Wrinkling and Strengthening Behaviors in the Two-Layer-Sheet Hot-Forming–Quenching Integrated Process for an Al–Cu–Mg-Alloy Thin-Walled Curved-Surface Shell

Abstract

1. Introduction

2. Materials and Procedures

2.1. Materials

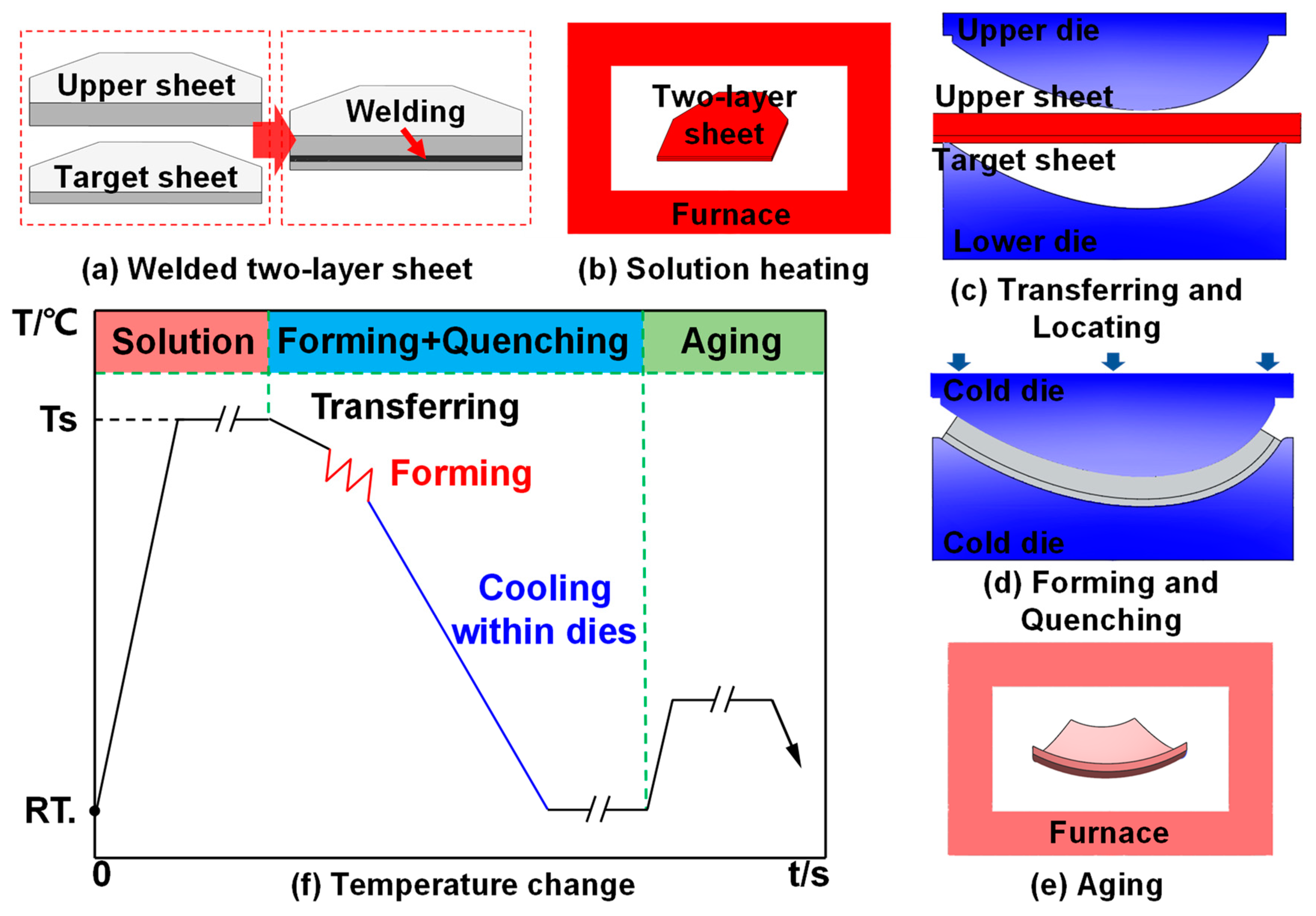

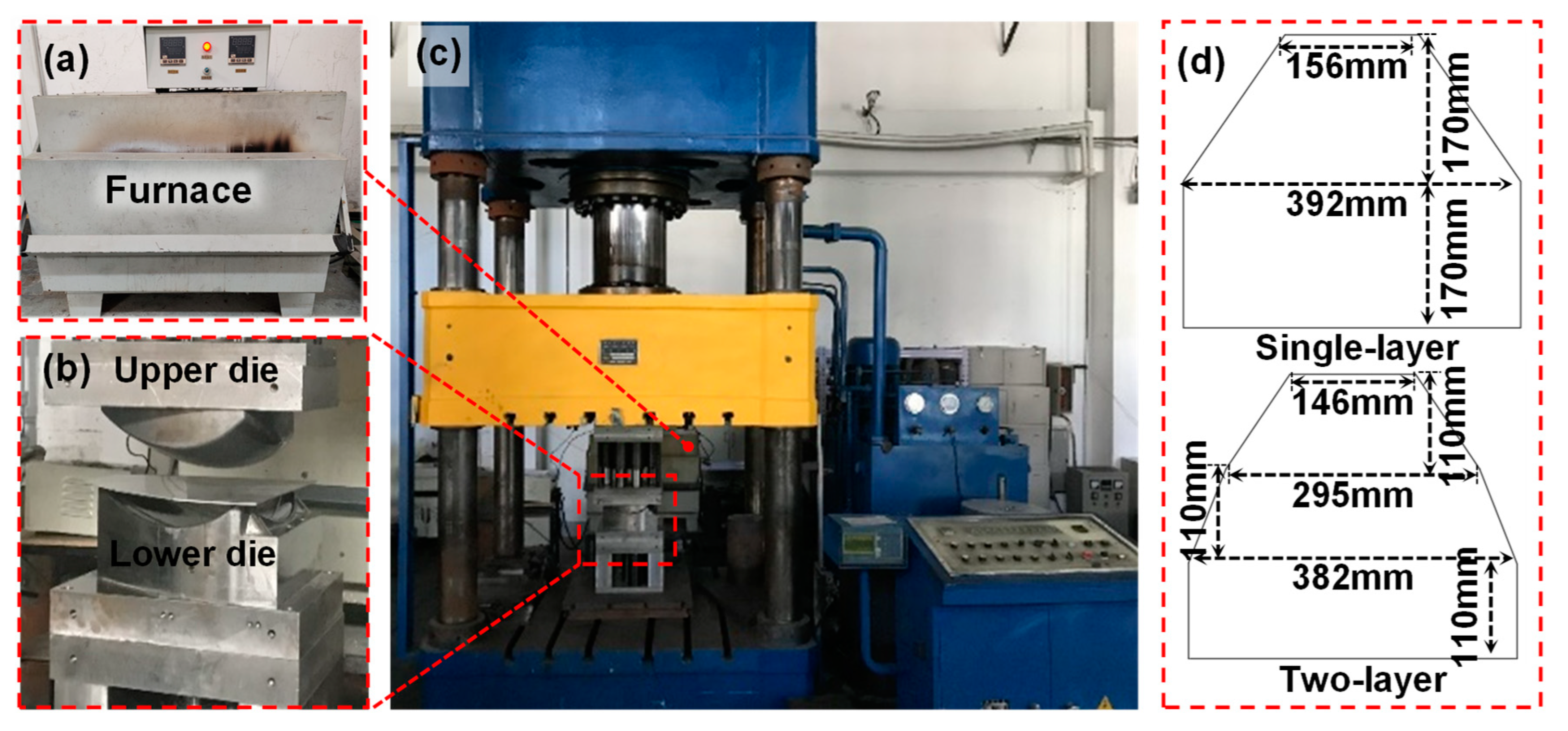

2.2. Experimental Procedure

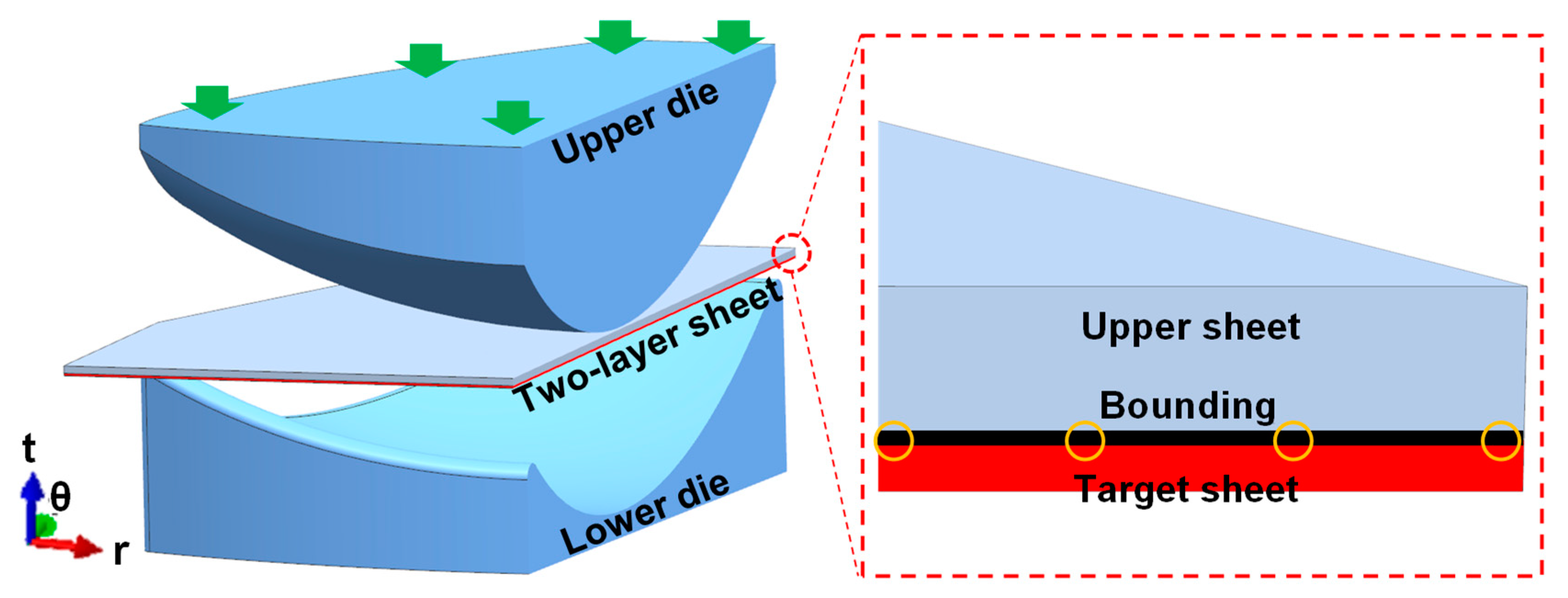

2.3. Numerical Simulation

3. Results and Discussion

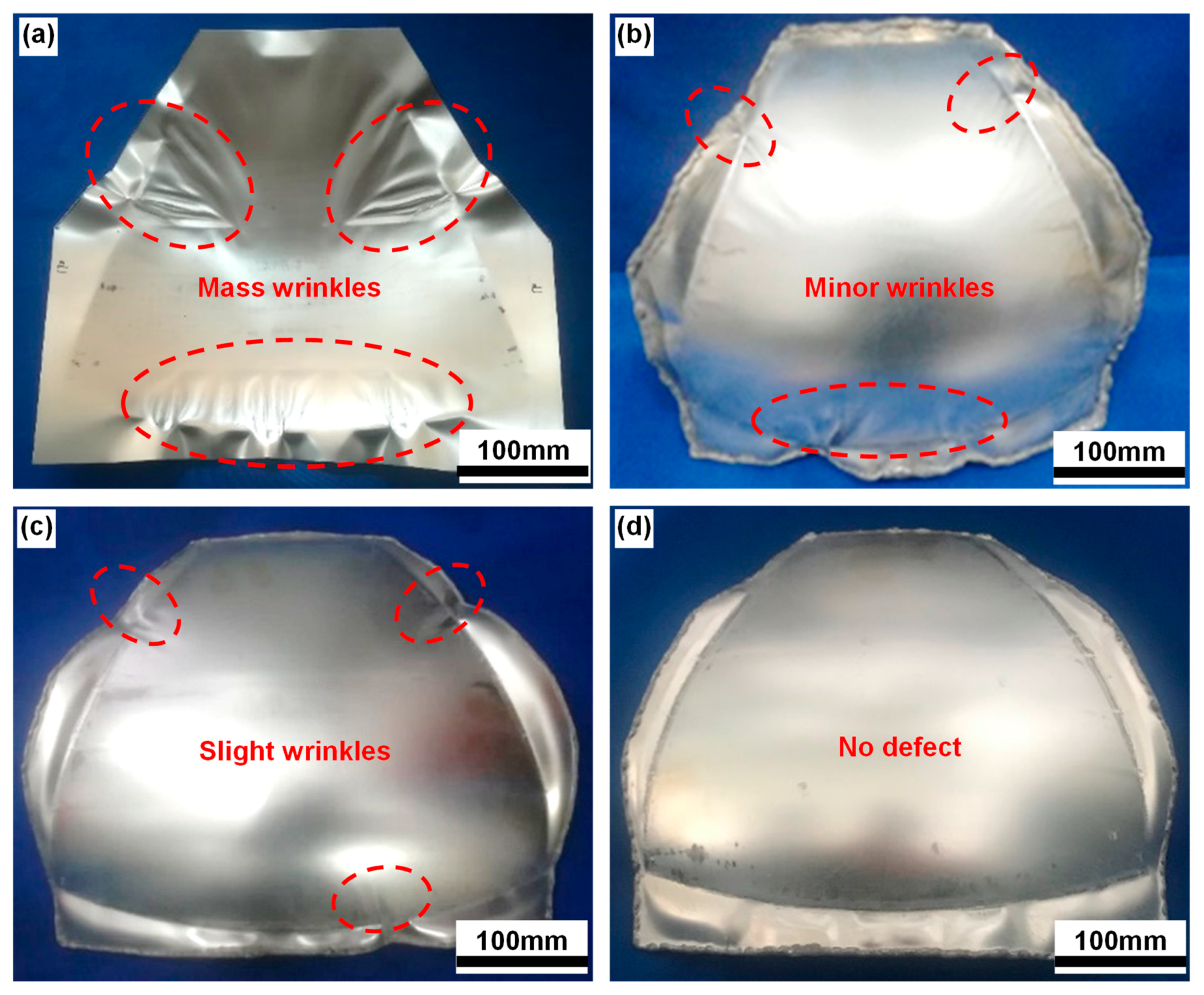

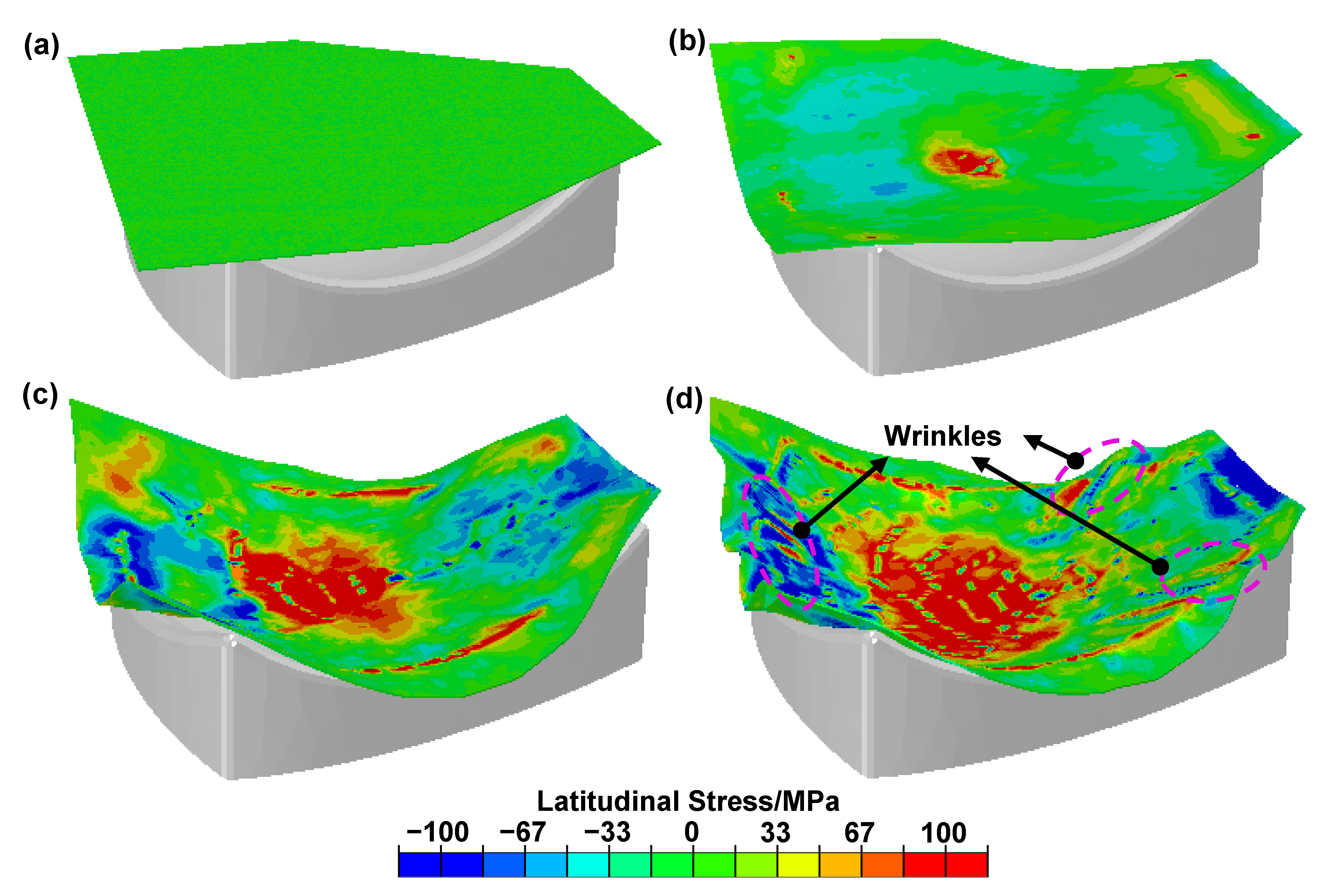

