Tensile Deformation and Fracture of Unreinforced AZ91 and Reinforced AZ91-C at Temperatures up to 300 °C

Abstract

1. Introduction

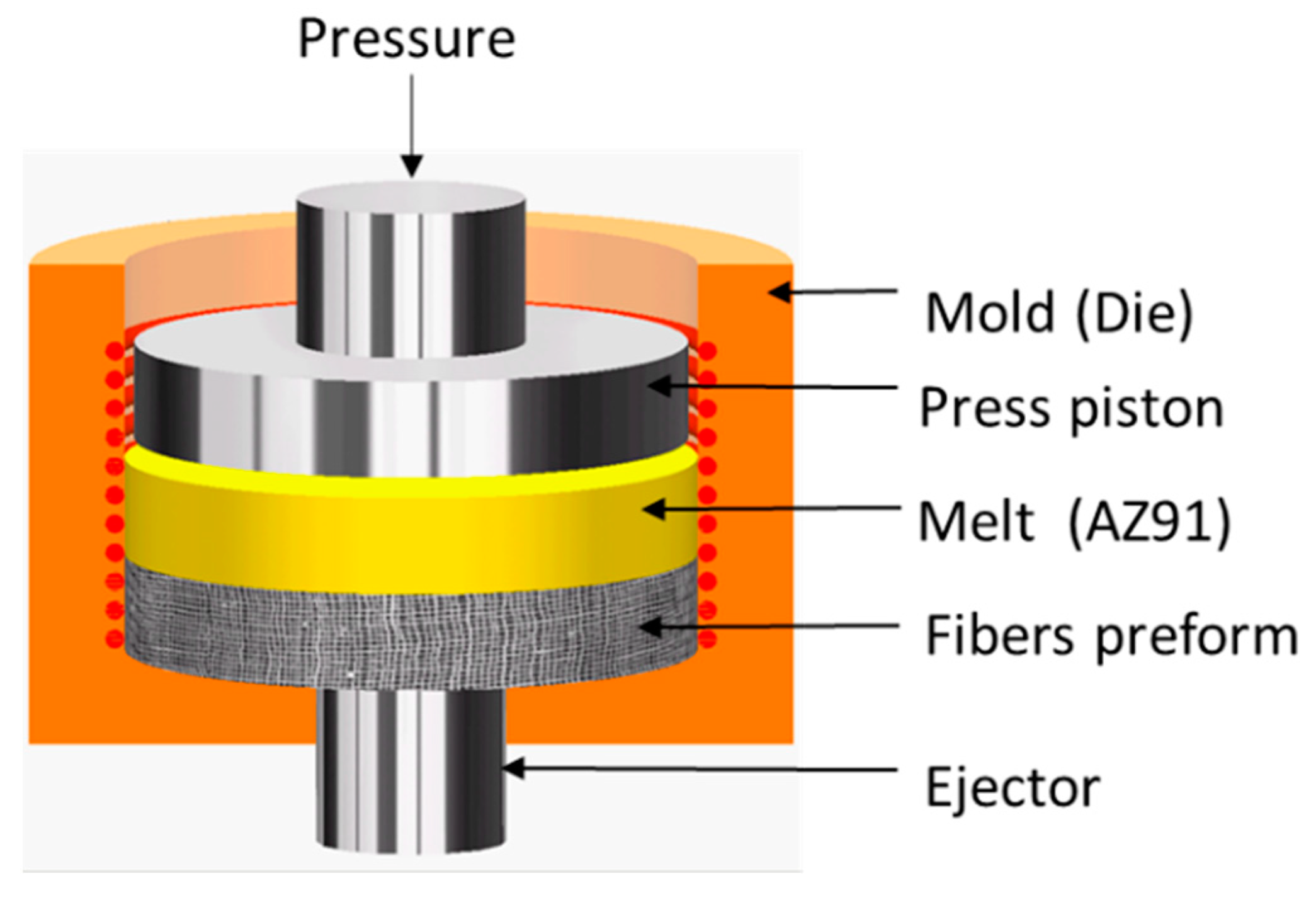

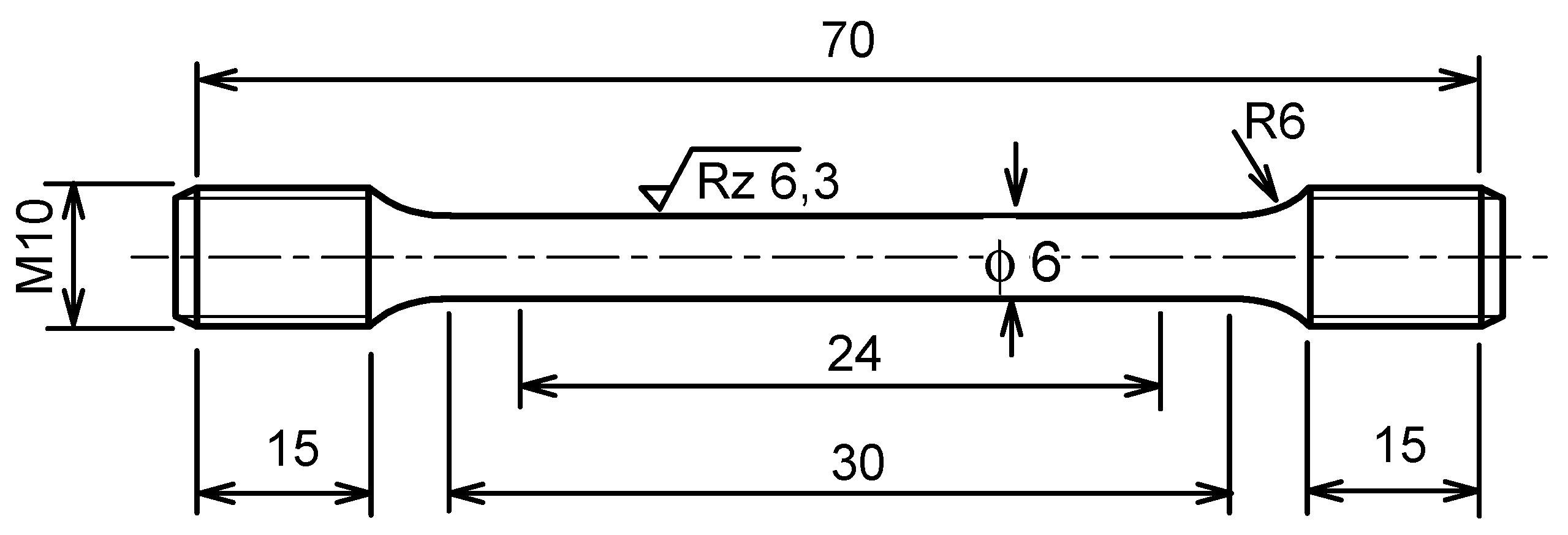

2. Materials and Methods

3. Results and Discussion

