Figure 1.

Photos of aeolian sand. (a) Digital photo. (b) SEM photo.

Figure 1.

Photos of aeolian sand. (a) Digital photo. (b) SEM photo.

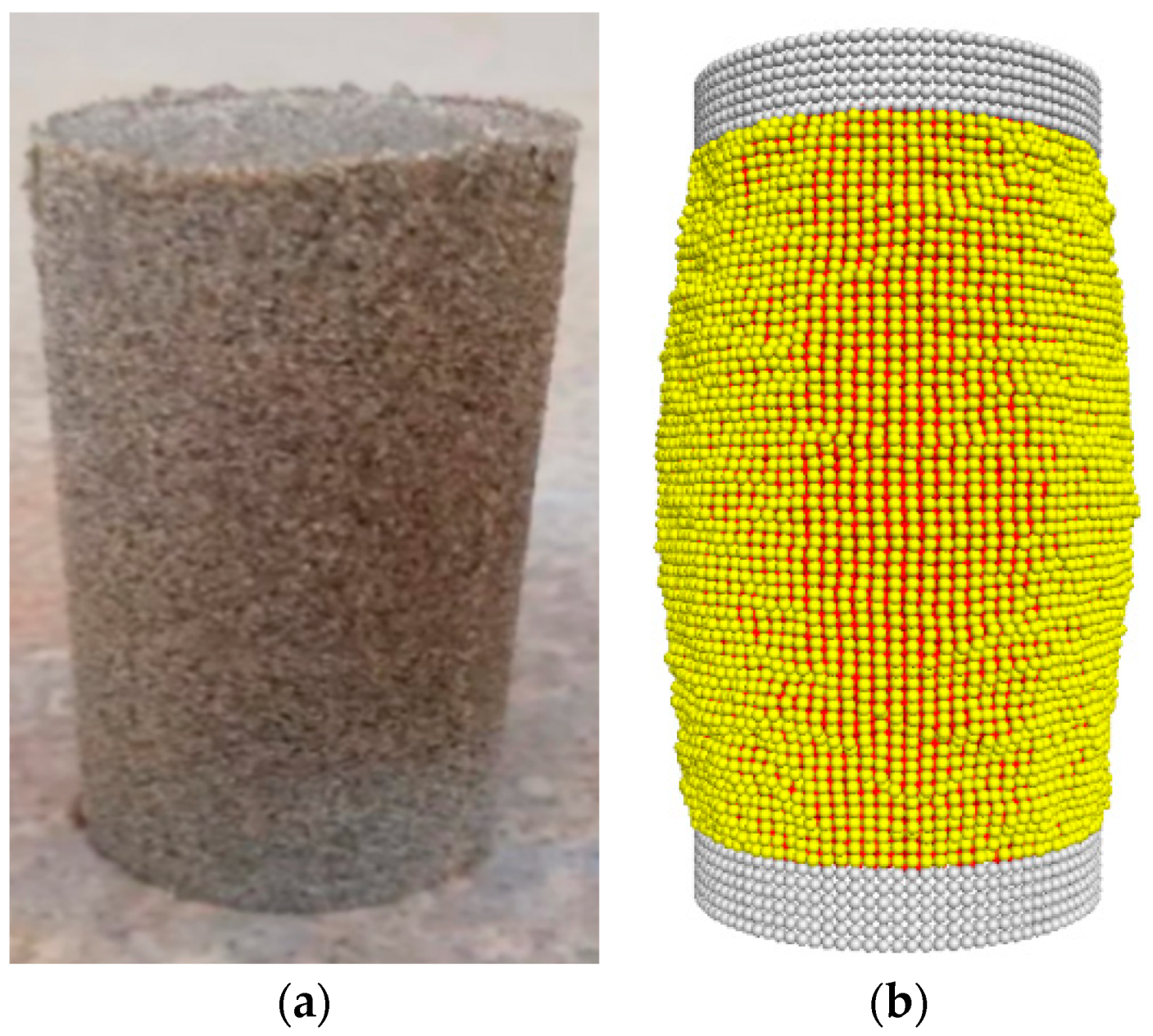

Figure 2.

The triaxial test and particle flow simulation. (a) Physical sample for triaxial testing. (b) Numerical model for triaxial testing.

Figure 2.

The triaxial test and particle flow simulation. (a) Physical sample for triaxial testing. (b) Numerical model for triaxial testing.

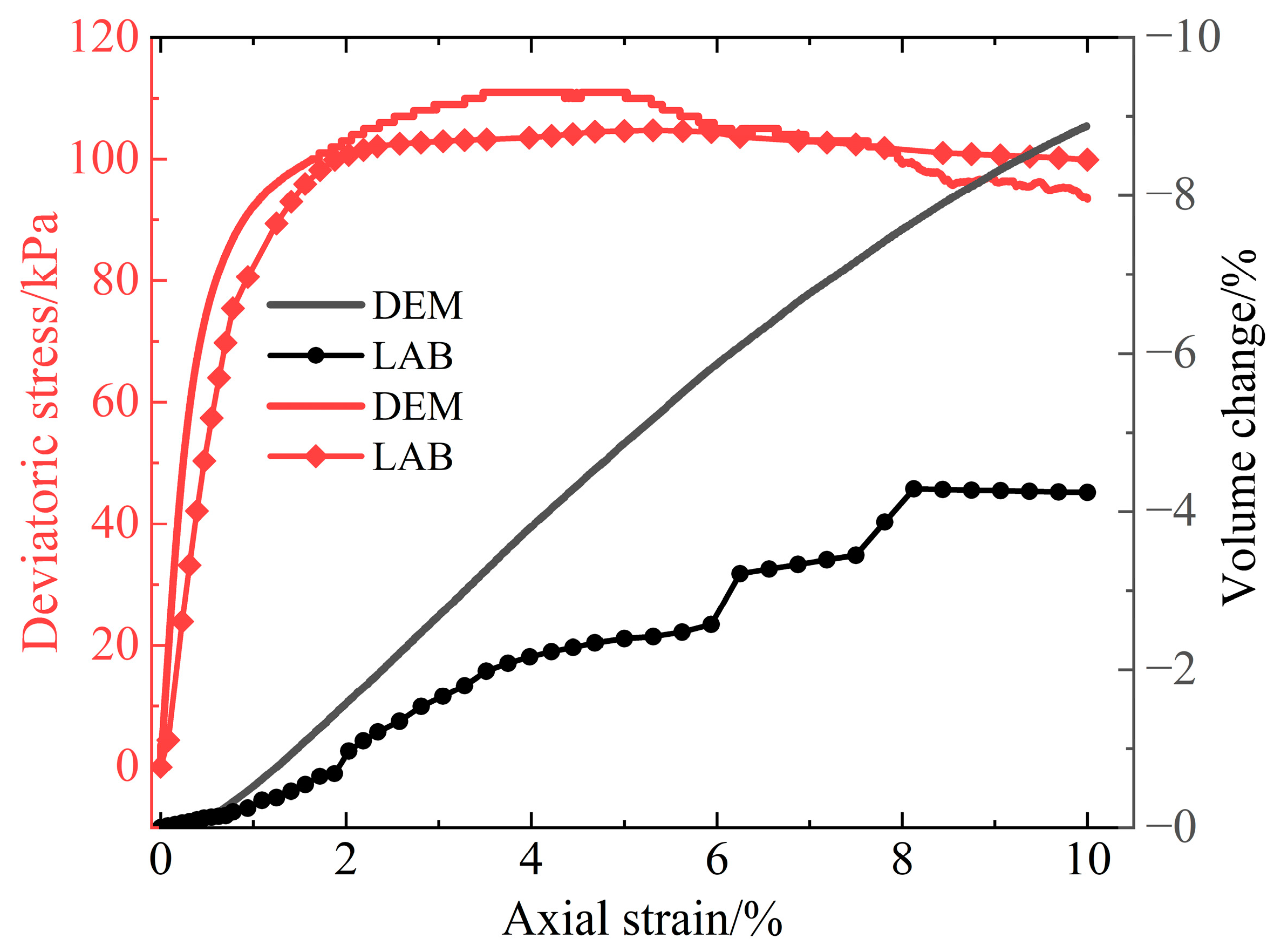

Figure 3.

Deviatoric stress and volume strain–axial strain curves.

Figure 3.

Deviatoric stress and volume strain–axial strain curves.

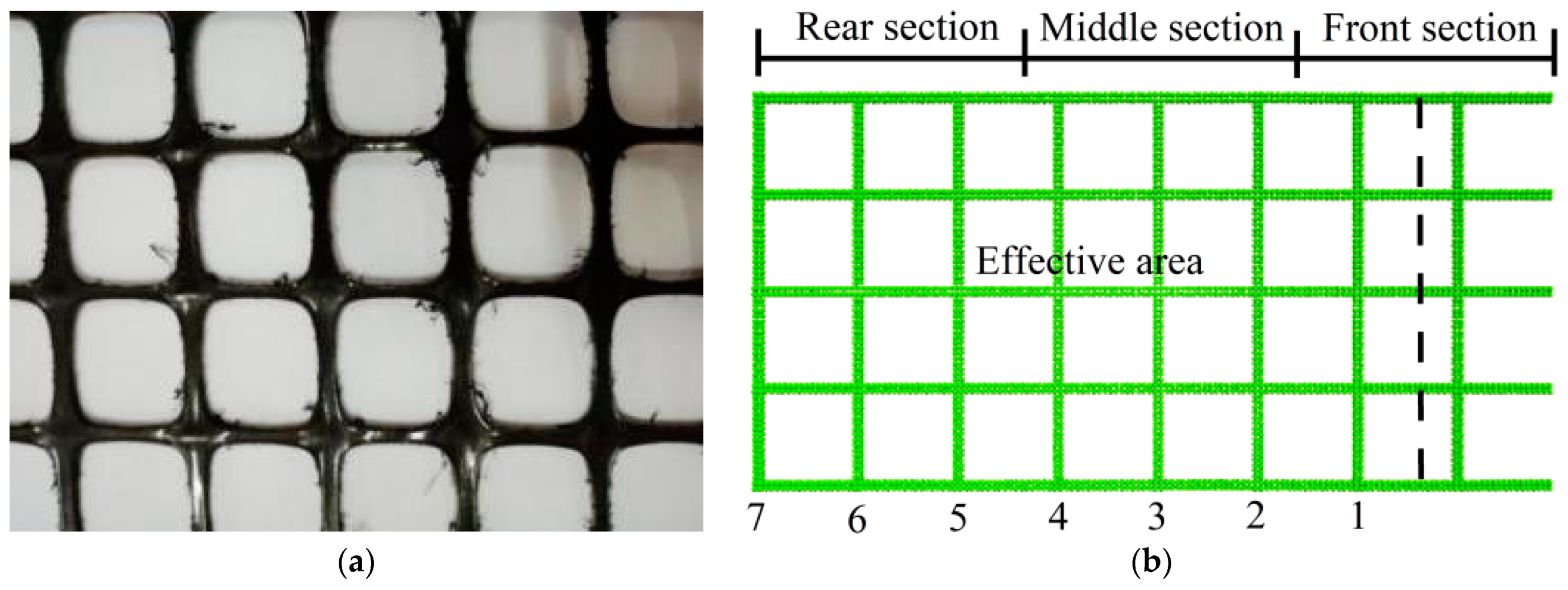

Figure 4.

Detailed diagrams of geogrid. (a) Conventional biaxial geogrid. (b) Numerical model of the geogrid.

Figure 4.

Detailed diagrams of geogrid. (a) Conventional biaxial geogrid. (b) Numerical model of the geogrid.

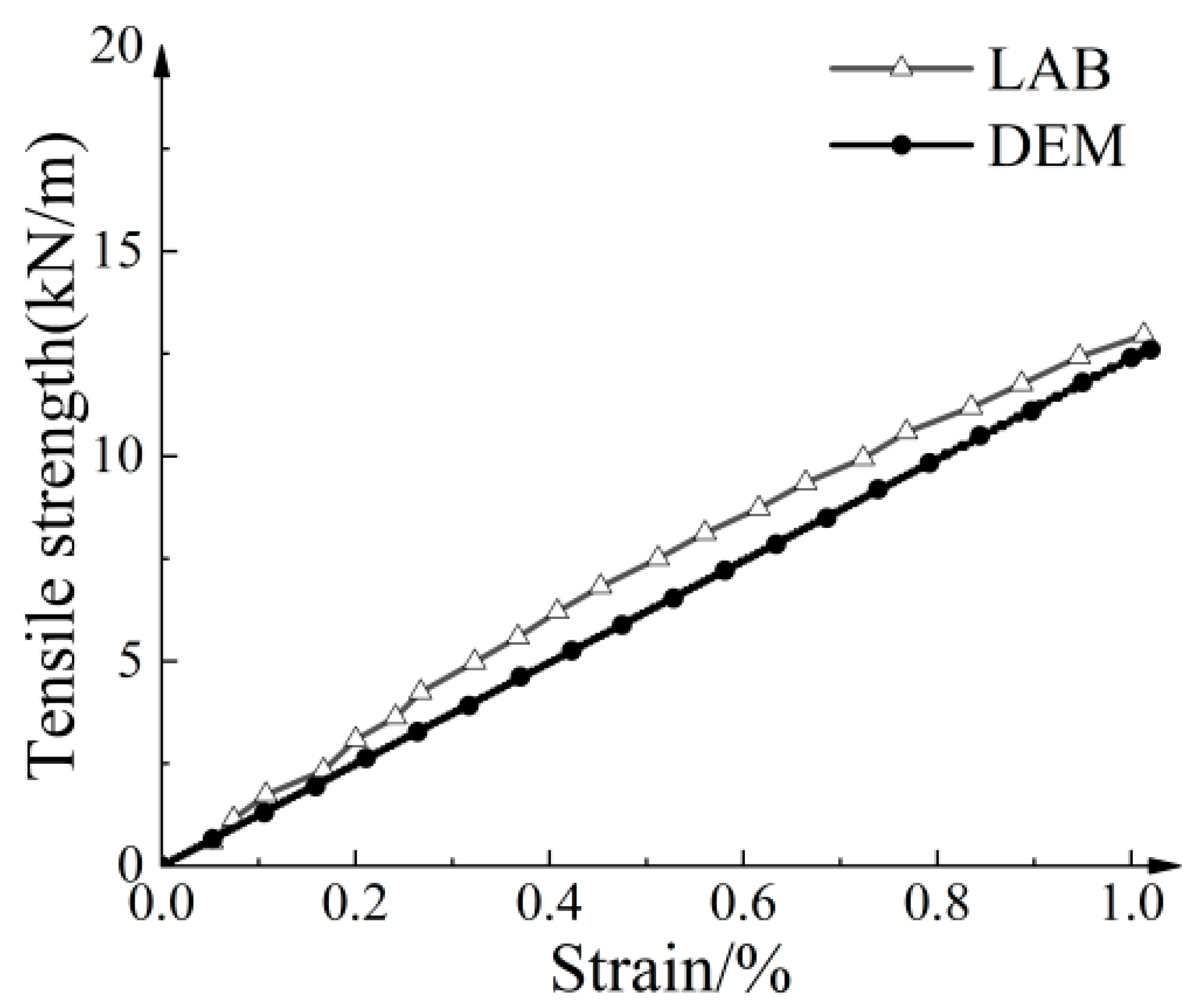

Figure 5.

Comparison of stress–strain relationship of geogrid between tensile test and numerical model.

Figure 5.

Comparison of stress–strain relationship of geogrid between tensile test and numerical model.

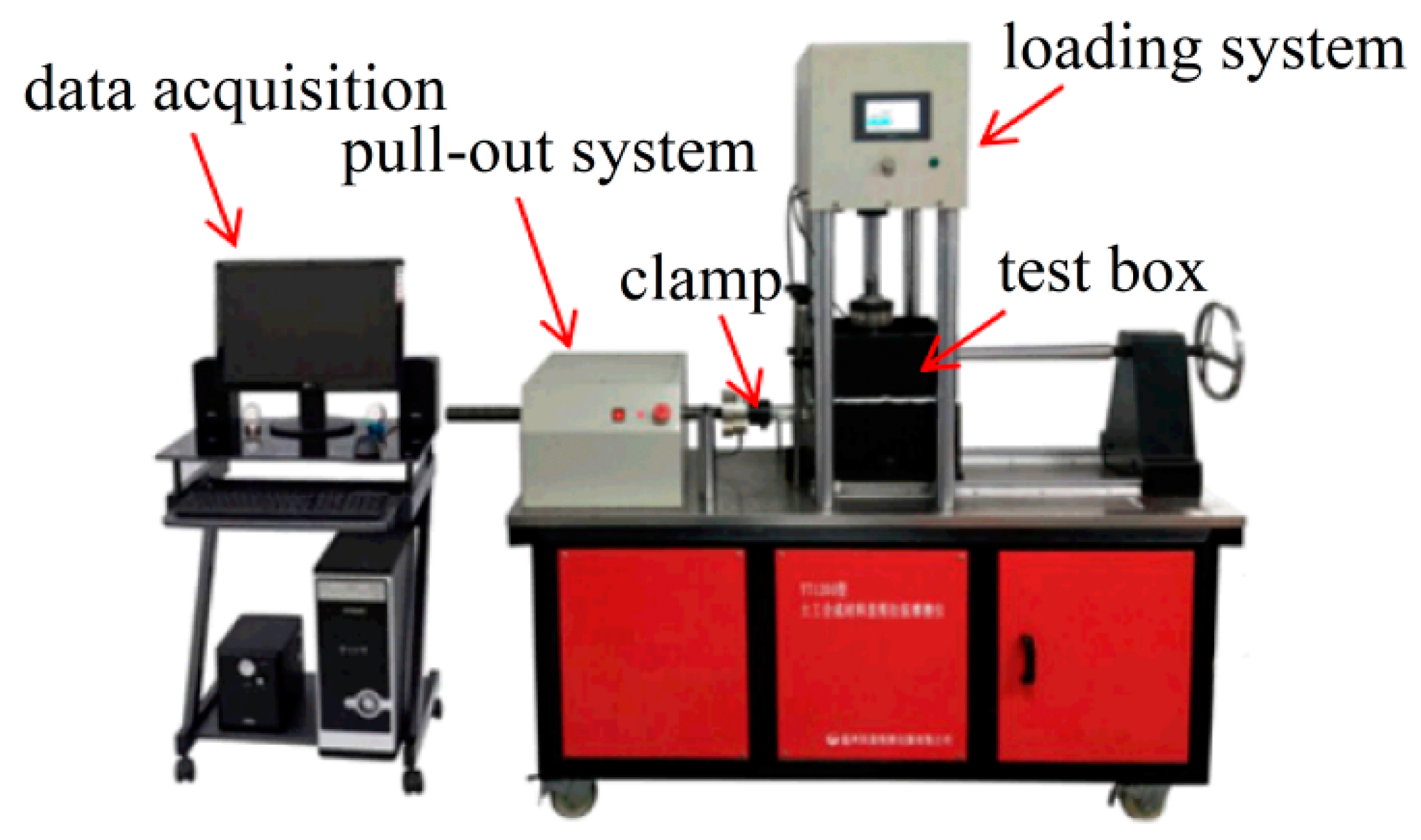

Figure 6.

