Plastic Roads in Asia: Current Implementations and Should It Be Considered?

Abstract

1. Introduction

2. Research Rationale and Methodology

2.1. The Planning Phases

2.2. Data Source and Search Strategy

2.3. Inclusion and Exclusion Criteria

2.4. Data Extraction and Synthesis

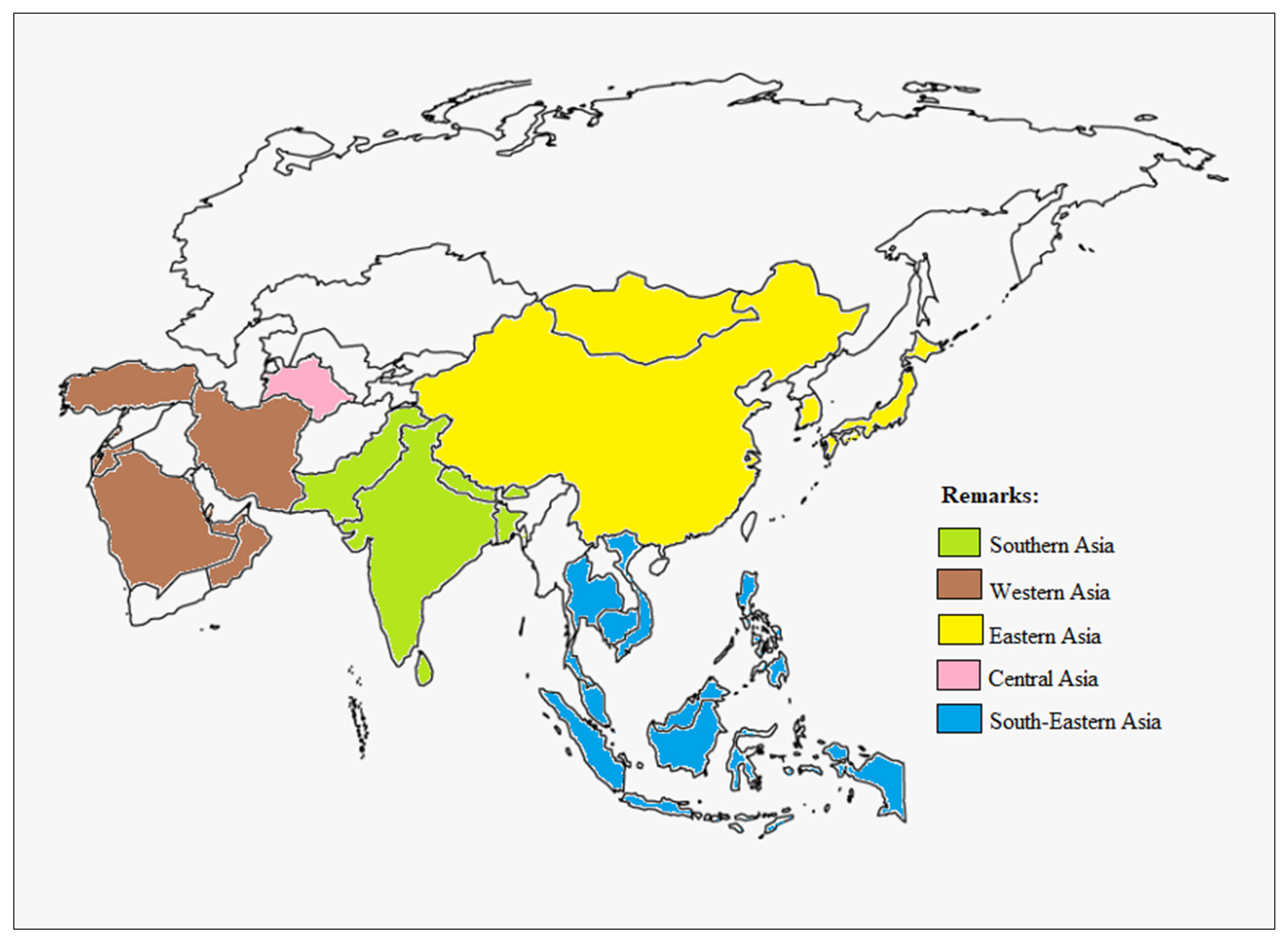

3. Plastic Roads Construction in Asian Countries

3.1. Expansion of Plastic Road Idea in Asia

- Collection and Sorting: Waste plastics, such as plastic bags, bottles, and packaging materials, are collected from various sources, including recycling centers, waste management facilities, and consumer collections. These plastics may undergo sorting to separate different types and remove any contaminants.

- Shredding and Granulation: The collected plastics are then shredded into smaller pieces or granulated into small pellets. This process helps reduce the plastic waste into a manageable size for incorporation into the asphalt mixture.

- Mixing with Asphalt: The shredded or granulated plastic pieces are mixed with hot bitumen, which is the binder material used in asphalt. The heat softens the plastic and allows it to blend homogeneously with the bitumen. The plastic content in the mixture can vary depending on the specific requirements and desired performance of the plastic-modified asphalt.

- Mixing with Aggregates: The plastic-modified bitumen is further mixed with aggregates, such as crushed stone or gravel, to create the final asphalt mixture. This mixture combines the properties of traditional asphalt with the benefits provided by the incorporation of plastic waste.

- Paving and Compaction: The plastic-modified asphalt mixture is then transported to the construction site and laid down on the prepared road surface using conventional paving equipment. The mixture is spread and compacted to achieve the desired thickness and smoothness.

- Road Application: After compaction, the plastic-modified asphalt forms a durable and flexible road surface, similar to conventional asphalt roads. The plastic content in the mixture enhances the strength, stability, and resistance to cracking, thereby improving the overall performance of the road.

- (a)

- Southern Asia

- Bangladesh

- ii.

- Bhutan

- iii.

- India

- iv.

- Iran

- v.

- Nepal

- vi.

- Pakistan

- vii.

- Sri Lanka

- (b)

- Western Asia

- Armenia

- ii.

- Azerbaijan

- iii.

- Bahrain

- iv.

- Israel

- v.

- Jordan

- vi.

- Kuwait

- vii.

- Lebanon

- viii.

- Oman

- ix.

- Qatar

- x.

- Saudi Arabia

- xi.

- Turkey

- xii.

- United Arab Emirates (UAE)

- (c)

- Eastern Asia

- China

- ii.

- Japan

- iii.

- Mongolia

- iv.

- South Korea

- (d)

- Central Asia

- Turkmenistan

- (e)

- South-Eastern Asia

- Cambodia

- ii.

- Indonesia

- iii.

- Malaysia

- iv.

- Philippines

- v.

- Singapore

- vi.

- Thailand

- vii.

- Timor-Leste

- viii.

- Vietnam

3.2. Difference between Polymer-Modified Asphalt and Plastic-Modified Asphalt

- (a)

- Polymer-modified asphalt: Polymer-modified asphalt refers to asphalt mixtures where polymers, such as styrene-butadiene-styrene (SBS) or styrene-butadiene rubber (SBR), are added to the asphalt binder. These polymers are usually derived from synthetic rubber or thermoplastic materials. The polymer content in polymer-modified asphalt is typically higher than that of plastic-modified asphalt.

