Investigation of the Mechanical Properties of Iron Tailings Concrete Subjected to Dry–Wet Cycle and Negative Temperature

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Materials

2.1.1. Cementitious Materials

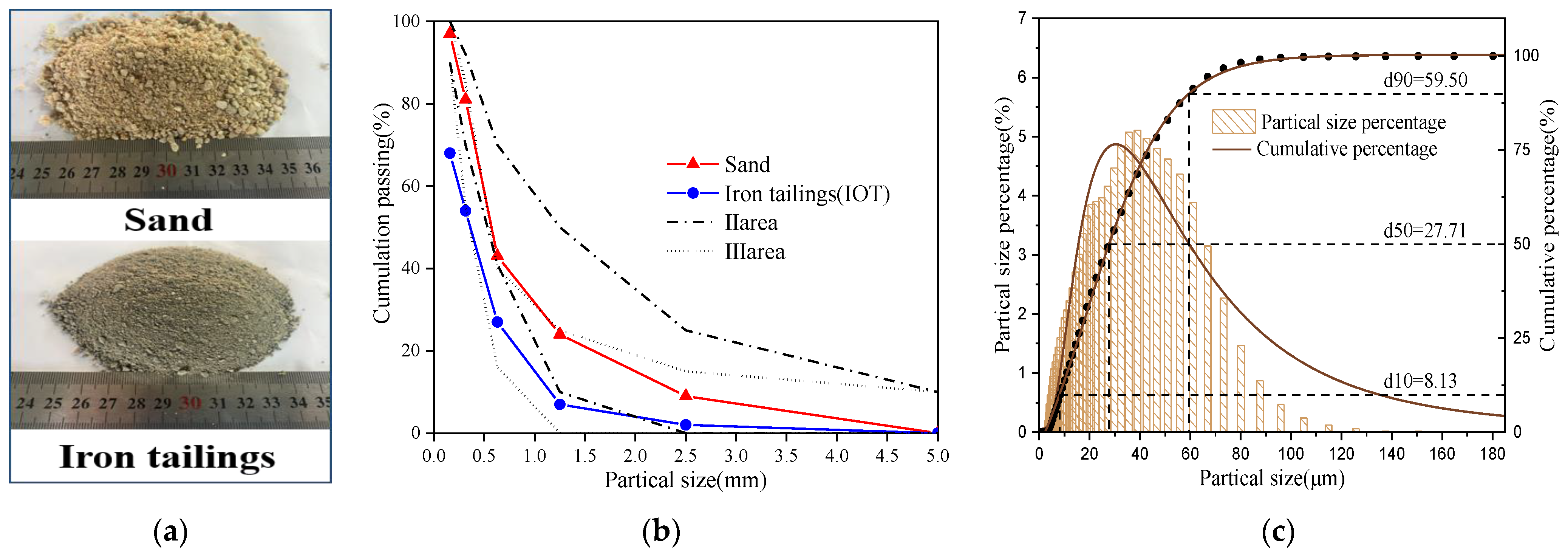

