Novel 3D-Printed Biocarriers from Aluminosilicate Materials

Abstract

1. Introduction

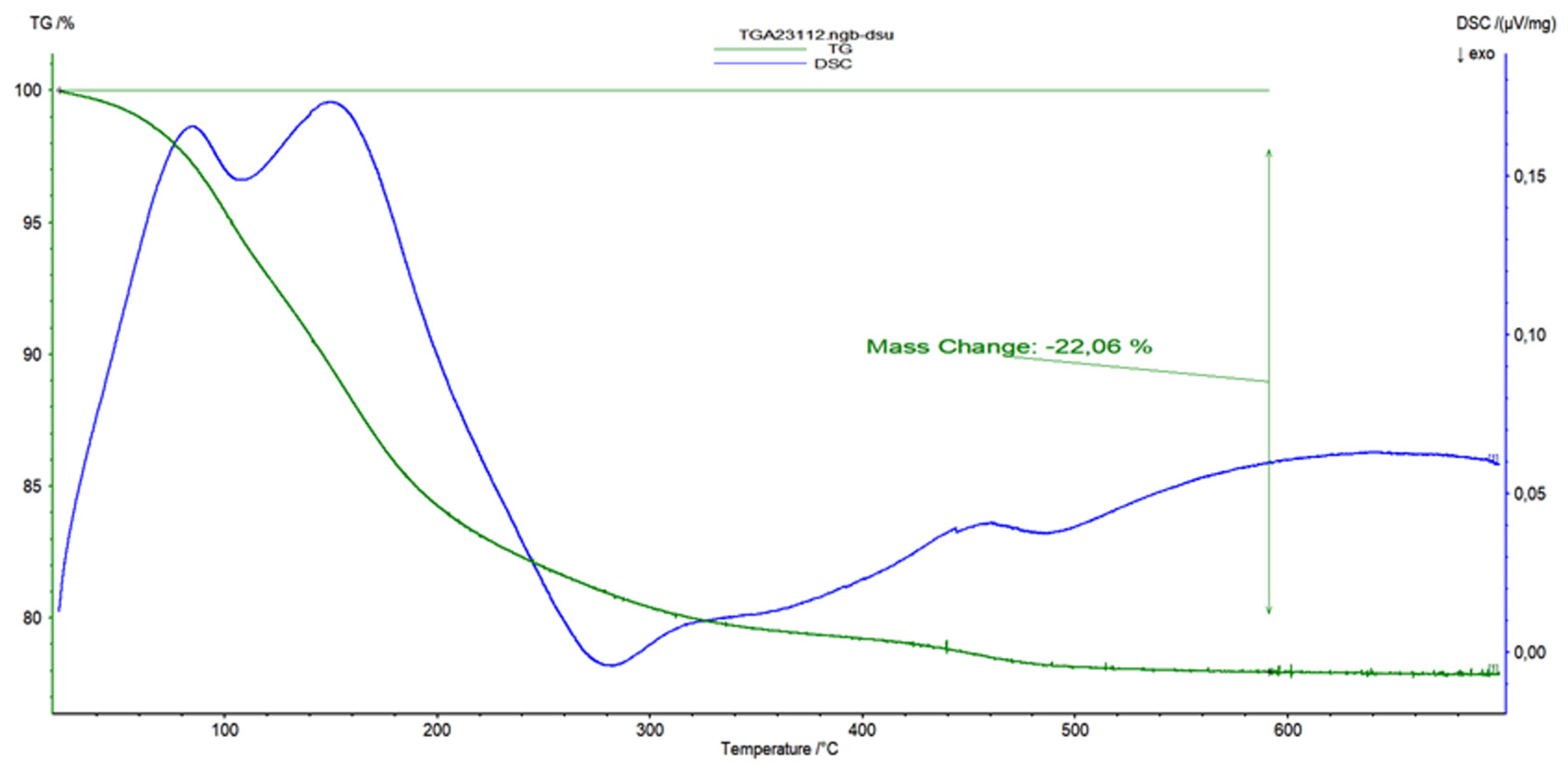

2. Materials and Methods

3. Results

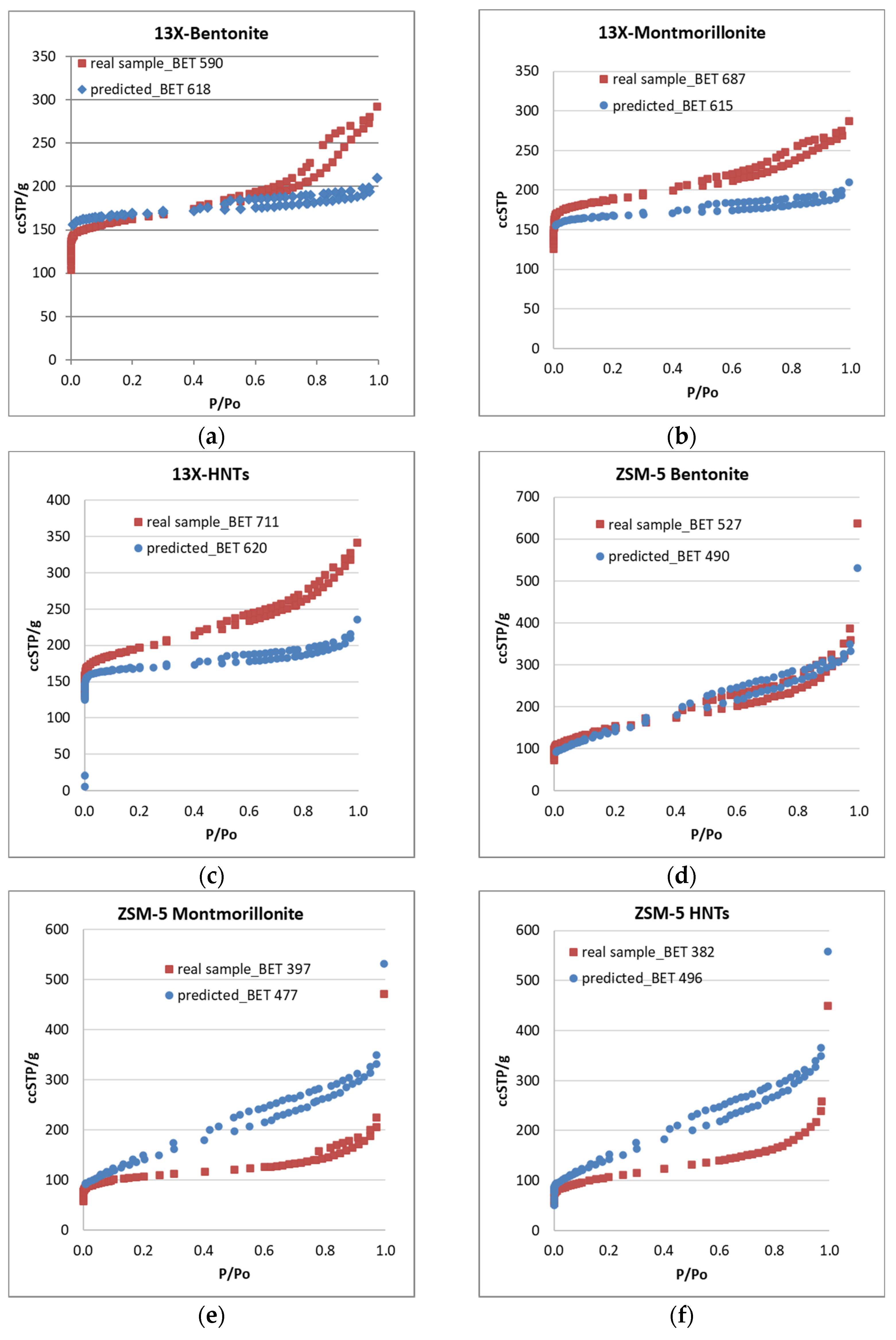

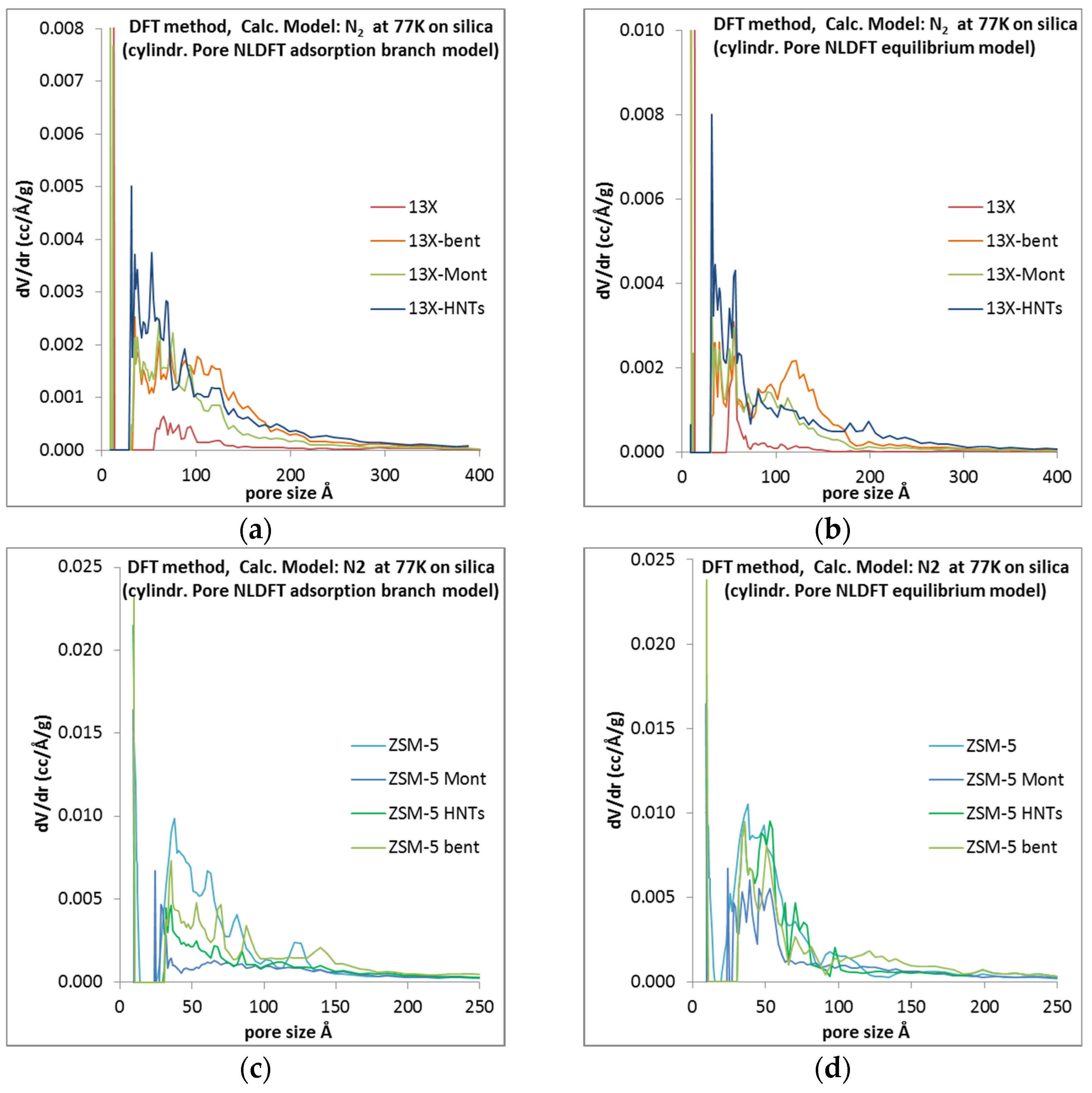

3.1. Pore Structural and Textural Features of the Novel 3D-Printed Biocarriers

3.2. Density Analysis of 3D-Printed Biocarriers

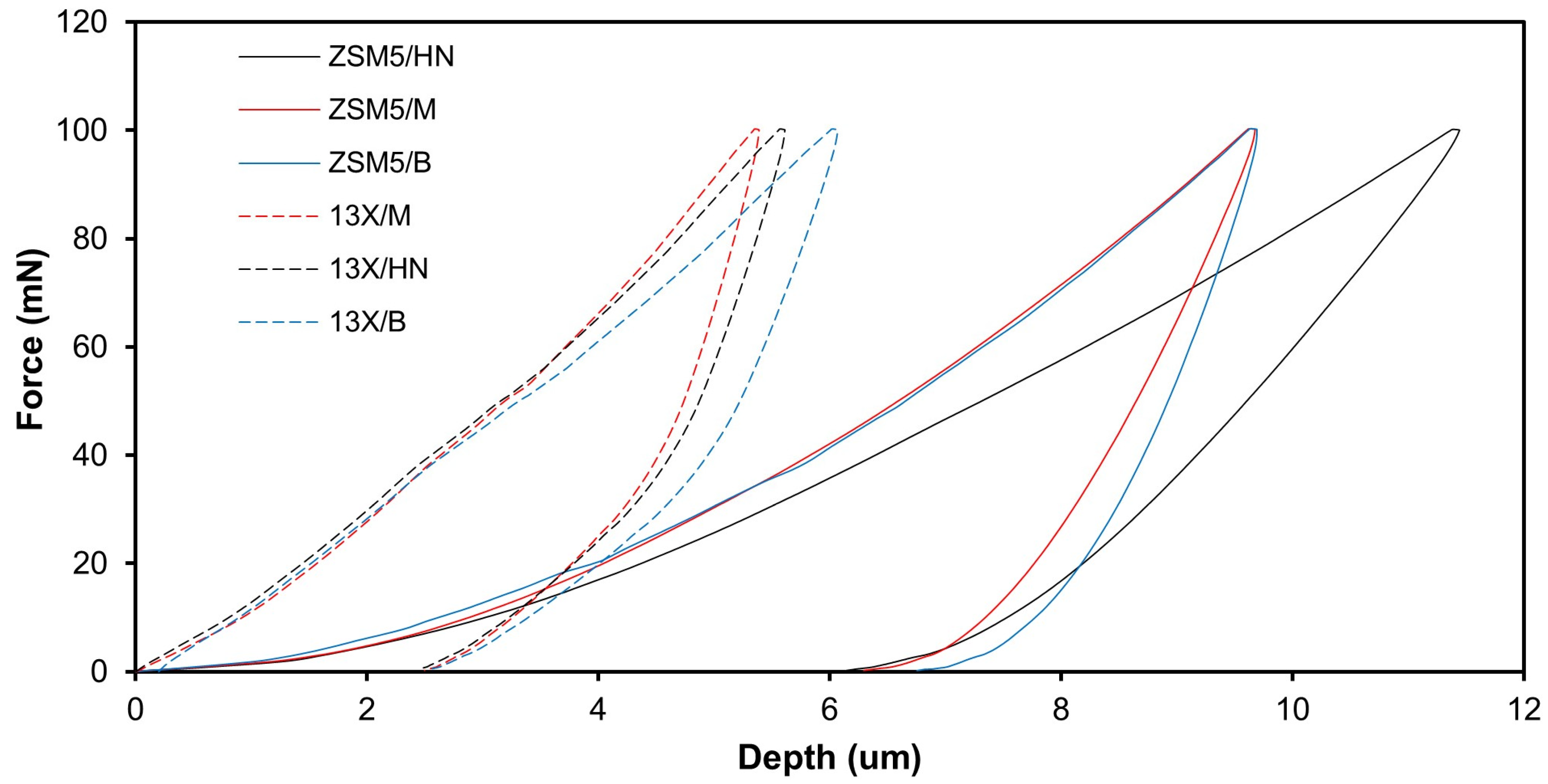

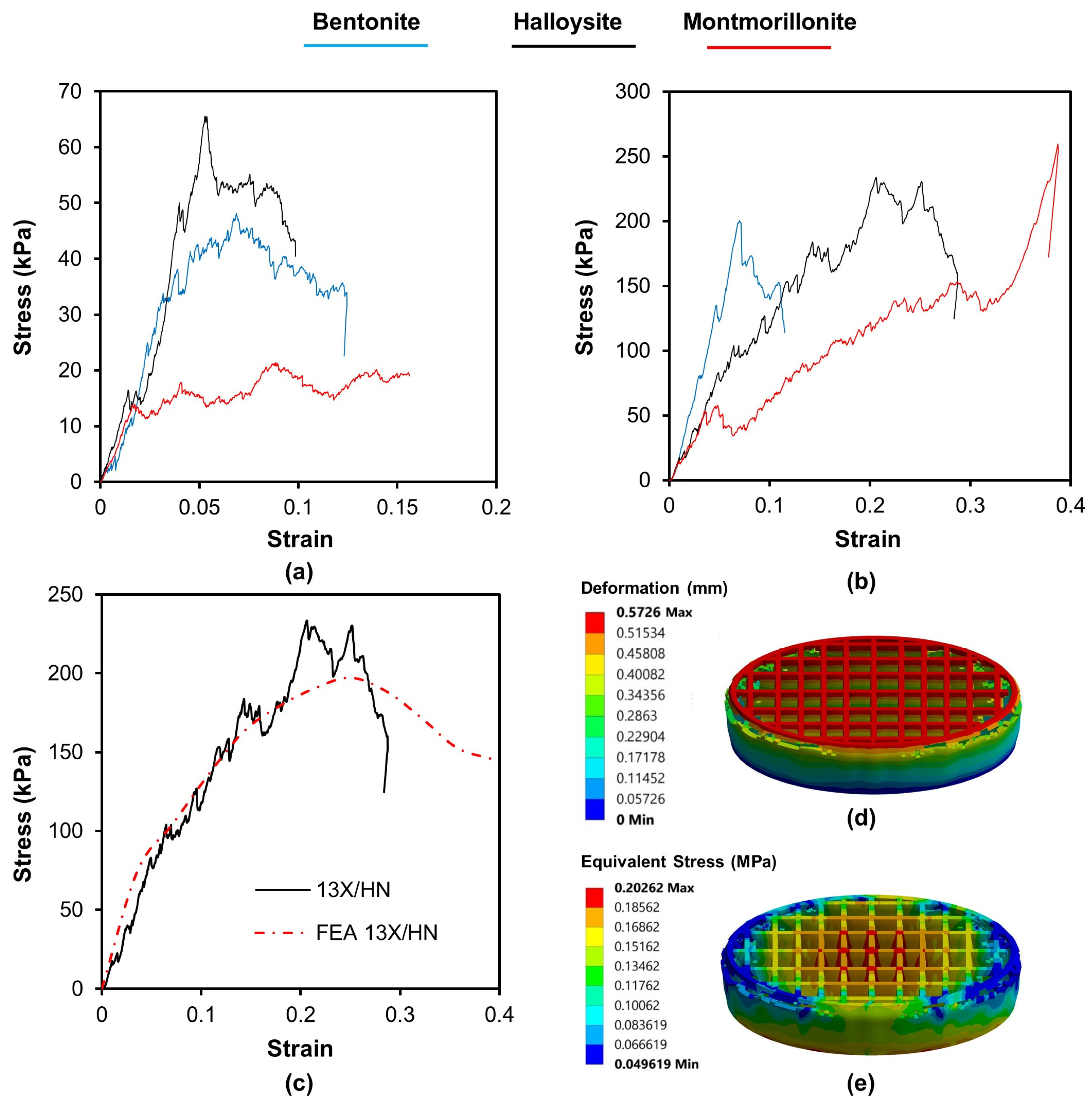

3.3. Mechanical Properties Analysis

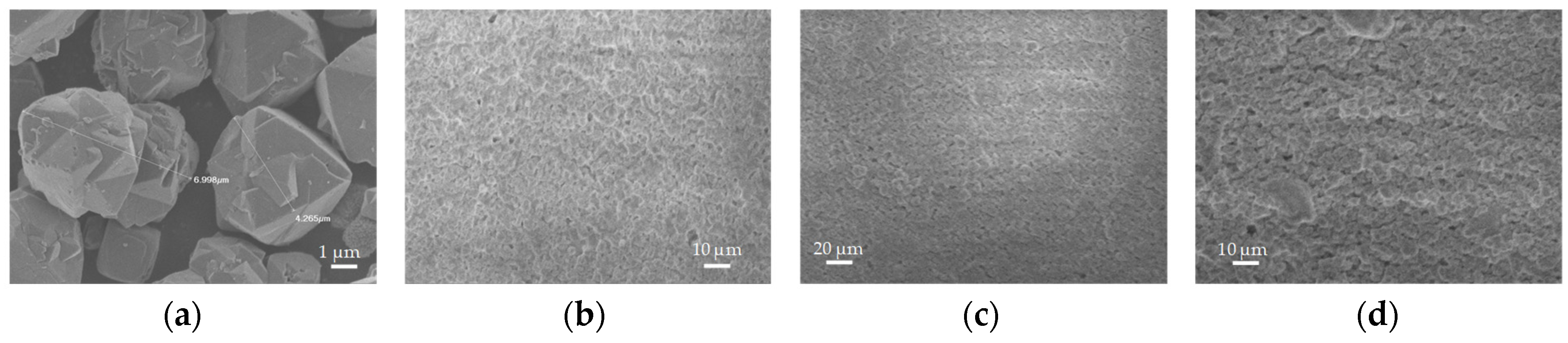

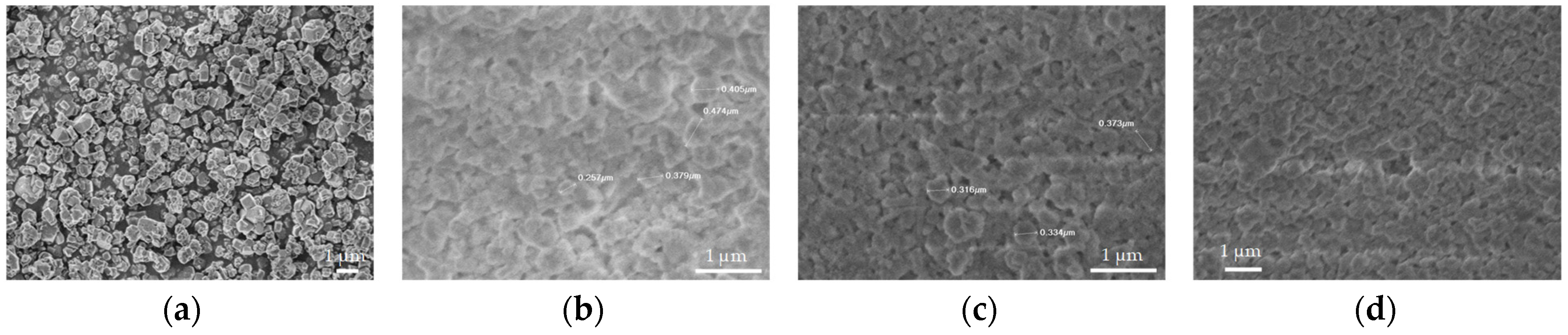

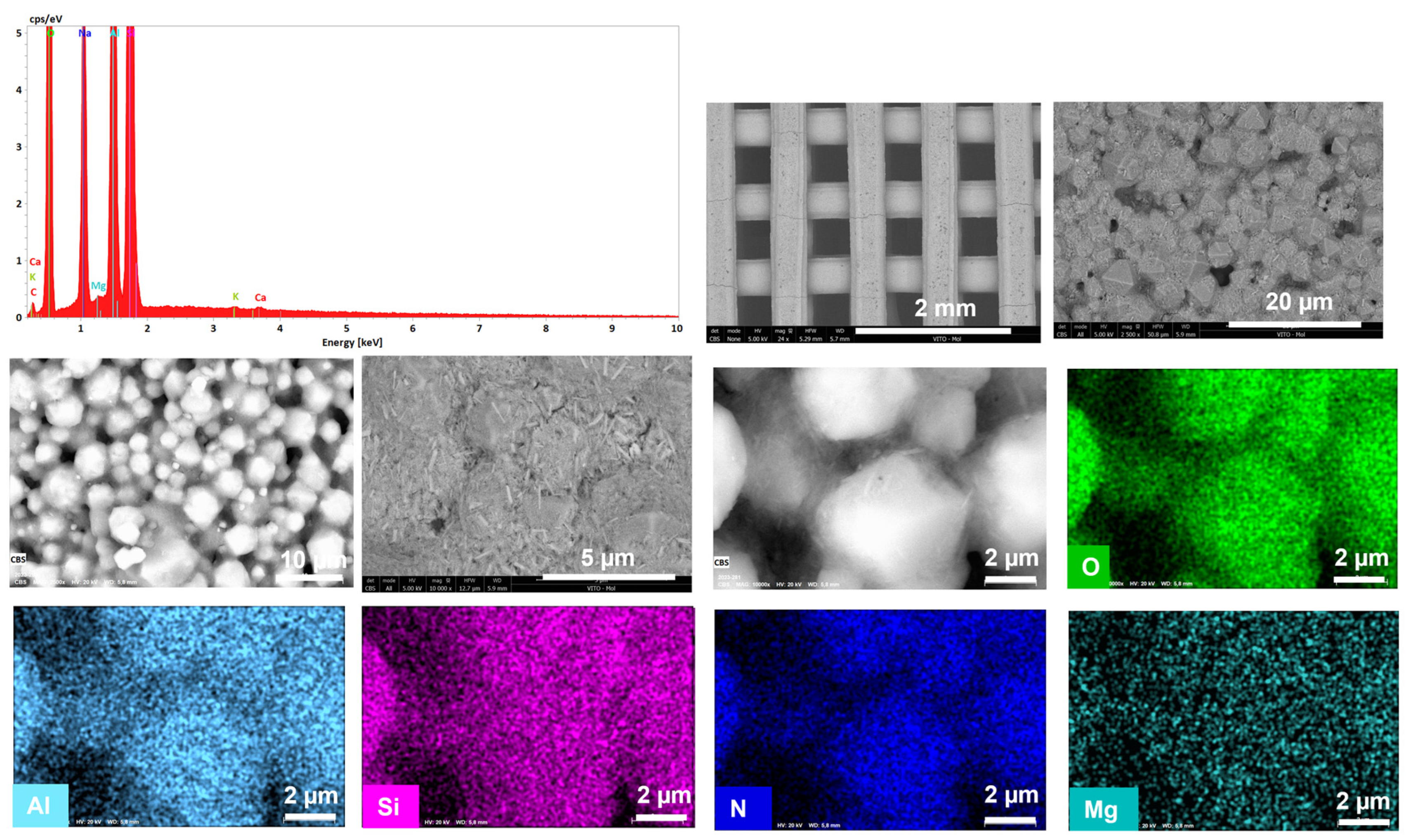

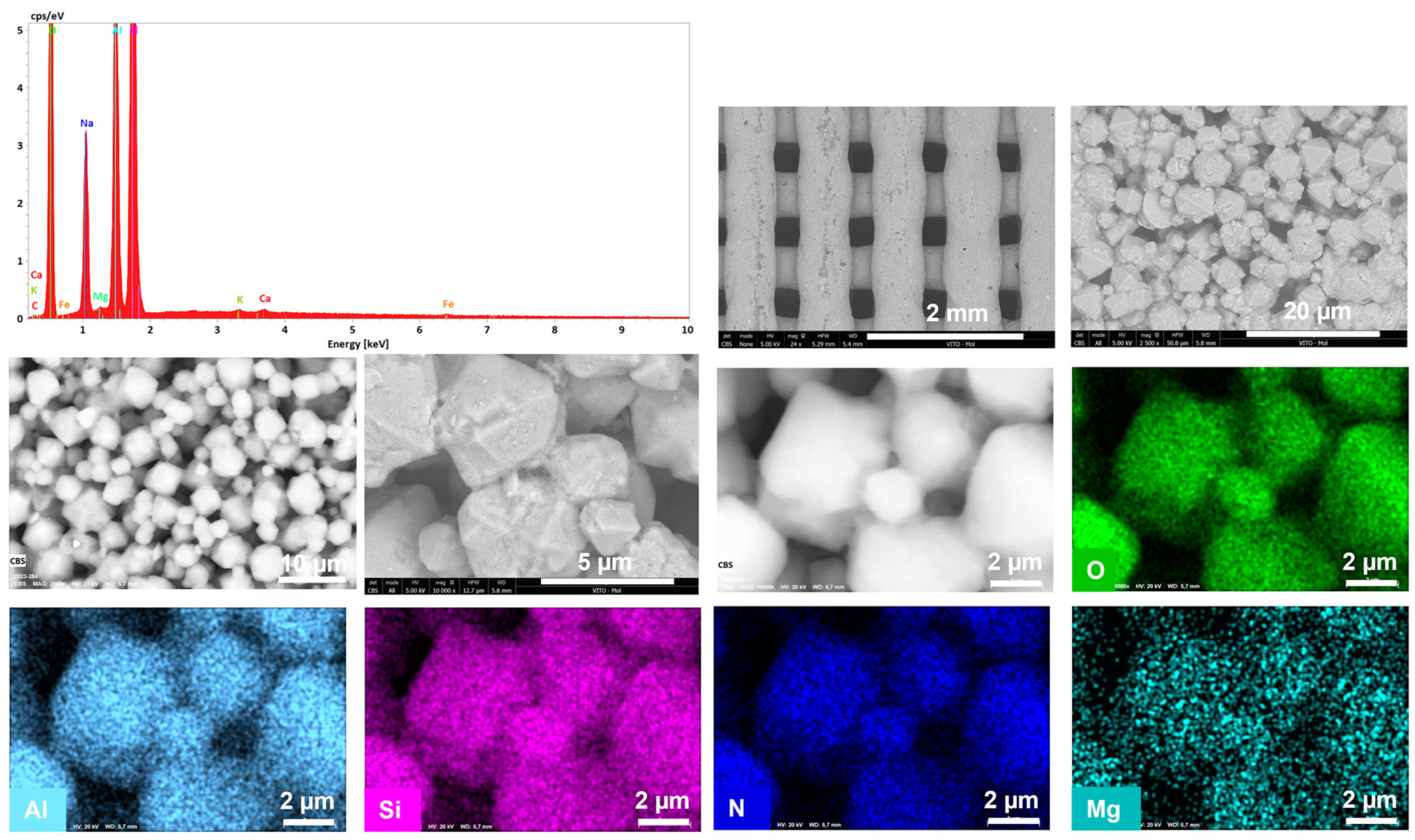

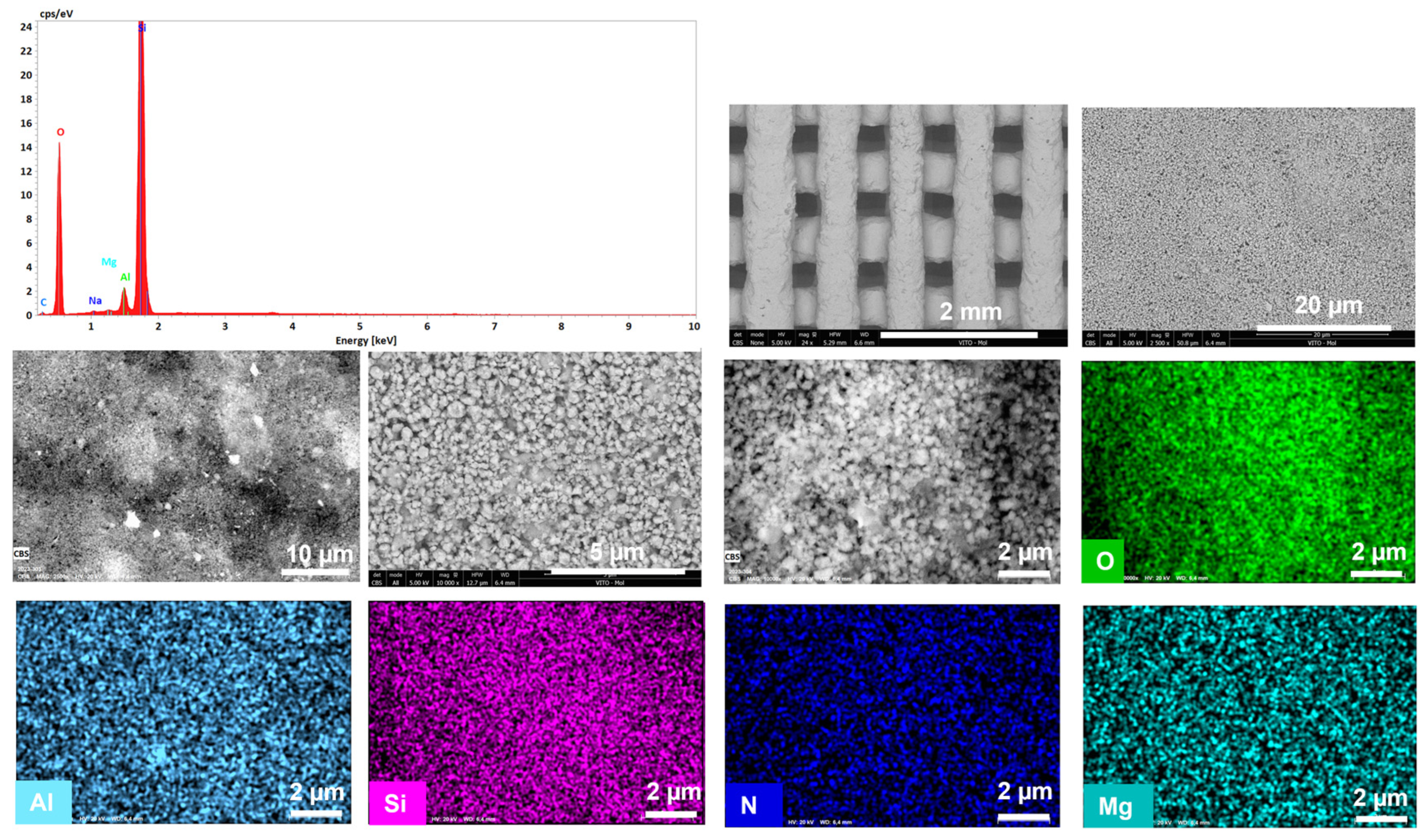

3.4. Scanning Electron Microscopy (SEM) Analysis of the Novel 3D-Printed Biocarriers