Pull-out test apparatus.

Figure 6.

Pull-out test apparatus.

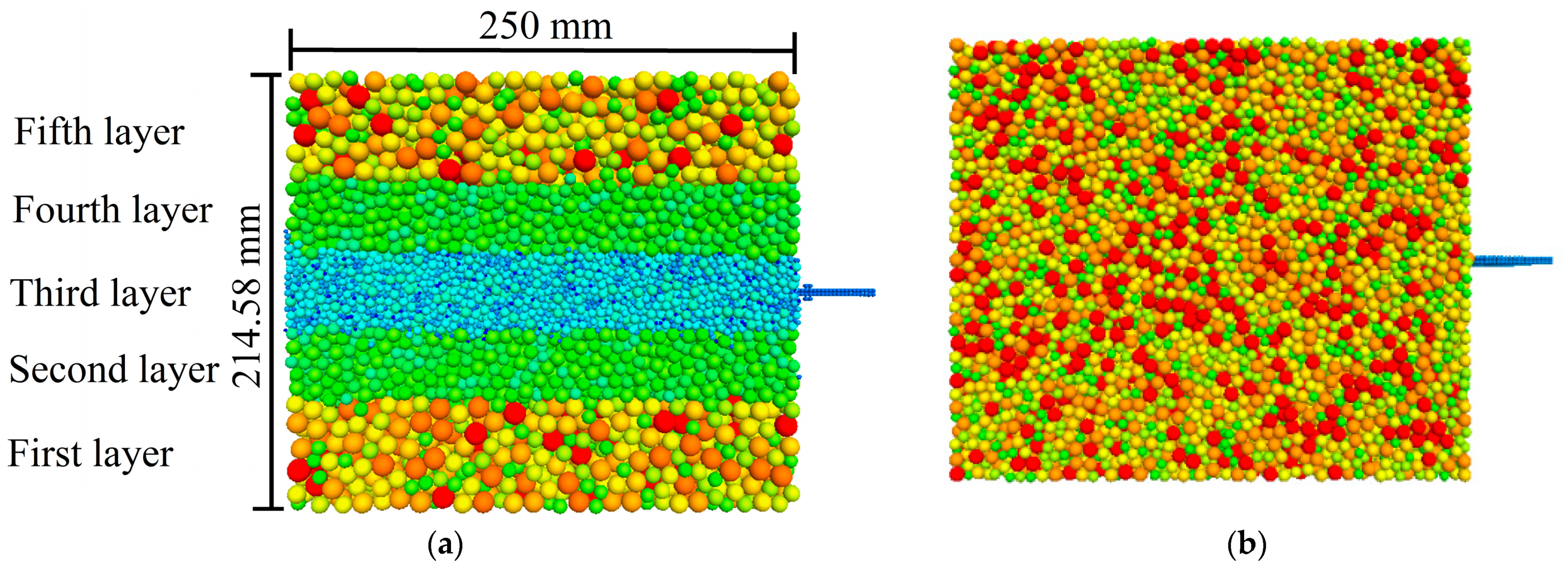

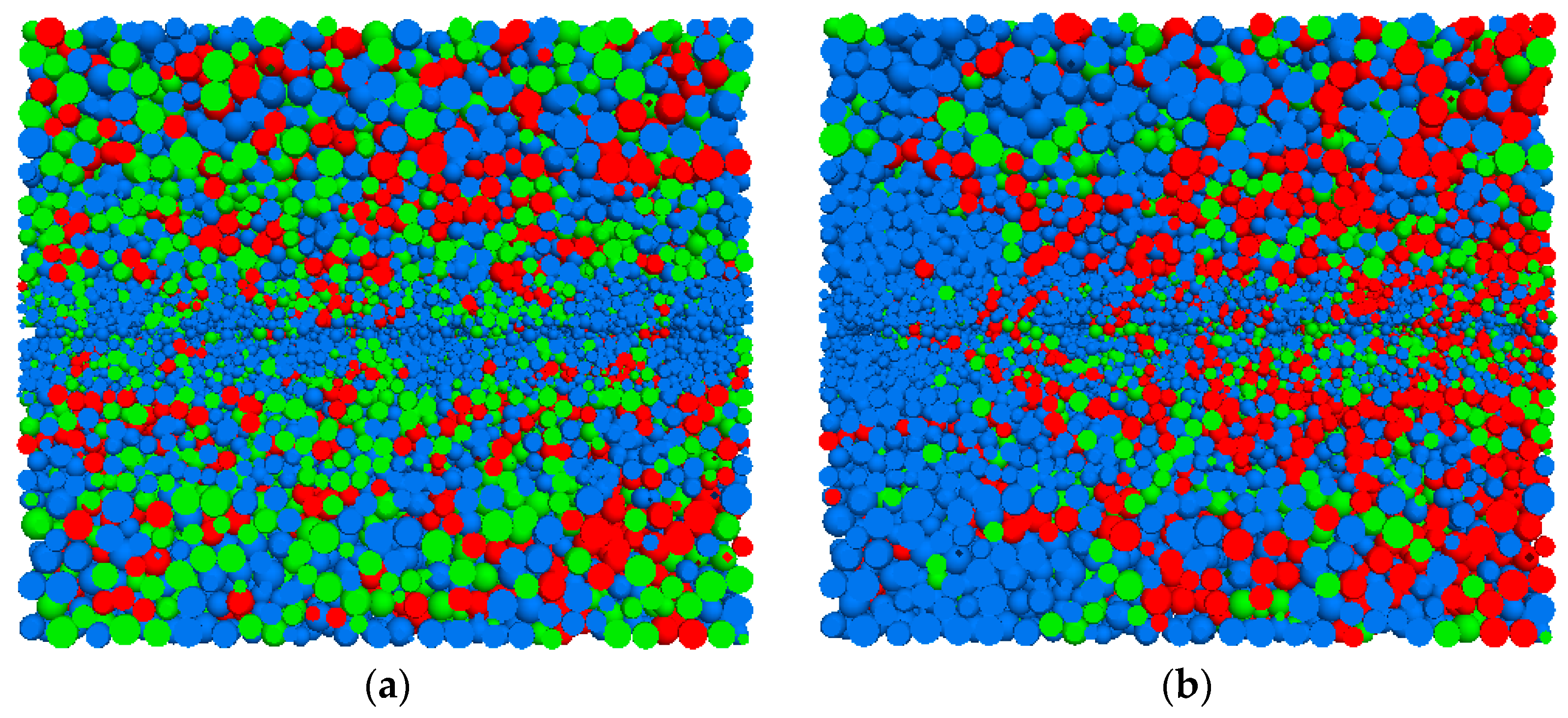

Figure 7.

Numerical models of aeolian sand. (a) Layered aeolian sand numerical model. (b) Homogeneous aeolian sand numerical model.

Figure 7.

Numerical models of aeolian sand. (a) Layered aeolian sand numerical model. (b) Homogeneous aeolian sand numerical model.

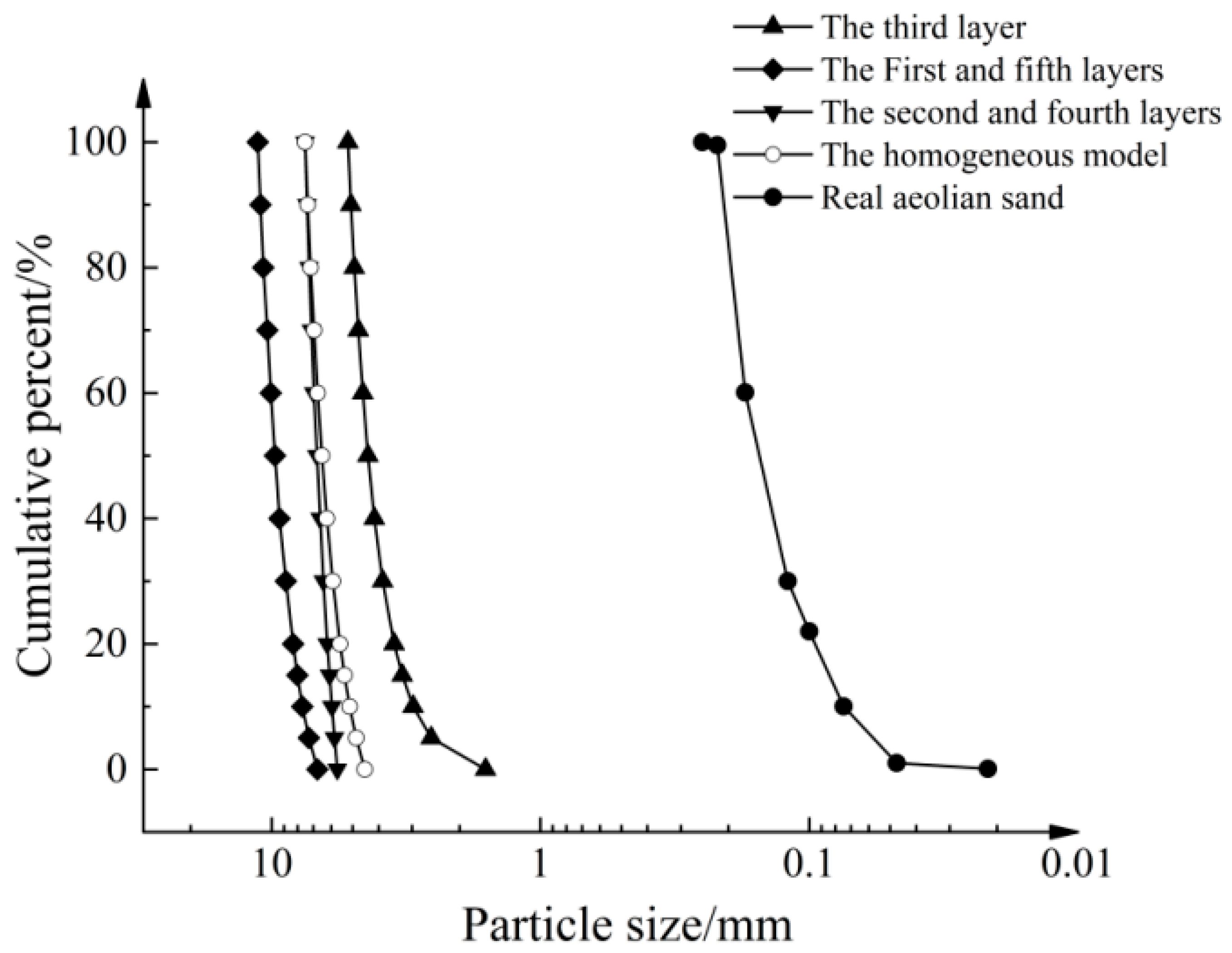

Figure 8.

Gradation curve of simulated particles and aeolian sand.

Figure 8.

Gradation curve of simulated particles and aeolian sand.

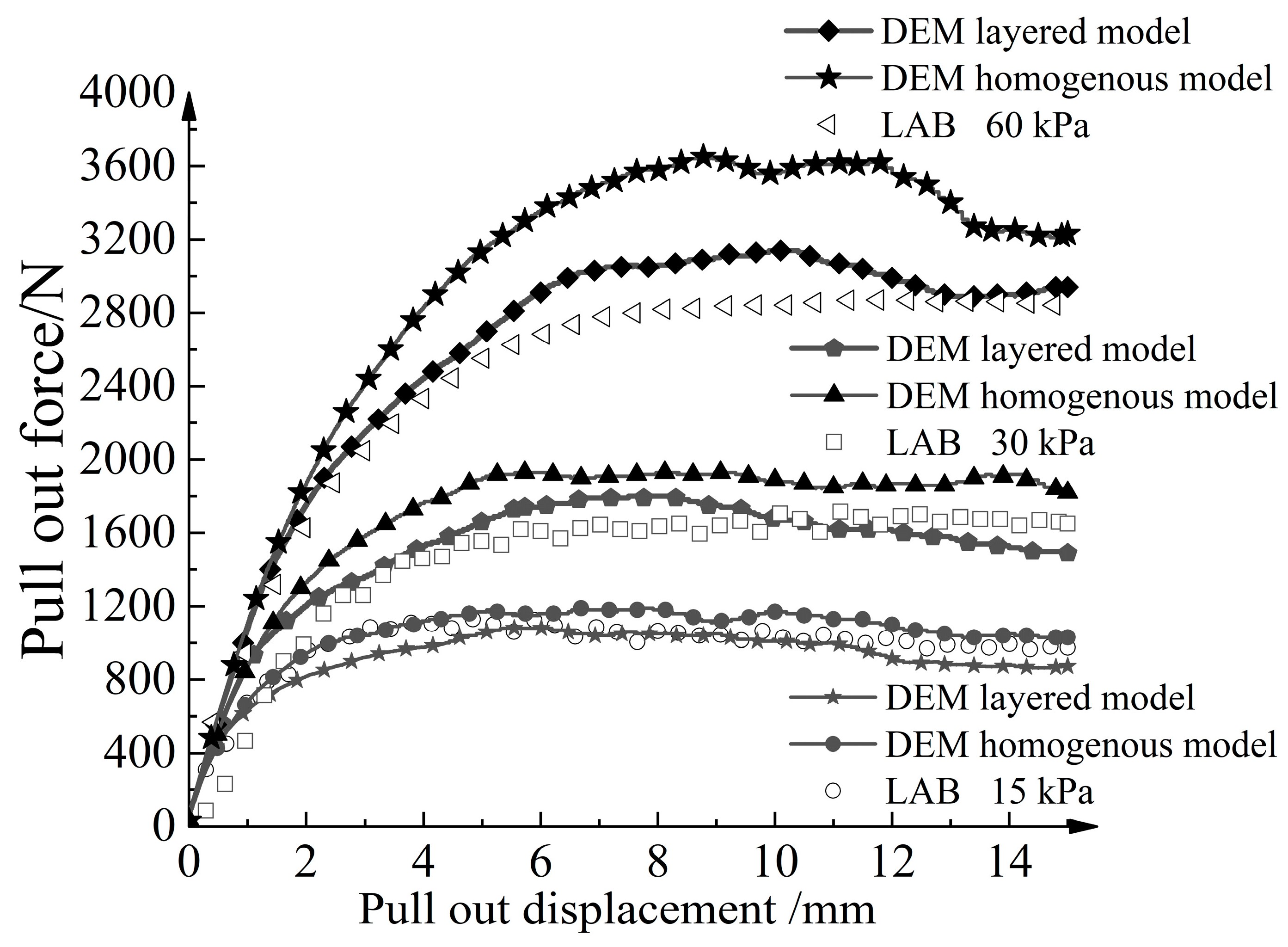

Figure 9.

Relationship curve between pull-out force and pull-out displacement.

Figure 9.

Relationship curve between pull-out force and pull-out displacement.