2.1.2. Aggregates

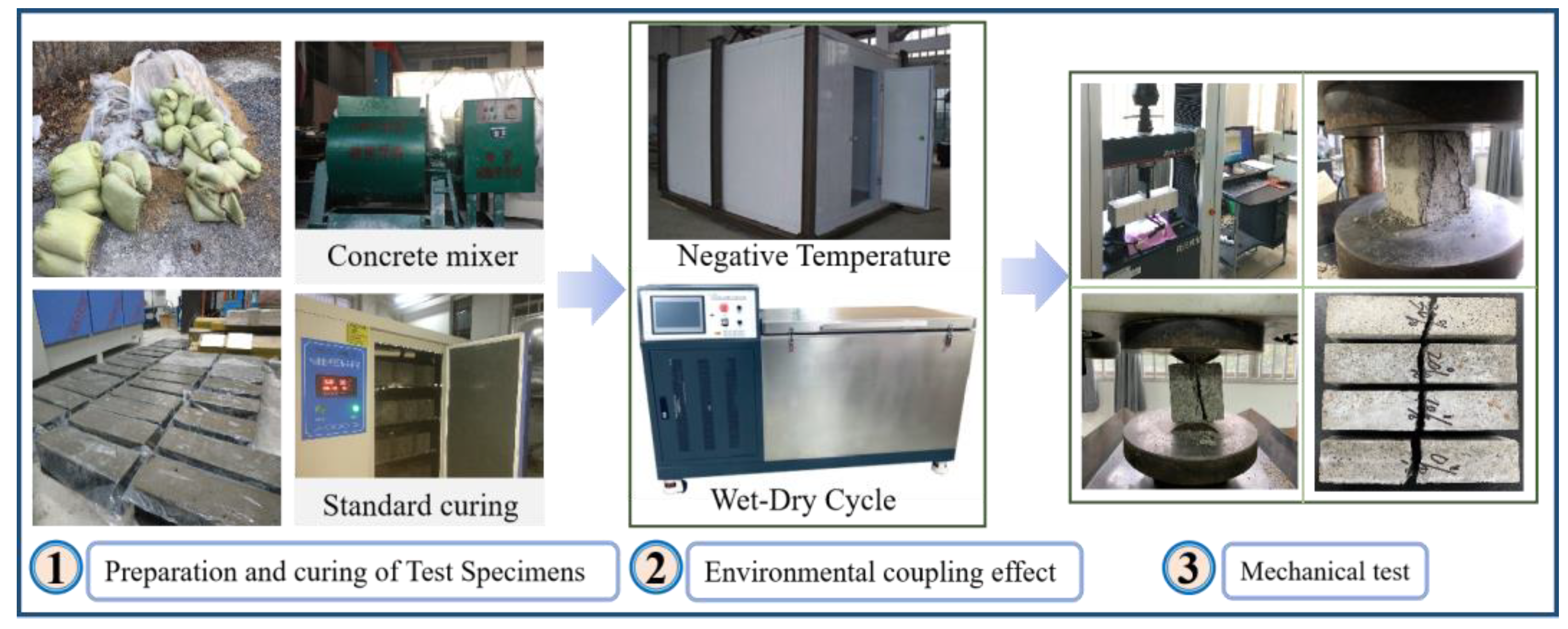

2.2. Specimen Casting and Curing Conditions

2.3. Test Method

2.3.1. The Dry–Wet Cycle and Negative Temperature Environment Tests of Concrete

2.3.2. Mechanics Test