- Purpose: The addition of polymers is aimed at improving the performance characteristics of the asphalt. Polymers enhance elasticity, flexibility, and resistance to deformation and cracking, making the asphalt binder more durable and able to withstand heavy traffic loads and harsh weather conditions.

- Properties: Polymer-modified asphalt exhibits improved rutting resistance, reduced cracking, and increased elasticity compared to conventional asphalt. It also offers enhanced adhesion to aggregates and improved resistance to moisture damage.

- Application: Polymer-modified asphalt is commonly used in high-stress areas such as intersections, heavy traffic zones, and airports. It is also employed in regions with extreme climates where asphalt durability is crucial.

- (b)

- Plastic-modified asphalt: Plastic-modified asphalt, as discussed earlier, involves incorporating waste plastics, such as plastic bags, bottles, and packaging materials, into the asphalt mixture.

- Purpose: The primary objective of adding plastic waste to the asphalt is waste management and recycling. By incorporating plastics into roads, it offers a sustainable solution for plastic waste disposal, reducing landfill usage and environmental pollution.

- Properties: Plastic-modified asphalt exhibits improved resistance to cracking, better durability, and reduced moisture susceptibility compared to conventional asphalt. The plastic content helps enhance the strength and stability of the road surface.

- Application: Plastic-modified asphalt is suitable for various road applications, including highways, urban roads, and residential streets. It is considered a greener alternative to conventional asphalt and is particularly relevant in regions with significant plastic waste generation.

4. Considering Plastic Roads in Asian Countries

4.1. Plastic-Modified Asphalt

4.2. Consideration Aspects

- Governmental policies

- b.

- Stakeholders’ perspectives

- c.

- Geographical characteristics

- d.

- Supply of raw materials and manpower

5. Environmental and Human Health Adverse Effects of Plastic Roads

5.1. Adverse Effects on the Environment and Human Health

5.2. Limited Risk Assessments

6. Conclusions

- Waste management: Plastic roads provide a sustainable solution for managing plastic waste by repurposing it into road construction materials. This helps reduce plastic pollution and landfill usage.

- Improved road performance: Plastic-modified asphalt can enhance the durability, flexibility, and resistance to cracking and deformation of road surfaces. This can result in longer lasting and more resilient roads, reducing the need for frequent repairs and maintenance.

- Cost savings: Plastic roads have the potential to offer cost savings over time due to their improved longevity and reduced maintenance requirements. This can be particularly beneficial in areas with limited resources for road infrastructure.

- Environmental benefits: By incorporating waste plastics into roads, there is a reduction in the demand for virgin materials such as bitumen, derived from fossil fuels. This can contribute to conserving natural resources and reducing carbon emissions associated with the production and transportation of conventional road construction materials.

7. Recommendation and Contribution of the Study

- Environmental impacts: Although plastic roads may help reduce plastic waste and the need for virgin materials, it is important to consider their overall environmental impact. This includes assessing the emissions produced during the manufacturing process, the potential environmental impact of toxic chemicals seeping from plastic components, and the long-term consequences on soil and water quality.

- Impacts on human health: The use of plastic in road building raises questions regarding potential hazards to human health, particularly if harmful materials from plastic seep into the environment. To protect the health of those involved in the manufacture and installation of plastic roadways, as well as the local communities, thorough health risk evaluations should be carried out.

- Control of quality: It is essential to maintain the plastic-modified asphalt’s reliability and performance. To guarantee that the plastic components fulfill necessary standards and operate as expected under various weather conditions and traffic loads, it is crucial to create standardized production procedures and quality control measures.

- Limitations of recycling: Although plastic roads offer a way to make use of discarded plastic, it is vital to take them into account. Some plastics could be harder to recycle or might only have a few recycling choices. It is essential to create effective recycling methods and investigate other uses for plastic trash than making roads.

- Performance over time: Plastic-modified asphalt must show endurance and longevity. To determine whether plastic roads can resist the anticipated lifespan of conventional asphalt roads, it is required to assess their long-term performance under various climatic conditions, traffic loads, and maintenance schedules.

- Economic viability: It is crucial to evaluate the economic viability of plastic roadways. This includes comparing the cost-effectiveness of generating plastic-modified asphalt to conventional asphalt while taking into account elements such as material accessibility, production prices, and upkeep needs.

- Policy and regulatory framework: It is essential to create proper policies, rules, and standards before implementing plastic roads. To ensure compliance with environmental and health legislation, this includes establishing standards for material selection, quality control, and monitoring practices.

- Comprehensive research: Further research is necessary to gain a deeper understanding of plastic roads’ environmental and health impacts. This includes studying the leaching behavior of plastic components, assessing the potential effects on soil and water quality, and conducting lifecycle assessments.

- Standardization and guidelines: Developing standardized protocols, material specifications, and guidelines for plastic road implementation can ensure consistency and safety. This will require collaboration between stakeholders, including government bodies, researchers, and industry experts.

- Technological advancements: Continued technological advancements can help optimize the manufacturing process of plastic-modified asphalt, improve recycling techniques, and enhance plastic roads’ overall performance and sustainability.

- Knowledge sharing and collaboration: Encouraging knowledge sharing and collaboration between different regions and countries can facilitate the exchange of best practices, lessons learned, and research findings related to plastic road technology. This can help overcome challenges and promote the widespread adoption of plastic roads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- The United Nations Economic and Social Commission for Asia and the Pacific. Economic and Social Survey of Asia and the Pacific 2018: Mobilizing Finance for Sustained, Inclusive and Sustainable Economic Growth; The United Nations Economic and Social Commission for Asia and the Pacific: Bangkok, Thailand, 2018. [Google Scholar]

- United Nations Centre for Regional Development. State of Plastics Waste in Asia and the Pacific—Issues, Challenges and Circular Economic Opportunities. 2020. Available online: https://sdgs.un.org/sites/default/files/2020-12/UNCRD_10th%203R%20Forum_Webinar%20III-Background%20paper-FINAL-on%20Report.pdf (accessed on 31 January 2022).

- Sha, A.; Liu, Z.; Jiang, W.; Qi, L.; Hu, L.; Jiao, W.; Barbieri, D.M. Advances and development trends in eco-friendly pavements. J. Road Eng. 2021, 1, 1–42. [Google Scholar] [CrossRef]

- Beckman, E. The World of Plastics, in Numbers. The Conversation, 9 August 2018. Available online: https://theconversation.com/the-world-of-plastics-in-numbers-100291 (accessed on 24 July 2022).

- Gourmelon, G. Global Plastic Production Rises, Recycling Lags. Vital Signs 2015, 22, 91–95. [Google Scholar]

- Thompson, R.C.; Moore, C.J.; vom Saal, F.S.; Swan, S.H. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 2153–2166. [Google Scholar] [CrossRef]

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1977–1984. [Google Scholar] [CrossRef]

- Benson, N.U.; Bassey, D.E.; Palanisami, T. COVID pollution: Impact of COVID-19 pandemic on global plastic waste footprint. Heliyon 2021, 7, e06343. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Ritchie, H.; Roser, M. Plastic Pollution. Our World in Data. 2018. Available online: https://ourworldindata.org/plastic-pollution (accessed on 26 July 2022).

