Abstract

According to the shear capacity test results of six steel-fiber-reinforced high-strength concrete (SFHSC) corbels with welded-anchorage longitudinal reinforcement under concentrated load, the effects of shear span ratio and steel fiber volume fraction on the failure mode, cracking load and ultimate load of corbel specimens were analyzed. On the basis of experimental research, the shear transfer mechanism of corbel structure was discussed. Then, a modified softened strut-and-tie model (MSSTM), composed of the diagonal and horizontal mechanisms, was proposed, for steel-fiber-reinforced high-strength concrete corbels. The contributions of concrete, steel fiber and horizontal stirrups to the shear bearing capacity of the corbels were clarified. A calculation method for the shear bearing capacity of steel-fiber-reinforced high-strength concrete corbels was established and was simplified on this basis. The calculation results of the model were compared with the test values and calculation results of the GB50010-2010 code, the ACI318-19 code, the EN 1992-1-1 code and the CSA A23.3-19 code. The results showed that the concrete corbel with small shear span ratio mainly has two typical failure modes: shear failure and diagonal compression failure. With the increase in shear span ratio, the shear capacity of corbels decreases. Steel fiber can improve the ductility of a reinforced concrete corbel, but has little effect on the failure mode of the diagonal section. The calculated values of the national codes were lower than the experimental values, and the results were conservative. The theoretical calculation values of the shear capacity calculation model of the corbels were close to the experimental results. In addition, the model has a clear mechanical concept considering the tensile properties of steel-fiber-reinforced high-strength concrete and the influence of horizontal stirrups, which can reasonably reflect the shear transfer mechanism of corbels.

1. Introduction

Corbels are defined as short cantilevers extending from a wall or column, usually used to support other superstructures such as prefabricated beams or floor slabs at building joints. They are important vertical local-compression components in structures. Due to the influence of concrete creep, shrinkage, thermal deformation and earthquake, corbels also endure certain horizontal loads [1]. When applied to cast-in-place and prefabricated structures, the requirements for the crack resistance and bearing capacity of corbels are high. Steel-fiber-reinforced high-strength concrete (SFHSC) is a new type of composite material formed by adding steel fibers that can enhance, toughen and resist cracking in concrete. The addition of steel fibers significantly improves the tensile, flexural and shear strength of concrete. Adding steel fibers to reinforced concrete corbels can effectively improve the load-bearing capacity and seismic performance of the corbels and improve the degree of reinforcement density [2]. Due to the presence of geometric dimensions and concentrated loads, the corbels are classified as discontinuous regions (D-regions), exhibiting nonlinear strain distribution under load, which does not conform to the plane section assumption of bending theory. The strength of corbels is mainly controlled by shear rather than bending [3], and the shear mechanism is complex, similar to the variable cross-section deep beam. Therefore, the traditional cross-sectional design method based on the plane section assumption is no longer applicable to such components.

Many scholars have systematically studied the mechanical properties of concrete corbels. Fattuhi [4,5] conducted vertical loading tests on reinforced concrete corbels using steel fibers as shear-toughening materials. The tests showed that the addition of steel fibers improved the ductility and strength of the corbels. When the longitudinal reinforcement ratio in the corbels was low, the failure mode changed from diagonal splitting or shear to bending, and the bending model method and truss model method were used to predict the bearing capacity of corbels. Campione et al. [6] studied the flexural behavior of corbels, and the results showed that adding fibers and configuring stirrups were beneficial to improve the bearing capacity and ductility of concrete corbels. A simplified calculation model of shear strength for fiber-reinforced concrete corbels with stirrups was proposed. Yang et al. [7] conducted experimental research on concrete corbels with different steel fiber volume fraction, which used two anchorage methods for the main tension tie: headed bars and welded anchorage. It was concluded that the corbels with headed bars have higher bearing capacity, stiffness and ductility. Gao et al. [8] discussed the mechanical properties and failure characteristics of steel-fiber-reinforced high-strength concrete. The study showed that the addition of steel fibers increased the diagonal crack load and ultimate load of the corbels, and the brittleness was improved. Gao et al. [9] concluded through the shear test of steel-fiber-reinforced concrete corbels that steel fiber has little effect on the failure mode of the corbels, but it can improve the ductility of the corbels. The shear bearing capacity of the corbel increases with the increase in steel fiber volume fraction and concrete strength, and it decreases with the increase in shear span ratio. At the same time, a formula for calculating the shear bearing capacity of steel-fiber-reinforced concrete corbels was derived. Kurtoglu et al. [10] proposed an empirical formula based on symbolic regression (SR) to predict the ultimate shear strength of steel-fiber-reinforced concrete and glass-fiber-reinforced concrete corbels without stirrups and verified its applicability. Huang et al. [11] analyzed the calculation method for the shear bearing capacity of the corbel based on the vertical shear test database of corbels, and they fitted a simplified formula for the design correction coefficient of the shear bearing capacity of corbels according to the parameter analysis results. The Chinese code GB50010-2010 [12] uses the triangular truss model for force analysis of corbels, but the proposed shear capacity formula is a semi-theoretical and semi-empirical formula based on the test, lacking a clear mechanical concept. Foreign scholars put forward the strut-and-tie model (STM) by improving the early truss model, making it a universal design method. The American code ACI318-19 [13], the European code EN 1992-1-1 [14] and the Canadian code CSA A23.3-19 [15] all introduce the strut-and-tie model for the bearing capacity design of D-region components. The strut-and-tie model has been widely used and continuously improved at home and abroad [16,17,18,19,20]. Subsequently, Hwang and Lee proposed the softened strut-and-tie model (SSTM) based on the strut-and-tie model, which considered the softening characteristics of concrete under compression, and its applicability was tested in shear analysis of various concrete components [21,22,23,24]. Khosravikia et al. [25] carried out finite element numerical simulation on the corbel structure, analyzed the shear transfer mechanism of the corbel structure and the influencing factors of the concrete strut coefficient, and improved the calculation method for the shear bearing capacity of corbels based on the strut-and-tie model. Based on the finite element method, Canha et al. [26] conducted research and analysis on parameters such as shear span ratio and reinforcement ratio using validated models, and they compared them with experimental results. The numerical simulation results were good.

Scholars have carried out a considerable amount of research on the SFHSC corbel, and put forward many calculation methods for the SFHSC corbel, but its applicability remains to be further verified. The current specifications for a SFHSC corbel design method are not perfect. In this study, experimental research and theoretical analysis on the shear performance of six SFHSC corbels with welded-anchorage longitudinal reinforcement were carried out. The effects of shear span ratio and steel fiber volume fraction on the failure mode, cracking load and ultimate load of corbel components were analyzed. According to the mechanical characteristics of steel-fiber-reinforced high-strength concrete corbels, the steel fibers distributed randomly in the concrete were equivalent to horizontal and vertical micro-reinforcement. Then, based on the softened strut-and-tie model, a calculation model for the shear bearing capacity of steel-fiber-reinforced high-strength concrete corbels was established. We calculated and compared the shear bearing capacity of the six steel-fiber-reinforced high-strength concrete corbels tested in this paper using the calculation model and national codes. The shear mechanism of corbels was analyzed. The applicability of the calculation model was verified, and the research related to the SFHSC corbel was further improved.