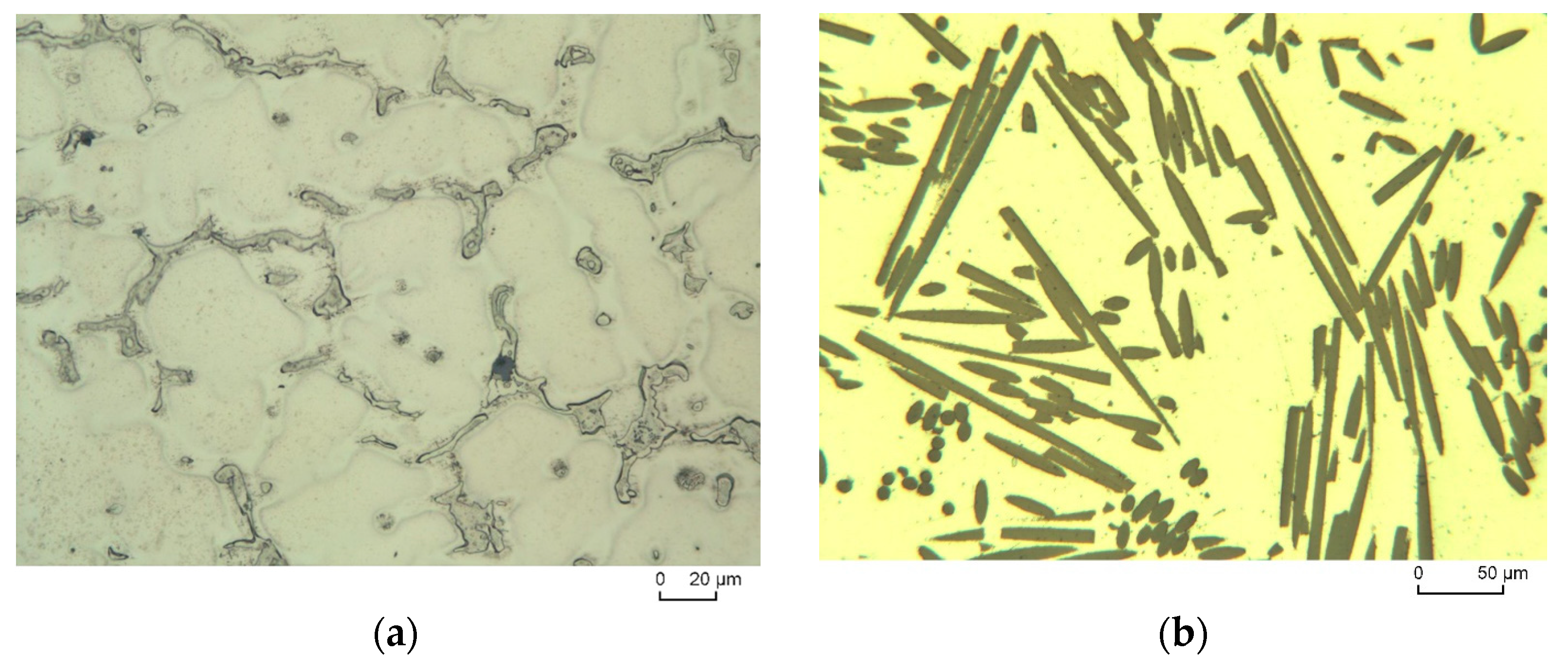

3.1. Initial Microstructure

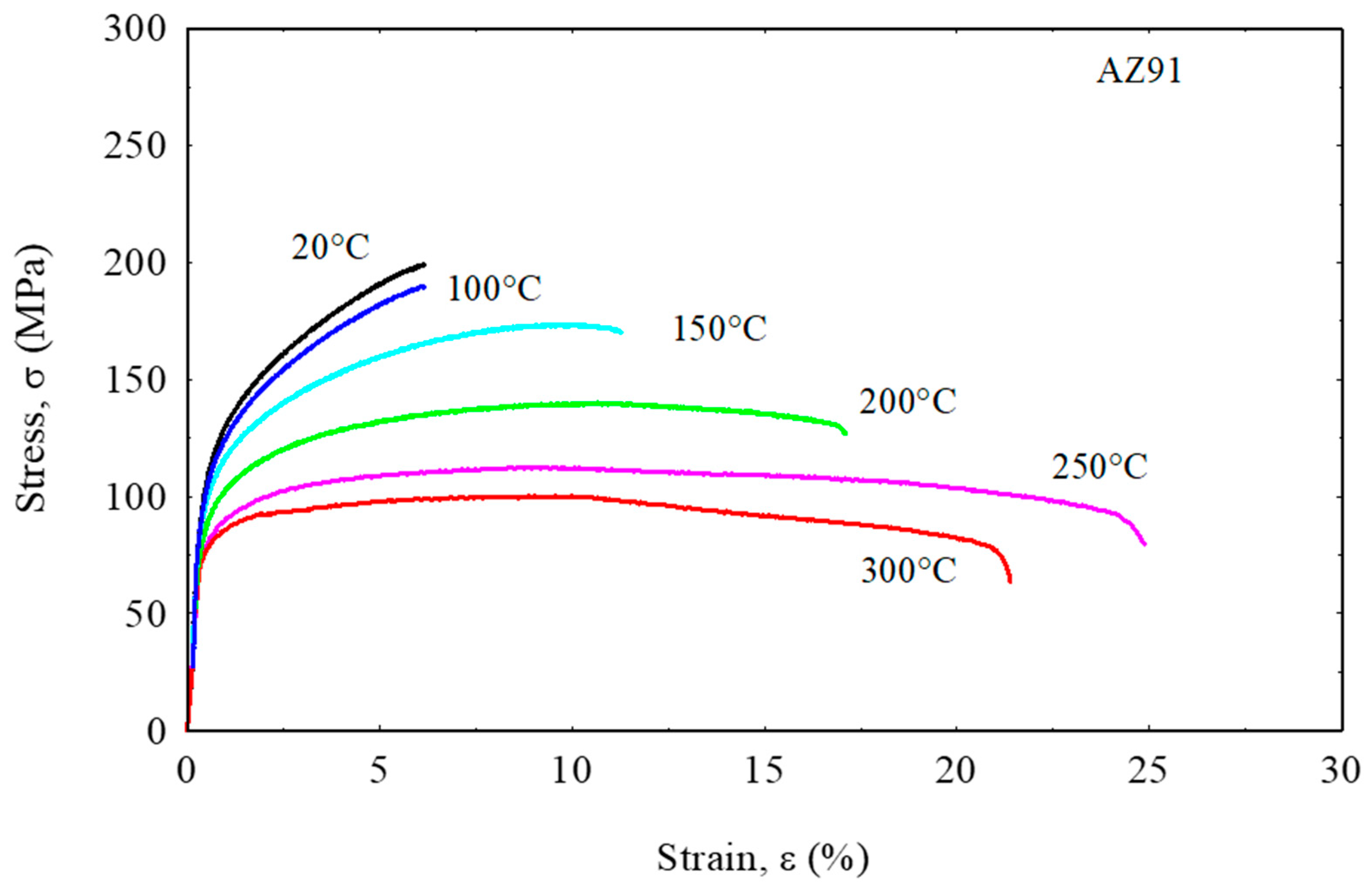

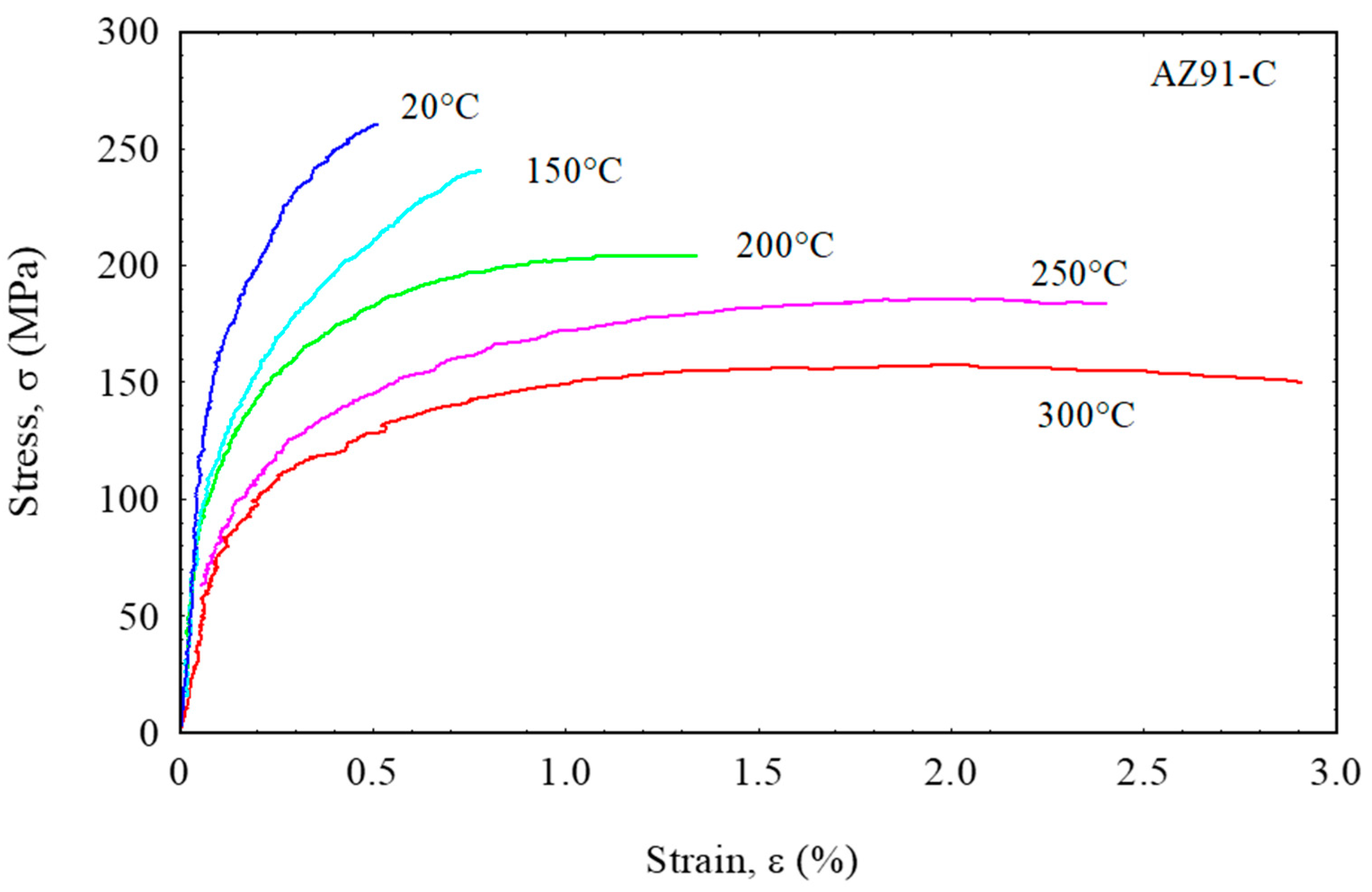

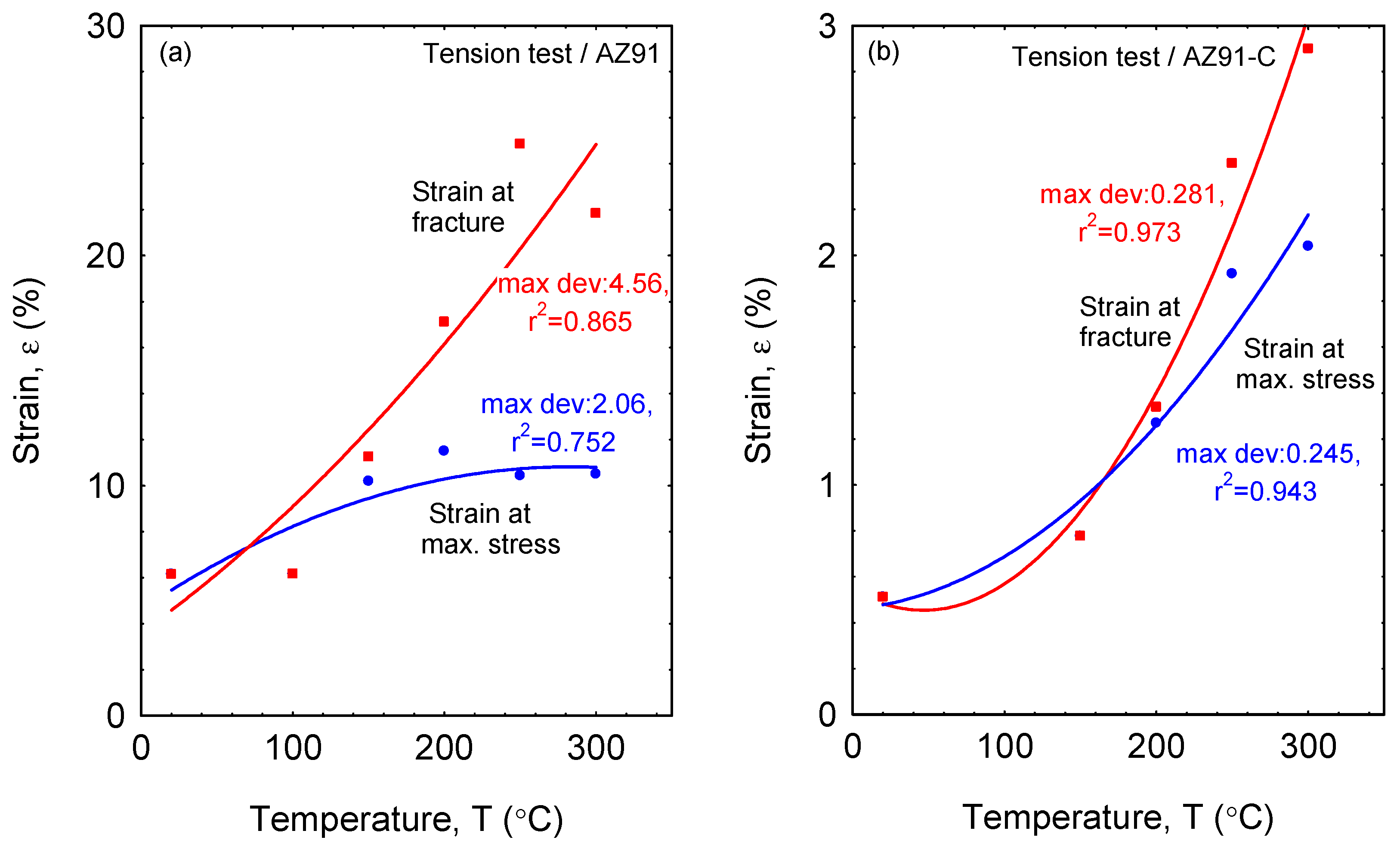

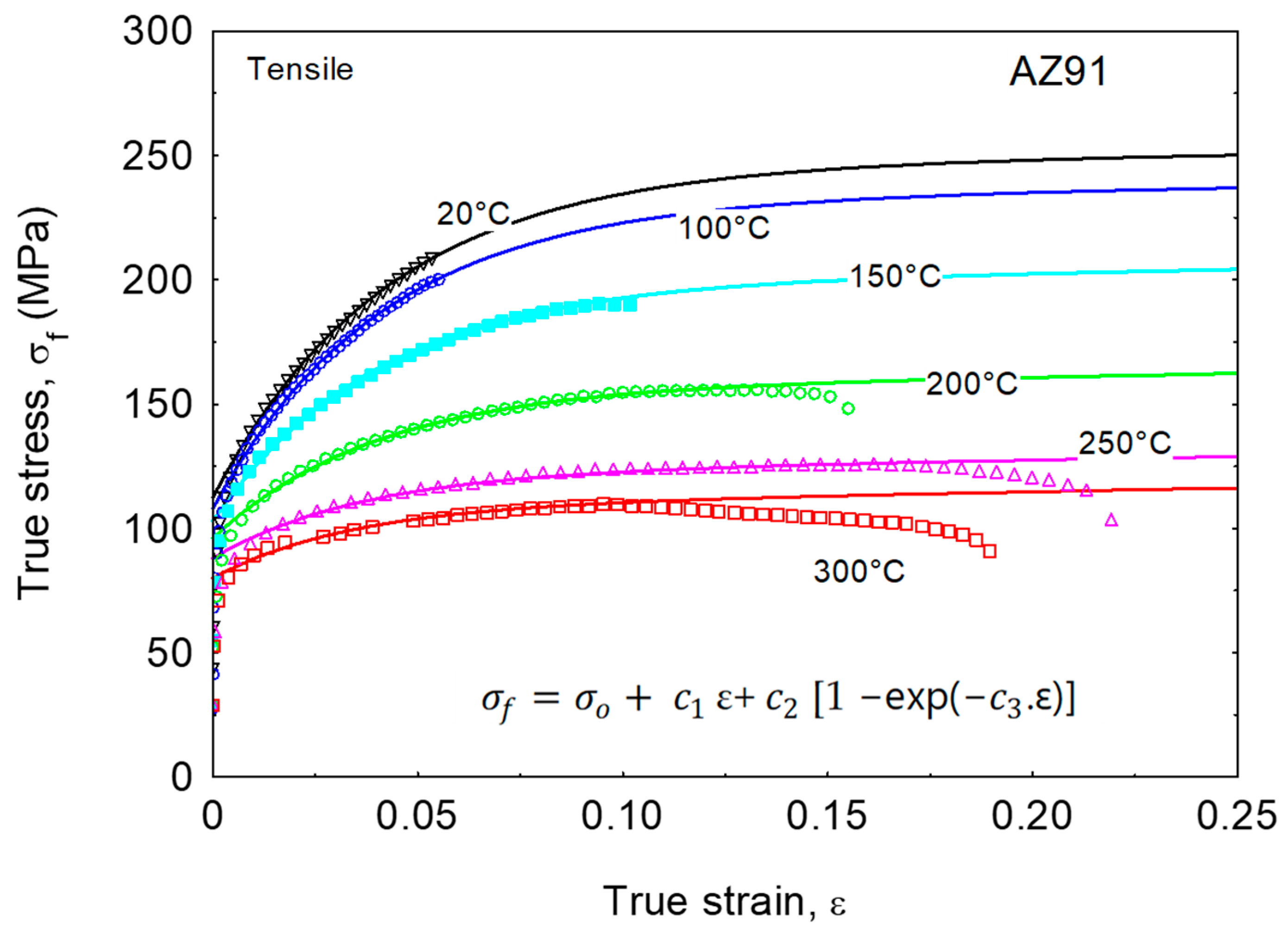

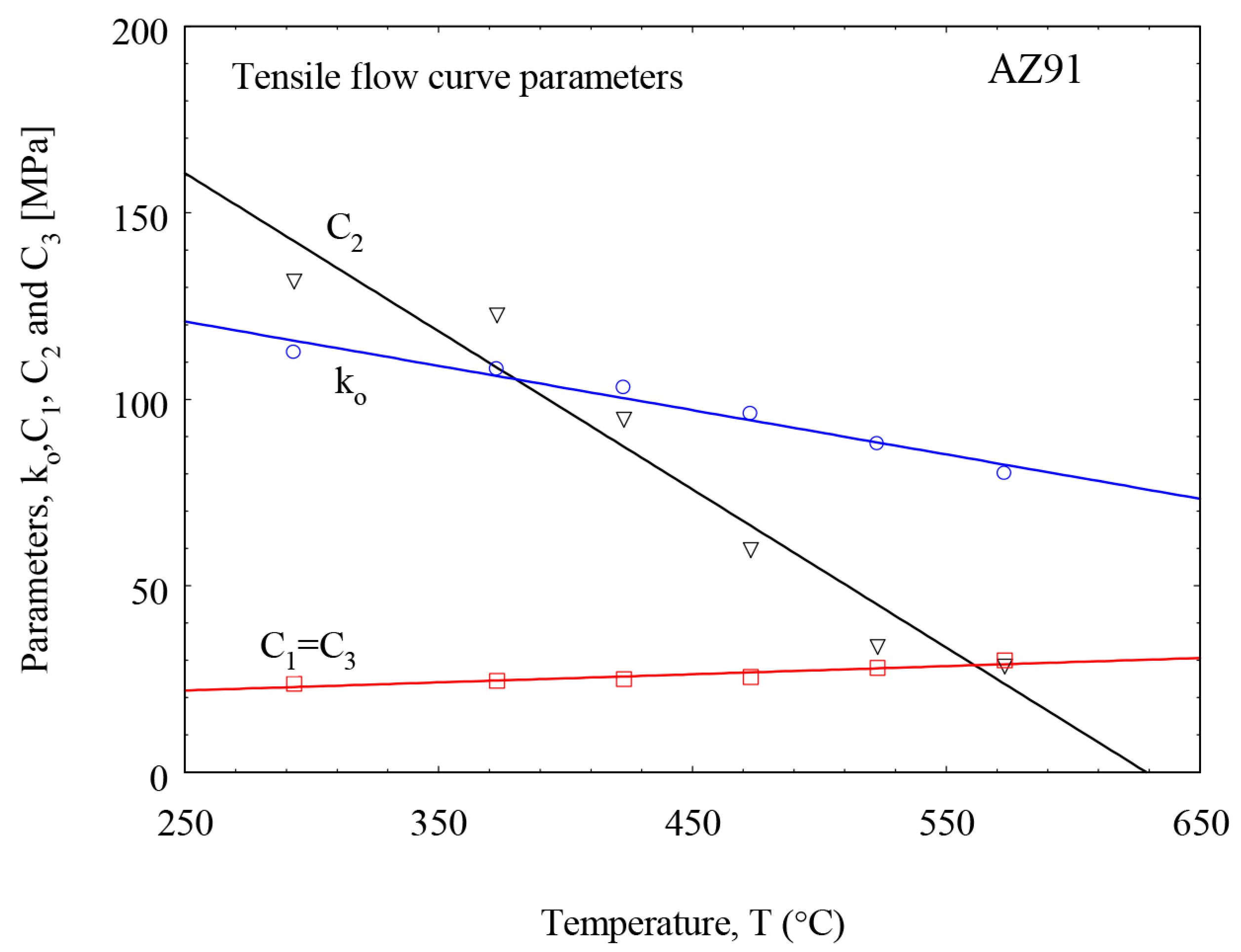