- Plastics Europe. The Circular Economy for Plastics: A European Overview; Plastics Europe: Brussels, Belgium, 2022. [Google Scholar]

- Filho, W.L.; Salvia, A.L.; Bonoli, A.; Saari, U.A.; Voronova, V.; Klõga, M.; Kumbhar, S.S.; Olszewski, K.; De Quevedo, D.M.; Barbir, J. An assessment of attitudes towards plastics and bioplastics in Europe. Sci. Total. Environ. 2021, 755, 142732. [Google Scholar] [CrossRef]

- Abrahms-Kavunenko, S.; Brox, T. Plastic Asia. Cph. J. Asian Stud. 2022, 40, 5–22. [Google Scholar] [CrossRef]

- Liang, Y.; Tan, Q.; Song, Q.; Li, J. An analysis of the plastic waste trade and management in Asia. Waste Manag. 2021, 119, 242–253. [Google Scholar] [CrossRef]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef]

- Akenji, L.; Bengtsson, M.; Hotta, Y.; Kato, M.; Hengesbaugh, M. Policy Responses to Plastic Pollution in Asia: Summary of a Regional Gap Analysis; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 531–567. [Google Scholar]

- Onyanga-Omara, J. Plastic Bag Backlash Gains Momentum; BBC News: London, UK, 2013. [Google Scholar]

- General Administration of Customs People’s Republic of China. The General Administration of Customs Deploys a Joint Special Campaign against Smuggling ‘National Sword 2017’; General Administration of Customs People’s Republic of China: Beijing, China, 2017. Available online: http://www.customs.gov.cn/customs/302249/302425/636280/index.html (accessed on 1 August 2022).

- Wang, C.; Zhao, L.; Lim, M.K.; Chen, W.-Q.; Sutherland, J.W. Structure of the global plastic waste trade network and the impact of China’s import Ban. Resour. Conserv. Recycl. 2020, 153, 104591. [Google Scholar] [CrossRef]

- Philippe, C. The History of Plastics: From the Capitol to the Tarpeian Rock; Veolia Institute: Aubervilliers, France, 2018. [Google Scholar]

- United Nations Environment Programme. Single-Use Plastics: A Roadmap for Sustainability; United Nations Environment Programme: Nairobi, Kenya, 2018. [Google Scholar]

- He, P.; Chen, L.; Shao, L.; Zhang, H.; Lü, F. Municipal solid waste (MSW) landfill: A source of microplastics?—Evidence of microplastics in landfill leachate. Water Res. 2019, 159, 38–45. [Google Scholar] [PubMed]

- Chen, H.L.; Nath, T.K.; Chong, S.; Foo, V.; Gibbins, C.; Lechner, A.M. The plastic waste problem in Malaysia: Management, recycling and disposal of local and global plastic waste. SN Appl. Sci. 2021, 3, 1–15. [Google Scholar] [CrossRef]

- Elrabay, D.; Marchenko, V. Identifying the full cost to landfill municipal solid waste by incorporating emissions impact and land development lost opportunity: Case study, Sharjah-UAE. Int. J. Eng. Sci. Invent. 2021, 10, 33–41. [Google Scholar] [CrossRef]

- Uding Rangga, J.; Syed Ismail, S.; Rasdi, I.; Karuppiah, K.; Ikmal Irozi, M. Environmental Impact, Health Risk, and Management Cost of Landfilling Practice: A Case Study in Klang, Selangor, Malaysia. J. Waste Manag. Dispos. 2019, 2, 1–12. [Google Scholar]

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-use plastics: Production, usage, disposal, and adverse impacts. Sci. Total Environ. 2021, 752, 141772. [Google Scholar] [CrossRef]

- Hall, F.; White, G. The Effect of Waste Plastics on the Ageing Phenomenon of Bituminous Binders and Asphalt Mixtures. Materials 2021, 14, 6176. [Google Scholar] [CrossRef]

- The United Nations Economic and Social Commission for Asia and the Pacific. Transport: Asian Highway Network; The United Nations Economic and Social Commission for Asia and the Pacific: Bangkok, Thailand, 2022. [Google Scholar]

- The United Nations Economic and Social Commission for Asia and the Pacific. Transport and Sustainable Development Goals. Transp. Commun. Bull. Asia Pacific 2017, 87, 1–99.

- Hedges & Company. How Many Cars Are There in the World in 2022? Statistics by Country. 2022. Available online: https://www.carsguide.com.au/car-advice/how-many-cars-are-there-in-the-world-70629 (accessed on 5 August 2022).

- Asian Development Bank. Meeting Asia’s Infrastructure Needs; Asian Development Bank: Mandaluyong, Philippines, 2017. [Google Scholar]

- Central Asia Data Gathering and Analysis Team. The Transport Sector in Central Asia Central Asia; OSCE Academy: Bishkek, Kyrgyzstan, 2012. [Google Scholar] [CrossRef]

- The United Nations Economic and Social Commission for Asia and the Pacific. Strengthening the Capacity of ESCAP Member STATES to Harmonize Standards on Weights, Dimensions and Emissions of Road Vehicles for Facilitation of Transport along the Asian Highway Network; The United Nations Economic and Social Commission for Asia and the Pacific: Bangkok, Thailand, 2019. [Google Scholar]

- Verdict Media Limited. Asian Highway Network, Great Asian Highway; Verdict Media Limited: London, UK, 2023. [Google Scholar]

- The United Nations Economic and Social Commission for Asia and the Pacific. Asian Highway Database Asian Highway Network in Member Countries; The United Nations Economic and Social Commission for Asia and the Pacific: Bangkok, Thailand, 2017. [Google Scholar]

- Zhekenov, D.K.; Meiyu, Z. A Study on Geopolitical Risk of the Belt and Road Construction in Central Asia. Вестник Казну Серия Междунарoдные Отнoшения И Междунарoднoе Правo 2022, 2, 52–61. [Google Scholar] [CrossRef]

- The Economist. Our Bulldozers, Our Rules; The Economist: London, UK, 2016. [Google Scholar]

- Nurmukhambetova, Z.; Panajyan, S. Improving Transport Connectivity in Central Asia Requires a Coherent Approach; The World Bank: Washington, DC, USA, 2021. [Google Scholar]

- Meng, S. Why is China’s the Belt One Road Initiative successful—Lessons from the Cooperation with the Five Central Asia Countries. Int. J. Environ. Agric. Biotechnol. 2021, 6, 175–189. [Google Scholar] [CrossRef]

- Bala, A.; Kumar, P.; Khanna, P. Environmental, Bio-Social and Economic Impact of Road Construction at Kunjwani-Nagrota Bypass Highway, Jammu Dist. (J&K), India. J. Environ. Sci. Toxicol. Food Technol. 2021, 15, 27–36. [Google Scholar] [CrossRef]

- Bryzhko, V.G.; Bryzhko, I.V. Comprehensive assessment of the impact of road infrastructure development in a rural municipal area (Russia). Espacios 2019, 40. [Google Scholar]

- Zhou, B.; Yao, D. Impact on society environment by road in operation and maintenance phase and the recovery solutions. In Proceedings of the 2011 International Symposium on Water Resource and Environmental Protection, Xi’an, China, 20–22 May 2011; Volume 4, pp. 2531–2534. [Google Scholar] [CrossRef]

- The United Nations Economic and Social Commission for Asia and the Pacific. Multistage Environmental and Social Impact Assessment of Road Projects Guidelines for a Comprehensive Process; The United Nations Economic and Social Commission for Asia and the Pacific: Bangkok, Thailand, 2001. [Google Scholar]

- The United Nations Economic and Social Commission for Asia and the Pacific. Review of Developments in Transport in Asia and the Pacific: Towards Sustainable, Inclusive and Resilient Urban Passenger Transport in Asian Cities; The United Nations Economic and Social Commission for Asia and the Pacific: Bangkok, Thailand, 2021. [Google Scholar]

- World Health Organization. Global Status Report on Road Safety 2018. 2018. Available online: https://www.who.int/publications/i/item/9789241565684 (accessed on 5 August 2022).

