Effect of Portland Cement on the Selected Properties of Flue Gas Desulfurization Gypsum-Based Plasters

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Gypsum–Cement Mortar Samples

2.2.2. Analytical Methods

Mechanical Strength

Dimension Changes

XRD Analysis

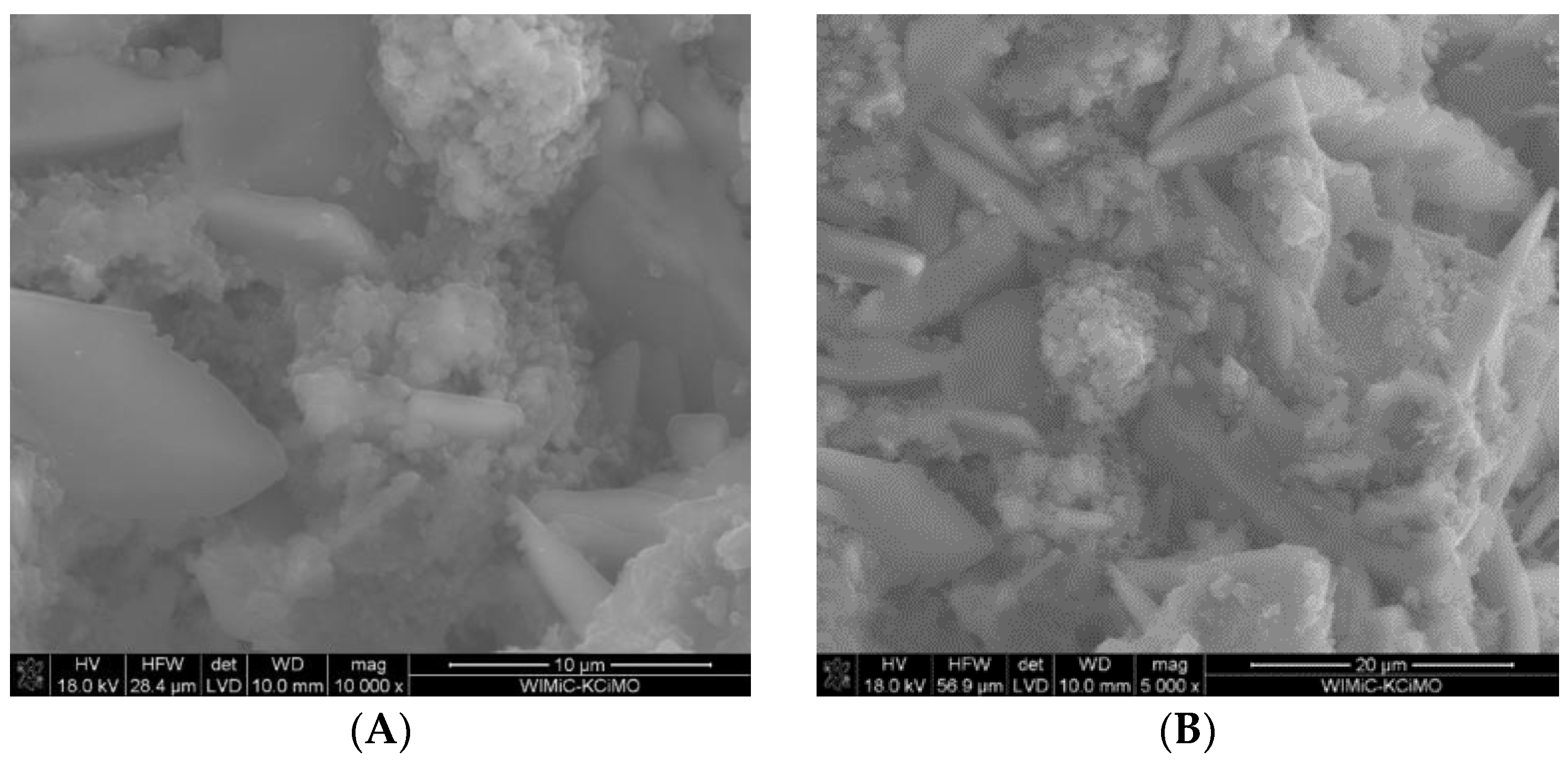

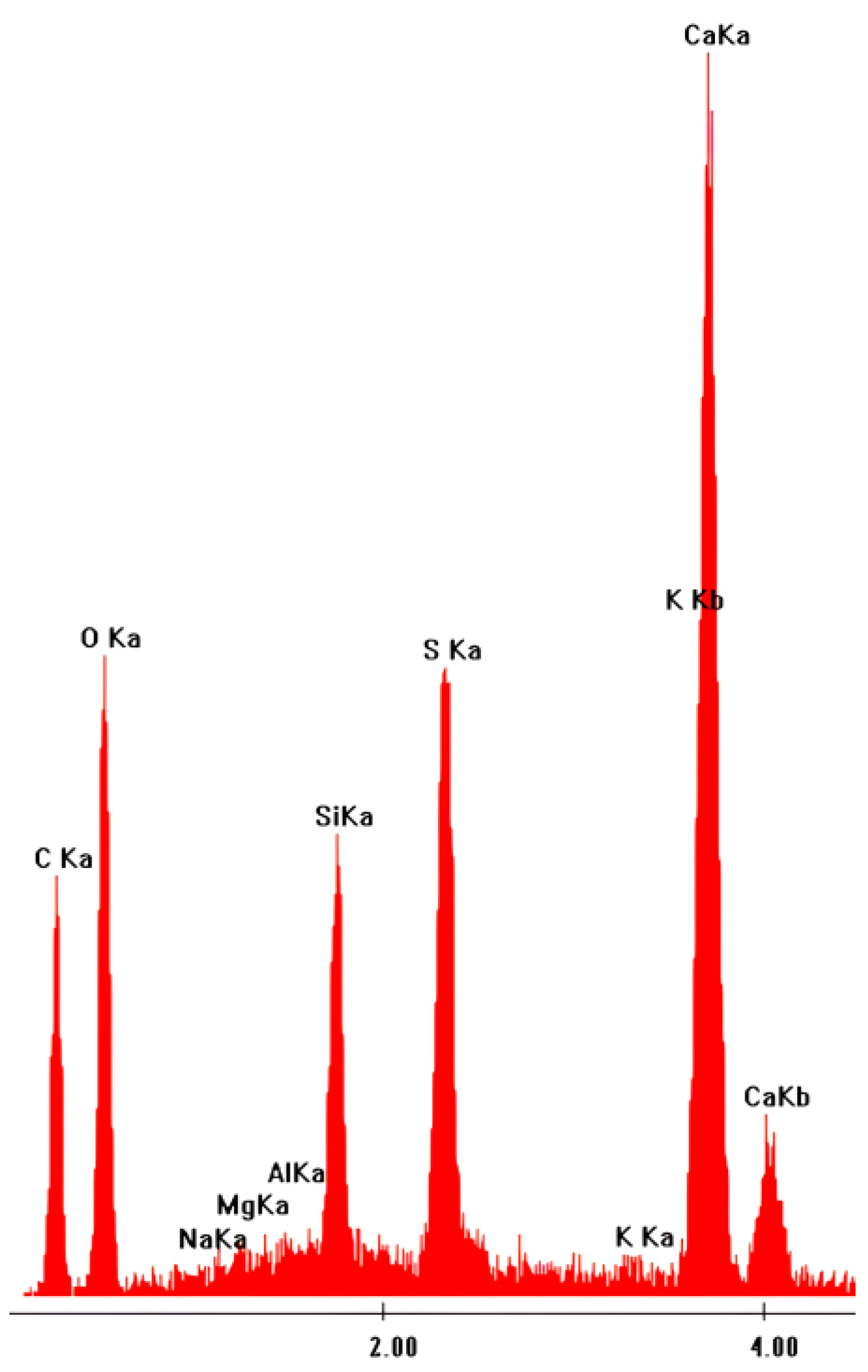

Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDS)

