Antibacterial and Antifungal Properties of Polyester, Polylactide, and Cotton Nonwovens and Fabrics, by Means of Stable Aqueous Dispersions Containing Copper Silicate and Some Metal Oxides

Abstract

:1. Introduction

2. Experimental Part

2.1. Materials

- -

- WIFP-270 with a surface mass of approx. 270 g/m2 (Łukasiewicz Research Network–Lodz Institute of Technology, Łódź, Poland),

- -

- Filter nonwovens: FS G-4 with a surface mass of approx. 210 g/m2 and FS F-5 with a surface mass of approx. 240 g/m2 (Filter Service Ltd., Zgierz, Poland),

- -

- Polyester nonwoven (aqua-jet, Hydronina) having a surface mass of approx. 100 g/m2 (Lentex, Lubliniec, Polska),

- -

- Polylactide nonwoven fabric (PLA-350) with a surface mass of approx. 350 g/m2 (ZPHU Gramix, Brzeziny, Poland),

- -

- Polyester fabric with a twill weave and a surface mass of approx. 140 g/m2 (Andropol S.A., Andrychów, Poland).

- -

- Cotton–polyester fabric with 70 wt.% content of PES (Figaro), having a twill weave and a surface mass of approx. 170 g/m2 (Andropol S.A., Andrychów, Poland),

- -

- Cotton fabric (Medical) with a plain weave and a surface mass of approx. 150 g/m2 (Andropol S.A., Andrychów, Poland).

2.2. Chemical Reagents

- Copper sulfate CuSO4∙5H2O, pure (Chempur, Piekary Śląskie, Poland),

- Vitrosilicon 137S, a water solution of sodium water glass, having a SiO2:Na2O molar ratio of 3.3 (CIECH Vitrosilicon, 68-120 Iłowa, Poland),

- CELLOSIZE HEC QP-40 (hydroxyethyl cellulose + sodium acetate) (Amerchol, Edison, NJ, USA)—a thickening agent,

- Poly (ethylene glycol) Polikol 400 (PEG400) (PCC Exol, Brzeg Dolny, Poland)—a wetting agent,

- Poly (ethylene glycol) Pluriol E600 (PEG600) (BASF, Ludwigshafen, Germany)—a wetting agent,

- Water dispersion of styrene–acrylic resin Revacryl 247® (Thorex, Łódź, Poland)—a binder.

- Water dispersion of acrylic resin Talens Amsterdam Acrylic Binder 005 (Talens, Amsterdam, Niderlands),

- Cinkarna CCA 100 BS, a water dispersion of acrylic resin, containing 20–22 wt.% nano-TiO2 (~10 nm) (Cinkarna Celje, d.d., Slovenia),

- Water dispersion of acrylic resin Dekoral Silver (PPG DECO Sp. z o.o., Wrocław, Poland)—a binder,

- Acrylic photocatalytic water dispersion Titanium IN (Pigment, Szczecin, Poland)—a binder,

- Silicate photocatalytic water dispersion Titanium FA (Pigment, Szczecin, Poland)—a binder,

- Synexil DN-50, water dispersion of poly (vinyl acetate), PVAc (Synthos S.A., Oświęcim, Poland)—a binder,

- Poly (vinyl alcohol) Mowiol 4-98 (Fluka, Germany) with an average molecular weight (Mw) of ~27,000 g/mol) — a thickening and pro-adhesion agent,

- Soluble starch (Chempur, Piekary Śląskie, Poland)—a thickening and pro-adhesion agent,

- Glycerin, pure (POCh, Gliwice, Poland)—a plasticizer,

- Bis (2-etylohexyl adipate) (Adoflex) (Zakłady Azotowe Kędzierzyn S.A., Kędzierzyn-Koźle, Poland)—a plasticizer,

- Nanosilica Aerosil 380 (Evonik, Essen, Germany) — a stabilizer of dispersions,

- Methyl silicone oil containing OH terminal groups, with a dynamic viscosity of 500 cP, Polastosil M-200 (Zakład Chemiczny “Silikony Polskie”, Nowa Sarzyna, Poland)—an antifoaming agent,

- Enzyme Texazym PES (INOTEX, Dvůr Králové n.L, Czechia);

- Synthetic acrylic thickening agent Lutexal Thickener HC (BASF, Ludwigshafen, Germany)—for our purpose, diluted with demineralized water (1:3, w/w),

- Copper silicate hydrate CuSiO3∙18.5H2O (Poznań University of Technology, Poznań, Poland) composed of 35.23 wt.% CuO, 62.16 wt.% SiO2, 18.52 wt.% H2O, 0.02 wt.% Na2O, and 0.01 wt.% K2O, with a particle diameter in the range of 1–100 µm [39],

- Titanium dioxide, TiO2 (TK44) (Poznań University of Technology, Poznań, Poland), with an average particle diameter of 615 nm and a polydispersity of 0.102, obtained from the anatase allotrope of TiO2, having the commercial name Tytanpol (Police S.A., Szczecin, Poland), with an average particle diameter of 712–825 nm and a polydispersity of 0.218—modified with 1 wt.% N-2-aminoethyl-3-aminopropyl-(trimethoxy)silane,

- Zinc oxide, ZnO (Z11) (Poznań University of Technology, Poznań, Poland), with an average particle diameter of 396 nm and a polydispersity of 0.161,

- Zinc lactate, p.a. (Xenon-Chemists’ Cooperative, Rąbień, Poland),

- Hybrid oxide ZnO∙SiO2, prepared as described in [46].

2.3. Modification of the Surface of Nonwovens and Polyester Fabrics before the Dip-Coating Process

- (1)

- Enzyme treatment was carried out at 35 °C for 30 min in a bath containing 1–2 wt.% enzyme from the group of esterases, Texazym PES, at pH 4.2 (adjusted with the addition of acetic acid). The bath ratio against polyester nonwovens was 10:1.

- (2)

- Alkaline treatment was carried out at 98 °C for 60 min in a bath containing sodium hydroxide at a concentration of 1.8 g/L, sodium carbonate (3.6 g/L), and a sequestering and wetting agent. The bath ratio was 10:1.

2.3.1. Synthesis of Copper Silicate Hydrate In Situ

2.3.2. Description of the Dip-Coating Method for Polymer Nonwovens and Fabrics

| CuSiO3∙xH2O | 1–7 wt.% |

| CellosizeHEC QP-40 | 0.9–1.0 wt.% |

| Polikol 400 (PEG400) | 5–10 wt.% |

| Dispersion of chosen acrylic resin (or PVAc) | 3–10 wt.% |

| 2 wt.% Water solution of soluble starch (or PVA) | 25 wt.% |

| Nanosilica (Aerosil 380) | 0.1–0.2 wt.% |

| Silicone oil (Polastosil M200) | 0.1 wt.% |

| Other additives | Changing amounts |

2.3.3. Description of the Coating Method for Polymer Fabrics and Nonwovens

| 3–10 wt.% | Reagents with antimicrobial properties (e.g., Cu silicate or/and metal oxide) |

| 5–10 wt.% | Wetting agent |

| 3–10 wt.% | Binders and thickeners |

2.3.4. Description of Dip-Coating and Coating Experiments (Chosen Examples)

2.3.5. Evaluation of Antimicrobial Activity of Polymeric Nonwovens Modified with Aqueous Dispersions Containing Copper Silicate

2.3.6. Scanning Electron Microscopy (SEM)

3. Research Results and Discussion

- -

- Copper silicate hydrate (CuSiO3∙18.5H2O) (which is a synthetic version of minerals: chrysicolla and dioptase),

- -

- Titanium dioxide, zinc oxide, zinc silicate (ZnO∙SiO2), and zinc lactate,

- -

- Their mixtures.

3.1. An Improvement in the Surface Wettability and Hydrophilicity of Textile Materials

3.2. Evaluation of the Results of Antimicrobial Modification of the Properties of Nonwovens and Fabrics Modified with Aqueous Dispersions Containing Copper Silicate

