Mechanical and Chemical Resistance of UV Coating Systems Prepared under Industrial Conditions

Abstract

1. Introduction

2. Materials and Methods

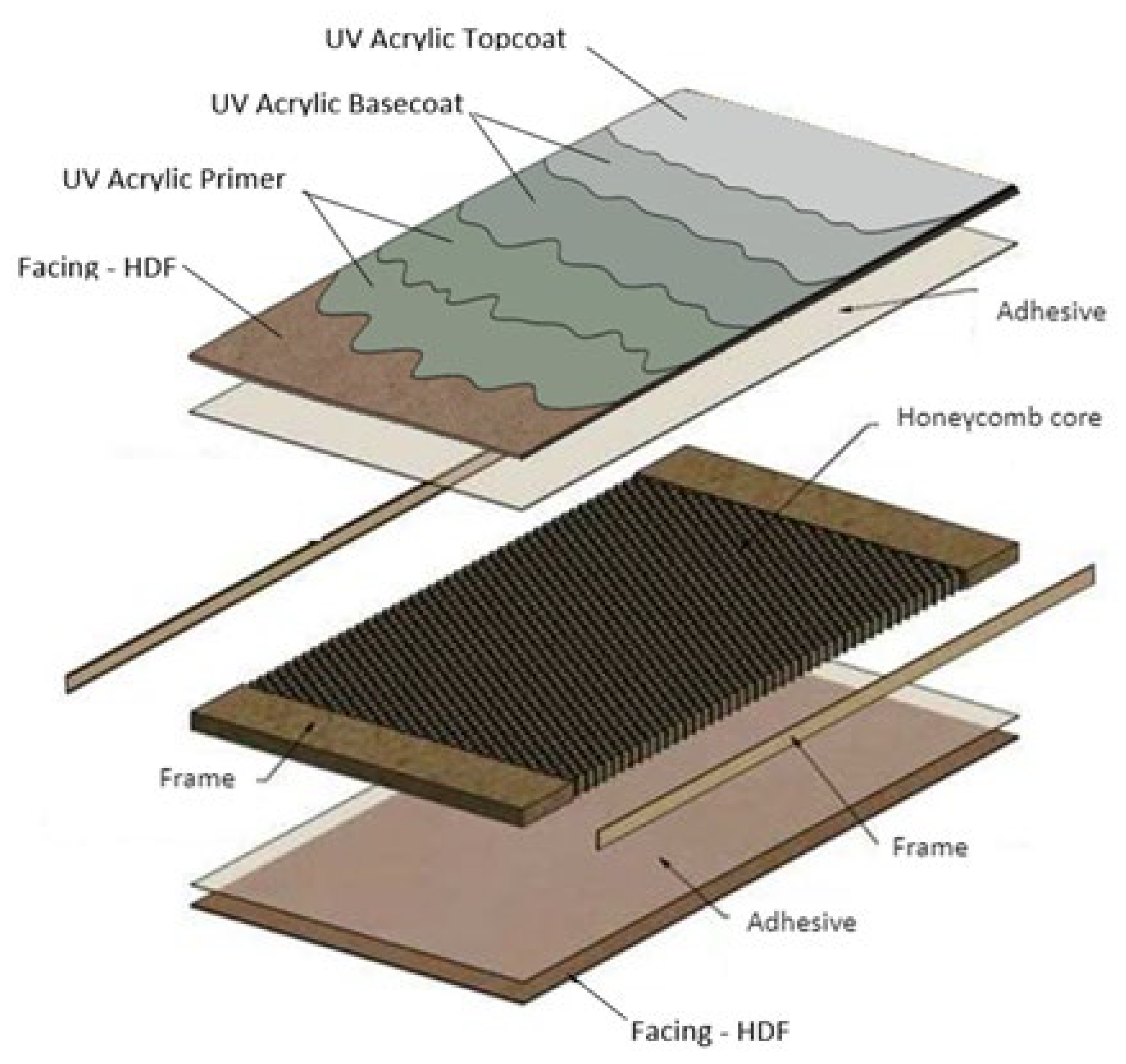

2.1. Materials

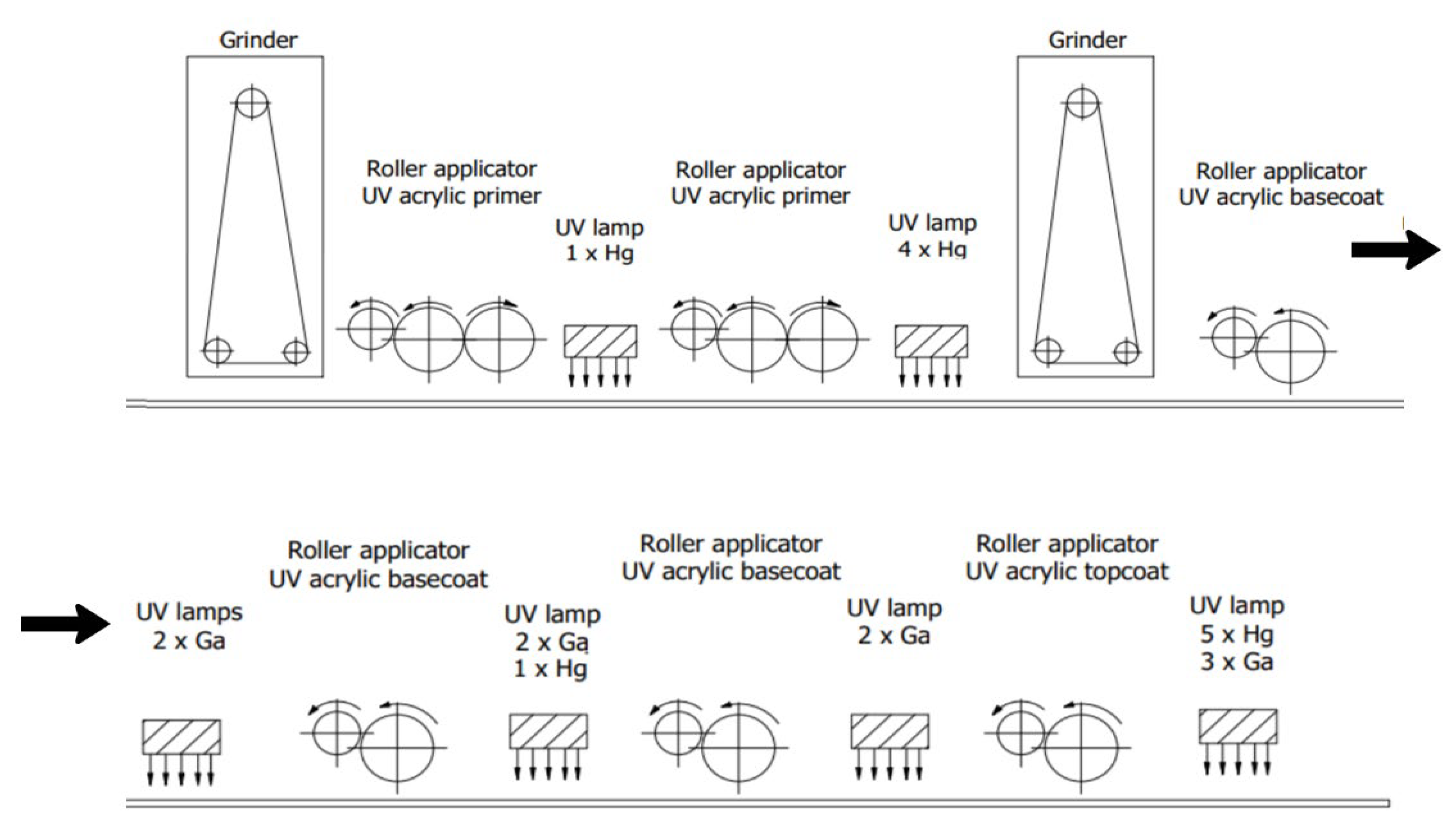

2.2. Surface Lacquer Finishing Process

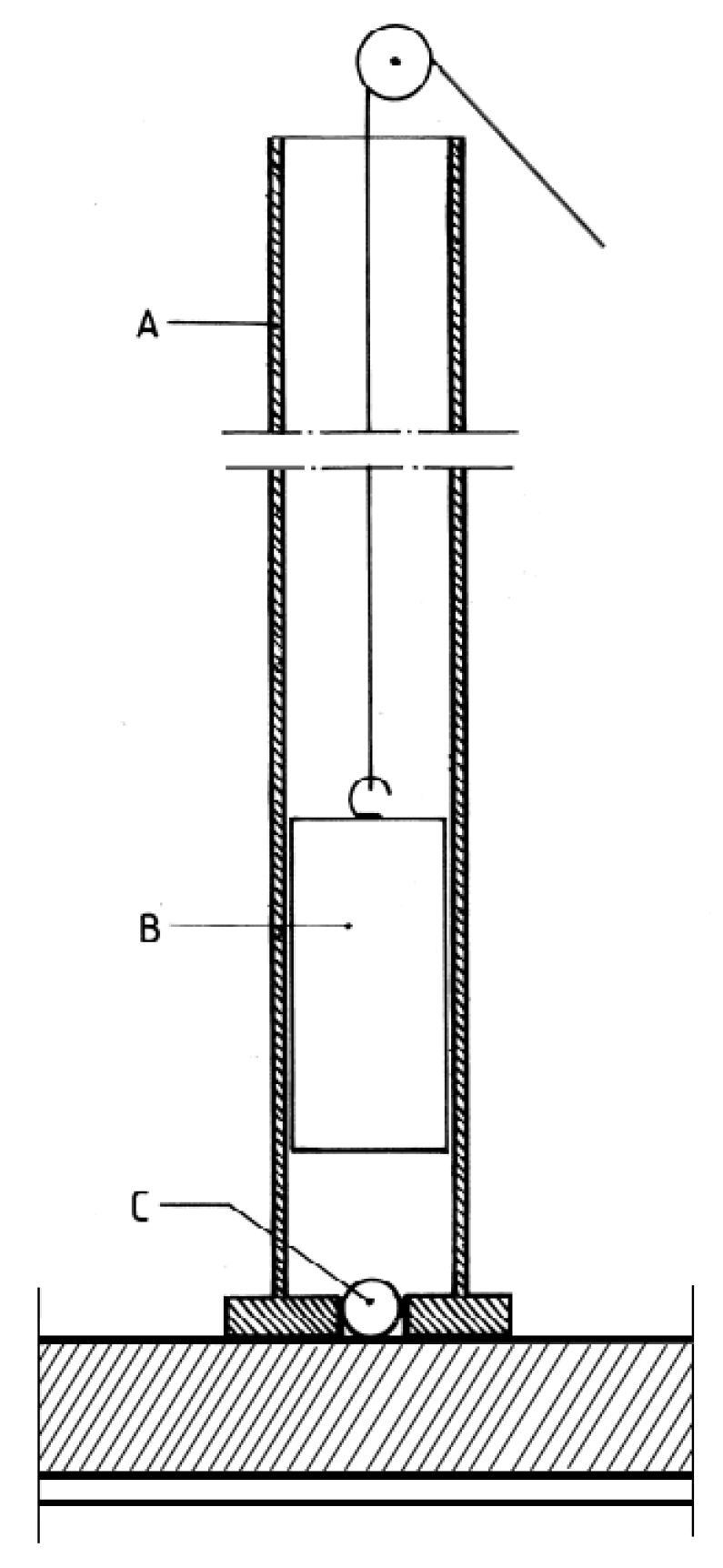

