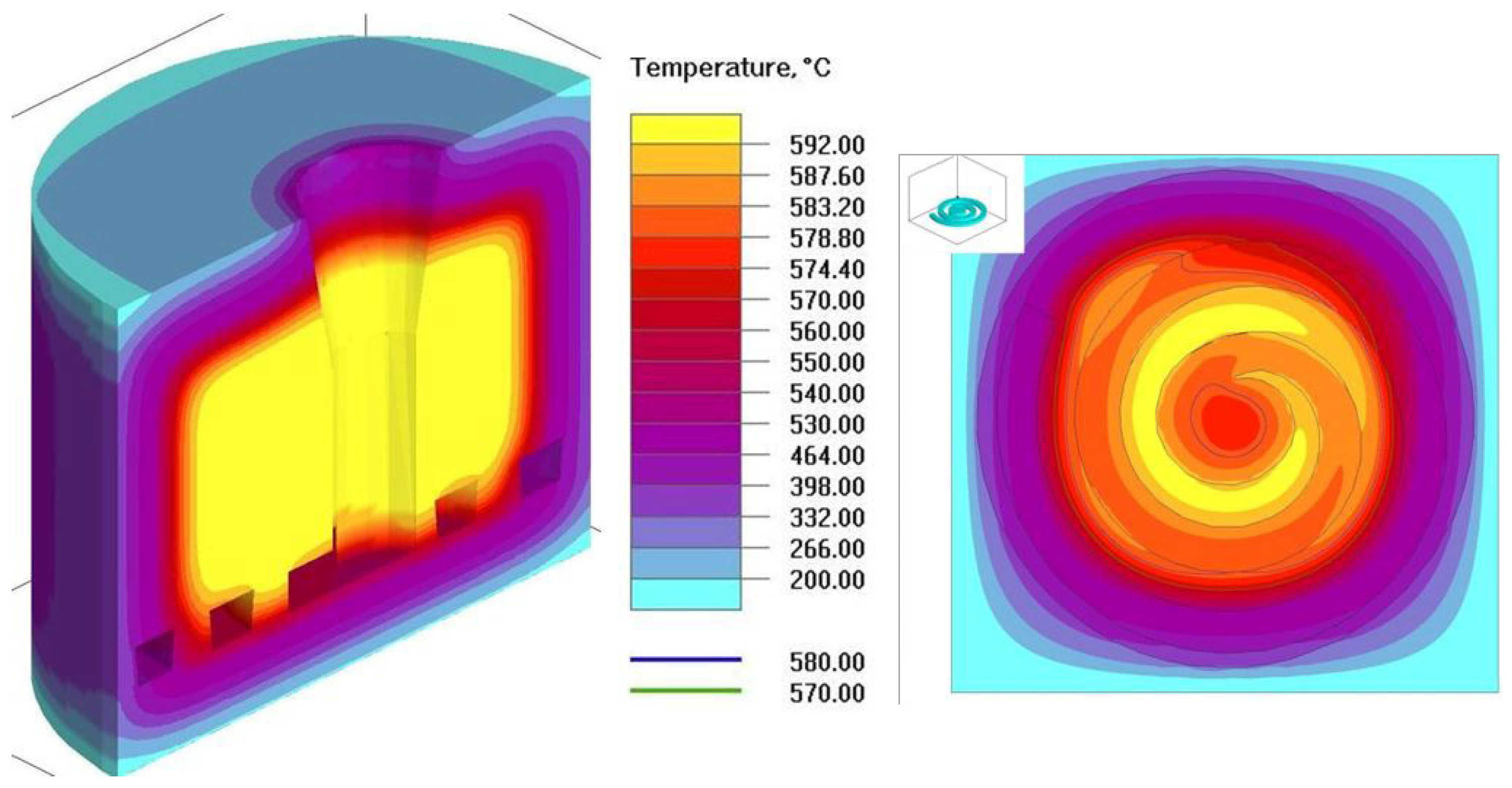

4.2. Energy Balance for the Production Process of Castings Reinforced with Al2O3 Sinter with an AlSi11 Matrix

5. Conclusions

- The use of rapid prototyping techniques for the production of reinforcement allowed for a significant reduction in the time and cost of the research. The reinforcement produced in this way makes it possible to obtain composite castings of a given shape, which is very important from the point of view of the use of castings. The analysis of the impact of polystyrene on ceramics, aluminum matrix requires further research, which exceeded the scope of this work.