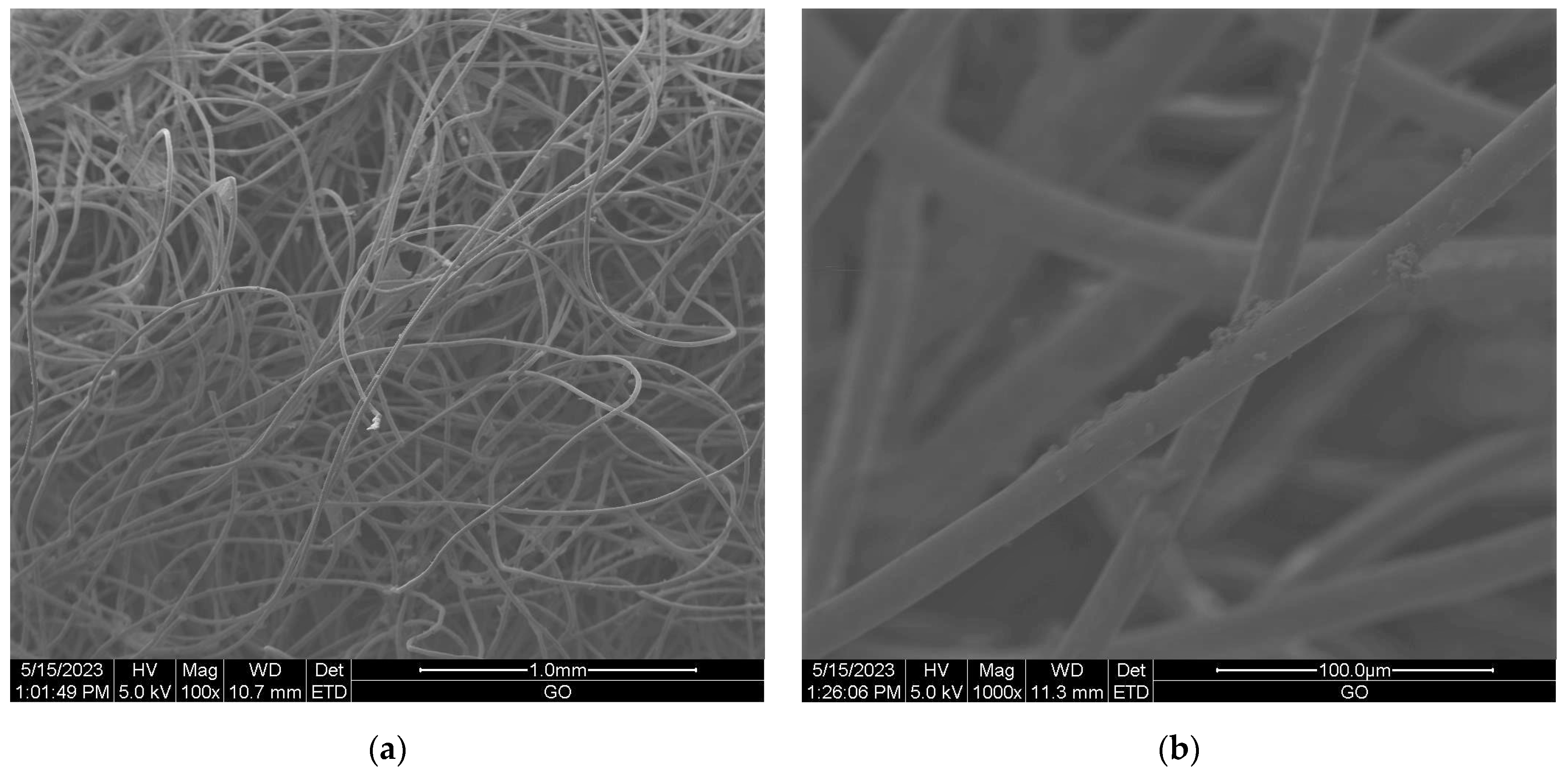

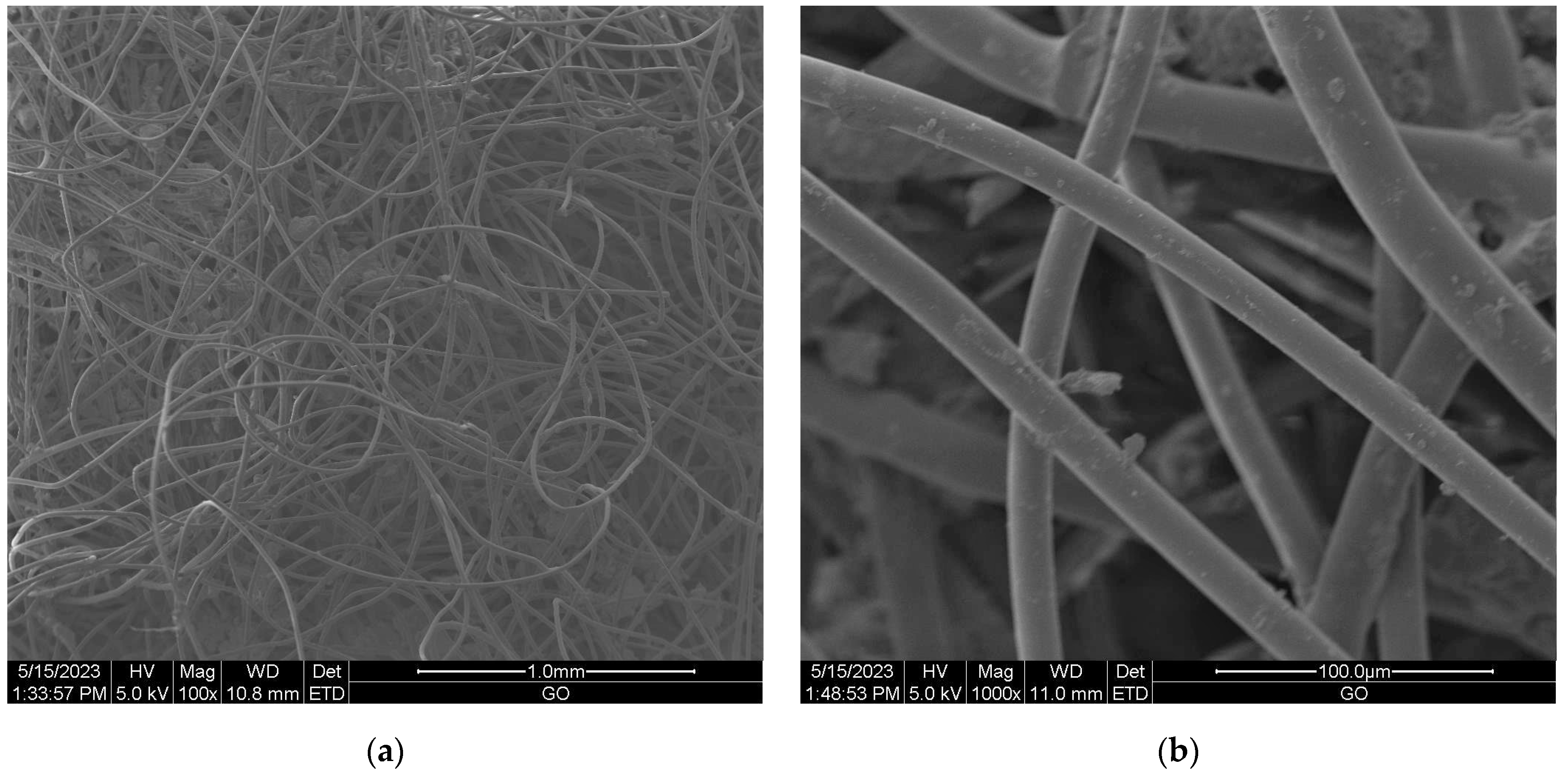

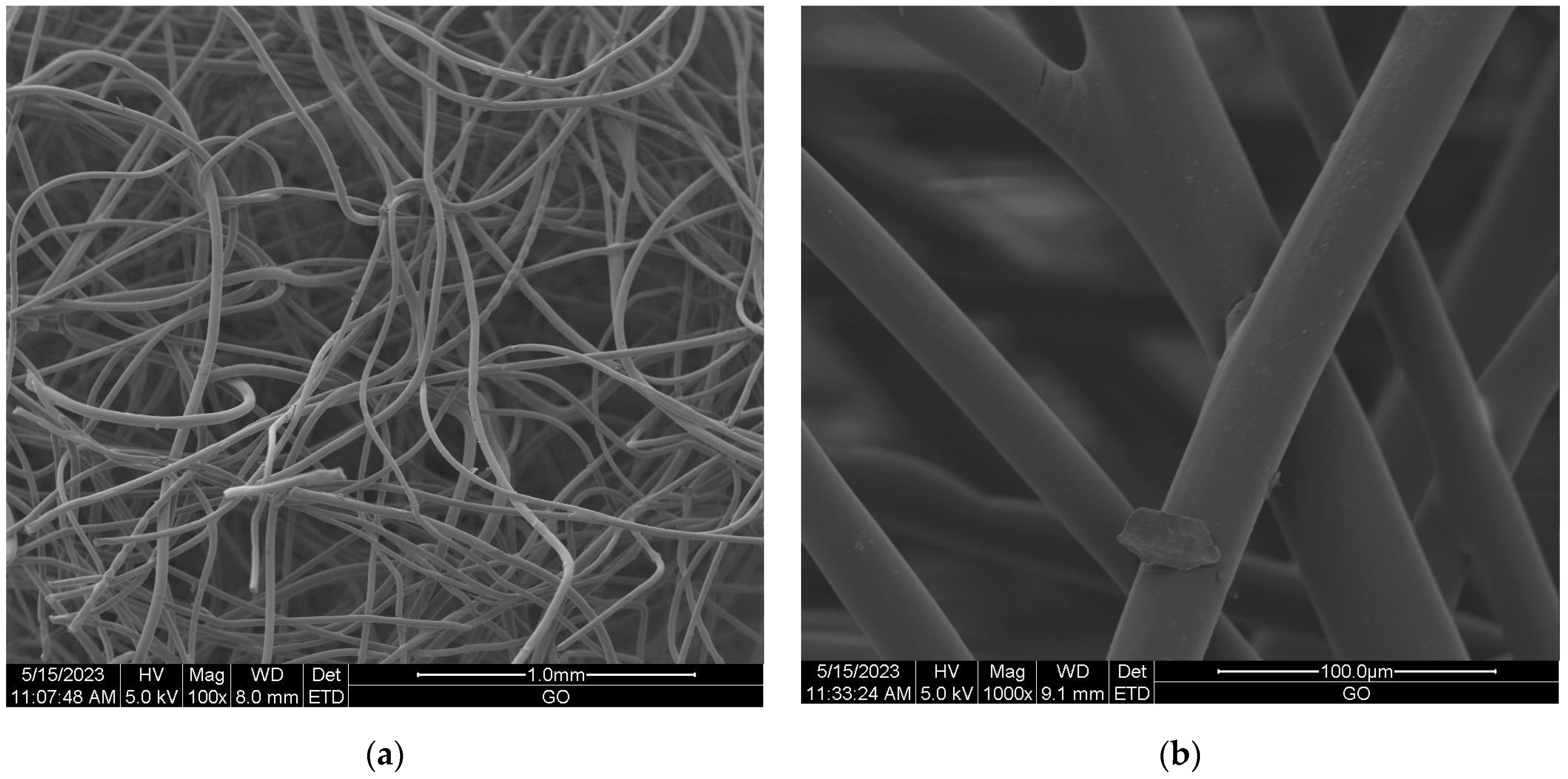

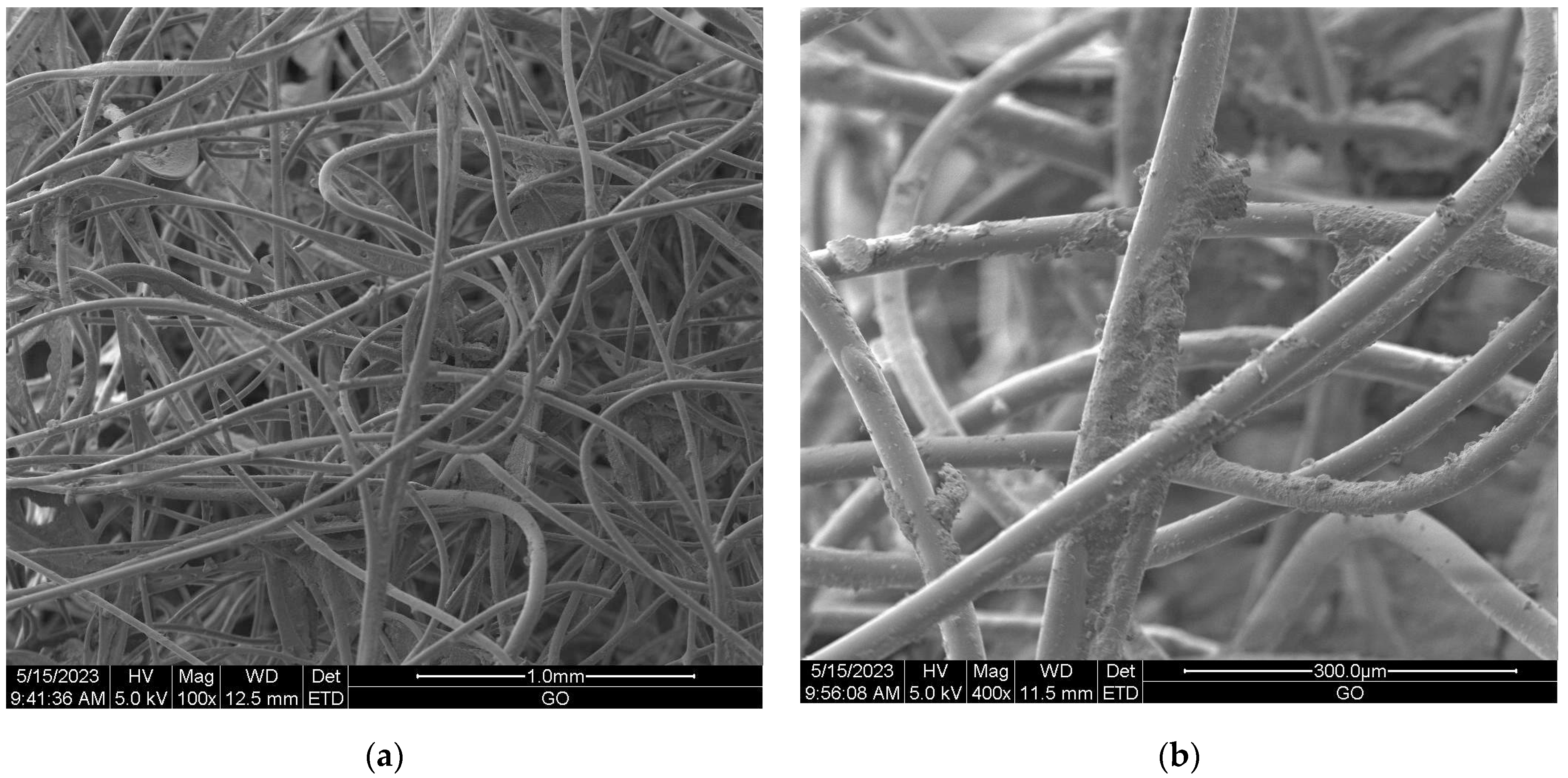

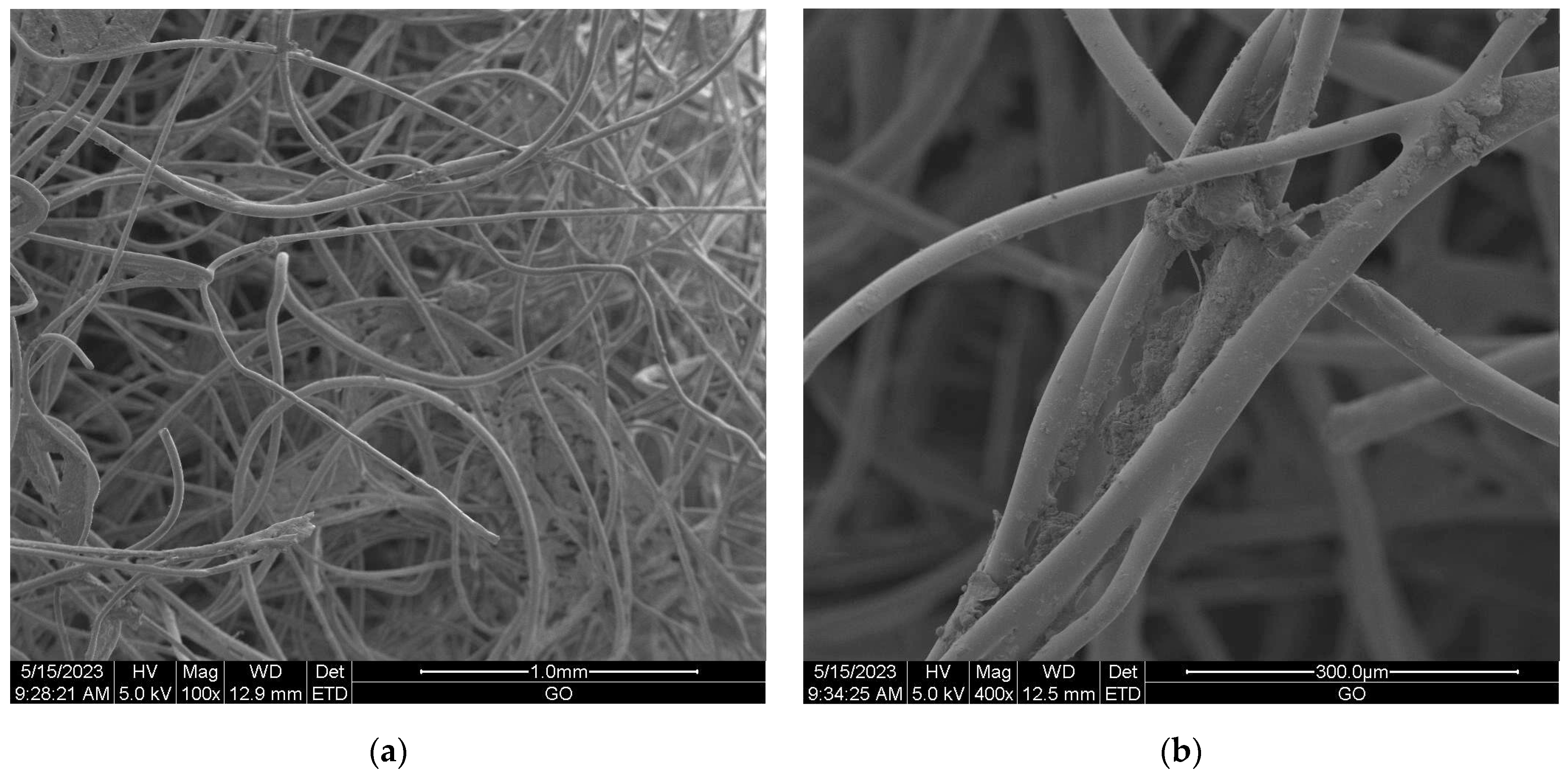

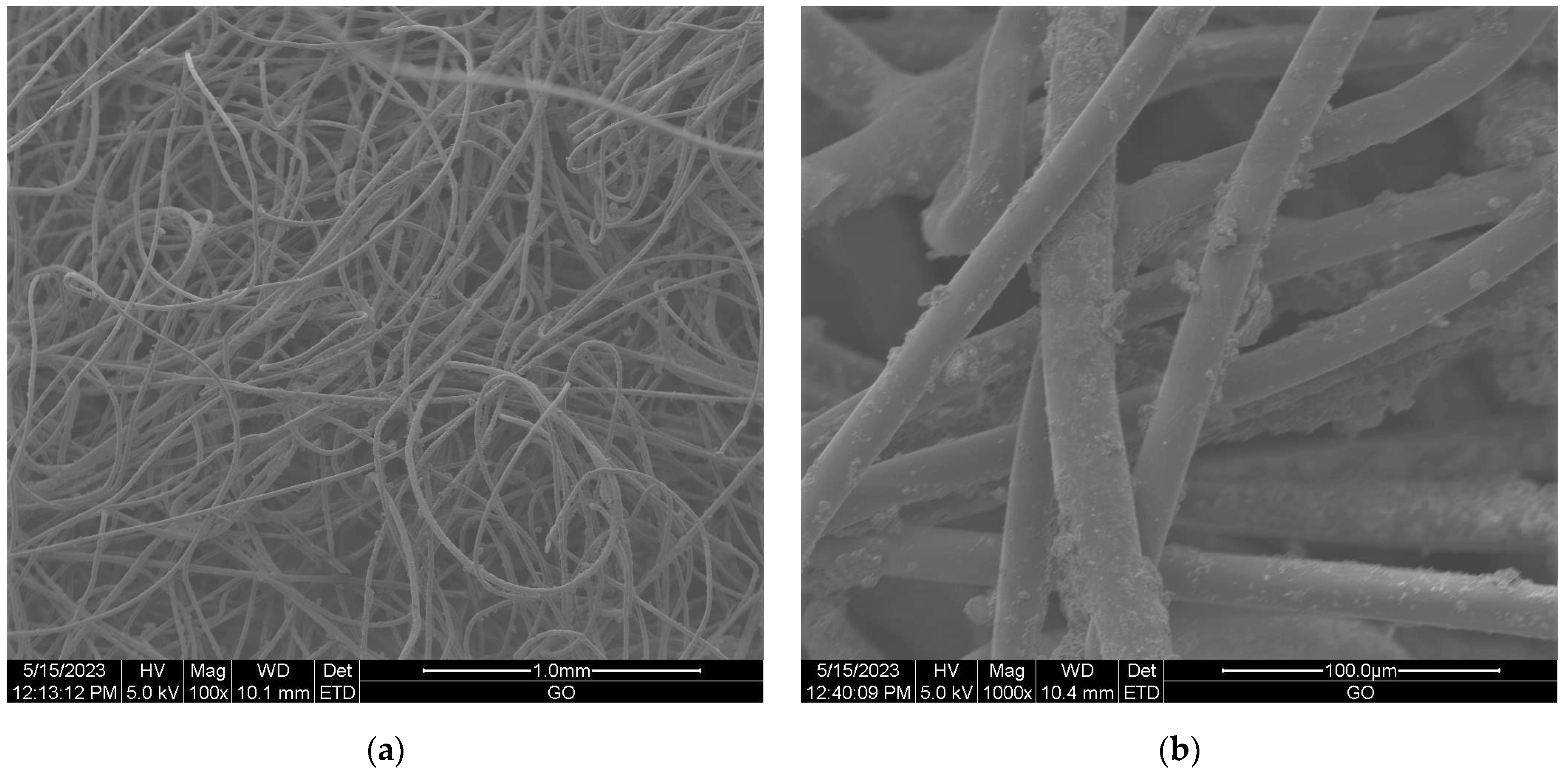

Scanning Electron Microscopy (SEM) of Nonwoven Samples

3.3. Evaluation of the Results of the Antimicrobial Modification of the Properties of Fabrics (and Nonwovens) with Copper Silicate and Composite Hybrid Oxide ZnO∙SiO2 Using the Dip-Coating and Coating Methods

- The cotton fabric Medical, the polyester fabric, the cotton–polyester fabric Figaro, and also the polyester nonwoven fabric Hydronina, biofunctionalized with the dip-coating method with dispersions containing 6.0 wt.% CuSiO3∙xH2O (where: x = 18.5) or the composite hybrid oxide ZnO∙SiO2 exhibited:

- (a)

- Against the Gram-negative bacteria Escherichia coli

- -

- Strong antibacterial properties (the antibacterial activity coefficient A reached values in the range of 3.1–6.2 for the samples modified with CuSiO3∙xH2O and 3.7–6.0 for the samples modified with ZnO∙SiO2),

- -

- Strong and significant bacteriostatic properties (the bacteriostatic coefficient S reached values in the range of 3.0–6.7 for the samples modified with CuSiO3∙xH2O and 2.1–6.6 for the samples modified with ZnO∙SiO2),

- -

- Good bactericidal properties (the bacterial growth reduction factor R was 77.5–96.8% for the samples modified with CuSiO3∙xH2O and 72.3–97.0% for samples modified with ZnO∙SiO2).

- (b)

- Against Gram-positive bacteria Staphylococcus aureus

- -

- Strong or significant antibacterial properties (the antibacterial activity coefficient A reached values in the range of 2.5–6.2 for the samples modified with CuSiO3∙xH2O and 2.8–4.8 for the samples modified with ZnO∙SiO2),

- -

- Strong and significant bacteriostatic properties (the bacteriostatic coefficient S reached values in the range of 2.6–6.5 for the samples modified with CuSiO3∙xH2O and 3.0–5.2 for the samples modified with ZnO∙SiO2),

- -

- Good and significant bactericidal properties (the bacterial growth reduction factor R was 89.6–99.0% for the samples modified with CuSiO3∙xH2O and 70.8% for the samples modified with ZnO∙SiO2).

