Fabrication and Luminescent Properties of Highly Transparent Er:Y2O3 Ceramics by Hot Pressing Sintering

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

- 4I15/2 → 4I11/2 (ground state absorption)

- 4I11/2 → 4F7/2 (excited stated absorption)

- 4F7/2 → 2H11/2/4S3/2 (multiphonon relaxation)

- 2H11/2/4S3/2 → 4I15/2 (radiative relaxation)

- 4I15/2 → 4I11/2 (ground state absorption)

- 4I11/2 → 4I13/2 (multiphonon relaxation)

- 4I13/2 → 4F9/2 (excited state absorption)

- 4F9/2 → 4I15/2 (radiative relaxation)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ikesue, A.; Aung, Y.L. Ceramic laser materials. Nat. Photonics 2008, 2, 721–727. [Google Scholar] [CrossRef]

- Wang, L.; Huang, H.; Shen, D.; Zhang, J.; Chen, H.; Wang, Y.; Liu, X.; Tang, D. Room temperature continuous-wave laser performance of LD pumped Er:Lu2O3 and Er:Y2O3 ceramic at 2.7 μm. Opt. Express 2014, 22, 19495–19503. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Wang, S.; Rong, T.; Chen, L. Upconversion luminescence in Er3+ doped and Yb3+/Er3+ codoped yttria nanocrystalline powders. J. Am. Ceram. Soc. 2004, 87, 1072–1075. [Google Scholar] [CrossRef]

- Wei, G. Transparent ceramic lamp envelope materials. J. Phys. D Appl. Phys. 2005, 38, 3057. [Google Scholar] [CrossRef]

- Hostaša, J.; Nečina, V.; Uhlířová, T.; Biasini, V. Effect of rare earth ions doping on the thermal properties of YAG transparent ceramics. J. Eur. Ceram. Soc. 2019, 39, 53–58. [Google Scholar] [CrossRef]

- Kong, J.; Lu, J.; Takaichi, K.; Uematsu, T.; Ueda, K.; Tang, D.; Shen, D.; Yagi, H.; Yanagitani, T.; Kaminskii, A. Diode-pumped Yb:Y2O3 ceramic laser. Appl. Phys. Lett. 2003, 82, 2556–2558. [Google Scholar] [CrossRef]

- Lu, J.R.; Murai, T.; Takaichi, K.; Uematsu, T.; Ueda, K.-I.; Yagi, H.; Yanagitani, T.; Kaminskii, A. Nd3+:Y2O3 Ceramic Laser. Jpn. J. Appl. Phys. 2001, 40, L1277. [Google Scholar]

- Shen, Y.; Li, E.; Wang, J.; Tang, D.; Shen, D. Stable Q-switched mode-locking of an in-band pumped Ho: Y2O3 ceramic laser at 2117 nm. Quantum Electron. 2021, 51, 41. [Google Scholar] [CrossRef]

- Sanamyan, T. Diode pumped cascade Er:Y2O3 laser. Laser Phys. Lett. 2015, 12, 125804. [Google Scholar] [CrossRef]

- Fleischman, Z.D.; Sanamyan, T. Spectroscopic analysis of Er3+: Y2O3 relevant to 2.7 µm mid-IR laser. Opt. Mater. Express 2016, 6, 3109–3118. [Google Scholar] [CrossRef]

- Kokuoz, B.Y.; Serivalsatit, K.; Kokuoz, B.; Geiculescu, O.; McCormick, E.; Ballato, J. Er-Doped Y2O3 Nanoparticles: A Comparison of Different Synthesis Methods. J. Am. Ceram. Soc. 2009, 92, 2247–2253. [Google Scholar] [CrossRef]

- Sanamyan, T.; Simmons, J.; Dubinskii, M. Er3+-doped Y2O3 ceramic laser at ~2.7 μm with direct diode pumping of the upper laser level. Laser Phys. Lett. 2010, 7, 206. [Google Scholar] [CrossRef]