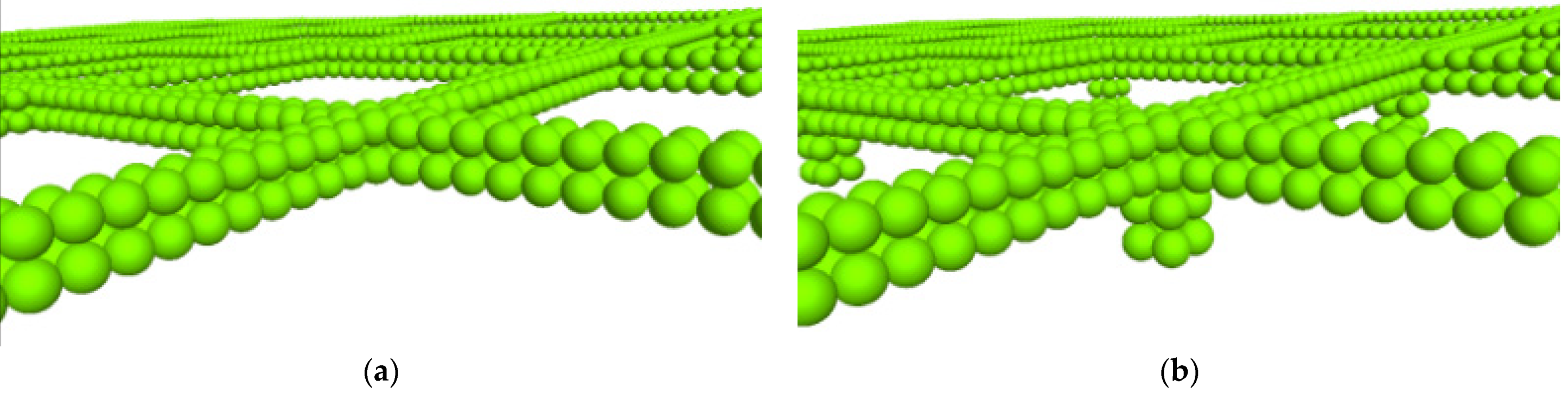

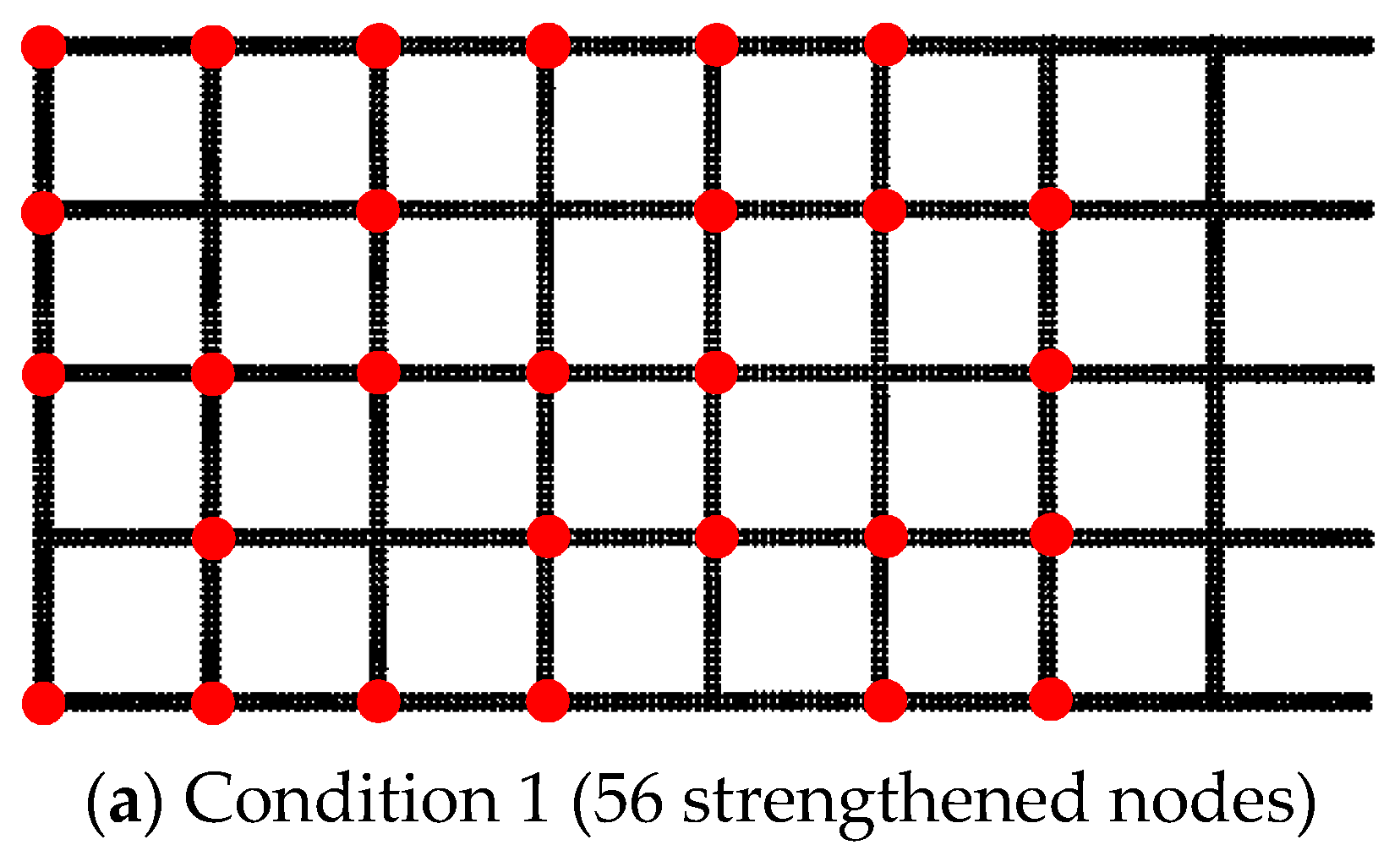

Figure 10.

Different node-thickening methods. (a) Regular nodes (Condition A). (b) Strengthened nodes (Condition B). (c) Strengthened nodes (Condition C). (d) Strengthened nodes (Condition D).

Figure 10.

Different node-thickening methods. (a) Regular nodes (Condition A). (b) Strengthened nodes (Condition B). (c) Strengthened nodes (Condition C). (d) Strengthened nodes (Condition D).

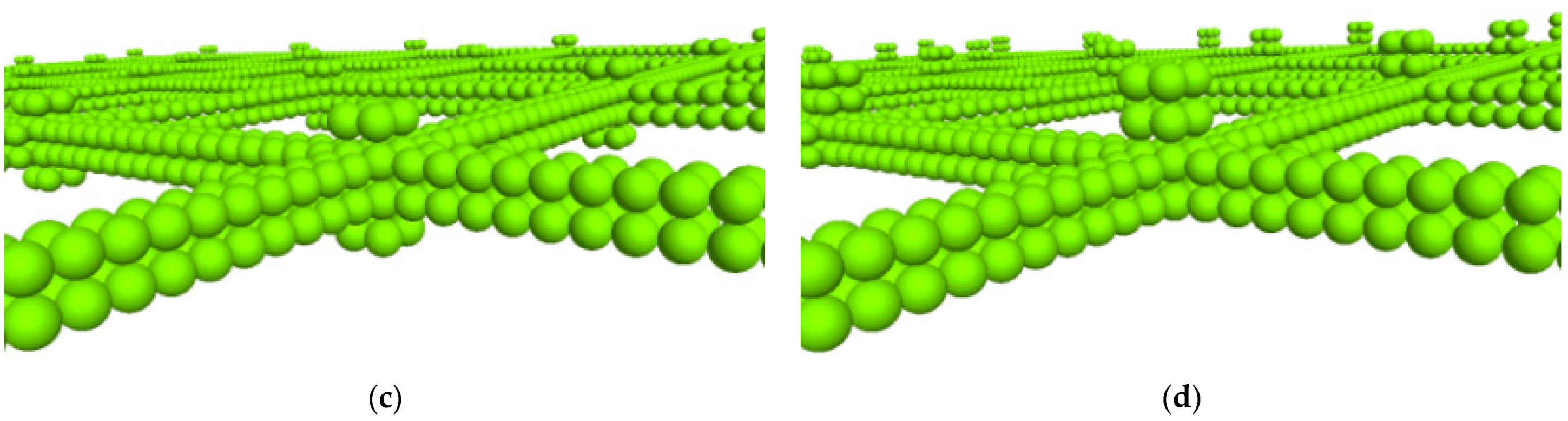

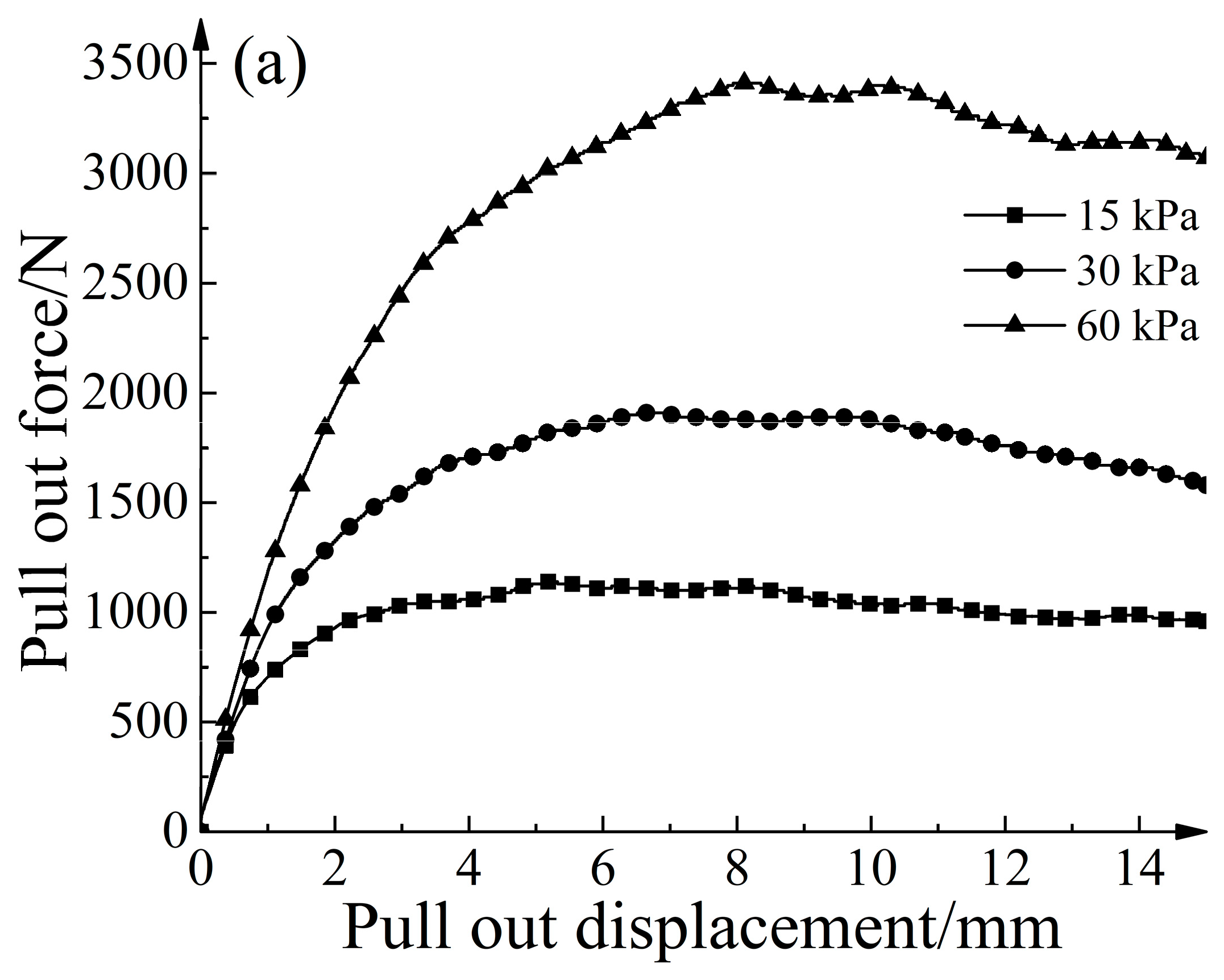

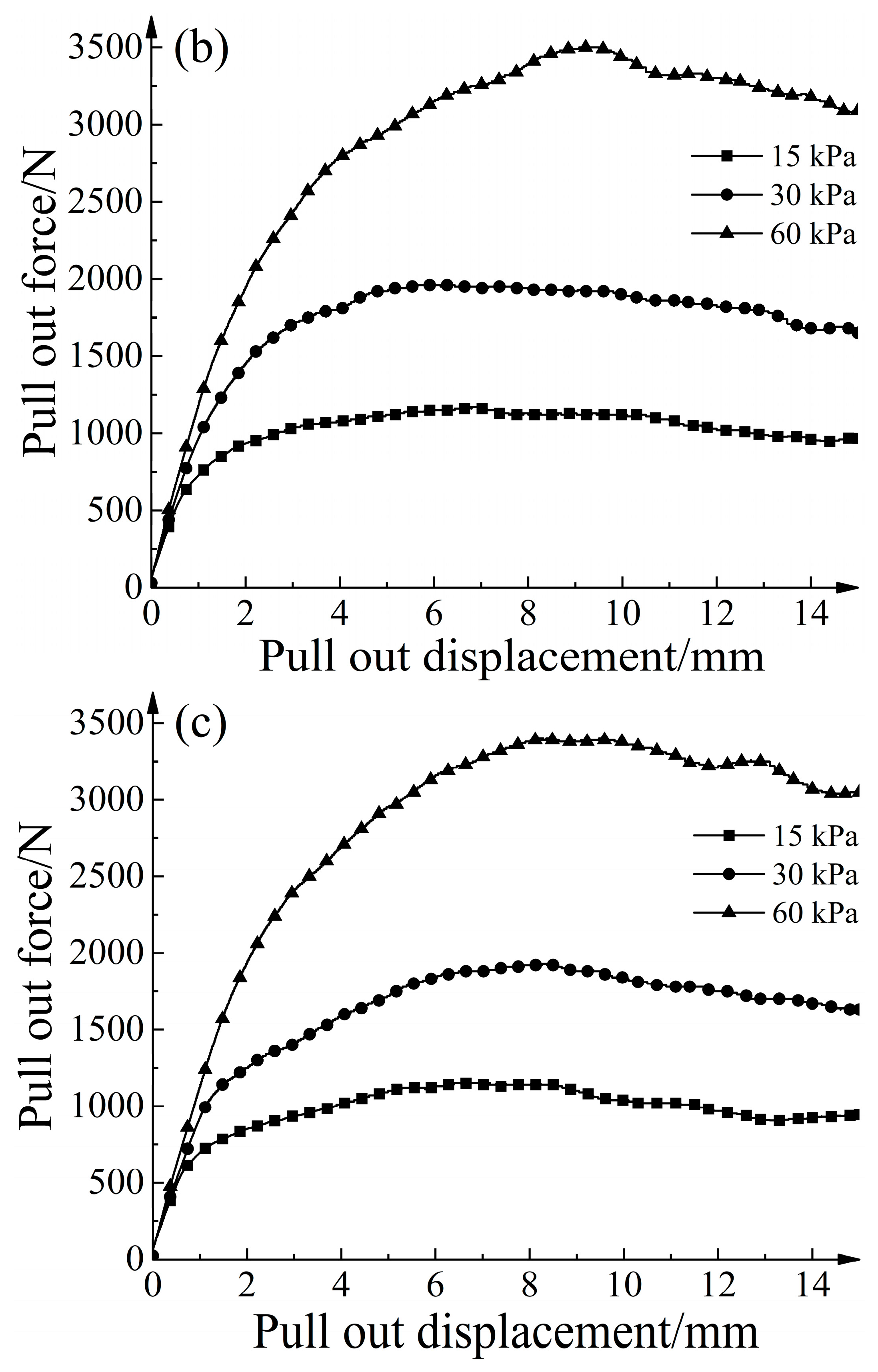

Figure 11.

The relationship curve between pull-out force and pull-out displacement for different methods of increasing node thickness. (a) Pull-out force in Condition B. (b) Pull-out force in Condition C. (c) Pull-out force in Condition D.

Figure 11.

The relationship curve between pull-out force and pull-out displacement for different methods of increasing node thickness. (a) Pull-out force in Condition B. (b) Pull-out force in Condition C. (c) Pull-out force in Condition D.