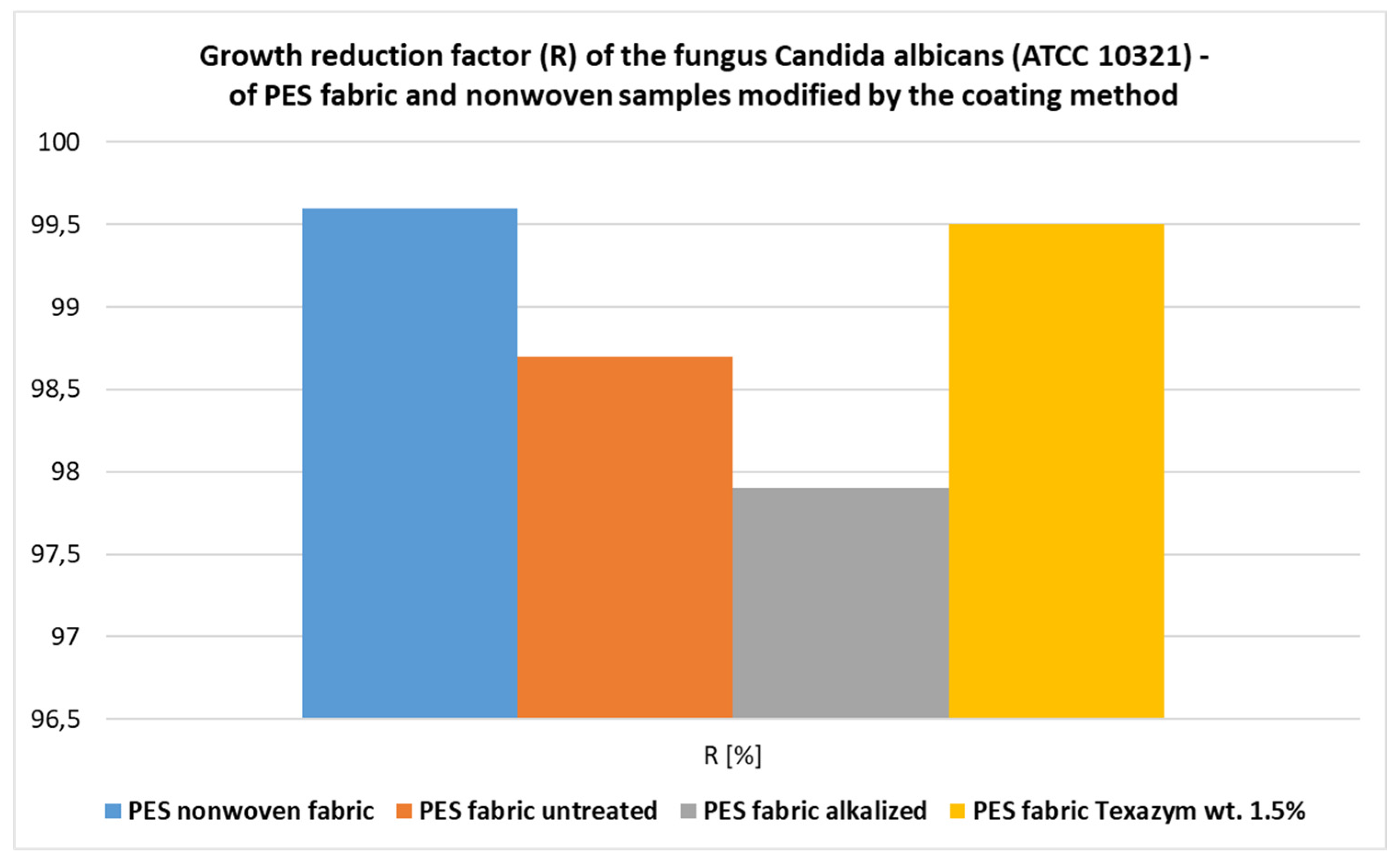

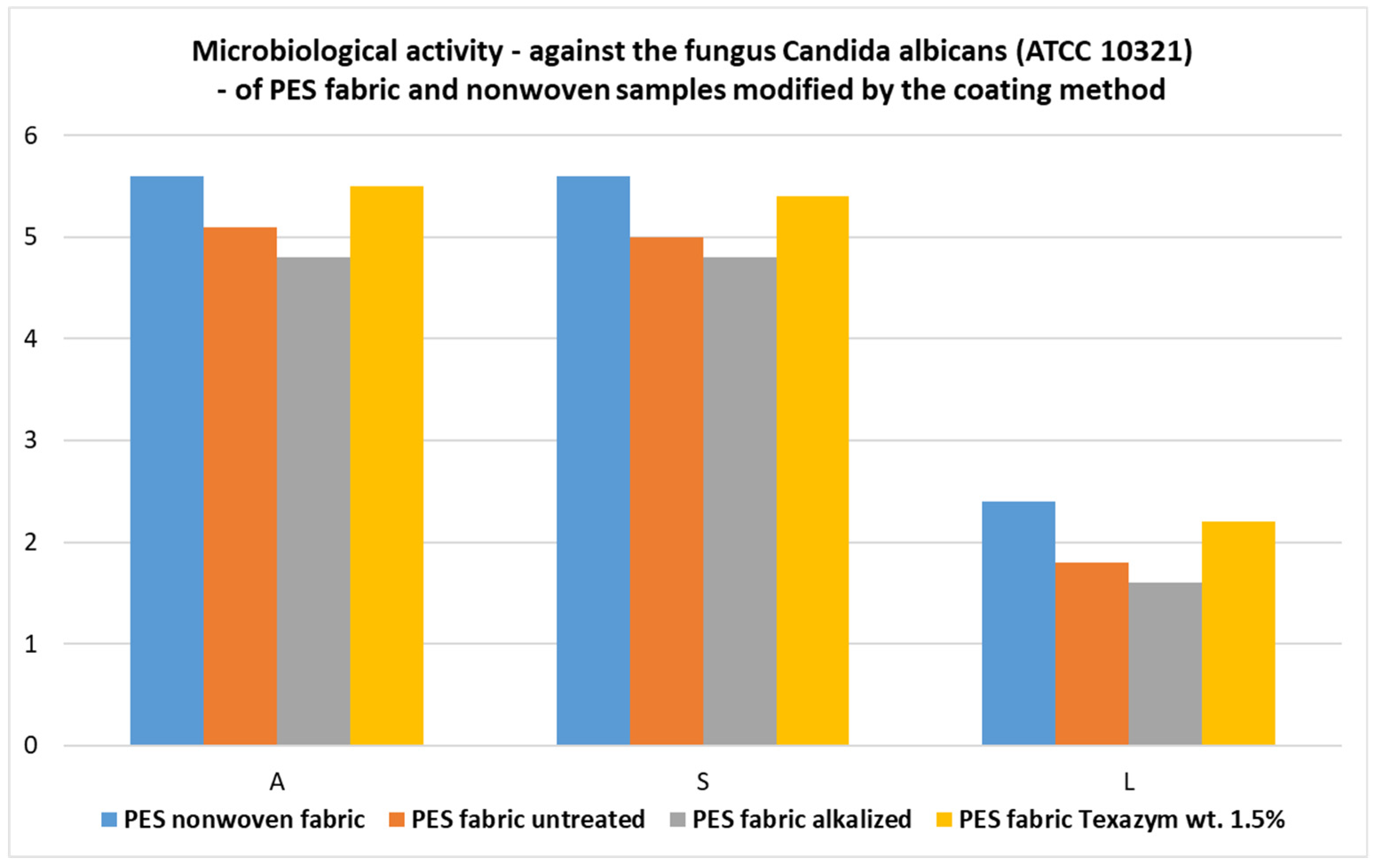

- For all samples of the PES fabric and the PES nonwoven Hydronina, modified with the coating method with a paste containing approx. 10 wt.% CuSiO3∙xH2O, the growth reduction factor for Candida albicans (R) reached values in the range of 97.9–99.6%, the antibacterial activity coefficient A was in the range of 4.8–5.6, the bacteriostatic coefficient S had the same value 4.8–5.6, and the bactericidal coefficient L was in the range of 1.6–2.4.

- The obtained composite polymer textile materials also showed a good inhibitory effect on the development of the mold fungus Chaetomium globosum. The samples of the textile materials coated with CuSiO3 hydrate, and especially the polyester fabric subjected to biomodification with 7.0 wt.% CuSiO3∙xH2O, showed a clear effect of antifungal activity against the fungus Chaetomium globosum, which grew on the surface of the samples only in the range of 0–25%.

- The new biofunctionalized textile materials obtained using the coating method (mainly cotton, cotton–polyester, and polyester fabrics) with pastes containing (a) CuSiO3 or (b) CuSiO3 + ZnO, or (c) CuSiO3 + TiO2 particles introduced onto the surface and incorporated into their structures also showed good barrier properties against UV radiation (UPF > 50) and the lowest transmittance (T average was 2.5–3.5), which was characteristic of the textile products subjected to the initial alkaline or biochemical (enzymatic) modifications, followed by biofunctionalization with mixtures containing a total of 10 wt.% CuSiO3∙xH2O and TiO2 (or ZnO) in a weight ratio of 7:3 or 1:1.

| Evaluation of antimicrobial activity | Reduction in microbial growth (A) |

| Lack | A < 0.5 |

| Weak | 0.5 ≤ A < 2 |

| Significant | 2 ≤ A < 3 |

| Strong | A ≥ 3 |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Berger, T.J.; Spadaro, J.A.; Bierman, R.; Chapin, S.E.; Becker, R.O. Antifungal Properties of Electrically Generated Metallic Ions. Antimicrob. Agents Chemother. 1976, 10, 856–860. [Google Scholar] [CrossRef]

- Hunter, J.M. Geophagy in Africa and the United States. Geogr. Rev. 1973, 63, 170–195. [Google Scholar] [CrossRef]

- Domek, M.J.; LeChevallier, M.W.; Cameron, S.C.; A McFeters, G. Evidence for the role of copper in the injury process of coliform bacteria in drinking water. Appl. Environ. Microbiol. 1984, 48, 289–293. [Google Scholar] [CrossRef] [PubMed]

- Bagchi, B.; Kara, S.; Deyb, S.K.; Bhandarya, S.; Roya, D.; Mukhopadhyayc, T.K.; Dasa, S.; Nandy, P. In situ synthesis and antibacterial activity of copper nanoparticle loaded natural montmorillonite clay based on contact inhibition and ion release. Colloilds Surf. B Biointerfaces 2013, 108, 358–365. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Yang, Q.; Wang, Y.; Yu, H.; Chen, X.; Jing, X. Biodegradable electrospun poly(l-lactide) fibers containing antibacterial silver nanoparticles. Eur. Polym. J. 2006, 42, 2081–2087. [Google Scholar] [CrossRef]

- Zou, K.; Liu, Q.; Chen, J.; Du, J. Silver-decorated biodegradable polymer vesicles with excellent antibacterial efficacy. Polym. Chem. 2013, 5, 405–411. [Google Scholar] [CrossRef]

- Van Hyning, D.L. Yarns and Fabrics Having a Wash-Durable Antimicrobial Silver Particulate Finish. U.S. Patent 7,232,777, 19 June 2007. [Google Scholar]

- Rybicki, E.; Filipowska, B.; Walawska, A.; Kozicki, M.; Matyjas-Zgondek, E. Sposób Nadawania Płaskim Wyrobom Włókienniczym Właściwości Antybakteryjnych i Antygrzybicznych. Patent PL 214689 B1, 30 September 2013. [Google Scholar]

- Lee, H.J.; Yeo, S.Y.; Jeong, S.H. Antibacterial effect of nanosized silver colloidal solution on textile fabrics. J. Mater. Sci. 2003, 38, 2199–2204. [Google Scholar] [CrossRef]