- Yanmin, Q.; Hai, G. Upconversion properties of Y2O3: Er films prepared by sol-gel method. J. Rare Earths 2009, 27, 406–410. [Google Scholar]

- Onodera, Y.; Nunokawa, T.; Odawara, O.; Wada, H. Upconversion properties of Y2O3: Er, Yb nanoparticles prepared by laser ablation in water. J. Lumin. 2013, 137, 220–224. [Google Scholar] [CrossRef]

- Capobianco, J.A.; Vetrone, F.; Boyer, J.C.; Speghini, A.; Bettinelli, M. Enhancement of red emission (4F9/2→ 4I15/2) via upconversion in bulk and nanocrystalline cubic Y2O3: Er3+. J. Phys. Chem. B 2002, 106, 1181–1187. [Google Scholar] [CrossRef]

- Vetrone, F.; Boyer, J.-C.; Capobianco, J.A.; Speghini, A.; Bettinelli, M. Concentration-dependent near-infrared to visible upconversion in nanocrystalline and bulk Y2O3: Er3+. Chem. Mater. 2003, 15, 2737–2743. [Google Scholar] [CrossRef]

- Zhang, J.; .Wang, S.W.; An, L.; Liu, M.; Chen, L. Infrared to visible upconversion luminescence in Er3+: Y2O3 transparent ceramics. J. Lumin. 2007, 122, 8–10. [Google Scholar] [CrossRef]

- Zhu, L.L.; Park, Y.-J.; Gan, L.; Go, S.-I.; Kim, H.-N.; Kim, J.-M.; Ko, J.-W. Fabrication and characterization of highly transparent Er: Y2O3 ceramics with ZrO2 and La2O3 additives. Ceram. Int. 2017, 43, 13127–13132. [Google Scholar] [CrossRef]

- Yin, D.; Wang, J.; Wang, Y.; Liu, P.; Ma, J.; Xu, X.; Shen, D.; Dong, Z.; Kong, L.B.; Tang, D. Fabrication of Er: Y2O3 transparent ceramics for 2.7 μm mid-infrared solid-state lasers. J. Eur. Ceram. Soc. 2020, 40, 444–448. [Google Scholar] [CrossRef]

- Chu, X.; Gan, L.; Ren, S.Q.; Wang, J.; Ma, Z.; Jiang, J.; Zhang, T.J. Low-loss and temperature-stable (1 − x) Li2TiO3–xLi3Mg2NbO6 microwave dielectric ceramics. Ceram. Int. 2020, 46, 8413–8419. [Google Scholar] [CrossRef]

- Cesar, P.F.; Della Bona, A.; Scherrer, S.S.; Tholey, M.; van Noort, A.; Vichi, A.; Kelly, R.; Lohbauer, U. ADM guidance—Ceramics: Fracture toughness testing and method selection. Dent. Mater. 2017, 33, 575–584. [Google Scholar] [CrossRef] [PubMed]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystallogr. Sect. A Cryst. Phys. Diffr. Theor. Gen. Crystallogr. 1976, 3, 751–767. [Google Scholar] [CrossRef]

- Liu, C.R.; Zhou, G.H.; Jiang, J.; Hu, S.; Zhang, T.J.; Wang, S.W.; Xue, Z.H.; Lin, H.; Qin, X.P.; Gan, L. Fabrication and luminescence properties of highly transparent and submicrometer-grained Yb: Y2O3 ceramics by hot-pressing sintering. J. Alloys Compd. 2022, 898, 163002. [Google Scholar] [CrossRef]

- Wang, L.; Huang, H.; Shen, D.; Zhang, J.; Chen, H.; Tang, D. Diode-pumped high power 2.7 μm Er: Y2O3 ceramic laser at room temperature. Opt. Mater. 2017, 71, 70–73. [Google Scholar] [CrossRef]

