Creep of Concrete in Shell Structures: Nonlinear Theory

Abstract

:1. Introduction

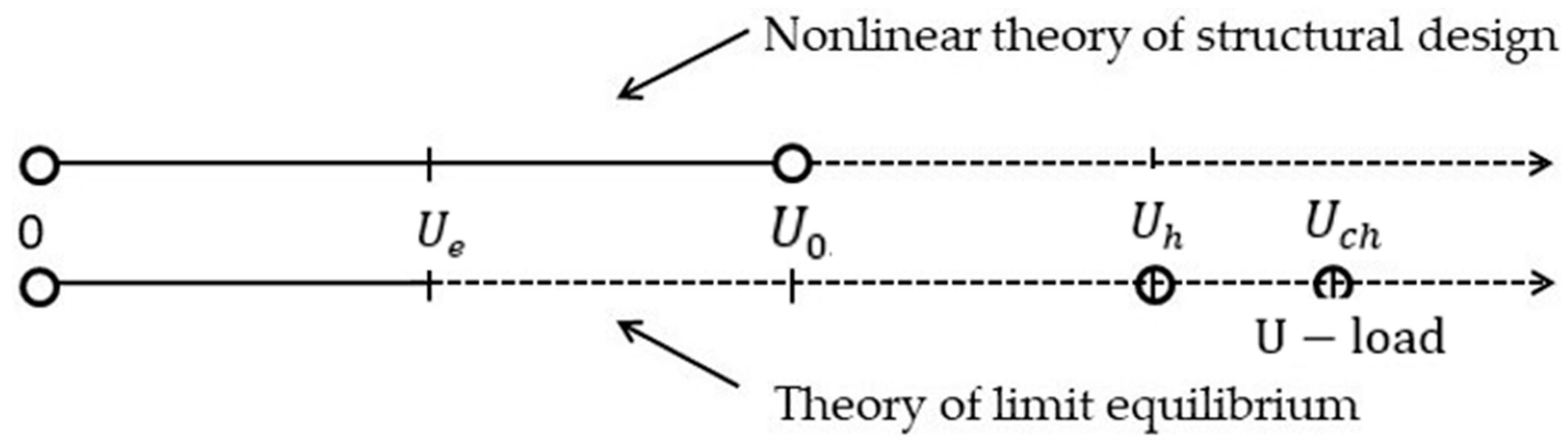

- Point —there is a real point completing the process of static loading of a compressed reinforced concrete structure; point —there is an unreal point, but it is used in the building codes and has nothing to do with the process of static loading of any compressed reinforced concrete structure;

- The nonlinear theory of the calculation of structures recognizes the unsatisfactory state of the structure, corresponding to the site (; building codes recognize the same deformation site satisfactory condition for construction;

- The nonlinear theory of the calculation of structures establishes the rules for calculating the value and characterizes the limiting state of the structure;

- The nonlinear theory of calculating structures naturally rejects the existence of a deflection at the column, with it having no length; the building codes give deflection to the column, with it having no length. This deflection reaches infinite values in absolute magnitude;

- Numerical values and differ from each other up to 100%.

