Influence of Additives on the Mechanical Characteristics of Hardox 450 Steel Welds

Abstract

:1. Introduction

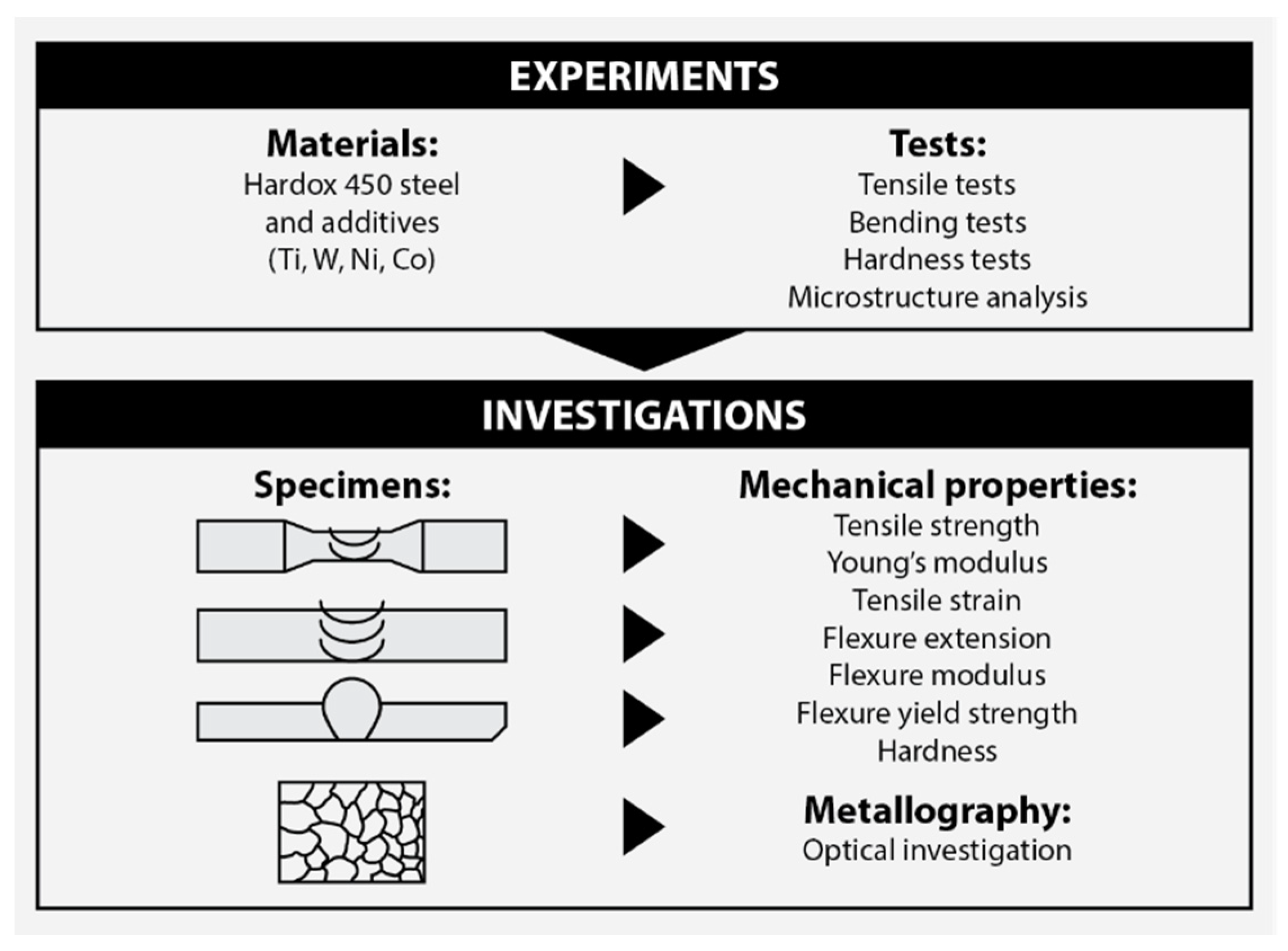

2. Materials and Experimental Procedure

2.1. Materials and Equipment for Welding

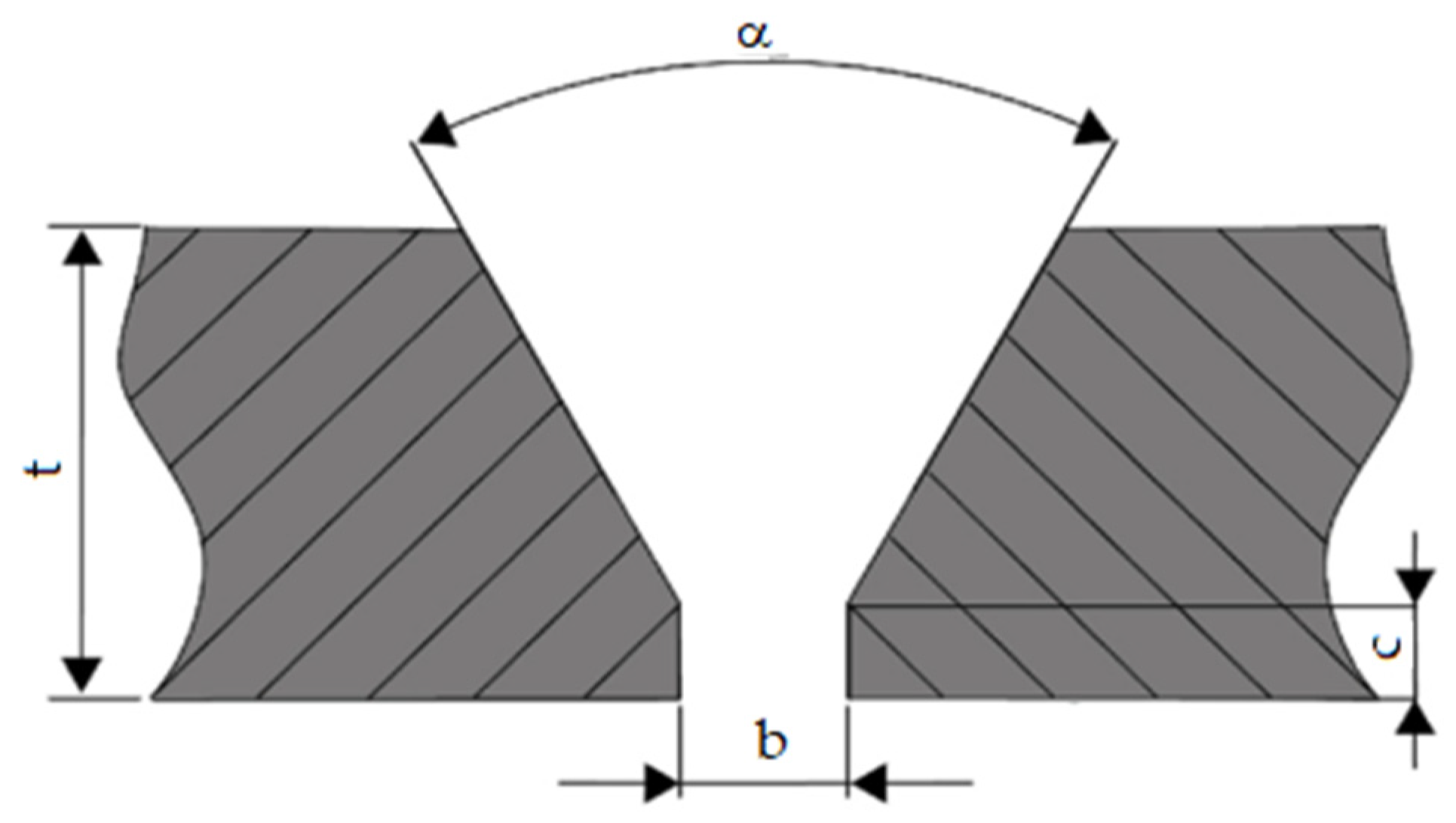

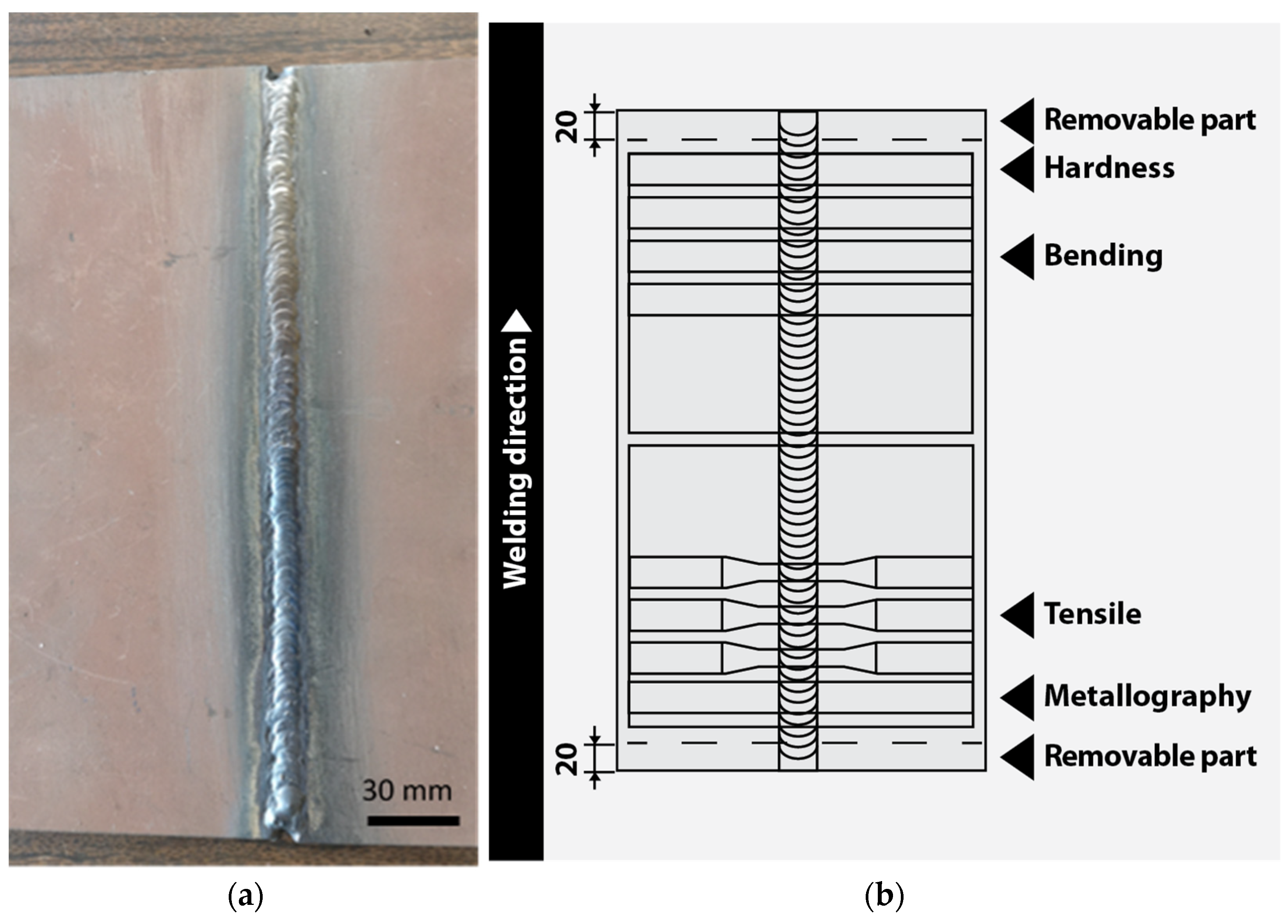

2.2. Preparation of the Specimens before and after Welding

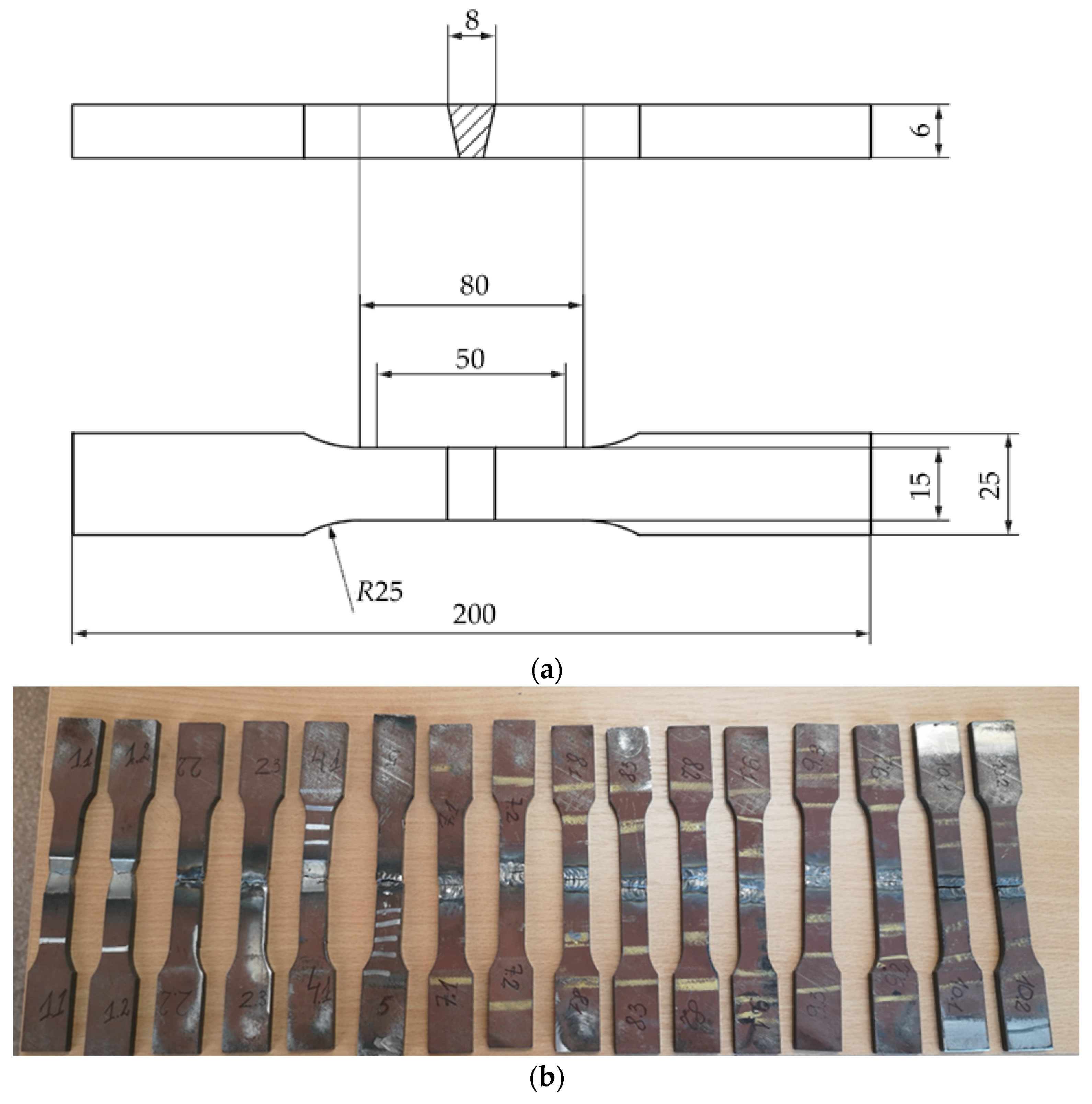

2.3. Mechanical Testing

2.4. Metallographic Preparation

3. Experimental Results

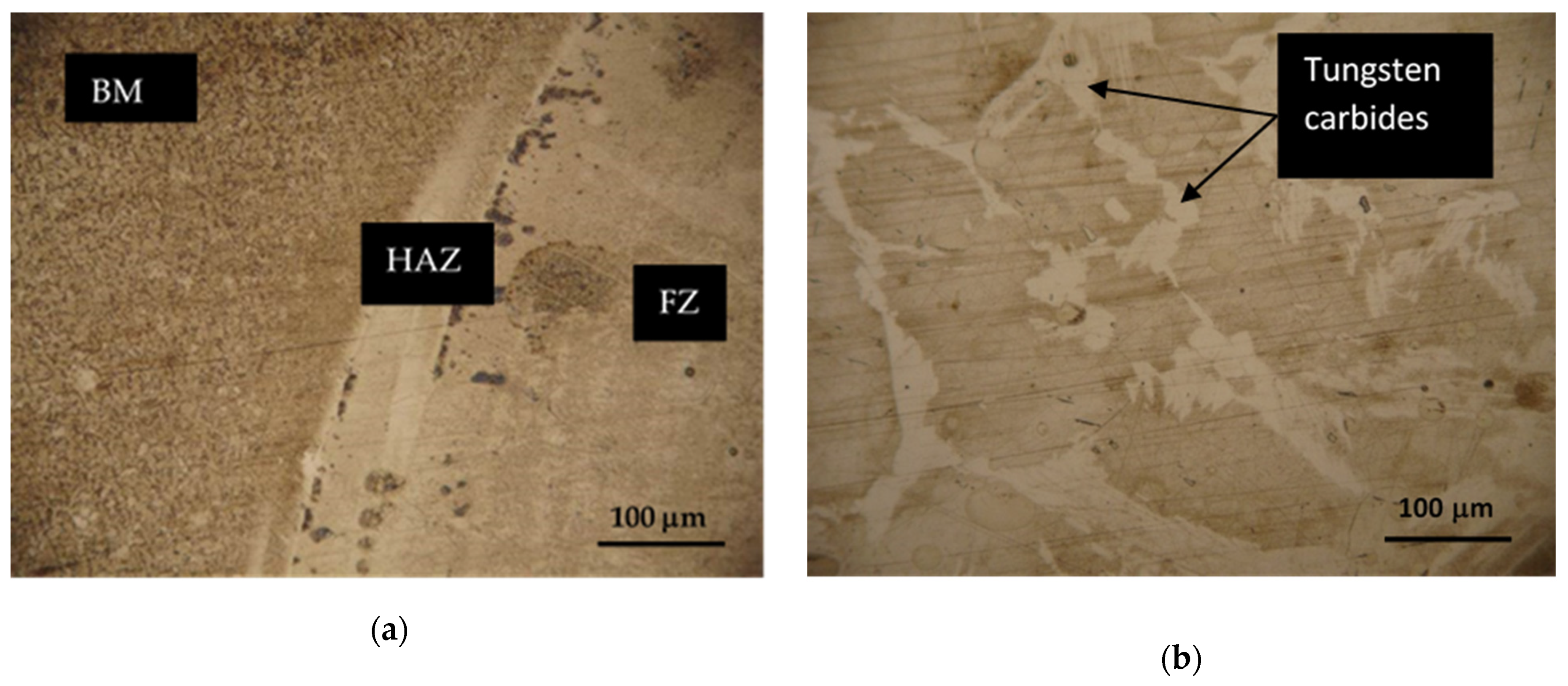

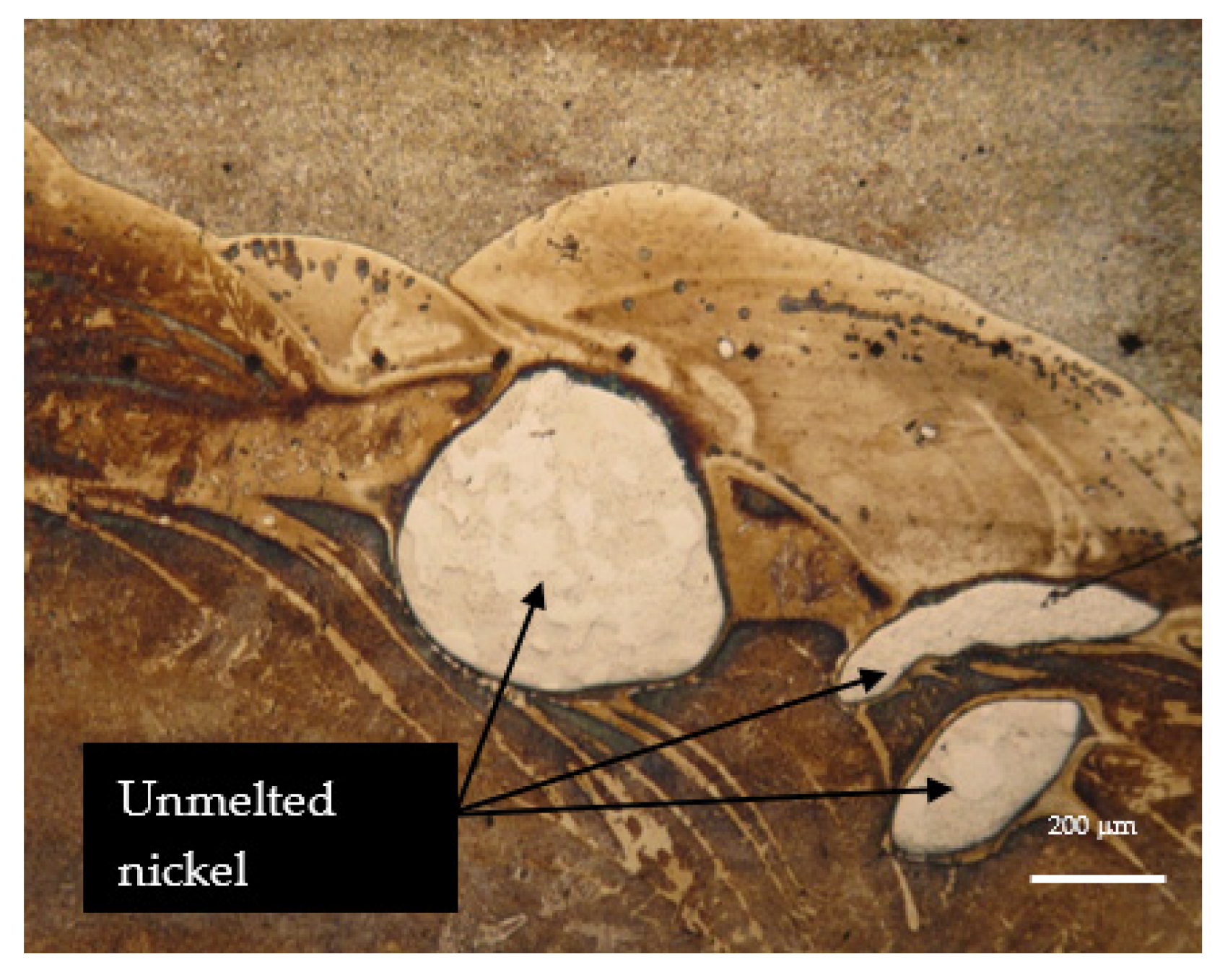

3.1. Microstructure

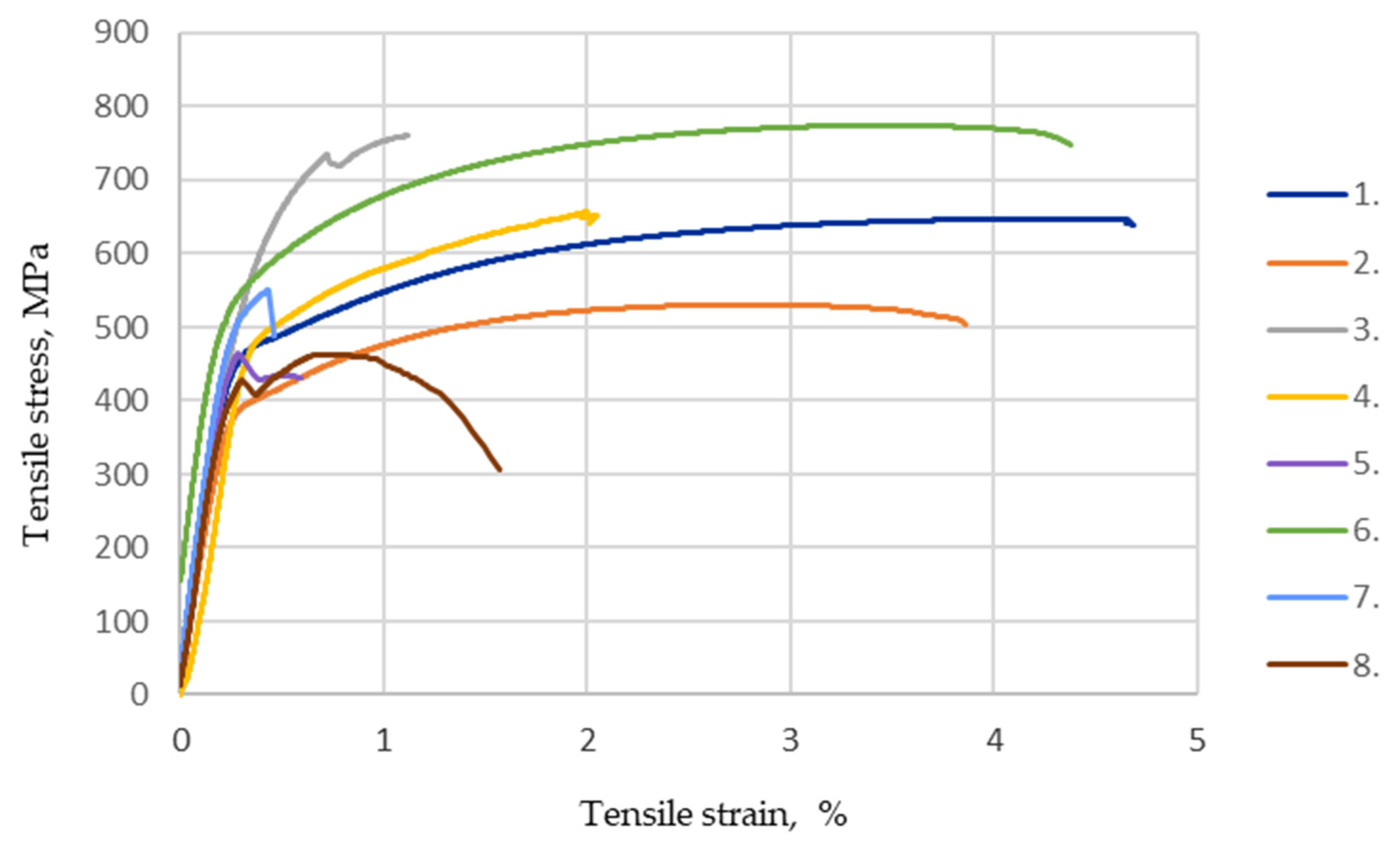

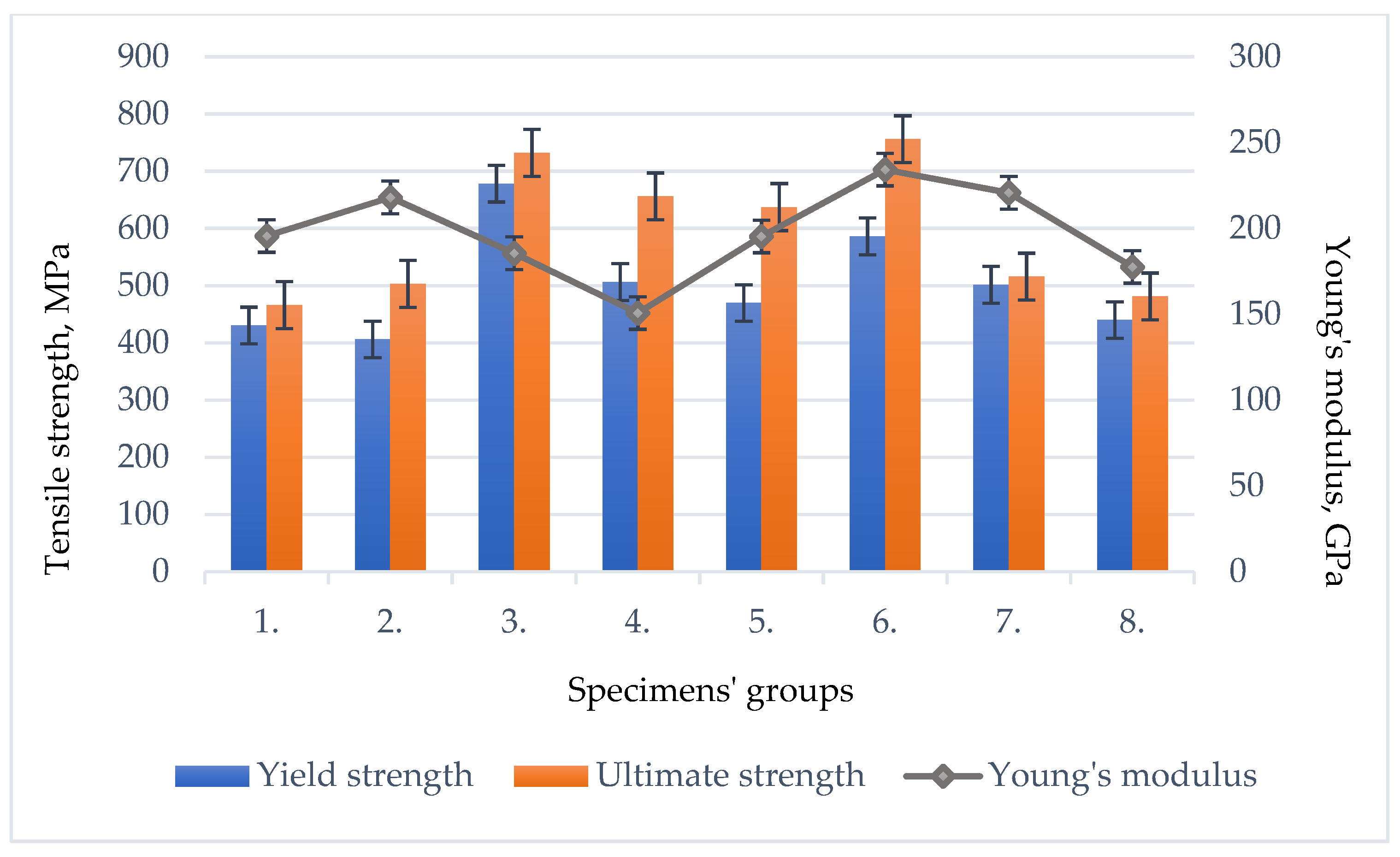

3.2. Tensile Test

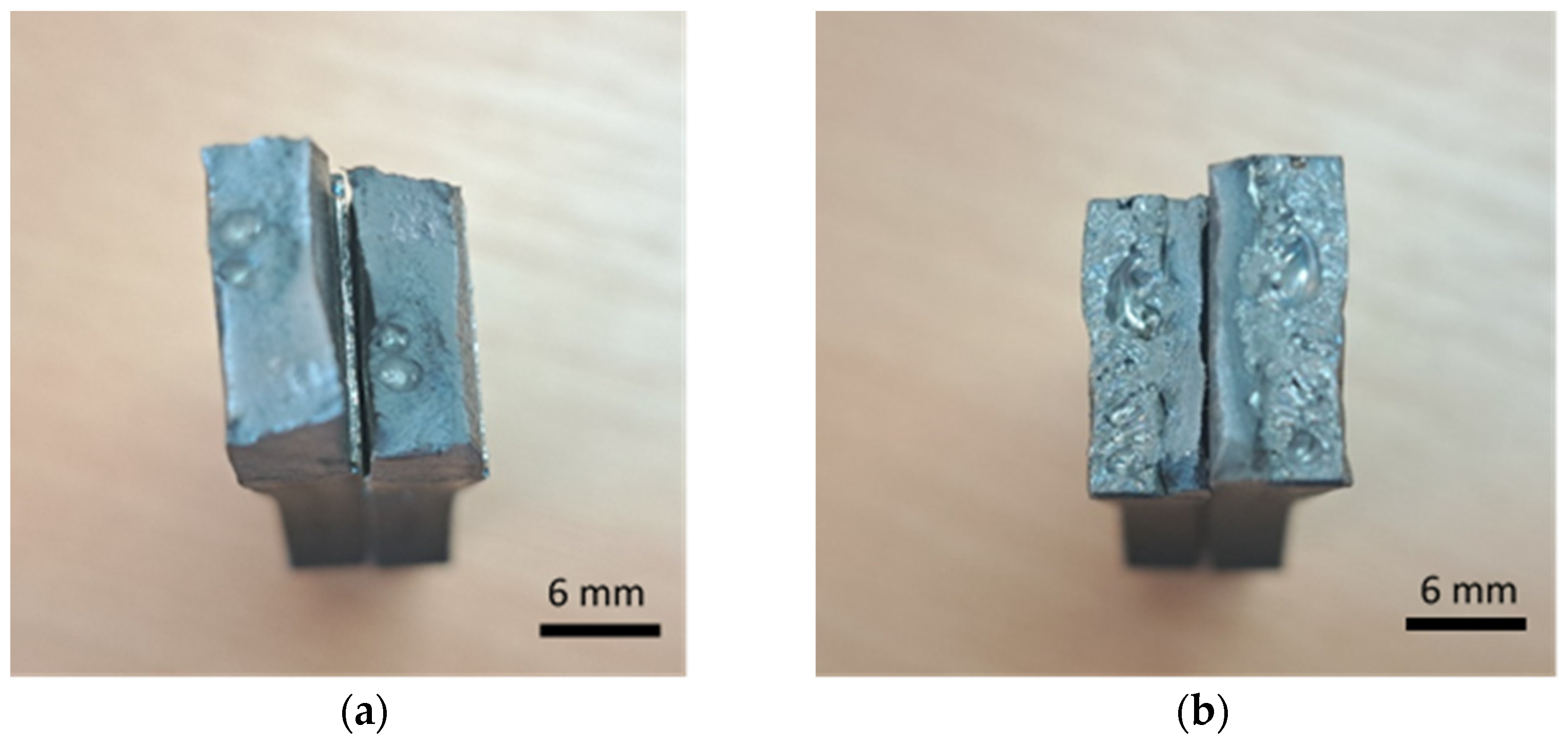

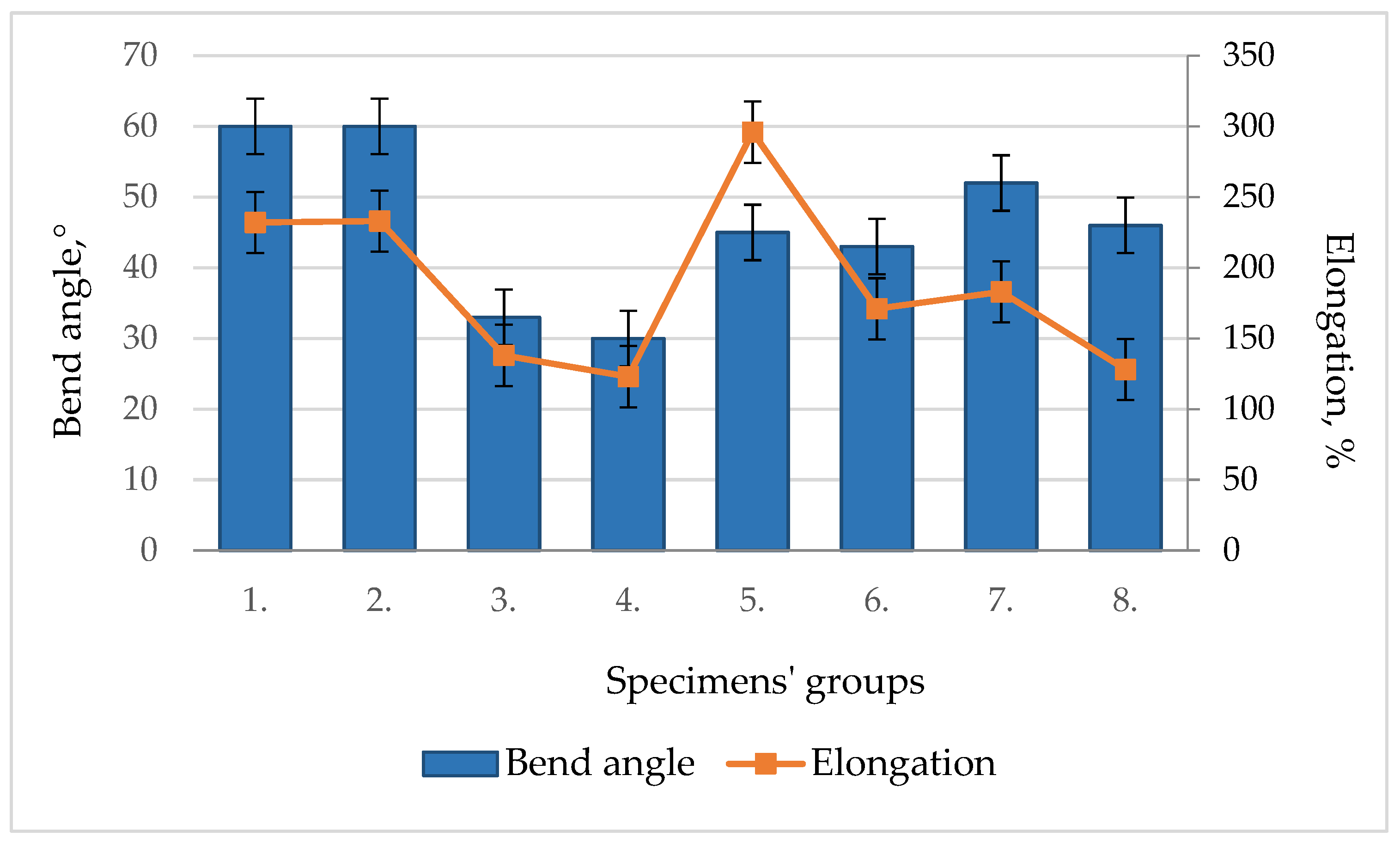

3.3. Bend Test

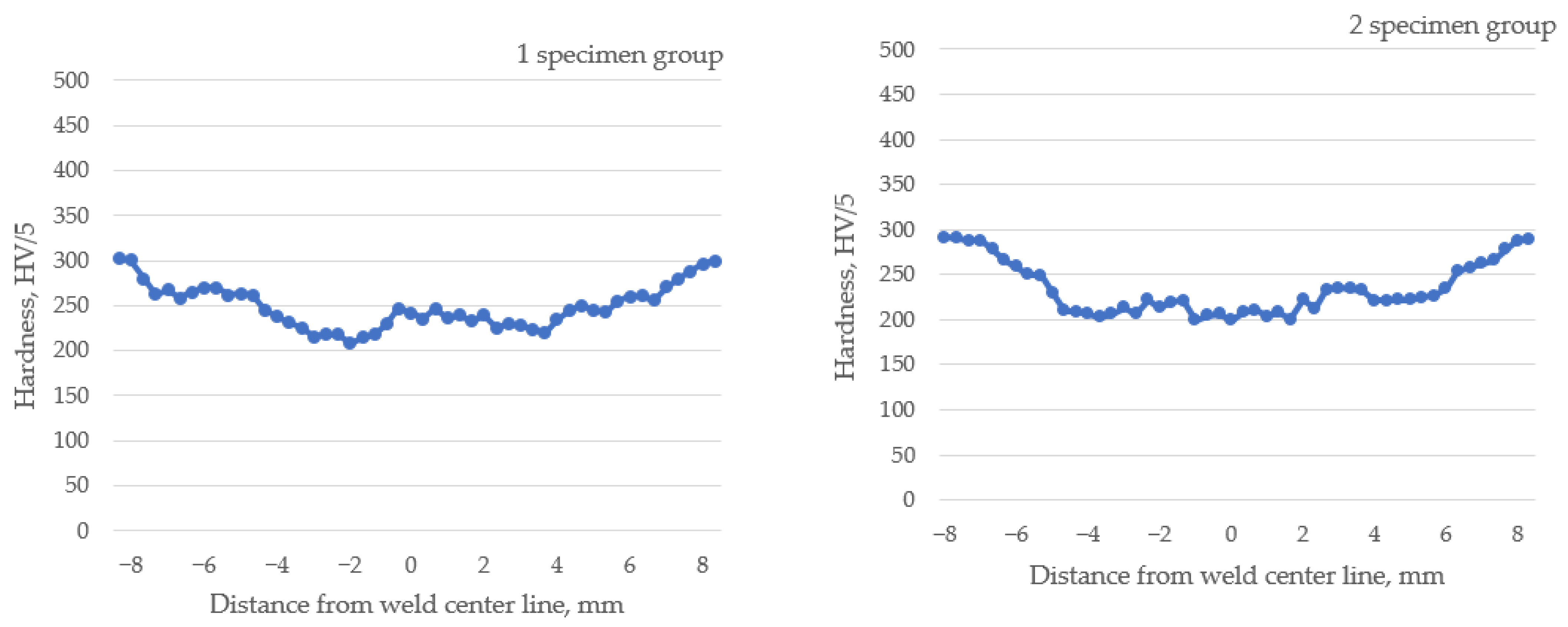

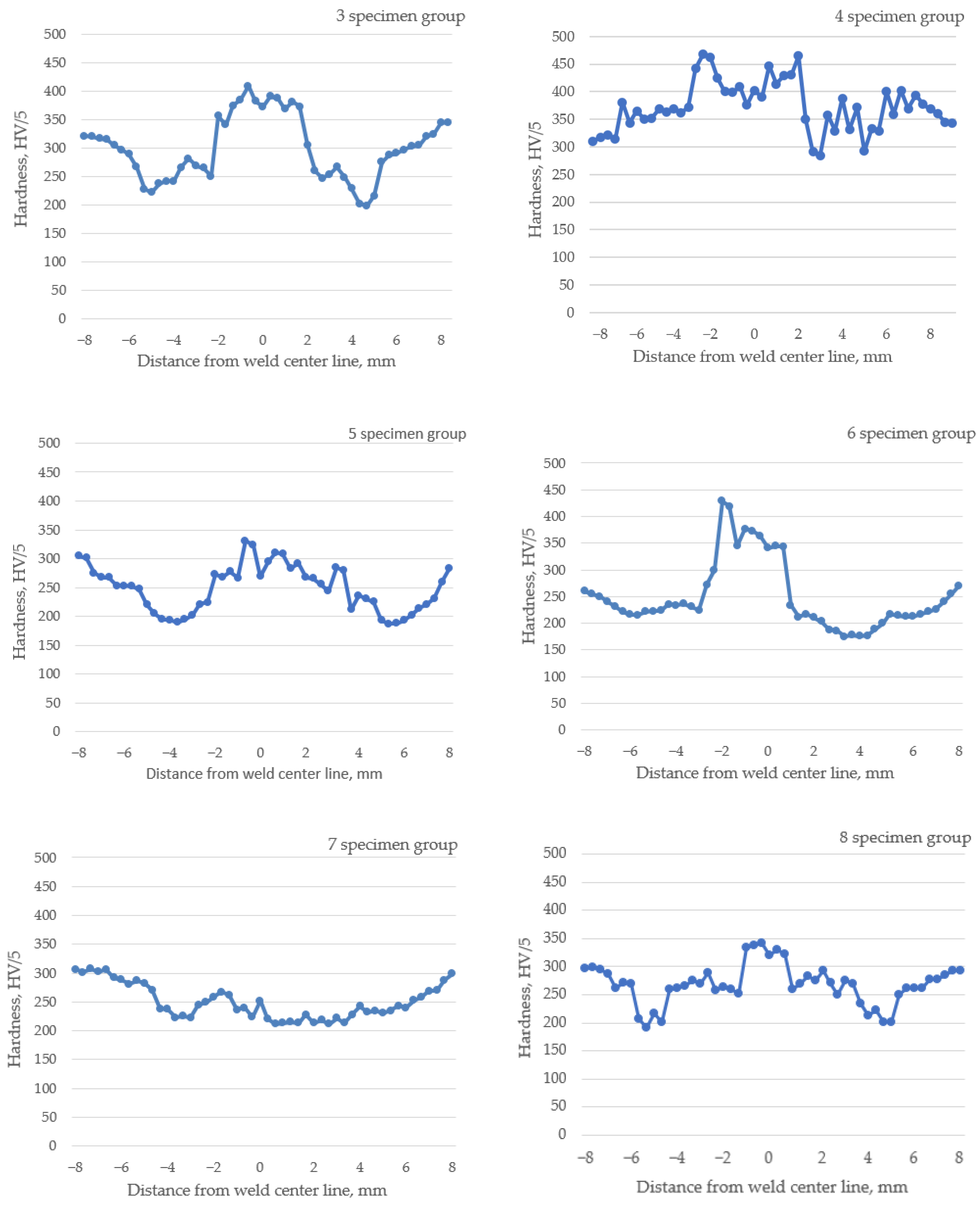

3.4. Hardness Test

4. Discussion