2. Experimental Study

2.1. Specimen Design and Production

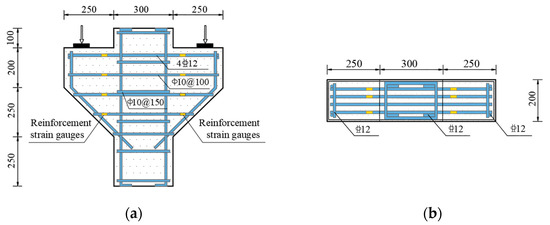

Six SFHSC corbel specimens with welded-anchorage longitudinal reinforcement specimens, numbered CW01 to CW06, were designed and manufactured for the experiment. Two control variables were set: shear span ratio and steel fiber volume fraction. The first group, CW01 to CW04, had shear span ratios of 0.2, 0.3, 0.4 and 0.5, respectively; the second group, CW02, CW05 and CW06, had steel fiber volume fractions of 1.5%, 0.75% and 0%, respectively. The cross-sectional width of the corbels was 200 mm, and the cantilever height of the outer corbels was 200 mm, with a total height of 450 mm. The reinforcement amount for each specimen was the same. Four hot-rolled ribbed steel bars with a diameter of 12 mm were used for the longitudinal reinforcement, with a reinforcement ratio of 0.55%. Ten smooth, round steel bars with a diameter of 10 mm were used for the stirrups, with a reinforcement ratio of 0.78%. The longitudinal reinforcements were arranged by welding and anchoring. In order to facilitate the monitoring of steel bar strain during the later loading process, six steel bar strain gauges were arranged on the longitudinal tensile reinforcement 10 cm away from the corbel lower column, symmetrically arranged on both sides (one longitudinal reinforcement was not measured). The steel bar strain gauges on the corbel stirrup were also evenly distributed on both sides 10 cm away from the corbel lower column. The size, reinforcement and reinforcement strain gauge arrangement of the corbel specimens are shown in Figure 1, and the design parameters of the specimens are shown in Table 1.

Figure 1.

Arrangement of reinforcement and reinforcement strain measuring points. (a) Front view. (b) Bird’s-eye view.

Table 1.

Design parameters of specimens.

C60 high-strength concrete was used in the experiment. The coarse aggregate was gravel with a particle size of no more than 20 mm. The fine aggregate was medium coarse sand. The gravel and sand were evenly graded, and the cement was 42.5 grade ordinary Portland cement. Milling steel fiber with a length of 32 mm, a diameter of 0.75 mm, a length-to-diameter ratio of 42.7 and a tensile strength greater than or equal to 600 MPa was added. The specific mix ratio of the SFHSC is shown in Table 2. Six 150 mm × 150 mm × 150 mm cube test blocks were reserved to measure the cube compressive strength and the tensile strength of the SFHSC. Six 150 mm × 150 mm × 300 mm prism test blocks were reserved to measure the axial compressive strength and the elastic modulus of the SFHSC. The measured mechanical properties of the SFHSC and the steel bars are shown in Table 3 and Table 4, respectively.

Table 2.

Mix proportion of SFHSC.

Table 3.

Mechanical properties of SFHSC.

Table 4.

Mechanical properties of reinforcement.

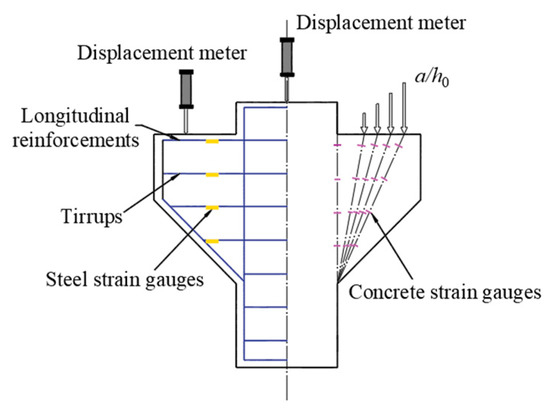

2.2. Measuring Points Arrangement and Loading Scheme

In order to conduct real-time observation on the strain changes of the concrete surface at the corbel normal section and the diagonal section during the test, and control the test process, 16 concrete strain gauges were arranged at the positions where the surface of each corbel specimen might be damaged, including 8 normal sections and 8 inclined sections (changing with the shear span ratio), symmetrically arranged on both sides, as shown in Figure 2. The corbel columns and supports were respectively set up with displacement meters to measure the deflection under each level of load and make settlement. The strain and displacement data of the steel and concrete were measured using an IMP data acquisition instrument. The crack width was observed using a KON-FK (N) crack observation instrument with a minimum scale of 0.01 mm.

Figure 2.

The layout of strain measuring points and displacement meters.

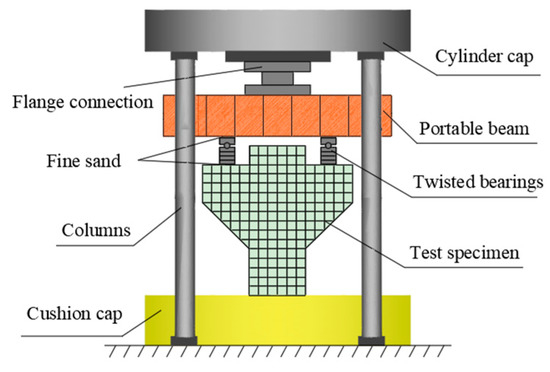

The experimental loading device was a 500 t three-beam, four-column hydraulic press. The symmetrical loading method was adopted. The size of the loading plate was 400 mm × 80 mm × 20 mm. The contact mode between the loading point and the press was non-rigid constraint. A constraint in the horizontal direction was reduced through the circular shaft, and the loading mode was maintained as vertical loading. In order to prevent stress concentration, fine sand was evenly smeared between the loading mold and the component, as shown in Figure 3. The specimen was preloaded before loading, the gap was compacted to level the loading device and the instrument was tested for normal operation. The preload size was 30 kN. After the preload was completed, the test monitoring data were cleared. Then, the load was increased to 480 kN per 60 kN level and kept stationary for 2 min to stabilize the readings before recording. After 480 kN, each level was loaded with 100 kN until failure. After the specimen was destroyed, the data were recorded every 100 kN in the descending stage until the test was completed when it dropped to 800 kN.

Figure 3.

Test loading device.

2.3. Test Results

The characteristic loads and failure modes for each stage of the corbels are shown in Table 5. The load when the first vertical crack occurred in the specimen was defined as the normal section cracking load, denoted by . The load corresponding to the first diagonal crack in the specimen was the diagonal section cracking load, which was recorded as . was the ultimate load that the specimen could bear. It can be seen from Table 5 that the cracking load of the normal section of steel-fiber-reinforced high-strength concrete corbels was about 15% to 25% of the ultimate load, and the cracking load of the diagonal section was about 40% to 60% of the ultimate load. Two typical failure modes of shear failure and diagonal compression failure occurred. As the shear span ratio increased, the bearing capacity of the steel-fiber-reinforced high-strength concrete corbels decreased significantly, and the failure mode gradually transformed from shear failure to diagonal compression failure. When the shear span ratio was the same, with the addition of steel fibers, the bearing capacity of the corbel increased with the increase in steel fiber volume fraction.

