Effect of Initial Orientation on the Anisotropy in Microstructure and Mechanical Properties of 2195 Al–Li Alloy Sheet during Hot Tensile Deformation

Abstract

1. Introduction

2. Experimentation

Material and Methods

3. Results and Discussion

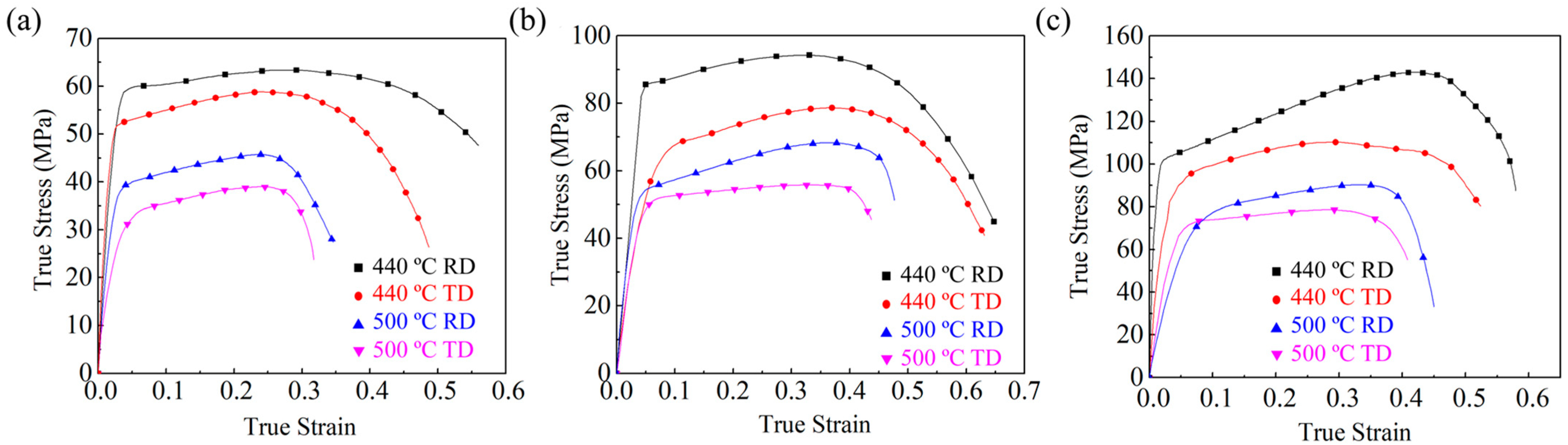