4.1. Microstructure Characterization

4.2. Mechanical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rubio-Ramizer, C.; Giarollo, D.F.; Mazzaferro, J.E.; Mazzaferro, C.P. Prediction of angular distortion due GMAW process of thin-sheets Hardox 450® steel by numerical model and artificial neutral network. J. Manuf. Process. 2021, 68, 1202–1213. [Google Scholar] [CrossRef]

- Kuntoglu, M. Machining induced tribological investigations in sustainable milling of Hardox 500 steel: A new approach of measurement science. Measurement 2022, 201, 111715. [Google Scholar] [CrossRef]

- Moayyedian, M.; Mohajer, A.; Kazemian, M.G.; Mamedov, A.; Derakhshandeh, J.F. Surface roughness analysis in milling machining using design of experiment. SN Appl. Sci. 2020, 2, 1698. [Google Scholar] [CrossRef]

- Szymczak, T.; Kowalewski, Z.L. The high-strength steel and its weld under impact. Mater. Today-Proc. 2022, 62, 2554–2559. [Google Scholar] [CrossRef]

- Yilmaz, D.; Aktas, B.; Calik, A.; Aytar, O.B. Boronizing effect on the radiation shielding properties of Hardox 450 and Hardox HiTuf steels. Radiat. Phys. Chem. 2019, 161, 55–59. [Google Scholar] [CrossRef]

- Konat, L.; Zemlik, M.; Jasinski, R.; Grygier, D. Austenite grain growth analysis in a welded joint of high-strength martensitic abrasion-resistant steel Hardox 450. Materials 2021, 14, 2850. [Google Scholar] [CrossRef] [PubMed]

- Ozturan, A.B.; Irsel, G.; Guzey, B.N. Study of the microstructure and mechanical property relationships of gas metal arc welded dissimilar Hardox 450 and S355J2C+N steel joints. Mater. Sci. Eng. A-Struct. 2022, 856, 143485. [Google Scholar] [CrossRef]

- Yuhua, C.; Yuqing, M.; Weiwei, L.; Peng, H. Investigation of weld crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metal joints. Opt. Lase Technol. 2017, 9, 197–202. [Google Scholar] [CrossRef]