Table 5.

Test results and failure modes of specimens.

2.4. Failure Process and Failure Forms

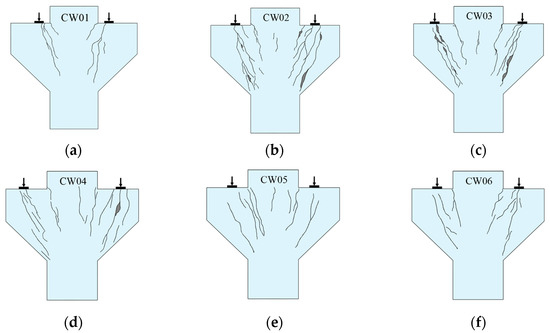

The failure form and crack development of each specimen are shown in Figure 4.

Figure 4.

Crack morphology of the specimens. (a) CW01; (b) CW02; (c) CW03; (d) CW04; (e) CW05; (f) CW06.

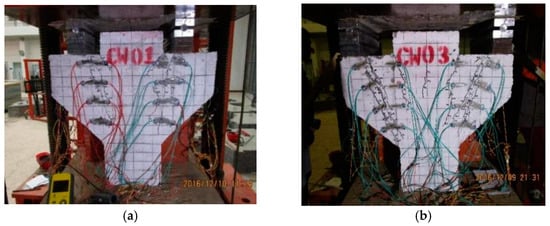

When the shear span ratio , the corbel undergoes shear failure. The typical specimen CW01 can be taken as an example to illustrate the shear failure process, and the failure mode is shown in Figure 5a. In this type of failure, the connection between the loading point and the junction point under the corbel column was the cracking connection, and the crack ran through the whole corbel component. When the load was about 20% to 30% of the failure load, the first crack appeared. At the same time, there were many small cracks under the loading plate, but the width of each crack was very small. When the load continued to 40% to 50% of the failure load, the crack continued to extend up and down from the midpoint of the crack, and the speed of crack width increase and extension speed increased together. Afterwards, as the load increased, the crack would eventually develop to the junction of the corbel and the column when the load was approaching the final failure. Finally, the cracks were connected up and down into a small diagonal crack and formed rapidly, converging into the widest crack. The specimen was cut along this crack and destroyed, at which point the longitudinal reinforcement did not reach its yield strength.

Figure 5.

Typical specimen failure mode. (a) CW01 (shear failure). (b) CW03 (diagonal compression failure).

When the shear span ratio , the corbel undergoes diagonal compression failure. The typical specimen CW03 can be taken as an example to illustrate the diagonal compression failure process, and the failure mode is shown in Figure 5b. When the load was increased to 17% to 28% of the ultimate load, the first crack would appear roughly. It had little effect on the mechanical properties of the corbels due to the newly generated crack width at this time. However, as the load continued to increase, the deflection of the component would have a certain increase, and the axis of the rod would also form a certain bending. In this case, when the load reached 40% to 60% of the failure load, the connecting line between the loading plate and the junction of the corbel lower part and the column, which was equivalent to the concrete strut, would generate a large number of cracks. After this, the load continued to increase. When the load was close to failure (about 80% of the failure load), a large number of new diagonal cracks suddenly appeared in the compression area, and the concrete skin cracked. Finally, the top tensile steel bar reached yield first, and the strain suddenly increased beyond the range. The concrete reached its axial compressive strength, and the specimen subsequently failed.

2.5. Analysis of Influencing Factors

2.5.1. Shear Span Ratio

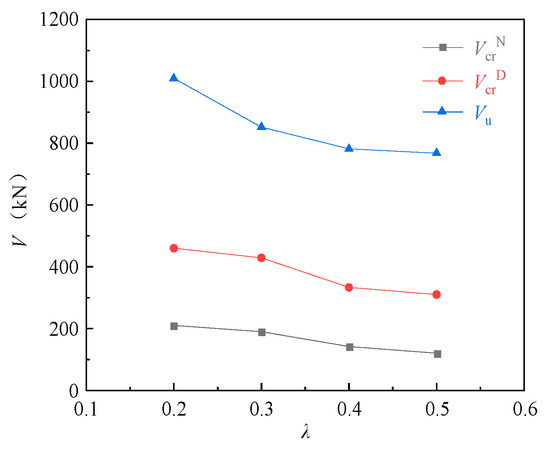

The effects of the shear span ratio on the cracking loads of the normal and diagonal sections and the ultimate load of the corbels were analyzed using specimens CW01 (0.2), CW02 (0.3), CW03 (0.4) and CW04 (0.5). It can be seen from Figure 6 that the shear span ratio is an important factor affecting the bearing capacity of the corbels. As the shear span ratio increased, the bearing capacity of the corbels decreased significantly, and the cracking loads of the normal and diagonal sections and the ultimate load decreased accordingly. For the normal section cracking load, CW02, CW03 and CW04 decreased by 9.5%, 32.4% and 42.9%, respectively, compared with CW01. For the diagonal section cracking load, CW02, CW03 and CW04 decreased by 6.7%, 27.6% and 32.6%, respectively, compared with CW01. For the ultimate load, CW02, CW03 and CW04 decreased by 15.6%, 22.6% and 24.0%, respectively, compared with CW01. The influence of the shear span ratio on the cracking load of the diagonal section of the corbels can be explained as follows: the main tensile stress will be generated in the vertical direction of connection between the concentrated load point and the lower column of the corbels, while the vertical compressive stress at the loading point and the bearing reaction force will reduce the main tensile stress, thereby improving the bearing capacity of the corbels. The cracking load of the diagonal section increases, and the vertical compressive stress increases with the decrease in the shear span ratio, and the cracking load of the diagonal section of the corbels increases.

Figure 6.

Relationship curve for load to shear span ratio.

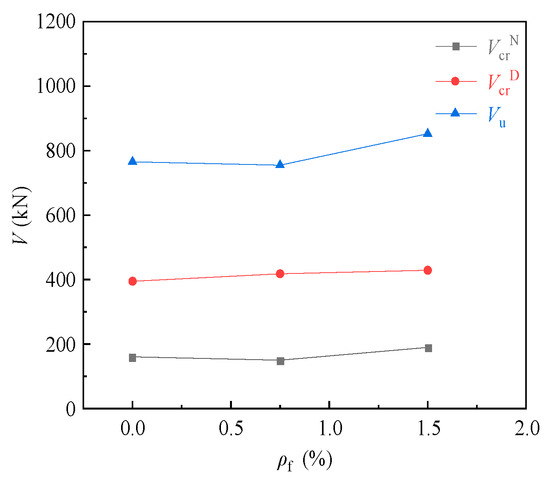

2.5.2. Steel Fiber Volume Fraction

Figure 7 shows the effect of the steel fiber volume fraction on the cracking loads of the normal and diagonal sections and the ultimate load of corbel specimens CW02 (1.5%), CW05 (0.75%) and CW06 (0%) with a shear span ratio of 0.3. It can be seen from the diagram that the cracking loads of the normal and diagonal sections and the ultimate load of the corbels increased with the increase in steel fiber volume fraction. For the normal section cracking load, CW02 increased by 26.7% compared to CW05 and 18.8% compared to CW06. For the diagonal section cracking load, CW02 increased by 2.6% compared to CW05 and 8.6% compared to CW06. For the ultimate load, CW02 increased by 12.8% compared to CW05 and 11.4% compared to CW06.