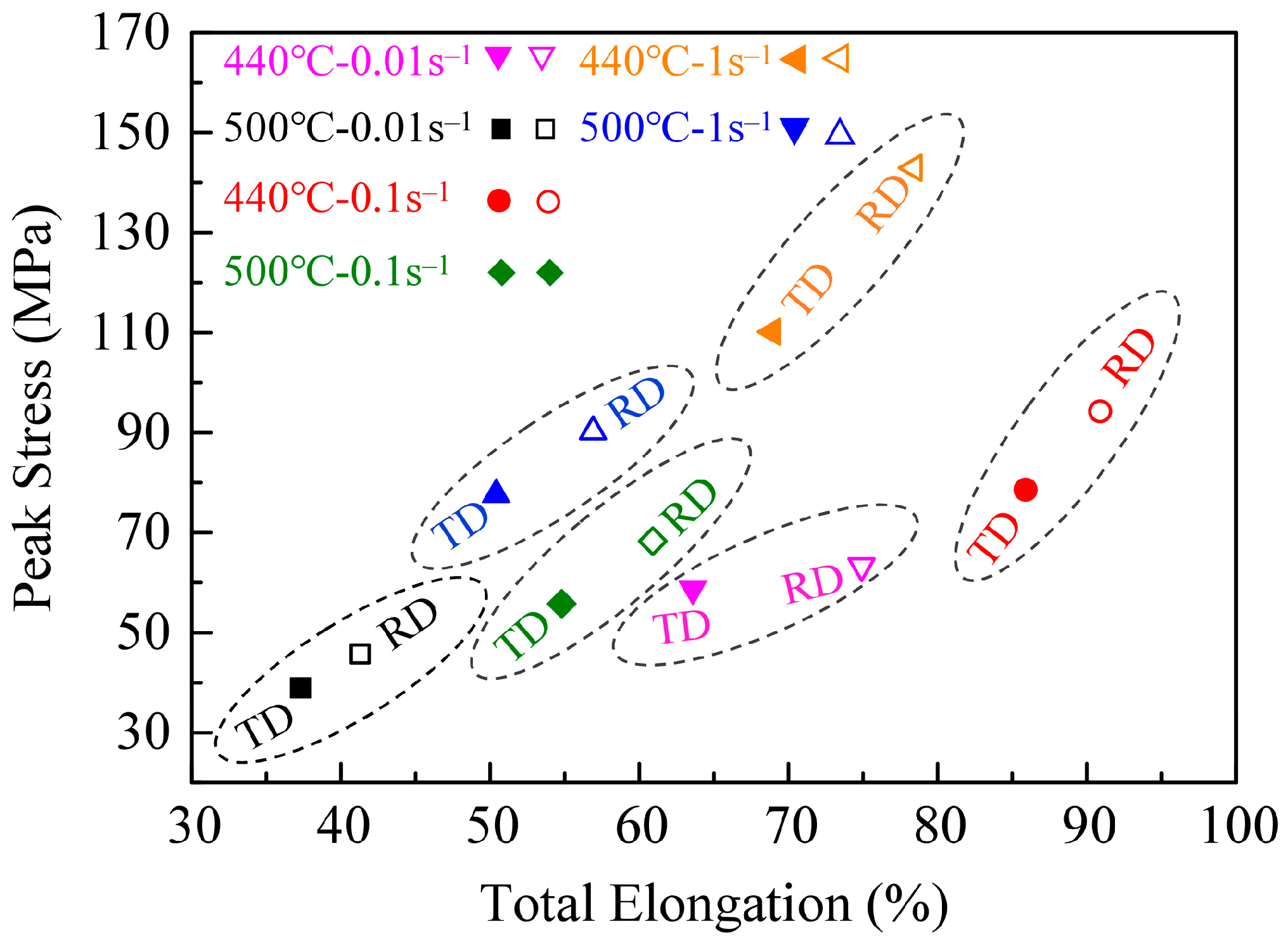

3.1. Flow Behavior and Mechanical Anisotropy

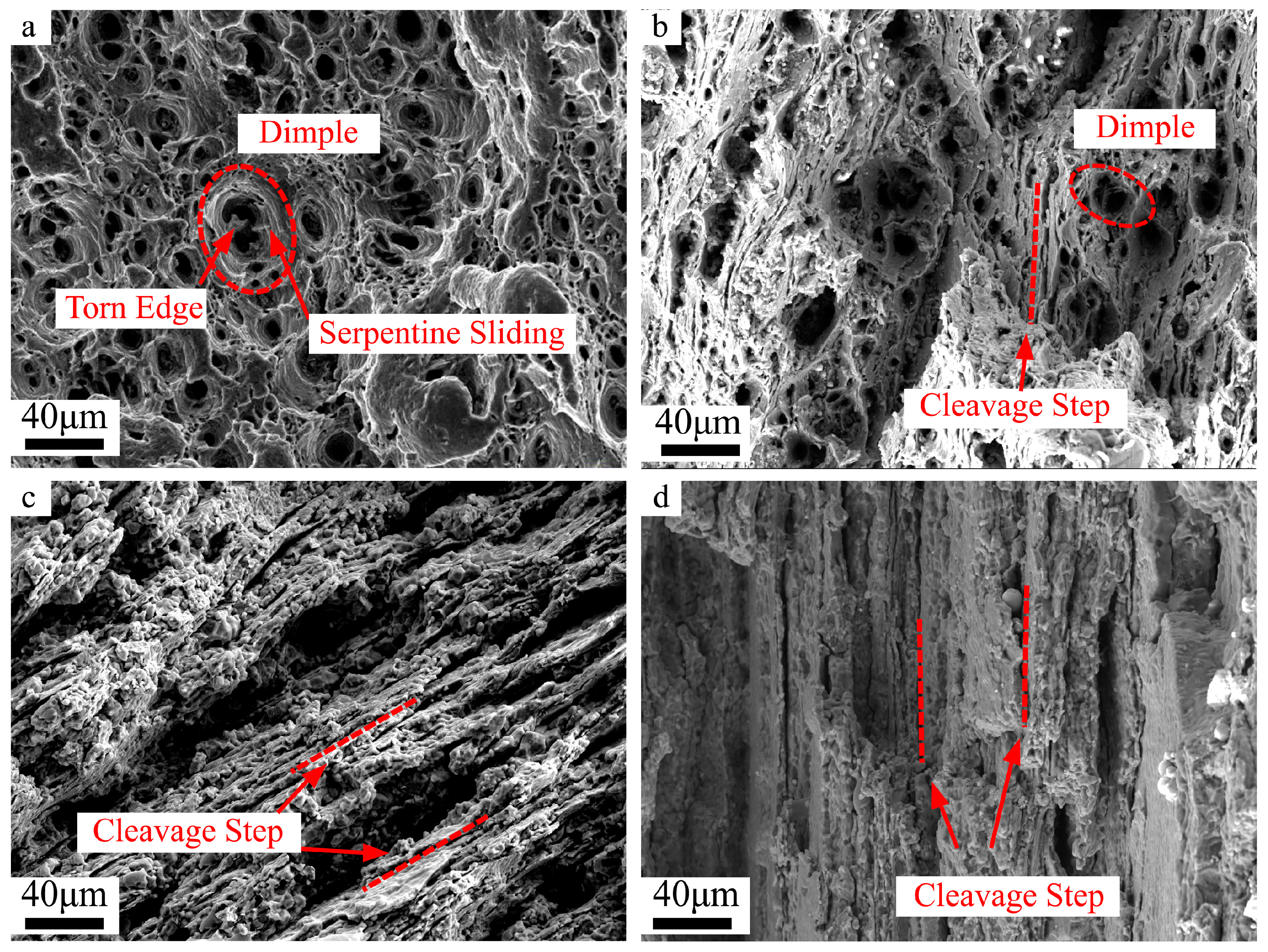

3.2. Fracture Surfaces of Different Deformation Conditions

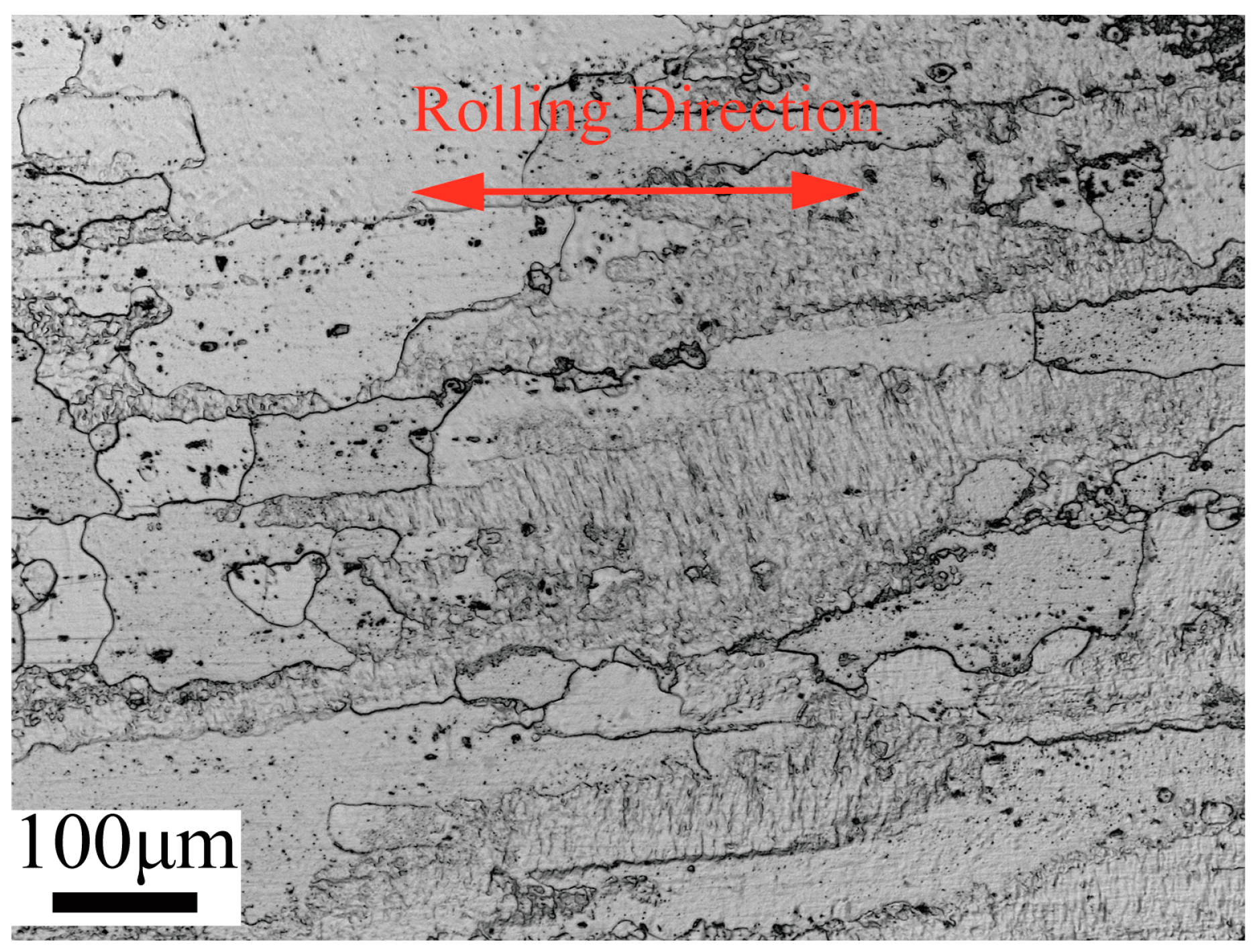

3.3. Microstructure Evolution

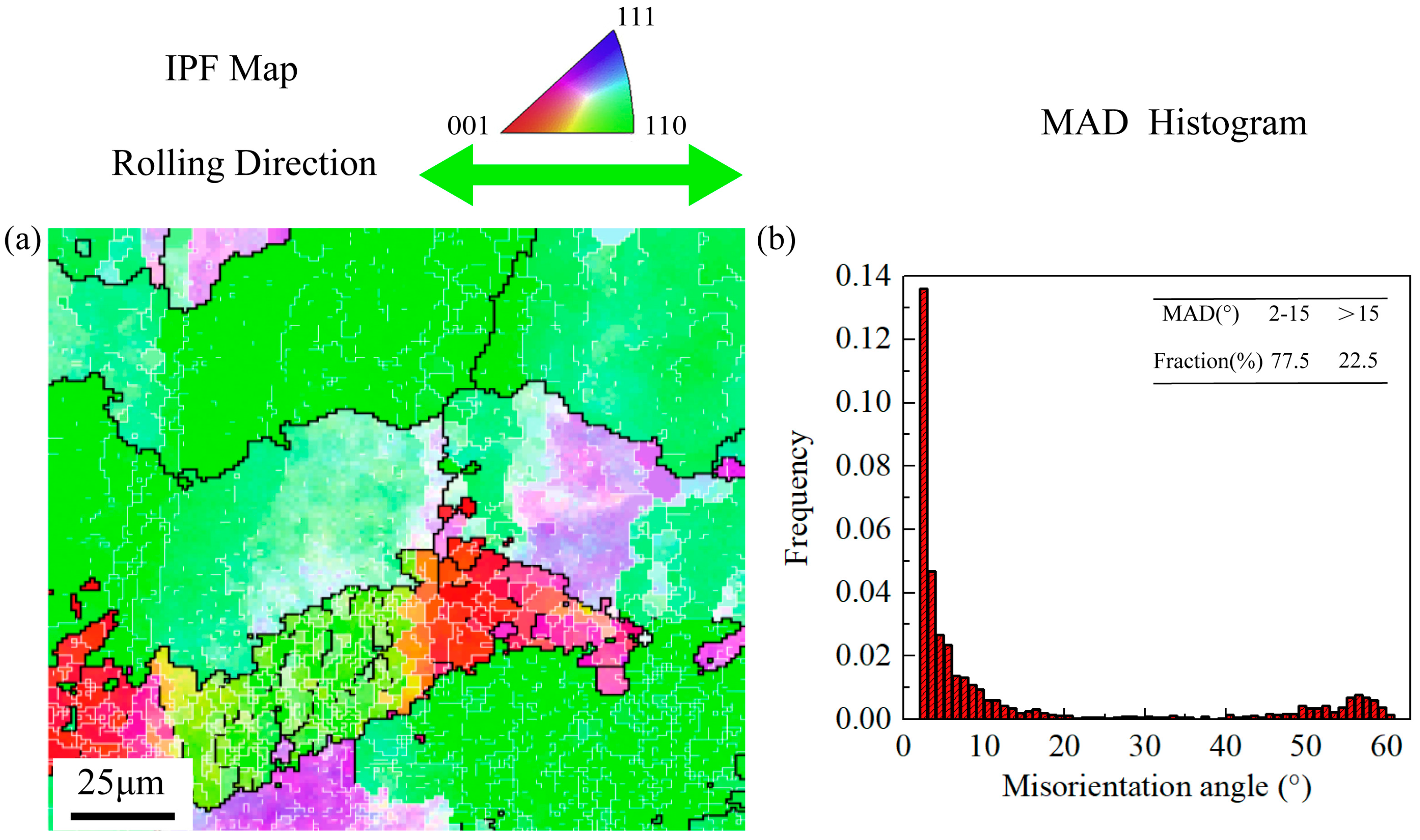