- Fang, J.X.; Wang, J.X.; Wang, Y.J.; He, H.T.; Zhang, D.B.; Cao, Y. Microstructure evolution and deformation behavior during stretching of a compositionally inhomogeneous TWIP-TRIP cantor-like alloy by laser powder deposition. Mater. Sci. Eng. A-Struct. 2022, 847, 143319. [Google Scholar] [CrossRef]

- Konat, L. Structural aspects of execution and thermal treatment of welded joints of Hardox extreme steels. Metals 2019, 9, 915. [Google Scholar] [CrossRef] [Green Version]

- Bialobrzeska, B.; Konat, L.; Jasinski, R. The influence of austenite grain size on the mechanical properties of low-alloy steel with boron. Metals 2017, 7, 26. [Google Scholar] [CrossRef] [Green Version]

- Konat, L.; Bialobrzeska, B.; Bialek, P. Effect of welding process on microstructural and mechanical characteristics of Hardox 600 steel. Metals 2017, 7, 349. [Google Scholar] [CrossRef] [Green Version]

- Gupta, A.; Sharma, V.; Kumar, P.; Thakur, A. Investigating the effect of ferritic filler materials on the mechanical and metallurgical properties of Hardox 400 steel welded joints. Mater. Today-Proc. 2021, 39, 1640–1646. [Google Scholar] [CrossRef]

- Uchino, K.; Kuroki, T.; Ueda, M. Rails of Pearlitic Steel with High Wear Resistance and Toughness and their Manufacturing Methods. U.S. Patent 5,658,400, 19 August 1997. [Google Scholar]

- Silva, H.R.; Ferraresi, V.A. Effect of cobalt alloy addition in erosive wear and cavitation of coatings welds. Wear 2019, 426–427, 302–313. [Google Scholar] [CrossRef]

- Shen, L.; Zhou, J.; Xiong, Y.-B.; Zhang, J.-S.; Meng, Y. Analysis of service condition of large hot forging die and refabrication of die by bimetal-layer weld surfacing technology with a cobalt-based superalloy and a ferrous alloy. J. Manuf. Process. 2018, 31, 731–743. [Google Scholar] [CrossRef]

- Tiwari, A.; Pankaj, P.; Biswas, P.; Kumar, A. Characterization of ultrafine grain tungsten carbide tool and its wear investigation in friction stir welding of HSLA steel. Tribol. Int. 2023, 186, 108579. [Google Scholar] [CrossRef]

- Ding, H.; Liu, T.; Wei, J.; Chen, L.; Cao, F.; Zhang, B.; Luo, R.; Cheng, X. Microstructure and tempering softening mechanism of modified H13 steel with the addition of Tungsten, Molybdenum, and lowering of Chromium. Mater. Design 2022, 224, 111317. [Google Scholar] [CrossRef]

- Liu, A.; Wang, L.; Pan, L.; Cheng, X. Microstructure and mechanical properties of a novel high-density steel having high tungsten content. Mater. Sci. Eng. A-Struct. 2021, 824, 141797. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, X.; Li, C.; Liu, W.; Zhang, Z. Effects of W and Ce micro addition in filler metal on microstructure and creep strength of Cr35Ni45NbM alloy weld joint. Mater. Today Commun. 2021, 28, 102600. [Google Scholar] [CrossRef]