2. Methods

3. Results and Discussion

3.1. Establishing a Functional Relationship between Stresses and Strains

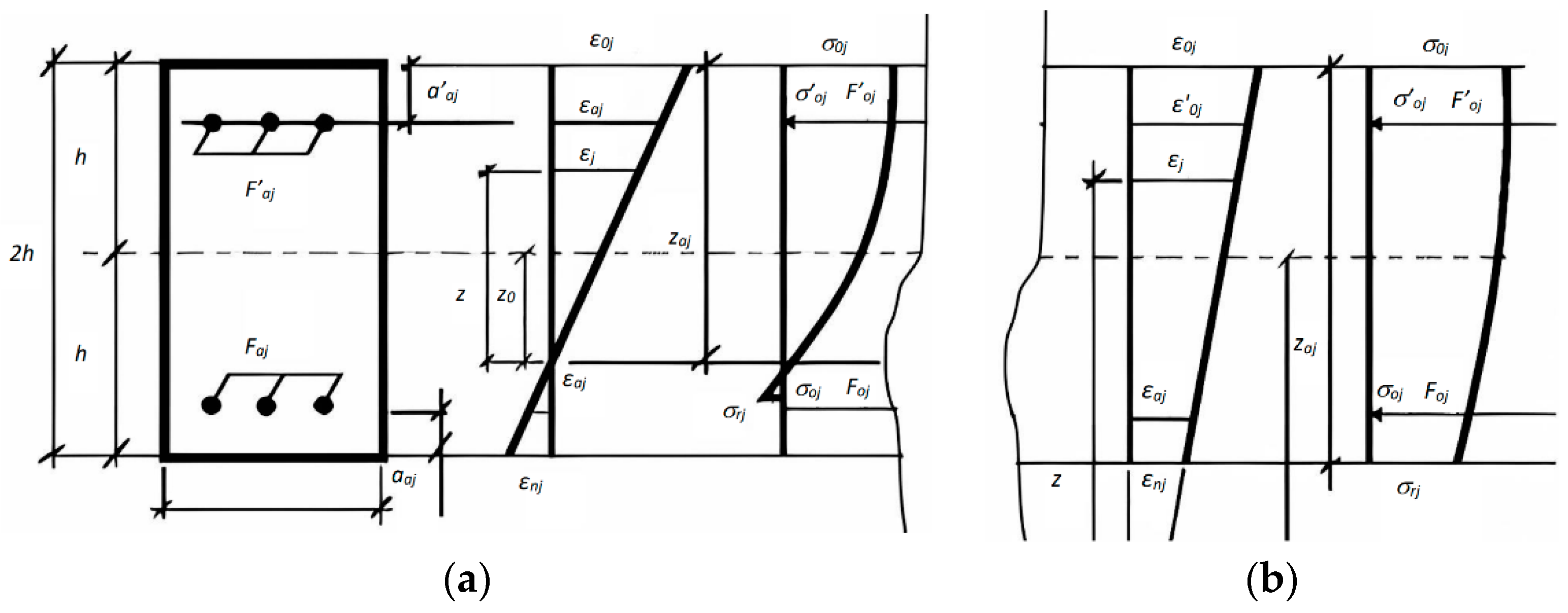

3.2. Creation of a Deformation Model of a Section with Cracks and the Inelastic Properties of Materials

3.3. Derivation of the Integral Relationship between Deformations and Stresses, and Finding Equivalent Elasticity Parameters

3.4. Description of the Shape of the Deformed Scheme and Nonlinear Analysis of Structures

3.5. Evaluation of the Stability of the Equilibrium under Study and the Establishment of the Criterion for the Loss of Bearing Capacity