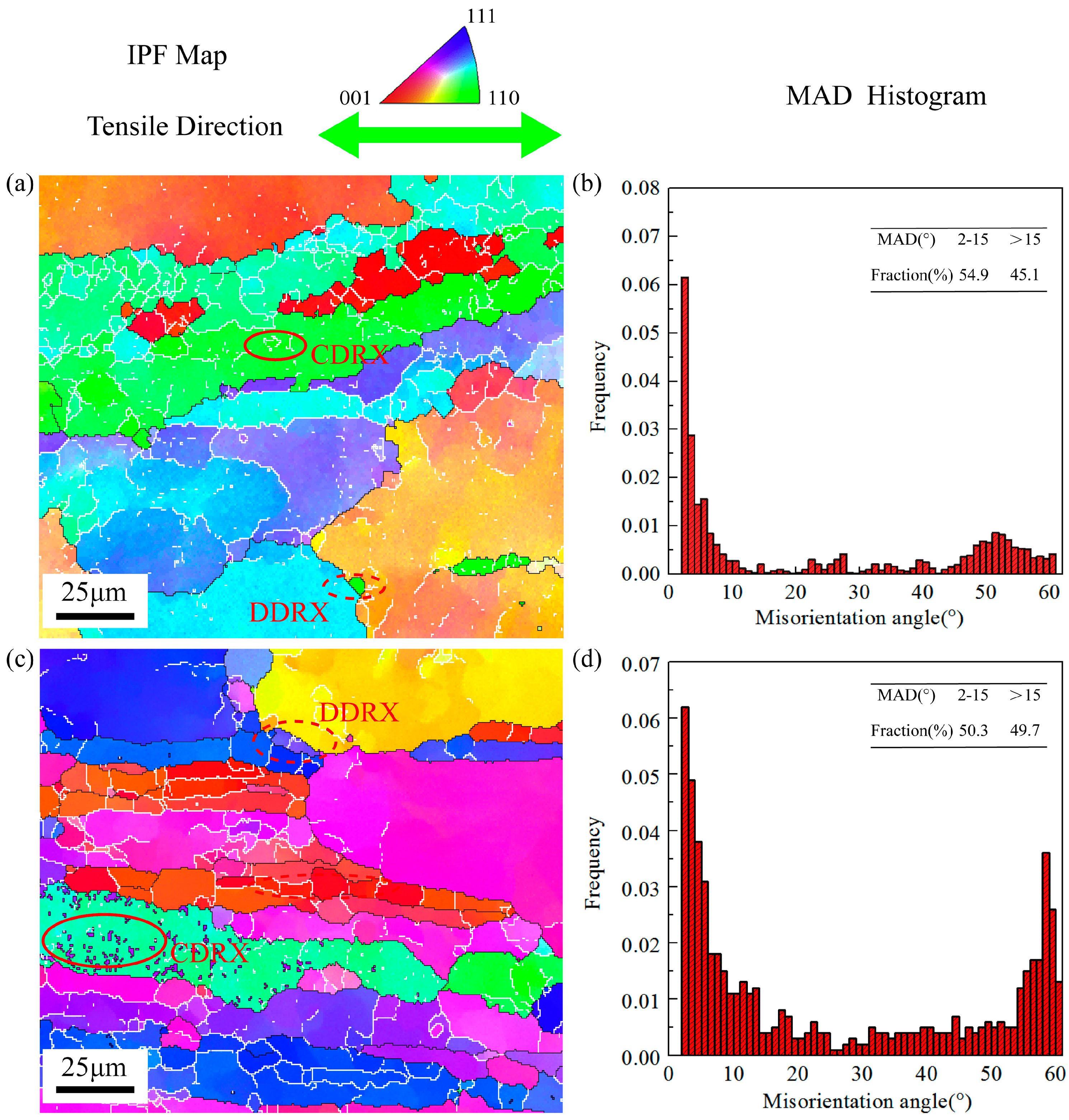

3.3.1. OM and EBSD Examination for Grain Structure

3.3.2. TEM Examination for Dislocation and Sub-Grain

3.4. Discussion

4. Conclusions

- (1)

- The PS and EL along the RD are all larger than the results of TD, and the anisotropy in PS is more significant than EL. Most of the PS anisotropy values are larger than 15%. For the tests carried out at 440 °C−1-1 s−1, the PS values of the sheets stretched along the RD and TD are 142.9 MPa and 110.2 MPa, respectively. For the EL anisotropy, all the values are about 10%.