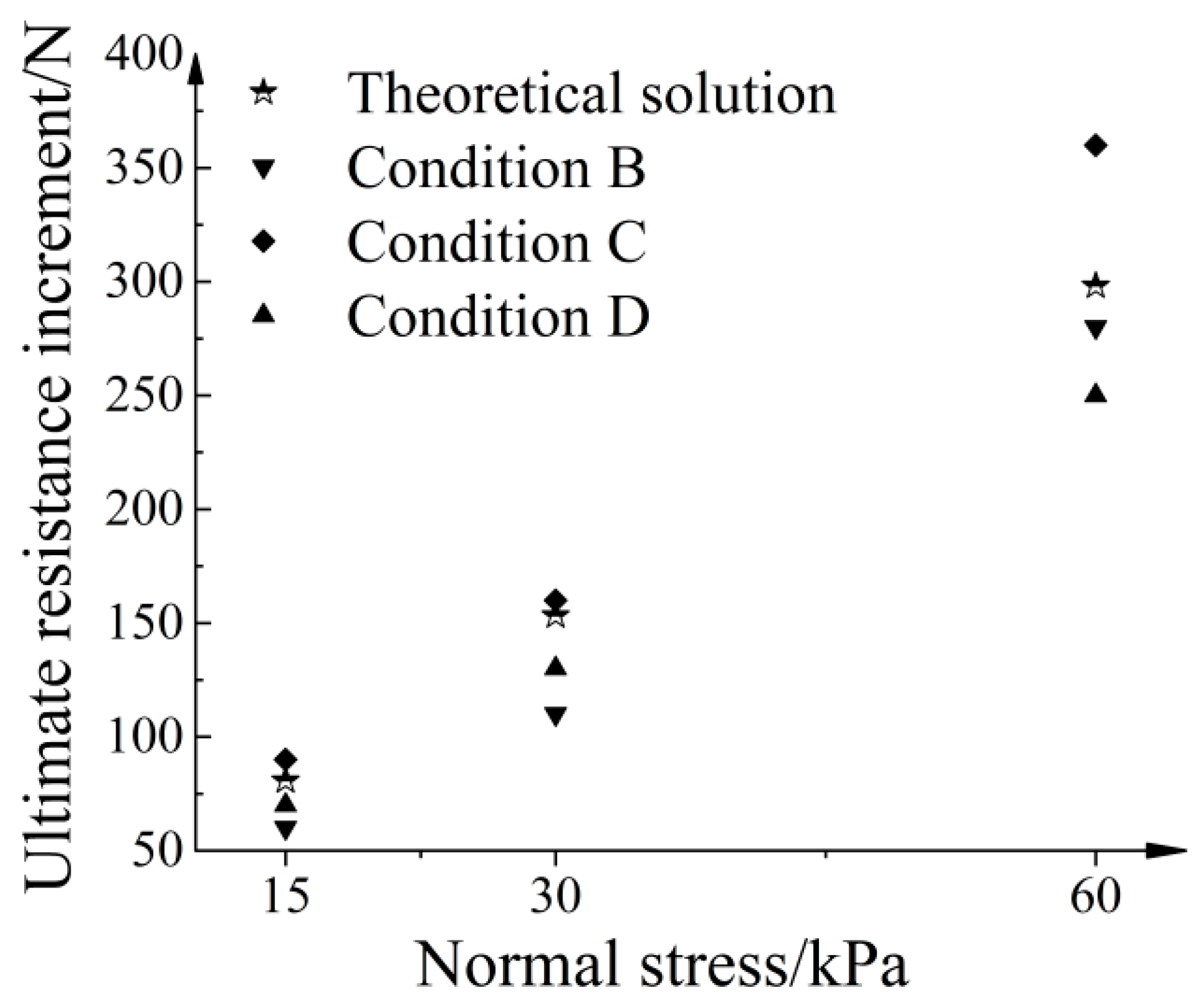

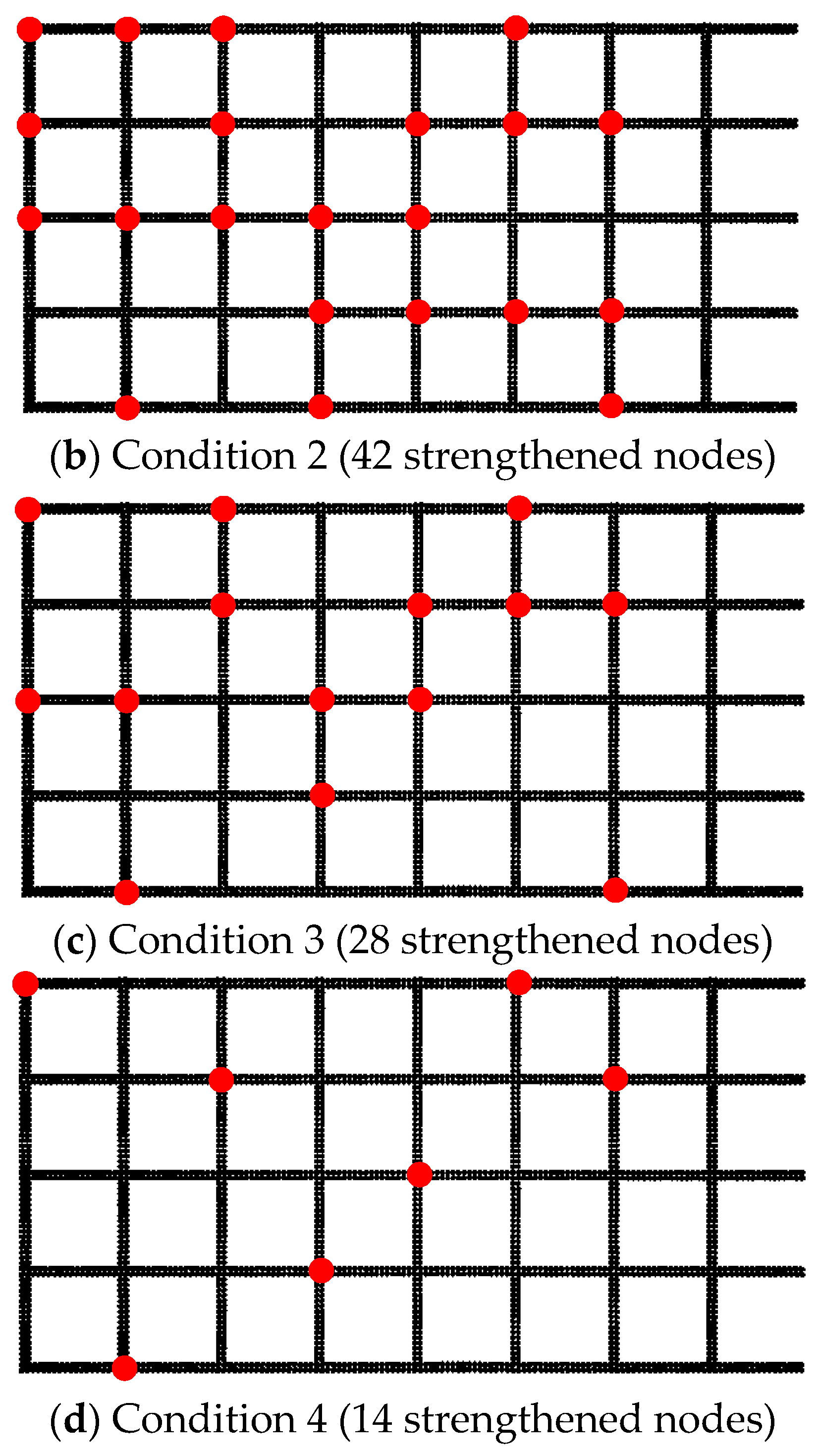

Figure 12.

Comparison of numerical and theoretical solutions.

Figure 12.

Comparison of numerical and theoretical solutions.

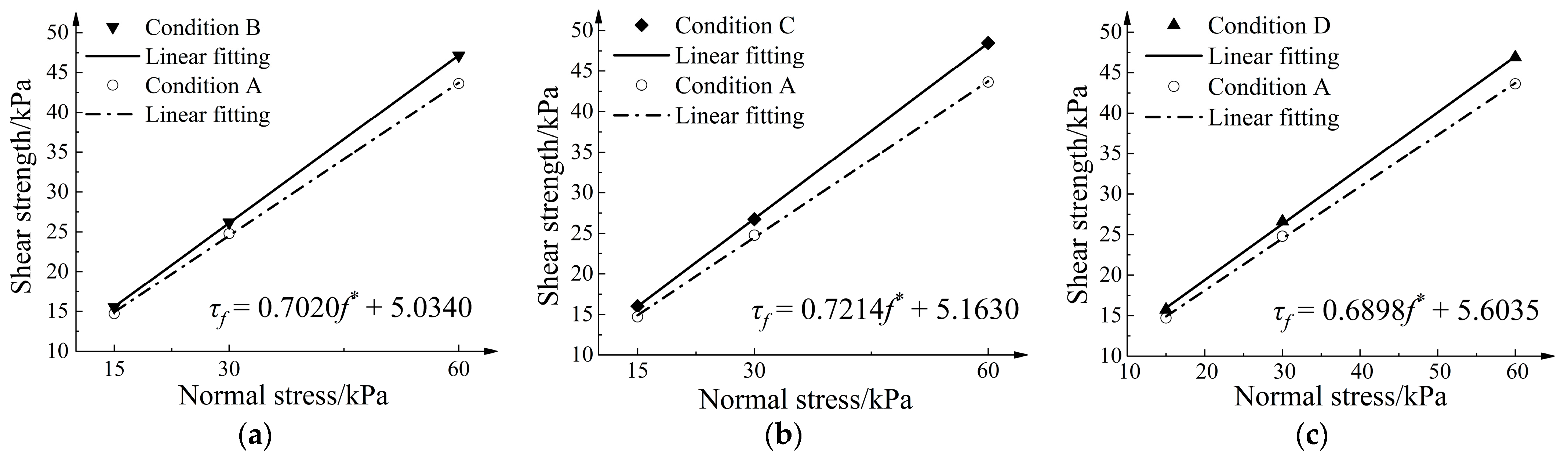

Figure 13.

Shear strength–normal stress fitting curve. (a) Condition B; (b) Condition C; (c) Condition D, f* is the apparent friction coefficient.

Figure 13.

Shear strength–normal stress fitting curve. (a) Condition B; (b) Condition C; (c) Condition D, f* is the apparent friction coefficient.

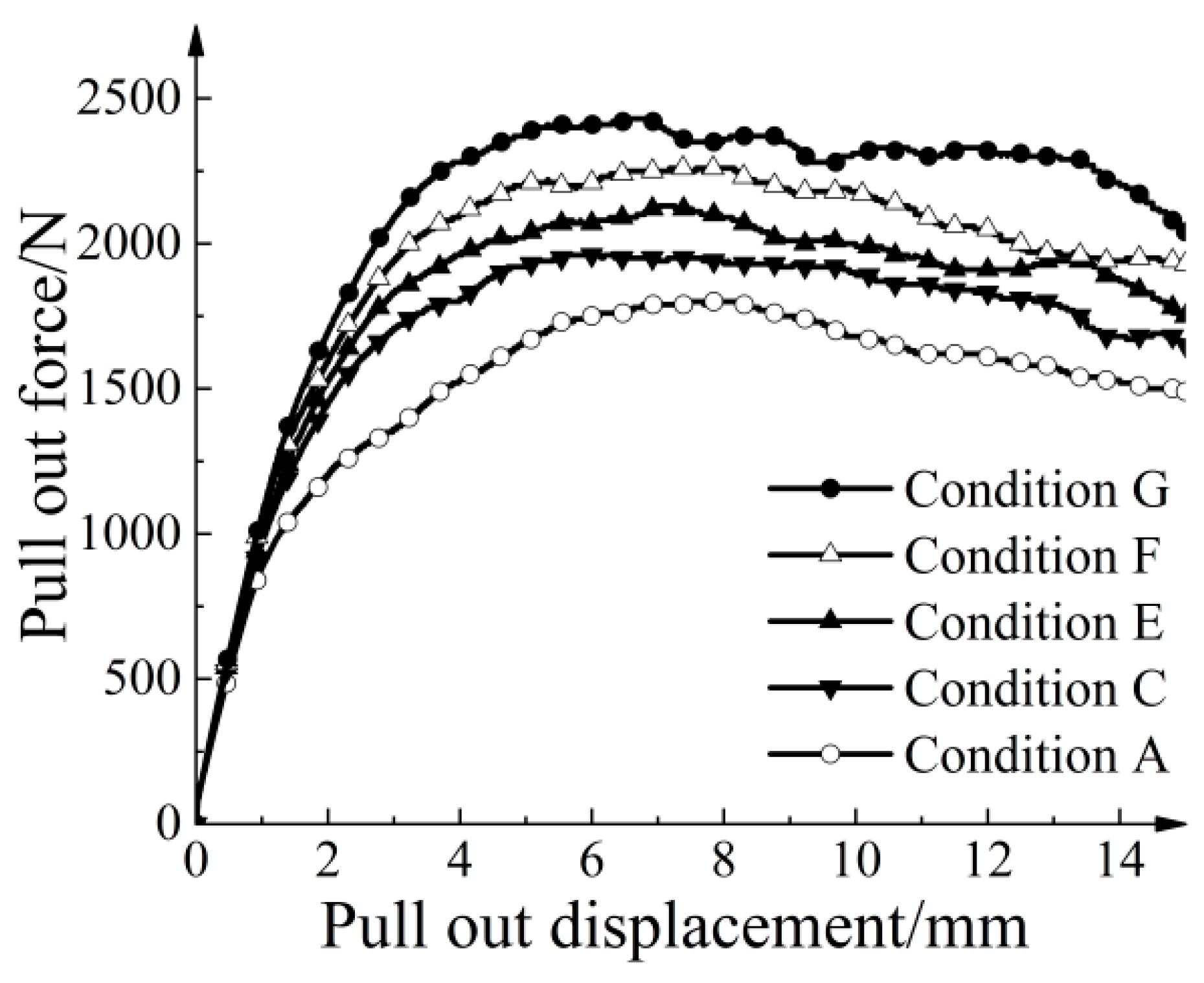

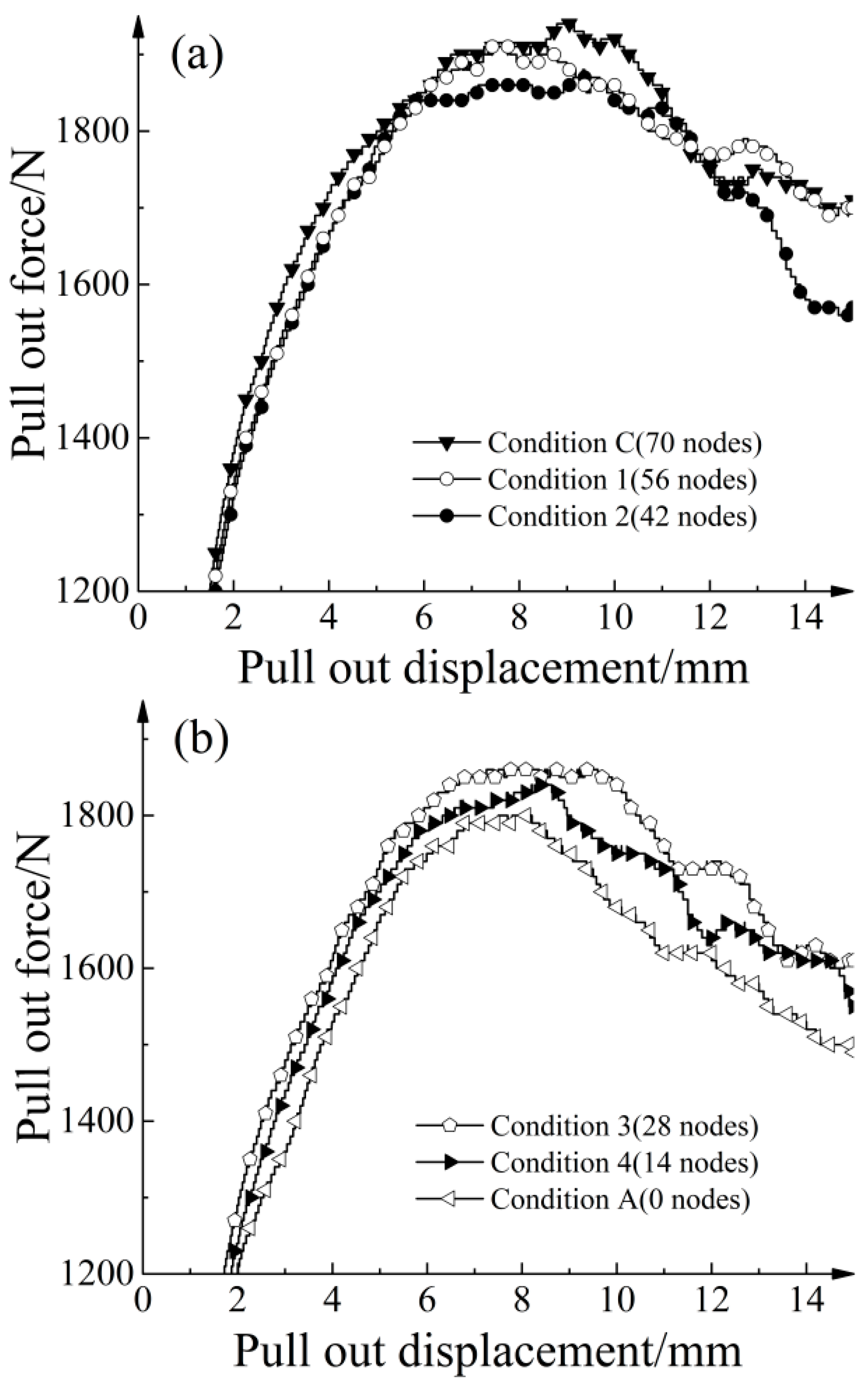

Figure 14.

Pull-out force versus pull-out displacement.

Figure 14.

Pull-out force versus pull-out displacement.

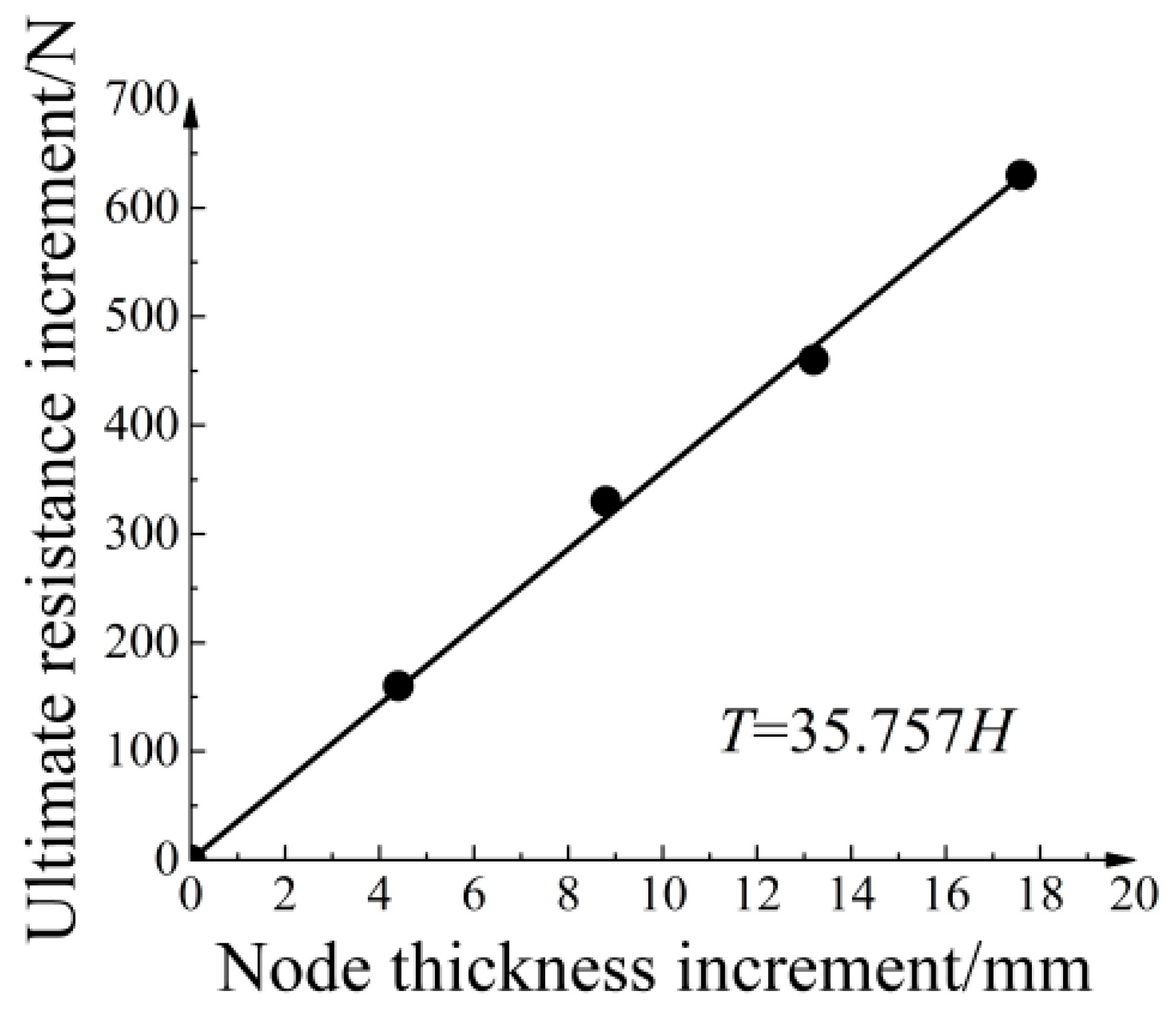

Figure 15.