3.2. Tensile Testing Results

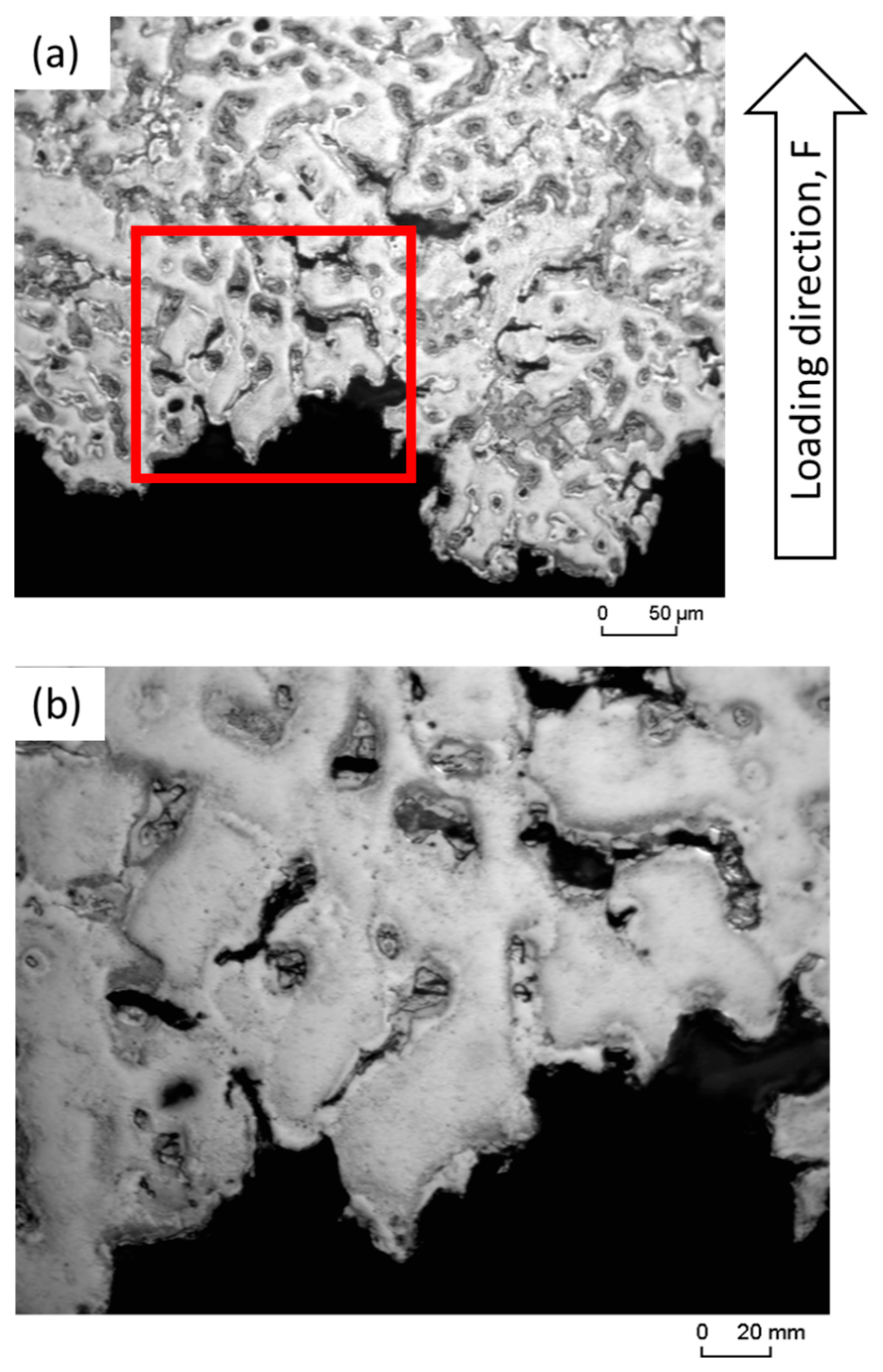

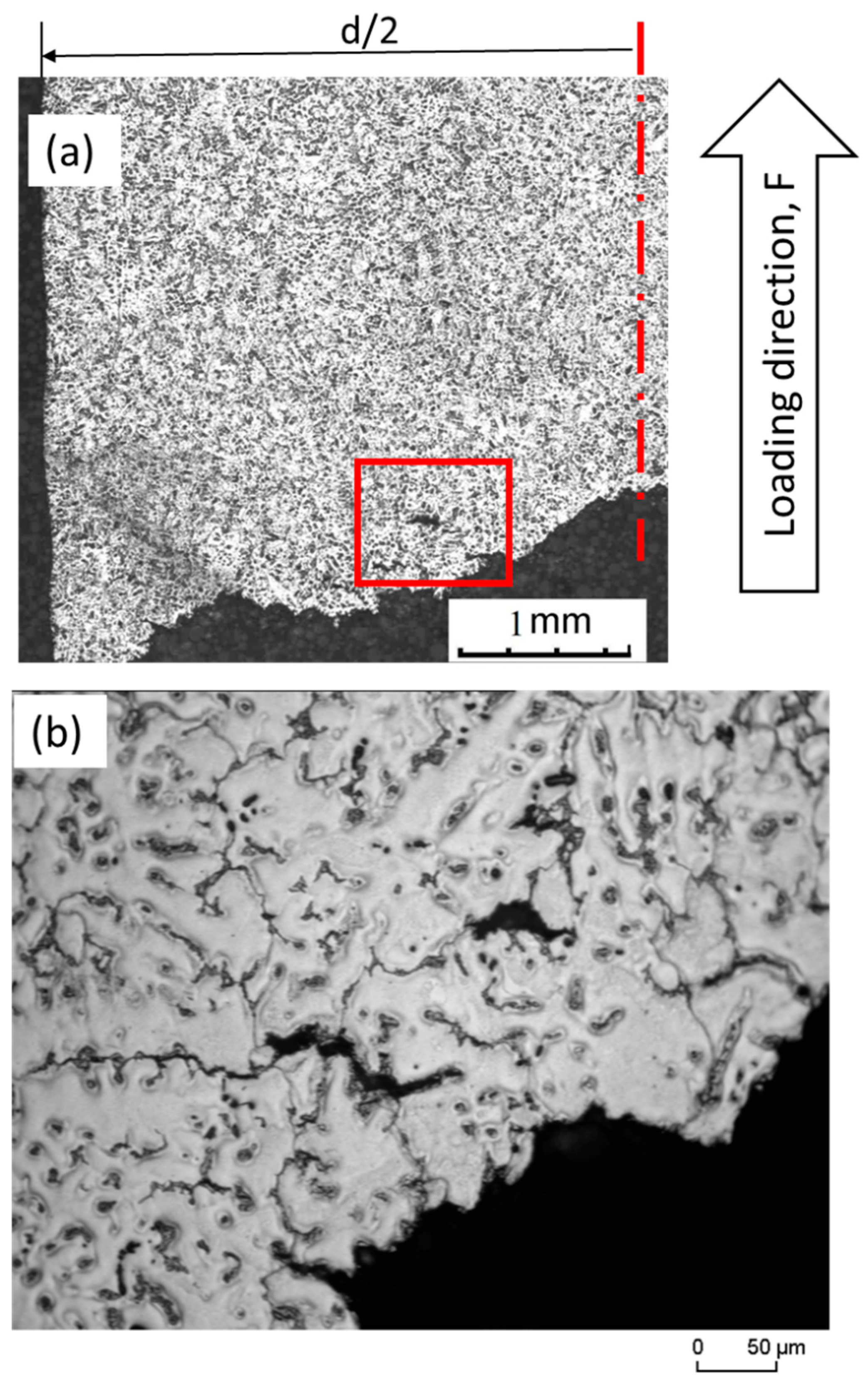

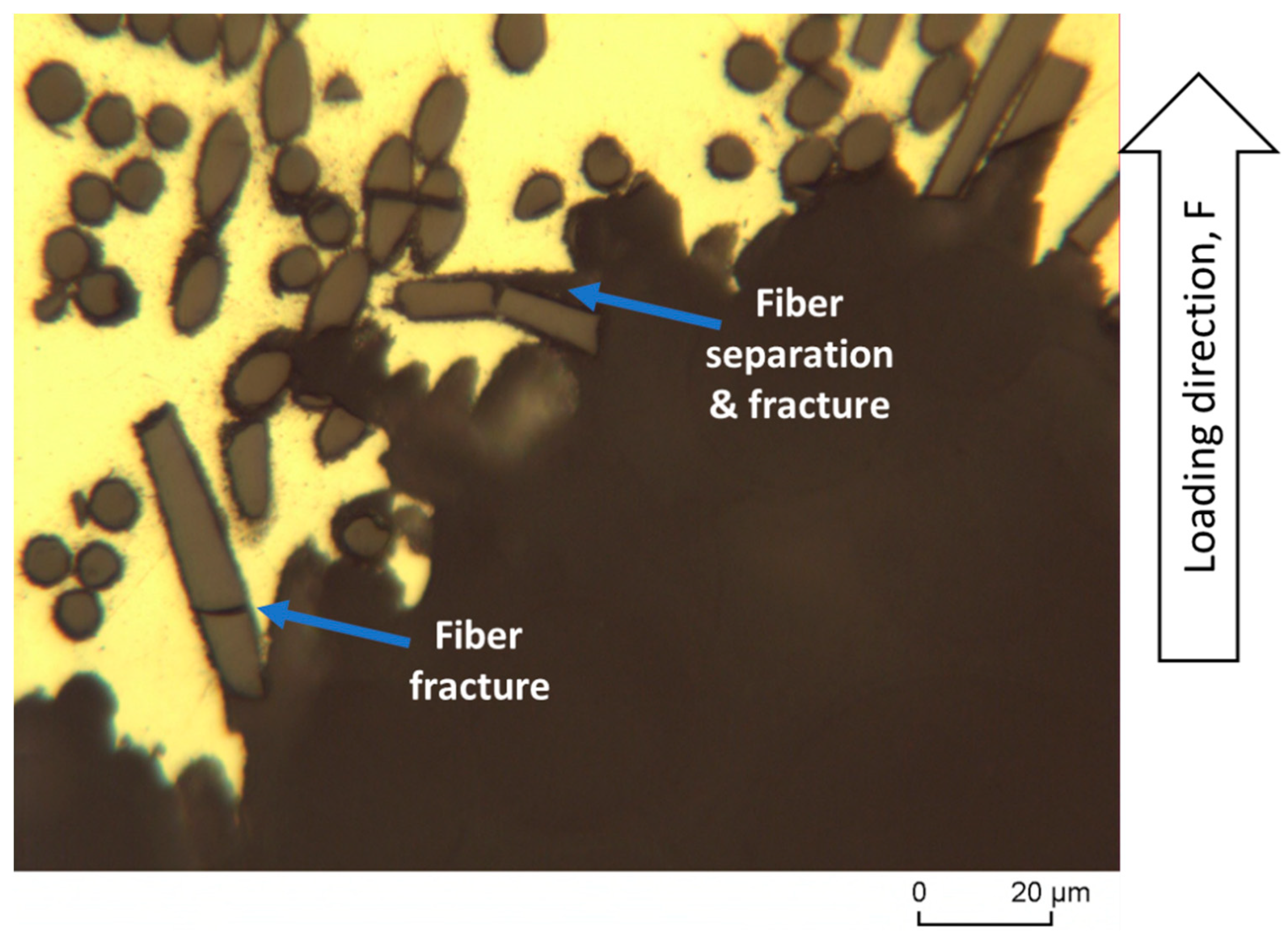

3.3. Optical Microscopy of Fracture Surface

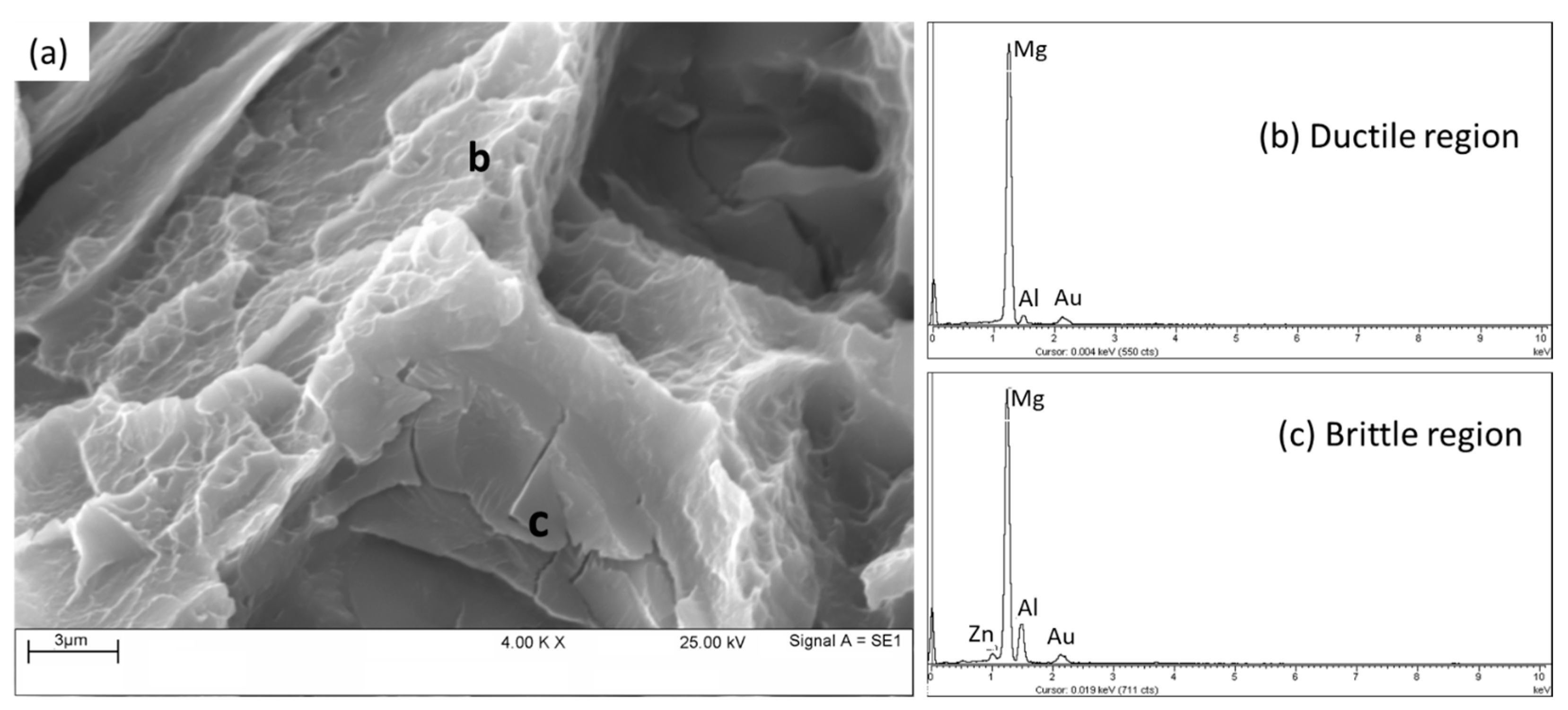

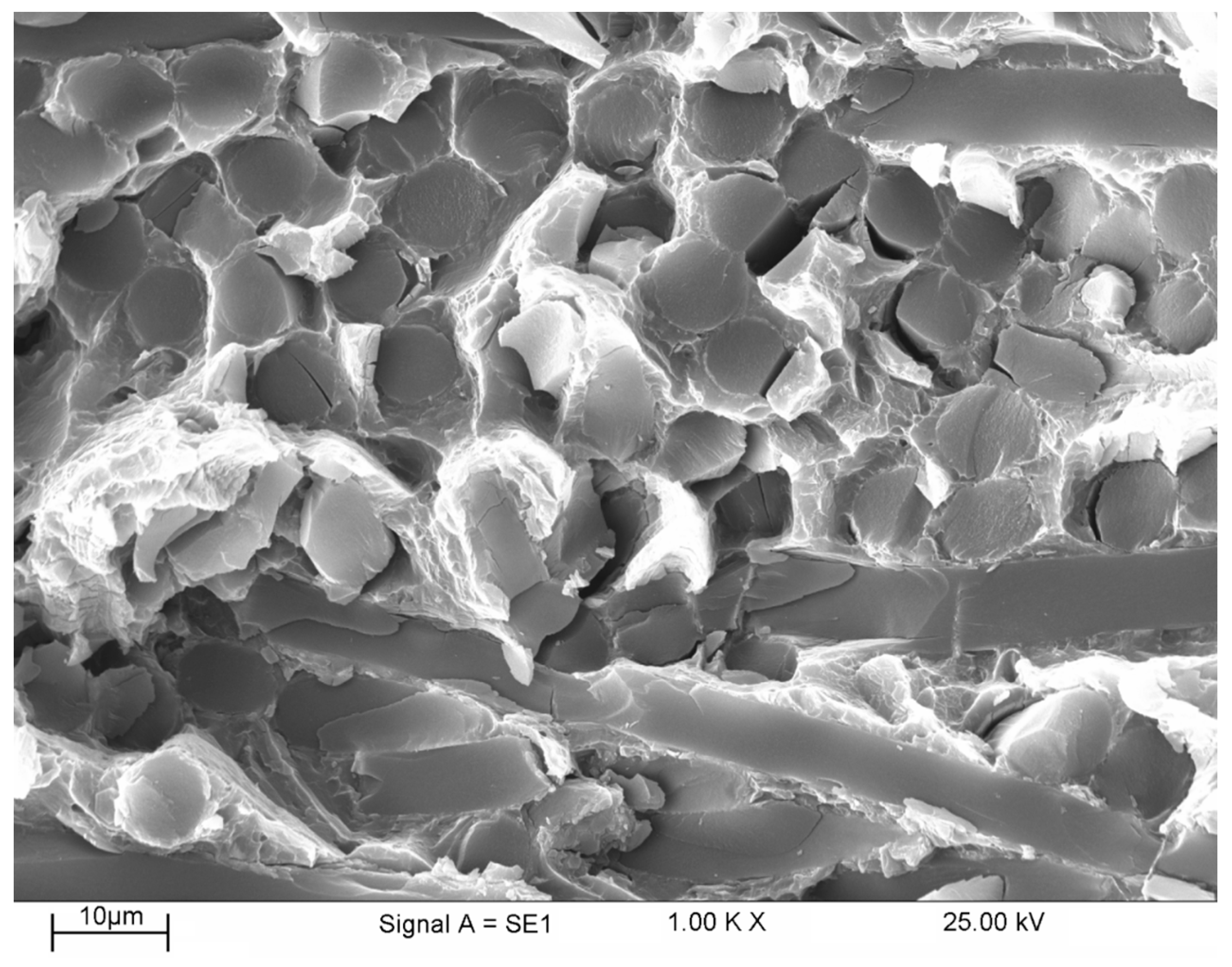