- Yan, J.; Cheng, J. Antimicrobial Yarn Having Nanosilver Particles and Methods for Manufacturing the Same. U.S. Patent 6,979,491, 27 December 2005. [Google Scholar]

- Bucheńska, J.; Słomkowski, S.; Tazbir, J.; Timler, D.; Sobolewska, E.; Karaszewska, A. Sposób Nadawania Włóknom Poliestrowym Właściwości Antybakteryjnych. Patent PL 196 213 B1, 2007. [Google Scholar]

- Rybicki, E.; Filipowska, B.; Walawska, A.; Grad, J.; Wilk, E.; Żakowska, Z.; Stobińska, H.; Rosiak, J. Sposób Nadawania Wyrobom Włókienniczym Właściwości Antybakteryjnych lub Terapeutycznych. Patent PL 200 059 B1, 2008. [Google Scholar]

- Min, K.D.; Youk, J.H.; Kwark, Y.-J.; Park, W.H. Preparation of inorganic silica nanofibers containing silver nanoparticles. Fibers Polym. 2007, 8, 591–600. [Google Scholar] [CrossRef]

- Au, H.T.; Pham, L.N.; Vu, T.H.T.; Park, J.S. Fabrication of an antibacterial non-woven mat of a poly(lactic acid)/chitosan blend by electrospinning. Macromol. Res. 2012, 20, 51–58. [Google Scholar] [CrossRef]

- Borkow, G.; Gabbay, J. Putting copper into action: Copper-impregnated products with potent biocidal activities. FASEB J. 2004, 18, 1728. [Google Scholar] [CrossRef]

- Borkow, G.; Sidwell, R.W.; Smee, D.F.; Barnard, D.L.; Morrey, J.D.; Lara-Villegas, H.H.; Shemer-Avni, Y.; Gabbay, J. Neutralizing viruses in suspensions by copper oxide-based filters. Antimicrob. Agents Chemother. 2007, 51, 2605–2607. [Google Scholar] [CrossRef] [PubMed]

- Ren, G.; Hu, D.; Cheng, E.W.C.; Vargas-Reusc, M.A.; Reipd, P.; Allaker, R.P. Characterisation of copper oxide nanoparticles for antimicrobial applications. Int. J. Antimicrob. Agents 2009, 33, 587–590. [Google Scholar] [CrossRef] [PubMed]

- Ravishankar, R.V.; Jamuna, B.A. Nanoparticles and their potential application as antimicrobials. Formatex 2011, 1, 197–209. [Google Scholar]

- Weinberg, I.; Lazary, A.; Jefidoff, A.; Vatine, J.J.; Borkow, G.; Ohana, N. Safety of using diapers containing copper oxide in chronic care elderly patients. Open Biol. J. 2013, 6, 1–7. [Google Scholar]

- Rani, R.; Kumar, H.; Salar, R.K.; Purewal, S.S. Antibacterial activity of copper oxide nanoparticles against gram negative bacterial strain synthesized by reverse micelle technique. Int. J. Pharm. Res. Dev. 2014, 6, 72–78. [Google Scholar]

- Pallavicini, P.; Dacarro, G.; Cucca, L.; Denat, F.; Grisoli, P.; Patrini, M.; Sok, N.; Taglietti, A. A monolayer of a Cu2+-tetraazamacrocyclic complex on glass as the adhesive layer for silver nanoparticles grafting, in the preparation of surface-active antibacterial materials. New J. Chem. 2011, 35, 1198–1201. [Google Scholar] [CrossRef]

- Gabbay, J.; Mishal, J.; Magen, E.; Zatcoff, R.; Shemer-Avni, Y.; Borkow, G. Copper oxide impregnated textiles with potent biocidal activities. J. Ind. Text. 2006, 35, 323–335. [Google Scholar] [CrossRef]

- Deng, D.; Cheng, Y.; Jin, Y.; Qi, T.; Xiao, F. Antioxidative effect of lactic acid-stabilized copper nanoparticles prepared in aqueous solution. J. Mater. Chem. 2012, 22, 23989–23995. [Google Scholar] [CrossRef]

- Shim, I.W.; Noh, W.T.; Kwon, J.; Cho, J.Y.; Kim, K.S.; Kang, D.H. Preparation of copper nanoparticles in cellulose acetate polymer and the reaction chemistry of copper complexes in the polymer. Bull. Korean Chem. Soc. 2002, 23, 563–566. [Google Scholar]

- Cioffi, N.; Torsi, L.; Ditaranto, N.; Tantillo, G.; Ghibelli, L.; Sabbatini, L.; Bleve-Zacheo, T.; D’Alessio, M.; Zambonin, P.G.; Traversa, E. Copper nanoparticle/polymer composites with antifungal and bacteriostatic properties. Chem. Mater. 2005, 17, 5255–5262. [Google Scholar] [CrossRef]

- Konieczny, J.; Rdzawski, Z. Antibacterial properties of copper and its alloys. Arch. Mater. Sci. Eng. 2012, 56, 53–60. [Google Scholar]

- Trapalis, C.C.; Kokkoris, M.; Perdikakis, G.; Kordas, G. Study of antibacterial composite Cu/SiO2 thin coatings. J. Sol-Gel Sci. Technol. 2003, 26, 1213–1218. [Google Scholar] [CrossRef]

- Singh, A.; Krishna, V.; Angerhofer, A.; Do, B.; MacDonald, G.; Moudgi, B. Copper coated silica nanoparticles for odor removal. Langmuir 2010, 26, 15837–15844. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Gao, Y.; Zhang, H.; Feng, X.; Cai, H.; Liu, Y. Preparation and characterization of core–shell structure of SiO2@Cu antibacterial agent. Colloids Surf. B Biointerfaces 2010, 81, 537–543. [Google Scholar] [CrossRef]

- Maniprasad, P.; Santra, S. Novel copper (Cu) loaded core-shell silica nanoparticles with improved Cu bioavailability: Synthesis, characterization and study of antibacterial properties. J. Biomed. Nanotechnol. 2012, 8, 558–566. [Google Scholar] [CrossRef] [PubMed]

- Varghese, S.; ElFakhri, S.O.; Sheel, D.W.; Sheel, P.; Bolton, F.J.E.; Foster, H.A. Antimicrobial activity of novel nanostructured Cu-SiO2 coatings prepared by chemical vapour deposition against hospital related pathogens. AMB Express 2013, 3, 53. [Google Scholar] [CrossRef]

- Grumezescu, V.; Chifiriuc, C.M.; Holban, A.M.; Stoica, P.; Grumezescu, A.M.; Voicu, G.; Socol, G.; Huang, K.S.; Bletou, C.; Radulescu, R. Antimicrobial and biocompatibility assay of newly fabricated materials based copper or zinc alginate and SiO2 network. Dig. J. Nanomater. Biostruct. 2013, 8, 869–876. [Google Scholar]

- Xia, M.S.; Hu, C.H.; Xu, Z.R.; Ye, Y.; Zhou, Y.H.; Xiong, L. Effects of Copper-bearing Montmorillonite (Cu-MMT) on Escherichia coli and Diarrhea on Weanling Pigs. Asian-Australas. J. Anim. Sci. 2004, 17, 1712–1716. [Google Scholar] [CrossRef]

- Hossain, S.I.; Kukushkina, E.A.; Izzi, M.; Sportelli, M.C.; Picca, R.A.; Ditaranto, N.; Cioffi, N. A Review on Montmorillonite-Based Nanoantimicrobials: State of the Art. Nanomaterials 2023, 13, 848. [Google Scholar] [CrossRef]

- Esteban-Cubillo, A.; Pecharromán, C.; Aguilar, E.; Santarén, J.; Moya, J.S. Antibacterial activity of copper monodispersed nanoparticles into sepiolite. J. Mater. Sci. 2006, 41, 5208–5212. [Google Scholar] [CrossRef]

- Kar, S.; Bagchi, B.; Kundu, B.; Bhandary, S.; Basu, R.; Nandy, P.; Das, S. Synthesis and characterization of Cu/Ag nanoparticle loaded mullite nanocomposite system: A potential candidate for antimicrobial and therapeutic applications. Biochim. Biophys. Acta 2014, 1840, 3264–3276. [Google Scholar] [CrossRef]

- Górecki, R.; Danielski-Busch, W.; Stępowski, J.; Jakubowski, T. Emulsja do Pojemników Szkółkarskich i Doniczek. Patent PL 196994, 2008. [Google Scholar]

- Wu, X.; Ye, L.; Liu, K.; Wang, W.; Wei, J.; Chen, F.; Liu, C. Antibacterial properties of mesoporous copper-doped silica xerogels. Biomed. Mater. 2009, 4, 045008. [Google Scholar] [CrossRef]

- Nowacka, M.; Modrzejewska-Sikorska, A.; Chrzanowski, Ł.; Ambrożewicz, D.; Rozmanowski, T.; Myszka, K.; Czaczyk, K.; Bula, K.; Jesionowski, T. Electrokinetic and bioactive properties of CuO∙SiO2 oxide composites. Bioelectrochemistry 2012, 87, 50–57. [Google Scholar] [CrossRef] [PubMed]