2.3.3. Low-Field Nuclear Magnetic Resonance (NMR)

3. Results and Discussion

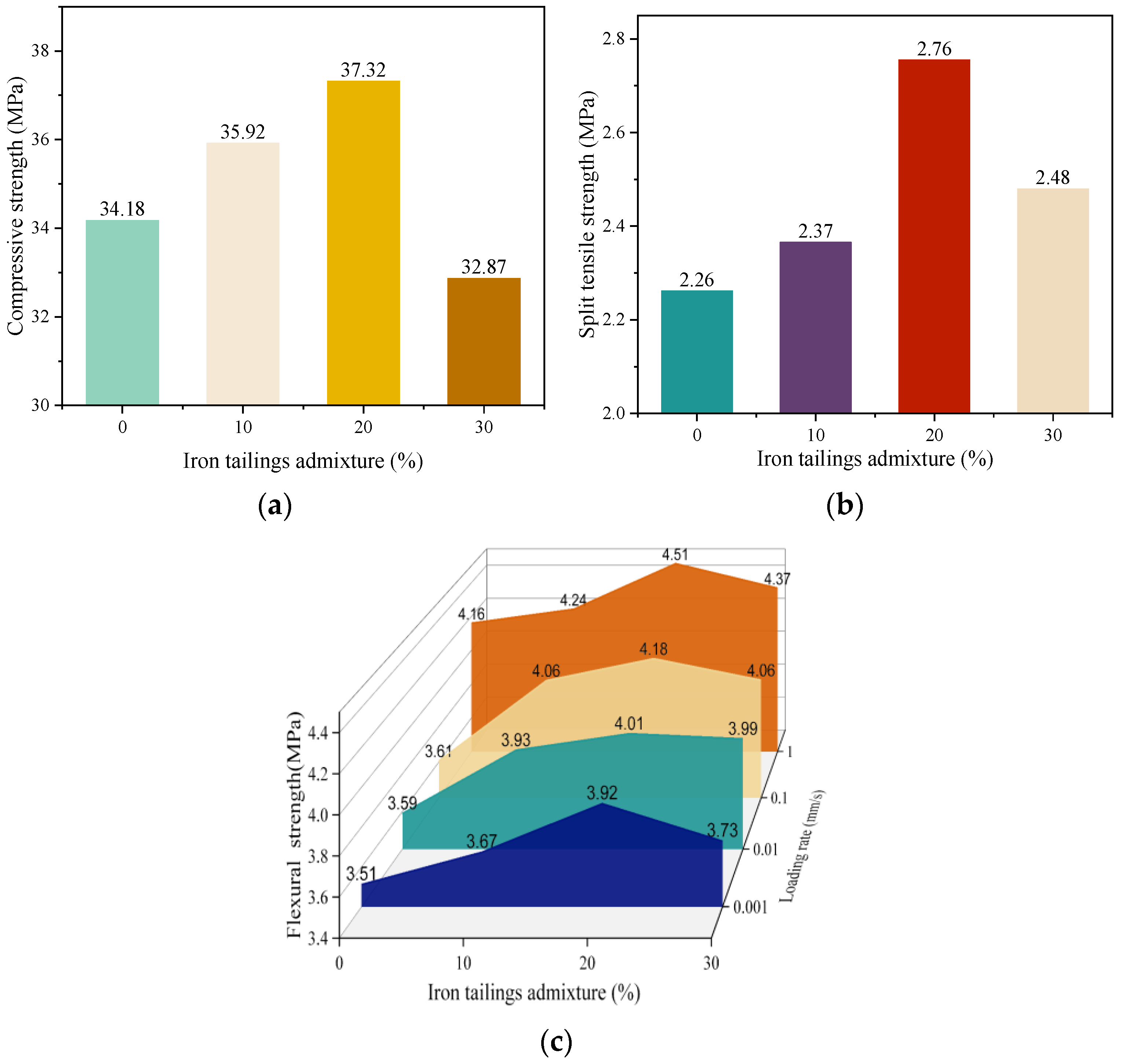

3.1. Analysis of the Mechanical Properties of ITC

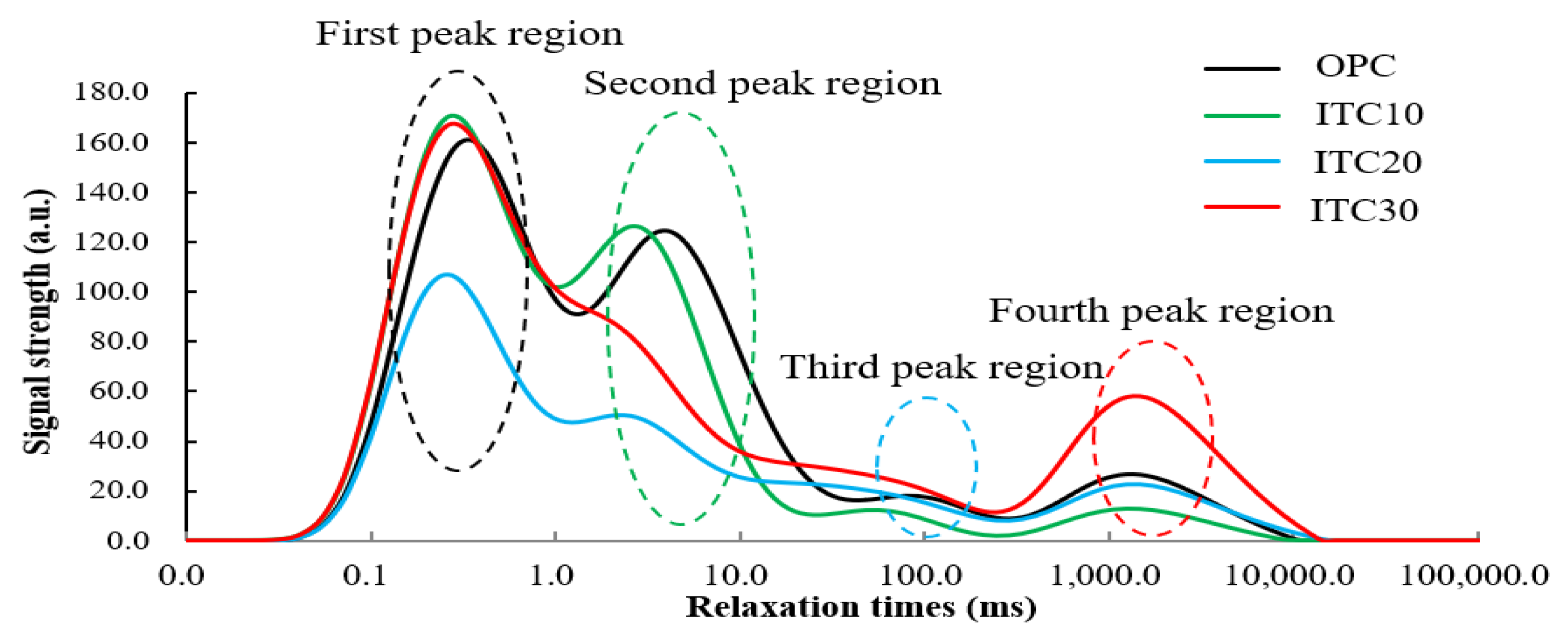

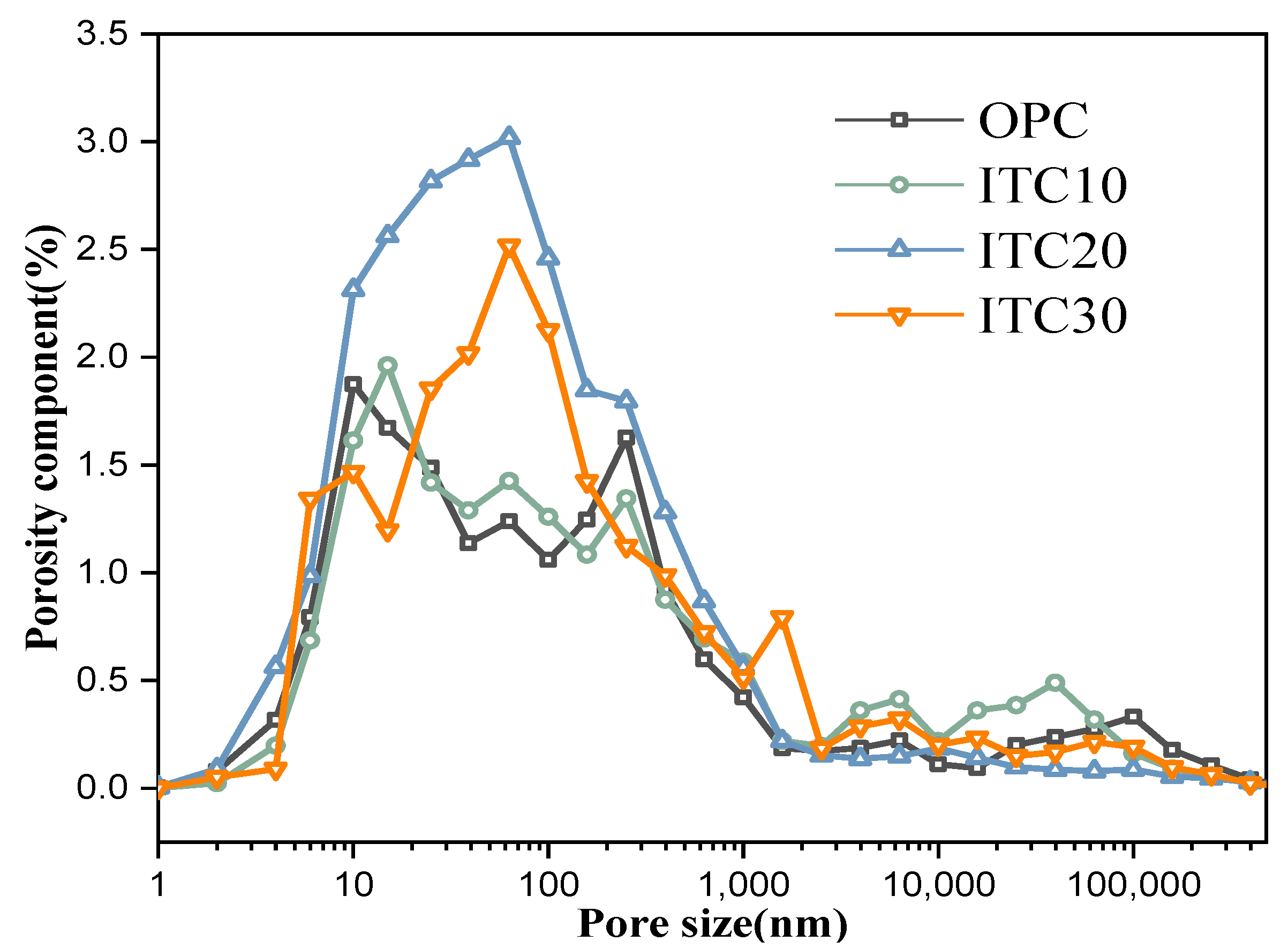