2.3. Determination of Scratch Resistance

2.4. Impact Test (Ball Method)

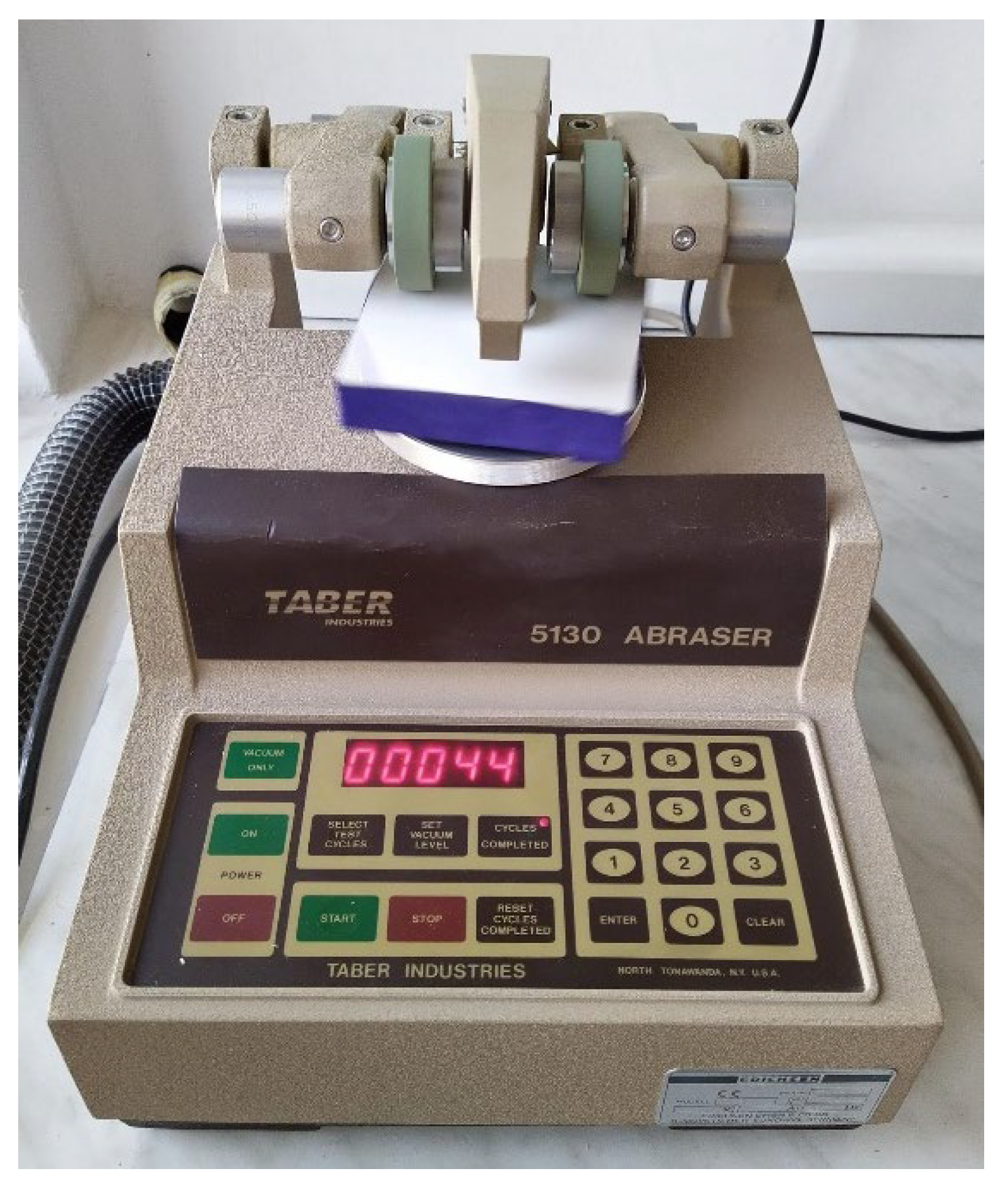

2.5. Abrasion Resistance