3. Results and Discussion

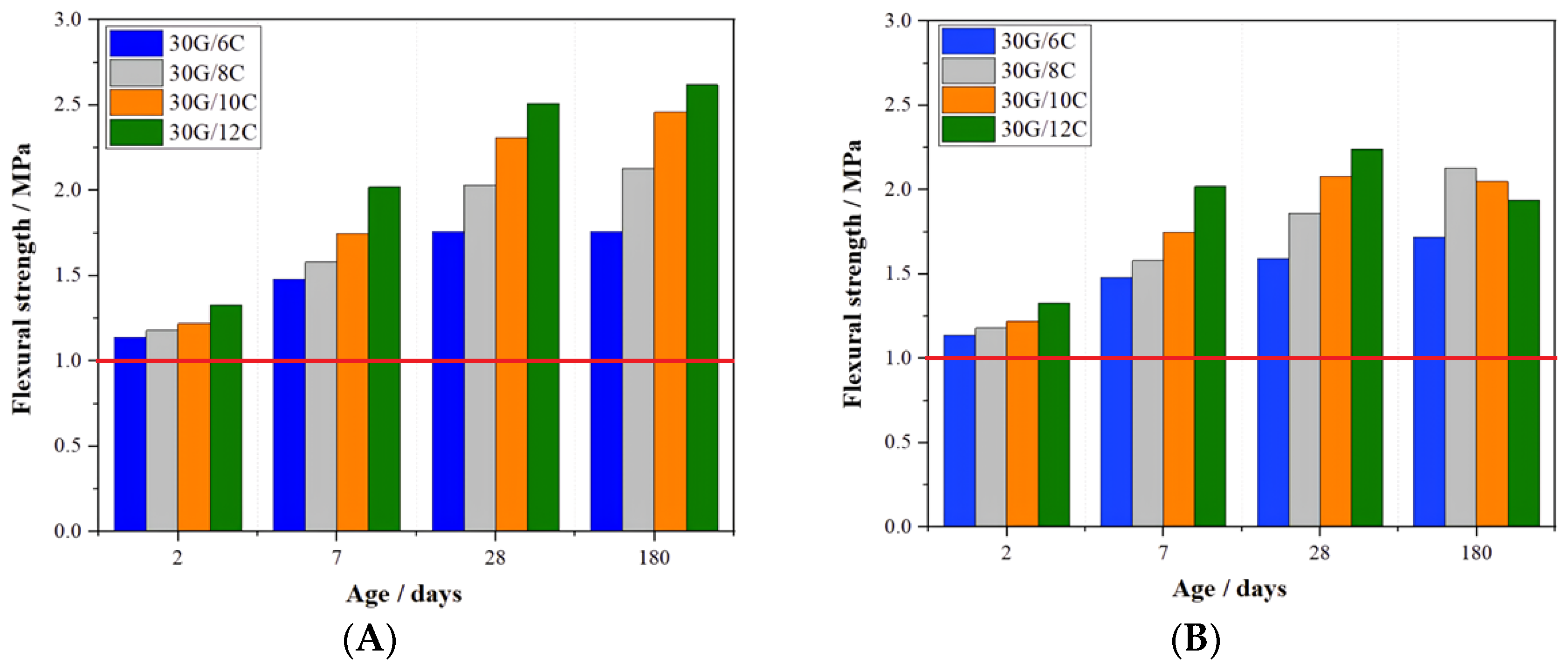

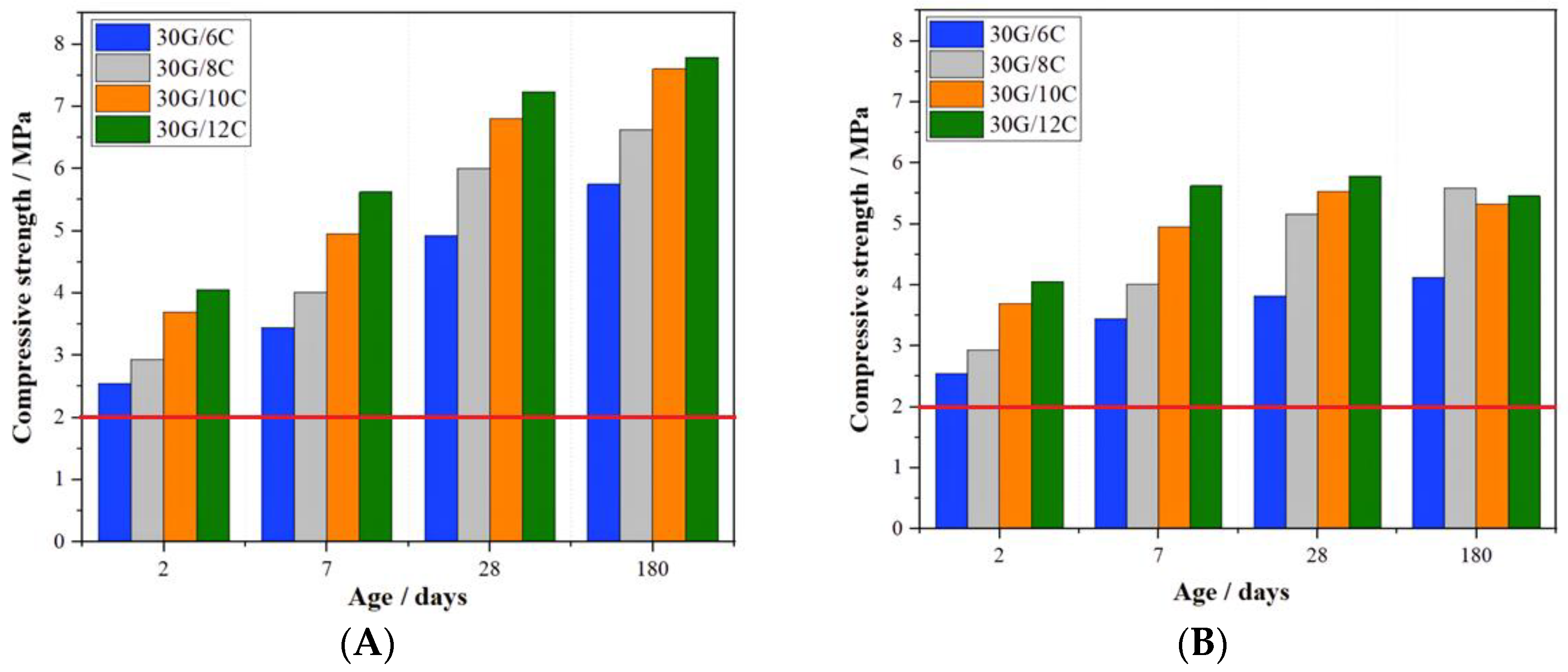

3.1. Mechanical Strength

3.2. Dimension Changes

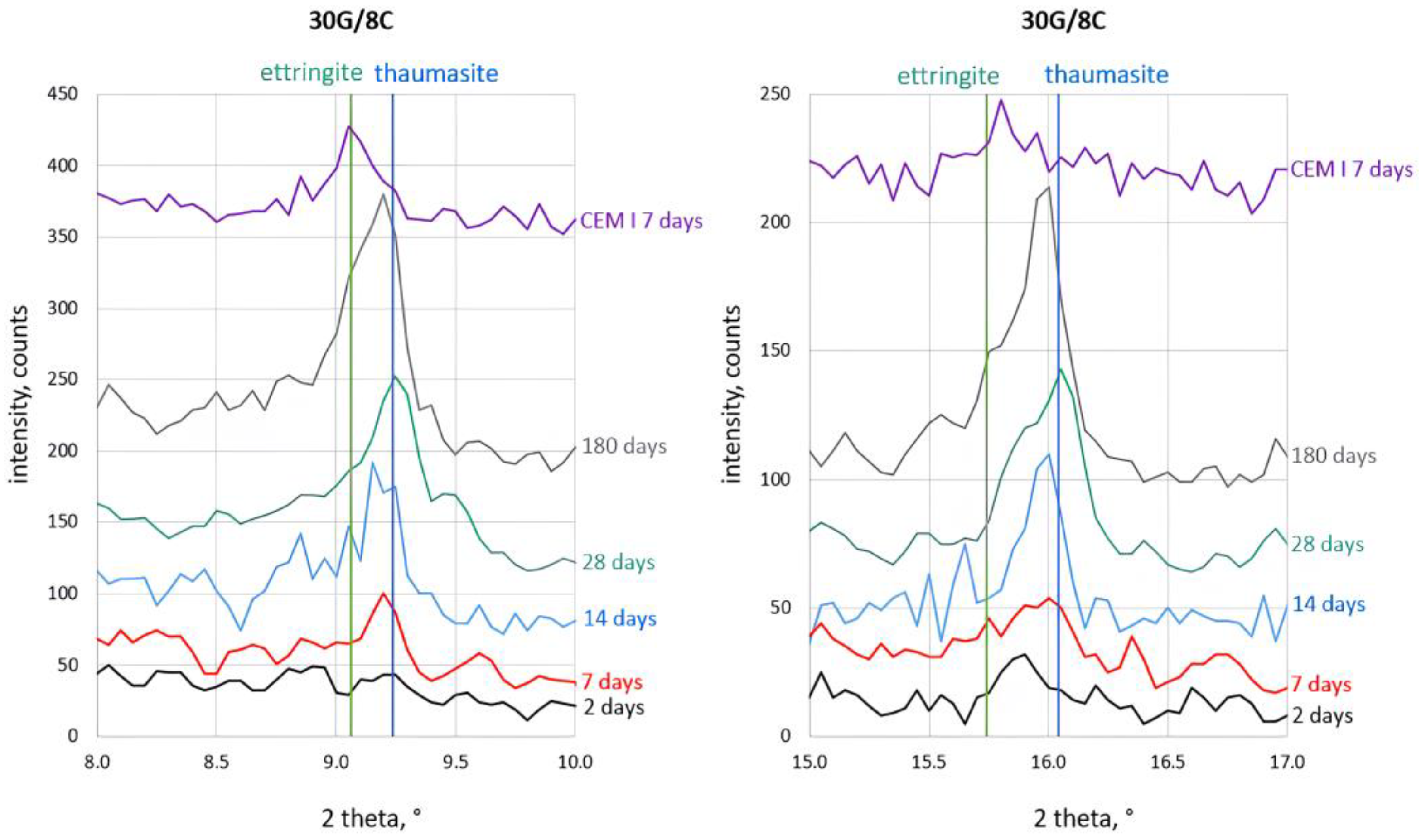

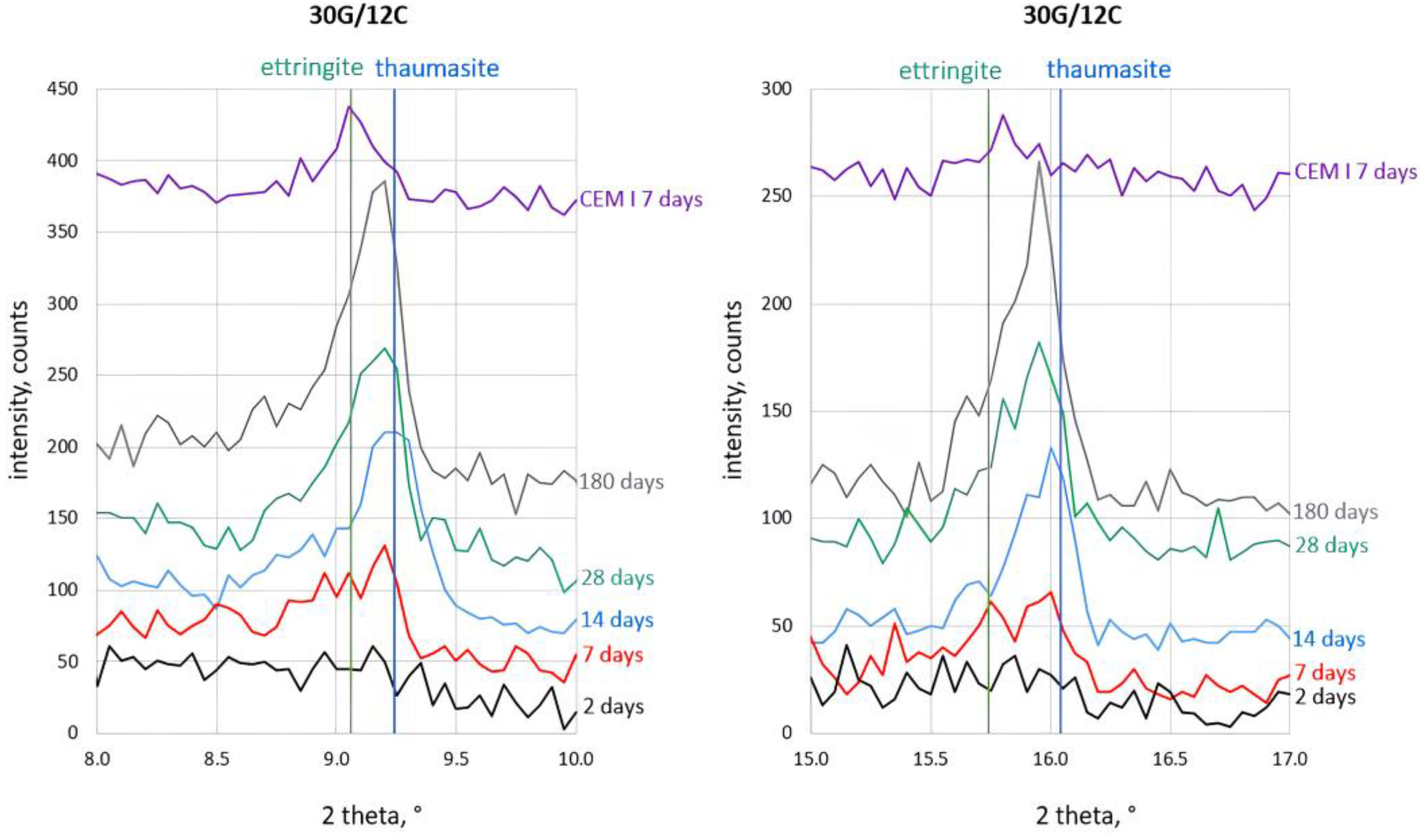

3.3. X-ray Diffractometry

3.4. Scanning Electron Microscopy and Energy-Dispersive Spectroscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Główny Urząd Statystyczny. Available online: https://stat.gov.pl/obszary-tematyczne/przemysl-budownictwo-srodki-trwale/przemysl/produkcja-wazniejszych-wyrobow-przemyslowych-w-marcu-2022-roku,2,120.html (accessed on 10 March 2023).