Figure 7.

Relationship curve for load to steel fiber volume fraction.

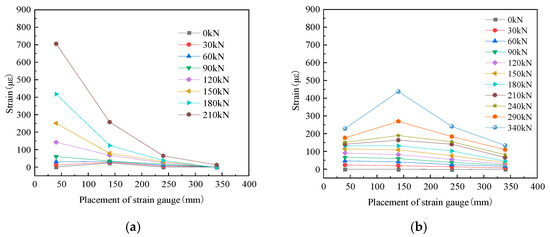

2.6. Concrete Strain

In Figure 8, the typical specimen CW02 is taken as an example to analyze the concrete strain of the normal and diagonal sections of the steel-fiber high-strength concrete corbel under load. It can be seen from the figure that the concrete strain of the normal section of the corbel specimen was obviously more intense than that of the diagonal section. The further away from the loading point it was, the lower the concrete strain was for both the normal and diagonal sections, which was the result of the torque change. It can be seen from Figure 8a that, before the cracking of the steel-fiber-reinforced high-strength concrete corbel, the normal section strain was small and basically linear, which satisfied the plane section assumption. With an increase in load, the strain of the normal section concrete increased nonlinearly, which did not conform to the plane section assumption. This indicated that the addition of steel fiber cannot change the characteristic that the normal section of the corbel does not comply with the plane section assumption. From Figure 8b, it can be seen that the strain of steel-fiber-reinforced high-strength concrete corbel diagonal section concrete was not as regular as that of the normal section, which was related to the complex stress state inside the concrete diagonal strut.

Figure 8.

Concrete strain distribution of specimen CW02. (a) Normal section strain. (b) Diagonal section strain.

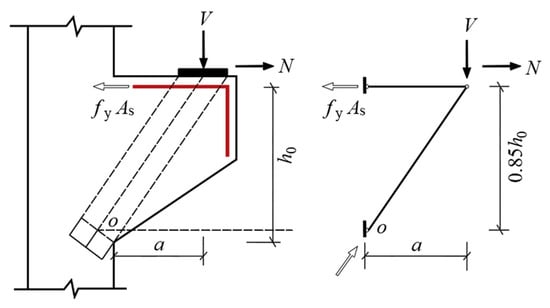

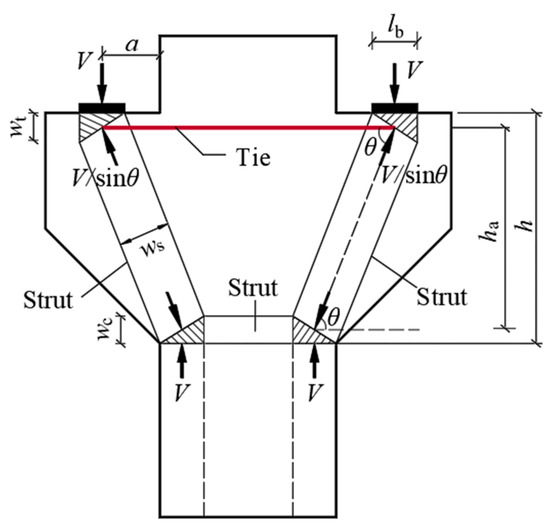

3. Calculation Methods of National Codes

The truss theory, which equates steel bar and concrete as truss ties and struts, is an early mechanical model of concrete corbels. Based on the triangular truss model (see Figure 9), the former Ministry of Metallurgy Building Research Institute proposed a practical calculation formula for determining the cross-sectional size and bearing capacity of corbels by analyzing a large number of test results [27], which became the basis for the design of the corbels in the GB50010-2010 code. The ACI318-19 code, EC1992-1-1 code and CSA A23.3-19 code suggest determining the ultimate bearing capacity of corbels by establishing a strut-and-tie model. The strut-and-tie model is a lower-bound analysis method of plastic mechanics [28], which abstracts the corbel into a discrete truss model consisting of a longitudinal reinforcement tie subjected to tensile stress, concrete struts subjected to compressive stress and nodes connecting the tie and struts. The actual shape of the concrete struts is that of bottle-shaped struts, but it is usually idealized as prismatic struts [29], as shown in Figure 10. The specific calculation formulas for the national codes are shown in Table 6.

Figure 9.

Triangle truss model.

Figure 10.

The strut-and-tie model of corbel.

Table 6.

Calculation models of shear bearing capacity for corbels in national codes.

4. The Calculation Model of Shear Bearing Capacity of Corbels Based on Softened Strut-and-Tie Model (MSSTM)

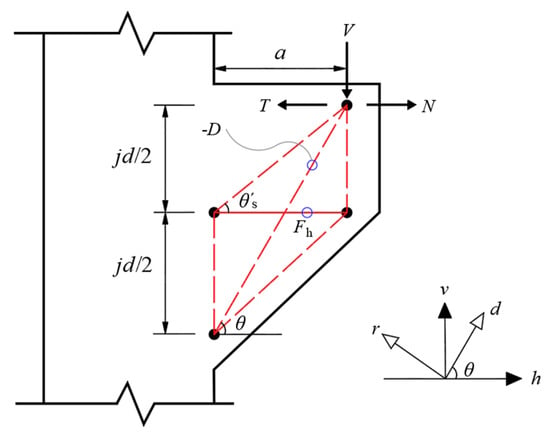

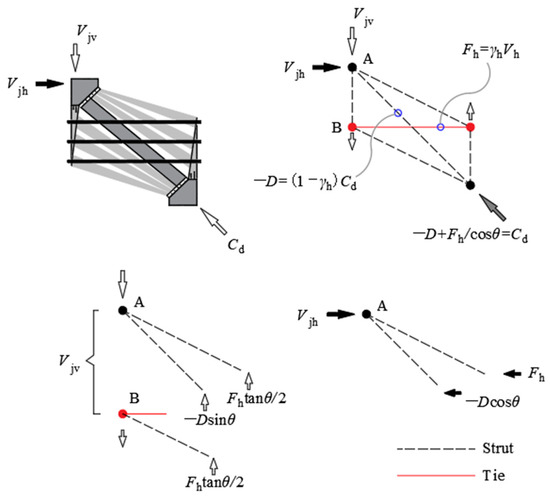

4.1. Shear Mechanism

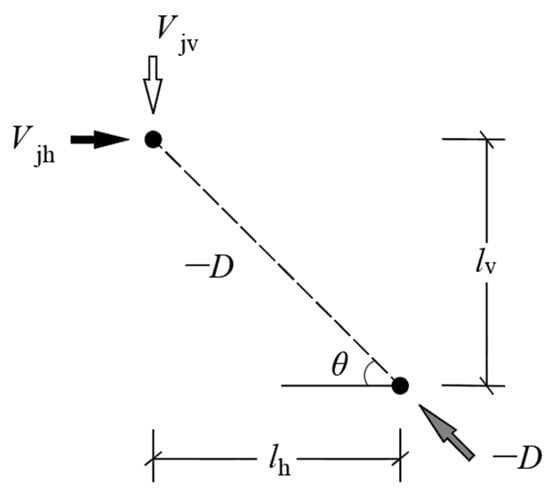

In the softened strut-and-tie model, there are usually three load paths to transmit diagonal compression, which are diagonal, horizontal and vertical mechanisms. The vertical stirrups in the corbels with small shear span ratio have a limited effect on the shear bearing capacity of the section. Therefore, the vertical mechanism is ignored in the corbel stress model. An incomplete, softened strut-and-tie model consisting of diagonal and horizontal mechanisms has been proposed for the corbel [30]. The diagonal mechanism is a steel-fiber concrete diagonal strut with an inclination angle of . The horizontal mechanism is composed of a horizontal tie and two gentle struts with the inclination angle of , as shown in Figure 11. The inclination angle is defined as , and the inclination angle is defined as , where is the lever arm. According to the linear bending theory, can be estimated as:

where is the effective height of the corbels; is the modular ratio of elasticity, that is, ; is the ratio of bending tensile reinforcement, is the cross-sectional area of longitudinal reinforcement; is the cross-sectional area of horizontal stirrup; and is the stirrup influence coefficient ( in this paper).