2.6. Resistance to Cold Liquids

2.7. Data Processing

3. Results and Discussion

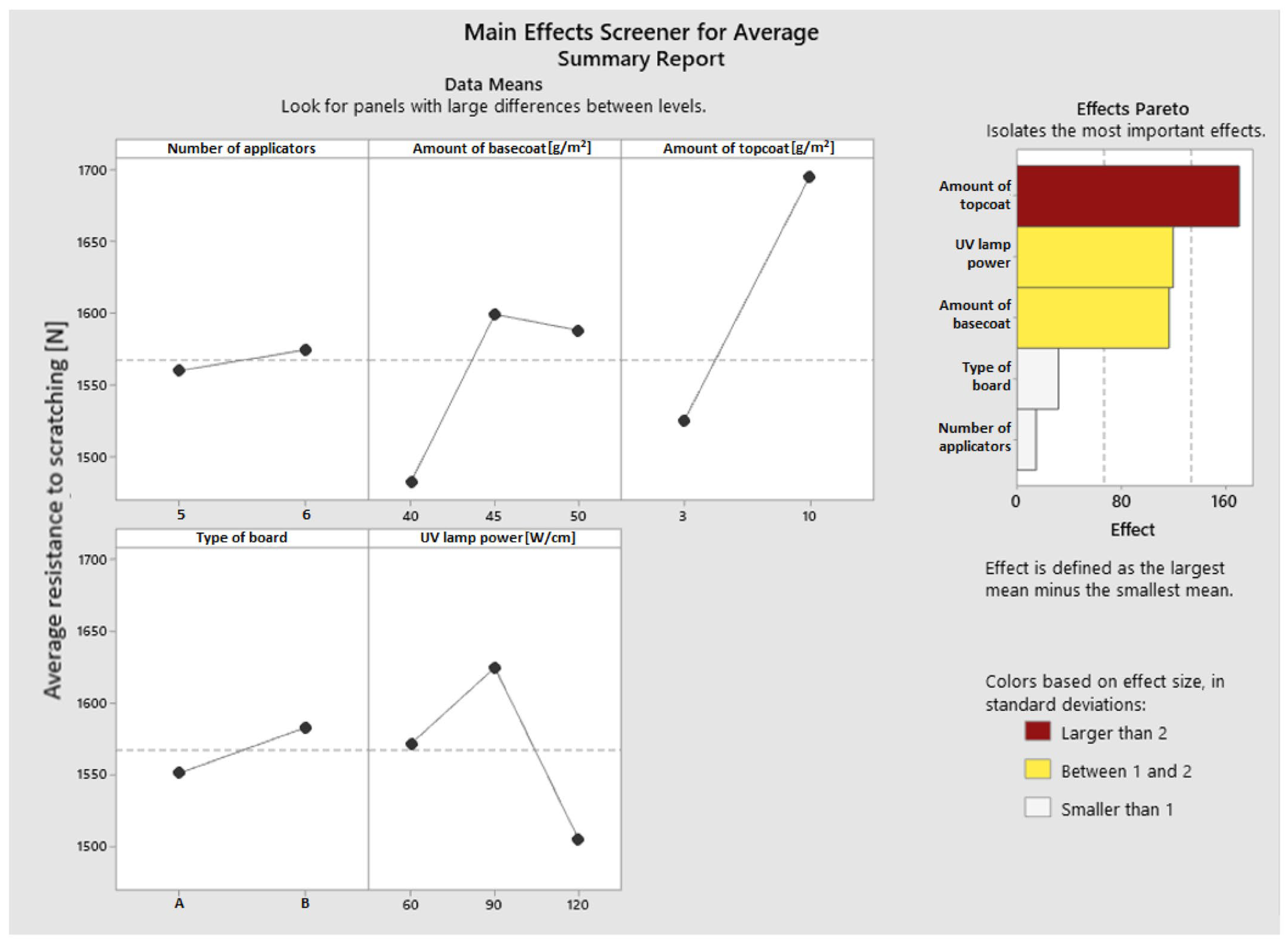

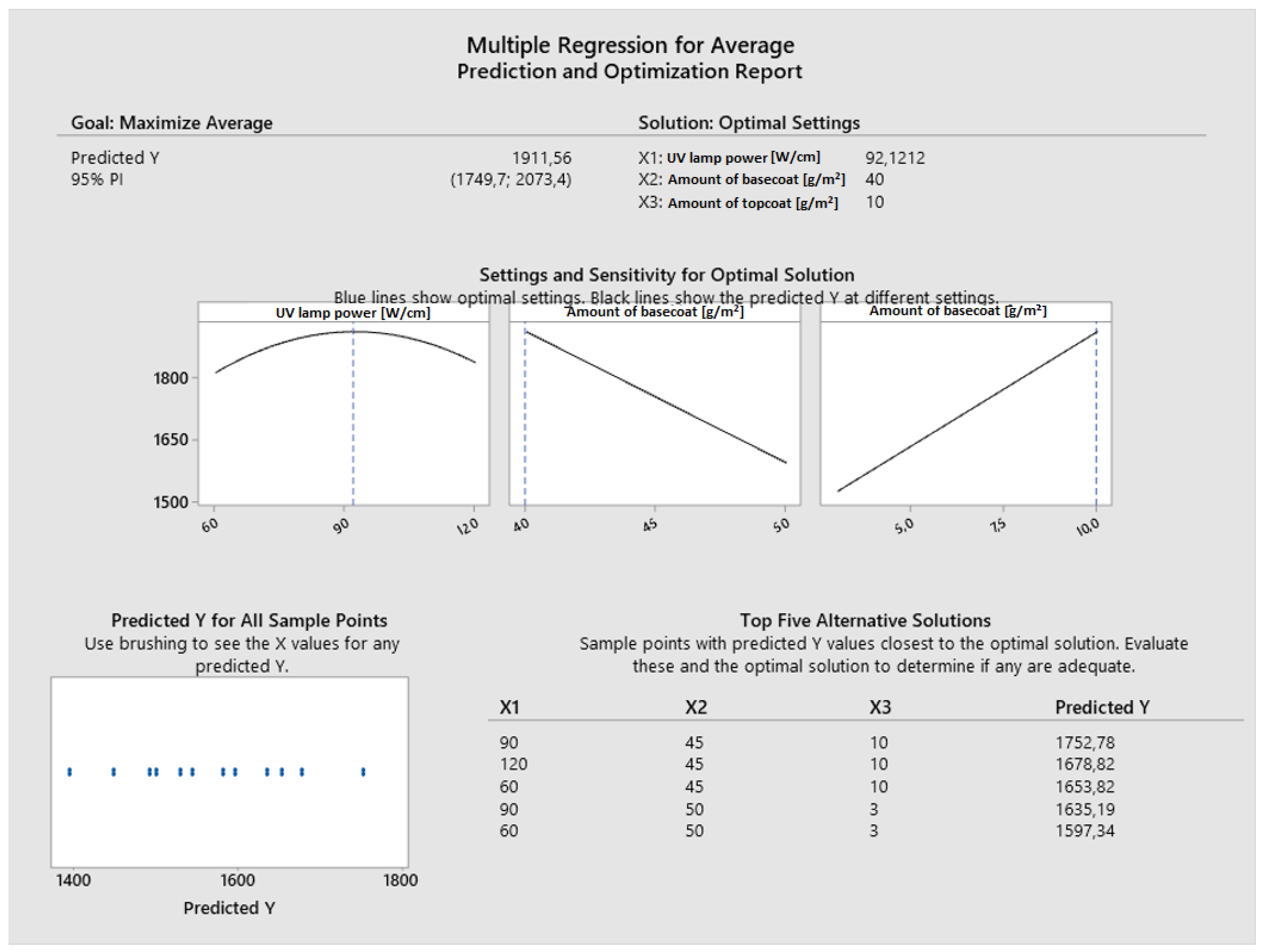