- (2)

- The fracture surface morphology is typical ductile characteristics at 440 °C. The dimples of the sample stretched along RD are more and deeper than those of TD. At 500 °C, the fracture mode turns into an entirely brittle cleavage fracture along RD and TD.

- (3)

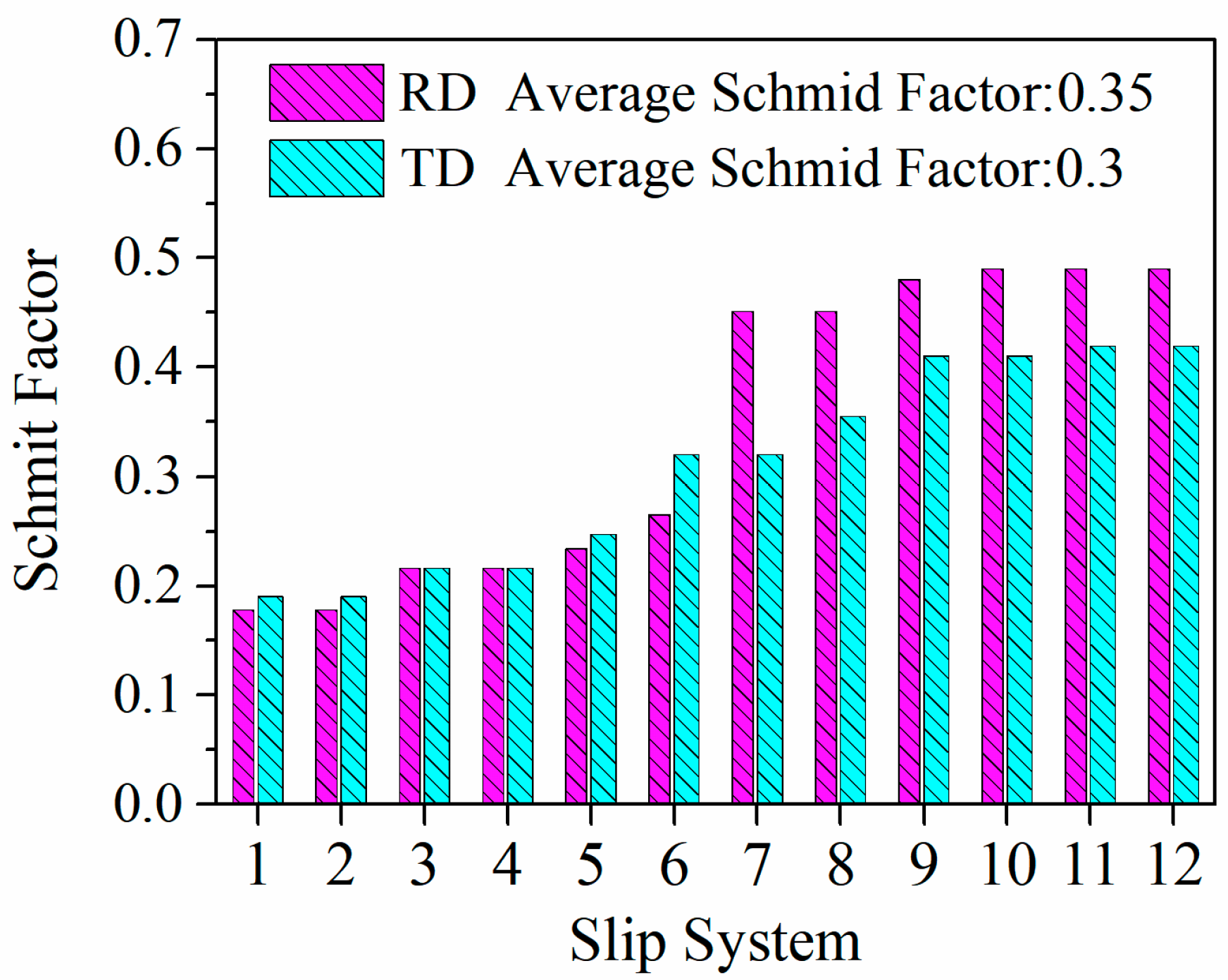

- Most initial grains are <101> orientation, and few <100> and <111> orientation grains exist. The average Schmid factor along RD and TD is 0.35 and 0.30, and the maximum Schmid factor along RD is also larger than TD; therefore, the deformation along RD is easier than along TD.