- The tests show that for the conditions presented in Table 3, it is possible to saturate a capillary with a diameter exceeding 25 microns.

- It is possible by experimental means to determine the basic parameters of infiltration for composite materials. However, the determination of the infiltration level using optical microscopy is poorly precise and requires the use of additional tests, e.g., computer microtomography, which will be the next stage of our work.

- The experimental results may be helpful for the numerical simulation of the mold-filling process in composite castings with reinforcement infiltration with a liquid silumin matrix.

- The energy balance shows that the limit temperature of the feeding was Tk = 580.7 °C, and hence this is the temperature above the liquidus temperature (Tliq = 579.3 °C) for the tested aluminum alloy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mutwil, J.; Janowski, R. Attributes of single-phase silumins flow in channnels of metal mould. Arch. Foundry 2001, 1, 257–262. (In Polish) [Google Scholar]

- Konopka, Z.; Cisowska, M. Flow estimation of AlMg10 liquid alloy in spiral castability test. Arch. Foundry 2002, 2, 135–140. [Google Scholar]

- Mutwil, J. Flow of AlCu4% alloy in a mould channel. In Communications on the Edge of the Millenniums; University of Żilina: Žilina, Slovakia, 1998; pp. 147–150. [Google Scholar]

- Popielarski, P.; Hajkowski, J.; Sika, R.; Ignaszak, Z. Computer simulation of cast iron flow in castability trials. Arch. Metall. Mater. 2019, 64, 1433–1439. [Google Scholar] [CrossRef]

- Mutwil, J.; Żygadło, M.; Janowski, R.; Niedźwiecki, D. New stand for fluidity investigation. Solidif. Met. Alloys 2000, 44, 497–502. (In Polish) [Google Scholar]

- Arnberg, L.; Mo, A. Castability-fluidity and hot tearing. In Metals Handbook; ASM: Almere, The Netherlands, 2008; p. 375. [Google Scholar]

- Fraś, E.; Górny, M.; Stachurski, W. Problem of super-thin wall nodular cast iron castings. Przegląd Odlew. 2006, 56, 230–238. [Google Scholar]

- Falęcki, Z. Analysis of Casting Defects; AGH: Crakow, Poland, 1997. [Google Scholar]

- Tabor, A. Odlewnictwo; Wydawnictwo Politechniki Krakowskiej: Kroków, Poland, 2007. (In Polish) [Google Scholar]

- Sabatino, M.D.; Arnberg, L. Castability of aluminium alloys. Trans. Indian Inst. Met. 2009, 62, 321–325. [Google Scholar] [CrossRef]

- Ray, S. Review: Synthesis of Cast Metal Matrix Particulate Composites. J. Mater. Sci. 1993, 28, 5397–5413. [Google Scholar] [CrossRef]

- Ignaszak, Z.; Popielarski, P.; Hajkowski, J. Sensitivity of models applied in selected simulation systems with respect to database quality for resolving of casting problems. Defect Diffus. Forum 2013, 336, 135–146. [Google Scholar] [CrossRef]

- Ignaszak, Z.; Popielarski, P.; Hajkowski, J.; Codina, E. Methodology of Comparative Validation of Selected Foundry Simulation Codes. Arch. Foundry Eng. 2015, 15, 37–44. [Google Scholar] [CrossRef]

- BN-79/4051-17; Technological Castability Trial for Alloys. Polish Industy Standard: Warsaw, Poland, 1979.