- Galos, K.; Lewicka, E. Gips i anhydryt. In Gospodarka Surowcami Mineralnymi w Polsce w Latach 2011–2020; IGSMiE PAN: Cracow, Poland, 2021; pp. 99–103. [Google Scholar]

- Czapowski, G. Gips i Anhydryt. In Bilans Zasobów Złóż Kopalin w Polsce wg Stanu na 31 XII 2021 r.; Szuflicki, M., Malon, A., Tymiński, M., Eds.; PIG-PIB: Warsaw, Poland, 2022; pp. 96–98. [Google Scholar]

- Szlugaj, J.; Naworyta, W. Analysis of the Changes in Polish Gypsum Resources in the Context of Flue Gas Desulfurization in Conventional Power Plant. Gospod. Surowcami Miner. 2015, 31, 93–108. [Google Scholar] [CrossRef]

- Mikoś, J. Budowlany gips syntetyczny z odsiarczania spalin. In Proceedings of the Konferencja Naukowo-Techniczna Procesy Budowlane, Gliwice-Kokotek, Poland, 29 September–October 2000; pp. 147–152. [Google Scholar]

- Wons, T.; Niziurska, M. Analiza Jakości Gipsów Syntetycznych z Krajowych Instalacji Odsiarczania Spalin Metodą Mokrą Wapienną Stosowanych Jako Substytut Gipsu Naturalnego Do Produkcji Wyrobów Budowlanych; Pr. Inst. Ceram. I Mater. Bud.: Cracow, Poland, 2013.