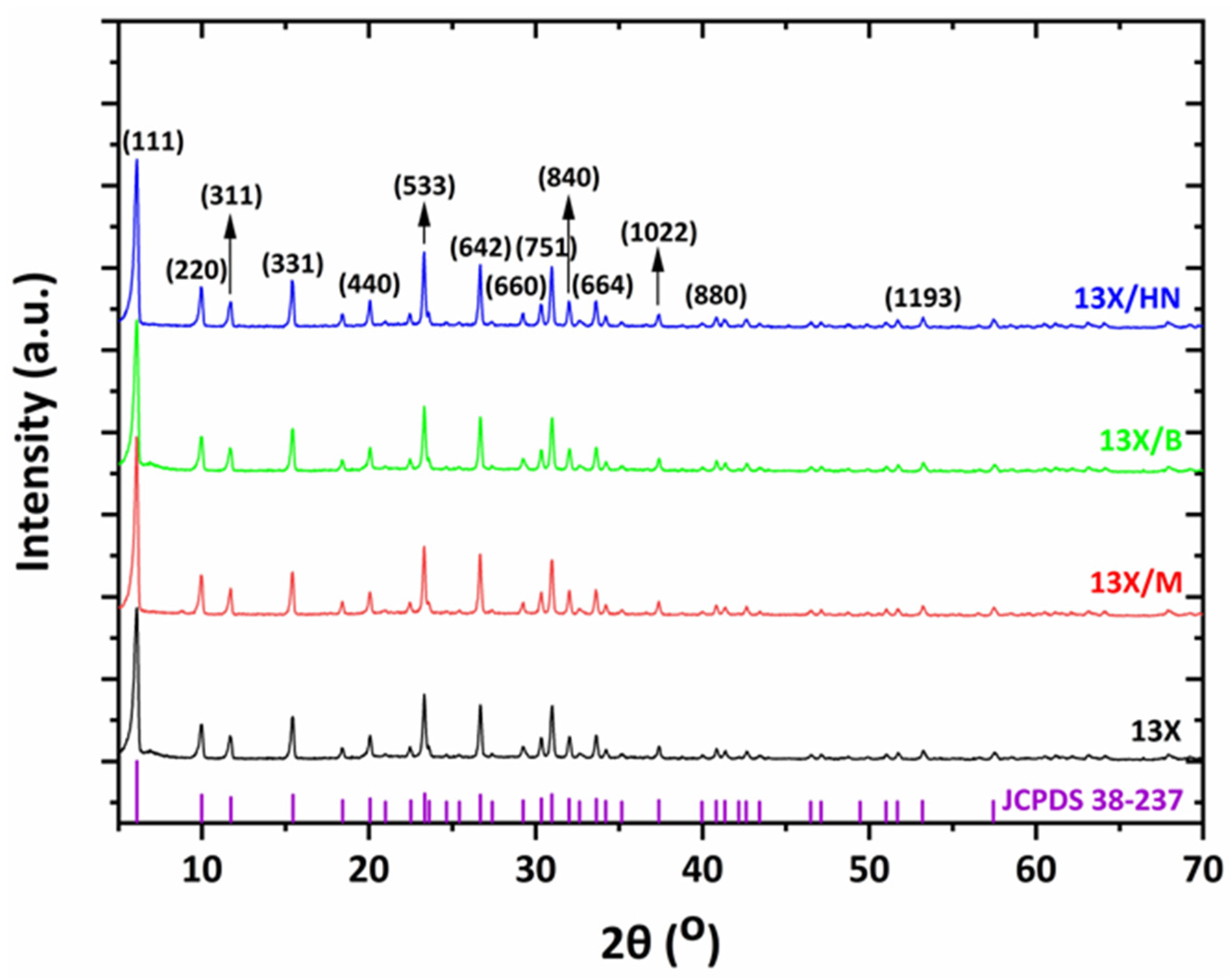

3.5. X-ray Diffraction (XRD) Analysis of the Novel 3D-Printed Biocarriers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Osman, A.I.; Hefny, M.; Maksoud, M.I.A.A.; Elgarahy, A.M.; Rooney, D.W. Recent advances in carbon capture storage and utilisation technologies: A review. Environ. Chem. Lett. 2021, 19, 797–849. [Google Scholar] [CrossRef]

- Montalvo, S.; Huiliñir, C.; Borja, R.; Sánchez, E.; Herrmann, C. Application of zeolites for biological treatment processes of solid wastes and wastewaters—A review. Bioresour. Technol. 2020, 301, 122808. [Google Scholar] [CrossRef] [PubMed]