4. Conclusions

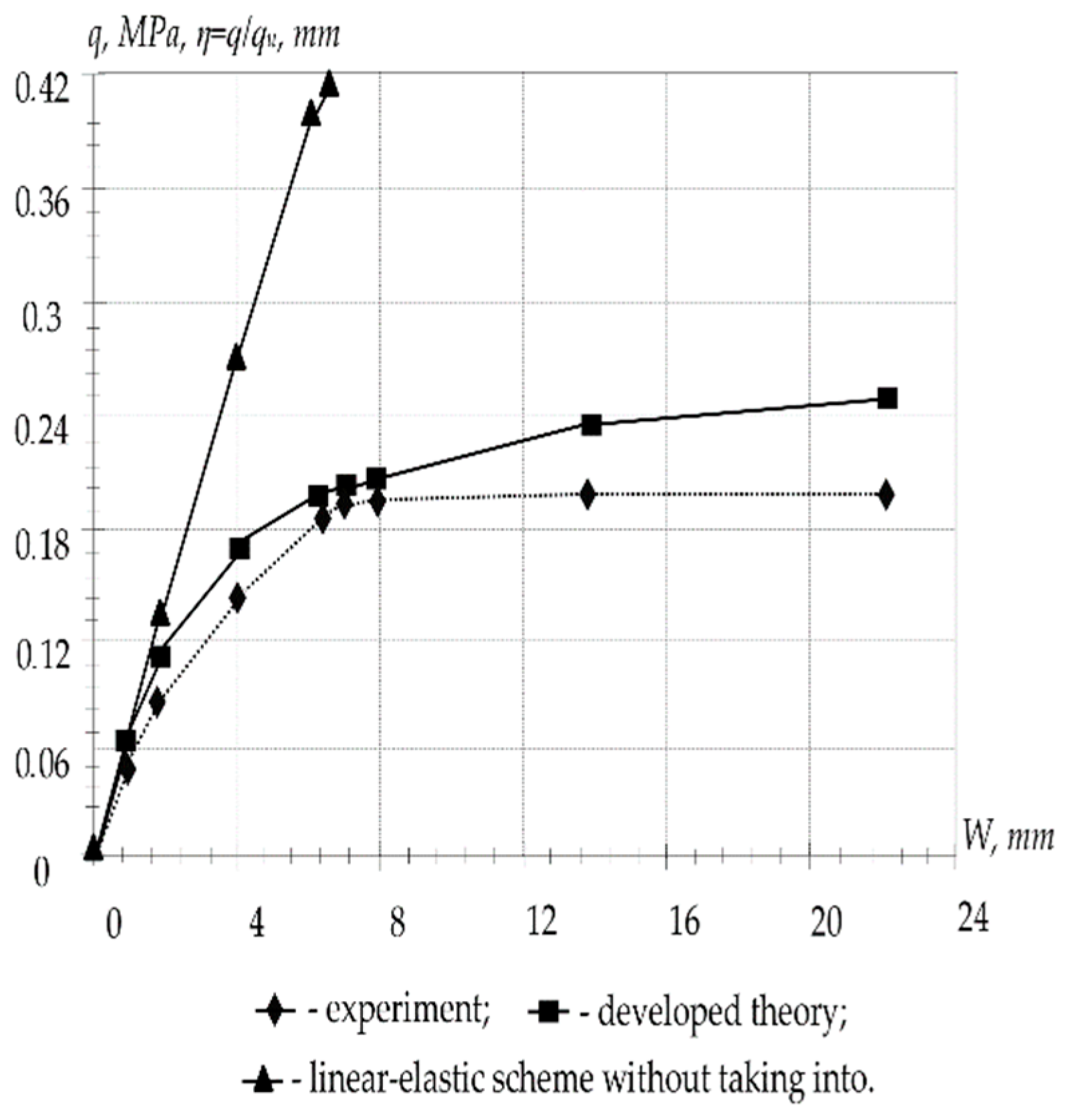

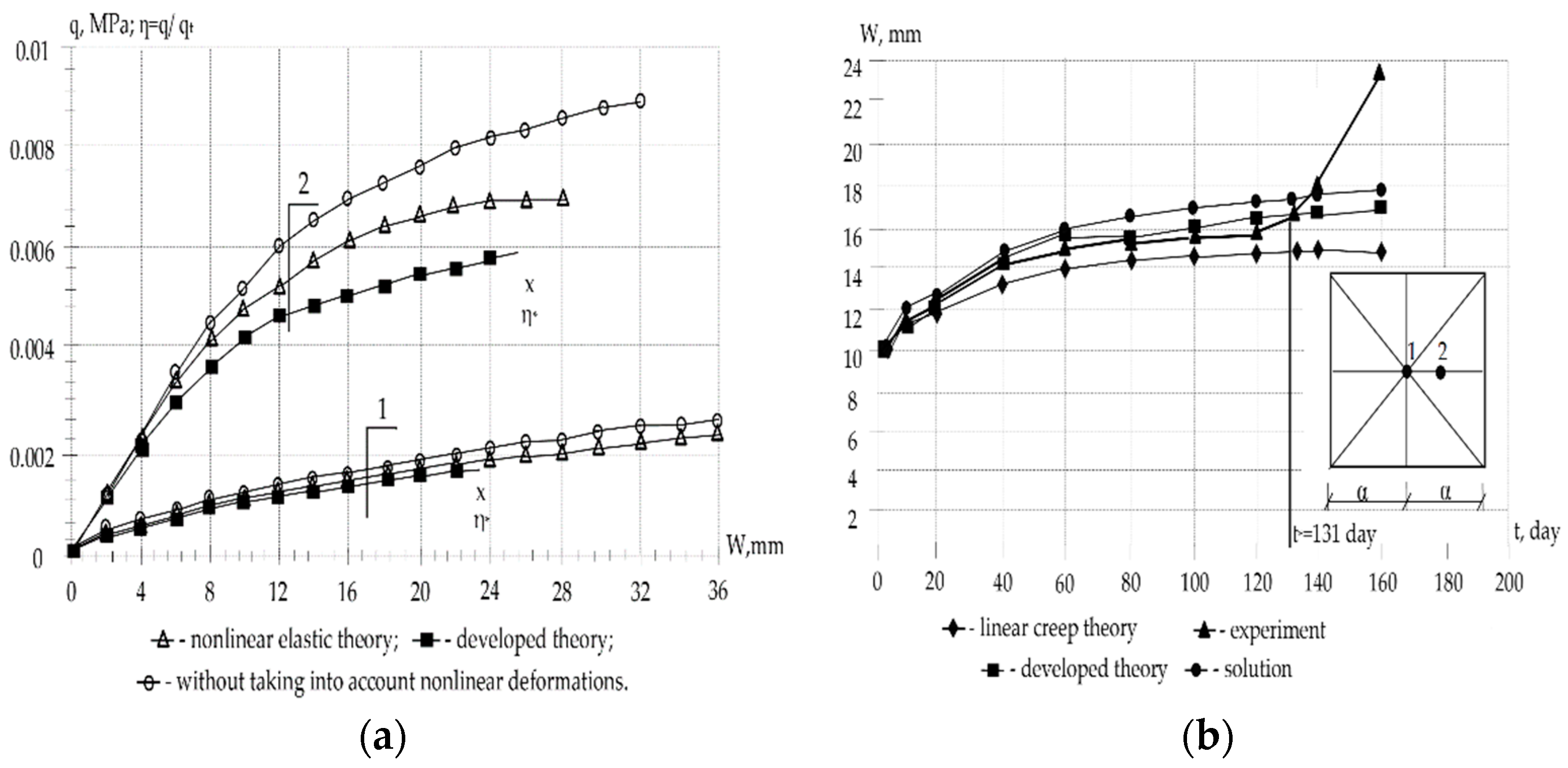

- To research the stability of an equilibrium state, it is not enough to use geometrically and physically nonlinear dependencies, based on the nonlinear theory of elasticity. Calculation of short-term and long-term critical load according to the linear elastic and nonlinear elastic scheme in comparison with the developed theory gives an overestimation of the values and ;

- The linear elastic calculation scheme overestimates the values up to 56%; calculation according to the linear theory of creep without taking into account crack formation overestimates the values up to 39%;

- The installed dependency from the load level, the parameters of plasticity, creep, reinforcement percentage, the crack formation scheme, geometric characteristics, initial deflection support conditions of support and other factors;

- Taking into account that physical nonlinearity gives a significant correction in the values of the ultimate load for shells with high lift and reinforcement content, for very shallow shells, it is essential to take geometric nonlinearity into account.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eagar, T.; Musso, C. Why Did the World Trade Center Collapse? Science, Engineering, and Speculation. JOM 2001, 53, 8–11. [Google Scholar] [CrossRef]

- Burdin, D. The Main Problems of the Methodology for Calculating Buildings and Structures for Resistance to Progressive Collapse in a Static Formulation. In Proceedings of the 16th International Scientific and Technical Conference ‘Contemporary Issues of Engineering and Building Industry’, Moscow, Russia, 21–22 April 2021; pp. 215–222. [Google Scholar]

- Luu, C.; Mo, Y.; Hsu, T. Development of CSMM-Based Shell Element for Reinforced Concrete Structures. Eng. Struct. 2017, 132, 778–790. [Google Scholar] [CrossRef] [Green Version]