3.2. Analysis of ITC Pore Structure

3.3. Effect of Dry–Wet Cycles on Mechanical Properties and Durability of ITC

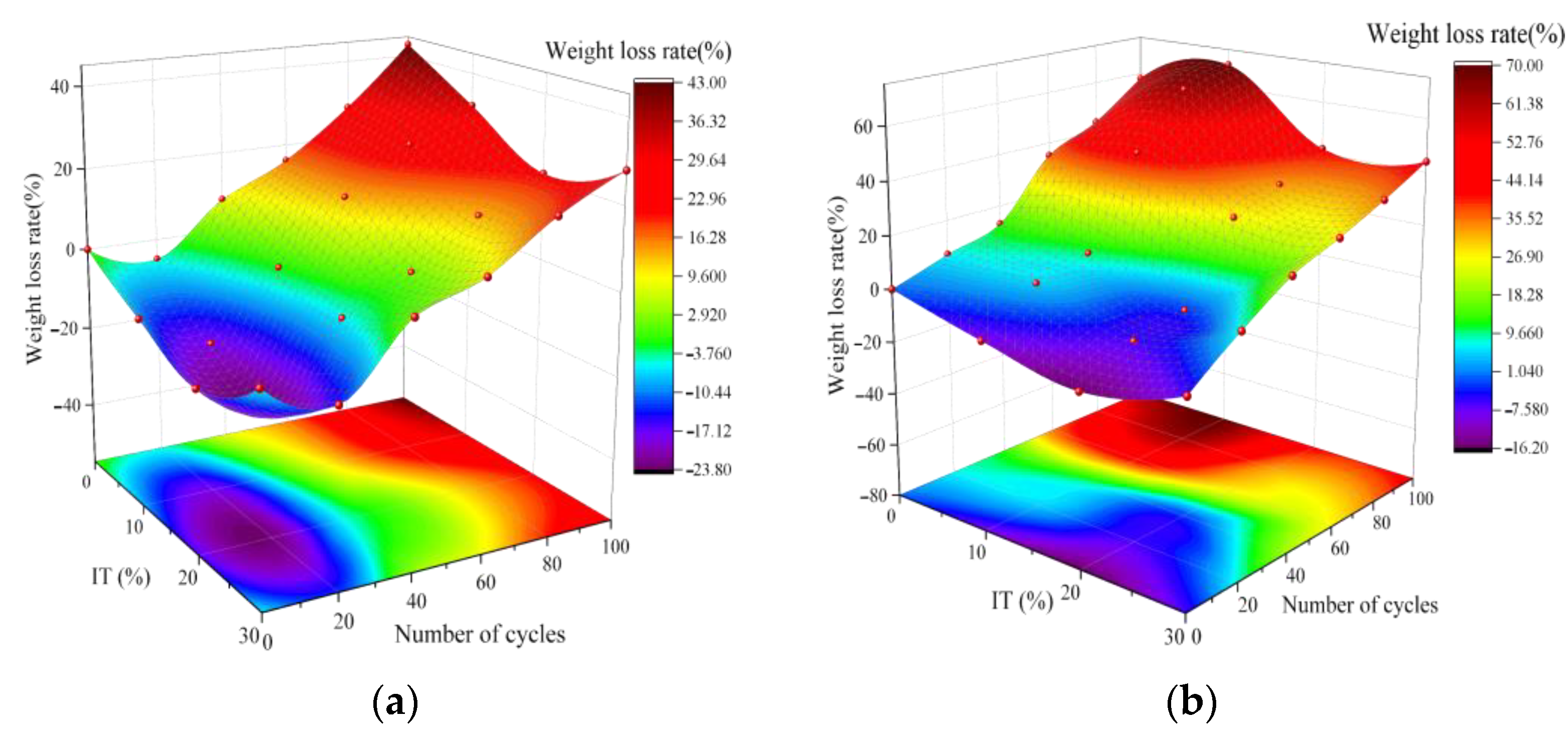

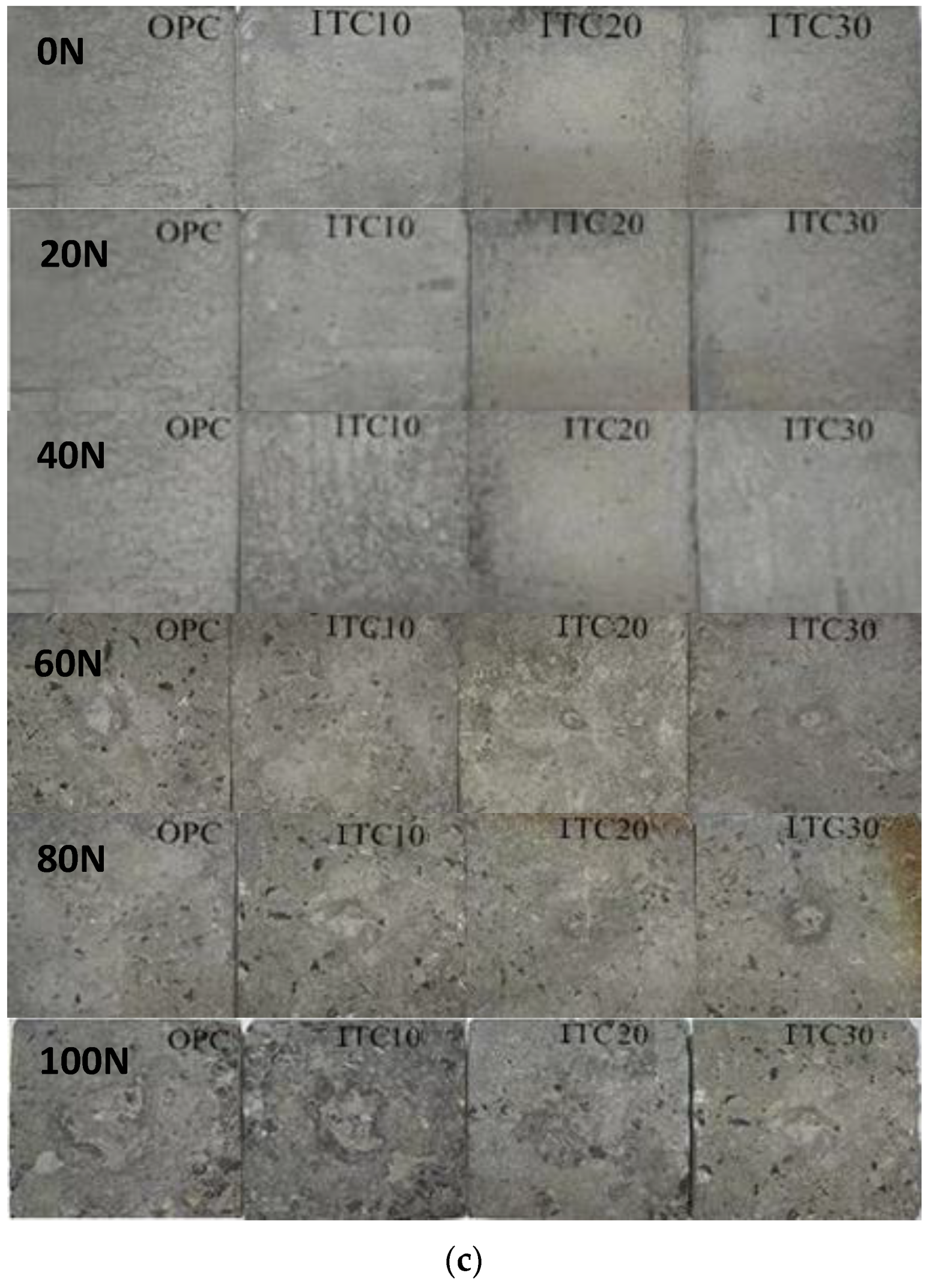

3.3.1. Weight Loss

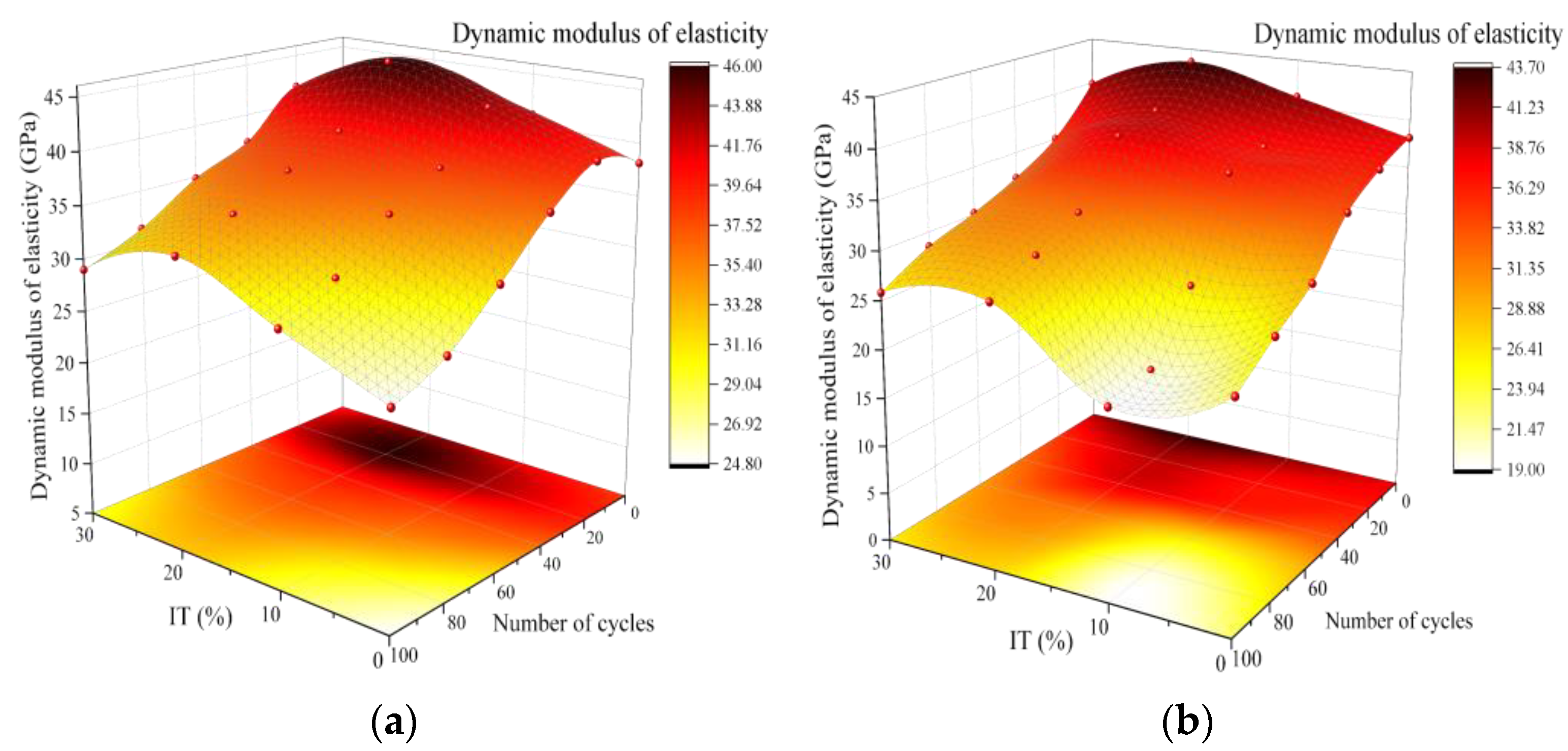