Relationship between node thickness increase and ultimate pull-out resistance increase.

Figure 15.

Relationship between node thickness increase and ultimate pull-out resistance increase.

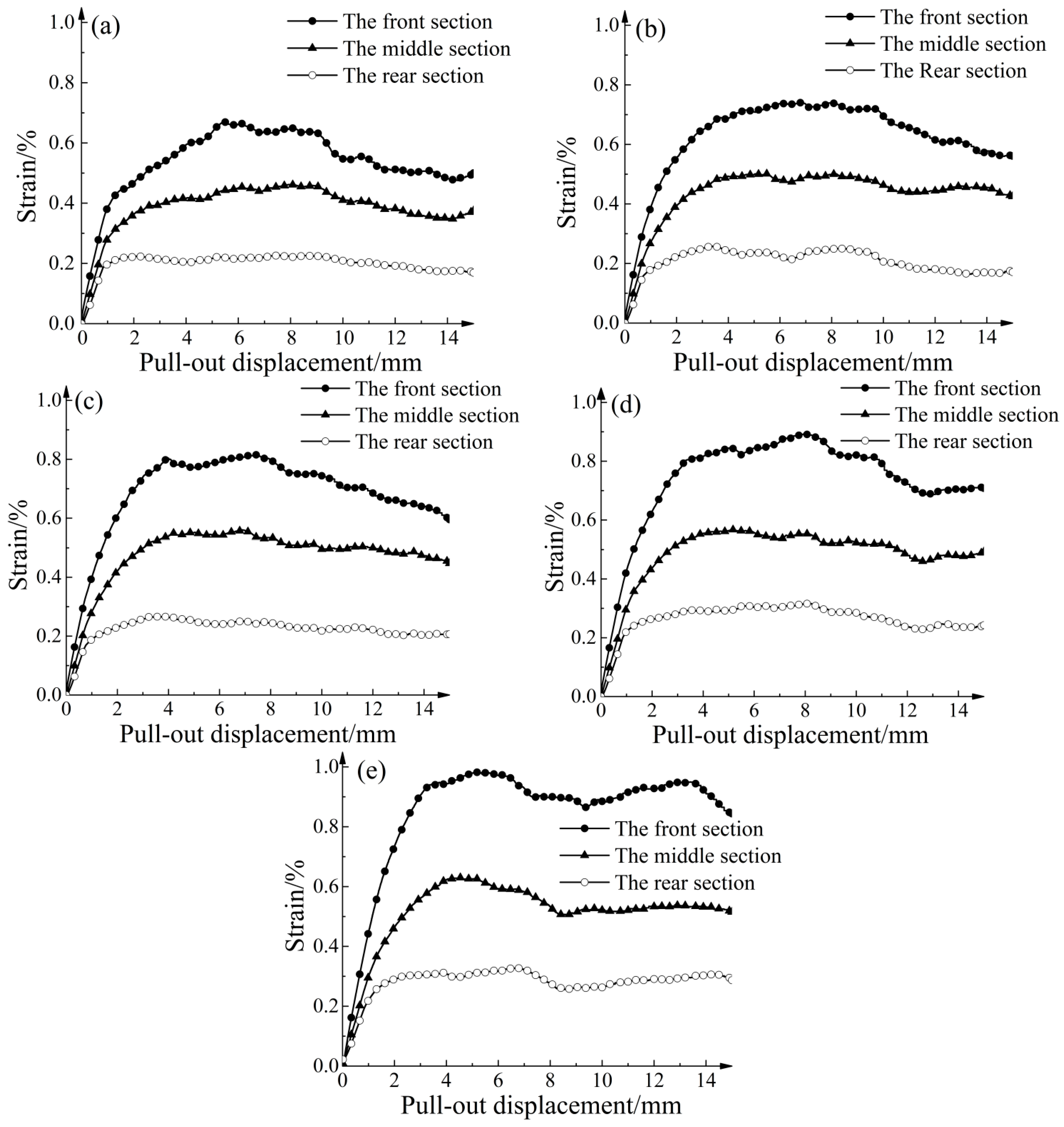

Figure 16.

Strain law of geogrids with different node thicknesses. (a) Condition A. (b) Condition C. (c) Condition E. (d) Condition F. (e) Condition G.

Figure 16.

Strain law of geogrids with different node thicknesses. (a) Condition A. (b) Condition C. (c) Condition E. (d) Condition F. (e) Condition G.

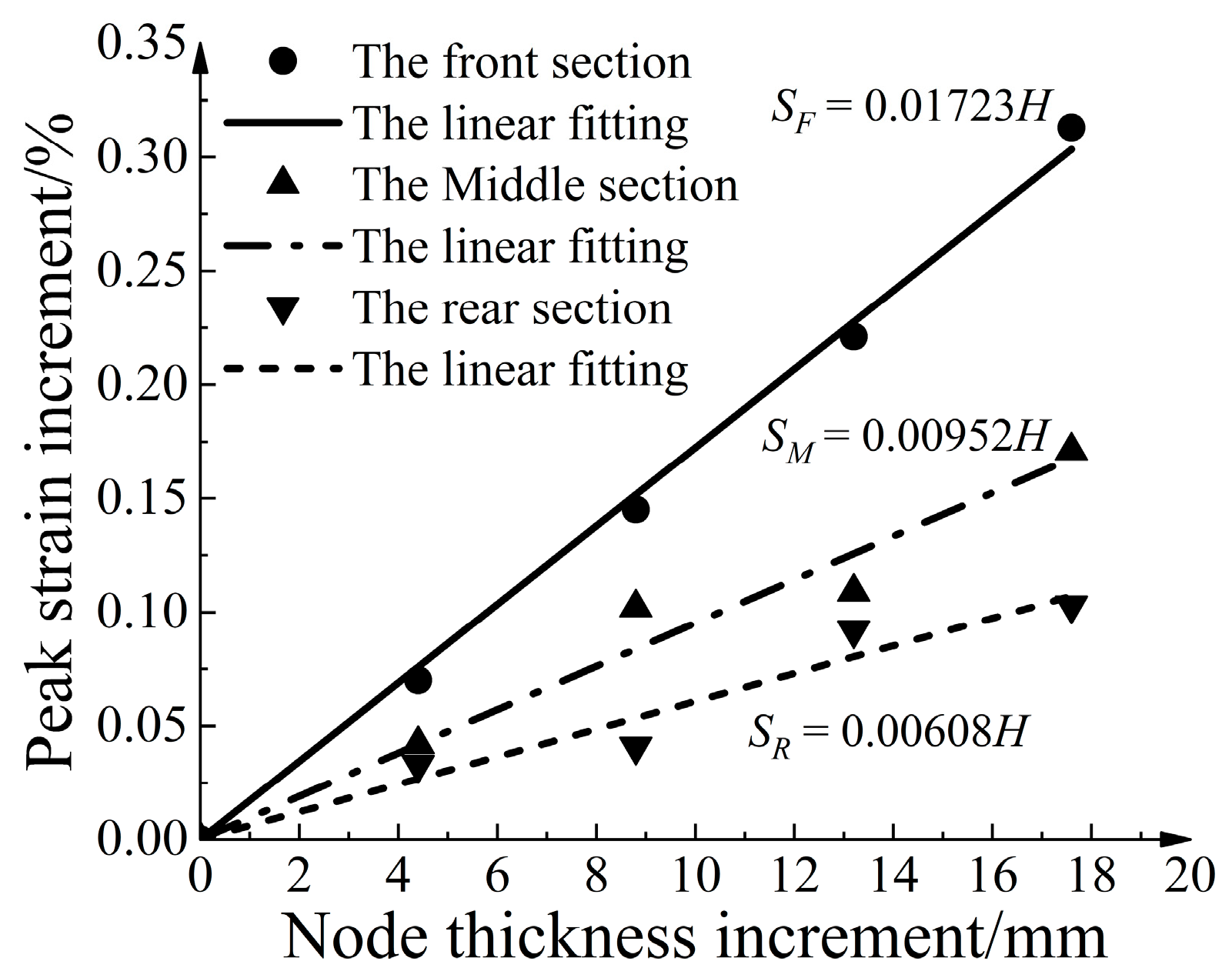

Figure 17.

Curve of relationship between peak strain increase and node thickness increase.

Figure 17.

Curve of relationship between peak strain increase and node thickness increase.

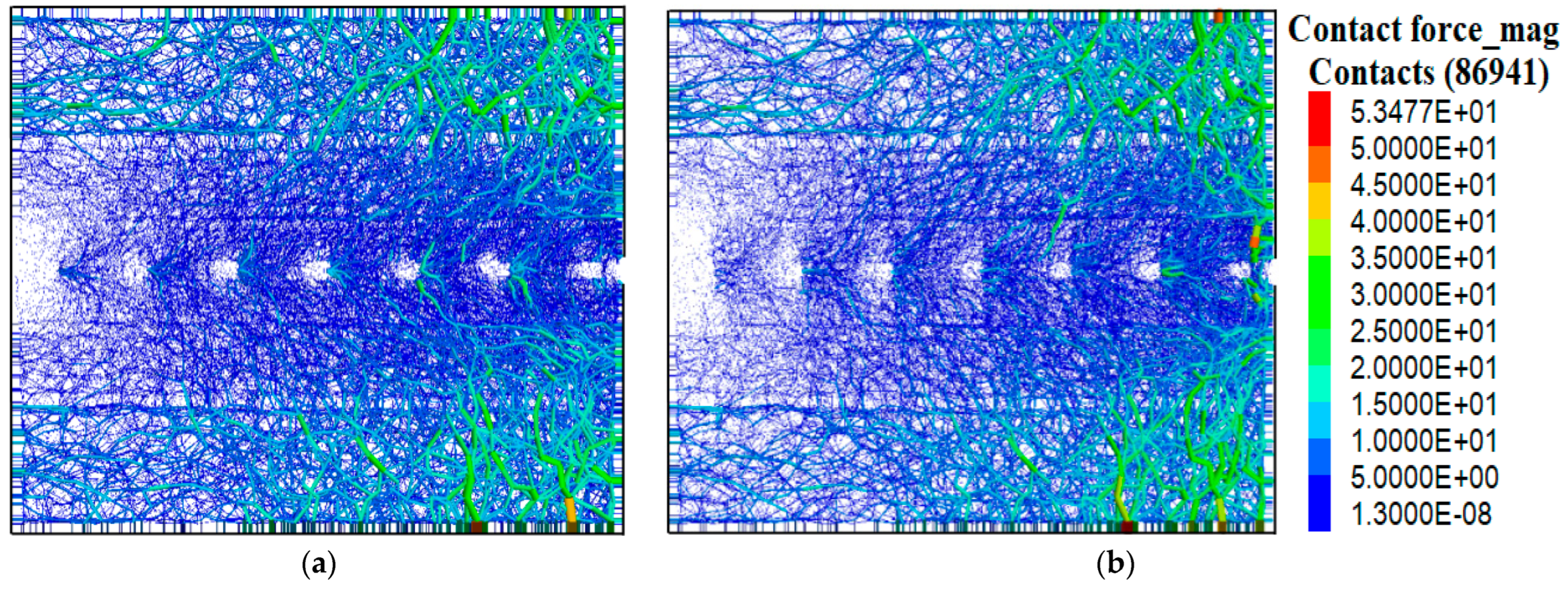

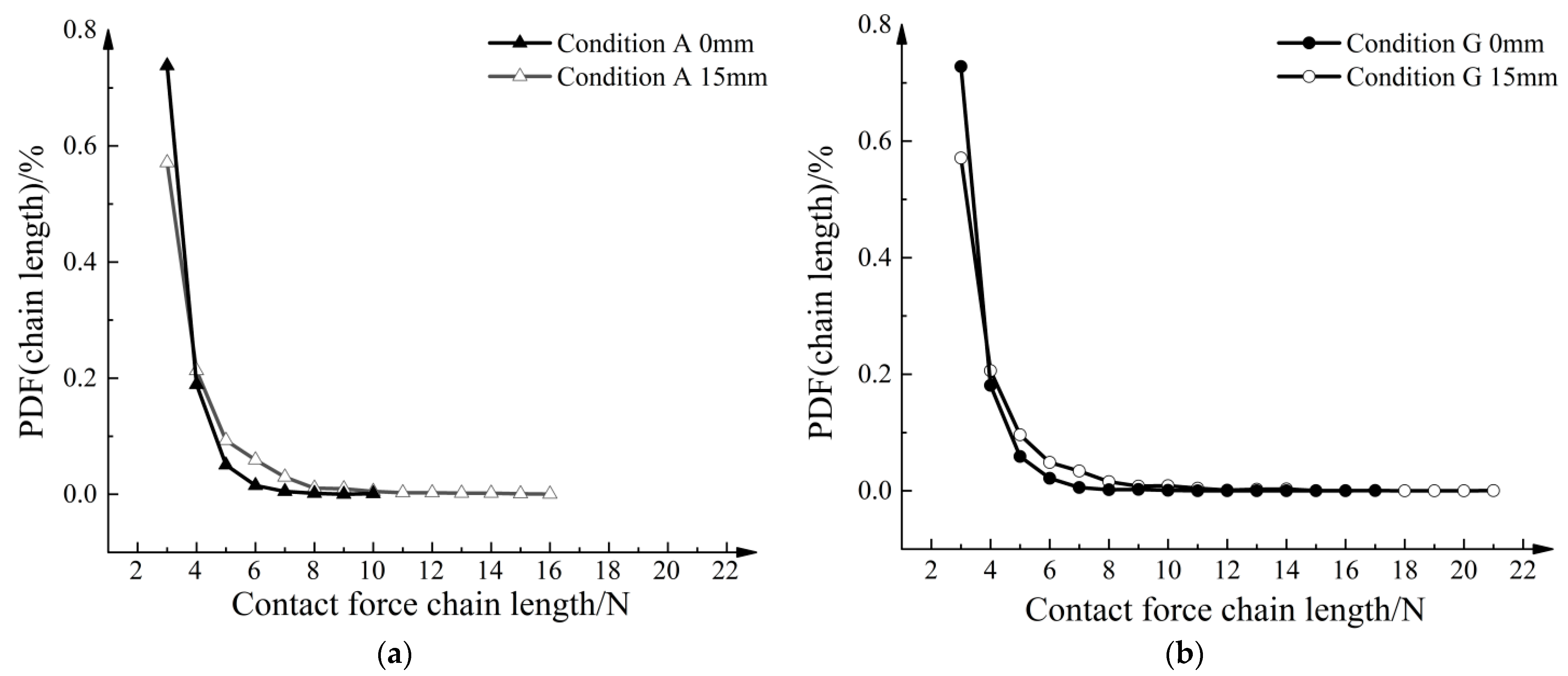

Figure 18.

The distribution of force chains under two conditions. (a) Condition A. (b) Condition G.

Figure 18.

The distribution of force chains under two conditions. (a) Condition A. (b) Condition G.

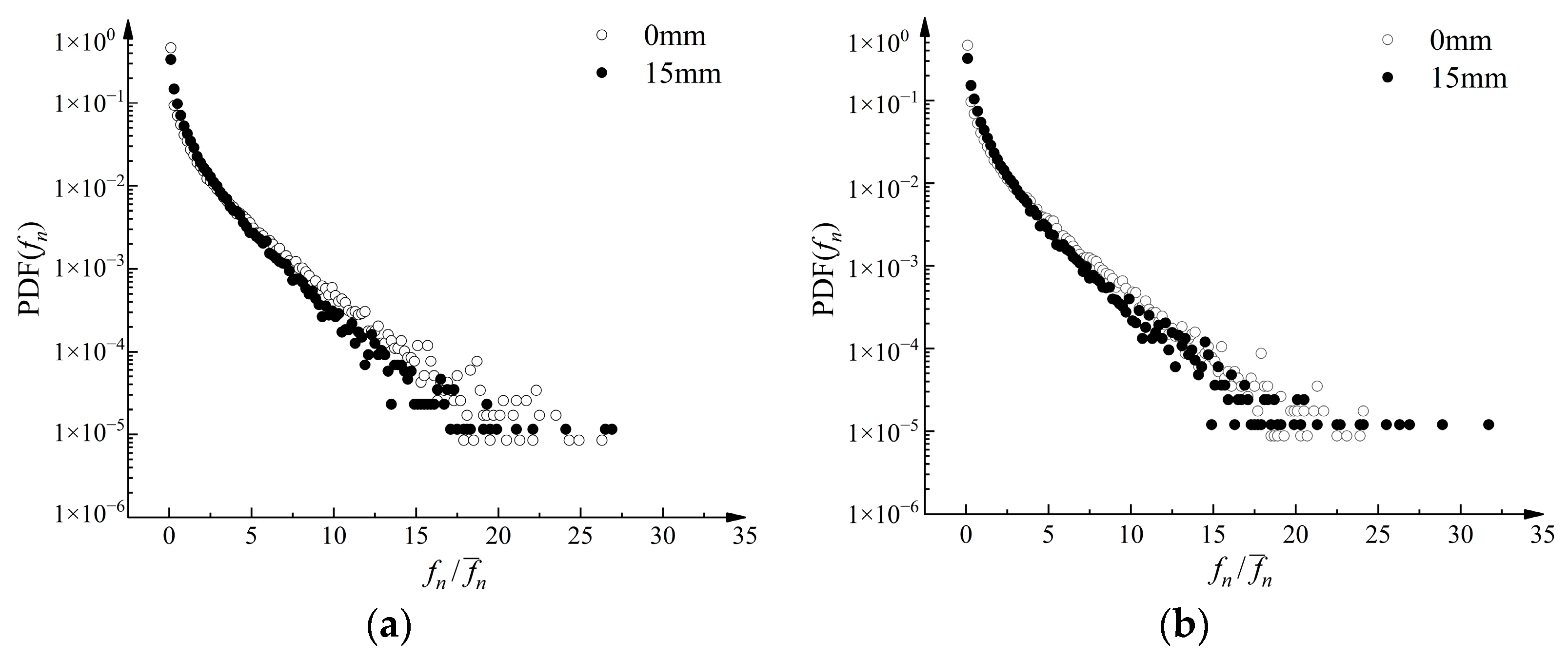

Figure 19.