- (4)

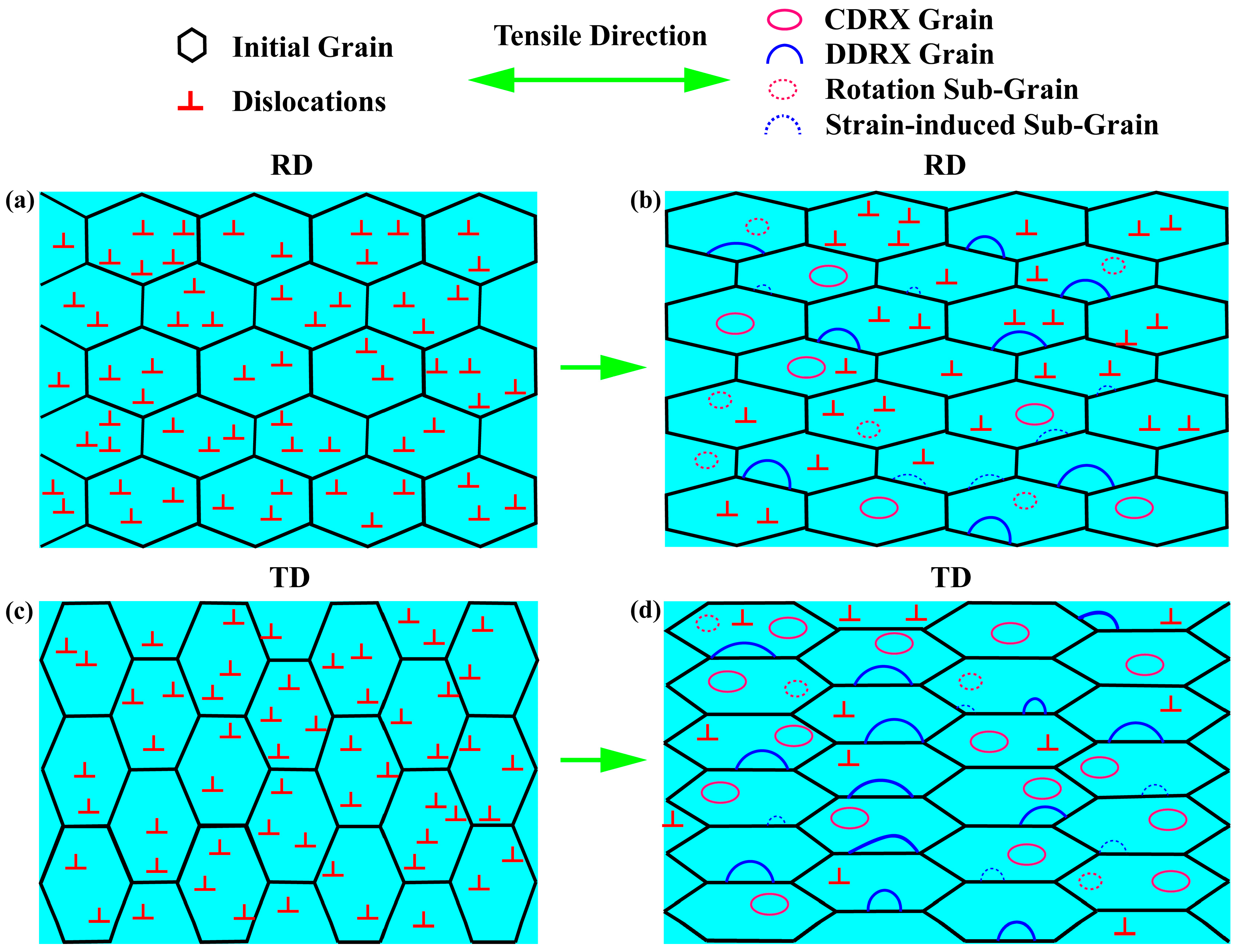

- The fractions of HAGBs along TD are all about 5% larger than those of RD, and there are more small-sized CDRX grains inside the initial grains and more DDRX grains at the initial grain boundaries along TD. This is caused by the difference in the Schmid factor and the initial grain shape along RD and TD. A model of grain DRX during the hot tensile deformation process is developed. Meanwhile, the effect of the Schmid factor and bonded structure formed after rolling on the hot ductility is more prominent, thus presenting a higher EL and a better hot ductility for the deformation along RD.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wanhill, R.J.H. Aerospace Applications of Aluminum-Lithium Alloys, in Aluminum-Lithium Alloys, 15th ed.; Prasad, N.E., Gokhale, A.A., Wanhill, R.J.H., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2014; pp. 503–535. [Google Scholar]

- Rambabu, P.; Prasad, N.E.; Kutumbarao, V.V.; Wanhill, R.J.H. Aluminum Alloys for Aerospace Applications. In Aerospace Materials and Material Technologies, 1st ed.; Prasad, N.E., Wanhill, R.J.H., Eds.; Springer: Singapore, 2017; Volume 1, pp. 29–52. [Google Scholar]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 45, 862–871. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, S.G.; Jin, Y.; Chen, Y. Microstructural characterization and mechanical performance of Al-Cu-Li alloy electron beam welded joint. Aerosp. Sci. Technol. 2018, 82–83, 61–69. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Csontos, A.; Gable, B.; Gaber, A.; Starke, E.A., Jr. The effect of quench rate on the microstructure and properties of AF/C-458 and AF/C-489 Al-Li-Cu-X alloys. Mater. Sci. Forum. 2000, 331, 1333–1340. [Google Scholar] [CrossRef]

- Fridlyander, I.N. Aluminum Alloys in Aircraft in the Periods of 1970–2000 and 2001–2015. Met. Sci. Heat Treat. 2001, 43, 6–10. [Google Scholar] [CrossRef]

- Wan, Z.D.; Wang, Q.; Zhao, Y.; Zhao, T.Y.; Shan, J.G.; Meng, D.Y.; Song, J.L.; Wu, A.P.; Wang, G.Q. Improvement in tensile properties of 2219-T8 aluminum alloy TIG welding joint by PMZ local properties and stress distribution. Mater. Sci. Eng. A 2022, 839, 142863. [Google Scholar] [CrossRef]