Figure 11.

The softened strut-and-tie model of corbel.

The effective area of the diagonal strut is defined as:

where is the width of the diagonal strut, and the definition of is different from the width of the diagonal strut in the strut-and-tie model.

The addition of steel fibers improves the tensile strength of concrete, making the mechanical performance of a steel-fiber-reinforced concrete corbel different from that of a reinforced concrete corbel. The horizontal tie is composed of two parts, the horizontal stirrups and the steel fibers, so [31]:

where , are the tension of the horizontal stirrup tie and the horizontal steel-fiber tie, respectively; , are the cross-sectional areas of horizontal stirrups and horizontal steel-fiber ties, respectively. is the effective coefficient of the horizontal stirrups’ shear resistance. According to the test results, the horizontal stirrups did not fully yield when the specimen was damaged. According to Hwang et al. [30], it is roughly assumed that 75% of horizontal stirrups are fully utilized, thus .

Steel fibers are randomly distributed in the concrete. Steel fibers are equivalent to an equal number of micro horizontal and vertical reinforcements [31]. Therefore, is calculated as follows:

where is the cross-sectional area of a single steel fiber; is the number of equivalent horizontal steel fibers, which is calculated by the following formula:

where is the steel fiber volume fraction; is the equivalent coefficient, and the approximate value of is 0.41 [32]. Therefore, .

4.2. Force Equilibrium

The internal force distribution mechanism of the softened strut-and-tie model is shown in Figure 12. According to the equilibrium condition, the resistances against the vertical shear and the horizontal shear are jointly borne by the diagonal and horizontal force transmission mechanisms, that is,

where is the compression force in the diagonal strut; is the tension force in the horizontal tie. The Equations (10) and (11) satisfy the relationship equation .

Figure 12.

Internal force distribution of the softened strut-and-tie model for corbel.

It is assumed that the ratios of the vertical shear allocated between the two mechanisms is [30]:

where and are, respectively, the ratios of the corbel shear resisted by the diagonal and horizontal mechanisms, which satisfy . The values of and are calculated by the following equations [33]:

where is the ratio of the horizontal tie to the horizontal shear without a vertical tie, and the value range of is . Two boundary conditions need to be met, namely, that the whole shear force is endured entirely by the horizontal mechanism when and that the whole shear force is endured entirely by the diagonal mechanism when .

The failure of the specimen can be considered as being when the maximum compressive forces in the nodal zone caused by the diagonal and flat struts in the resistance mechanisms reach the ultimate strength of the concrete; can be expressed as:

4.3. Constitutive Laws

According to Zhang and Hsu [34], the softening stress–strain relationship of cracked steel-fiber-reinforced concrete can be expressed as:

where is the principal stress of concrete in the d-direction; ζ is the softening coefficient of steel-fiber-reinforced concrete. Relevant studies have shown that the softening coefficients of ordinary-strength-grade steel-fiber-reinforced concrete and steel-fiber high-strength concrete are different [35,36], being valued according to either or , respectively, in Equation (18); is the compressive strength of the concrete cylinder; and are the principal compressive strain and principal tensile strain of concrete, respectively. Peak strain of steel-fiber-reinforced concrete can be calculated by the following equation:

When the following equations are met, it can be determined that the corbel has reached its ultimate shear bearing capacity:

It is assumed that the stress–strain relationship of steel bars satisfies the complete elastic–plastic model:

where is the elastic modulus of the steel bars; and are the tensile stress and strain of the horizontal stirrups, respectively; and are the yield stress and strain of the horizontal stirrups, respectively.

Then, Formula (6) can be changed to:

The stress–strain relationship of steel fibers can be expressed as:

where is the elastic modulus of steel fibers, the value of which is [31]; and are the tensile stress and strain of the steel fiber, respectively.

Formula (7) can be changed to:

The steel fibers are mainly pulled out rather than broken when the specimens are destroyed, owing to fact that the tensile strength of the steel fibers is relatively high. The shear resistance of the steel fibers is limited by the bonding strength of steel-fiber concrete. Therefore, needs to meet the following conditions:

where is the maximum bond strength between steel fiber and concrete, and that [37], and is the tensile strength of steel-fiber concrete; is the influencing factor for different types of steel fibers, with values of 0.5, 0.75 and 1.0 for long straight, wavy and curved steel fibers, respectively [38] (the value for the experiment is 1.0); is the surface area of the steel fiber, and , in which is the diameter of steel fiber and is the effective anchorage length of steel fiber, taken as , and is the length of steel fiber.

Formula (26) can be changed to:

4.4. Strain Compatibility

The analysis of two-dimensional membrane elements should strictly satisfy the Mohr circle strain compatibility condition, namely:

where and are the principal compressive strain and principal tensile strain of steel-fiber-reinforced concrete, respectively; and are the average strains in the horizontal and vertical directions of steel-fiber-reinforced concrete, respectively.

Then, is solved by combining Equations (23) and (25), satisfying [39], and thus obtaining:

Since there is no detailed description of the vertical stirrup in the corbel, there is no vertical tie that limits the development of horizontal cracks. The value of is 0.002 for the corbel with and it is 0 for the corbel with [30].

4.5. Solution Process

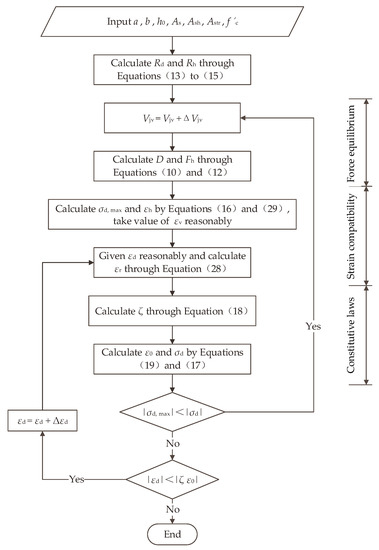

The shear bearing capacity of corbels is solved by the equilibrium equations, constitutive laws and compatibility equation above, and the solution process is shown in Figure 13. The detailed calculation steps are as follows:

Figure 13.

Solution flowchart.