- Shah, S.A.R.; Ahmad, N.; Shen, Y.; Pirdavani, A.; Basheer, M.A.; Brijs, T. Road Safety Risk Assessment: An Analysis of Transport Policy and Management for Low-, Middle-, and High-Income Asian Countries. Sustainability 2018, 10, 389. [Google Scholar] [CrossRef]

- Lechner, A.M.; Chan, F.K.S.; Campos-Arceiz, A. Biodiversity conservation should be a core value of China’s Belt and Road Initiative. Nat. Ecol. Evol. 2018, 2, 408–409. [Google Scholar] [CrossRef]

- Lin, S.-C. Landscape and Traffic Factors Affecting Animal Road Mortality. J. Environ. Eng. Landsc. Manag. 2016, 24, 10–20. [Google Scholar] [CrossRef]

- Jacobson, S.L.; Bliss-Ketchum, L.L.; de Rivera, C.E.; Smith, W.P. A behavior-based framework for assessing barrier effects to wildlife from vehicle traffic volume. Ecosphere 2016, 7, e01345. [Google Scholar] [CrossRef]

- Fahrig, L.; Rytwinski, T. Effects of Roads on Animal Abundance: An Empirical Review and Synthesis. Ecol. Soc. 2009, 14, 21. [Google Scholar] [CrossRef]

- Carter, N.; Killion, A.; Easter, T.; Brandt, J.; Ford, A. Road development in Asia: Assessing the range-wide risks to tigers. Sci. Adv. 2020, 6, eaaz9619. [Google Scholar] [CrossRef] [PubMed]

- Farhadinia, M.S.; Maheshwari, A.; Nawaz, M.A.; Ambarlı, H.; Gritsina, M.A.; Koshkin, M.A.; Rosen, T.; Hinsley, A.; Macdonald, D.W. Belt and Road Initiative may create new supplies for illegal wildlife trade in large carnivores. Nat. Ecol. Evol. 2019, 3, 1267–1268. [Google Scholar] [CrossRef] [PubMed]

- Moretti, L.; Mascio, P.D.; D’Andrea, A. Environmental Impact Assessment of Road Asphalt Pavements. Mod. Appl. Sci. 2013, 7, 1. [Google Scholar] [CrossRef]

- Washington Internships for Students of Engineering. Introduction. In Greenroads TM Manual v1.5; Greenroads: Deerfield Beach, FL, USA, 2011. [Google Scholar]

- Bryce, J.M. Developing Sustainable Transportation Infrastructure. In Exploring the Development and Implementation of a Green Highway Rating System; International Standards Worlwide: West Conshohocken, PA, USA.

- Alamgir, M.; Campbell, M.J.; Sloan, S.; Phin, W.E.; Laurance, W.F. Road risks & environmental impact assessments in Malaysian road infrastructure projects. Jurutera 2018, 13–16. [Google Scholar]

- Marzouk, M.; Abdelkader, E.M.; El-Zayat, M.; Aboushady, A. Assessing Environmental Impact Indicators in Road Construction Projects in Developing Countries. Sustainability 2017, 9, 843. [Google Scholar] [CrossRef]

- Hanson Malaysia. What Is Asphalt? How Is It Used? Hanson Heildelberg Cement Group: London, UK, 2020; Available online: https://www.hanson.my/en/what-asphalt-used (accessed on 18 August 2022).

- Pavement Interactive. Energy and Road Construction—What’s the Mileage of Roadway? Pavement Interactive, 2012. Available online: https://pavementinteractive.org/energy-and-road-construction-whats-the-mileage-of-roadway/ (accessed on 30 August 2022).

- Muench, S.T. Roadway Construction Sustainability Impacts. Transp. Res. Rec. J. Transp. Res. Board 2010, 2151, 36–45. [Google Scholar] [CrossRef]

- Fernandes, S.; Silva, H.M.R.D.; Oliveira, J.R.M. Mechanical, surface and environmental evaluation of stone mastic asphalt mixtures with advanced asphalt binders using waste materials. Road Mater. Pavement Des. 2017, 20, 316–333. [Google Scholar] [CrossRef]

- Park, W.-J.; Kim, R.; Roh, S.; Ban, H. Analysis of Major Environmental Impact Categories of Road Construction Materials. Sustainability 2020, 12, 6951. [Google Scholar] [CrossRef]

- Sun, W.; Lu, G.; Ye, C.; Chen, S.; Hou, Y.; Wang, D.; Wang, L.; Oeser, M. The State of the Art: Application of Green Technology in Sustainable Pavement. Adv. Mater. Sci. Eng. 2018, 2018, 9760464. [Google Scholar] [CrossRef]

- Praticò, F.G.; Giunta, M.; Mistretta, M.; Gulotta, T.M. Energy and Environmental Life Cycle Assessment of Sustainable Pavement Materials and Technologies for Urban Roads. Sustainability 2020, 12, 704. [Google Scholar] [CrossRef]

- Rahman, T.; Mohajerani, A.; Giustozzi, F. Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review. Materials 2020, 13, 1495. [Google Scholar] [CrossRef] [PubMed]

- Edel, D. How an Indian Man Inspired Strong Plastic Roads Across the World. Intelligent Living, 2020. Available online: https://www.intelligentliving.co/indian-man-inspired-strong-plastic-roads/ (accessed on 30 August 2022).

- Salehi, S.; Arashpour, M.; Kodikara, J.; Guppy, R. Sustainable pavement construction: A systematic literature review of environmental and economic analysis of recycled materials. J. Clean. Prod. 2021, 313, 127936. [Google Scholar] [CrossRef]

- Bangladesh Sangbad Sangstha. RHD Expects to Build 100 km Road in a Month Using Nanotech; Bangladesh Sangbad Sangstha: Dhaka, Bangladesh, 2022; Available online: https://www.bssnews.net/news/69995 (accessed on 31 August 2022).

- Sundas, S. Thomson Reuters Foundation. Bhutan, the Road to Green Development Is Paved with Plastic; Thomson Reuters: Singapore, 2015; Available online: https://www.reuters.com/article/bhutan-green-paving-idUSL8N12X21M20151102 (accessed on 31 August 2022).

- Nepali Times. Pokhara’s Plastic Road. Nepali Times, 2018. Available online: https://www.nepalitimes.com/from-the-nepali-press/pokharas-plastic-road/ (accessed on 31 August 2022).

- Karelia, G.; Bhaskar, S. One Lakh Kilometres of Roads in India Are Being Made from Plastic Waste, Is This the Solution to End Plastic Crisis? Swach Hindia, 2018. Available online: https://swachhindia.ndtv.com/plastic-waste-roads-one-lakh-kilometre-india-20274/ (accessed on 31 August 2022).