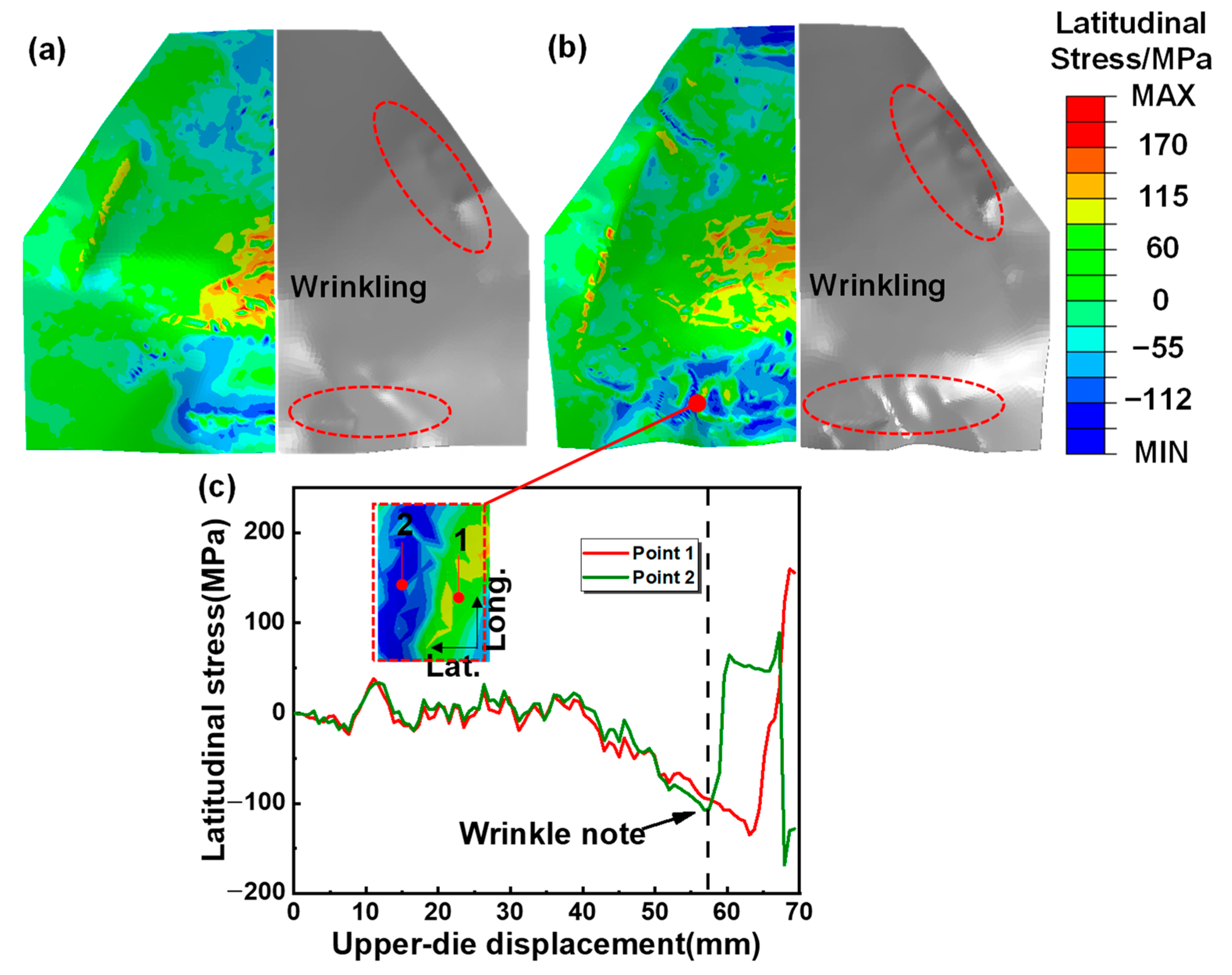

3.1. Wrinkling Behavior

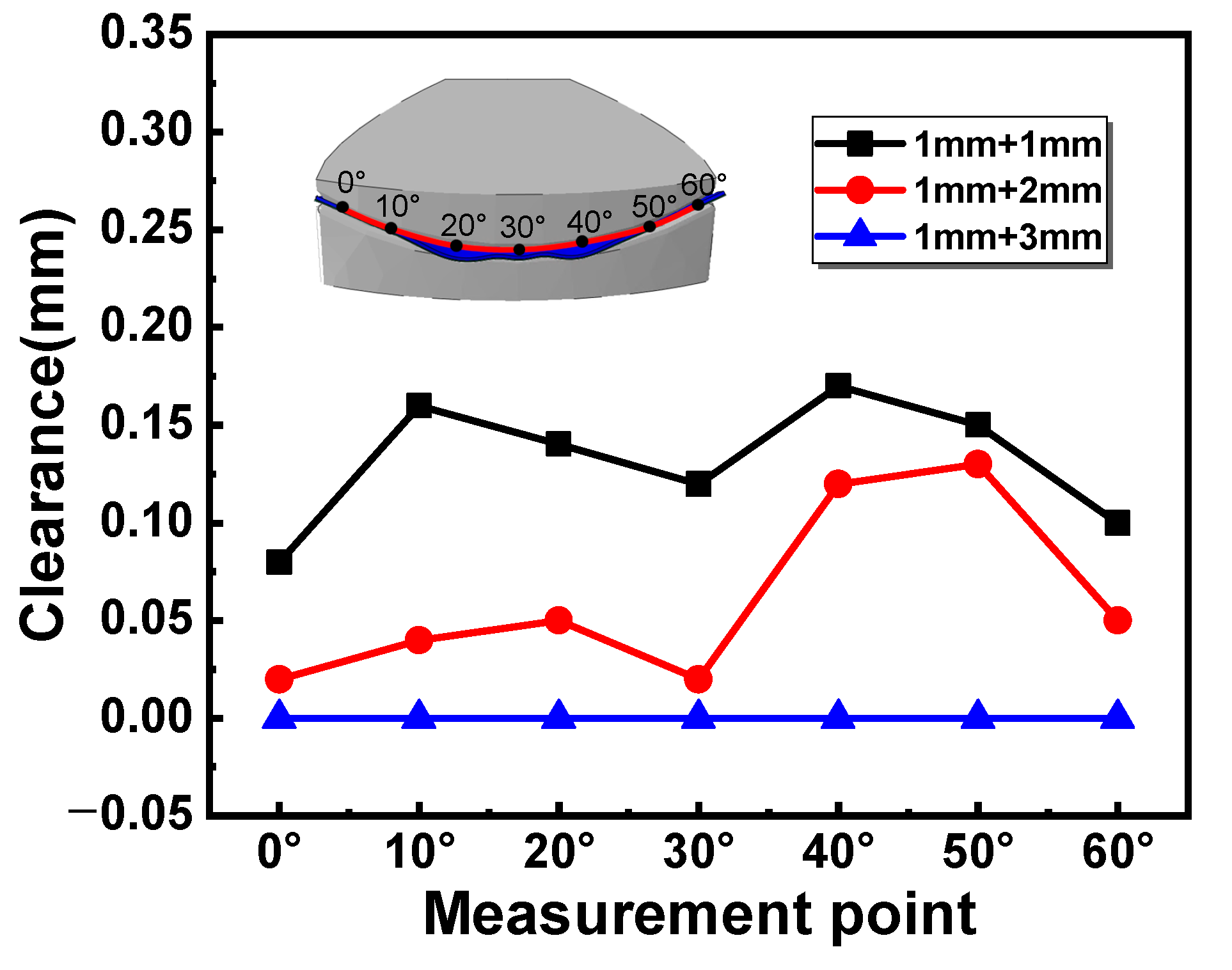

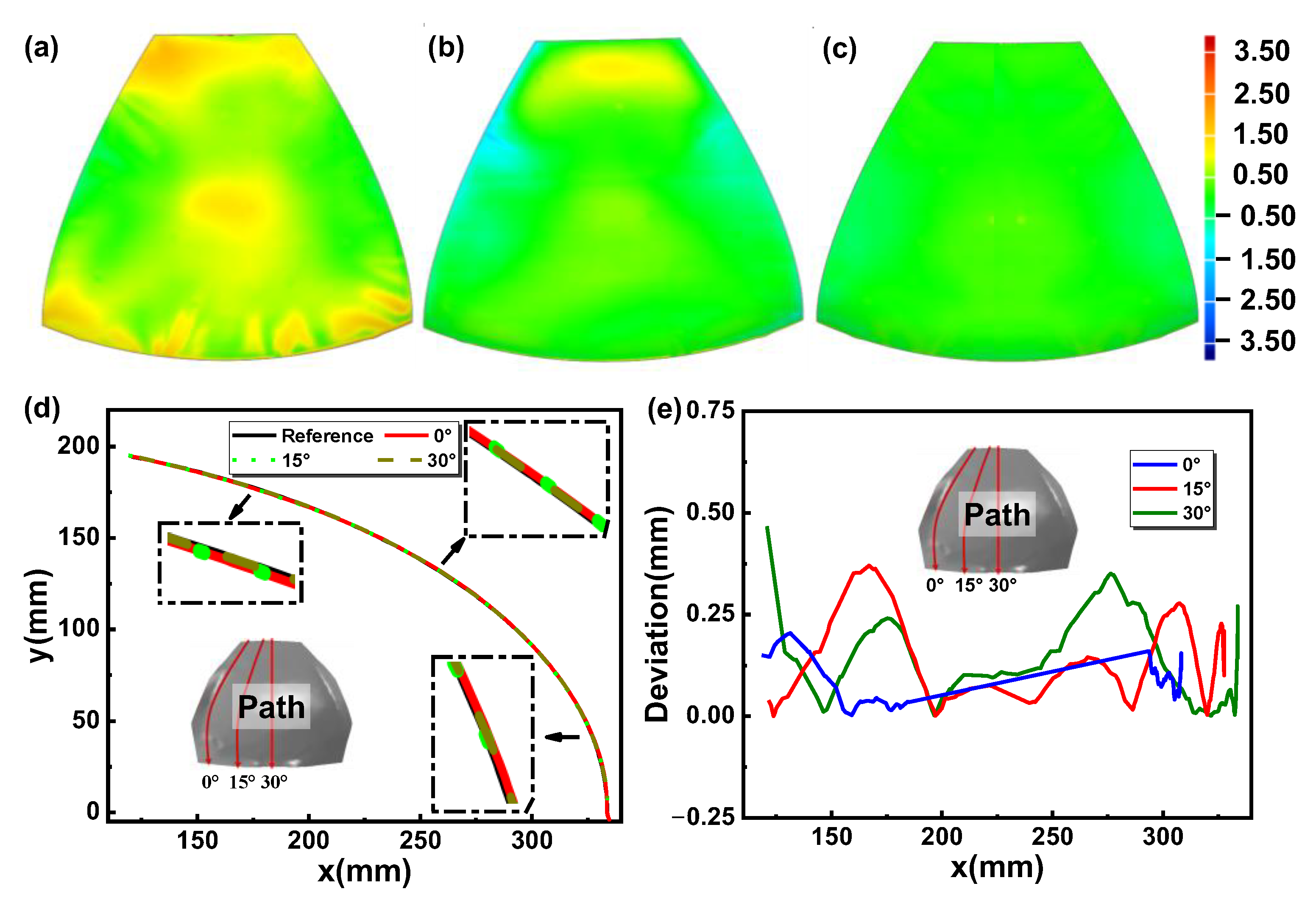

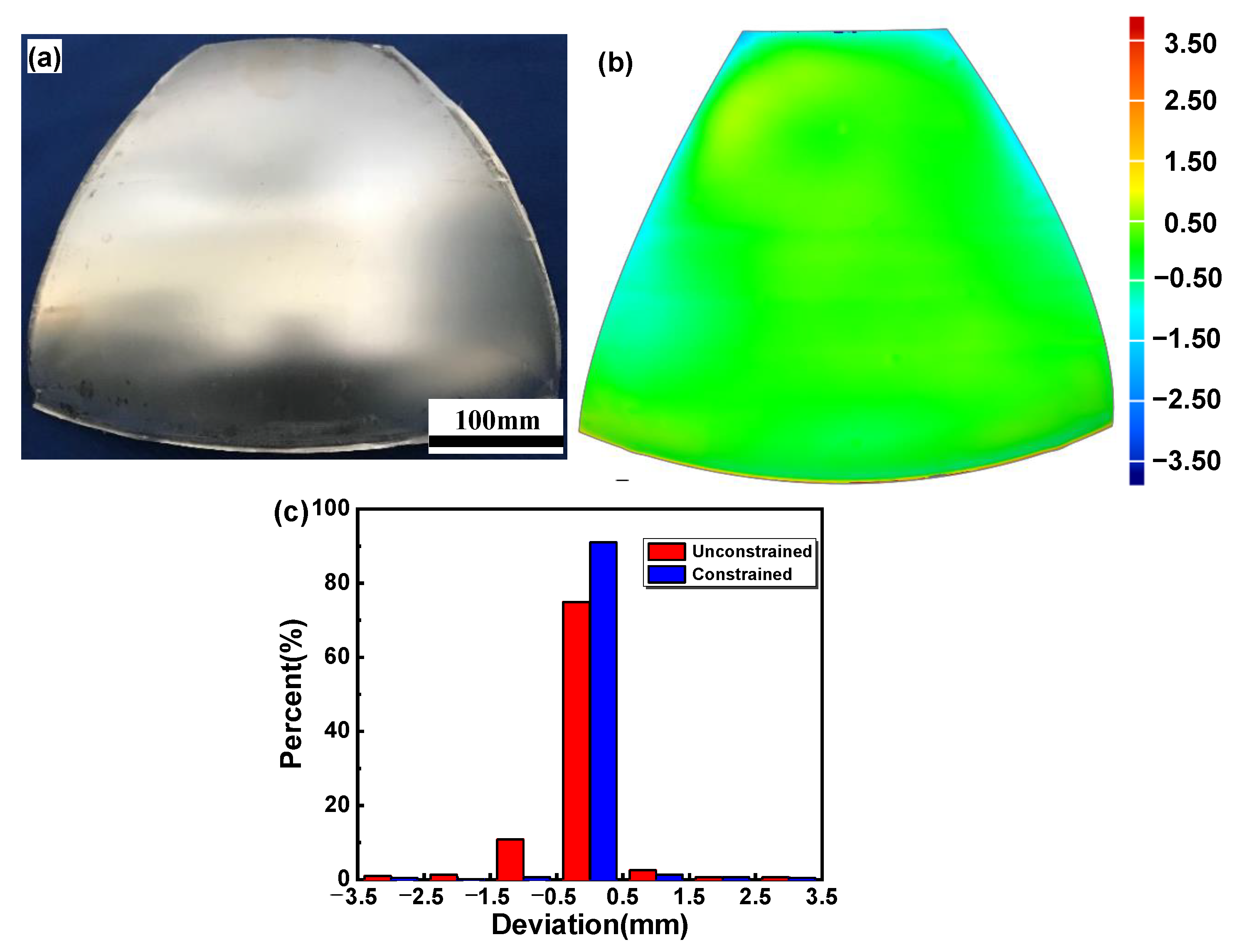

3.2. Forming Precision

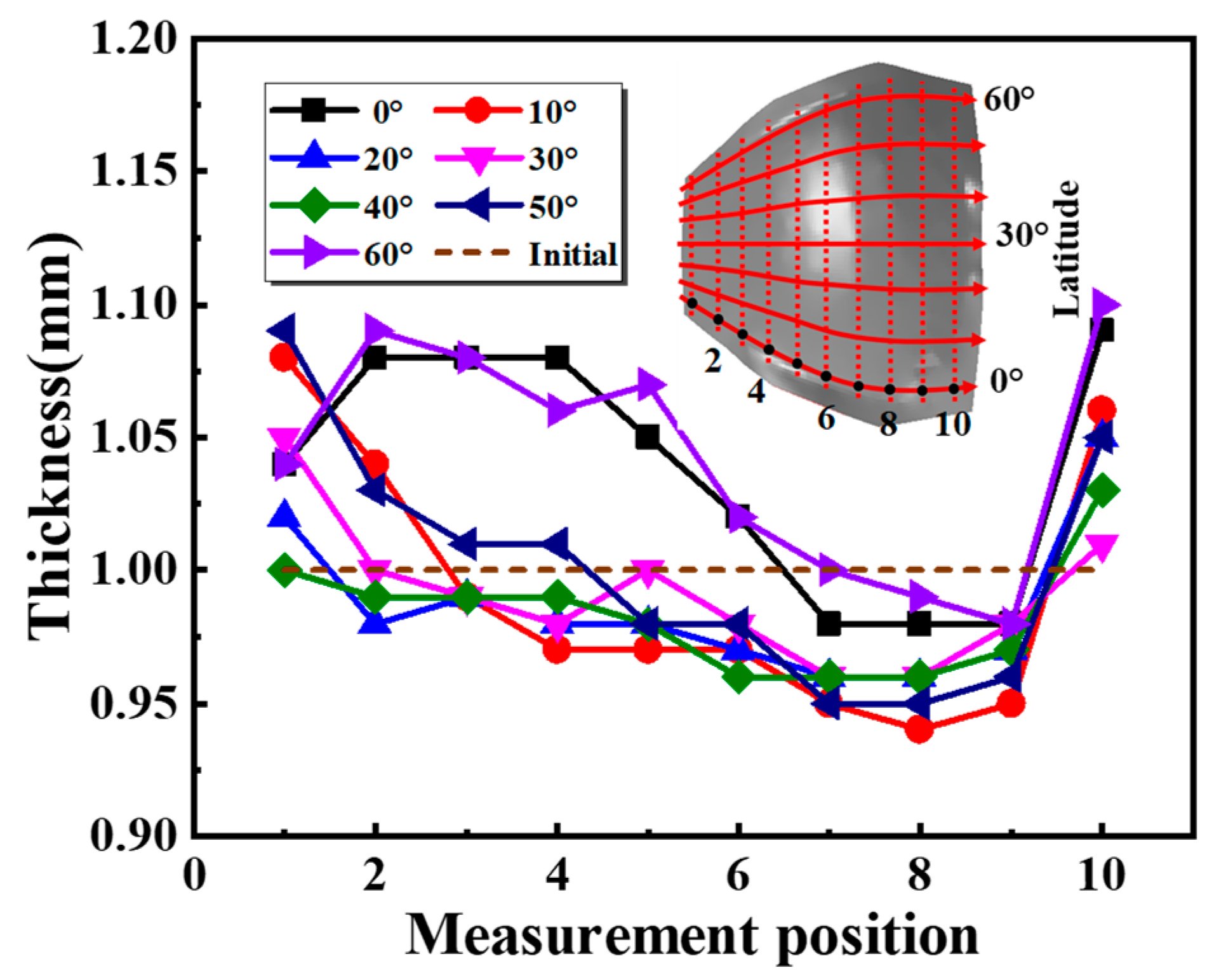

3.3. Thickness Distribution

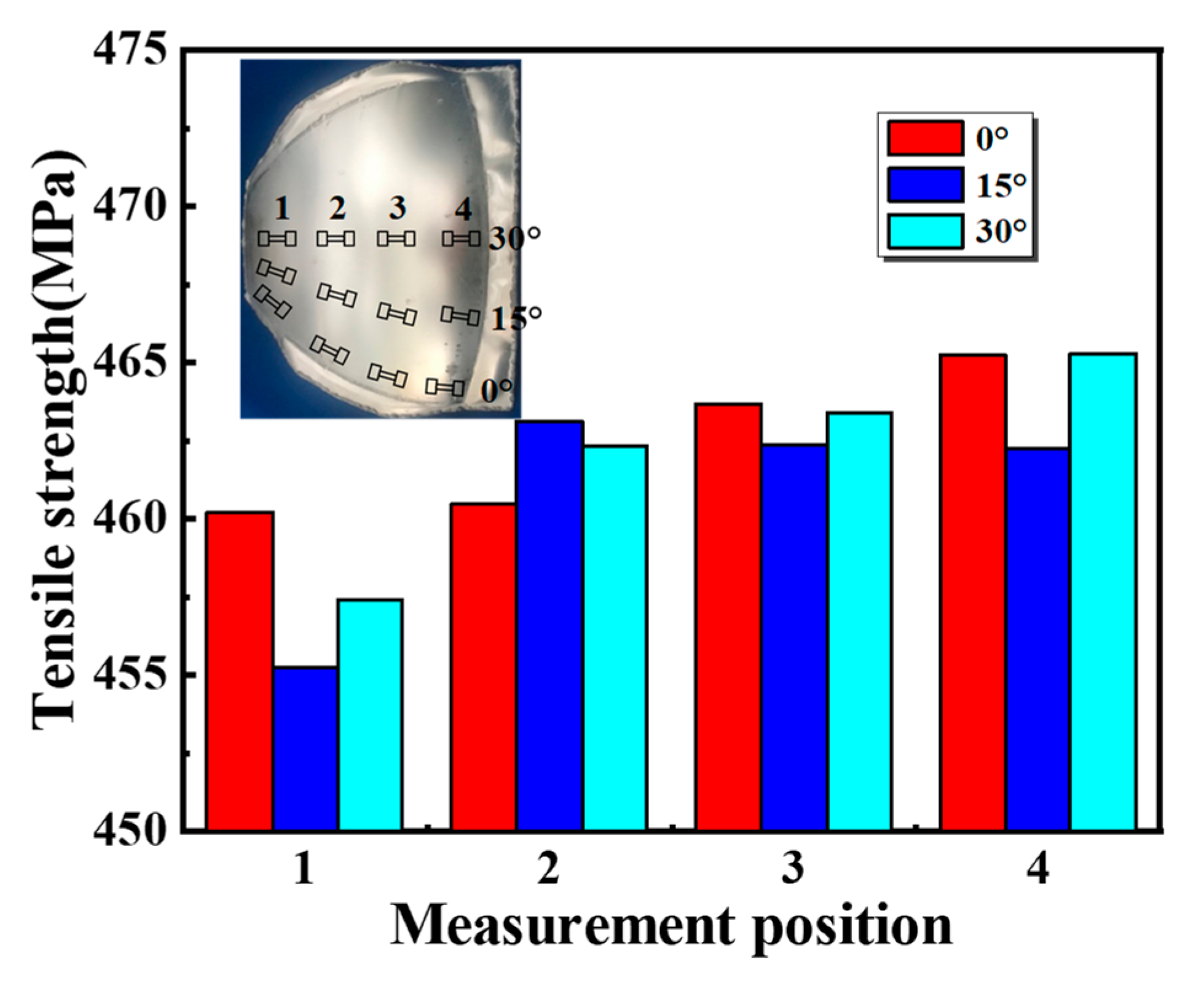

3.4. Strength Distribution

4. Conclusions

- The thicker upper sheet is beneficial to suppress wrinkling. When the thickness of the upper sheet increases to three times that of the target sheet, a curved-surface