Probability density function curve of normal contact forces. (a) PDF in Condition A. (b) PDF in Condition G.

Figure 19.

Probability density function curve of normal contact forces. (a) PDF in Condition A. (b) PDF in Condition G.

Figure 20.

Distribution map of high-stress particles and force chain particles. (a) Pulling out 0 mm. (b) Pulling out 15 mm.

Figure 20.

Distribution map of high-stress particles and force chain particles. (a) Pulling out 0 mm. (b) Pulling out 15 mm.

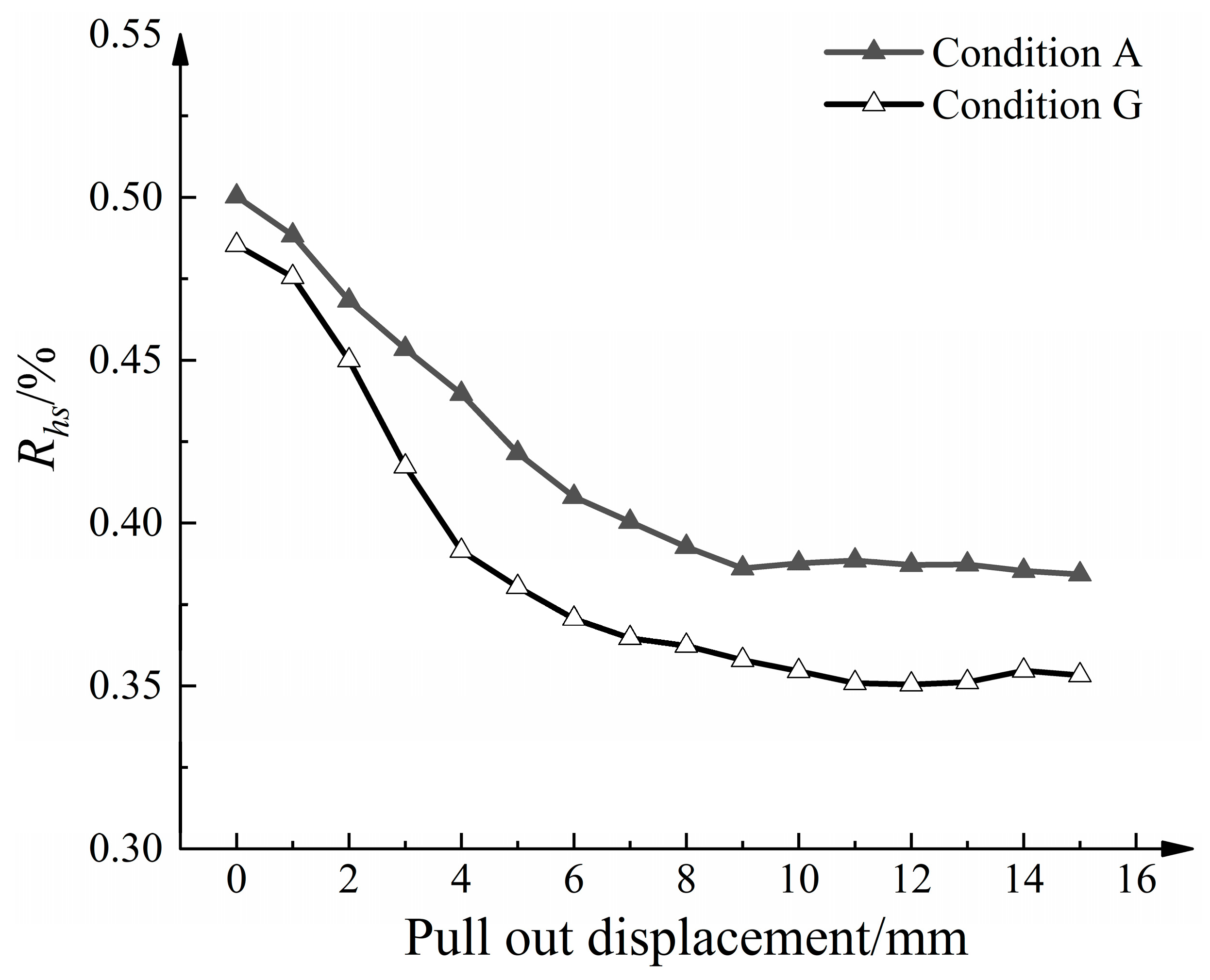

Figure 21.

Relationship curve between high-stress particle content and pull-out displacement.

Figure 21.

Relationship curve between high-stress particle content and pull-out displacement.

Figure 22.

Relationship curve between strong force chain particle content and pull-out displacement.

Figure 22.

Relationship curve between strong force chain particle content and pull-out displacement.

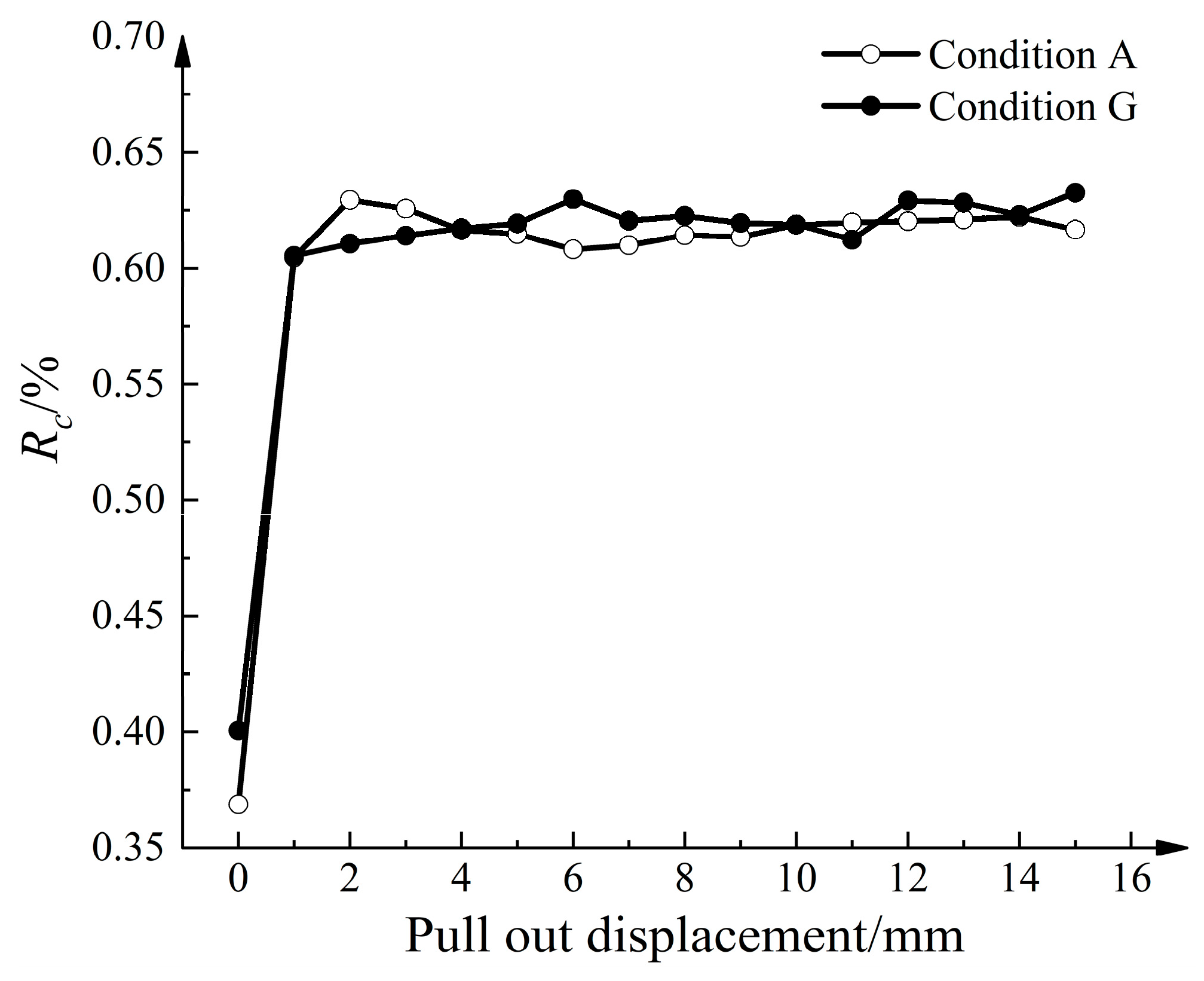

Figure 23.

Probability density function curve of contact force chain length. (a) Condition A. (b) Condition G.

Figure 23.

Probability density function curve of contact force chain length. (a) Condition A. (b) Condition G.

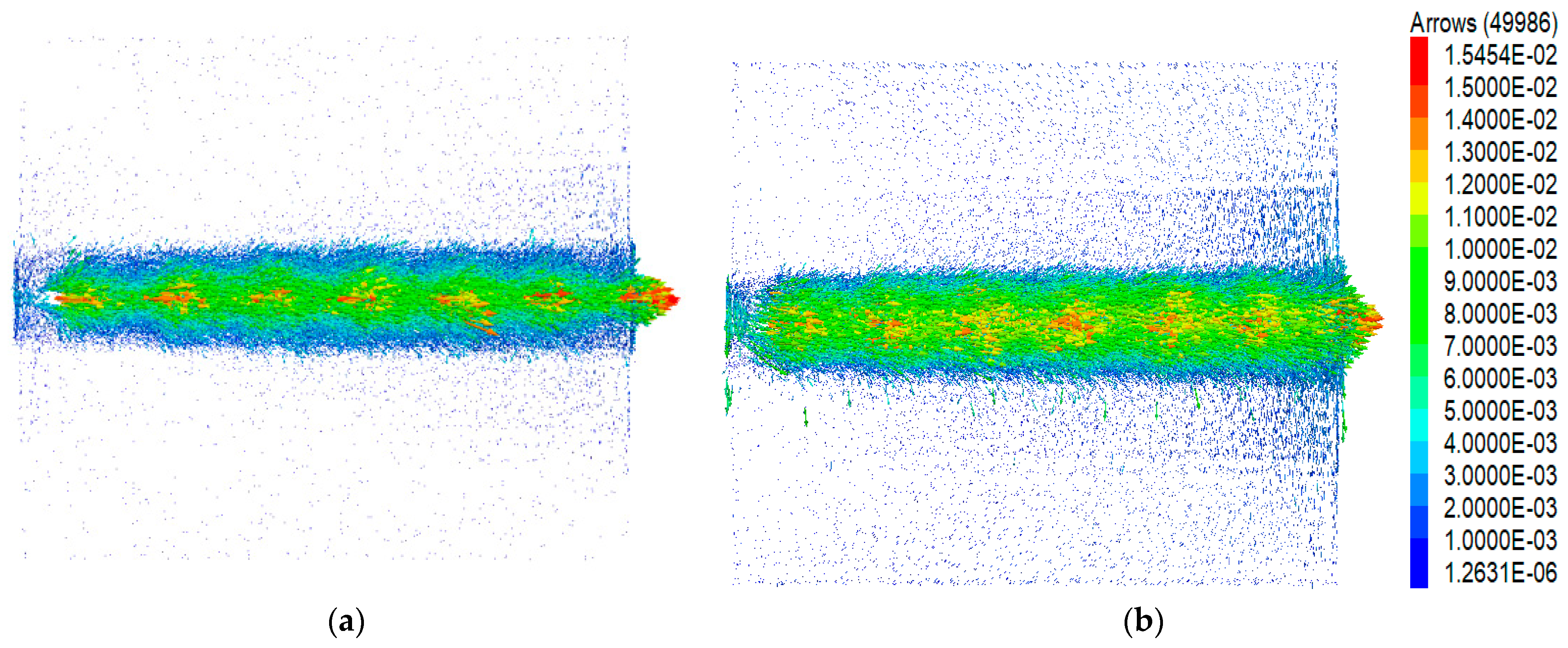

Figure 24.

Detail of displacement vectors of aeolian sand particles. (a) Condition A. (b) Condition G.

Figure 24.

Detail of displacement vectors of aeolian sand particles. (a) Condition A. (b) Condition G.

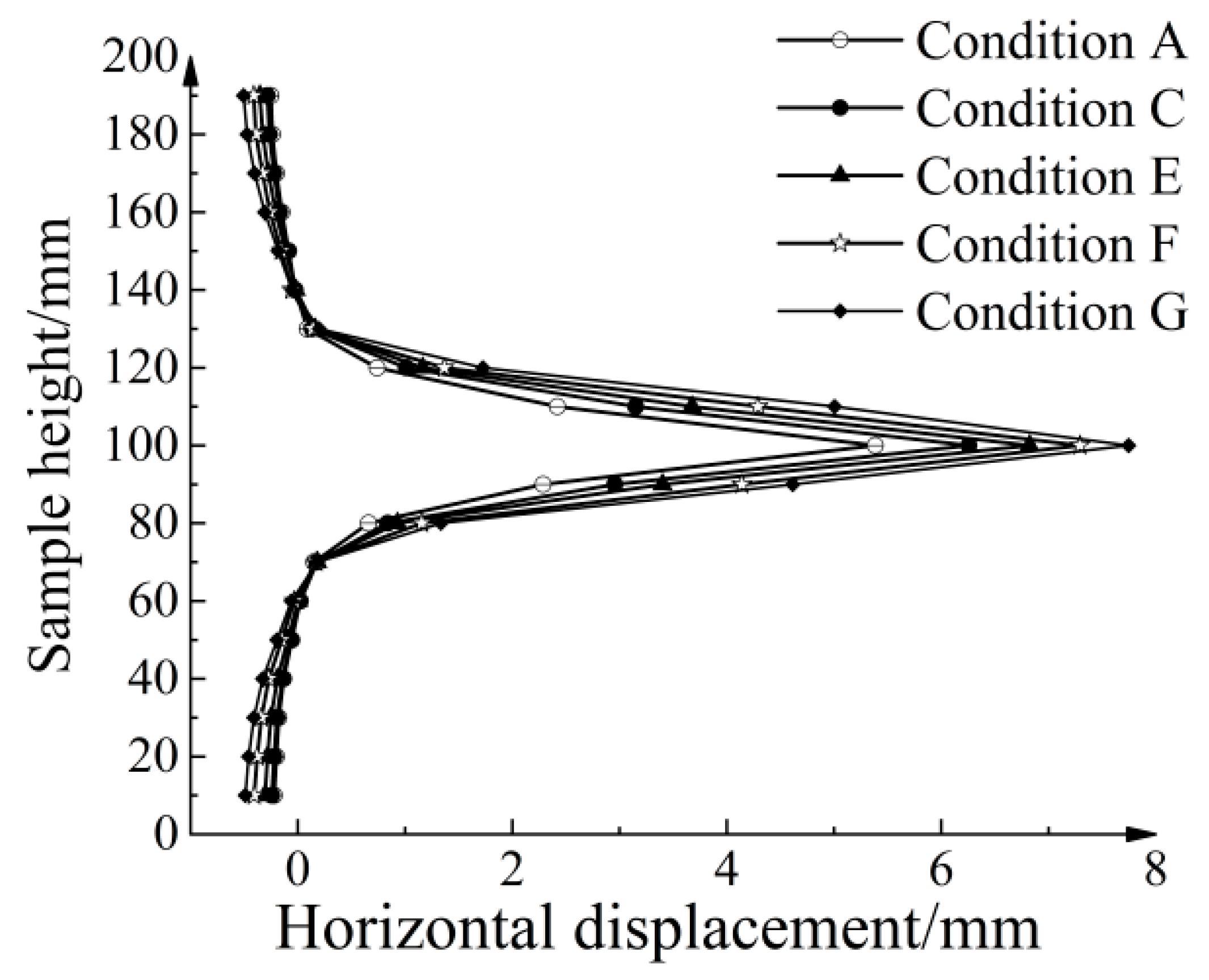

Figure 25.

Average horizontal displacement of particles at different heights.

Figure 25.

Average horizontal displacement of particles at different heights.