3.3.2. Relative Dynamic Elastic Modulus

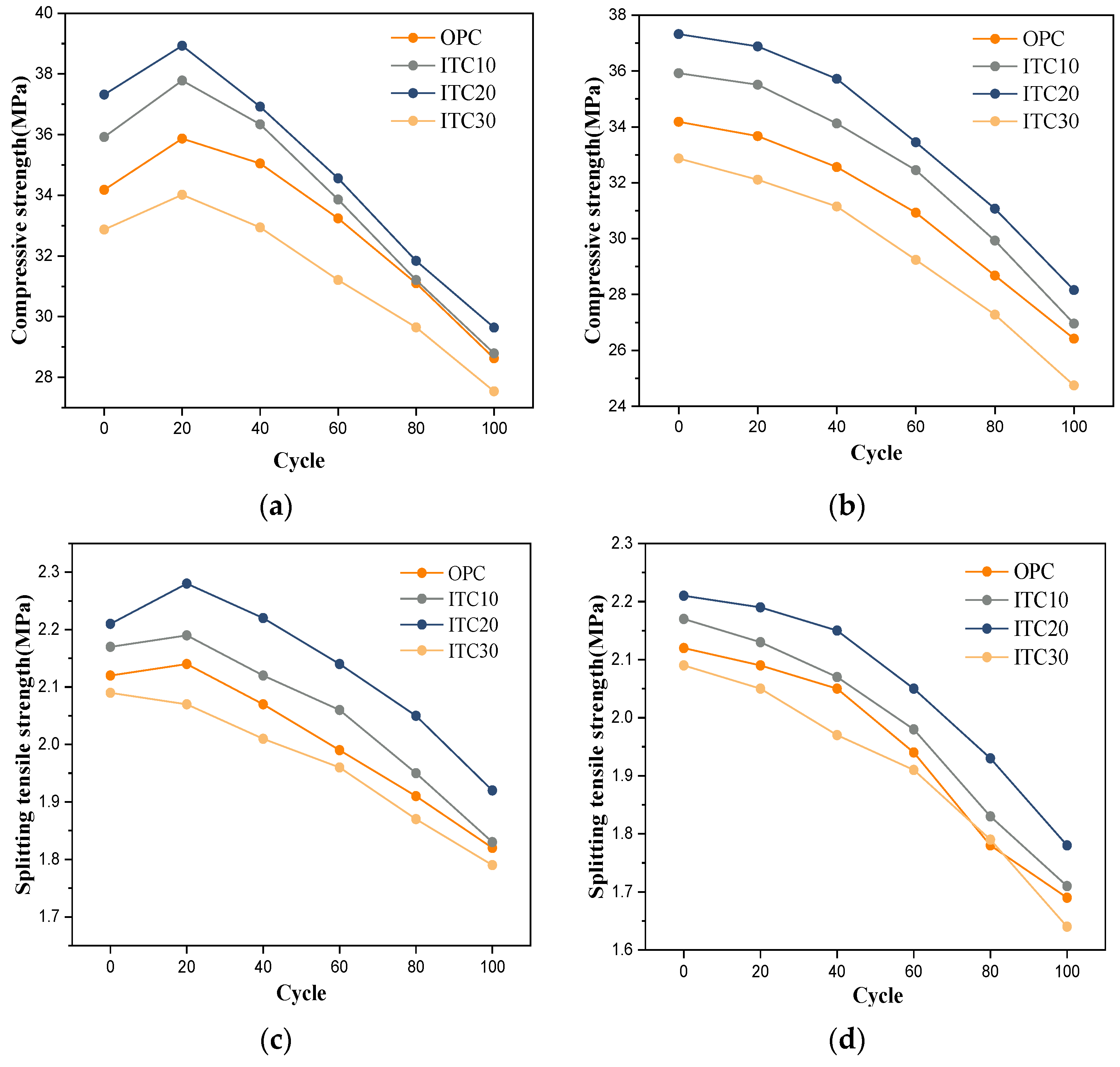

3.3.3. Mechanical Property

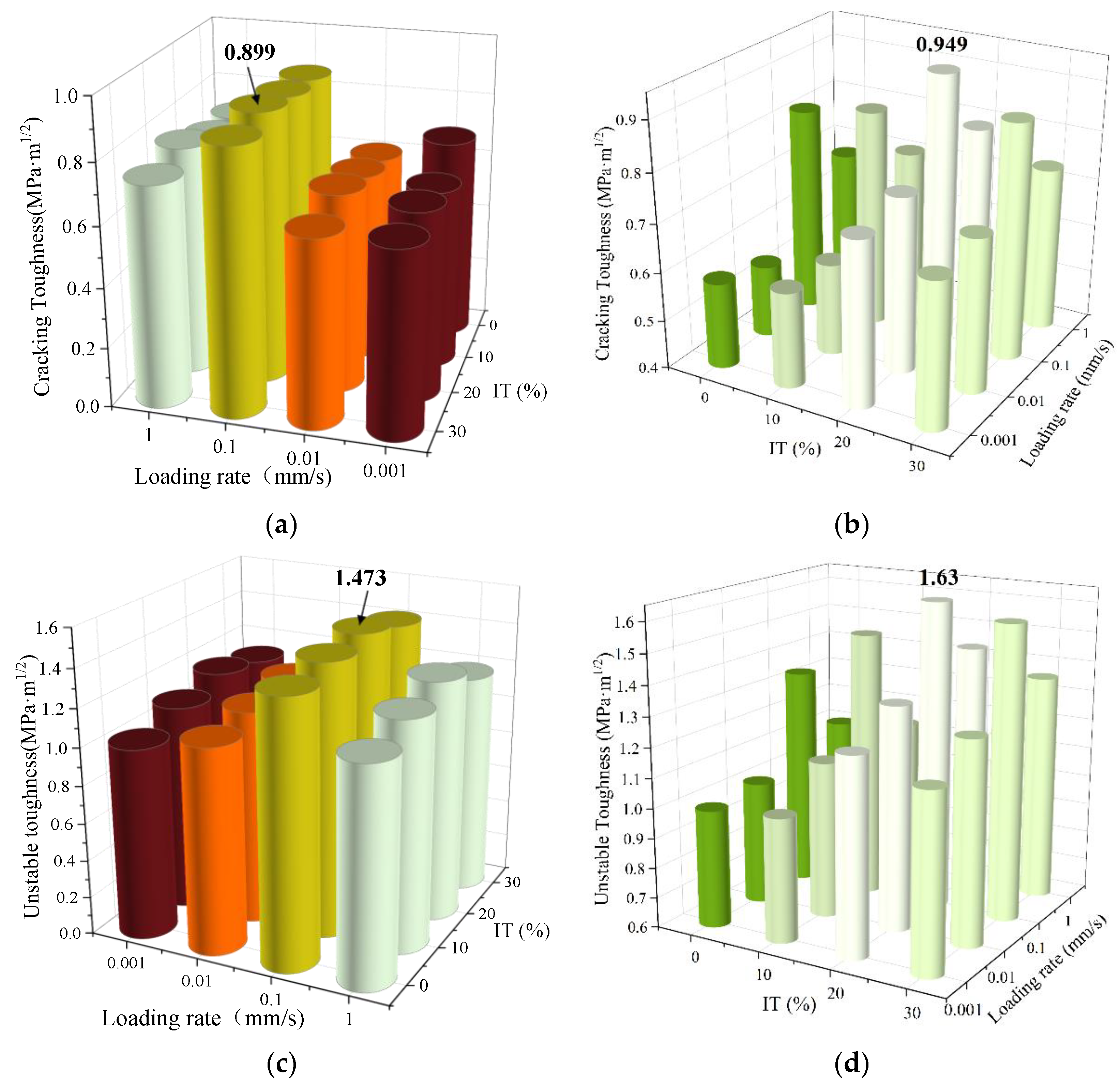

3.4. Effect of Negative Temperature on Mechanical Properties of ITC

3.5. Effect of Negative Temperature and Dry–Wet Cycles on Mechanical Properties of ITC

4. Conclusions

- The optimal replacement rate of iron tailings for river sand is 20%, at which point the concrete exhibits the smallest porosity and the best mechanical performance.