component with a smooth surface and no defects can finally be formed. The upper auxiliary sheet can effectively reduce the compressive stress at the edge of the target forming sheet, thus inhibiting the wrinkling defect.

- A melon petal can be formed with high precision. The profile deviation in the desired region is between −0.5 mm and 0.5 mm. This is due to the fact that a temperature close to the solution temperature and die quenching are utilized to suppress springback and avoid thermal deformation.

- Full strength can be obtained by die quenching in the two-layer-sheet hot-forming–quenching integrated process. The tensile strength in all regions ranges from 455 MPa to 466 MPa, reaching the full strength of the used material and ensuring uniform quenching.

- Thin-walled curved-surface components such as melon petals with high forming quality and full strength can be formed by this two-layer-sheet hot-forming–quenching integrated process, which has great potential for fabricating aluminum-alloy thin-walled curved-surface components.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Liu, W.; An, L.H.; Yuan, S.J. Enhancement on deformation uniformity of double curvature shell by hydroforming process and curved blank-holder surface. Int. J. Adv. Manuf. Technol. 2017, 92, 1913–1922. [Google Scholar] [CrossRef]

- Wang, G.Q.; Zhao, Y.H.; Hao, Y.F. Friction stir welding of high-strength aerospace aluminum alloy and application in rocket tank manufacturing. J. Mater. Sci. Technol. 2018, 34, 73–91. [Google Scholar] [CrossRef]