- Biswas, A.; Potnis, S. Plastic Bituminous Roads: A Sustainable Technology—For Better Handling Distresses. Eur. J. Eng. Technol. Res. 2022, 7, 63–69. [Google Scholar] [CrossRef]

- Hadizadeh, E.; Pazokifard, S.; Mirabedini, S.; Ashrafian, H. Optimizing practical properties of MMA-based cold plastic road marking paints using mixture experimental design. Prog. Org. Coat. 2020, 147, 105784. [Google Scholar] [CrossRef]

- Rana, S.; Khwaja, M.A. Plastic Waste Use in Road Construction: Viable Waste Management? SDPI: Islamabad, Pakistan, 2022. [Google Scholar]

- The Nation. Coca-Cola Kicks off Pakistan’s First Plastic Road Project. Nation, 2021. Available online: https://www.nation.com.pk/27-Sep-2021/coca-cola-kicks-off-pakistan-s-first-plastic-road-project (accessed on 31 August 2022).

- Daily News. SAGT Road Resurfacing Project with Modified Plastic Asphalt. Daily News, 2021. Available online: https://www.dailynews.lk/2021/09/18/local/259662/sagt-road-resurfacing-project-modified-plastic-asphalt (accessed on 2 September 2022).

- Martirosyan, A. Plastic waste to be recycled into building materials for the first time in Armenia. EU NEIGHBHOURSEAST, 2018. Available online: https://euneighbourseast.eu/news/stories/plastic-waste-to-be-recycled-into-building-materials-for-the-first-time-in-armenia/ (accessed on 24 September 2022).

- APA. A Scottish Company Will Build a Plastic Road in Azerbaijan; APA: Washington, DC, USA, 2021; Available online: https://apa.az/az/xeber/infrastruktur/sotlandiya-sirketi-azerbaycanda-plastik-yol-cekecek-foto-663524 (accessed on 2 September 2022).

- Parson, A. How Paving with Plastic Could Make a Dent in the Global Waste Problem. YaleEnvironment360, 2021. Available online: https://e360.yale.edu/features/how-paving-with-plastic-could-make-a-dent-in-the-global-waste-problem (accessed on 2 September 2022).

- Circular Glasgow. The End of the Road for Plastic Waste; Circular Glasgow: Glasgow, UK, 2021; Available online: https://www.circularglasgow.com/story/macrebur/ (accessed on 2 September 2022).

- Alsaegh, R. Construction Waste as an Environmental Dilemma in Bahrain. 2019. Available online: https://www.researchgate.net/publication/346576762_Construction_waste_as_an_environmental_dilemma_in_Bahrain (accessed on 5 August 2022).

- Gulf Daily News. Plan to Create Roads with Recycled Waste in Bahrain; Gulf Daily News: Manama, Bahrain, 2021; Available online: https://www.zawya.com/en/business/plan-to-create-roads-with-recycled-waste-in-bahrain-tmpm10fk (accessed on 1 September 2022).

- Morrison, J.; Kordova, S. Revolutionary Recycling? A New Technology Turns Everyday Trash into Plastic Treasure. Washington Post, 2019. Available online: https://www.washingtonpost.com/graphics/2019/climate-solutions/israeli-startup-ubq-turning-trash-into-plastic-products/ (accessed on 2 September 2022).

- Haaretz, R.S. Israeli Startup Converts Garbage into Construction Products. Hindu, 2019. Available online: https://www.thehindu.com/sci-tech/energy-and-environment/israeli-startup-converts-garbage-into-building-products/article26768075.ece#:~:text=UBQ%20invented%20a%20patented%20new,no%20water%20in%20the%20process&text=The%20UBQ%20plant%20in%20the,plastic%2C%20bricks%20and%20road%20paving (accessed on 2 September 2022).

- Ben Zion, I. Israeli firm says it can turn garbage into plastic gold. The Times of Israel, 2018. Available online: https://www.timesofisrael.com/israeli-firm-says-it-can-turn-garbage-into-plastic-gold/ (accessed on 2 September 2022).

- Awad, A.; Al Adday, F. Utilization of waste plastics to enhance the performance of modified hot mix asphalt. Int. J. GEOMATE 2017, 13, 132–139. [Google Scholar] [CrossRef]

- Gulseven, O.; Ashkanani, S.; Abdullah, S.; Ismaeil, H.; Alkandari, H.; Baroun, M. A sustainable model for enhancing road quality with recycled plastic bags. Kuwait J. Sci. 2019, 46, 112–119. [Google Scholar]

- Al Mahmoud, F.; Anderson, F. Saving Lebanon’s Streets: The Engineer with a Sustainable Fix. The National News, 2021. Available online: https://www.thenationalnews.com/mena/lebanon/saving-lebanon-s-streets-the-engineer-with-a-sustainable-fix-1.1212567 (accessed on 2 September 2022).

- Prabhu, C. Omans Beah Ramps Up Roll-Out of Recycling Machines for PET Bottles. Oman Establ. Press Publ. Advert. 2020. Available online: https://www.zawya.com/en/projects/omans-beah-ramps-up-roll-out-of-recycling-machines-for-pet-bottles-gpw7g3aw (accessed on 5 September 2022).

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Oman. In Proceedings of the 1st Engineering Exhibition for Innovative Graduation Projects; 2020. [Google Scholar] [CrossRef]

- Kazmi, S.; Rao, D.G. Utilization of Waste Plastic Materials as Bitumen-Blends for Road Construction in Oman. Sch. J. Eng. Technol. 2015, 3, 9–13. [Google Scholar]

- Zafar, S. Waste Management Outlook for the Middle East. In The Palgrave Handbook of Sustainability; Palgrave Macmillan: New York, NY, USA, 2018; pp. 159–181. [Google Scholar]

- Tokgoz, D.D.G.; Ozerkan, N.G.; Kowita, O.S.; Antony, S.J. Strength and Durability of Composite Concretes with Municipal Wastes. ACI Mater. J. 2016, 113, 669–678. [Google Scholar] [CrossRef]

- Hashem, S.; Cardino, C. Innovative Pavement Materials and Design: Smart Roadways and Smart Road Maintenance for the Future. In Proceedings of the International Conference on Civil Infrastructure and Construction, Doha, Qatar, 2–5 February 2020; pp. 75–83. [Google Scholar]

- Arab News. Saudi Arabia’s KAUST Launches Green Roads Initiative to Convert Plastic into Latest Updates Sustainable Material. Arab News, 2022. Available online: https://www.arabnews.com/node/2056341/saudi-arabia (accessed on 6 September 2022).

- Fast Company. Saudi Arabia’s KAUST Will Now Build Roads from Plastic; Fast Company: New York, NY, USA, 2022; Available online: https://fastcompanyme.com/news/saudi-arabias-kaust-will-now-build-roads-from-plastic/ (accessed on 6 September 2022).