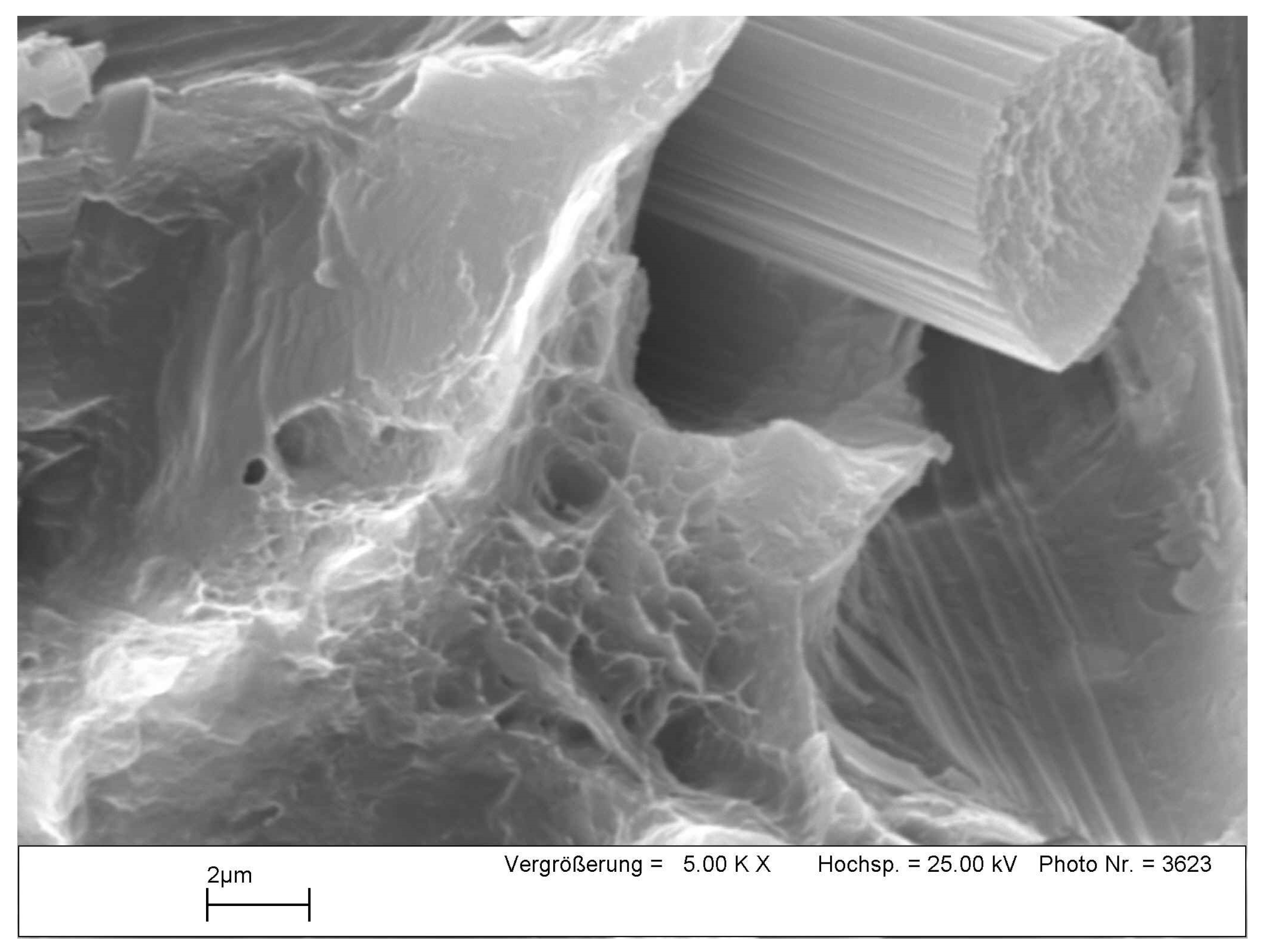

3.4. SEM Investigation Fracture Surface

4. Conclusions

- Magnesium alloy AZ91 is successfully reinforced by carbon short fiber with a volume fraction of Vf = 0.23 by squeeze casting.

- The yield stress of AZ91 at 20 °C (109 MPa) is doubled (226 MPa) in the reinforced AZ91-C. The improvement of the yield stress due to reinforcing slightly decreases with increasing the test temperature.

- The ultimate tensile strength of AZ91 at 20 °C (198 MPa) is increased to 262 MPa in the reinforced AZ91-C. The ultimate tensile strength of AZ91-C increases with increasing the test temperature.

- Quasi-static tensile flow curves up to 300 °C are well described by the modified Mecking–Kocks method and the material parameters are determined as a function of the test temperature.