3.1. Resistance to Scratching

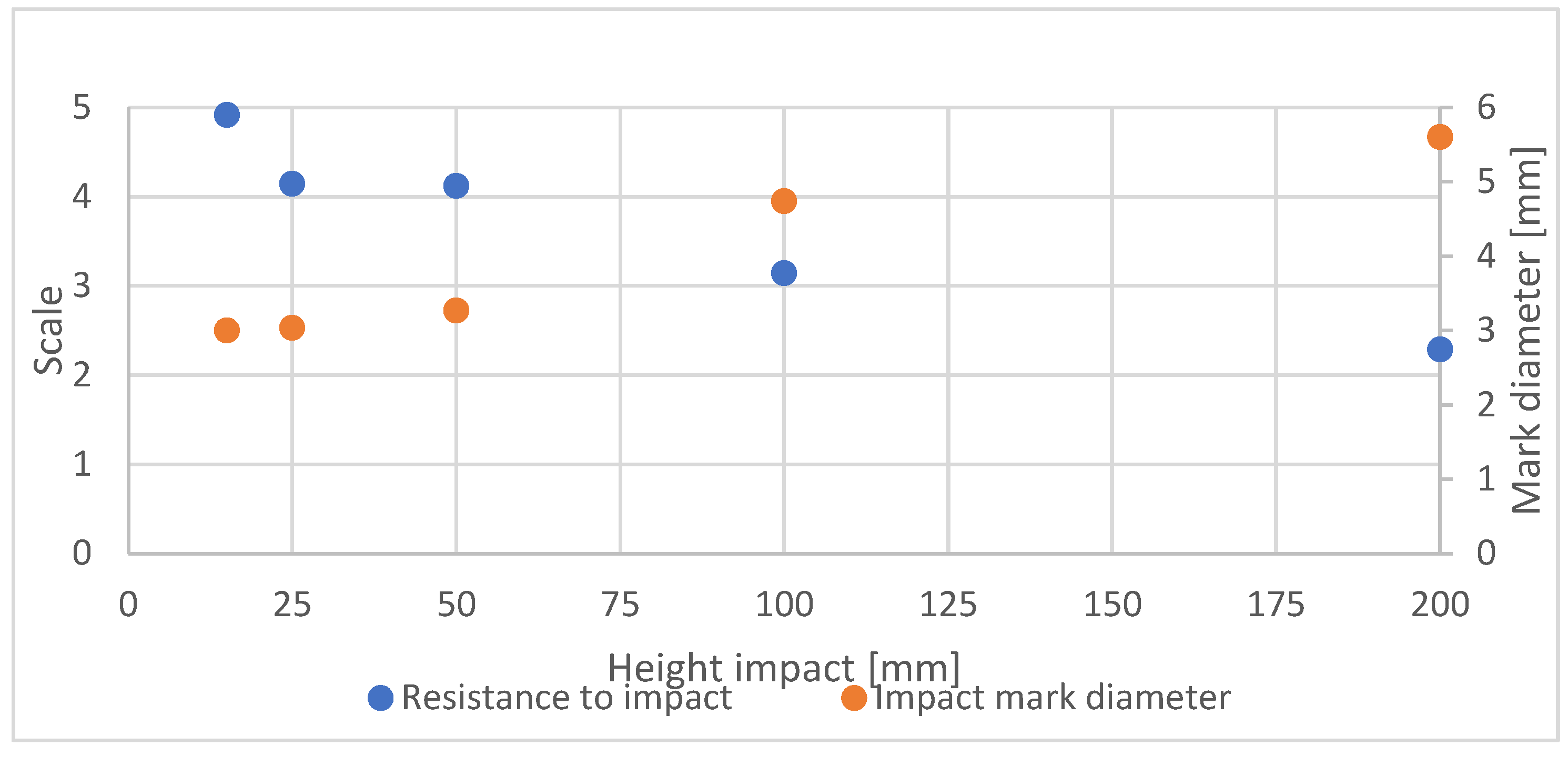

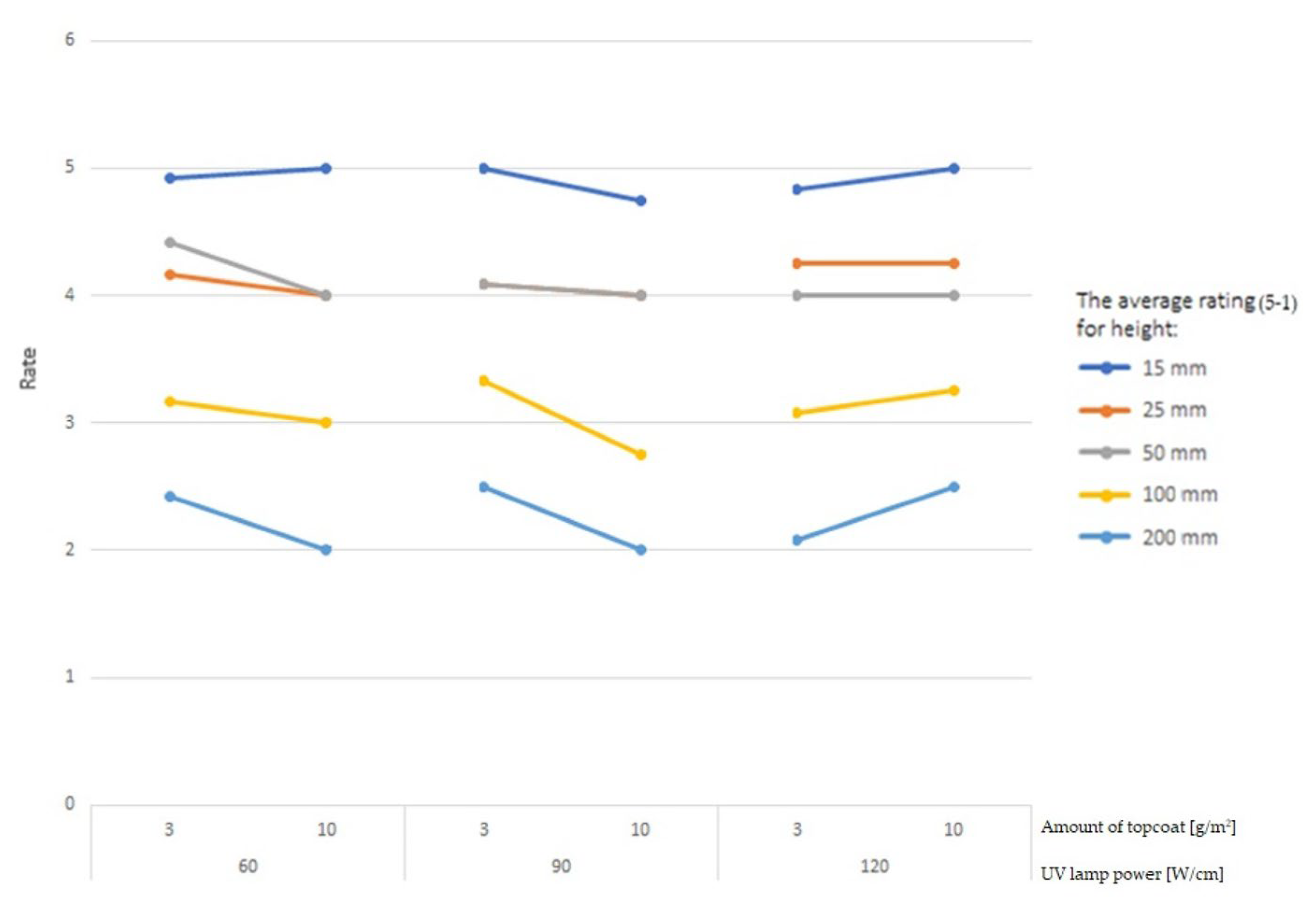

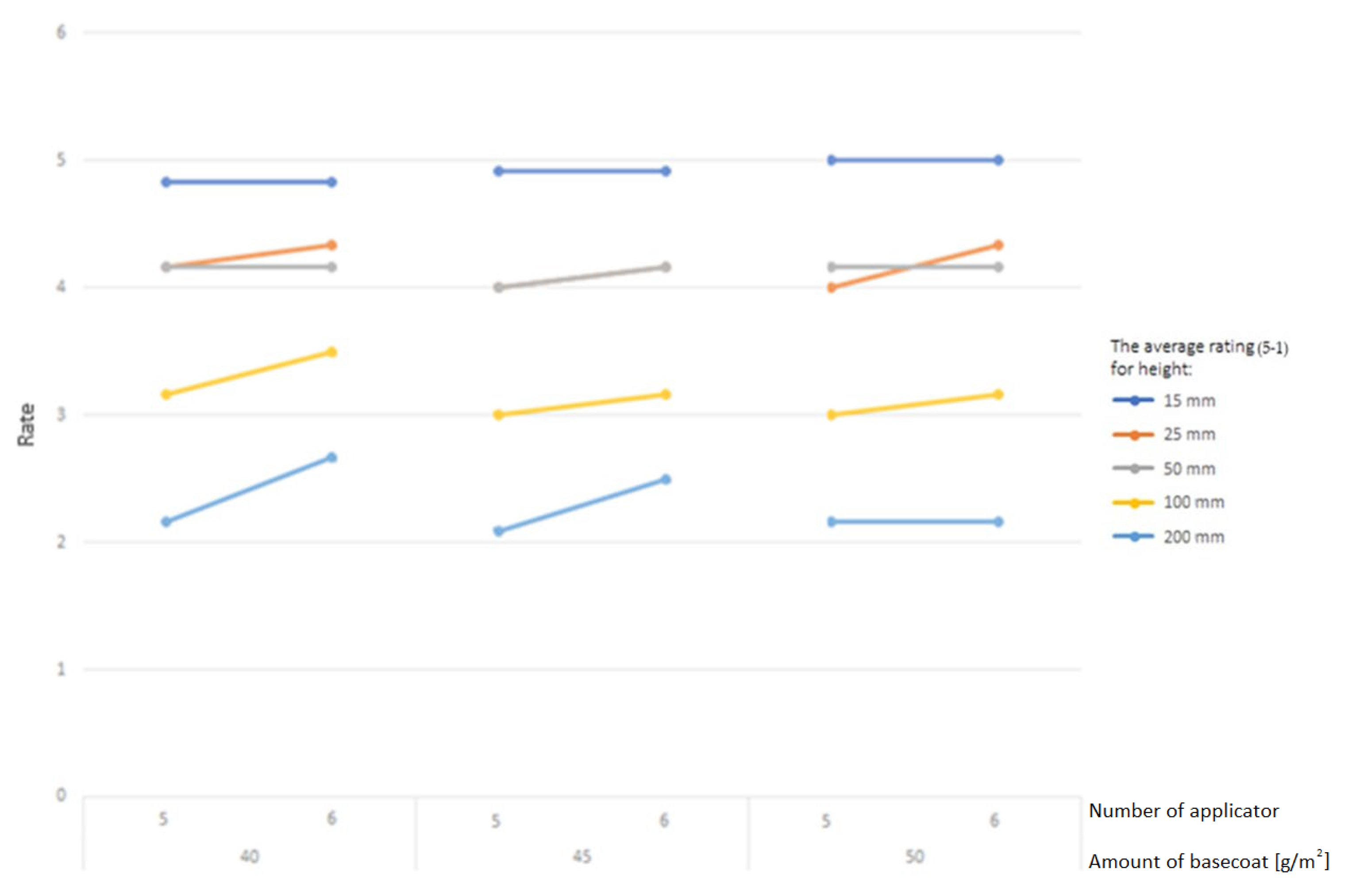