- Zhang, R.Z.; Ma, Y.L.; Liu, D.Y.; Ning, H.; Li, J.F.; Cai, C. Dependence of mechanical properties and microstructures of 2195 Al-Li alloy on cold and hot deformation process. Chin. J. Rare Met. 2021, 45, 129–136. [Google Scholar] [CrossRef]

- Lin, J.; Dean, T.; Garrett, R. A Process in Forming High Strength and Complex-Shaped Al-Alloy Sheet Components. UK Patent WO2008059242, 22 May 2008. [Google Scholar]

- Fan, X.B.; He, Z.B.; Lin, P.; Yuan, S.J. Microstructure, texture and hardness of Al-Cu-Li alloy sheet during hot gas forming with integrated heat treatment. Mater. Des. 2016, 94, 449–456. [Google Scholar] [CrossRef]

- Jata, K.V.; Hopkins, A.K.; Rioja, R.J. The anisotropy and texture of Al-Li alloys. Mater. Sci. Forum 1996, 217–222, 647–652. [Google Scholar] [CrossRef]

- Kim, N.J.; Lee, E.W. Effect of T1 precipitate on the anisotropy of Al-Li alloy 2090. Acta Metall. Mater. 1993, 41, 941–948. [Google Scholar] [CrossRef]

- Cho, K.K.; Chung, Y.H. Effects of grain shape and texture on the yield strength anisotropy of A-l Li alloy sheet. Scr. Mater. 1996, 40, 651–657. [Google Scholar] [CrossRef]

- Wang, D.; Gao, C.; Luo, H.Y.; Yang, Y.H.; Ma, Y. Texture evolution behavior and anisotropy of 2A97 Al-Li alloy during recrystallization at elevated temperature. Rare Met. 2018, 1–11. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Xu, Y.; Zhang, S.H.; Ma, Y.; Chen, D.Y. Experimental investigation of tensile properties and anisotropy of 1420, 8090 and 2060 Al-Li alloys sheet undergoing different strain rates and fibre orientation: A comparative study. Procedia Eng. 2017, 207, 13–18. [Google Scholar] [CrossRef]

- Zhao, T.Z.; Jin, L.; Xu, Y.; Zhang, S.H. Anisotropic yielding stress of 2198 Al–Li alloy sheet and mechanisms. Mater. Sci. Eng. A 2020, 771, 138572. [Google Scholar] [CrossRef]

- Wang, Y.X.; Zhao, G.Q.; Xu, X.; Chen, X.X. Effect of extrusion parameters on microstructure, texture and mechanical property anisotropy of spray deposited 2195 Al–Li alloy profile. Mater. Sci. Eng. A 2021, 818, 141406. [Google Scholar] [CrossRef]

- Peng, N.H.; Zhan, L.H.; Xu, Y.Q.; Liu, C.H.; Ma, B.L.; Chen, K.; Ren, H.B. Anisotropy in creep-aging behavior of Al–Li alloy under different stress levels: Experimental and constitutive modeling. J. Mater. Res. Technol. 2022, 20, 3456–3470. [Google Scholar] [CrossRef]

- Ning, J.; Li, Q.; Zou, Z.Y.; Liu, T.W.; Chen, L. Hot tensile deformation behavior and microstructural evolution of 2195 Al–Li alloy. Vacuum 2021, 188, 110176. [Google Scholar] [CrossRef]

- Li, Q.; Ning, J.; Chen, L.; Hu, J.L.; Liu, Y.X. The mechanical response and microstructural evolution of 2195 Al-Li alloy during hot tensile deformation. J. Alloy. Compd. 2020, 848, 156515. [Google Scholar] [CrossRef]

- Yang, G.J.; Xu, W.C.; Jin, X.Z.; Wang, Z.Y.; Shan, D.B.; Guo, B. Hot deformation behavior and microstructure evolution of the spray deposited and secondary hot extruded 2195 Al-Li alloy. J. Mater. Res. Technol. 2022, 20, 2748–2798. [Google Scholar] [CrossRef]

- Chen, X.X.; Zhao, G.Q.; Xu, X.; Wang, Y.X. Effects of heat treatment on the microstructure, texture and mechanical property anisotropy of extruded 2196 Al-Cu-Li alloy. J. Alloy. Compd. 2021, 862, 158102. [Google Scholar] [CrossRef]

- Xu, X.; Hao, M.; Chen, J.; He, W.; Li, G.; Jiao, C.; Burnett, T.L.; Zhou, X. Influence of microstructural and crystallographic inhomogeneity on tensile anisotropy in thick-section Al-Li-Cu-Mg plates. Mater. Sci. Eng. A 2022, 829, 142135. [Google Scholar] [CrossRef]

- Mishra, S.; Suresh, M.; More, A.M.; Bisht, A.; Nayan, N.; Suwas, S. Texture control to reduce yield strength anisotropy in the third generation aluminum-copper-lithium alloy: Experiments and modeling. Mater. Sci. Eng. A 2021, 799, 140047. [Google Scholar] [CrossRef]

- Liu, T.L.; Li, H.R.; Ma, Y.L.; Li, J.F.; Liu, D.Y.; Lu, D.D.; Guo, Y.J. Investigation of anisotropy and structure variation of spray-formed 2195 Al-Li alloy via final temperature-controlled rolling and cold rolling. J. Alloy. Compd. 2023, 937, 168414. [Google Scholar] [CrossRef]

- Fattah-alhosseini, A.; Naseri, M.; Gholami, D.; Imantalab, O.; Attarzadeh, F.R.; Keshavarz, M.K. Microstructure and corrosion characterization of the nugget region in dissimilar friction-stir-welded AA5083 and AA1050. J. Mater. Sci. 2019, 54, 777–790. [Google Scholar] [CrossRef]