- Nikolaeva, S.; Sánchez, E.; Borja, R.; Raposo, F.; Colmenarejo, M.F.; Montalvo, S.; Jiménez-Rodríguez, A. Kinetics of anaerobic degradation of screened dairy manure by upflow fixed bed digesters: Effect of natural zeolite addition. J. Environ. Sci. Health A 2009, 44, 146–154. [Google Scholar] [CrossRef] [PubMed]

- Chioti, A.G.; Tsioni, V.; Patsatzis, S.; Filidou, E.; Banti, D.; Samaras, P.; Economou, E.A.; Kostopoulou, E.; Sfetsas, T. Characterization of Biofilm Microbiome Formation Developed on Novel 3D-Printed Zeolite Biocarriers during Aerobic and Anaerobic Digestion Processes. Fermentation 2022, 8, 746. [Google Scholar] [CrossRef]

- Aranzabal, A.; Iturbe, D.; Romero-Sáez, M.; González-Marcos, M.; González-Velasco, J.; González-Marcos, J. Optimization of process parameters on the extrusion of honeycomb shaped monolith of H-ZSM-5 zeolite. Chem. Eng. J. 2010, 162, 415–423. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Kim, Y.-W.; Jun, K.-W.; Viswanadham, N.; Bae, J.W.; Park, H.-S. Textural Properties and Catalytic Applications of ZSM-5 Monolith Foam for Methanol Conversion. Catal. Lett. 2009, 129, 408–415. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, J.S.; Park, Y.S.; Yoon, K.B. Synthesis of large monolithic zeolite foamswith variable macropore architectures. Adv. Mater. 2001, 13, 1259. [Google Scholar] [CrossRef]

- Yang, H.; Liu, Z.; Gao, H.; Xie, Z. Synthesis and catalytic performances of hierarchical SAPO-34 monolith. J. Mater. Chem. 2010, 20, 3227–3231. [Google Scholar] [CrossRef]