- The fracture mode of the unreinforced AZ91 at room temperature is mixed with brittle cleavage fracture areas and a lower fraction of ductile deformation dimples.

- The reinforced AZ91-C fracture is achieved by breaking the fibers parallel to the loading direction and detachment of the carbon fibers perpendicular to the line of loading from the matrix alloy (AZ91).

5. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Srinivasan, A.; Ajithkumar, K.K.; Swaminathan, J.; Pillai, U.T.S.; Pai, B.C. Creep Behavior of AZ91 Magnesium Alloy. Procedia Eng. 2013, 55, 109–113. [Google Scholar] [CrossRef]

- Friedrich, H.; Schumann, S. Research for a ‘New Age of Magnesium’ in the Automotive Industry. J. Mater. Process. Technol. 2001, 117, 276–281. [Google Scholar] [CrossRef]

- Zhang, X.; Liao, L.; Ma, N.; Wang, H. Mechanical Properties and Damping Capacity of Magnesium Matrix Composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2011–2016. [Google Scholar] [CrossRef]

- Ding, H.; Liu, L.; Kamado, S.; Ding, W.; Kojima, Y. Study of the Microstructure, Texture and Tensile Properties of as-Extruded AZ91 Magnesium Alloy. J. Alloys Compd. 2008, 456, 400–406. [Google Scholar] [CrossRef]

- Khoubrou, I.; Nami, B.; Miresmaeili, S.M. Investigation on the Creep Behavior of AZ91 Magnesium Alloy Processed by Severe Plastic Deformation. Met. Mater. Int. 2020, 26, 196–204. [Google Scholar] [CrossRef]

- Raja, A.; Pancholi, V. Effect of Friction Stir Processing on Tensile and Fracture Behaviour of AZ91 Alloy. J. Mater. Process. Technol. 2017, 248, 8–17. [Google Scholar] [CrossRef]

- Luong, D.D.; Shunmugasamy, V.C.; Cox, J.; Gupta, N.; Rohatgi, P.K. Heat Treatment of AZ91D Mg-Al-Zn Alloy: Microstructural Evolution and Dynamic Response. JOM 2014, 66, 312–321. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, L.; Lyu, S.; You, C.; Tian, L.; Chen, M. Effect of Pre-Heat Treatment on Microstructure and Properties of As-Extruded AZ91-CaO Alloy. Materials 2022, 12, 2060. [Google Scholar] [CrossRef]

- Tan, M.; Liu, Z.; Quan, G. Effects of Hot Extrusion and Heat Treatment on Mechanical Properties and Microstructures of AZ91 Magnesium Alloy. Energy Procedia 2012, 16, 457–460. [Google Scholar] [CrossRef]

- Meng, C.; Chen, Z.; Li, G.; Dong, P. Effect of Laser Surface Melting on High Temperature Tensile Properties of AZ91D Magnesium Alloy. J. Alloys Compd. 2017, 711, 258–266. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, Q.; Zhai, C.; Zhu, Y. Effects of Strontium and Titanium on the Microstructure, Tensile Properties and Creep Behavior of AM50 Alloys. Mater. Sci. Eng. A 2007, 444, 318–326. [Google Scholar] [CrossRef]

- Mahmudi, R.; Kabirian, F.; Nematollahi, Z. Microstructural Stability and High-Temperature Mechanical Properties of AZ91 and AZ91 + 2RE Magnesium Alloys. Mater. Des. 2011, 32, 2583–2589. [Google Scholar] [CrossRef]

- Fata, A.; Faraji, G.; Mashhadi, M.M.; Tavakkoli, V. Hot Tensile Deformation and Fracture Behavior of Ultrafine-Grained AZ31 Magnesium Alloy Processed by Severe Plastic Deformation. Mater. Sci. Eng. A 2016, 674, 9–17. [Google Scholar] [CrossRef]

- Ataya, S.; El-Sayed Seleman, M.M.; Latief, F.H.; Ahmed, M.M.Z.; Hajlaoui, K.; Soliman, A.M.; Alsaleh, N.A.; Habba, M.I.A. Wear Characteristics of Mg Alloy AZ91 Reinforced with Oriented Short Carbon Fibers. Materials 2022, 15, 4841. [Google Scholar] [CrossRef]

- Zimmerman, M.; Peterson, N.A.; Zimmerman, M.A. Beyond the Individual: Toward a Nomological Network of Organizational Empowerment. Am. J. Community Psychol. 2016, 34, 129–145. [Google Scholar] [CrossRef]

- Shastri, H.; Mondal, A.K.; Dutta, K.; Dieringa, H.; Kumar, S. Microstructural Correlation with Tensile and Creep Properties of AZ91 Alloy in Three Casting Techniques. J. Manuf. Process. 2020, 57, 566–573. [Google Scholar] [CrossRef]

- Xiao, R.; Liu, W.; Wu, G.; Zhang, L.; Liu, B.; Ding, W. Effect of Ca Content and Rheo-Squeeze Casting Parameters on Microstructure and Mechanical Properties of AZ91−1Ce−xCa Alloys. Trans. Nonferrous Met. Soc. China 2021, 31, 1572–1586. [Google Scholar] [CrossRef]

- Istrate, B.; Munteanu, C.; Cimpoesu, R.; Cimpoesu, N.; Popescu, O.D.; Vlad, M.D. Microstructural, Electrochemical and In Vitro Analysis of Mg-0.5ca-Xgd Biodegradable Alloys. Appl. Sci. 2021, 11, 981. [Google Scholar] [CrossRef]

- Baltatu, M.S.; Spataru, M.C.; Verestiuc, L.; Balan, V.; Solcan, C.; Sandu, A.V.; Geanta, V.; Voiculescu, I.; Vizureanu, P. Design, Synthesis, and Preliminary Evaluation for Ti-Mo-Zr-Ta-Si Alloys for Potential Implant Applications. Materials 2021, 14, 6806. [Google Scholar] [CrossRef]

- Aravindan, S.; Rao, P.V.; Ponappa, K. Evaluation of Physical and Mechanical Properties of AZ91D/SiC Composites by Two Step Stir Casting Process. J. Magnes. Alloy. 2015, 3, 52–62. [Google Scholar] [CrossRef]

- Lü, L.; Lai, M.O.; Gupta, M.; Chua, B.W.; Osman, A. Improvement of Microstructure and Mechanical Properties of AZ91/SiC Composite by Mechanical Alloying. J. Mater. Sci. 2000, 35, 5553–5561. [Google Scholar] [CrossRef]

- Wang, X.J.; Hu, X.S.; Wu, K.; Wang, L.Y.; Huang, Y.D. Evolutions of Microstructure and Mechanical Properties for SiCp/AZ91 Composites with Different Particle Contents during Extrusion. Mater. Sci. Eng. A 2015, 636, 138–147. [Google Scholar] [CrossRef]

- Khandelwal, A.; Mani, K.; Srivastava, N.; Gupta, R.; Chaudhari, G.P. Mechanical Behavior of AZ31/Al2O3 Magnesium Alloy Nanocomposites Prepared Using Ultrasound Assisted Stir Casting. Compos. Part B Eng. 2017, 123, 64–73. [Google Scholar] [CrossRef]

- Yuan, Q.H.; Zeng, X.S.; Liu, Y.; Luo, L.; Wu, J.B.; Wang, Y.C.; Zhou, G.H. Microstructure and Mechanical Properties of AZ91 Alloy Reinforced by Carbon Nanotubes Coated with MgO. Carbon 2016, 96, 843–855. [Google Scholar] [CrossRef]

- Huang, S.J.; Abbas, A. Effects of Tungsten Disulfide on Microstructure and Mechanical Properties of AZ91 Magnesium Alloy Manufactured by Stir Casting. J. Alloys Compd. 2020, 817, 153321. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S.; Mukhopadhyay, N.K.; Yadav, A.; Sinha, D.K. Effect of TiC Reinforcement on Mechanical and Wear Properties of AZ91 Matrix Composites. Int. J. Met. 2022, 16, 2128–2143. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Xu, F.; Yang, S.; Li, B.; Li, Y.; Huang, Z.; Zheng, Q. An Investigation on Grain Refinement Mechanism of TiB2 Particulate Reinforced AZ91 Composites and Its Effect on Mechanical Properties. J. Alloys Compd. 2019, 780, 237–244. [Google Scholar] [CrossRef]

- Vaidya, A.R.; Lewandowski, J.J. Effects of SiCp Size and Volume Fraction on the High Cycle Fatigue Behavior of AZ91D Magnesium Alloy Composites. Mater. Sci. Eng. A 1996, 220, 85–92. [Google Scholar] [CrossRef]

- Llorca, N.; Bloyce, A.; Yue, T.M. Fatigue Behaviour of Short Alumina Fibre Reinforced AZ91 Magnesium Alloy Metal Matrix Composite. Mater. Sci. Eng. A 1991, 135, 247–252. [Google Scholar] [CrossRef]