- Xing, J.; Li, M.Z.; Cheng, Y.Y.; Wang, B.L.; Yang, Z.; Wang, Y. Effect of the arrangement of the punch units in multi-point stretch forming process. Int. J. Adv. Manuf. Technol. 2016, 86, 2309–2317. [Google Scholar] [CrossRef]

- Tian, S.; Li, J.G.; Liu, Y.P.; Zhang, J.G.; Yang, S.W.; Yu, H.Z.; Lang, L.H. Springback control on hydroforming for various specifications ellipsoidal scalloped segment. Forg. Stamp. Technol. 2019, 44, 55–61. [Google Scholar]

- Zhan, L.H.; Lin, J.G.; Dean, T.A.; Huang, M.H. Experimental studies and constitutive modelling of the hardening of aluminium alloy 7055 under creep age forming conditions. Int. J. Mech. Sci. 2011, 53, 595–605. [Google Scholar] [CrossRef]

- Zhan, L.H.; Lin, J.G.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tools Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

- Lam, A.C.; Shi, Z.S.; Yang, H.L.; Wan, L.; Davies, C.M.; Lin, J.G.; Zhou, S. Creep-age forming AA2219 plates with different stiffener designs and pre-form age conditions: Experimental and finite element studies. J. Mater. Process. Technol. 2015, 219, 155–163. [Google Scholar] [CrossRef]