- Gan, L.; Park, Y.-J.; Zhu, L.L.; Go, S.-I.; Kim, H.; Kim, J.-M.; Ko, J.-W. Fabrication and properties of La2O3-doped transparent yttria ceramics by hot-pressing sintering. J. Alloys Compd. 2017, 695, 2142–2148. [Google Scholar] [CrossRef]

- Gheorghe, C.; Georgescu, S.; Lupei, V.; Lupei, A.; Ikesue, A. Absorption intensities and emission cross section of Er3+ in Sc2O3 transparent ceramics. J. Appl. Phys. 2008, 103, 083116. [Google Scholar] [CrossRef]

- Xue, Y.L.; Zhu, F.; Wang, J.; Sun, S.; Hu, L.; Tang, D. Fabrication and comprehensive structural and spectroscopic properties of Er: Y2O3 transparent ceramics. J. Rare Earths 2022, 40, 1913–1919. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, W. Structural and thermo-mechanical properties of Nd:Y2O3 transparent ceramics. J. Am. Ceram. Soc. 2015, 98, 3326–3331. [Google Scholar] [CrossRef]

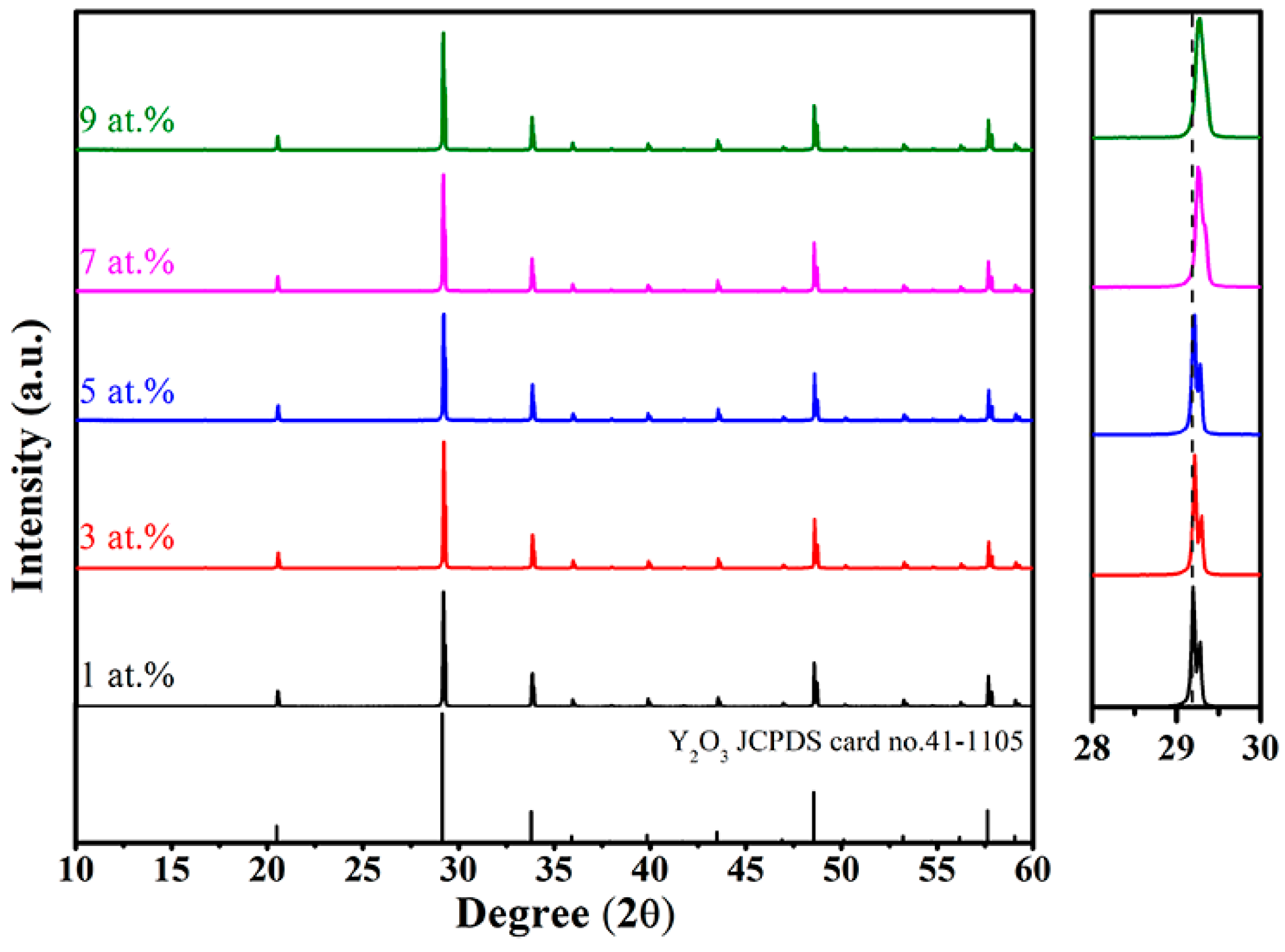

| Samples (at.%) | Lattice Parameters a = b = c (nm) | Unit Cell Volume (nm3) | Calculated Theoretical Density (g/cm3) | Bulk Density (g/cm3) | Relative Density (%) |