- Gündoğdu, S.; Walker, T.R. Why Turkey should not import plastic waste pollution from developed countries? Mar. Pollut. Bull. 2021, 171, 112772. [Google Scholar] [CrossRef]

- Gökalp, I. Green and sustainable production of waste styrofoam-modified bitumen: A laboratory-based investigation on physical, rheological properties, and storage stability. Polym. Bull. 2022, 79, 7989–8008. [Google Scholar] [CrossRef]

- Gökalp, I.; Çetin, H.M.; Özinal, Y.; Gündoğan, H.; Uz, V.E. A Literature Survey on Parameters Affecting Modification of Polymer Modified Bitumen. Ömer Halisdemir Univ. Muhendis. Bilim. Derg. 2019, 8, 954–964. [Google Scholar] [CrossRef]

- Trident Trackway. 2019. Available online: https://trident-trackway.com/ (accessed on 7 September 2022).

- Ayub, D. Temporary Roads Made from Recycled Plastic Ease Vehicles through Rocky Terrain in the UAE; Mashable Middle East: Dubai, United Arab Emirates, 2021; Available online: https://me.mashable.com/tech/15807/temporary-roads-made-from-recycled-plastic-ease-vehicles-through-rocky-terrain-in-the-uae (accessed on 7 September 2022).

- Cornall, J. Dow and Shiny Meadow Making Roads from Milk Bottles in China. Dairy Reporter, 2021. Available online: https://www.dairyreporter.com/Article/2021/04/22/Dow-and-Shiny-Meadow-making-roads-from-milk-bottles-in-China (accessed on 7 September 2022).

- Dow Chemical Company. Creating China’s First ‘Milk Bottle Road’; Dow Chemical Company: Midland, MI, USA, 2021; Available online: https://corporate.dow.com/en-us/science-and-sustainability/2025-goals/earth-day/shiny-meadow-partnership.html (accessed on 7 September 2022).

- Kao Specialties Americas LLC. Highly Durable Asphalt Modifier Made from Waste PET Developed at Kao Corporation; Kao Corporation: Tokyo, Japan, 2021; Available online: https://www.kao.com/global/en/news/rd/2021/20210205-002/ (accessed on 7 September 2022).

- Kao Specialties Americas LLC. Recycled Plastic Technology in Paving Embraced by City; PR Newswire: Chicago, IL, USA, 2021; Available online: https://www.prnewswire.com/news-releases/recycled-plastic-technology-in-paving-embraced-by-city-301338166.html (accessed on 7 September 2022).

- Kim, Y. Development and Application of Polymer-Modified Warm-Mix Asphalt Technology Customized for Mongolia Road Condition; Mongolian Road Association: Ulaanbaatar, Mongolia, 2014. [Google Scholar]

- Ki, D.; Kang, S.Y.; Ma, G.; Oh, H.J. Application of Waste Plastic Films in Road Infrastructure and Construction. Front. Sustain. 2021, 2, 756723. [Google Scholar] [CrossRef]

- Berdimuhamedov, G.; Allaberdi, I. Innovations in Road Construction to Help Turkmenistan Save Nature. Central Asia News, 2021. Available online: https://centralasia.news/10855-innovations-in-road-construction-to-help-turkmenistan-save-nature.html (accessed on 20 September 2022).

- Vanyuth, C. Turning Plastic Waste into Concrete to Build Roads. Khmer Times, 2022. Available online: https://www.khmertimeskh.com/501013986/turning-plastic-waste-into-concrete-to-build-roads/ (accessed on 1 September 2022).

- Ministry for Maritime Affairs Republic of Indonesia. Developing Plastic-Tar Roads; Ministry for Maritime Affairs Republic of Indonesia: Jakarta, Indonesia, 2018. [Google Scholar]

- Chandra Asri Petrochemical. Our Sustainability—Incorporating Esg Commitment and Clear Focus on Environmental, Social and Governance Principles. 2021. [Google Scholar]

- Harun, M.H. Plastic Waste Recycled to Build Roads. 2019. [Google Scholar]

- Focus Malaysia. Malaysian Roads to Be Paved with Recycled Plastics; Focus Malaysia: Selangor, Malaysia, 2020; Available online: https://focusmalaysia.my/msian-roads-to-be-paved-with-recycled-plastics/ (accessed on 1 September 2022).

- Ang, R. Philippines Builds Roads from Plastic Waste; Atlas of the Future. 2020. Available online: https://atlasofthefuture.org/project/smc-recycled-plastic-road/ (accessed on 31 August 2022).

- Kit, T.S. This Singapore Start-Up Hopes to Make Roads with Plastic Waste. Channel News Asia, 2020. Available online: https://www.channelnewsasia.com/climatechange/start-up-make-roads-with-plastic-waste-singapore-1340136 (accessed on 20 September 2022).

- All Around Plastics. Recycled Plastic Roads: A New Road towards Creating a Complete Value Cycle for Plastics; All Around Plastics. 2019. Available online: https://www.allaroundplastics.com/en/article/innovation-en/2189 (accessed on 31 August 2022).

- Usaid Private Sector Engagement. Timor-Leste: Paving the Way on Plastics Recycling; Usaid Private Sector Engagement. 2020. Available online: https://usaid-pse.exposure.co/timorleste-paving-the-way-on-plastics-recycling (accessed on 20 September 2022).

- Dow Vietnam. Dow and DEEP C Successfully Complete the First Asphalt Road Using Recycled Plastics in Vietnam; Dow Chemical Company: Midland, MI, USA, 2019; Available online: https://www.dow.com/ja-jp/news/first-asphalt-road-using-recycled-plastics-in-vietnam.html (accessed on 24 September 2022).

- Hwa, T.E.; Hong, M.; Chu, E.Y. Congestion Pricing in Selected Cities in Southeast Asia. J. Islam. Soc. Econ. Dev. 2022, 7, 12–21. [Google Scholar] [CrossRef]

- Aflaki, S.; Tabatabaee, N. Proposals for modification of Iranian bitumen to meet the climatic requirements of Iran. Constr. Build. Mater. 2009, 23, 2141–2150. [Google Scholar] [CrossRef]

- Bulatović, V.O.; Rek, V.; Bajsić, E.G. The Effects of Ageing on Road Bitumen Modified with the Ethylene Vinyl Acetate Polymer. In Proceedings of the 3rd International Conference on Road and Rail Infrastructure, Split, Croatia, 28–30 April 2014; pp. 425–430. [Google Scholar]

- Rodrigues, C.; Hanumanthgari, R. Polymer modified bitumens and other modified binders. In The Shell Bitumen Handbook; ICE Virtual Library: Leeds, UK, 2015; pp. 149–183. [Google Scholar]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Abdy, C.; Zhang, Y.; Wang, J.; Yang, Y.; Artamendi, I.; Allen, B. Pyrolysis of polyolefin plastic waste and potential applications in asphalt road construction: A technical review. Resour. Conserv. Recycl. 2022, 180, 106213. [Google Scholar] [CrossRef]

- Conlon, K. Plastic roads: Not all they’re paved up to be. Int. J. Sustain. Dev. World Ecol. 2021, 29, 80–83. [Google Scholar] [CrossRef]

- Statistics Times. List of Asian Countries by GDP. Statistics Times, 2021. Available online: https://statisticstimes.com/economy/asian-countries-by-gdp.php (accessed on 21 November 2022).