- Lewis, J.A.; Smay, J.E.; Stuecker, J.; Cesarano, J. Direct Ink Writing of Three-Dimensional Ceramic Structures. J. Am. Ceram. Soc. 2006, 89, 3599–3609. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. Manuf. Technol. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Zhu, J.; Fan, Y.; Xu, N. Modified dip-coating method for preparation of pinhole-free ceramic membranes. J. Membr. Sci. 2011, 367, 14. [Google Scholar] [CrossRef]

- Shan, Z.; Van Kooten, W.E.J.; Oudshoorn, O.L.; Jansen, J.C.; Van Bekkum, H.; Van Den Bleek, C.M.; Calis, H.P.A. Optimization of the preparation of binderless ZSM-5 coatings on stainless steel monoliths by in situ hydrothermal synthesis. Microporous Mesoporous Mater. 2000, 34, 81–91. [Google Scholar] [CrossRef]

- Zamaro, J.M.; Miró, E.E. Novel binderless zeolite-coated monolith reactor for environmental applications. Chem. Eng. J. 2010, 165, 701. [Google Scholar] [CrossRef]

- Shao, Y.; Liao, Z.; Gao, B.; He, B. Emerging 3D Printing Strategies for Enzyme Immobilization: Materials, Methods, and Applications. ACS Omega 2022, 7, 11530–11543. [Google Scholar] [CrossRef] [PubMed]

- Gordeev, E.G.; Ananikov, V.P. Widely accessible 3D printing technologies in chemistry, biochemistry and pharmaceutics: Applications, materials and prospects. Russ. Chem. Rev. 2020, 89, 1507–1561. [Google Scholar] [CrossRef]

- Callister, W.D. Fundamentals of Materials Science and Engineering; Wiley: London, UK, 2000; Volume 471660817. [Google Scholar]

- Hisour. Available online: https://www.hisour.com/binder-material-21546/amp/ (accessed on 23 May 2023).