- (1)

- Input the basic parameters of the corbel: , , , , , , , etc.;

- (2)

- and are calculated through Equations (13) to (15);

- (3)

- Select the initial , and solve D and using Equations (10) and (12);

- (4)

- Calculate and through Equations (16) and (29), and take values of reasonably based on the size of the corbels;

- (5)

- Given reasonably, is solved using Equation (28), and then the softening coefficient ζ is solved using Equation (18);

- (6)

- is calculated using Formula (19), and then the value corresponding to a given is calculated by the steel bar constitutive Equation (17);

- (7)

- Compare the values of and , and if , repeat steps (3) to (6) until ;

- (8)

- After satisfying step (7), compare and . If , repeat steps (5) to (7) until , at which point the solving is completed. At this point, the maximum stress in the node zone has reached the strength limit of the concrete, and the is the bearing capacity value of the corbel.

5. Simplification of the Calculation Model for the Shear Bearing Capacity of the Corbels (SMSSTM)

Due to the iterative process of the softened strut-and-tie model for a steel-fiber-reinforced concrete corbel being complicated, the model was simplified to fully describe the shear mechanism of the corbel while reducing the variables.

Hwang et al. [30] pointed out in a study on the shear strength analysis of corbels that there is a bilinear relationship between the shear strength of corbels and horizontal reinforcement. The compressive strength of concrete seems to set an upper limit value for the amount of horizontal reinforcement. Below this value, the compressive strength of concrete increases with the increase in the horizontal reinforcement. At this equilibrium limit, the shear strength of the corbel will also reach its extreme value when the horizontal reinforcement yields. When the amount of horizontal reinforcement exceeds the limit value, the horizontal reinforcement exceeding the equilibrium amount only plays a role in delaying the softening effect of concrete, and it has little effect on preventing the reduction of concrete compressive strength, so its beneficial effect on shear strength can be ignored. The linear relationship between shear strength and reinforcement shows that the shear strength prediction of corbels that do not reach the equilibrium reinforcement can be obtained by linear interpolation.

The beneficial effect of horizontal ties in improving the shear strength of corbels can be understood as follows: when the corbels are reinforced with horizontal stirrups, diagonal compression will be borne by additional load paths in addition to the diagonal struts, which will activate more concrete to participate in shear, thereby improving the shear strength of the corbels. The beneficial effect of horizontal ties on shear strength can be expressed by the index K [40]:

Correspondingly, the nominal diagonal compressive strength of the corbel can be expressed as [41]:

where is the nominal diagonal compressive strength of corbels; is the strut-and-tie index.

5.1. Approximation of Softening Effect

The softening coefficient of concrete is directly related to the value of the principal tensile strain . Vecchio et al. [42] suggested that the value of should be limited to the strain level at which the reinforcement yields through a crack. In order to simplify the calculation, the values of and are both 0.002, and can be approximately taken as −0.001 [24], so the value of calculated using Equation (28) is 0.005 (0.002 + 0.002 + 0.001). Therefore, the softening coefficient can be expressed as:

5.2. Strut-and-Tie Index K

For discontinuous region components subjected to diagonal compression, there are usually four possible combinations of resistance mechanisms, namely, the diagonal mechanism, the diagonal plus horizontal mechanisms, the diagonal plus vertical mechanisms, and complete mechanisms. For corbels, only two incomplete load-bearing mechanisms, diagonal mechanism and diagonal plus horizontal mechanisms, could be developed in shear analysis. The determination process of the strut-and-tie index K for each combination is as follows.

If there is no horizontal tie reinforcement in the corbel, the diagonal compression is only provided by the diagonal mechanism, as shown in Figure 14. Then, through Equation (30), we can obtain:

where is the diagonal strut index.

Figure 14.

Diagonal mechanism.

If the flow of forces at nodes is realized by the strut-and-tie model composed of the diagonal and horizontal mechanisms shown in Figure 12, more flat struts will be formed, and the internal force flows deviate from the direction of [24]. When there are sufficient horizontal reinforcements, the concrete strut would reach its compressive strength when the horizontal tie is maintained within the elastic range, and the index at this time is:

Formula (34) above can be further simplified to:

where is the horizontal tie index with sufficient horizontal reinforcement. At this time, the balanced amount of the horizontal tie force is:

In the case of insufficient reinforcement, the horizontal tie index after linear interpolation is approximately:

where is the yield strength of the horizontal tie; and are the yield stresses of the horizontal stirrup tie and the horizontal steel-fiber tie, respectively; is the yield strain of the horizontal tie.

Therefore, for corbels with sufficient horizontal reinforcement, the value of the strut-and-tie index is:

Similarly, in the case of insufficient horizontal reinforcement, the value of can be estimated approximately as:

6. Example Verification

The test results for the six steel-fiber-reinforced high-strength concrete corbels in this paper were calculated by using the abovementioned national codes and the established calculation model for the shear bearing capacity of corbels, and the test values and calculated values were compared and analyzed. The results are shown in Table 7. From the table, we can see that:

Table 7.

Comparison of experimental results and calculation results for shear bearing capacity.

- (1)

- The mean values of the ratios of the test values to the calculated values of the GB50010-2010 code, the ACI318-19 code, the EN 1992-1-1 code and the CSA A23.3-19 code were 1.564, 1.373, 1.533 and 1.153, respectively, and the variances were 0.131, 0.025, 0.046 and 0.011, respectively. It can be seen that all the calculation results were lower than the experimental values, and the results were conservative, which indicates that the various national codes are applicable to the calculation of the shear capacity of steel-fiber-reinforced concrete corbels. However, the calculation results of the GB50010-2010 code were relatively discrete, while the variances of the calculation results of the ACI318-19 code, the EN 1992-1-1 code and the CSA A23.3-19 code based on the strut-and-tie model were relatively small.

- (2)

- The mean value of the ratio of the test value to the calculated value of the established shear bearing capacity calculation model was 0.965, and the variance was 0.016. The mean value of the ratio between the experimental value and calculation value of the simplified model was 1.014, and the variance was 0.008. The calculated results were in good agreement with the experimental values. The established model for calculating the shear bearing capacity of the corbel has a clear mechanical concept, which can be used for the calculation and prediction of the shear bearing capacity of steel-fiber-reinforced high-strength concrete corbels.

7. Conclusions

- The experimental studies showed that the steel-fiber-reinforced high-strength concrete corbels with shear span ratio from 0.2 to 0.5 mainly exhibit two typical failure modes: shear failure and diagonal compression failure. With an increase in shear span ratio, the bearing capacity of the corbel specimens decreases gradually, and the failure mode of specimens transitions from shear failure to diagonal compression failure. At the same time, with the same shear span ratio and the addition of steel fibers, the bearing capacity of the corbels increases with the increase in the steel fiber volume fraction.

- Steel fiber can improve the ductility of reinforced concrete corbels, but it has little effect on the failure mode of the diagonal section. The addition of steel fiber cannot change the characteristic that the normal section of the corbel does not comply with the plane section assumption.

- The shear mechanism of steel-fiber-reinforced high-strength concrete corbels can be described by the softened strut-and-tie model composed of diagonal struts and horizontal resistance mechanisms. In the analysis of shear capacity, randomly distributed steel fibers in concrete can be equivalent to an equal number of horizontal and vertical reinforcements, making the contribution of steel fiber dimensions to the bearing capacity of corbels more clear.