- EN 13279-1:2008; Gypsum Binders and Gypsum Plasters—Part 1: Definitions and Requirements. European Committee for Standarization (CEN): Brussels, Belgium, 2008.

- Ministry of Climate and Environment. Available online: http://www.gov.pl/web/klimat/krajowy-plan-na-rzecz-energii-i-klimatu (accessed on 10 March 2023).

- Bielecka, A.; Kulczycka, J. Coal Combustion Products Management toward a Circular Economy—A Case Study of the Coal Power Plant Sector in Poland. Energies 2020, 13, 3603. [Google Scholar] [CrossRef]

- Haba, S.; Nocuń-Wczelik, W. The future of Polish desulphogypsum from flue gas desulphurization using the wet lime method in the light of the national climate and energy policy—A review. Ceram. Mater. 2021, 73, 3–13. [Google Scholar]

- Wołżeński, A.W.; Stambułko, W.I.; Ferrońskaja, A.W. Spoiwa, Betony i Wyroby Gipsowo-Cementowo-Pucolanowe; Arkady: Warsaw, Poland, 1977. [Google Scholar]

- Butakova, M.D.; Gorbunov, S.P. Study of the influence of complex additives on properties of the gypsum-cement-puzzolan binder and concretes on its basis. Procedia Eng. 2016, 150, 1461–1467. [Google Scholar] [CrossRef]

- Kovler, K. Setting and Hardening of Gypsum-Portland Cement-Silica Fume Blends, Part 1: Temperature and Setting Expansion. Cem. Concr. Res. 1998, 28, 423–437. [Google Scholar] [CrossRef]

- Gou, H.; Wang, Q.; Zhang, G.; Li, W.; Meng, E.; Chen, W.; Hui, S.; Zhou, L. Water Resistance of Flue Gas Desulfurization Building Gypsum Modified by Ordinary Portland Cement. Bull. Chin. Ceram. Soc. 2021, 40, 2288–2295. [Google Scholar]

- Camarini, G.; De Milito, J.A. Gypsum hemihydrate-cement blends to improve rendering durability. Constr. Build. Mater. 2011, 25, 4121–4125. [Google Scholar] [CrossRef]

- Kovler, K. Role of ettringite, thaumasite and monocarbonate in hardening and destruction of Portland cement-gypsum system. In ConcreteLife’06—International RILEM-JCI Seminar on Concrete Durability and Service Life Planning: Curing, Crack Control, Performance in Harsh Environments; Kovler, A., Ed.; RILEM Publications SARL: Bagneaux, France, 2006; pp. 70–80. [Google Scholar]

- Klin, S. Wpływ obecności i migracji wody na właściwości stwardniałego wyrobu gipsowego. In Zeszyty Naukowe Akademii Rolniczej we Wrocławiu Nr 510 Rozprawy CCXXVII.; Wydawnictwo Akademii Rolniczej: Wrocław, Poland, 2005; pp. 248–272. [Google Scholar]

- Wu, G.; Ma, H.; Chen, Q.; Huang, Z.; Zhang, C.; Yang, T. Preparation of waterproof block by silicate clinker modified FGD gypsum. Constr. Build. Mater. 2019, 214, 318–325. [Google Scholar] [CrossRef]

- Kurdowski, W.; Garbacik, A.; Chłądzyński, S. Problem za dużej zawartości gipsu w cemencie. Cem. Wapno Beton 2004, 71, 81–86. [Google Scholar]

- Tesch, V.; Middendorf, B. Occurrence of thaumasite in gypsum lime mortars for restoration. Cem. Concr. Res. 2006, 36, 1516–1522. [Google Scholar] [CrossRef]

- Crammond, N. The occurrence of thaumasite in modern construction—A review. Cem. Concr. Compos. 2002, 24, 393–402. [Google Scholar] [CrossRef]

- Macphee, D.E.; Diamond, S. Guest Editorial—Thaumasite in Cementitious Materials. Cem. Concr. Compos. 2003, 25, 805–807. [Google Scholar] [CrossRef]

- Kurdowski, W. Chemia Cementu i Betonu; Stowarzyszenie Producentów Cementu: Cracow, Poland, 2010. [Google Scholar]