- Koltsakidis, S.; Koidi, V.; Lappas, A.; Heracleous, E.; Tzetzis, D. Influence of binder concentration in zeolitic ZSM-5/bentonite 3D-printed monoliths manufactured through robocasting for catalytic applications. Int. J. Adv. Manuf. Technol. 2023, 126, 259–271. [Google Scholar] [CrossRef]

- Lawson, S.; Newport, K.; Al-Naddaf, Q.; Ameh, A.E.; Rownaghi, A.A.; Petrik, L.F.; Rezaei, F. Binderless zeolite monoliths production with sacrificial biopolymers. Chem. Eng. J. 2020, 407, 128011. [Google Scholar] [CrossRef]

- Lefevere, J.; Protasova, L.; Mullens, S.; Meynen, V. 3D-printing of hierarchical porous ZSM-5: The importance of the binder system. Mater. Des. 2017, 134, 331–341. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, Y.; Xie, P.; Shang, R.; Ma, J. Removal of Microcystis aeruginosa by UV-activated persulfate: Performance and characteristics. Chem. Eng. J. 2016, 300, 245–253. [Google Scholar] [CrossRef]

- Corrosionpedia. Available online: https://www.corrosionpedia.com/definition/1620/compressive-strength-material-science (accessed on 23 May 2023).

- Kladovasilakis, N.; Charalampous, P.; Tsongas, K.; Kostavelis, I.; Tzetzis, D.; Tzovaras, D. Experimental and Computational Investigation of Lattice Sandwich Structures Constructed by Additive Manufacturing Technologies. J. Manuf. Mater. Process. 2021, 5, 95. [Google Scholar] [CrossRef]

- Jones, D.R.; Ashby, M.F. Engineering Materials 1 An Introduction to Properties, Applications and Design, 5th ed.; Butterworth-Heinemann: Oxford, UK, 2018. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Mansour, G.; Tzetzis, D.; Bouzakis, K.D. A Nanomechanical Approach on the Measurement of the Elastic Properties of Epoxy Reinforced Carbon Nanotube Nanocomposites. Tribol. Ind. 2013, 35, 190–199. [Google Scholar]

- Tsongas, K.; Tzetzis, D.; Karantzalis, A.; Banias, G.; Exarchos, D.; Ahmadkhaniha, D.; Zanella, C.; Matikas, T.; Bochtis, D. Microstructural, Surface Topology and Nanomechanical Characterization of Electrodeposited Ni-P/SiC Nanocomposite Coatings. Appl. Sci. 2019, 9, 2901. [Google Scholar] [CrossRef]

- Yarusova, S.; Shichalin, O.; Belov, A.; Azon, S.; Buravlev, I.Y.; Golub, A.; Mayorov, V.Y.; Gerasimenko, A.; Papynov, E.; Ivanets, A.; et al. Synthesis of amorphous KAlSi3O8 for cesium radionuclide immobilization into solid matrices using spark plasma sintering technique. Ceram. Int. 2021, 48, 3808–3817. [Google Scholar] [CrossRef]

- Shichalin, O.; Papynov, E.; Nepomnyushchaya, V.; Ivanets, A.; Belov, A.; Dran’kov, A.; Yarusova, S.; Buravlev, I.; Tarabanova, A.; Fedorets, A.; et al. Hydrothermal synthesis and spark plasma sintering of NaY zeolite as solid-state matrices for cesium-137 immobilization. J. Eur. Ceram. Soc. 2022, 42, 3004–3014. [Google Scholar] [CrossRef]

- Thakkar, H.; Eastman, S.; Hajari, A.; Rownaghi, A.A.; Knox, J.C.; Rezaei, F. 3D-printed zeolite monoliths for CO2 removal from enclosed environments. ACS Appl. Mater. Int. 2016, 8, 27753–27761. [Google Scholar] [CrossRef]

- Abruzzi, R.C.; Pires, M.J.R.; Dedavid, B.A.; Galli, C.F. Application of SnO2 nanoparticles and zeolites in coal mine methane sensors. Mater. Res. 2019, 22 (Suppl. S1), e20180818. [Google Scholar] [CrossRef]

- Middelkoop, V.; Coenen, K.; Schalck, J.; van Sint Annaland, M.; Gallucci, F. 3D printed versus spherical adsorbents for gas sweetening. Chem. Eng. J. 2019, 357, 309–319. [Google Scholar] [CrossRef]

- Dong, H.; Zhang, L.; Fang, Z.; Fu, W.; Tang, T.; Feng, Y.; Tang, T. Acidic hierarchical zeolite ZSM-5 supported Ru catalyst with high activity and selectivity in the seleno-functionalization of alkenes. RSC Adv. 2017, 7, 22008–22016. [Google Scholar] [CrossRef]

- Wang, P.; Xiao, X.; Pan, Y.; Zhao, Z.; Jiang, G.; Zhang, Z.; Xie, Z. Facile synthesis of nanosheet-stacked hierarchical ZSM-5 zeolite for efficient catalytic cracking of n-octane to produce light olefins. Catalysts 2022, 12, 351. [Google Scholar] [CrossRef]

| Material | Paste Content (%) | Percentage of Zeolites and Clays (%) | Material Quantities (g) | ||