- Bažant, Z.; Hubler, M.; Yu, Q. Damage in Prestressed Concrete. In Handbook of Damage Mechanics; Springer: New York, NY, USA, 2015; pp. 515–564. [Google Scholar] [CrossRef]

- Aitcin, P.-C. Concrete Structure, Properties and Materials. Can. J. Civ. Eng. 2011, 13, 499. [Google Scholar] [CrossRef]

- Klausen, A.; Kanstad, T.; Bjøntegaard, Ø.; Sellevold, E. Comparison of Tensile and Compressive Creep of Fly Ash Concretes in the Hardening Phase. Cem. Concr. Res. 2017, 95, 188–194. [Google Scholar] [CrossRef]

- Weizu, Z. Creep of Concrete at Early Age and Its Effect on Cracking Sensitivity. Ind. Constr. 2005, 35, 89–92. [Google Scholar]

- Bažant, Z.; Hauggaard, A.; Baweja, S.; Ulm, F.-J. Microprestress-Solidification Theory for Concrete Creep.I: Aging and Drying Effects. J. Eng. Mech. 1997, 123, 1188–1194. [Google Scholar] [CrossRef] [Green Version]

- Bažant, Z. Creep of Concrete. Sci. Technol. 2001, 1797–1800. [Google Scholar]

- Zhao, Z.; Zhang, H.; Fang, B.; Sun, Y.; Zhong, Y.; Shi, T. Tensile Creep Model of Slab Concrete Based on Microprestress-Solidification Theory. Materials 2020, 13, 3157. [Google Scholar] [CrossRef]

- Duissenbekov, B.; Tokmuratov, A.; Zhangabay, N.; Orazbayev, Z.; Yerimbetov, B.; Aldiyarov, Z. Finite-Difference Equations of Quasistatic Motion of the Shallow Concrete Shells in Nonlinear Setting. Curved Layer. Struct. 2020, 7, 48–55. [Google Scholar] [CrossRef]

- Pane, I.; Hansen, W. Early Age Creep and Stress Relaxation of Concrete Containing Blended Cements. Mater. Struct. 2002, 35, 92–96. [Google Scholar] [CrossRef]

- Boumakis, I.; Di Luzio, G.; Marcon, M.; Vorel, J.; Wan-Wendner, R. Discrete Element Framework for Modeling Tertiary Creep of Concrete in Tension and Compression. Eng. Fract. Mech. 2018, 200, 263–282. [Google Scholar] [CrossRef] [Green Version]

- Rzhanitsyn, A. Creep Theory; Stroyizdat: Moscow, Russia, 1968; p. 416. [Google Scholar]

- YuN, R. Elements of Hereditary Mechanics of Solid Bodies; Nauka: Moscow, Russia, 1977; p. 383. [Google Scholar]

- Lokoshchvnko, A.; Shesterikov, S. Method of describing creep and long-term strength in pure tension. PMTF 1980, 3, 155–159. [Google Scholar]

- Ruiz, M.F.; Muttoni, A.; Gambarova, P.G. Relationship between nonlinear creep and cracking of concrete under uniaxial compression. J. Adv. Concrete Technol. 2007, 5, 383–393. [Google Scholar] [CrossRef] [Green Version]

- Bunatyan, L. Ustoychivost’ tonkostennyh sterzhney s uchetom polzuchesti materiala. Izv. USSR Acad. Sci. Ser. Fiz.-Mat Est. I Tehn. Nauk. 1953, 6, 19. [Google Scholar]

- Afanasiev, V.; Kolmanovsky, V.; Nosov, V. Mathematical Theory of Designing Control Systems: Textbook for Universities, 3rd ed.; Rev. and Additional; Higher School: St. Petersburg, Russia, 2003; p. 614. [Google Scholar]

- Prokopovich, I. Influence of Long-Term Processes on the Stress-Reinforced State of Structures; Gosstroyizdat: Moscow, Russia, 1963; 260p. [Google Scholar]

- Yatsenko, E. Creep of Concrete and Reinforced Concrete Structures: Lecture Notes; Dnepropetrovsk Inst. railroad transport, the Department is Building Structures: Dnepropetrovsk, Ukraine, 1973; p. 97. [Google Scholar]