- Sidle, R.C. Dark Clouds over the Silk Road: Challenges Facing Mountain Environments in Central Asia. Sustainability 2020, 12, 9467. [Google Scholar] [CrossRef]

- Lemaire, X.; Kerr, D. International Literature Review on Urban Energy Transitions; SAMSET: London, UK, 2014. [Google Scholar]

- Sasidharan, M.; Eskandari Torbaghan, M.; Burrow, M. Using Waste Plastics in Road Construction. 2019. Available online: https://www.xe.com/ (accessed on 5 August 2022).

- Oropeza, D. The Problem with Plastic Roads; The California Aggie: Davis, CA, USA, 2019; Available online: https://theaggie.org/2019/01/30/the-problem-with-plastic-roads/ (accessed on 21 November 2022).

- Wu, S.; Liu, L.; Liu, Y.; Gao, J.; Dai, E.; Feng, A.; Wang, W. The Belt and Road: Geographical pattern and regional risks. J. Geogr. Sci. 2019, 29, 483–495. [Google Scholar] [CrossRef]

- Regmi, M.B.; Hanaoka, S. A survey on impacts of climate change on road transport infrastructure and adaptation strategies in Asia. Environ. Econ. Policy Stud. 2011, 13, 21–41. [Google Scholar] [CrossRef]

- Vittal, U.K.G.; Pateria, I. Using Locally Available Materials in Road Construction—Problems & Possibilities. 2016. In Proceedings of the A National Conference on Fifteen Years of PMGSY (FYPMGSY), Roorkee, India, 6–7 August 2016. [Google Scholar]

- Manikandan, K. Gold in Exchange for Polythene Waste. The Hindu, 2012. Available online: https://www.thehindu.com/news/cities/chennai/gold-in-exchange-for-polythene-waste (accessed on 21 November 2022).

- Pawar, A.V.; Jankar, S.V.; Jadhav, G.S.; Kanbarkar, M.V.; Sawant, S.S.; Shinde, A.S.; Patil, P.S. Review Paper on Experimental Study on Use of Plastic in Flexible Pavement. Int. Res. J. Eng. Technol. 2021, 8, 2670–2673. [Google Scholar]

- Advanced Plastiform Inc. How Plastic Asphalt Is Paving the Road to the Future; Advanced Plastiform Inc.: Zebulon, NC, USA, 2020; Available online: https://advancedplastiform.com/plastic-asphalt-for-new-roads/ (accessed on 18 October 2022).

- Habib, N.Z.; Kamaruddin, I.; Napiah, M.; Mohd Tan, I. Rheological properties of polyethylene and polypropylene modified bitumen. Int. J. Civ. Environ. Eng. 2011, 3, 96–100. [Google Scholar]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef]

- Ravve, A. Principles of Polymer Chemistry, 2nd ed.; Springer: New York, NY, USA, 2000. [Google Scholar]

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Perez-Lepe, A.; Martinez-Boza, F.J.; Gallegos, C. High Temperature Stability of Different Polymer-Modified Bitumens: A Rheological Evaluation. J. Appl. Polym. Sci. 2006, 103, 1166–1174. [Google Scholar] [CrossRef]

- Plastic Industry Association. Performance Evaluation and Chemical Characterization of Asphalt Binders and Mixtures Containing Recycled Polyethylene; Plastic Industry Association: Hongkong, China, 2020. [Google Scholar]

- Hou, Y.; Sun, W.; Das, P.; Song, X.; Wang, L.; Ge, Z.; Huang, Y. Coupled Navier–Stokes Phase-Field Model to Evaluate the Microscopic Phase Separation in Asphalt Binder under Thermal Loading. J. Mater. Civ. Eng. 2016, 28, 1–8. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- MacRebur Ltd. Technical Data Leaching of MR Modified Asphalt; MacRebur Ltd.: Lockerbie, UK, 2020. [Google Scholar]

- Thompson, R.C.; Olsen, Y.; Mitchell, R.P.; Davis, A.; Rowland, S.J.; John, A.W.; McGonigle, D.; Russell, A.E. Lost at Sea: Where Is All the Plastic? Science 2004, 304, 838. [Google Scholar] [CrossRef]

- Jacques, O.; Prosser, R. A probabilistic risk assessment of microplastics in soil ecosystems. Sci. Total Environ. 2020, 757, 143987. [Google Scholar] [CrossRef]

- Li, C.; Gan, Y.; Zhang, C.; He, H.; Fang, J.; Wang, L.; Wang, Y.; Liu, J. “Microplastic communities” in different environments: Differences, links, and role of diversity index in source analysis. Water Res. 2020, 188, 116574. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Liu, K.; Zhu, L.; Song, Z.; Li, D. Atmospheric microplastic over the South China Sea and East Indian Ocean: Abundance, distribution and source. J. Hazards Mater. 2020, 389, 121846. [Google Scholar] [CrossRef]

- Lebreton, L.C.M.; van der Zwet, J.; Damsteeg, J.-W.; Slat, B.; Andrady, A.; Reisser, J. River plastic emissions to the world’s oceans. Nat. Commun. 2017, 8, 15611. [Google Scholar] [CrossRef]

- Allen, S.; Allen, D.; Phoenix, V.R.; Le Roux, G.; Jiménez, P.D.; Simonneau, A.; Binet, S.; Galop, D. Atmospheric transport and deposition of microplastics in a remote mountain catchment. Nat. Geosci. 2019, 12, 339–344. [Google Scholar] [CrossRef]

- Liu, K.; Wu, T.; Wang, X.; Song, Z.; Zong, C.; Wei, N.; Li, D. Consistent Transport of Terrestrial Microplastics to the Ocean through Atmosphere. Environ. Sci. Technol. 2019, 53, 10612–10619. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Zhang, Y.; Kang, S.; Wang, Z.; Wu, C. Microplastics in soil: A review on methods, occurrence, sources, and potential risk. Sci. Total Environ. 2021, 780, 146546. [Google Scholar] [CrossRef]

- Bellasi, A.; Binda, G.; Pozzi, A.; Galafassi, S.; Volta, P.; Bettinetti, R. Microplastic Contamination in Freshwater Environments: A Review, Focusing on Interactions with Sediments and Benthic Organisms. Environments 2020, 7, 30. [Google Scholar] [CrossRef]

- De-la-Torre, G.E. Microplastics: An emerging threat to food security and human health. J. Food Sci. Technol. 2020, 57, 1601–1608. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Ge, J.; Yu, X. Bioavailability and toxicity of microplastics to fish species: A review. Ecotoxicol. Environ. Saf. 2019, 189, 109913. [Google Scholar] [CrossRef]

- Prata, J.C.; da Costa, J.P.; Lopes, I.; Duarte, A.C.; Rocha-Santos, T. Environmental exposure to microplastics: An overview on possible human health effects. Sci. Total Environ. 2019, 702, 134455. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, Y.; Shi, Z.; Li, Z.; Liang, X. Ecotoxicoproteomic assessment of microplastics and plastic additives in aquatic organisms: A review. Comp. Biochem. Physiol. Part D Genom. Proteom. 2020, 36, 100713. [Google Scholar] [CrossRef]

- De Wit, C.A.; Kierkegaard, A.; Ricklund, N.; Sellstrom, U. Emerging Brominated Flame Retardants in the Environment. In The Handbook of Environmental Chemistry; Speinger: Berlin/Heidelberg, Germany, 2011; pp. 241–286. [Google Scholar]