- The incorporation of iron tailings increases the water demand of concrete, which promotes the hydration reaction of cement, resulting in increases in mass, relative dynamic elastic modulus, and mechanical performance during the early stages of the dry–wet cycle tests.

- At a single factor of negative temperature, the best crack resistance was achieved at a 20% iron tailings replacement admixture rate. This crack resistance was higher than that of the same concrete material at room temperature. Moreover, the greatest fracture toughness value was achieved at a controlled loading rate of 0.1 mm/s.

- In a combined negative temperature and dry–wet cycle environment, the mechanical properties of concrete with a 20% iron tailings replacement rate surpass those of standard concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Zhang, Y.; Chen, T.; Zhao, Y.; Bao, S. Preparation of eco-friendly construction bricks from hematite tailings. Constr. Build. Mater. 2011, 25, 2107–2111. [Google Scholar] [CrossRef]

- Gayana, B.C.; Chandar, K.R. Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements—A review. Adv. Concr. Constr. 2018, 6, 221–243. [Google Scholar]

- Tan, Y.L.; Ning, J.G.; Zhao, T.B. Design and construction of entry retaining wall along a gob side under hard roof stratum. Int. J. Rock Mech. Min. Sci. 2015, 77, 115–121. [Google Scholar] [CrossRef]

- Zhao, Z.; Lv, X.; Wang, W.; Tan, Y. Damage evolution of bi-body model composed of weakly cemented soft rock and coal considering different interface effect. SpringerPlus 2016, 5, 292. [Google Scholar] [CrossRef]

- Pan, H.; Zhou, G.; Cheng, Z.; Yang, R.; He, L.; Zeng, D.; Sun, B. Advances in geochemical survey of mine tailings project in China. J. Geochem. Explor. 2014, 139, 193–200. [Google Scholar] [CrossRef]

- Zhao, T.; Li, B.W.; Gao, Z.Y.; Chang, D.Q. The utilization of rare earth tailing for the production of glass–ceramics. Mater. Sci. Eng. B 2010, 170, 22–25. [Google Scholar] [CrossRef]

- Xiao, L.G.; Yi, J.H.; Cui, Z.X. Iron tailings comprehensive utilization at home and abroad. Jilin Inst. Archit. Civ. Eng. 2010, 27, 22–26. [Google Scholar]

- Luana, C.; Vsévolod, M.; Avanci, M.A.; Povaluk, A.E. Ceramics composites from iron ore tailings and blast furnace slag. Ceram. Int. 2022, 48, 10506–10515. [Google Scholar]

- Liu, F.H.; Li, L.; Song, S.M.; Liu, J. Early-age hydration characteristics of composite binder containing iron tailing powder. Powder Technol. 2017, 315, 322–331. [Google Scholar]

- Liu, J.H.; Zhou, Y.C.; Wu, A.X.; Wang, H. Reconstruction of broken Si-O-Si bonds in iron ore tailings (IOTs) in concrete. Miner. Metall. Mater. 2019, 26, 1329–1336. [Google Scholar] [CrossRef]

- Lv, X.D.; Shen, W.G.; Wang, L.; Dong, Y.; Zhang, J.; Xie, Z. A coMParative research on the practical utilization of iron tailings as a complete replacement of normal aggregates in dam concrete with different gradation. J. Clean. Prod. 2019, 211, 704–715. [Google Scholar] [CrossRef]

- Shettima, A.U.; Hussin, M.W.; Ahmad, Y.; Mirza, J. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Constr. Build. Mater. 2016, 120, 72–79. [Google Scholar] [CrossRef]

- Arum, C.; Owolabi, A.O. Suitability of iron ore tailings and quarry dust as fine aggregates for concrete production. J. Appl. Sci. Technol. 2012, 17, 46–52. [Google Scholar]

- Hou, Y.F. Comparison of Effect of Iron Tailing Sand and Natural Sand on Concrete Properties. Key Eng. Mater. 2014, 599, 11–14. [Google Scholar] [CrossRef]

- Yellishetty, M.; Karpe, V.; Reddy, E.H.; Subhash, K.N.; Ranjith, P.G. Reuse of iron ore mineral wastes in civil engineering constructions: A case research. Resour. Conserv. Recycl. 2008, 52, 1283–1289. [Google Scholar] [CrossRef]

- Tiwari, S.; Rai, A.; Bajpai, Y.K. Effect of Partial Replacement of Sand by Iron Ore Tailings on the Compressive Strength of Concrete. Int. Res. J. Eng. Technol. (IRJET) 2017, 4, 56–72. [Google Scholar]

- Zhang, G.D.; Zhang, X.Z.; Zhou, Z.H.; Cheng, X. Preparation and properties of concrete containing iron tailings/manufactured sand as fine aggregate. Adv. Mater. Res. 2013, 838–841, 152–155. [Google Scholar] [CrossRef]

- Uchechukwu, E.A.; Ezekiel, M.J. Evaluation of the Iron Ore Tailings from Itakpe in Nigeria as Concrete Material. Adv. Mater. 2014, 3, 27–32. [Google Scholar] [CrossRef]

- Ugama, T.I.; Ejeh, S.P. Iron ore tailing as fine aggregate in mortar used for masonry. Adv. Eng. Technol. 2014, 7, 1170–1178. [Google Scholar]

- Feng, X.X.; Xi, X.L.; Cai, J.W.; Chai, H.J.; Song, Y.Z. Investigation of Drying Shrinkage of Concrete Prepared with Iron Mine Tailings. Key Eng. Mater. 2011, 477, 37–41. [Google Scholar] [CrossRef]

- Bai, Y.; Darcy, F.; Basheer, P.A.M. Strength and drying shrinkage properties of concrete containing furnace bottom ash as fine aggregate. Constr. Build. Mater. 2005, 19, 691–697. [Google Scholar] [CrossRef]

- Li, J.; Yao, Y. A research on creep and drying shrinkage of high performance concrete. Cem. Concr. Res. 2001, 31, 1203–1206. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, J.X.; Mu, K. Relationships between Compressive Strength and Microstructure in Mortars with Iron Ore Tailings as Fine Aggregate. Appl. Mech. Mater. 2012, 188, 211–218. [Google Scholar] [CrossRef]

- Chan, D.; Poon, C.S. Effects of Fine Recycled Aggregate as Sand Replacement in Concrete. HKIE Trans. 2006, 13, 2–7. [Google Scholar] [CrossRef]

- Siddique, R.; Aggarwal, Y.; Aggarwal, P.; Kadri, E.-H.; Bennacer, R. Strength, durability, and micro-structural properties of concrete made with used-foundry sand (UFS). Constr. Build. Mater. 2011, 25, 1916–1925. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S. Long-term mechanical and durability properties of recycled aggregate concrete prepared with the incorporation of fly ash. Cem. Concr. Compos. 2013, 37, 12–19. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- GBT50082-2019; Standard Test Methods for Long-Term Performance and Durability of Ordinary Concrete. China Academy of Building Research: Shenzhen, China, 2019.