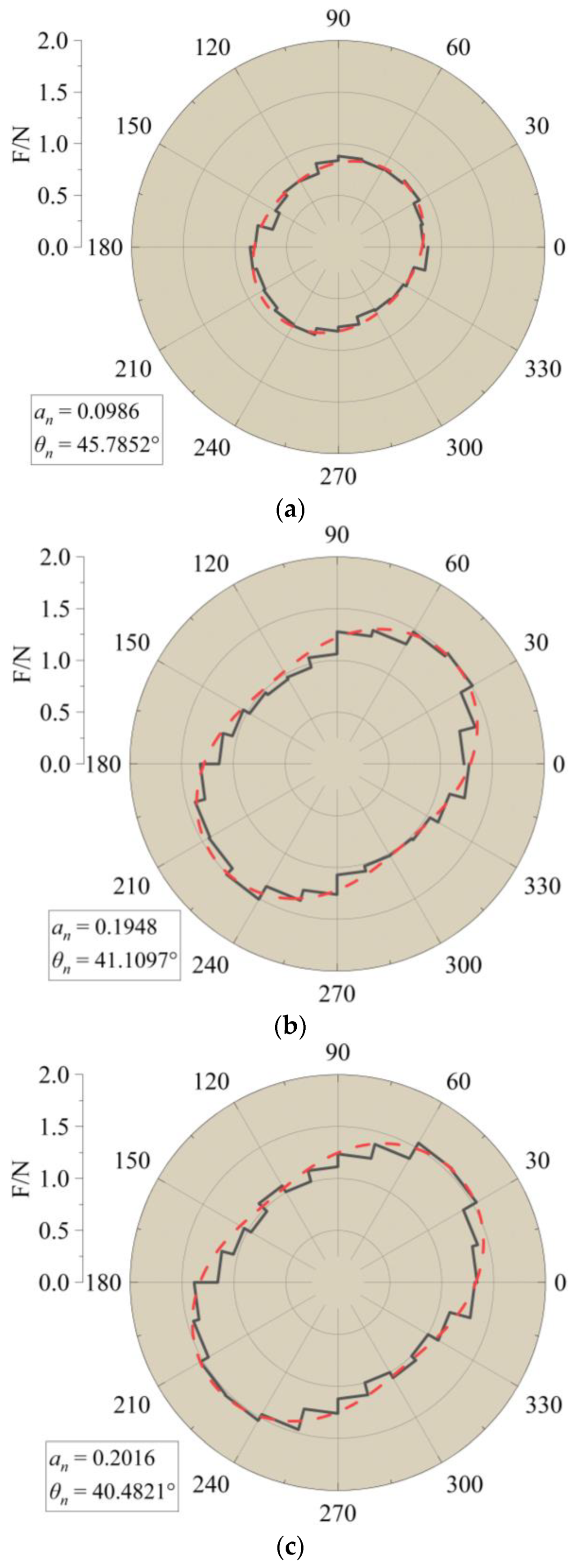

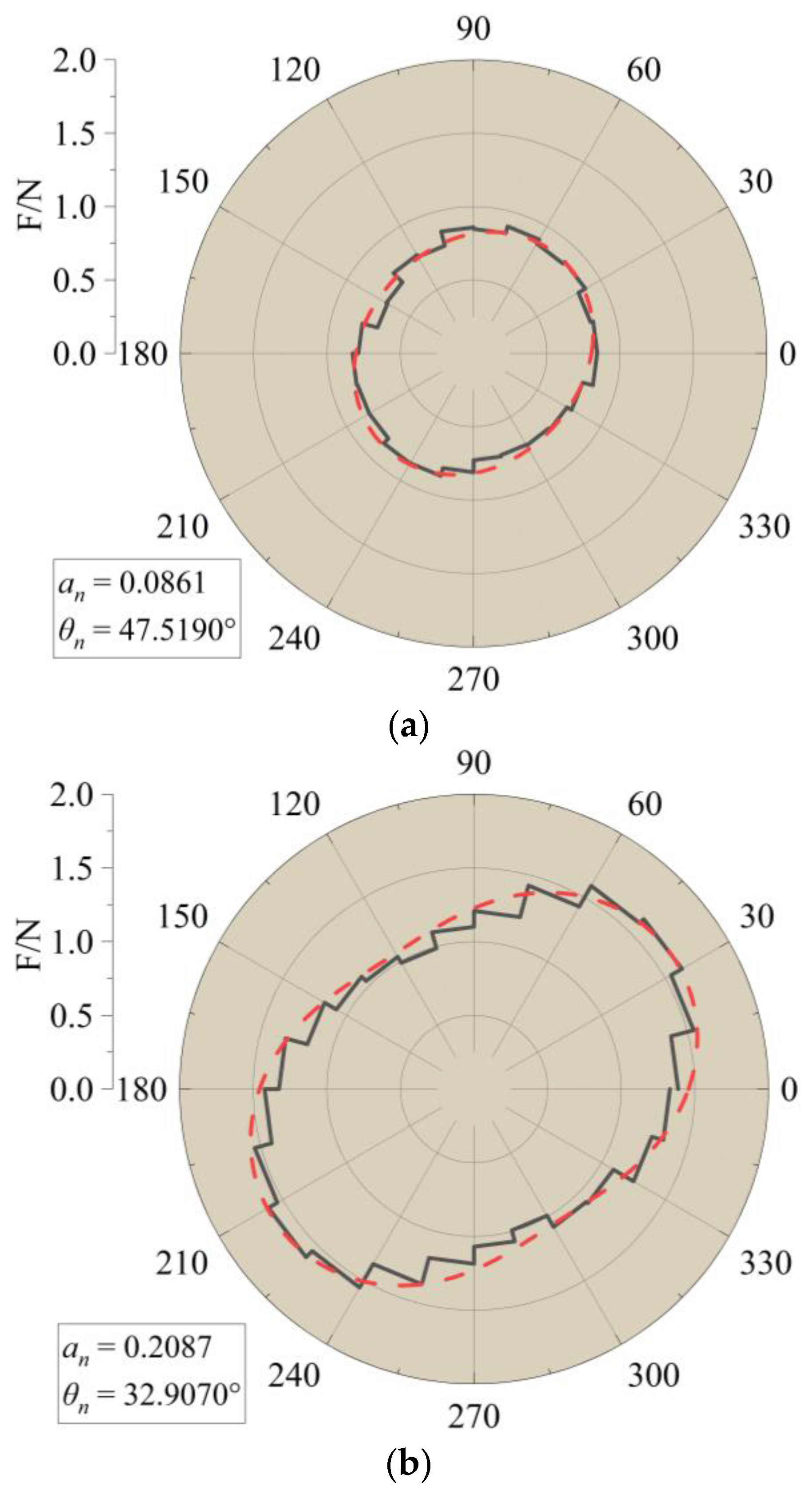

Figure 26.

Evolution law of meso fabric in Condition A. (a) Before pull-out (0 mm). (b) When pull-out displacement reaches 5 mm. (c) When pull-out displacement reaches 10 mm. (d) When pull-out displacement reaches 15 mm.

Figure 26.

Evolution law of meso fabric in Condition A. (a) Before pull-out (0 mm). (b) When pull-out displacement reaches 5 mm. (c) When pull-out displacement reaches 10 mm. (d) When pull-out displacement reaches 15 mm.

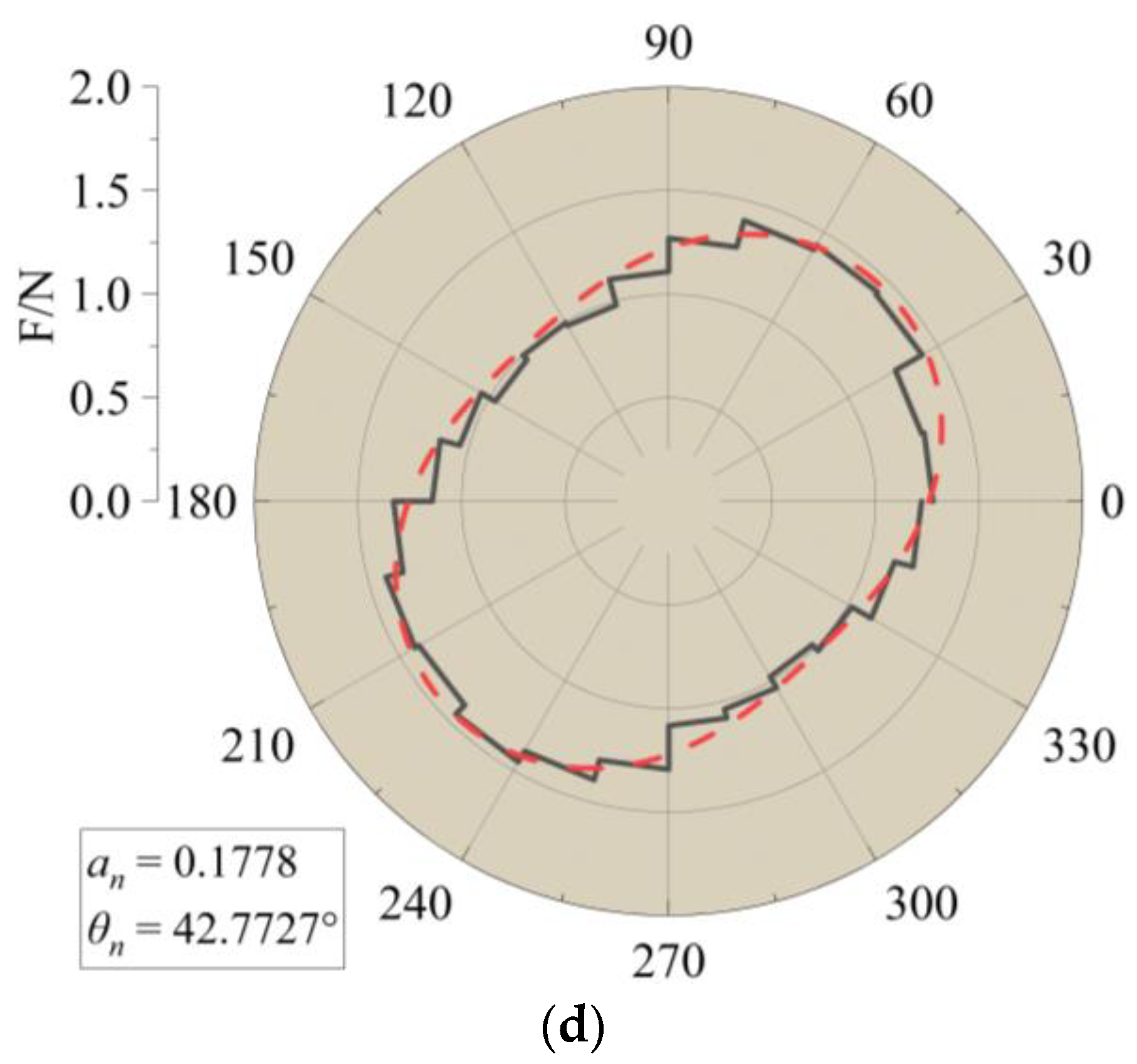

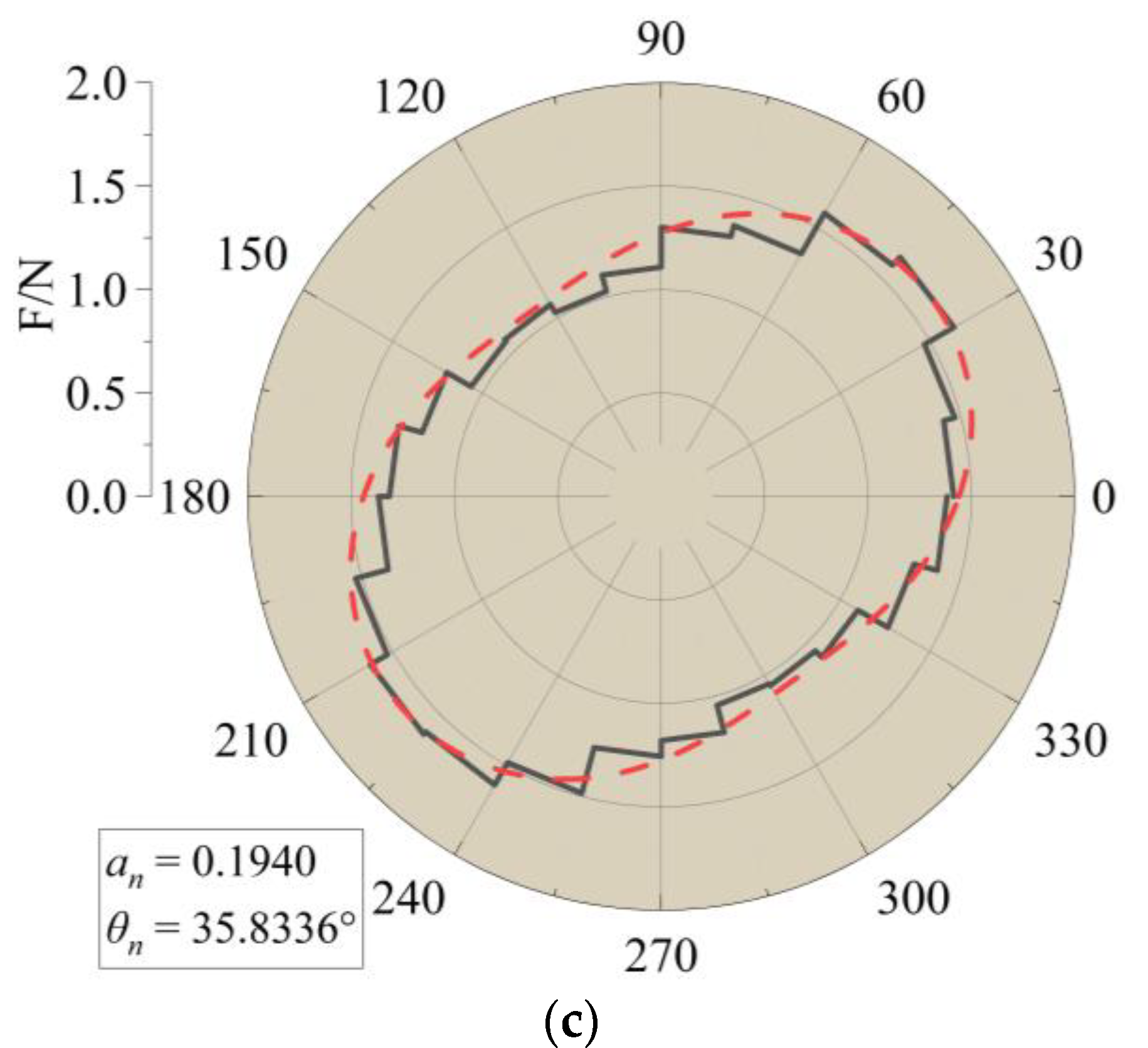

Figure 27.

Evolution law of microstructure in Condition G. (a) Before pull-out (0 mm). (b) When pull-out displacement reaches 5 mm. (c) When pull-out displacement reaches 10 mm. (d) When pull-out displacement reaches 15 mm.

Figure 27.

Evolution law of microstructure in Condition G. (a) Before pull-out (0 mm). (b) When pull-out displacement reaches 5 mm. (c) When pull-out displacement reaches 10 mm. (d) When pull-out displacement reaches 15 mm.

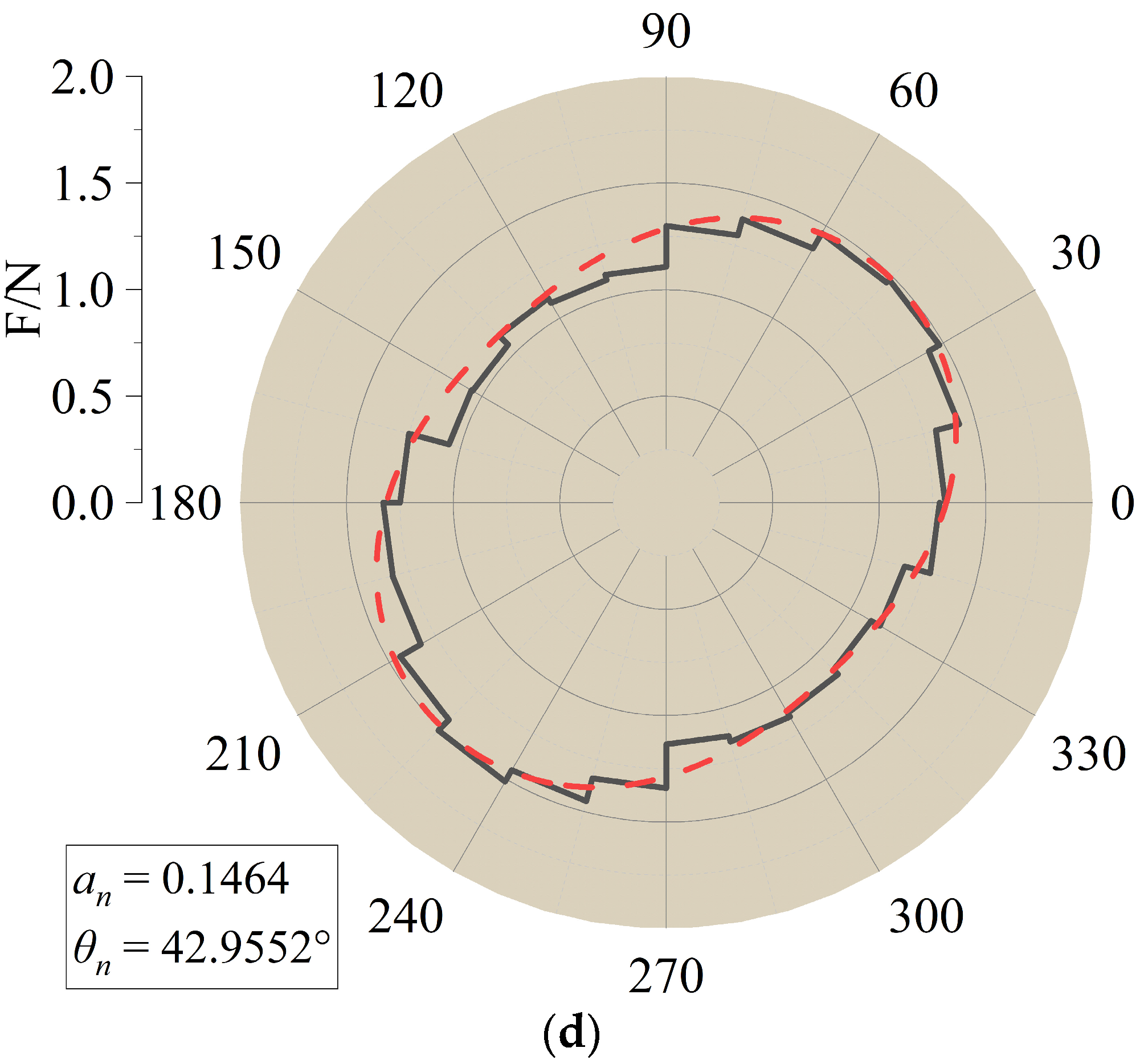

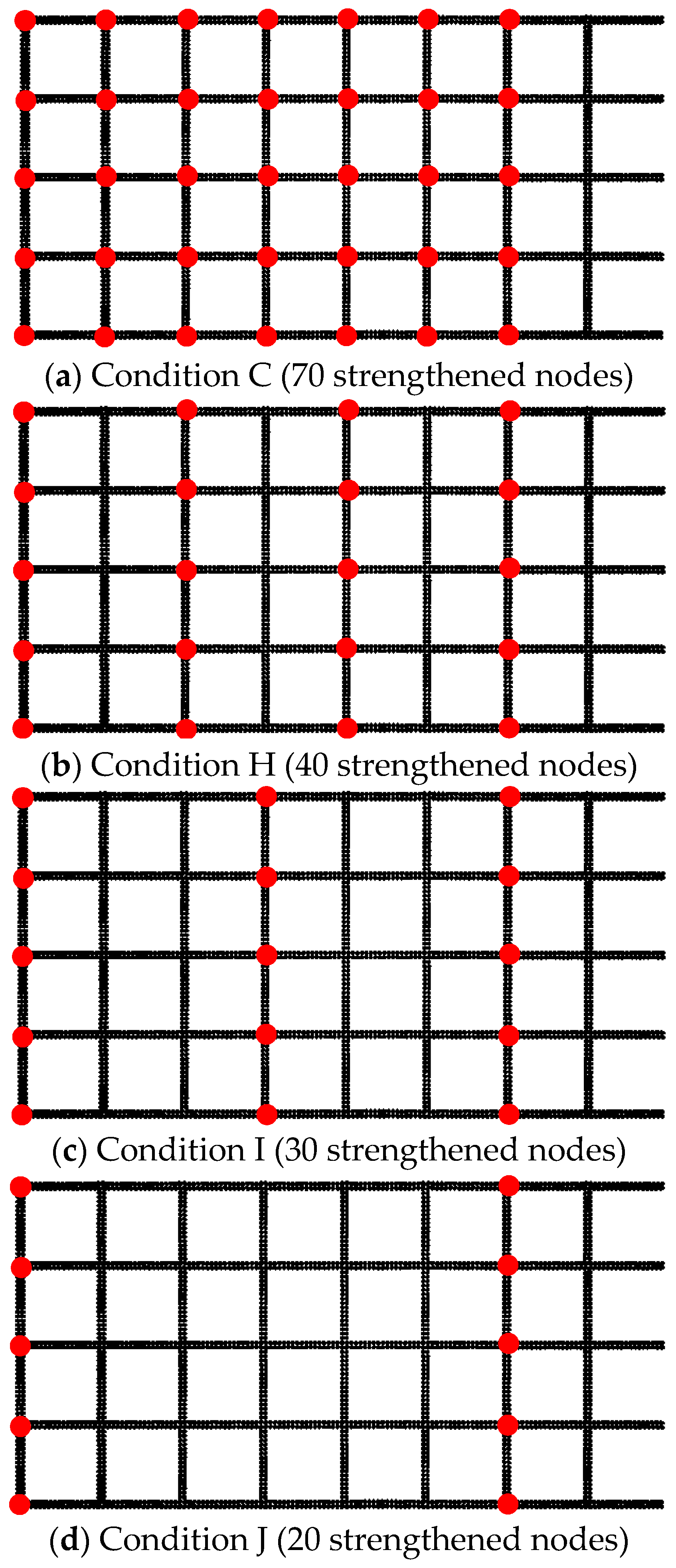

Figure 28.