- Kloziński, A.; Jakubowska, P.; Ambrożewicz, D.; Jesionowski, T. Thermal Properties of Polyolefin Composites with Copper Silicate. AIP Conf. Proc. 2015, 1664, 060016. [Google Scholar] [CrossRef]

- Young, M.; Santra, S. Copper (Cu)-silica nanocomposite containing valence-engineered Cu: A new strategy for improving the antimicrobial efficacy of Cu biocides. J. Agric. Food Chem. 2014, 62, 6043–6052. [Google Scholar] [CrossRef] [PubMed]

- Sójka-Ledakowicz, J.; Olczyk, J.; Walawska, A.; Kamińska, I.; Gutarowska, B.; Żakowska, Z.; Kozanecka, E. Nowe materiały włókiennicze o właściwościach barierowych przed promieniowaniem nadfioletowym i drobnoustrojami. Cz. I. Przegląd Włókienniczy—Włókno Odzież Skóra 2010, 4, 43–45. [Google Scholar]

- Sójka-Ledakowicz, J.; Olczyk, J.; Walawska, A.; Kamińska, I.; Gutarowska, B.; Żakowska, Z.; Kozanecka, E. Nowe materiały włókiennicze o właściwościach barierowych przed promieniowaniem nadfioletowym i drobnoustrojami. Cz. II. Przegląd Włókienniczy—Włókno Odzież Skóra 2010, 5, 40–43. [Google Scholar]

- Jesionowski, T.; Kołodziejczak-Radzimska, A.; Ciesielczyk, F.; Sójka-Ledakowicz, J.; Olczyk, J.; Sielski, J. Synthesis of Zinc Oxide in an Emulsion System and its Deposition on PES Nonwoven Fabrics. Fibres Text. East. Eur. 2011, 19, 70–75. [Google Scholar]

- Sójka-Ledakowicz, J.; Olczyk, J.; Walawska, A.; Laurentowska, A.; Kołodziejczak-Radzimska, A.; Jesionowski, T. Modyfikacja wyrobów włókienniczych przy wykorzystaniu tlenku cynku o cząstkach nanometrycznych oraz kompozytu tlenkowego ZnO-SiO2. Przemysł Chem. 2010, 89, 1648–1652. [Google Scholar]

- Laurentowska, A.; Jesionowski, T. ZnO-SiO2 Oxide Composites Synthesis During Precipitation From Emulsion System, Physicochem. Probl. Miner. Process. 2012, 48, 63–76. [Google Scholar]

- Sójka-Ledakowicz, J.; Chruściel, J.; Kudzin, M.; Kiwała, M. Antimicrobial Functionalization of Textile Materials with Copper Silicate. Fibers Text. East. Eur. 2016, 24, 151–156. [Google Scholar] [CrossRef]

- Sójka-Ledakowicz, J.; Chruściel, J.; Kudzin, M.; Kiwała, M. A Method for Biofunctionalization of Textile Materials. Patent EP 3067445 A1, 7 September 2017. [Google Scholar]

- Sójka-Ledakowicz, J.; Chruściel, J.; Kudzin, M.; Kiwała, M. Sposób Biofunkcjonalizacji Materiałów Włókienniczych. Patent PL 231089, 31 January 2019. [Google Scholar]

- Sójka-Ledakowicz, J.; Chruściel, J.J.; Kudzin, M.H.; Olczyk, J.; Kiwała, M.; Jesionowski, T. Hybrid modifiers for antimicrobial functionalization of textile materials. In Proceedings of the 6th International Conference on Multifunctional, Hybrid and Nanomaterials, Sitges, Spain, 11–15 March 2019. poster P1-066. [Google Scholar]

- Łatwińska, M.; Sójka-Ledakowicz, J.; Chruściel, J.; Piórkowski, M. PLA and PP Composite Nonwoven with Antimicrobial Activity for Filtration Applications. Int. J. Polym. Sci. 2016, 2016, 2510372. [Google Scholar] [CrossRef]

- Luckachan, G.E.; Pillai, C.K.S. Biodegradable polymers—A review on recent trends and emerging perspectives. J. Polym. Environ. 2011, 19, 637–676. [Google Scholar] [CrossRef]

- Auras, R.; Lim, L.-T.; Selke, S.E.M.; Tsuji, H. Poly(lactic acid): Synthesis, Structures, Properties, Processing and Applications; John Willey & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Garlotta, D. A literature review of poly(lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- BChieng, W.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hussein, M.Z. Plasticized poly(lactic acid) with low molecular weight poly(ethylene glycol): Mechanical, thermal, and morphology properties. J. Appl. Polym. Sci. 2013, 130, 4576–4580. [Google Scholar]

- Chan, R.T.H.; Marçal, H.; Russell, R.A.; Holden, P.J.; Foster, L.J.R. Application of polyethylene glycol to promote cellular biocompatibility of polyhydroxybutyrate films. Int. J. Polym. Sci. 2011, 2011, 473045. [Google Scholar] [CrossRef]

- Olczyk, J.; Sójka-Ledakowicz, J.; Walawska, A.; Antecka, A.; Siwińska-Ciesielczyk, K.; Zdarta, J.; Jesionowski, T. Antimicrobial Activity and Barrier Properties against UV Radiation of Alkaline and Enzymatically Treated Linen Woven Fabrics Coated with Inorganic Hybrid Material. Molecules 2020, 25, 5701. [Google Scholar] [CrossRef]

- Kudzin, M.H.; Boguń, M.; Mrozińska, Z.; Kaczmarek, A. Physical Properties, Chemical Analysis, and Evaluation of Antimicrobial Response of New Polylactide/Alginate/Copper Composite Materials. Mar. Drugs 2020, 18, 660. [Google Scholar] [CrossRef]

- Román, L.E.; Gomez, E.D.; Solís, J.L.; Gómez, M.M. Antibacterial Cotton Fabric Functionalized with Copper Oxide Nanoparticles. Molecules 2020, 25, 5802. [Google Scholar] [CrossRef]

- Hanga, X.; Pengb, H.; Songc, H.; Qib, Z.; Miaoa, X.; Xu, W. Antiviral activity of cuprous oxide nanoparticles against Hepatitis C Virus in vitro. J. Virol. Methods 2015, 222, 150–157. [Google Scholar] [CrossRef] [PubMed]

- van Doremalen, N.; Bushmaker, T.; Morris, D.H.; Holbrook, M.G.; Gamble, A.; Williamson, B.N.; Tamin, A.; Harcourt, J.L.; Thornburg, N.J.; Gerber, S.I.; et al. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Engl. J. Med. 2020, 382, 1564–1567. [Google Scholar] [CrossRef]

- Behzadinasab, S.; Chin, A.; Hosseini, M.; Poon, L.; Ducker, W.A. A surface coating that rapidly inactivates SARS-CoV-2. ACS Appl. Mater. Interfaces 2020, 12, 34723–34727. [Google Scholar] [CrossRef]

- Raha, S.; Mallick, R.; Basak, S.; Duttaroy, A.K. Is copper beneficial for COVID-19 patients? Med. Hypotheses 2020, 142, 109814. [Google Scholar] [CrossRef]

- da Silva, D.J.; Duran, A.; Cabral, A.D.; Fonseca, F.L.A.; Bueno, R.F.; Rosa, D.S. Questioning ZnO, Ag, and Ag/ZnO nanoparticles as antimicrobial agents for textiles: Do they guarantee total protection against bacteria and SARS-CoV-2? J. Photochem. Photobiol. B Biol. 2022, 234, 112538. [Google Scholar] [CrossRef]

- Roman, L.E.; Gomez, E.D.; Solis, J.L.; Gomez, M.M. Antimicrobial effect of cotton fabric functionalized with a kaolinite-titania nano-hybrid composite. Mater. Chem. Phys. 2023, 295, 127078. [Google Scholar] [CrossRef]