3.2. Impact Resistance

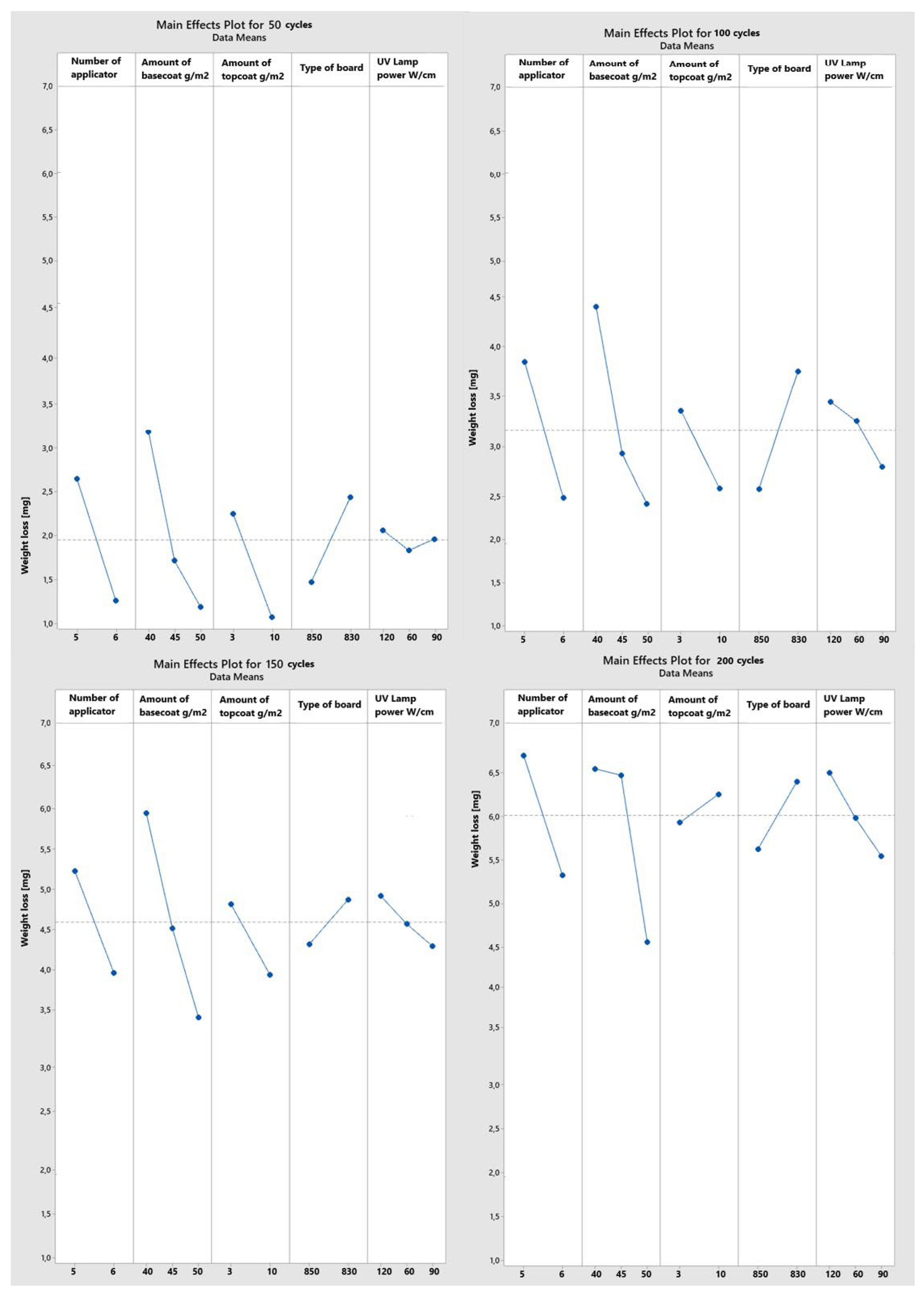

3.3. Abrasion Resistance

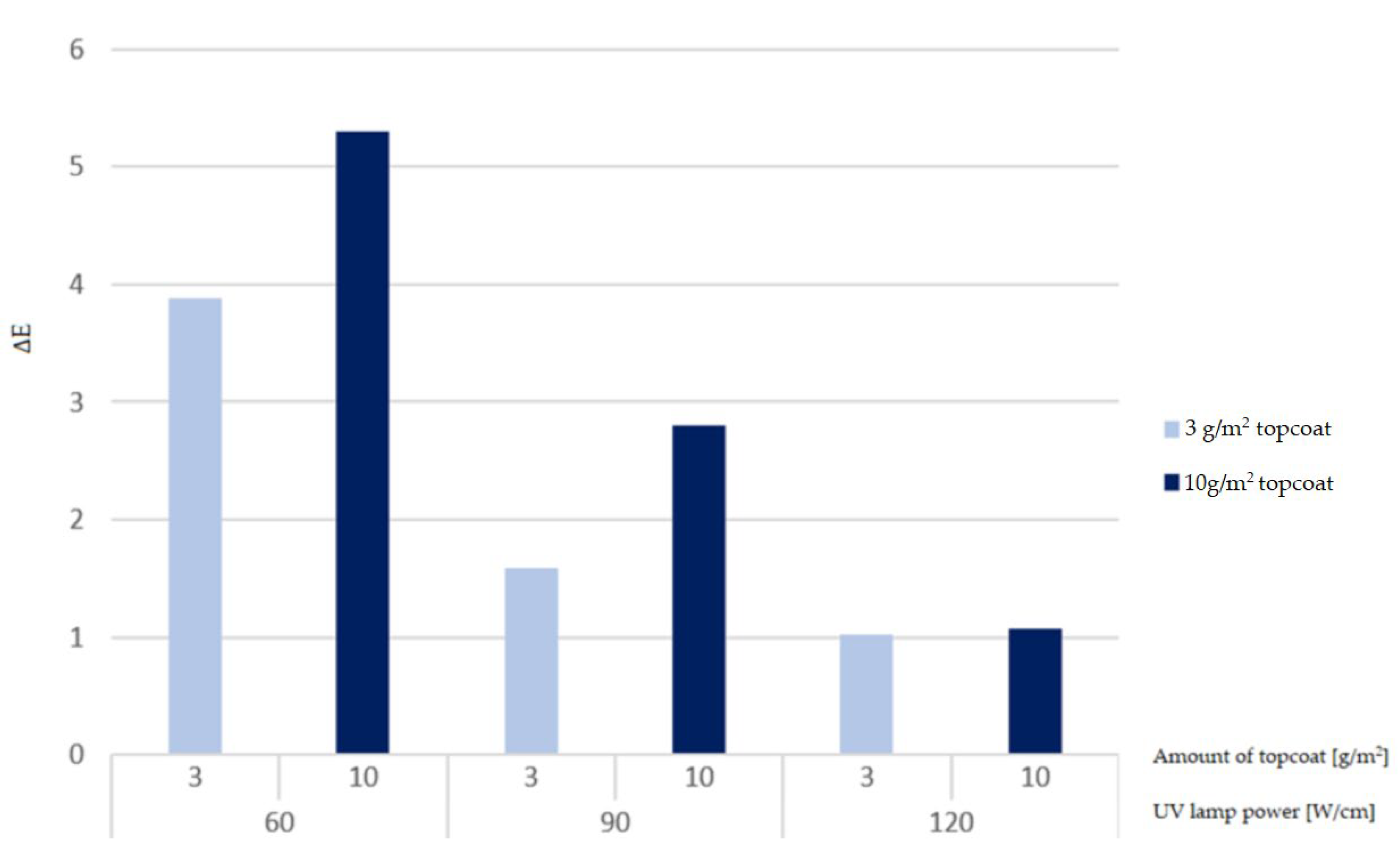

3.4. Resistance to Cold Liquid

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission. New EU Forest Strategy for 2030. Eur. Commun. 2021, 25, 5–24. [Google Scholar]