- Ulitsky, I. Theory and Calculation of Reinforced Concrete rod Structures Taking into Account Long-Term Processes; Budivelnik: Kyiv, Ukraine, 1967; p. 307. [Google Scholar]

- Distefano, N. On the Identification of a Nonlinear Viscoelastic Spring under Dynamic Conditions. Applying Filters. // Mechanics of Deformable Bodies and Structures: Collection of Articles; Mashinostroyeniye: Moscow, Russia, 1975; pp. 163–170. [Google Scholar]

- Linnik, A. On the bearing capacity of compressed rods under conditions of nonlinear creep/Problems of creep and shrinkage of concrete (Applied problems of the theory of reinforced concrete associated with long-term processes). In MISI Named after V.V. Kuibyshev; MISI (Moscow Institute of Civil Engineering): Moscow, Russia, 1974; p. 205. [Google Scholar]

- Rossi, P.; Tailhan, J.-L.; Le Maou, F. Comparison of Concrete Creep in Tension and in Compression: Influence of Concrete Age at Loading and Drying Conditions. Cem. Concr. Res. 2013, 51, 78–84. [Google Scholar] [CrossRef]

- Nastic, M.; Bentz, E.; Kwon, O.; Papanikolaou, V.; Tcherner, J. Shrinkage and Creep Strains of Concrete Exposed to Low Relative Humidity and High Temperature Environments. Nucl. Eng. Des. 2019, 352, 110154. [Google Scholar] [CrossRef] [Green Version]

- Bažant, Z.; Hauggaard, A.; Baweja, S. Microprestress-Solidification Theory for Concrete Creep. II: Algorithm and Verification. J. Eng. Mech. 1997, 123, 1195–1201. [Google Scholar] [CrossRef] [Green Version]

- Wei, Y.; Guo, W.; Liang, S. Microprestress-Solidification Theory-Based Tensile Creep Modeling of Early-Age Concrete: Considering Temperature and Relative Humidity Effects. Constr. Build. Mater. 2016, 127, 618–626. [Google Scholar] [CrossRef]

- EN 1992-1-2:2004. Eurocode 2: Design of Concrete Structures. Available online: https://standards.iteh.ai/catalog/standards/cen/597bff7e-4f49-446f-ac9b-69829a09d098/en-1992-1-2-2004 (accessed on 5 June 2022).

- Gailitis, R.; Figiela, B.; Abelkalns, K.; Sprince, A.; Sahmenko, G.; Choinska, M.; Guigou, M.D. Creep and Shrinkage Behaviour of Disintegrated and Non-Disintegrated Cement Mortar. Materials 2021, 14, 7510. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Z.; Zhu, S.; He, Z.; Zhu, D.; Liu, J.; Meng, S. Nonlinear Creep Damage Constitutive Model of Concrete Based on Fractional Calculus Theory. Materials 2019, 12, 1505. [Google Scholar] [CrossRef] [Green Version]

- Mussabayev, T.; Tulebekova, A. To the Question of Harmonization of Eurocode 2 ‘Design of Concrete Structures’. In Proceedings of the Issues of Design and Installation of Above-Ground and Underground Structures of Buildings and Structures; St. Petersburg State University of Architecture and Civil Engineering: St. Petersburg, Russia, 2018; pp. 79–85. [Google Scholar]

- Russian Applicable Code Design SP 63.13330.2018 Concrete and Reinforced Concrete Structures. General Provisions. Available online: https://docs.cntd.ru/document/554403082 (accessed on 10 June 2022).