- Refaee, A.A.; El-Naggar, M.E.; Mostafa, T.B.; Elshaarawy, R.F.M.; Nasr, A.M. Nano-bio finishing of cotton fabric with quaternized chitosan Schiff base-TiO2-ZnO nanocomposites for antimicrobial and UV protection applications. Eur. Polym. J. 2022, 166, 111040. [Google Scholar] [CrossRef]

| Components of Dispersions | Water Dispersion Number | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 5 | 6 | 7 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | |

| CuSiO3∙xH2O a | 3.0 | 5.0 | 3.0 | 2.0 | 1.0 | 1.0 | 3.0 | 5.0 | 5.0 | 7.0 | 6.9 | 7.0 | 5.0 | 5.0 | 7.0 | 5.0 | 5.0 | 7.0 | 5.0 | 5.0 |

| Cellosize HEC QP-40 | 1.5 | 1.0 | 1.0 | 0.9 | 0.9 | 0.9 | 0.8 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Polikol 400 (PEG400) | 7.5 | 5.0 | - | - | - | - | 6.0 | 7.5 | - | - | 10.0 | 10.0 | 7.5 | 7.5 | - | 7.5 | 7.5 | 10.0 | 10.0 | 10.0 |

| Pluriol E600 (PEG600) | - | - | 7.5 | 5.0 | 5.0 | 5.0 | - | - | 7.5 | 10.0 | - | - | - | - | 10.0 | - | - | - | - | - |

| Copolymer dispersion Revacryl 247 | - | 5.0 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Cinkarna 100 BS | - | - | - | - | - | - | - | - | - | - | 1.0 b | 2.1 b | 4.2 b | - | - | 5.0 b | 5.0 b | - | - | - |

| Talens Amsterdam Acrylic Binder 005 c | 4.5 | - | 3.0 | 5.0 | 3.0 | 5.0 | 3.0 | 1.0 | 1.0 | 1.0 | - | - | - | - | 1.0 | - | - | - | - | - |

| Acrylic dispersion Dekoral Silver c | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 2.0 | 2.0 | - | - | - |

| Photocatalytic acrylic dispersion Titanium IN c | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 25.0 | - |

| Photocatalytic silicate dispersion Titanium FA c | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 25.0 |

| Zinc lactate pure | - | - | - | - | - | - | - | - | - | - | - | - | - | 5.0 | - | - | - | - | - | - |

| Glycerin | - | - | 0.5 | 0.4 | 0.4 | 0.4 | 0.5 | 1.0 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 0.5 | 1.0 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Synexil DN-50 | - | - | - | - | - | - | 1.0 | 4.0 | 4.0 | 4.0 | 2.50 | 2.0 | 2.0 | 2.0 | 4.0 | 2.0 | - | - | - | - |

| Bis(2-ethylhexyl adipate) (Adoflex) | - | - | - | - | - | - | 0.5 | 2.0 | 2.0 | 2.0 | 1.25 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | - | - | - | - |

| 2 wt.% Water solution of soluble starch | - | - | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 | 25.0 |

| 5 wt.% Water solution of PVA | - | 10.0 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Nanosilica (Aerosil 380) | - | - | - | - | - | 0.1 | 0.1 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Silicone oil (Polastosil M200) | - | - | - | - | - | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Demineralized water | 83.5 | 74.0 | 60.0 | 61.5 | 64.5 | 62.5 | 60.0 | 53.2 | 53.2 | 48.7 | 48.5 | 43.2 | 37.7 | 51.7 | 49.7 | 33.9 | 34.9 | 31.2 | 33.2 | 33.2 |

| Wetted Surface | Image of a Drop of Water | Contact Angle Θ (deg) | Surface Free Energy (SFE) (mJ/m2) | ||||

|---|---|---|---|---|---|---|---|

| ΘW | ΘF | ΘDIM | γSLW | γSAB | γS | ||

| PES fabric (unmodified) |  | 112.6 | 79.0 | 0.0 | 50.8 | 0.1 | 50.9 |

| PES fabric + 1 wt.% Texazym |  | 82.9 | 46.8 | 0.0 | 50.8 | 1.1 | 51.9 |

| PES fabric + 1.5 wt.% Texazym |  | 66.9 | 28.6 | 0.0 | 50.8 | 5.3 | 56.1 |

| PES fabric + 2 wt.% Texazym |  | 35.9 | 11.2 | 0.0 | 50.8 | 8.7 | 59.5 |

| PES fabric after alkalization |  | 103.2 | 62.7 | 0.0 | 50.8 | 2.0 | 52.8 |

| No. | Type of Nonwoven Fabric Sample | Values of the Growth Reduction Factor (R) (%) against Different Microorganisms | ||

|---|---|---|---|---|

| Escherichia coli (ATCC 25922) | Staphylococcus aureus (ATCC 6538) | Candida albicans (ATCC 10231) | ||

| 1. | PES WIFP-270 + 1.0% CuSiO3 | 89.7 | 43.0 | 0.0 |

| 2. | PES FS G-4 + 1.0% CuSiO3 | 97.4 | 16.8 | 0.0 |

| 3. | PES FS F-5 + 1.0% CuSiO3 | 99.1 | 20.6 | 1.4 |

| 4. | PLA-350 + 1.0% CuSiO3 | >99.4 | 28.0 | 0.0 |

| 5. | PES WIFP-270 + 2.0% CuSiO3 | 99.6 | 59.1 | 26.8 |

| 6. | PES WIFP-270 + 3.0% CuSiO3 | 99.8 | 66.9 | 27.8 |

| 7. | PES WIFP-270 + 5.0% CuSiO3 | >99.8 | 87.6 | 30.6 |

| 8. | PES FS F-5 + 5.0% CuSiO3 | 99.4 | 98.7 | 35.4 |

| 9. | PLA-350 + 5.0% CuSiO3 | >99.8 | 97.0 | 30.8 |

| 10. | PES WIFP-270 + 7.0% CuSiO3 | >99.98 | 94.4 | 37.6 |

| 11. | PES FS F-5 + 7.0% CuSiO3 | >99.98 | 99.5 | 49.5 |

| 12. | PLA-350 + 7.0% CuSiO3 | >99.98 | >99.9 | 38.6 |

| 13. | PES WIFP-270 + 6.9% CuSiO3 + 1.0% TiO2 | >99.97 | 92.2 | 48.5 |

| 14. | PES WIFP-270 + 7.0% CuSiO3 + 2.1% TiO2 | >99.97 | 99.7 | 58.8 |

| 15. | PES WIFP-270 + 5.0% CuSiO3 + 4.2% TiO2 | > 99.97 | 99.5 | 80.9 |

| 16. | PES WIFP-270 + 5.0% CuSiO3 + 5.0% TiO2 | >99.99 | 99.4 | 87.5 |

| 17. | PES FS F-5 + 5.0% CuSiO3 + 5.0% TiO2 | 99.06 | 98.1 | 93.9 |

| 18. | PES FS F-5 + 5.0% CuSiO3 + 5.0% TiO2 + 2% Dekoral Silver | 95.63 | 94.6 | 92.7 |

| 19. | PES WIFP-270 + 5.0% CuSiO3 + 5.0% TiO2 + 2% Dekoral Silver | 97.08 | 92.6 | 98.0 |

| 20. | PES WIFP-270 + 5.0% CuSiO3 + 25% Ti-IN | >99.87 | 97.7 | 89.2 |

| 21. | PES FS F-5 + 5.0% CuSiO3 + 25% Ti-IN | >99.97 | 94.8 | 95.0 |

| Sample No. | Sample Type | CuSiO3 xH2O | PEG600 | Revacryl 247 | Lutexal HC | Microbiological Activity against the Fungus Candida albicans (ATCC 10321) | |||

|---|---|---|---|---|---|---|---|---|---|

| (wt.%) | A | S | L | R (%) | |||||

| 1 | PES nonwoven fabric (Hydronina) | 10.36 | 5.18 | 10.36 | 1.67 | 5.6 | 5.6 | 2.4 | 99.6 |

| 2 | PES fabric (untreated) | 10.36 | 5.18 | 10.36 | 1.67 | 5.1 | 5.0 | 1.8 | 98.7 |

| 3 | PES fabric alkalized | 10.36 | 5.18 | 10.36 | 1.67 | 4.8 | 4.8 | 1.6 | 97.9 |

| 4 | PES fabric + Texazym (1.5 wt.%) | 10.21 | 5.11 | 10.21 | 1.72 | 5.5 | 5.4 | 2.2 | 99.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chruściel, J.J.; Olczyk, J.; Kudzin, M.H.; Kaczmarek, P.; Król, P.; Tarzyńska, N. Antibacterial and Antifungal Properties of Polyester, Polylactide, and Cotton Nonwovens and Fabrics, by Means of Stable Aqueous Dispersions Containing Copper Silicate and Some Metal Oxides. Materials 2023, 16, 5647. https://doi.org/10.3390/ma16165647

Chruściel JJ, Olczyk J, Kudzin MH, Kaczmarek P, Król P, Tarzyńska N. Antibacterial and Antifungal Properties of Polyester, Polylactide, and Cotton Nonwovens and Fabrics, by Means of Stable Aqueous Dispersions Containing Copper Silicate and Some Metal Oxides. Materials. 2023; 16(16):5647. https://doi.org/10.3390/ma16165647

Chicago/Turabian StyleChruściel, Jerzy J., Joanna Olczyk, Marcin H. Kudzin, Piotr Kaczmarek, Paulina Król, and Nina Tarzyńska. 2023. "Antibacterial and Antifungal Properties of Polyester, Polylactide, and Cotton Nonwovens and Fabrics, by Means of Stable Aqueous Dispersions Containing Copper Silicate and Some Metal Oxides" Materials 16, no. 16: 5647. https://doi.org/10.3390/ma16165647

APA StyleChruściel, J. J., Olczyk, J., Kudzin, M. H., Kaczmarek, P., Król, P., & Tarzyńska, N. (2023). Antibacterial and Antifungal Properties of Polyester, Polylactide, and Cotton Nonwovens and Fabrics, by Means of Stable Aqueous Dispersions Containing Copper Silicate and Some Metal Oxides. Materials, 16(16), 5647. https://doi.org/10.3390/ma16165647