|---|---|---|---|---|---|

| 13X/Bentonite | Zeolite | 13X | 45 | 89 | 16 |

| Inorganic Binder | Bentonite | 6 | 11 | 2 | |

| Alumina Silicate Binder | Ludox AS-40 | 14 | 5 | ||

| Moisture | Water | 34 | 17.2 | ||

| Organic Binder | Methylcellulose | 1 | 0.3 | ||

| Total amount of paste | 40.5 g | ||||

| Total Solids | 50% | ||||

| 13X/Halloysite Nanotubes | Zeolite | 13X | 50 | 89 | 22.4 |

| Inorganic Binder | Halloysite Nanotubes | 6 | 11 | 2.8 | |

| Alumina Silicate Binder | Ludox AS-40 | 16 | 7 | ||

| Moisture | Water | 27 | 13.7 | ||

| Organic Binder | Methylcellulose | 1 | 0.3 | ||

| Total amount of paste | 46.2 g | ||||

| Total Solids | 61% | ||||

| 13X/Montmorillonite | Zeolite | 13X | 49 | 89 | 16 |

| Inorganic Binder | Montmorillonite | 6 | 11 | 2 | |

| Alumina Silicate Binder | Ludox AS-40 | 15 | 5 | ||

| Moisture | Water | 29 | 12.2 | ||

| Organic Binder | Methylcellulose | 1 | 0.3 | ||

| Total amount of paste | 35.4 g | ||||

| Total Solids | 57% | ||||

| ZSM-5/Bentonite | Zeolite | ZSM-5 | 37 | 89 | 8 |

| Inorganic Binder | Bentonite | 5 | 11 | 1 | |

| Alumina Silicate Binder | Ludox AS-40 | 12 | 2.5 | ||

| Moisture | Water | 45 | 11.7 | ||

| Organic Binder | Methylcellulose | 2 | 0.4 | ||

| Total amount of paste | 23.6 g | ||||

| Total Solids | 44% | ||||

| ZSM-5/Montmorillonite | Zeolite | ZSM-5 | 43 | 89 | 8 |

| Inorganic Binder | Montmorillonite | 5 | 11 | 1 | |

| Alumina Silicate Binder | Ludox AS-40 | 14 | 2.5 | ||

| Moisture | Water | 37 | 7.8 | ||

| Organic Binder | Methylcellulose | 1 | 0.2 | ||

| Total amount of paste | 19.5 g | ||||

| Total Solids | 52% | ||||

| ZSM-5/Halloysite Nanotubes | Zeolite | ZSM-5 | 43 | 89 | 8 |

| Inorganic Binder | Montmorillonite | 5 | 11 | 1 | |

| Alumina Silicate Binder | Ludox AS-40 | 14 | 2.5 | ||

| Moisture | Water | 37 | 6.8 | ||

| Organic Binder | Methylcellulose | 1 | 0.2 | ||

| Total amount of paste | 18.5 g | ||||

| Total Solids | 55% | ||||

| Specific Surface Area (m2/g) | Total Pore Volume (cc/g) | Micropore Volume (cc/g) | Mesopore Volume (cc/g) | Micropore Diameter (Å) | Mesopore Diameter (Å) | |

|---|---|---|---|---|---|---|

| 13X | 688 | 0.35 | 0.29 | 0.06 | 10.2 | 55 |

| ZSM-5 | 549 | 0.57 | 0.21 | 0.36 | 5 | 42 |

| Bentonite | 52 | 0.15 | 0.02 | 0.13 | na | 55 |

| Montmorillonite | 32 | 0.16 | 0.01 | 0.15 | na | 55 |

| Halloysite Nanotubes | 89 | 0.32 | 0.03 | 0.29 | na | 55 and 116 |

| 13X/Bentonite | 590 | 0.42 | 0.24 | 0.18 | 9 | 42, 116 |

| 13X/Halloysite Nanotubes | 711 | 0.49 | 0.29 | 0.20 | 9 | 34, 55, 97 |

| 13X/Montmorillonite | 687 | 0.42 | 0.28 | 0.14 | 9 | 39, 54, 94 |

| ZSM-5/Bentonite | 527 | 0.56 | 0.21 | 0.35 | 9.4 | 35, 51, 116 |

| ZSM-5/Montmorillonite | 397 | 0.32 | 0.16 | 0.16 | 9 | 24, 35, 54 |

| ZSM-5/Halloysite Nanotubes | 383 | 0.37 | 0.15 | 0.22 | 9 | 35, 53, 78 |

| 3D-Printed Biocarriers | Density of Biocarriers (g/cm3) |

|---|---|

| 13X | 0.60 |

| ZSM-5 | 0.4–0.8 |

| Bentonite | 0.8–1.0 |

| Montmorillonite | 0.52 |

| Halloysite Nanotubes | 2.53 |

| 13X/Bentonite | 1.42 ± 0.03 |

| 13X/Montmorillonite | 1.64 ± 0.03 |

| 13X/Halloysite Nanotubes | 1.67 ± 0.02 |

| ZSM-5/Bentonite | 1.97 ± 0.01 |

| ZSM-5/Montmorillonite | 1.98 ± 0.16 |

| ZSM-5/Halloysite Nanotubes | 1.94 ± 0.20 |

| 3D-Printed Biocarriers | Hardness (MPa) | Elastic Modulus (MPa) |

|---|---|---|

| 13X/Bentonite | 44.35 ± 5.39 | 3378.67 ± 383.89 |

| 13X/Halloysite Nanotubes | 45.64 ± 5.47 | 3422 ± 130.11 |

| 13X/Montmorillonite | 52.57 ± 4.60 | 3223 ± 335.71 |

| ZSM-5/Bentonite | 38.45 ± 7.64 | 1347.75 ± 47.53 |

| ZSM-5/Montmorillonite | 38.21 ± 2.37 | 1188.5 ± 204.19 |

| ZSM-5/Halloysite Nanotubes | 29.01 ± 6.01 | 545.5 ± 52.39 |

| 3D-Printed Biocarriers | Compressive Strength (kPa) |

|---|---|

| 13X/Bentonite | 175.85 ± 34.93 |

| 13X/Halloysite Nanotubes | 215.89 ± 35.36 |

| 13X/Montmorillonite | 261 ± 2.28 |

| ZSM-5/Bentonite | 50.95 ± 10.38 |

| ZSM-5/Montmorillonite | 20.52 ± 4.90 |

| ZSM-5/Halloysite Nanotubes | 57.78 ± 11.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Economou, E.A.; Koltsakidis, S.; Dalla, I.; Tsongas, K.; Romanos, G.E.; Tzetzis, D.; Falaras, P.; Theodorakopoulos, G.; Middelkoop, V.; Sfetsas, T. Novel 3D-Printed Biocarriers from Aluminosilicate Materials. Materials 2023, 16, 4826. https://doi.org/10.3390/ma16134826

Economou EA, Koltsakidis S, Dalla I, Tsongas K, Romanos GE, Tzetzis D, Falaras P, Theodorakopoulos G, Middelkoop V, Sfetsas T. Novel 3D-Printed Biocarriers from Aluminosilicate Materials. Materials. 2023; 16(13):4826. https://doi.org/10.3390/ma16134826

Chicago/Turabian StyleEconomou, Eleni Anna, Savvas Koltsakidis, Ioanna Dalla, Konstantinos Tsongas, George Em. Romanos, Dimitrios Tzetzis, Polycarpos Falaras, George Theodorakopoulos, Vesna Middelkoop, and Themistoklis Sfetsas. 2023. "Novel 3D-Printed Biocarriers from Aluminosilicate Materials" Materials 16, no. 13: 4826. https://doi.org/10.3390/ma16134826

APA StyleEconomou, E. A., Koltsakidis, S., Dalla, I., Tsongas, K., Romanos, G. E., Tzetzis, D., Falaras, P., Theodorakopoulos, G., Middelkoop, V., & Sfetsas, T. (2023). Novel 3D-Printed Biocarriers from Aluminosilicate Materials. Materials, 16(13), 4826. https://doi.org/10.3390/ma16134826