- Sanzharovsky, R.; Manchenko, M. Nonlinear Theory of Concrete and Reinforced Concrete Creep and Modern Standards. Struct. Mech. Eng. Constr. Build. 2017, 19, 23–35. [Google Scholar]

- Sanzharovskij, R. Non-Linear Hereditary Creep Theory. Struct. Mech. Eng. Constr. Build. 2014, 19, 63–68. [Google Scholar]

- Bondarenko, V.; Rimshin, V. Linear Equations of Force Resistance and Diagram σ–ε of Concrete. Struct. Mech. Eng. Constr. Build. 2014, 19, 40–44. [Google Scholar]

- Harutyunyan, N.K. Some Questions of the Theory of Creep; State Publishing House of Technical and Theoretical Literature: Moscow, Russia, 1952; p. 323. [Google Scholar]

- Aleksandrovsky, S.V. Calculation of Concrete and Reinforced Concrete Structures for Changes in Temperature and Humidity, Taking into Account Creep; RICRC: Moscow, Russia, 1973; p. 432. [Google Scholar]

- Sanzharovsky, R.; Ter-Emmanuilyan, T.; Manchenko, M. Superposition Principle as the Fundamental Error of the Creep Theory and Standards of the Reinforced Concrete. Struct. Mech. Eng. Constr. Build. 2018, 14, 92–104. [Google Scholar] [CrossRef] [Green Version]

- Sanjarovskiy, R.; Sieber, F.; Ter-Emmanuilyan, T.; Manchenko, M.; Mussabayev, T.; Gadzhiev, M. Theory of the Calculation of the Reinforced Concrete and Inconsistency It to Eurocode. Struct. Mech. Eng. Constr. Build. 2020, 16, 185–192. [Google Scholar] [CrossRef]

- Sanzharovsky, R.; Manchenko, M.; Hadzhiev, M.; Mussabayev, T.; Ter-Emmanuilyan, T.; Varenik, K. System of Insufficiency of the Modern Theory of Long-Term Resistance of Reinforced Concrete and Designers’ Warnings. Struct. Mech. Eng. Constr. Build. 2019, 15, 3–24. [Google Scholar] [CrossRef]

- Sanjarovsky, R.; Ter-Emmanuilyan, T.; Manchenko, M. Insolvent Ways of Development of the Modern Theory of Reinforced Concrete. Struct. Mech. Eng. Constr. Build. 2018, 14, 379–389. [Google Scholar] [CrossRef]

- Aleksandrovskiy, M. Using the Method of Sequential Approximations for the Calculation of Beams from a Nonlinear-Elastic Material. Technol. Text. Ind. 2019, 5, 242–247. [Google Scholar]

- Mussabayev, T. Nonlinear Model for Calculating Reinforced Shells and Plates. Available online: https://www.dissercat.com/content/nelineinaya-teoriya-rascheta-zhelezobetonnykh-obolochek-i-plastin (accessed on 5 June 2022).

- Geniev, G.; Knssyuk, V.; Tyupin, G. Theory of Plasticity of Concrete and Reinforced Concrete; Stroyizdat: Moscow, Russia, 1974; 316p. [Google Scholar]

- Duisenbekov, B. Investigation of the Stress-Strain State of Shallow Shells of a Coating Based on Nonlinear Creep Equations. Available online: https://www.kstu.kz/o-zashhite-doktorskoj-dissertatsii-dujsenbekova-bolata-kambarovicha/?lang=en (accessed on 5 June 2022).

- Khaidukov, G.; Shugaev, V.M.Y. Study on Models of the Bearing Capacity of Shallow Reinforced Concrete Shells under Short-Term and Long-Term Loads. Proc. Res. Inst. Concr. Reinf. Concr. 1974, 9, 76–99. [Google Scholar]

- Suslov, I. Reinforced Concrete Plates Appear in the Thickness of Slab-and-Beam Systems in the Flat and Bending State of Sensitivity. Available online: https://search.rsl.ru/ru/record/01008475995 (accessed on 5 June 2022).

- Oatul, A.; Novoselov, A. Experimental Study of Short-Term and Long-Term Stability of Models of Shallow Reinforced Concrete Shells. Build. Constr. 1969, 11, 79–86. [Google Scholar]

- Awwad, T.; Mussabayev, T.; Tulebekova, A.; Jumabayev, A. Development of the Computer Program of Calculation of Concrete Bored Piles in Soil Ground of Astana City. Int. J. GEOMATE 2019, 17, 176–182. [Google Scholar] [CrossRef]

- Mussabayev, T. Nonlinear Theory of Concrete Creep in Structures and International Design Standards. Available online: https://drive.google.com/file/d/1hkr5d5JcewOqsSlsCyL77G321GcMQgYi/view (accessed on 5 June 2022).