- Kayal, S.; Behera, R.; Sutradhar, G. Castability of Al-SiCp metal matrix composites in thin walled castings. Int. J. Eng. Sci. Technol. 2012, 4, 3481–3488. [Google Scholar]

- Grabian, J. The Saturation of Reinforcement with Ceramic Disordered Fibres during the Production of Cast of Metal Composites; Wydawnictwo WSM: Szczecin, Poland, 2001. (In Polish) [Google Scholar]

- Szymański, P.; Gawdzińska, K.; Nagolska, D. Attempts to prepare precision composite castings by sintering Al2O3/AlSi11 using underpressure. Arch. Foundry Eng. 2020, 20, 49–54. [Google Scholar] [CrossRef]

- Dolata, A.J. Fabrication and Structure Characterization of Alumina-Aluminum Interpenetrating Phase Composites. J. Mater. Eng. Perform. 2016, 25, 3098–3106. [Google Scholar] [CrossRef]

- Dmitruk, A.; Naplocha, K.; Żak, A.; Dieringa, H.; Kainer, K.U. Development of Pore-Free Ti-Si-C MAX/Al-Si Composite Materials Manufactured by Squeeze Casting Infiltration. J. Mater. Eng. Perform. 2019, 28, 6248–6257. [Google Scholar] [CrossRef]

- Kapłon, H.; Dmitruk, A.; Naplocha, K. Investment casting of AZ91 Magnesium Open-Cell Foams. Arch. Foundry Eng. 2023, 23, 11–16. [Google Scholar] [CrossRef]

- Pazhani, A.; Venkatraman, M.; Xavior, A.M.; Moganraj, M.; Batako, A.; Paulsamy, J.; Jayaseelan, J.; Anbalagan, A.; Bavan, S.J. Synthesis and characterisation of graphene-reinforced AA 2014 MMC using squeeze casting method for lightweight aerospace structural applications. Mater. Des. 2023, 230, 111990. [Google Scholar] [CrossRef]

- Calin, R.; Citak, R. Effect of Powder size on infiltration height in producing MgO reinforced Al matrix composites by vacuum infiltration method. Mater. Sci. Forum 2007, 534–536, 797–800. [Google Scholar] [CrossRef]

- Szweycer, M. Surface Phenomene in Metal-Matrix Cast Composites Technology, Cast Composites, Commission 8.1; CIATF: Poznan, Poland, 1998. [Google Scholar]

- Gawdzińska, K.; Chybowski, L.; Bejger, J.A.; Krile, S. Determination of technological parameters of saturated composites based on sic by means of a model liquid. Metalurgija 2016, 55, 659–662. [Google Scholar]

- Dolata, A.J. Centrifugal infiltration of porous ceramic preforms by the liquid Al alloy—Theoretical background and experimental verification. Arch. Metall. Mater. 2016, 61, 411–418. [Google Scholar] [CrossRef]

- Travitzky, N.; Kumar, P.; Sandhage, K.H.; Janssen, R.; Claussen, N. Rapid synthesis of Al2O3 reinforced Fe-CrNi composites. Mater. Sci. Eng. A 2003, 344, 245–252. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Grześkowiak, K.; Popielarski, P.; Barczewski, M.; Gawdzińska, K.; Popławski, M. Polyethylene Wax Modified by Organoclay Bentonite Used in the Lost-Wax Casting Process: Processing−Structure−Property Relationships. Materials 2020, 13, 2255. [Google Scholar] [CrossRef]

- Aziz, M.N.A.; Rusnaldy; Munyensanga, P.; Widyanto, S.A.; Paryanto. Application of lost wax casting for manufacturing of orthopedic screw: A review. Procedia CIRP 2018, 78, 149–154. [Google Scholar] [CrossRef]