- Verla, A.W.; Enyoh, C.E.; Verla, E.N.; Nwarnorh, K.O. Microplastic–toxic chemical interaction: A review study on quantified levels, mechanism and implication. SN Appl. Sci. 2019, 1, 1400. [Google Scholar] [CrossRef]

- Horodytska, O.; Cabanes, A.; Fullana, A. Non-intentionally added substances (NIAS) in recycled plastics. Chemosphere 2020, 251, 126373. [Google Scholar] [CrossRef]

- Eriksen, M.; Pivnenko, K.; Olsson, M.; Astrup, T. Contamination in plastic recycling: Influence of metals on the quality of reprocessed plastic. Waste Manag. 2018, 79, 595–606. [Google Scholar] [CrossRef] [PubMed]

- Enfrin, M.; Giustozzi, F. Recent advances in the construction of sustainable asphalt roads with recycled plastic. Polym. Int. 2022, 71, 1376–1383. [Google Scholar] [CrossRef]

- Bradney, L.; Wijesekara, H.; Palansooriya, K.N.; Obadamudalige, N.; Bolan, N.S.; Ok, Y.S.; Rinklebe, J.; Kim, K.-H.; Kirkham, M. Particulate plastics as a vector for toxic trace-element uptake by aquatic and terrestrial organisms and human health risk. Environ. Int. 2019, 131, 104937. [Google Scholar] [CrossRef] [PubMed]

- Bowley, J.; Baker-Austin, C.; Porter, A.; Hartnell, R.; Lewis, C. Oceanic Hitchhikers—Assessing Pathogen Risks from Marine Microplastic. Trends Microbiol. 2021, 29, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Masud, N.; Davies-Jones, A.; Griffin, B.; Cable, J. Differential effects of two prevalent environmental pollutants on host-pathogen dynamics. Chemosphere 2022, 295, 133879. [Google Scholar] [CrossRef]

- Ahmad, M.; Li, J.-L.; Wang, P.-D.; Hozzein, W.N.; Li, W.-J. Environmental perspectives of microplastic pollution in the aquatic environment: A review. Mar. Life Sci. Technol. 2020, 2, 414–430. [Google Scholar] [CrossRef]

- Coopland, P.; Winter, M.G. The Use of Waste-Derived Materials in Road Construction; Coopland Consultancy Ltd.: Dumfries, UK, 2021. [Google Scholar]

- Austroads Ltd. Review of Australasian and Overseas Specifications and Performance Tests for Bitumen; Austroads Ltd.: Sydney, Australia, 2016. [Google Scholar]

- Ldu Plessis, L.; Ulloa-Calderon, A.; Harvey, J.; Coetzee, N. Accelerated pavement testing efforts using the Heavy Vehicle Simulator. Int. J. Pavement Res. Technol. 2018, 11, 327–338. [Google Scholar] [CrossRef]

- Dérobert, X.; Baltazart, V.; Simonin, J.-M.; Todkar, S.S.; Norgeot, C.; Hui, H.-Y. GPR Monitoring of Artificial Debonded Pavement Structures throughout Its Life Cycle during Accelerated Pavement Testing. Remote. Sens. 2021, 13, 1474. [Google Scholar] [CrossRef]

- Santos, J.; Pham, A.; Stasinopoulos, P.; Giustozzi, F. Recycling waste plastics in roads: A life-cycle assessment study using primary data. Sci. Total Environ. 2020, 751, 141842. [Google Scholar] [CrossRef]

- Mo, S.; Wang, Y.; Xiong, F.; Ai, C. Effects of asphalt source and mixing temperature on the generated asphalt fumes. J. Hazards Mater. 2019, 371, 342–351. [Google Scholar] [CrossRef]

- Ličbinský, R.; Adamec, V. The Unfavorable Influence of Transport on the Environment. Trans. Transp. Sci. 2011, 4, 91–112. [Google Scholar] [CrossRef]

- Boom, Y.J.; Enfrin, M.; Grist, S.; Giustozzi, F. Analysis of possible carcinogenic compounds in recycled plastic modified asphalt. Sci. Total Environ. 2023, 858, 159910. [Google Scholar] [CrossRef] [PubMed]

| Country | Total Plastic Waste (Mt) | ||

|---|---|---|---|

| 2016 | 2017 | 2018 | |

| China | 49.04 | 49.19 | 49.71 |

| India | 17.48 | 17.58 | 17.66 |

| Japan | 10.95 | 11.07 | 11.19 |

| Turkey | 6.13 | 6.21 | 6.28 |

| Thailand | 5.85 | 5.88 | 5.96 |

| Pakistan | 5.30 | 5.40 | 5.51 |

| South Korea | 4.40 | 4.39 | 4.38 |

| Vietnam | 3.28 | 3.29 | 3.30 |

| Iran | 3.20 | 3.19 | 3.24 |

| Saudi Arabia | 2.97 | 3.05 | 3.11 |

| Indonesia | 2.74 | 2.95 | 3.01 |

| Philippine | 2.53 | 2.58 | 2.61 |

| Malaysia | 2.45 | 2.60 | 2.65 |

| Singapore | 1.19 | 1.22 | 1.24 |

| Israel | 1.02 | 1.02 | 1.03 |

| Yemen | 0.91 | 0.92 | 0.93 |

| Sri Lanka | 0.54 | 0.55 | 0.56 |

| Mongolia | 0.46 | 0.46 | 0.46 |

| Tajikistan | 0.35 | 0.36 | 0.36 |

| Qatar | 0.24 | 0.24 | 0.25 |

| Turkmenistan | 0.16 | 0.16 | 0.16 |

| Brunei | 0.05 | 0.05 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abd Karim, S.B.; Norman, S.; Koting, S.; Simarani, K.; Loo, S.-C.; Mohd Rahim, F.A.; Ibrahim, M.R.; Md Yusoff, N.I.; Nagor Mohamed, A.H. Plastic Roads in Asia: Current Implementations and Should It Be Considered? Materials 2023, 16, 5515. https://doi.org/10.3390/ma16165515

Abd Karim SB, Norman S, Koting S, Simarani K, Loo S-C, Mohd Rahim FA, Ibrahim MR, Md Yusoff NI, Nagor Mohamed AH. Plastic Roads in Asia: Current Implementations and Should It Be Considered? Materials. 2023; 16(16):5515. https://doi.org/10.3390/ma16165515

Chicago/Turabian StyleAbd Karim, Saipol Bari, Syuhada Norman, Suhana Koting, Khanom Simarani, Siaw-Chuing Loo, Faizul Azli Mohd Rahim, Mohd Rasdan Ibrahim, Nur Izzi Md Yusoff, and Abdul Halim Nagor Mohamed. 2023. "Plastic Roads in Asia: Current Implementations and Should It Be Considered?" Materials 16, no. 16: 5515. https://doi.org/10.3390/ma16165515

APA StyleAbd Karim, S. B., Norman, S., Koting, S., Simarani, K., Loo, S.-C., Mohd Rahim, F. A., Ibrahim, M. R., Md Yusoff, N. I., & Nagor Mohamed, A. H. (2023). Plastic Roads in Asia: Current Implementations and Should It Be Considered? Materials, 16(16), 5515. https://doi.org/10.3390/ma16165515