|---|---|---|---|---|---|

| 1 | 1.06001 | 1.19104 | 5.0785 | 5.077 ± 0.007 | 99.97 |

| 3 | 1.05993 | 1.19079 | 5.1495 | 5.143 ± 0.012 | 99.87 |

| 5 | 1.05989 | 1.19066 | 5.2201 | 5.212 ± 0.005 | 99.84 |

| 7 | 1.05958 | 1.18960 | 5.2947 | 5.286 ± 0.010 | 99.84 |

| 9 | 1.05943 | 1.18910 | 5.3670 | 5.361 ± 0.006 | 99.88 |

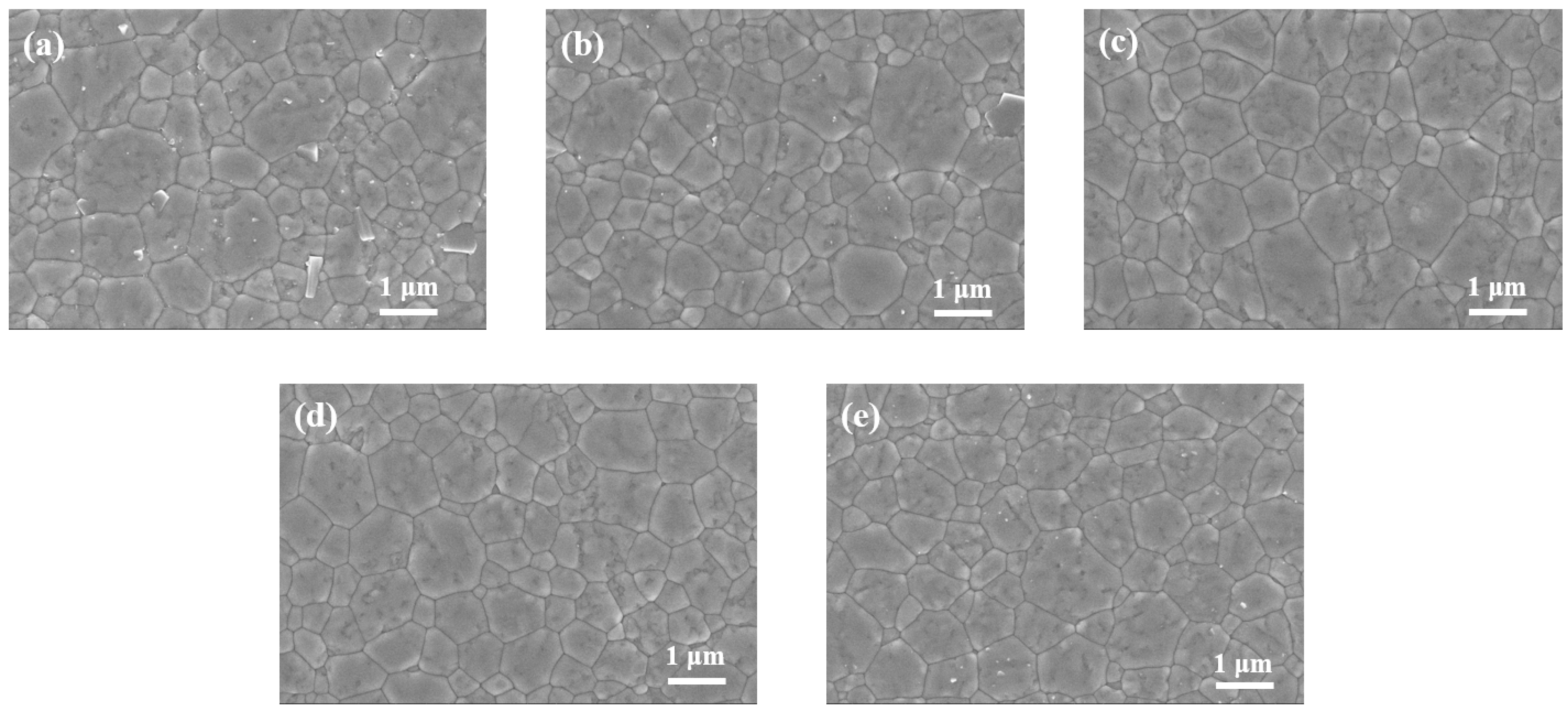

| Er Concentration (at.%) | Grain Size (μm) | Microhardness (GPa) | Fracture Toughness (MPa·m1/2) |

|---|---|---|---|

| 1 | 0.85 ± 0.41 | 8.51 ± 0.03 | 1.03 ± 0.02 |

| 3 | 0.81 ± 0.37 | 8.53 ± 0.05 | 1.02 ± 0.01 |

| 5 | 0.82 ± 0.38 | 8.57 ± 0.14 | 1.03 ± 0.03 |

| 7 | 0.77 ± 0.34 | 8.59 ± 0.09 | 1.04 ± 0.01 |

| 9 | 0.76 ± 0.32 | 8.63 ± 0.08 | 1.05 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Liu, C.; Qin, X.; Gan, L.; Zhou, G.; Jiang, J.; Zhang, T.; Chen, H.; Wang, Z.; Wang, S. Fabrication and Luminescent Properties of Highly Transparent Er:Y2O3 Ceramics by Hot Pressing Sintering. Materials 2023, 16, 4504. https://doi.org/10.3390/ma16134504

Liu Y, Liu C, Qin X, Gan L, Zhou G, Jiang J, Zhang T, Chen H, Wang Z, Wang S. Fabrication and Luminescent Properties of Highly Transparent Er:Y2O3 Ceramics by Hot Pressing Sintering. Materials. 2023; 16(13):4504. https://doi.org/10.3390/ma16134504

Chicago/Turabian StyleLiu, Yan, Chengrui Liu, Xianpeng Qin, Lin Gan, Guohong Zhou, Juan Jiang, Tianjin Zhang, Hetuo Chen, Zhengjuan Wang, and Shiwei Wang. 2023. "Fabrication and Luminescent Properties of Highly Transparent Er:Y2O3 Ceramics by Hot Pressing Sintering" Materials 16, no. 13: 4504. https://doi.org/10.3390/ma16134504

APA StyleLiu, Y., Liu, C., Qin, X., Gan, L., Zhou, G., Jiang, J., Zhang, T., Chen, H., Wang, Z., & Wang, S. (2023). Fabrication and Luminescent Properties of Highly Transparent Er:Y2O3 Ceramics by Hot Pressing Sintering. Materials, 16(13), 4504. https://doi.org/10.3390/ma16134504