- The shear bearing capacity of steel-fiber-reinforced high-strength concrete corbels was calculated by using the national codes and the established corbel shear bearing capacity calculation model in this paper. The results showed that the calculation results of the national codes are lower than the experimental values, and the results are conservative. The national codes can be used for the shear bearing capacity calculation of steel-fiber-reinforced high-strength concrete corbels. However, the calculation results of the Chinese code (GB50010-2010) were more discrete, while the variances of the calculation results of the American code (ACI318-19), European code (EN 1992-1-1) and Canadian code (CSA A23.3-19), which are based on the strut-and-tie model, were relatively small. The theoretical calculation of the shear capacity calculation model for the corbels established in this paper was close to the experimental results. Moreover, the model has a clear mechanical concept considering the tensile properties of steel-fiber-reinforced concrete and the influence of horizontal stirrups, which can reasonably reflect the stress mechanism of the corbels and provide a theoretical reference for improving the design of steel-fiber-reinforced high-strength concrete corbels.

Author Contributions

Conceptualization, W.X. and A.-J.C.; methodology, S.-S.L. and D.P.; test, S.-S.L. and F.-J.Z.; software, S.-S.L. and D.P.; validation, D.P. and S.-S.L.; formal analysis, S.-S.L. and D.P.; investigation, D.P. and H.-M.L.; resources, H.W. and Y.-J.X.; data curation, D.P.; writing—original draft preparation, D.P. and S.-S.L.; writing—review and editing, D.P. and S.-S.L.; visualization, D.P.; supervision, W.X. and A.-J.C.; project administration, H.-M.L.; funding acquisition, W.X. and A.-J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (No. U1404526, No. 52179133).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Nomenclature

| shear-span ratio, dimensionless | ratio of the horizontal tie to the horizontal shear without a vertical tie, dimensionless | ||

| longitudinal reinforcement ratio, dimensionless | maximum compressive forces in the nodal zone | ||

| stirrup ratio, dimensionless | principal stress of concrete in the d-direction | ||

| steel fiber volume fraction, dimensionless | ζ | softening coefficient of steel-fiber-reinforced concrete | |

| cube compressive strength of concrete, MPa | principal compressive strain of concrete | ||

| prism compressive strength of concrete, MPa | principal tensile strain of concrete | ||

| tensile strength of concrete, MPa | peak strain of steel-fiber-reinforced concrete | ||

| elastic modulus of concrete, MPa | tensile stress of the horizontal stirrups, MPa | ||

| yield strength of reinforcement, MPa | tensile strain of the horizontal stirrups, dimensionless | ||

| elastic modulus of reinforcement, MPa | yield stress of horizontal stirrups, MPa | ||

| ultimate strength of reinforcement, MPa | yield strain of horizontal stirrups, dimensionless | ||

| yield strain of reinforcement, dimensionless | tensile stress of the steel fiber, MPa | ||

| cracking load of the normal section, kN | tensile stress of the horizontal steel fiber, MPa | ||

| cracking load of the diagonal section, kN | elastic modulus of steel fibers, MPa | ||

| ultimate load, kN | tensile strain of the steel fiber, dimensionless | ||

| inclination angle of two gentle struts in SSTM | tensile strain of horizontal steel fiber, dimensionless | ||

| lever arm, mm | maximum bond strength between steel fiber and concrete, MPa | ||

| modular ratio of elasticity, dimensionless | tensile strength of steel-fiber concrete, MPa | ||

| ratio of bending tensile reinforcement, dimensionless | influencing factor for different types of steel fibers, dimensionless | ||

| cross-sectional area of longitudinal reinforcement, mm² | surface area of the steel fiber, mm² | ||

| cross-sectional area of horizontal stirrup, mm² | diameter of steel fiber, mm | ||

| stirrup influence coefficient, dimensionless | effective anchorage length of steel fiber, mm | ||

| effective area of the diagonal strut, mm² | length of steel fiber, mm | ||

| width of the diagonal strut in SSTM, mm | average strain in the horizontal direction of steel-fiber-reinforced concrete, dimensionless | ||

| tension of the horizontal stirrup tie, kN | average strain in the vertical direction of steel-fiber-reinforced concrete, dimensionless | ||

| tension of the horizontal steel-fiber tie, kN | strut-and-tie index, dimensionless | ||

| cross-sectional area of horizontal steel-fiber tie, mm² | nominal diagonal compressive strength of corbels, kN | ||

| cross-sectional area of a single steel fiber, mm² | diagonal compression, kN | ||

| the number of equivalent horizontal steel fibers | diagonal strut index, dimensionless | ||

| effective coefficient of horizontal stirrup shear resistance, dimensionless | horizontal tie index with sufficient horizontal reinforcement, dimensionless | ||

| equivalent coefficient for steel fiber, dimensionless | balanced amount of the horizontal tie force, kN | ||

| resistance against the vertical shear, kN | horizontal tie index with insufficient horizontal reinforcement, dimensionless | ||

| resistance against the horizontal shear, kN | yield strength of the horizontal tie, kN | ||

| compression force in the diagonal strut, kN | yield stress of horizontal steel-fiber tie, MPa | ||

| tension force in the horizontal tie, kN | yield strain of horizontal tie, dimensionless | ||

| ratio of the corbel shear resisted by the diagonal mechanism, dimensionless | strut-and-tie index with sufficient horizontal reinforcement, dimensionless | ||

| ratio of the corbel shear resisted by the horizontal mechanism, dimensionless |

References

- Wang, Y.W.; Wang, M.T. An Experimental investigation of the Strength of Bracket Under the Mutual Actions of Vertical Loads and Horizontal Thrusts. J. Tsinghua Univ. (Sci. Technol.) 1975, 4, 93–118. [Google Scholar]

- Xu, L. Testing Research on Mechanic Properties of Steel Fiber Reinforced Concrete Corbel. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2002. [Google Scholar]

- Wilson, H.R.; Yousefpour, H. Investigation of Corbels Designed According to Strut-and-Tie and Empirical Methods. ACI Struct. J. 2018, 115, 813–824. [Google Scholar] [CrossRef]

- Fattuhi, N.I. Strength of SFRC corbels subjected to vertical load. J. Struct. Eng. 1990, 116, 701–718. [Google Scholar] [CrossRef]

- Fattuhi, N.I. Strength of FRC corbels in flexure. J. Struct. Eng. 1994, 120, 360–377. [Google Scholar] [CrossRef]

- Campione, G.; La Mendola, L.; Mangiavillano, M.L. Steel fiber-reinforced concrete corbels: Experimental behavior and shear strength prediction. ACI Struct. J. 2007, 104, 570–579. [Google Scholar]

- Yang, J.-M.; Lee, J.-H.; Yoon, Y.-S.; Cook, W.D.; Mitchell, D. Influence of steel fibers and headed bars on the serviceability of high-strength concrete corbels. J. Struct. Eng. 2012, 138, 123–129. [Google Scholar] [CrossRef]

- Gao, J.F.; Qiu, H.X.; Jiang, Y.S. Investigation on Design Method of the Steel-Fiber High-Strength Concrete Bracket. J. Southeast Univ. (Nat. Sci. Ed.) 1993, 23, 41–46. [Google Scholar]

- Gao, D.Y.; Zhao, J.; Zhu, H.T. Experimental study on shear capacity of reinforced concrete corbel with steel fiber. J. Build. Struct. 2006, 27, 100–106. [Google Scholar]

- Kurtoglu, A.E.; Gulsan, M.E.; Abdi, H.A.; Kamil, M.A.; Cevik, A. Fiber reinforced concrete corbels: Modeling shear strength via symbolic regression. Comp. Concr. 2017, 20, 1–10. [Google Scholar]

- Huang, Y.; Yin, W.M.; Yi, W.J. Study on Design Modification Factor for Shear Capacity of Reinforced Concrete Corbels. J. Hunan Univ. (Nat. Sci.) 2021, 48, 61–70. [Google Scholar]

- GB50010-2010; Code for Design of Concrete Structures. China Building Industry Press: Beijing, China, 2010.