- Zhang, J.; Li, G.; Wang, H.; Wan, X.; Hu, M.; Cao, Y. Achieving superior cryogenic impact toughness and sufficient tensile properties in a novel high-Mn austenitic steel weld metal via cerium addition. J. Mater. Res. Technol. 2023, 23, 5016–5030. [Google Scholar] [CrossRef]

- Li, K.; Liu, J.; Cai, Z.; Han, C.; Li, X. Microstructure and creep properties of graded transition joints between nickel-based alloys and martensitic heat-resistant steels. Mater. Sci. Eng. A-Struct. 2023, 872, 144962. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, L.; Andersson, J.; Ojo, O. Additive manufacturing of 18% nickel maraging steels: Defect, structure and mechanical properties: A review. J. Mater. Sci. Technol. 2022, 120, 227–252. [Google Scholar] [CrossRef]

- Ravikiran, K.; Mehtani, H.; Sivaprasad, K.; Prasad, M.J.N.V.; Kumar, S.; Singh, P.K.; Ghosh, M. Influence of nickel-based buttering material on welded joint between SA509 low alloy steel and 304LN stainless steel. Int. J. Press. Vessel. Pip. 2022, 195, 104576. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, S.; Zhang, T.; Zhou, X.; Li, S. Effects of post-weld heat treatment on the microstructure and mechanical properties of laser-welded NiTi/304SS joint with Ni filler. Mater. Sci. Eng. A-Struct. 2020, 771, 138545. [Google Scholar] [CrossRef]

- Bhole, S.D.; Nemade, J.B.; Collins, L.; Liu, C. Effect of nickel and molybdenum additions on weld metal toughness in a submerged arc welded HSLA line-pipe steel. J. Mater. Process. Technol. 2006, 173, 92–100. [Google Scholar] [CrossRef]

- Ostovan, F.; Shafiei, E.; Toozandehjani, M.; Mohamed, I.F.; Soltani, M. On the role of molybdenum on the microstructural, mechanical and corrosion properties of the GTAW AISI 316 stainless steel welds. J. Mater. Res. Technol. 2021, 13, 2115–2125. [Google Scholar] [CrossRef]

- Wu, M.-W.; Tsao, L.-C.; Chang, S.-Y. The influence of chromium addition and quenching treatment on the mechanical properties and fracture behaviors of diffusion-alloyed powder metal steels. Mater. Sci. Eng. A-Struct. 2013, 565, 196–202. [Google Scholar] [CrossRef]

- Cui, S.; Shi, Y.; Cui, Y.; Zhu, T. The influence of microstructure and chromium nitride precipitations on the mechanical and intergranular corrosion properties of K-TIG weld metals. Constr. Build. Mater. 2019, 210, 71–77. [Google Scholar] [CrossRef]

- Liu, J.; Sun, J.; Wei, S.; Lu, S. Influence of chromium content on the bainite transformation nucleation mechanism and the properties of 800 MPa grade low carbon bainite weld deposited metal. Mater. Sci. Eng. A-Struct. 2022, 840, 142893. [Google Scholar] [CrossRef]

- Fajardo, S.; Llorente, I.; Jimenez, J.A.; Calderon, N.; Herran-Medina, D.; Bastidas, J.M.; Ress, J.; Bastidas, D.M. Influence of chromium on the passivity of thermo=mechanically processed high-Mn TWIP steels. Appl. Surf. Sci. 2020, 513, 145852. [Google Scholar] [CrossRef]

- Li, S.; Yu, H.; Lu, Y.; Lu, J.; Wang, W.; Yang, S. Effects of titanium content on the impact wear properties of high-strength low-alloy steels. Wear 2021, 474–475, 203647. [Google Scholar] [CrossRef]

- Beidokhti, B.; Koukabi, A.H.; Dolati, A. Effect of titanium addition on the microstructure and inclusion formation in submerged arc welded HSLA pipeline steel. J. Mater. Process. Technol. 2009, 209, 4027–4035. [Google Scholar] [CrossRef]

- Mallaiah, G.; Ravinder Reddy, P.; Kumar, A. Influence of titanium addition on mechanical properties, residual stresses and corrosion behavior of AISI 430 grade ferritic stainless steel GTA welds. Proc. Mater. Sci. 2014, 6, 1740–1751. [Google Scholar] [CrossRef] [Green Version]

- Paulo de Oliveira, A.; Gonzalez, B.M. The engineering behind the mechanical properties enhancement on HSLA steels, microalloyed with niobium: Effect of boron and titanium. J. Mater. Res. Technol. 2020, 9, 9372–9379. [Google Scholar] [CrossRef]

- Guo, X.; Zhao, L.; Liu, X.; Lu, F. Investigation on the resistance to fatigue crack growth for weld metals with different Ti addition in near-threshold regime. Int. J. Fatigue 2019, 120, 1–11. [Google Scholar] [CrossRef]

- Shin, S.-S.; Lee, M.; Kim, K.-H. Role of minor addition of B in submerged arc weld metal for 500 MPa grade seismic steel plates. J. Manuf. Process. 2021, 68, 1418–1429. [Google Scholar] [CrossRef]

- Abe, F.; Tabuchi, M.; Kondo, M.; Tsukamoto, S. Suppression of Type IV fracture and improvement of creep strength of 9Cr steel welded joints by boron addition. Int. J. Press. Vessels Pip. 2007, 84, 44–52. [Google Scholar] [CrossRef]

- Long, J.; Zhang, L.-J.; Zhang, L.-L.; Wang, X.; Zhang, G.-F.; Zhang, J.-X. Effects of minor Zr addition on the microstructure and mechanical properties of laser welded joint of Al/SiCp metal-matrix composite. J. Manuf. Process. 2020, 49, 373–384. [Google Scholar] [CrossRef]

- Guo, A.M.; Li, S.R.; Guo, J.; Li, P.H.; Ding, Q.F.; Wu, K.M.; He, X.L. Effect of zirconium addition on the impact toughness of the heat affected zone in a high strength low alloy pipeline steel. Mater. Charact. 2008, 59, 134–339. [Google Scholar] [CrossRef]

- Zuma, B.N.; van der Merwe, J.W. Effect of Ru addition on the mechanical properties and microstructure of 316L austenitic stainless steel weld metal. Procedia Manuf. 2017, 7, 2–7. [Google Scholar] [CrossRef]

- EN ISO 9692-1:2013; Welding and Allied Processes—Types of Joint Preparation—Part 1: Manual Metal Arc Welding, Gas-shielded Metal Arc Welding, Gas Welding, TIG Welding and Beam Welding of Steels. European Committee for Standartization: Brussels, Belgium, 2013.

- EN ISO 9015-2:2016; Destructive Tests on Welds in Metallic—Hardness Testing—Part 2: Microhardness Testing of Welded Joints. European Committee for Standartization: Brussels, Belgium, 2016.

- EN ISO 4136:2012; Destructive Tests on Welds in Metallic Materials—Transverse Tensile Test. European Committee for Standartization: Brussels, Belgium, 2012.

- EN ISO 6892-1:2016; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. European Committee for Standartization: Brussels, Belgium, 2016.

- EN ISO 5173:2010/A1:2013; Destructive Tests on Welds in Metallic Materials—Bend Tests—Amendment 1 (ISO 5173:2009/Amd 1:2011). European Committee for Standartization: Brussels, Belgium, 2013.

- ES ISO 7438: 2020; Metallic Materials—Bend Test/Annex A. Determination of the Bend Angle from the Measurement of the Displacement of the Former. European Committee for Standartization: Brussels, Belgium, 2020.