- Xu, S.; Zhao, Y. Criteria and analysis of fracture process of concrete crack propagation. Eng. Mech. 2008, 25, 20–33. [Google Scholar]

- Li, T.; Wang, S.L.; Xu, F.; Meng, X.; Li, B.; Zhan, M. Study of the basic mechanical properties and degradation mechanism of recycled concrete with tailings before and after carbonation. J. Clean. Prod. 2020, 259, 120923. [Google Scholar] [CrossRef]

- Fu, H.C.; Erki, M.A.; Seckin, M. Review of Effects of Loading Rate on Concrete in Compression. J. Struct. Eng. 1991, 117, 3645–3659. [Google Scholar] [CrossRef]

- Lun, L.W.; Shen, P.; Cai, Y.; Sun, Y.; Zhang, Y.; Poon, C.S. Effects of seawater on UHPC: Macro and microstructure properties. Constr. Build. Mater. 2022, 340, 127767. [Google Scholar] [CrossRef]

- Li, H.; Farzadnia, N.; Shi, C. The role of seawater in interaction of slag and silica fume with cement in low water-to-binder ratio pastes at the early age of hydration. Constr. Build. Mater. 2018, 185, 508–518. [Google Scholar] [CrossRef]

- Arbili, M.M.; Alqurashi, M.; Majdi, A.; Ahmad, J.; Deifalla, A.F. Concrete Made with Iron Ore Tailings as a Fine Aggregate: Step towards Sustainable Concrete. Materials 2022, 15, 6236. [Google Scholar] [CrossRef]

- Xiao, S.; Wang, L.; Liu, G. Loading Rate Effect on the Damage of Reinforced Concrete Structures. J. Shenyang Jianzhu Univ. 2013, 29, 628–634. [Google Scholar]

| Flexural Strength (MPa) | Compressive Strength (MPa) | Specific Surface Area (g/cm2) | Setting Time (min) | |||

|---|---|---|---|---|---|---|

| 3 days | 28 days | 3 days | 28 days | 367 | Initial setting | Final setting |

| 4.1 | 9.3 | 21.2 | 46.1 | 164 | 272 | |

| Physical Properties | Apparent Density (kg/m3) | Fineness Modulus (MX) | Type | Water Absorption (%) | PH Value |

|---|---|---|---|---|---|

| Sand | 2.620 | 2.49 | Medium sand | 1.67 | 8 |

| Iron tailings | 2.855 | 1.29 | Fine sand | 3.65 | 10 |

| Element | MgO | Fe2O3 | Al2O3 | SiO2 | CaO | K2O | Other |

|---|---|---|---|---|---|---|---|

| Cement | 1.40 | 4.04 | 5.80 | 21.47 | 59.64 | - | 4.67 |

| Iron tailings | 16.7 | 10.80 | 8.19 | 41.11 | 13.99 | 0.72 | 0.75 |

| Sand | - | - | - | 99.8 | - | - | 0.2 |

| Coarse Aggregates | Particle Size (mm) | Apparent Density (kg/m3) | Water Absorption (%) | Crushing Index (%) |

|---|---|---|---|---|

| Natural Crushed Stone | 5–16 | 2530 | 1.17 | 13 |

| Sample Number | Water (kg/m3) | Cement (kg/m3) | Sand (kg/m3) | Iron Tailing (kg/m3) | Stone (kg/m3) | W/C | Slump (mm) |

|---|---|---|---|---|---|---|---|

| OPC | 180 | 409 | 535 | 0 | 1249 | 0.44 | 200 |

| ITC-10% | 180 | 409 | 481 | 54 | 1249 | 0.44 | 196 |

| ITC-20% | 180 | 409 | 427 | 108 | 1249 | 0.44 | 191 |

| ITC-30% | 180 | 409 | 378 | 162 | 1249 | 0.44 | 183 |

| Sample | V/cm3 | NMR Signal Intensity (a.u.) | Water Content (g) | Porosity (%) |

|---|---|---|---|---|

| OPC | 60.76 | 4193.56 | 9.92 | 12.83 |

| ITC10 | 63.89 | 3806.29 | 9.28 | 11.36 |

| ITC20 | 58.16 | 2520.14 | 6.14 | 9.56 |

| ITC30 | 61.68 | 4089.27 | 10.48 | 13.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Xu, H.; Li, B.; Zhang, C.; Zhang, Y.; Zhao, C.; Li, K. Investigation of the Mechanical Properties of Iron Tailings Concrete Subjected to Dry–Wet Cycle and Negative Temperature. Materials 2023, 16, 4602. https://doi.org/10.3390/ma16134602

Liu X, Xu H, Li B, Zhang C, Zhang Y, Zhao C, Li K. Investigation of the Mechanical Properties of Iron Tailings Concrete Subjected to Dry–Wet Cycle and Negative Temperature. Materials. 2023; 16(13):4602. https://doi.org/10.3390/ma16134602

Chicago/Turabian StyleLiu, Xiaozhou, Hu Xu, Ben Li, Chen Zhang, Yu Zhang, Canhao Zhao, and Kaihang Li. 2023. "Investigation of the Mechanical Properties of Iron Tailings Concrete Subjected to Dry–Wet Cycle and Negative Temperature" Materials 16, no. 13: 4602. https://doi.org/10.3390/ma16134602

APA StyleLiu, X., Xu, H., Li, B., Zhang, C., Zhang, Y., Zhao, C., & Li, K. (2023). Investigation of the Mechanical Properties of Iron Tailings Concrete Subjected to Dry–Wet Cycle and Negative Temperature. Materials, 16(13), 4602. https://doi.org/10.3390/ma16134602