- Gawlicki, M.; Mróz, R. Korozja starych betonów i zapraw. In Proceedings of the Konferencja Dni Betonu—Tradycja I Nowoczesność, Wisła, Poland, 11–13 October 2021. [Google Scholar]

- Bensted, J. Thaumasite—direct, woodfordite and other possible formation routes. Cem. Concr. Compos. 2003, 25, 873–877. [Google Scholar] [CrossRef]

- Barnett, S.J.; Adam, C.D.; Jackson, A.R.W. Solid solutions between ettringite, Ca6Al2(SO4)3(OH)12∙26H2O, and thaumasite, Ca3SiSO4CO3(OH)6∙12H2O. J. Mater. Sci. 2000, 35, 4109–4114. [Google Scholar] [CrossRef]

- Barnett, S.J.; Macphee, D.E.; Crammond, N.J. Solid solutions between thaumasite and ettringite and their role in sulfate attack. Concr. Sci. Eng. 2001, 3, 209–215. [Google Scholar]

- Dąbrowska, M. Wpływ Popiołu Lotnego Wapiennego na Odporność Korozyjną Kompozytów Wykonanych z Cementu Portlandzkiego Wieloskładnikowego. Ph.D. Thesis, Wydział Budownictwa, Politechnika Śląska, Gliwice, Poland, 2014. [Google Scholar]

- Ping, X.; Beaudoin, J.J. Mechanism of sulphate expansion I. Thermodynamic principle of crystallization pressure. Cem. Concr. Res. 1992, 22, 631–640. [Google Scholar] [CrossRef]

- Min, D.; Mingshu, T. Formation and expansion of ettringite crystals. Cem. Concr. Res. 1994, 24, 119–126. [Google Scholar] [CrossRef]

- Scherer, G.W. Crystallization in pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Kunther, W.; Lothenbach, B.; Scrivener, K.L. On the relevance of volume increase for the length changes of mortar bars in sulfate solutions. Cem. Concr. Res. 2013, 46, 23–29. [Google Scholar] [CrossRef]

- Bensted, J.; Munn, J. Thaumasyt—nieporozumienia towarzyszące tej fazie. Cem. Wapno Beton 2013, 5, 301–309. [Google Scholar]

- Bensted, J. Korozja siarczanowa betonu z utworzeniem thaumazytu—stan wiedzy. In Proceedings of the Konferencja Dni Betonu—Tradycja i Nowoczesność, Wisła, Poland, 9–11 October 2006. [Google Scholar]

- Rahman, M.M.; Bassuoni, M.T. Thaumasite sulfate attack on concrete: Mechanisms influential factors and mitigations. Constr. Build. Mater. 2014, 73, 652–662. [Google Scholar] [CrossRef]

- Shi, C.; Wang, D.; Behnood, A. Review of Thaumasite Sulfate Attack on Cement Mortar and Concrete. J. Mater. Civ. Eng. 2012, 24, 1450–1460. [Google Scholar] [CrossRef]

- Daeizadeh, J.M.; Ebrahimi, K.; Mirvalad, S. Field occurrence of thaumasite sulfate attack: Prevention perspective. Asian J. Civ. Eng. 2020, 21, 1183–1192. [Google Scholar] [CrossRef]

- Mróz, R.; Gawlicki, M. Rola siarczanów i węglanów w korozji betonów w niskich temperaturach. In Proceedings of the Konferencja Dni Betonu—Tradycja i Nowoczesność, Wisła, Poland, 13–15 October 2008. [Google Scholar]

- Bentur, A.; Kovler, K.; Goldman, A. Gypsum of improved performance using blends with Portland Cement and silica fume. Adv. Cem. Res. 1994, 6, 109–116. [Google Scholar] [CrossRef]

- Kovler, K. Enhancing Water Resistance of Cement and Gypsum-Cement Materials. J. Mater. Civ. Eng. 2001, 13, 349–355. [Google Scholar] [CrossRef]

- Kovler, K. Strength and water absorption for gypsum-cement-silica fume blends of improved performance. Adv. Cem. Res. 1998, 10, 81–92. [Google Scholar] [CrossRef]

- Potapova, E.; Nyein, A.K.; Tsvetkova, E.; Fischer, H.B. Modification of the structure of gypsum-cement-pozzolanic binder. In Proceedings of the International Conference on Modern Trends in Manufacturing Technologies and Equipment: Mechanical Engineering and Materials Science (ICMTMTE 2020), Sevastopol, Russia, 7–11 September 2020. [Google Scholar]

- Çolak, A. Physical, mechanical and durability properties of gypsum-Portland cement-natural pozzolan blends. Can. J. Civ. Eng. 2001, 28, 375–382. [Google Scholar]

- Singh, M.; Garg, M. Relationship between mechanical properties and porosity of water resistant gypsum binder. Cem. Concr. Res. 1996, 26, 449–456. [Google Scholar] [CrossRef]

- Wansom, S.; Chintasongkro, P.; Srijampan, W. Water resistant blended cements containing flue-gas-desulfurization gypsum, Portland cement and flu ash for structural applications. Cem. Concr. Compos. 2019, 103, 134–148. [Google Scholar] [CrossRef]

- EN 13279-2:2014; Gypsum Binders and Gypsum Plasters—Part 2: Test Methods. European Committee for Standarization (CEN): Brussels, Belgium, 2014.