Random distribution of different numbers of strengthened nodes.

Figure 28.

Random distribution of different numbers of strengthened nodes.

Figure 29.

Pull-out results with different numbers of strengthened nodes under random distribution.

Figure 29.

Pull-out results with different numbers of strengthened nodes under random distribution.

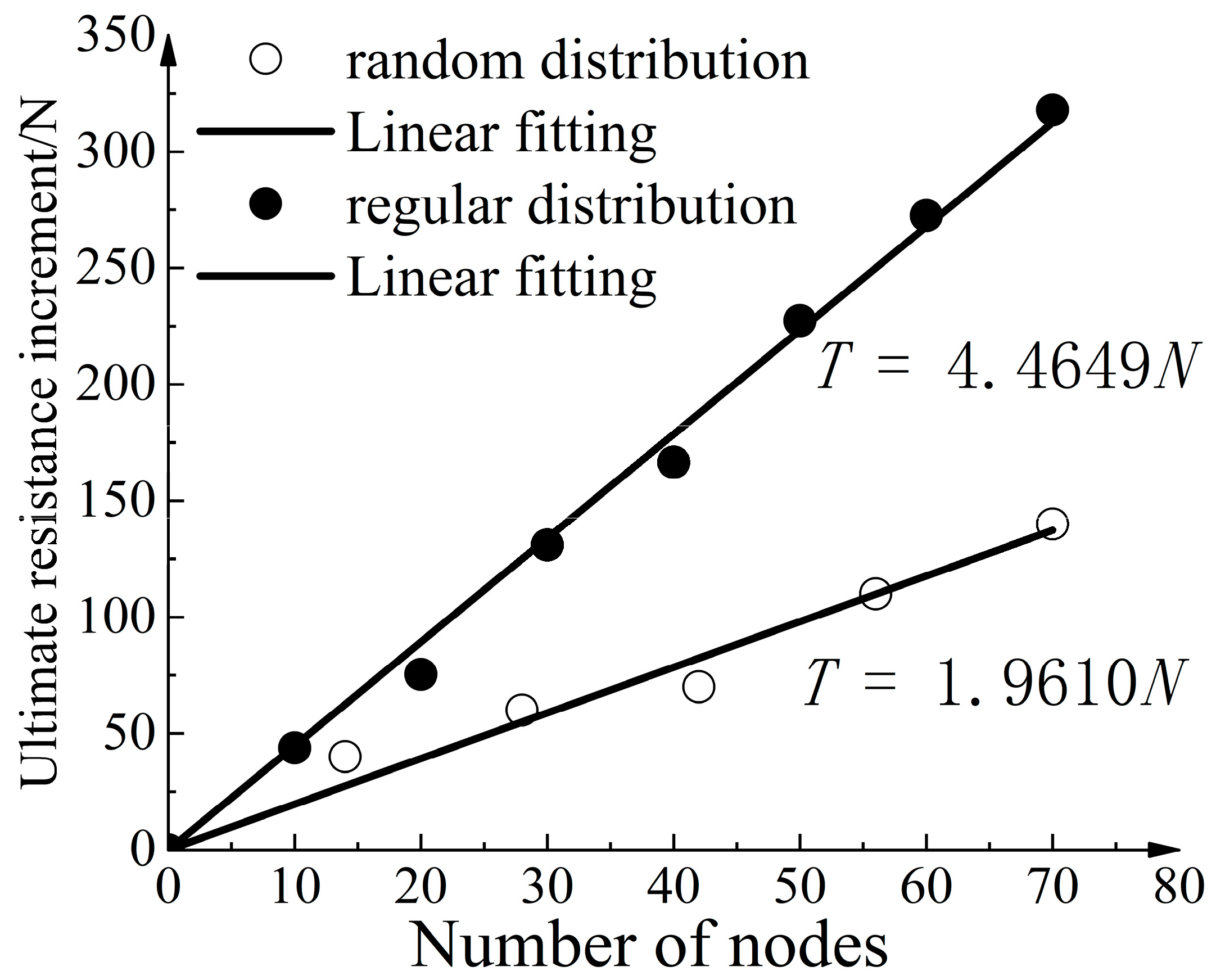

Figure 30.

Relationship curve between number of strengthened nodes and ultimate pull-out resistance increase.

Figure 30.

Relationship curve between number of strengthened nodes and ultimate pull-out resistance increase.

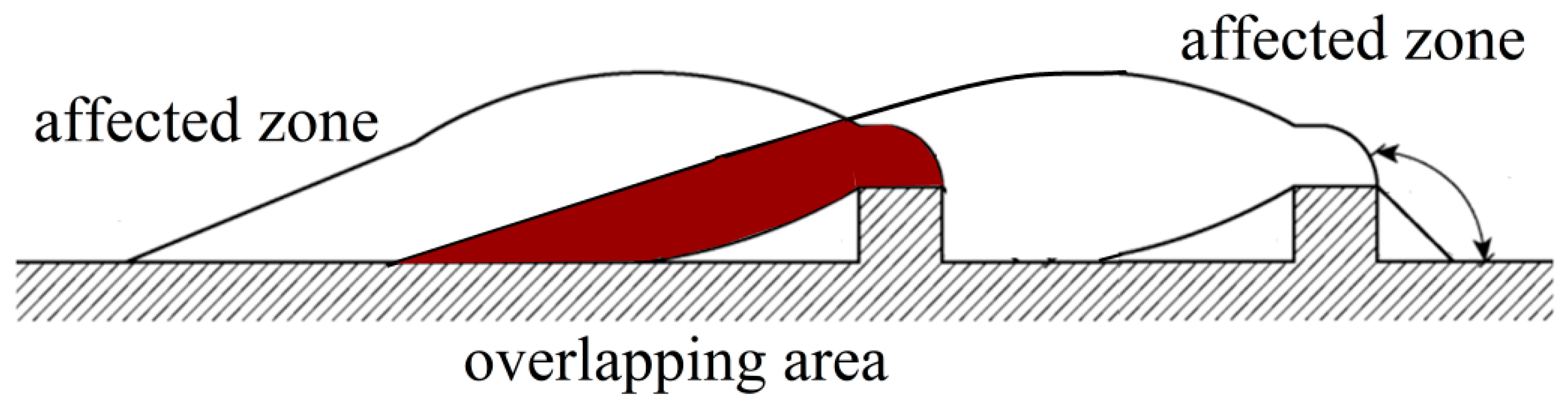

Figure 31.

Analysis of slip fracture surface of two strengthened nodes.

Figure 31.

Analysis of slip fracture surface of two strengthened nodes.

Figure 32.

Design conditions of different strengthened node spacings.

Figure 32.

Design conditions of different strengthened node spacings.

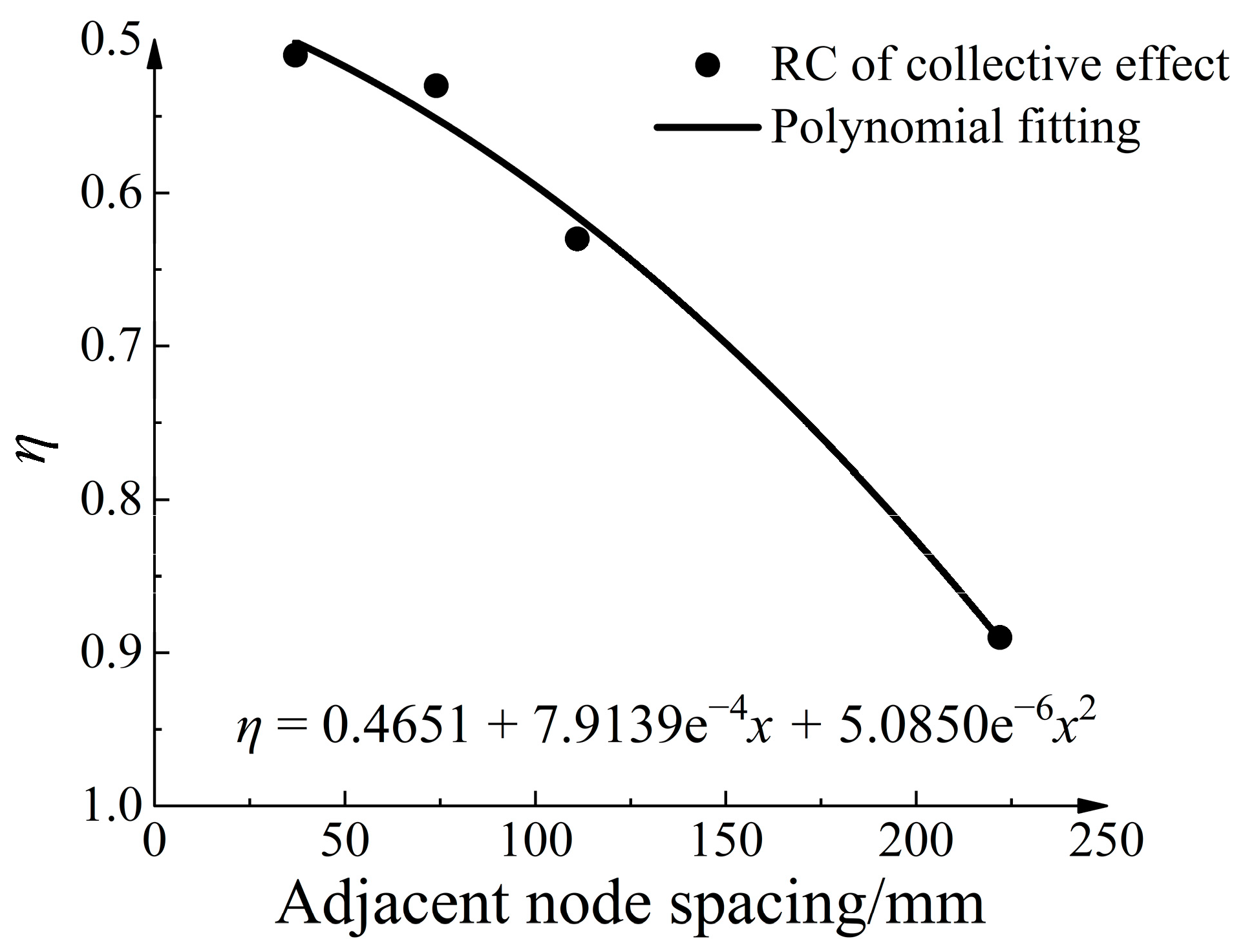

Figure 33.

Relationship between collective effect reduction coefficient and adjacent strengthened node spacing.

Figure 33.

Relationship between collective effect reduction coefficient and adjacent strengthened node spacing.

Table 1.

Physical parameters of aeolian sand.

Table 1.

Physical parameters of aeolian sand.

| Parameter | Value | Parameter | Value |

|---|

| Specific gravity | 2.70 | Maximum dry density (g·cm−3) | 1.71 |

| Unit weight (kN·m−3) | 15.8 | Maximum void ratio | 0.92 |

| Natural moisture content (%) | 0.9 | Minimum void ratio | 0.54 |

| Optimum moisture content (%) | 14.0 | Cohesion (kPa) | 0 |

| Density (g·cm−3) | 1.58 | Internal friction angle (°) | 27.4 |

Table 2.

Mesoscopic parameters of flexible films.

Table 2.

Mesoscopic parameters of flexible films.

| Parameter | Value |

|---|

| Deformation modulus (Pa) | 1 × 106 |

| Normal contact stiffness kn (N·m−1) | 3927 |

| Tangential contact stiffness ks (N·m−1) | 2617 |

| Bond strength (N·m−2) | 1 × 10300 |

| Membrane particle radius (mm) | 2.5 |

Table 3.

Calibration parameters of aeolian sand.

Table 3.

Calibration parameters of aeolian sand.

| Parameter | Value | Parameter | Value |

|---|

| Deformation modulus (MPa) | 80 | Friction coefficient | 0.55 |

| Stiffness ratio | 5.0 | Rotational resistance coefficient | 0.15 |

| Radius coefficient | 1.0 | Porosity | 0.40 |

Table 4.

Macro parameters of geogrid.

Table 4.

Macro parameters of geogrid.

| Aperture size (mm) | 34 × 31 | Transverse rib width (mm) | 5.00 |

| Longitudinal rib width (mm) | 3.00 | Transverse rib thickness (mm) | 1.60 |

| 2% elongation tensile strength (kN·m−1) | 21.20 | Ultimate tensile Strength (kN·m−1) | 46.92 |

| 5% elongation tensile strength (kN·m−1) | 37.96 | Longitudinal rib thickness (mm) | 3.80 |

Table 5.

Meso parameters of geogrid.

Table 5.

Meso parameters of geogrid.

| Density (kg·m−3) | 1000 | Damping ratio | 0.7 |

| Deformation modulus (MPa) | 3.3 × 103 | Friction coefficient | 0.5 |

| Particle size of transverse ribs (mm) | 1.97 | Normal bonding strength (N·m−2) | 4.2 × 1010 |

| Particle size of longitudinal ribs (mm) | 2.03 | Tangential bonding strength (N·m−2) | 4.2 × 1010 |

| Particle size of nodes (mm) | 2.2 | Radius coefficient | 1.0 |

Table 6.

Interface strength parameters under different node -thickening methods.

Table 6.

Interface strength parameters under different node -thickening methods.

| Method | Linear Fitting Expression | Quasi Cohesion (kPa) | Interface Friction Angle (°) |

|---|

| Condition B | | 5.0340 | 35.0688 |

| Condition C | | 5.1630 | 35.8067 |

| Condition D | | 5.6035 | 34.5979 |

| Condition A | | 5.2965 | 32.6355 |

Table 7.

Local porosity and sample volume change at the interface between reinforcement and soil.

Table 7.

Local porosity and sample volume change at the interface between reinforcement and soil.

| Condition | Porosity before Pulling | Porosity after Pulling | Sample Height before Pulling (mm) | Specimen Height after Pulling (mm) |

|---|

| Condition A | 0.4563 | 0.4920 | 214.580 | 215.176 |

| Condition C | 0.4541 | 0.4954 | 214.342 | 215.380 |

| Condition E | 0.4523 | 0.4977 | 214.374 | 215.612 |

| Condition F | 0.4556 | 0.4981 | 214.594 | 215.820 |

| Condition G | 0.4549 | 0.4972 | 214.596 | 216.088 |

Table 8.

Ultimate pull-out resistance increase of strengthened nodes under regular distribution.

Table 8.

Ultimate pull-out resistance increase of strengthened nodes under regular distribution.

| Position | Row 1 | Row 2 | Row 3 | Row 4 | Row 5 | Row 6 | Row 7 |

|---|

| Distance from front wall (mm) | 27 | 64 | 101 | 138 | 175 | 212 | 249 |

| Ultimate pull-out force increase (N) | 45.4 | 45.1 | 60.9 | 35.5 | 55.6 | 31.6 | 43.8 |

Table 9.

Effect of different strengthened node spacings on collective effect.

Table 9.

Effect of different strengthened node spacings on collective effect.

| Different Working Conditions | Cond C | Cond H | Cond I | Cond J |

|---|

| Adjacent strengthened node spacing (mm) | 37 | 74 | 111 | 222 |

| Ultimate pull-out resistance (N) | 1960 | 1894 | 1885 | 1879 |

| Ultimate pull-out resistance increase (N) | 160 | 94 | 85 | 79 |

| Increase when the node exist separately (N) | 313 | 179 | 134 | 89 |

| Reduction coefficient of collective effect | 0.51 | 0.53 | 0.63 | 0.89 |