- ACI Committee 318; Building Code Requirement for Structure Concrete (ACI318-19) and Commentary (ACI318R-19). American Concrete Institute: Farmington Hills, MI, USA, 2019.

- BS EN 1992–1–1:2004; Eurocode 2: Design of Concrete Structures. British Standards Institution: Brussels, Belgium, 2004.

- CSA A23.3-19; Design of Concrete Structures. Canadian Standards Association: Mississauga, ON, Canada, 2019.

- Zhou, L.Y.; Liu, Z.; He, Z.Q. Elastic-to-Plastic Strut-and-Tie Model for Deep Beams. J. Bridge Eng. 2018, 23, 04018007. [Google Scholar] [CrossRef]

- Chen, H.; Yi, W.J. Evaluation and modification of strut-and-tie model for simply-supported and continuous deep reinforced concrete beams without stirrups. J. Build. Struct. 2019, 40, 154–161. [Google Scholar]

- Zhou, M.; Zhong, J.T.; Wang, L.; Chen, H.T. Application of Evaluation System for Strut-and-Tie Models of Reinforced Concrete Structures. ACI Struct. J. 2021, 118, 17–30. [Google Scholar]

- Chetchotisak, P.; Teerawong, J.; Yindeesuk, S. Modified interactive strut-and-tie modeling of reinforced concrete deep beams and corbels. Structures 2022, 45, 284–298. [Google Scholar] [CrossRef]

- Yi, W.J.; Li, Y.; Chen, H.; Ma, Z.J.; Zhou, K.J.; Huang, Y.; Zhou, Y. Shear strength evaluation of RC D-Regions based on Single-Panel Strut-and-Tie model. Eng. Struct. 2022, 265, 114500. [Google Scholar] [CrossRef]

- Hwang, S.; Lee, H. Analytical model for predicting shear strengths of interior reinforced concrete beam-column joints for seismic resistance. ACI Struct. J. 2000, 97, 35–44. [Google Scholar]

- Hwang, S.; Lu, W.; Lee, H. Shear strength prediction for deep beams. ACI Struct. J. 2000, 97, 367–376. [Google Scholar]

- Hwang, S.J.; Fang, W.H.; Lee, H.J.; Yu, H.W. Analytical model for predicting shear strength of squat walls. J. Struct. Eng. 2001, 127, 43–50. [Google Scholar] [CrossRef]

- Hwang, S.J.; Lee, H.J. Strength prediction for discontinuity regions by softened strut-and-tie model. J. Struct. Eng. 2002, 128, 1519–1526. [Google Scholar] [CrossRef]

- Khosravikia, F.; Kim, H.S.; Yi, Y.; Wilson, H.; Yousefpour, H.; Hrynyk, T.; Bayrak, O. Experimental and numerical assessment of corbels designed based on strut-and-tie provisions. J. Struct. Eng. 2018, 144, 04018138. [Google Scholar] [CrossRef]

- Canha, R.M.F.; Kuchma, D.A.; El Debs, M.K.; de Souza, R.A. Numerical analysis of reinforced high strength concrete corbels. Eng. Struct. 2014, 74, 130–144. [Google Scholar] [CrossRef]

- Ding, B.Y. Calculation of Reinforced Concrete Corbels. Ind. Constr. 1974, 2, 31–36+51. [Google Scholar]

- He, Z.Q.; Liu, Z.; Ma, Z.J. Investigation of Load-Transfer Mechanisms in Deep Beams and Corbels. ACI Struct. J. 2012, 109, 467–476. [Google Scholar]

- Shen, Y. The Research of Shear Bearing Capacity of Reinforced Concrete Deep Beam Based on the Softened Strut-and-Tie Model. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

- Hwang, S.J.; Lu, W.Y.; Lee, H.J. Shear strength prediction for reinforced concrete corbels. ACI Struct. J. 2000, 97, 543–552. [Google Scholar]

- Gao, D.Y.; Shi, K.; Zhao, S.B. Calculation method for shear capacity of steel fiber reinforced concrete beam-column joints based on softened strut-and-tie model. China Civ. Eng. J. 2014, 47, 101–109. [Google Scholar]

- Romualdi, J.P.; Mandel, J.A. Tensile strength of concrete affected by uniformly distributed and closely spaced short lengths of wire reinforcement. ACI Mater. J. 1964, 61, 657–672. [Google Scholar]

- Schấfer, K. Strut-and-Tie Models for the Design of Structural Concrete. National Cheng Kung University: Tainan, Taiwan, 1996. [Google Scholar]

- Zhang, L.X.B.; Hsu, T.T.C. Behavior and analysis of 100 MPa concrete membrane elements. J. Struct. Div. 1998, 124, 24–34. [Google Scholar] [CrossRef]

- Zhu, M.Q.; Fang, Z.; Chen, H.Y. Torsional behavior of reinforced SFHSC thin-walled box girder. J. Build. Struct. 2005, 26, 108–113. [Google Scholar]

- Tang, X.R.; Jiang, Y.S.; Ding, D.J. Application of the Theory of Softened Truss to Low-Rise Steel Fiber High Strength Concrete Shear Walls. J. Build. Struct. 1993, 14, 2–11. [Google Scholar]

- Foster, S.J.; Voo, J. Variable Engagement Model for Fibre Reinforced Concrete in Tension; University of New South Wales: Sydney, Australia, 2003. [Google Scholar]

- Khuntia, M.; Stojadinovic, B.; Goel, S.C. Shear strength of normal and high-strength fiber reinforced concrete beams without stirrups. ACI Struct. J. 1999, 96, 282–289. [Google Scholar]

- Cui, L.H. Behavior and Bearing Capacity of Steel Fiber Reinforced High-Strength Concrete Shear Wall. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2017. [Google Scholar]

- Wu, T.; Xing, G.H.; Liu, B.Q.; Huang, H. Shear Strength of RC Frame Joints Connecting Beams with Different Depths Using Softened Strut-and-Tie Model. Eng. Mech. 2010, 27, 201–208. [Google Scholar]

- Zhang, L.; Jirsa, J.O. A Study of Shear Behavior of Reinforced Concrete Beam-Column Joints; Phil M. Ferguson Structural Engineering Laboratory, University of Texas: Austin, TX, USA, 1982. [Google Scholar]

- Vecchio, F.J.; Collins, M.P. Compression response of cracked reinforced concrete. J. Struct. Div. 1993, 119, 3590–3610. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).