- Burlaga, B.; Kroma, A.; Poszwa, P.; Kłosowiak, R.; Popielarski, P.; Stręk, T. Heat Transfer Analysis of 3D Printed Wax Injection Mold Used in Investment Casting. Materials 2022, 15, 6545. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Sama, S.R.; Lynch, P.C.; Manogharan, G. Design and Topology Optimization of 3D-Printed Wax Patterns for Rapid Investment Casting. Procedia Manuf. 2019, 34, 683–694. [Google Scholar] [CrossRef]

- Kim, G.B.; Lee, S.; Kim, H.; Yang, D.H.; Kim, Y.H.; Kyung, Y.S.; Kim, N. Three-Dimensional Printing: Basic Principles and Applications in Medicine and Radiology. Korean J. Radiol. 2016, 17, 182–197. [Google Scholar] [CrossRef]

- Garzon-Hernandezab, S.; Arias, A.; Garcia-Gonzalez, D. A continuum constitutive model for FDM 3D printed thermoplastics. Compos. Part B Eng. 2020, 201, 108373. [Google Scholar] [CrossRef]

- Kroma, A.; Mendak, M.; Jakubowicz, M.; Gapiński, B.; Popielarski, P. Non-Contact Multiscale Analysis of a DPP 3D-Printed Injection Die for Investment Casting. Materials 2021, 14, 6758. [Google Scholar] [CrossRef]

- Yuen, P.K. Embedding objects during 3D printing to add new functionalities. Biomicrofluidics 2016, 10, 044104. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef]

- Duffy, D.C.; McDonald, J.C.; Schueller, O.J.A.; Whitesides, G.M. Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal. Chem. 1998, 70, 4974–4984. [Google Scholar] [CrossRef]

- An, W.; Sun, J.; Liew, K.M.; Zhu, G. Flammability and safety design of thermal insulation materials comprising PS foams and fire barrier materials. Mater. Des. 2016, 99, 500–508. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Hittini, W.; Mourad, A.H. Development of date pit-polystyrene thermoplastic heat insulator material: Physical and thermal properties. Int. J. Polym. Sci. 2019, 2019, 1697627. [Google Scholar] [CrossRef]

- Martins, C.R.; Ruggeri, G.; De Paoli, M.A. Synthesis in Pilot Plant Scale and Physical Properties of Sulfonated Polystyrene. J. Braz. Chem. Soc. 2003, 14, 797–802. [Google Scholar] [CrossRef]

- Sika, R.; Rogalewicz, M.; Popielarski, P.; Czarnecka-Komorowska, D.; Przestacki, D.; Gawdzińska, K.; Szymański, P. Decision Support System in the Field of Defects Assessment in the Metal Matrix Composites Castings. Materials 2020, 13, 3552. [Google Scholar] [CrossRef]

- Krawiec, P.; Różański, L.; Czarnecka-Komorowska, D.; Warguła, Ł. Evaluation of the Thermal Stability and Surface Characteristics of Thermoplastic Polyurethane V-Belt. Materials 2020, 13, 1502. [Google Scholar] [CrossRef]

- Product Card. Available online: https://devildesign.com/download/HIPS_-_product_card.pdf (accessed on 29 October 2020).

- Granulacje Ziarna Ściernego. Available online: https://www.korund.pl/granulacje (accessed on 29 October 2020). (In Polish).

- Guzera, J. Wykonywanie odlewów metodą wytapianych modeli w autoklawizowanych formach gipsowych. Arch. Foundry Eng. 2010, 10, 307–310. (In Polish) [Google Scholar]

- Jackowski, J.; Szweycer, M.; Szymański, P. Assessment of surface properties of liquid metals and alloys in liquid media. Kompozyty (Composites) 2006, 2, 60–64. (In Polish) [Google Scholar]

- Nagolska, D.; Szymański, P.; Pędzich, Z. The role of the parameters of reinforcing profile structure in the recycling process of metal composites with saturated reinforcement. Arch. Technol. Masz. I Autom. 2006, 26, 77–86. (In Polish) [Google Scholar]