- Le, G.M.; Godfrey, A.; Hong, C.S.; Huang, X.; Winther, C. Orientation dependence of the deformation microstructure in compressed aluminum. Scr. Mater. 2012, 66, 359–362. [Google Scholar] [CrossRef]

- Hansen, N.; Huang, X. Microstructure and flow stress of polycrystals and singlecrystals. Acta Mater. 1998, 46, 1827–1836. [Google Scholar] [CrossRef]

- Wang, X.Y.; Shen, B.; Deng, L.; Li, J.J. Effects of original orientation combination on substructure characteristics during continuous dynamic recrystallization in an extruded Al-Cu-Li alloy. Mater. Charact. 2017, 130, 113–122. [Google Scholar] [CrossRef]

- Wu, Y.Q. Mesoscopic Mechanical Behavior of Polycrystalline Materials Subject to Large Deformation at Elevated Temperatures. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, October 2003. [Google Scholar]

- Chen, X.X.; Zhao, G.Q.; Liu, G.L.; Sun, L.; Chen, L.; Zhang, C.S. Microstructure evolution and mechanical properties of 2196 Al-Li alloy in hot extrusion process. J. Mater. Process. Technol. 2020, 275, 116348. [Google Scholar] [CrossRef]

| Ele. | Cu | Li | Mg | Ag | Zr | Fe | Al |

|---|---|---|---|---|---|---|---|

| wt % | 4.1 | 1.01 | 0.43 | 0.4 | 0.11 | 0.05 | Bal. |

| Deformation Condition | Loading Direction | PS/MPa | PS Anisotropy/% | EL/% | EL Anisotropy/% |

|---|---|---|---|---|---|

| 440 °C-0.01 s−1 | RD | 63.3 ± 2 | 7.8 | 74.8 ± 2 | 17.6 |

| TD | 58.7 ± 2 | 63.5 ± 2 | |||

| 440 °C-0.1 s−1 | RD | 94.2 ± 3 | 19.9 | 90.9 ± 3 | 5.8 |

| TD | 78.6 ± 2 | 85.9 ± 3 | |||

| 440 °C-1 s−1 | RD | 142.9 ± 5 | 29.7 | 78.4 ± 2 | 13.8 |

| TD | 110.2 ± 4 | 68.8 ± 2 | |||

| 500 °C-0.01 s−1 | RD | 45.7 ± 1 | 17.3 | 41.3 ± 1 | 10.8 |

| TD | 38.9 ± 1 | 37.3 ± 1 | |||

| 500 °C-0.1 s−1 | RD | 68.2 ± 2 | 22.4 | 60.9 ± 2 | 11.2 |

| TD | 55.7 ± 2 | 54.8 ± 2 | |||

| 500 °C-1 s−1 | RD | 90.2 ± 3 | 16.2 | 56.9 ± 2 | 13.1 |

| Slip Plane | Slip System | Schmid Factor |

|---|---|---|

| (111) [1–10] | 0.451 | |

| [111] | (111) [10–1] | 0.178 |

| (111) [01–1] | 0.234 | |

| (−111) [110] | 0.216 | |

| [−111] | (−111) [101] | 0.49 |

| (−111) [01–1] | 0.265 | |

| (111) [110] | 0.216 | |

| [1–11] | (111) [10–1] | 0.178 |

| (111) [011] | 0.49 | |

| (111) [1–10] | 0.451 | |

| [11–1] | (111) [101] | 0.49 |

| (111) [011] | 0.48 |

| Slip Plane | Slip System | Schmid Factor |

|---|---|---|

| (111) [1–10] | 0.410 | |

| [111] | (111) [10–1] | 0.216 |

| (111) [01–1] | 0.355 | |

| (−111) [110] | 0.419 | |

| [−111] | (−111) [101] | 0.19 |

| (−111) [01–1] | 0.247 | |

| (111) [110] | 0.419 | |

| [1–11] | (111) [10–1] | 0.216 |

| (111) [011] | 0.32 | |

| (111) [1–10] | 0.41 | |

| [11–1] | (111) [101] | 0.19 |

| (111) [011] | 0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, J.; Liang, J.; Hu, X.; Ruan, X.; He, Z. Effect of Initial Orientation on the Anisotropy in Microstructure and Mechanical Properties of 2195 Al–Li Alloy Sheet during Hot Tensile Deformation. Materials 2023, 16, 5012. https://doi.org/10.3390/ma16145012

Ning J, Liang J, Hu X, Ruan X, He Z. Effect of Initial Orientation on the Anisotropy in Microstructure and Mechanical Properties of 2195 Al–Li Alloy Sheet during Hot Tensile Deformation. Materials. 2023; 16(14):5012. https://doi.org/10.3390/ma16145012

Chicago/Turabian StyleNing, Jian, Jiangkai Liang, Xinyu Hu, Xianggang Ruan, and Zhubin He. 2023. "Effect of Initial Orientation on the Anisotropy in Microstructure and Mechanical Properties of 2195 Al–Li Alloy Sheet during Hot Tensile Deformation" Materials 16, no. 14: 5012. https://doi.org/10.3390/ma16145012

APA StyleNing, J., Liang, J., Hu, X., Ruan, X., & He, Z. (2023). Effect of Initial Orientation on the Anisotropy in Microstructure and Mechanical Properties of 2195 Al–Li Alloy Sheet during Hot Tensile Deformation. Materials, 16(14), 5012. https://doi.org/10.3390/ma16145012