- Li, N.; Mohamed, M.S.; Cai, J.; Lin, J.; Balint, D.; Dean, T.A. Experimental and numerical studies on the formability of materials in hot stamping and cold die quenching processes. AIP Conf. Proc. 2011, 1353, 1555–1561. [Google Scholar]

- Dang, K.X.; Wang, K.H.; Chen, W.T.; Liu, G. Study on fast gas forming with in-die quenching for titanium alloys and the strengthening mechanisms of the components. J. Mater. Res. Technol. 2022, 18, 3916–3932. [Google Scholar] [CrossRef]

- Foster, A.; Szegda, D.; Sellors, J. Design considerations for HFQ® hot stamped aluminium structural panels. MATEC Web Conf. 2015, 21, 05014. [Google Scholar] [CrossRef]

- Fakir, O.E.; Wang, L.L.; Balint, D.; Dear, J.P.; Lin, J.G.; Dean, T.A. Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754. Int. J. Mach. Tools Manuf. 2014, 87, 39–48. [Google Scholar] [CrossRef]

- Fan, X.B.; Wang, X.G.; Lin, Y.L.; He, Z.B.; Yuan, S.J. Deformation and strengthening behaviors of Al–Cu–Mg alloy thick plate during hot forming-quenching integrated process. J. Mater. Res. Technol. 2022, 16, 1231–1242. [Google Scholar] [CrossRef]

- Fan, X.B.; He, Z.B.; Yuan, S.J.; Zheng, K.L. Experimental investigation on hot forming–quenching integrated process of 6A02 aluminum alloy sheet. Mater. Sci. Eng. A 2013, 573, 154–160. [Google Scholar] [CrossRef]

- Fan, X.B.; He, Z.B.; Zheng, K.L.; Yuan, S.J. Strengthening behavior of Al–Cu–Mg alloy sheet in hot forming–quenching integrated process with cold–hot dies. Mater. Des. 2015, 83, 557–565. [Google Scholar] [CrossRef]

- Jiang, Y.F.; Ding, H.; Cai, M.H.; Chen, Y.; Liu, Y.; Zhang, Y.S. Investigation into the hot forming-quenching integrated process with cold dies for high strength aluminum alloy. Mater. Charact. 2019, 158, 109967. [Google Scholar] [CrossRef]

- Harhash, M.; Palkowski, H. Incremental sheet forming of steel/polymer/steel sandwich composites. J. Mater. Res. Technol. 2021, 13, 417–430. [Google Scholar] [CrossRef]

- Azodi, H.D.; Safari, M.; Darabi, R. Formability Prediction of Two-Layer Sheets Based on Ductile Fracture Criteria. Trans. Indian. Inst. Met. 2017, 70, 1841–1847. [Google Scholar] [CrossRef]

- Zhou, B.J.; Xu, Y.C. Wrinkle behavior of hydroforming of aluminum alloy double-layer sheets. JOM 2016, 68, 3201–3207. [Google Scholar] [CrossRef]

- Zhou, B.J.; Xu, Y.C. The effect of upper sheet on wrinkling and thickness distribution of formed sheet part using double-layer sheet hydroforming. Int. J. Adv. Manuf. Technol. 2018, 99, 1175–1182. [Google Scholar] [CrossRef]

- Zhou, B.J.; Xu, Y.C.; Zhang, Z.C. Research on the selection principle of upper sheet in double-layer sheets hydroforming. Int. J. Adv. Manuf. Technol. 2020, 109, 1663–1669. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, L.; Bai, B.; Lang, L.H. Evaluation of limit deformation behavior in hydro-bulging of the double-layer sheet metal using diffuse and localized instability theories. Int. J. Mech. Sci. 2019, 150, 145–153. [Google Scholar] [CrossRef]

- Liu, X.J.; Zhang, Z.H.; Ma, X.F.; Li, C.; Zhou, Y.Y. Study on hydroforming of AA6061-T6 aluminum alloy sheet based on upper sheet. Int. J. Adv. Manuf. Technol. 2022, 123, 4447–4464. [Google Scholar] [CrossRef]

- Karajibani, E.; Fazli, A.; Hashemi, R. Numerical and experimental study of formability in deep drawing of two-layer metallic sheets. Int. J. Adv. Manuf. Technol. 2015, 80, 113–121. [Google Scholar] [CrossRef]

- Khorasani, M.; Gibson, I.; Ghasemi, A.H.; Hadavi, E.; Rolfe, B. Laser subtractive and laser powder bed fusion of metals: Review of process and production features. Rapid Prototyp. J. 2023, 29, 935–958. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Liu, W.; Yuan, S.J. Research development on wrinkling prediction and suppression for sheet hydroforming of thin-walled deep drawing parts. J. Mech. Eng. 2016, 52, 20–28. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, X.; Sun, B.; Qu, W.; Chen, X.; Wang, X. Wrinkling and Strengthening Behaviors in the Two-Layer-Sheet Hot-Forming–Quenching Integrated Process for an Al–Cu–Mg-Alloy Thin-Walled Curved-Surface Shell. Materials 2023, 16, 4766. https://doi.org/10.3390/ma16134766

Fan X, Sun B, Qu W, Chen X, Wang X. Wrinkling and Strengthening Behaviors in the Two-Layer-Sheet Hot-Forming–Quenching Integrated Process for an Al–Cu–Mg-Alloy Thin-Walled Curved-Surface Shell. Materials. 2023; 16(13):4766. https://doi.org/10.3390/ma16134766

Chicago/Turabian StyleFan, Xiaobo, Baoshan Sun, Wenliang Qu, Xianshuo Chen, and Xugang Wang. 2023. "Wrinkling and Strengthening Behaviors in the Two-Layer-Sheet Hot-Forming–Quenching Integrated Process for an Al–Cu–Mg-Alloy Thin-Walled Curved-Surface Shell" Materials 16, no. 13: 4766. https://doi.org/10.3390/ma16134766

APA StyleFan, X., Sun, B., Qu, W., Chen, X., & Wang, X. (2023). Wrinkling and Strengthening Behaviors in the Two-Layer-Sheet Hot-Forming–Quenching Integrated Process for an Al–Cu–Mg-Alloy Thin-Walled Curved-Surface Shell. Materials, 16(13), 4766. https://doi.org/10.3390/ma16134766