- Sobczak, N. Zwilżalność, struktura i właściwości granic rozdziału w układzie Al/Al2O3. Kompozyty (Composites) 2003, 7, 301–313. (In Polish) [Google Scholar]

- Takahashi, M.; Giuranno, D.; Ricci, E.; Arato, E.; Novakovic, R.M. Surface Properties of Liquid Al-Si Alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 1050–1060. [Google Scholar] [CrossRef]

- Bernat, Ł.; Popielarski, P. Identification of substitute thermophysical properties of gypsum mould. Arch. Foundry Eng. 2020, 20, 5–8. [Google Scholar] [CrossRef]

| Material | Bonding Agent | Grain Sizes of Sintered Particles (μm) | Average Porosity of the Preform (%) | Theoretical Mean Size of Pores (μm) |

|---|---|---|---|---|

| powder Al2O3 | Water glass | 100 | 46.6 | 64.6 |

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|

| 11.4 | 0.14 | 0.01 | 0.05 | 0.4 | 0.02 | 0.11 | Rest |

| No. | Alloy Temp. [°C] | Reinforcement Temp. [°C] | Mold Temp. [°C] | Infiltration [mm] |

|---|---|---|---|---|

| 1 | 680 | 600 | 600 | 350 (max) |

| 2 | 640 | 600 | 600 | 350 (max) |

| 3 | 600 | 599 | 590 | 350 (max) |

| 4 | 590 | 599 | 590 | 350 (max) |

| 5 | 585 | 597 | 580 | 163 |

| 6 | 591 | 582 | 510 | 178 |

| 7 | 589 | 587 | 546 | 164 |

| 8 | 589 | 585 | 514 | 154 |

| Parameter | Value |

|---|---|

| External pressure | 0.98 atm |

| Pressure in chamber | 0.05 atm |

| Infiltration time | 15 min |

| Capillary Diameter d [µm] | Pressure Value, Pa | ||

|---|---|---|---|

| Capillary Pressure (-) Pk | Infiltration Pressure (+) Pn | Resultant Pressure ΔP = Pk + Pn | |

| 10 | 241,698 | 96,380 | −145,318 |

| 15 | 161,132 | 96,380 | −64,752 |

| 20 | 120,849 | 96,380 | −24,469 |

| 25 | 96,679 | 96,380 | −299 |

| 25.08 | 96,370 | 96,380 | 10 |

| 30 | 80,566 | 96,380 | 15,814 |

| 35 | 69,056 | 96,380 | 27,324 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szymański, P.; Popielarski, P.; Czarnecka-Komorowska, D.; Sika, R.; Gawdzińska, K. Determination of Saturation Conditions of the Aluminum Metal Matrix Composites Reinforced with Al2O3 Sinter. Materials 2023, 16, 6106. https://doi.org/10.3390/ma16186106

Szymański P, Popielarski P, Czarnecka-Komorowska D, Sika R, Gawdzińska K. Determination of Saturation Conditions of the Aluminum Metal Matrix Composites Reinforced with Al2O3 Sinter. Materials. 2023; 16(18):6106. https://doi.org/10.3390/ma16186106

Chicago/Turabian StyleSzymański, Paweł, Paweł Popielarski, Dorota Czarnecka-Komorowska, Robert Sika, and Katarzyna Gawdzińska. 2023. "Determination of Saturation Conditions of the Aluminum Metal Matrix Composites Reinforced with Al2O3 Sinter" Materials 16, no. 18: 6106. https://doi.org/10.3390/ma16186106

APA StyleSzymański, P., Popielarski, P., Czarnecka-Komorowska, D., Sika, R., & Gawdzińska, K. (2023). Determination of Saturation Conditions of the Aluminum Metal Matrix Composites Reinforced with Al2O3 Sinter. Materials, 16(18), 6106. https://doi.org/10.3390/ma16186106