- Hatano, Y.; Takamori, M.; Matsuda, K.; Ikeno, S.; Fujii, K.; Watanabe, K. Solid state reaction between tungsten and amorphous carbon. J. Nucl. Mater. 2002, 307–311, 1339–1343. [Google Scholar] [CrossRef]

- Shibuya, M.; Toda, Y.; Sawada, K.; Kushima, H.; Kimura, K. Effect of nickel and cobalt addition on the precipitation-strength of 15Cr ferritic steels. Mater. Sci. Eng. A-Struct. 2011, 528, 5387–5393. [Google Scholar] [CrossRef]

- Kou, S. Weld metal solidification I: Grain structure. In Book Welding Metallurgy, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; pp. 170–198. ISBN 0-471-43491-4. [Google Scholar]

- Dobrzanski, L.A.; Kasprzak, W. The influence of 5% cobalt addition on structure and working properties of the 9-2-2-5, 11-2-2-5 and 11-0-2-5 high-speed steels. J. Mater. Process. Technol. 2001, 109, 52–64. [Google Scholar] [CrossRef]

- Hong, S.G.; Lee, W.B.; Park, C.G. The effects of tungsten addition on the microstructural stability of 9Cr-Mo steels. J. Nucl. Mater. 2001, 288, 202–207. [Google Scholar] [CrossRef]

- Mazilkin, A.; Abramova, M.M.; Enikeev, N.A.; Lomakin, I.V.; Valiev, R.Z.; Ivanisenko, Y.; Kübel, C.; Etienne, A.; Sauvage, X.; Radiguet, B. The effect of tungsten on microstructure and mechanical performance of an ultrafine Fe-Cr steel. Mater. Lett. 2018, 227, 292–295. [Google Scholar] [CrossRef]

- Arici, G.; Acarer, M.; Uyaner, M. Effect of Co addition on microstructure and mechanical properties of new generation 3Cr-3W and 5Cr-3W steels. Eng. Sci. Technol. Int. J. 2021, 24, 974–989. [Google Scholar] [CrossRef]

- Magudeeswaran, G.; Balasubramanian, V.; Reddy, G.M. Hydrogen induced cold cracking studies on armour grade high strength, quenched and tempered steel weldments. Int. J. Hydrogen Energy 2008, 33, 1897–1908. [Google Scholar] [CrossRef]

- Gou, J.; Nie, R.; Xing, X.; Li, Z.; Cui, G.; Liu, J.; Deng, X.; Frank Cheng, Y. Hydrogen-induced cracking of welded X80 steel studies by experimental testing and molecular dynamics modeling. Corros. Sci. 2023, 214, 111027. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Q.; Yu, S.-M.; Liu, H.; Hu, L.; Ren, Y.-Y. Laves-phase evolution during aging in fine grained heat-affected zone of a tungsten-strengthened 9% Cr steel weldment. J. Mater. Process. Technol. 2015, 219, 60–69. [Google Scholar] [CrossRef]

- Wang, D.; Zhong, Q.; Yang, J.; Zhang, S. Effects of Cr and Ni on the microstructure and corrosion resistance of high-strength low alloy steel. J. Mater. Res. Technol. 2023, 23, 36–52. [Google Scholar] [CrossRef]

| Grade | Chemical Composition [%] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Cr | Ni | B | Mo | C14 | |

| Hardox 450 | 0.190 | 1.200 | 0.250 | 0.007 | 0.002 | 0.050 | 0.060 | 0.001 | 0.024 | 0.312 |

| ER 70S-6 * | 0.150 | 1.850 | 1.150 | 0.025 | 0.035 | 0.150 | 0.150 | - | 0.150 | - |

| E 7018 * | 0.150 | 1.600 | 0.750 | 0.040 | 0.035 | 0.200 | 0.300 | - | 0.300 | - |

| Grade | Mechanical Properties | ||||

|---|---|---|---|---|---|

| Yield Point Rp (0.2) [MPa] | Tensile Strength Rm [MPa] | Elongation A5 [%] | Impact Strength KCV-40 [J/cm2] | Brinell Hardness [HBW] | |

| Hardox 450 | 1200 | 1400 | 10 | 50 | 425–475 |

| ER 70S-6 * | 483 | 583 | 28 | 30–40 | - |

| E 7018 * | 400 | 490 | 22 | 27 | - |

| Welding Passes | Current [A] | Arc Voltage [V] | Travel Speed [mm/min] | Flow Rate of Shielding Argon Gas [L/min] | Heat Input [kJ/mm] |

|---|---|---|---|---|---|

| 1 (root pass) | 90 | 19.5 | 33.0 | 12.0 | 1.92 |

| 2 (hot pass) | 110 | 19.5 | 75.0 | 10.0 | 1.03 |

| 3 (fill up pass) | 110 | 19.5 | 75.0 | 10.0 | 1.03 |

| 4 (cap pass) | 110 | 19.5 | 75.0 | 10.0 | 1.03 |

| Specimen Group | Filler Rod (Standard) ER 70S-6 | Filler Rod (Standard) E 7018 | Ti Powder | W Powder | NI Powder | Co Powder |

|---|---|---|---|---|---|---|

| 1. | ✓ | |||||

| 2. | ✓ | |||||

| 3. | ✓ | ✓ (50%) | ✓ (50%) | |||

| 4. | ✓ | ✓ | ||||

| 5. | ✓ | |||||

| 6. | ✓ | ✓ (50%) | ✓ (50%) | |||

| 7. | ✓ | ✓ | ||||

| 8. | ✓ | ✓ | ||||

| 9. | ✓ | ✓ |

| Specimen Groups | Ultimate Tensile Strength, [MPa] | Strain at Ultimate Tensile Strength, [%] | Location of Fracture | Remark/e.g., Fracture Appearance | Hardness, [HV/5] |

|---|---|---|---|---|---|

| 1. | 466.00 | 0.28 | through welding | ductile fracture | 252.3 |

| 2. | 530.46 | 2.79 | through welding | ductile fracture | 225.7 |

| 3. | 760.28 | 1.12 | through welding | brittle fracture | 428.1 |

| 4. | 656.98 | 2.00 | through welding | brittle fracture | 478.2 |

| 5. | 647.19 | 4.63 | through welding | ductile fracture/a neck is formed | 344.4 |

| 6. | 774.39 | 3.45 | through welding | brittle fracture | 436.7 |

| 7. | 551.29 | 0.43 | through welding | brittle fracture | 277.8 |

| 8. | 462.30 | 0.72 | through welding | brittle fracture/negligible gas porosity | 349.6 |

| Specimen Group | Original Gauge Length, [mm] | Bending Modulus, [GPa] | Bending Yield Strength, [MPa] | Remark/e.g., Fracture Appearance | A View of the Seams after the Bend Tests |

|---|---|---|---|---|---|

| 1. | 6.00 | 88.12 | 426.77 | Ductile fracture in the tensile zone; open cracks at the edges and center of the seam. |  |

| 2. | 6.00 | 72.65 | 329.25 | Ductile fracture in the tensile zone; open cracks at the edges of the seam. |  |

| 3. | 6.02 | 82.76 | 491.69 | A longitudinal crack is observed in the seam zone. |  |

| 4. | 6.01 | 79.95 | 532.21 | A crack has formed in the tensile zone across the entire width of the seam; small defects are visible. |  |

| 5. | 6.00 | 93.64 | 464.59 | No cracks were detected in the tensile zone; plastic deformations are visible on the sides. |  |

| 6. | 6.00 | 83.32 | 506.81 | Slight fracture in tensile zone; lateral crack visible in transverse direction. |  |

| 7. | 6.01 | 76.62 | 464.12 | Deep lateral fracture in the tensile zone. |  |

| 8. | 6.01 | 81.71 | 391.22 | Cracks are observed on both sides of the weld. |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baskutis, S.; Baskutiene, J.; Dragašius, E.; Kavaliauskiene, L.; Keršiene, N.; Kusyi, Y.; Stupnytskyy, V. Influence of Additives on the Mechanical Characteristics of Hardox 450 Steel Welds. Materials 2023, 16, 5593. https://doi.org/10.3390/ma16165593

Baskutis S, Baskutiene J, Dragašius E, Kavaliauskiene L, Keršiene N, Kusyi Y, Stupnytskyy V. Influence of Additives on the Mechanical Characteristics of Hardox 450 Steel Welds. Materials. 2023; 16(16):5593. https://doi.org/10.3390/ma16165593

Chicago/Turabian StyleBaskutis, Saulius, Jolanta Baskutiene, Egidijus Dragašius, Lina Kavaliauskiene, Neringa Keršiene, Yaroslav Kusyi, and Vadym Stupnytskyy. 2023. "Influence of Additives on the Mechanical Characteristics of Hardox 450 Steel Welds" Materials 16, no. 16: 5593. https://doi.org/10.3390/ma16165593

APA StyleBaskutis, S., Baskutiene, J., Dragašius, E., Kavaliauskiene, L., Keršiene, N., Kusyi, Y., & Stupnytskyy, V. (2023). Influence of Additives on the Mechanical Characteristics of Hardox 450 Steel Welds. Materials, 16(16), 5593. https://doi.org/10.3390/ma16165593