- Ataya, S.; El-Sayed Seleman, M.M.; Latief, F.H.; Ahmed, M.M.Z.; Hajlaoui, K.; Elshaghoul, Y.G.Y.; Habba, M.I.A. Microstructure and Mechanical Properties of AZ91 Rein-Forced with High Volume Fraction of Oriented Short Carbon Fibers. Materials 2022, 15, 4818. [Google Scholar] [CrossRef]

- Ch, F. Faserverstärkte Magnesiumverbundwerkstoffe. In Magnesium Eigenschaften, Anwendung, Potenzial; Kainer, K.U., Ed.; Wiley-VHC: Weinheim, Germany, 2000; p. 202, ISBN 10: 3527299793, ISBN 13: 9783527299799. [Google Scholar]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef]

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials 1. ASTM: West Conshehoken, PA, USA, 2010; pp. 1–27. [CrossRef]

- Ataya, S.; El-Magd, E. Modeling the Creep Behavior of Mg Alloys with and without Short-Fiber Reinforcement. Comput. Mater. Sci. 2007, 39, 155–159. [Google Scholar] [CrossRef]

- Wang, M.; Jin, P.; Wang, J. Hot Deformation and Processing Maps of 7005 Aluminum Alloy. High Temp. Mater. Process. 2014, 33, 369–375. [Google Scholar] [CrossRef]

- Wang, J.; Shi, B.; Yang, Y. Hot Compression Behavior and Processing Map of Cast Mg-4Al-2Sn-Y-Nd Alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 626–631. [Google Scholar] [CrossRef]

- Fatemi, S.M.; Aliyari, S.; Miresmaeili, S.M. Dynamic Precipitation and Dynamic Recrystallization during Hot Deformation of a Solutionized WE43 Magnesium Alloy. Mater. Sci. Eng. A 2019, 762, 138076. [Google Scholar] [CrossRef]

- Chen, M.-S.; Yuan, W.-Q.; Li, H.-B.; Zou, Z.-H. New Insights on the Relationship between Flow Stress Softening and Dynamic Recrystallization Behavior of Magnesium Alloy AZ31B. Mater. Charact. 2019, 147, 173–183. [Google Scholar] [CrossRef]

- Xu, H.; Yang, Z.; Hu, M.; Ji, Z. Effect of Short Carbon Fiber Content on SCFs/AZ31 Composite Microstructure and Mechanical Properties. Results Phys. 2020, 17, 103074. [Google Scholar] [CrossRef]

- Minárik, P.; Král, R.; Čížek, J.; Chmelík, F. Effect of Different c/a Ratio on the Microstructure and Mechanical Properties in Magnesium Alloys Processed by ECAP. Acta Mater. 2016, 107, 83–95. [Google Scholar] [CrossRef]

- Harhash, M.; Ataya, S.; Abd El Hady, M.; El Mahallawy, N. Microstructural Characterization and Kinetics of Diffusion Bonded AZ31/Al by Hot Press Cladding. Mater. Werkst. 2014, 45, 15–20. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, C.; Liu, X. Effect of Ca Addition on the Microstructure and Tensile Property of AE42 Alloy. Mater. Lett. 2019, 252, 150–154. [Google Scholar] [CrossRef]

- Ishikawa, K.; Watanabe, H.; Mukai, T. High Strain Rate Deformation Behavior of an AZ91 Magnesium Alloy at Elevated Temperatures. Mater. Lett. 2005, 59, 1511–1515. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Kailas, S.V.; Seshan, S.; Kim, K.B.; Fleury, E. Tensile Strength and Fracture Toughness of Two Magnesium Metal Matrix Composites. J. Ceram. Process. Res. 2006, 7, 261–265. [Google Scholar]

- Mondal, A.K.; Blawert, C.; Kumar, S. Corrosion Behaviour of Creep-Resistant AE42 Magnesium Alloy-Based Hybrid Composites Developed for Powertrain Applications. Mater. Corros. 2015, 66, 1150–1158. [Google Scholar] [CrossRef]

- Changizian, P.; Zarei-Hanzaki, A.; Roostaei, A.A. The High Temperature Flow Behavior Modeling of AZ81 Magnesium Alloy Considering Strain Effects. Mater. Des. 2012, 39, 384–389. [Google Scholar] [CrossRef]

- El-Magd, E. Modelling and Simulation of Mechanical Behaviour. In Modelling and Simulation for Material Selection and Mechanical Design; Totten, G.E., Xie, L., Funatani, K., Eds.; CRC Press: New York, NY, USA, 2003; pp. 207–213. ISBN 9781351254502. [Google Scholar]

- Swift, H.W. Plastic Instability under Plane Stress. J. Mech. Phys. Solids 1952, 1, 1–18. [Google Scholar] [CrossRef]

- Voce, E. Deformation, The Relationship between Stress and Strain for Homogeneous. J. Inst. Met. 1948, 74, 537–562. [Google Scholar]

- Ataya, S.; El-Magd, E. Quasi-Static Behavior of Mg-Alloys with and without Short-Fiber Reinforcement. Theor. Appl. Fract. Mech. 2007, 47, 102–112. [Google Scholar] [CrossRef]

- Patel, H.A.; Chen, D.L.; Bhole, S.D.; Sadayappan, K. Microstructure and Tensile Properties of Thixomolded Magnesium Alloys. J. Alloys Compd. 2010, 496, 140–148. [Google Scholar] [CrossRef]

- Lu, L.; Liu, T.; Chen, Y.; Wang, Z. Deformation and Fracture Behavior of Hot Extruded Mg Alloys AZ31. Mater. Charact. 2012, 67, 93–100. [Google Scholar] [CrossRef]

- Shi, H.; Xu, C.; Hu, X.; Gan, W.; Wu, K.; Wang, X. Improving the Young’s Modulus of Mg via Alloying and Compositing—A Short Review. J. Magnes. Alloy. 2022, 10, 2009–2024. [Google Scholar] [CrossRef]

- He, K.; Zhao, J.; Cheng, J.; Shangguan, J.; Wen, F.; Wang, Y. Influence of a Zn Interlayer on the Interfacial Microstructures and Mechanical Properties of Arc-Sprayed Al/AZ91D Bimetals Manufactured by the Solid-Liquid Compound Casting Process. Materials 2019, 12, 3273. [Google Scholar] [CrossRef] [PubMed]

- Krizik, P.; Balog, M.; Matko, I.; Svec, P.; Cavojsky, M.; Simancik, F. The Effect of a Particle–Matrix Interface on the Young’s Modulus of Al–SiC Composites. J. Compos. Mater. 2015, 50, 99–108. [Google Scholar] [CrossRef]

| Components | Composition (wt. %) | Density (gm/cm3) | CTE (10−6 K−1) | Strength (MPa) | E-Modul (GPa) | Strain at Fracture ε (%) |

|---|---|---|---|---|---|---|

| Carbon Fibers (PAN) [31] | >95 % C L ≈ 92, d ≈ 7 µm | 1.78 | 0.3 RT-100 °C | 2000– 3500 | 225 | 1.2–1.5 |

| AZ91 | Mg—9 Al, 1 Zn | 1.8 | 19–23 50–200 °C | 240 | 45 | 9 |

| Elements | Al | Zn | Si | Mn | Fe | Ni | Mg |

|---|---|---|---|---|---|---|---|

| wt. % | 9.05 | 0.88 | 0.05 | 0.28 | 0.004 | 0.001 | Rest |

| Parameter | c (K/MPa) | |

|---|---|---|

| ko | 151 | 2.45 |

| C1 = C3 | 22.4 | −0.85 |

| C2 | 118 | 0.878 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alrasheedi, N.H.; Ataya, S.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z. Tensile Deformation and Fracture of Unreinforced AZ91 and Reinforced AZ91-C at Temperatures up to 300 °C. Materials 2023, 16, 4785. https://doi.org/10.3390/ma16134785

Alrasheedi NH, Ataya S, El-Sayed Seleman MM, Ahmed MMZ. Tensile Deformation and Fracture of Unreinforced AZ91 and Reinforced AZ91-C at Temperatures up to 300 °C. Materials. 2023; 16(13):4785. https://doi.org/10.3390/ma16134785

Chicago/Turabian StyleAlrasheedi, Nashmi H., Sabbah Ataya, Mohamed M. El-Sayed Seleman, and Mohamed M. Z. Ahmed. 2023. "Tensile Deformation and Fracture of Unreinforced AZ91 and Reinforced AZ91-C at Temperatures up to 300 °C" Materials 16, no. 13: 4785. https://doi.org/10.3390/ma16134785

APA StyleAlrasheedi, N. H., Ataya, S., El-Sayed Seleman, M. M., & Ahmed, M. M. Z. (2023). Tensile Deformation and Fracture of Unreinforced AZ91 and Reinforced AZ91-C at Temperatures up to 300 °C. Materials, 16(13), 4785. https://doi.org/10.3390/ma16134785