- Nuguzhinov, Z.S. Comparative analysis of the results of probabilistic and deterministic approaches in calculations of carrying capacity and reliability of building structures. In RAACS Fundamental, Exploratory and Applied Research on Scientific Support of the Development of Architecture, Urban Planning and Construction Industry of the Russian Federation in 2021: A Collection of Scientific Papers of RAACS; Publishing House ACB: Moscow, Russia, 2022; Volume 2, pp. 282–292. [Google Scholar]

- Nuguzhinov, Z.S.; Baidzhanov, D.O.; Fedorchenko, V.I.; Rakhimov, A.M.; Divak, L.A. Thermal insulation material based on local technogenic raw material. Glass Ceram. (Engl. Transl. Steklo I Keram.) 2017, 73, 427–430. [Google Scholar] [CrossRef]

- Bakirov, Z.; Bakirov, M.; Tazhenova, G.D.; Nuguzhinov, Z. Structural optimization of linear vibration isolation systems. J. Theor. Appl. Mech. (Bulg.) This Link Is Disabl. 2020, 50, 36–49. [Google Scholar] [CrossRef]

| Type of Calculation | P-1 | S-1 | S-2 | |||

|---|---|---|---|---|---|---|

| Critical Load Value, MPa | Comparati-Ve Assessment, % | Critical Load Value, MPa | Comparati-Ve Assessment, % | Critical Load Value, MPa | Comparati-Ve Assessment, % | |

| Short-term | ||||||

| Elastic-linear scheme | 0.046 | 254.9 | 0.0022 | 100 | 0.0087 | 100 |

| Developed theory | 0.02 | 114.3 | 0.00175 | 79.6 | 0.0058 | 66.7 |

| Experiment [48] | 0.0185 | 100 | ||||

| Long-term | ||||||

| Method of calculation [47] | 0.0027 | 71.1 | ||||

| Developed theory for linear creep: | ||||||

| excluding cracks | 0.00162 | 100 | 0.0056 | 147.4 | ||

| taking into account cracks formation | 0.00151 | 93.2 | 0.0047 | 123.7 | ||

| The developed theory takes into account nonlinear creep: | ||||||

| according to the criterion [29] | 0.00146 | 90.1 | 0.0043 | 113.2 | ||

| Experiment [49] | 0.0038 | 100 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mussabayev, T.T.; Nuguzhinov, Z.S.; Nemova, D.; Kayupov, T.; Tolkynbaev, T.A.; Akmakanova, A.Z.; Khafizova, G.S. Creep of Concrete in Shell Structures: Nonlinear Theory. Materials 2023, 16, 5587. https://doi.org/10.3390/ma16165587

Mussabayev TT, Nuguzhinov ZS, Nemova D, Kayupov T, Tolkynbaev TA, Akmakanova AZ, Khafizova GS. Creep of Concrete in Shell Structures: Nonlinear Theory. Materials. 2023; 16(16):5587. https://doi.org/10.3390/ma16165587

Chicago/Turabian StyleMussabayev, Turlybek Turkpenovich, Zhmagul Smagulovich Nuguzhinov, Darya Nemova, Tabyldy Kayupov, Temirkhan Anapiyaevich Tolkynbaev, Assel Zhanalykovna Akmakanova, and Gulzhan Sailaubekovna Khafizova. 2023. "Creep of Concrete in Shell Structures: Nonlinear Theory" Materials 16, no. 16: 5587. https://doi.org/10.3390/ma16165587

APA StyleMussabayev, T. T., Nuguzhinov, Z. S., Nemova, D., Kayupov, T., Tolkynbaev, T. A., Akmakanova, A. Z., & Khafizova, G. S. (2023). Creep of Concrete in Shell Structures: Nonlinear Theory. Materials, 16(16), 5587. https://doi.org/10.3390/ma16165587