- PN-B-04500:1985; Zaprawy budowlane. Badanie cech fizycznych i wytrzymałościowych. Polski Komitet Normalizacji, Miar i Jakości: Warsaw, Poland, 1985.

- Bobrowski, A.; Gawlicki, M.; Łagosz, A.; Nocuń-Wczelik, W. Cement. Metody Badań. Wybrane Kierunki Stosowania; Wydawnictwo AGH: Cracow, Poland, 2010. [Google Scholar]

- The International Center of Diffraction Data. Available online: www.icdd.com (accessed on 10 May 2022).

- Mróz, R. Rola glinianów i glinożelazianów wapnia w kształtowaniu trwałości spoiw cementowych w warunkach korozji siarczanowo-węglanowej. Prz. Bud. 2014, 5, 49–51. [Google Scholar]

- Barnett, S.J.; Macphee, D.E.; Lachowski, E.E.; Crammond, N.J. XRD, EDS and IR analysis of solid solutions between thaumasite and ettringite. Cem. Concr. Res. 2002, 32, 719–730. [Google Scholar] [CrossRef]

- Bellmann, F.; Stark, J. The role of calcium hydroxide in the formation of thaumasite. Cem. Concr. Res. 2008, 38, 1154–1161. [Google Scholar] [CrossRef]

- Doleželová, M.; Krejsová, I.; Scheinherrová, L.; Keppert, M.; Vimmrová, A. Investigation on the environmentally friendly gypsum based composites with improved water resistance. J. Clean. Prod. 2022, 370, 133278. [Google Scholar] [CrossRef]

| Components | Type of Plaster | |||

|---|---|---|---|---|

| 30G/6C | 30G/8C | 30G/10C | 30G/12C | |

| % | ||||

| Gypsum | 30.00 | 30.00 | 30.00 | 30.00 |

| CEM I 42,5R | 6.00 | 8.00 | 10.00 | 12.00 |

| Quartz sand (0.1–0.5 mm) | 48.59 | 46.59 | 44.59 | 42.59 |

| Limestone powder (0.0–0.2 mm) | 10.00 | 10.00 | 10.00 | 10.00 |

| Hydrated lime | 2.00 | 2.00 | 2.00 | 2.00 |

| Expanded perlite (0.0–2.0 mm) | 3.00 | 3.00 | 3.00 | 3.00 |

| Admixtures Modified methyl cellulose Starch ether Sodium lauryl sulfate L (+) tartaric acid | 0.23 0.03 0.02 0.13 | 0.23 0.03 0.02 0.13 | 0.23 0.03 0.02 0.13 | 0.23 0.03 0.02 0.13 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 |

| Type of Mortar | Expansion | |

|---|---|---|

| mm·m−1 | % | |

| 30G/6C | 1.19 | 0.12 |

| 30G/8C | 2.54 | 0.25 |

| 30G/10C | 6.27 | 0.63 |

| 30G/12C | 6.31 | 0.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baran, E.; Hynowski, M.; Kotwica, Ł.; Rogowski, J. Effect of Portland Cement on the Selected Properties of Flue Gas Desulfurization Gypsum-Based Plasters. Materials 2023, 16, 5058. https://doi.org/10.3390/ma16145058

Baran E, Hynowski M, Kotwica Ł, Rogowski J. Effect of Portland Cement on the Selected Properties of Flue Gas Desulfurization Gypsum-Based Plasters. Materials. 2023; 16(14):5058. https://doi.org/10.3390/ma16145058

Chicago/Turabian StyleBaran, Edyta, Mariusz Hynowski, Łukasz Kotwica, and Jacek Rogowski. 2023. "Effect of Portland Cement on the Selected Properties of Flue Gas Desulfurization Gypsum-Based Plasters" Materials 16, no. 14: 5058. https://doi.org/10.3390/ma16145058

APA StyleBaran, E., Hynowski, M., Kotwica, Ł., & Rogowski, J. (2023). Effect of Portland Cement on the Selected Properties of Flue Gas Desulfurization Gypsum-Based Plasters. Materials, 16(14), 5058. https://doi.org/10.3390/ma16145058