- FAO. Global Forest Resources Assessment, Key Findings; FAO: Rome, Italy, 2020; Available online: http://www.fao.org/3/ca8753en/CA8753EN.pdf (accessed on 17 May 2023).

- Eurostat European Commission. Agriculture, Forestry and Fishery Statistics: 2020 Edition; Eurostat European Commission: Luksemburg, 2020. [Google Scholar]

- Food and Agriculture Organization of the United Nations. World Food and Agriculture–Statistical Yearbook 2021; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021. [Google Scholar]

- Doğan, K.; Akylidz, M.H. Situation of wood-based panel industry in Turkey. PRO LINGO 2017, 13, 617–629. [Google Scholar]

- Statistical Office, Centre for Energy and Material Market Statistics. Gospodarka Materiałowa w 2020 r; Statistics Poland: Rzeszów, Poland, 2020. [Google Scholar]

- Yildrim, İ.; Alveli, C.; Akyüz, K.C. The Analysis and Estimate of Wood-Based Panel Foreign Trade. Kastamonu Üniversitesi Orman Fakültesi Derg. 2016, 16, 370–382. [Google Scholar] [CrossRef]

- Immonen, K.; Lyytikäinen, J.; Keränen, J.; Eiroma, K.; Suhonen, M.; Vikman, M.; Leminen, V.; Välimäki, M.; Hakola, L. Potential of Commercial Wood-Based Materials as PCB Substrate. Materials 2022, 15, 2679. [Google Scholar] [CrossRef] [PubMed]

- Jivkov, V.; Petrova, B.; Yavorov, N. Comparative analysis of physical and mechanical properties of some thin and ultra-thin wood-based and non-wood-based. In Proceedings of the Eleventh International Scientific and Technical Conference “Innovations in Forest Industry and Engenieering Design” INNO 2022, Borovets, Bulgaria, 3–5 October 2022; pp. 83–98. [Google Scholar]

- Youngquist, J.A.; Myers, G.E.; Muehl, J.H.; Krzysik, A.M.; Clemons, C.M. Composites from Recycled Wood and Plants; Report for May 1990–July 1993; Forest Service: Madison, WI, USA, 1995. [Google Scholar]

- Cai, Z.; Robert, J.R. Chapter 12: Mechanical Properties of Wood-Based Composite Materials; General Technical Report FPL–GTR–190; FPL-GTR, United States Department of Agriculture: Madison, WI, USA, 2006; pp. 1–12. [Google Scholar]

- Smardzewski, J.; Maslej, M.; Wojciechowski, K.W. Compression and low velocity impact response of wood-based sandwich panels with auxetic lattice core. Eur. J. Wood Wood Prod. 2021, 79, 797–810. [Google Scholar] [CrossRef]

- Khalil, D. Simulate the Honeycomb System as an Inspirational Design Concept in the Field of Furniture. J. Des. Sci. Appl. Arts 2021, 2, 32–43. [Google Scholar] [CrossRef]

- Bitzer, T. Honeycomb Technology; Springer: Berlin/Heidelberg, Germany, 1997; p. 6474. [Google Scholar]

- Michanickl, A. Development of a new light wood-based panel. In Proceedings of the 5th European Wood-Based Panel Symposium, Hannover, Germany, 4–6 October 2006. [Google Scholar]

- Barboutis, I.; Vassiliou, V. Strength properties of lightweight paper honeycomb panels for the furniture. In Proceedings of the 10th International Scientific Conference of Engineering Design (Interior and Furniture Design), Sofia, Bulgaria, 17–18 October 2005; pp. 17–18. [Google Scholar]

- Weber, H.G.; Schatz, J. Honeycomb technology-Homag plant concept for the production of lightweight paper honeycomb panels in through feed. In Proceedings of the Honeycomb Colloquium, Schopfloch, Germany; 2004. [Google Scholar]

- Gindl, M.; Sinn, G.; Gindl, W.; Reiterer, A.; Tschegg, S. A comparison of different methods to calculate the surface free energy of wood using contact angle measurements. Colloids Surfaces A Physicochem. Eng. Asp. 2001, 181, 279–287. [Google Scholar] [CrossRef]

- Proszyk, S. Postęp w dziedzinie wyrobów lakierowych i technologii ich stosowania w drzewnictwie. In Studia i Szkice na Jubileusz Profesora Ryszarda Babickiego; ITD: Poznań, Poland, 2007; pp. 115–124. [Google Scholar]

- Chrystian, H.D. Controlling glos. How silica types and formulation variables affect the matting of 100% UV coatings. Eur. Coat. J. 2006, 4, 26–30. [Google Scholar]

- Van Den Branden, S. Survey of radiation-curable systems for wood coatings. Surf. Coat. Int. 2002, 85 Pt A, 189–191. [Google Scholar]

- Wnuk, R. Wodne materiały utwardzane promieniowaniem UV. Przyszłość w lakierowaniu drewna. In Lakiernictwo Przem. Uszlachetnianie Powierzchni Drewna cz.2. Goldman; Goldman: Tczew, Poland, 2010; pp. 16–18. [Google Scholar]

- Lis, B.; Proszyk, S.; Krystofiak, T. Low energy consuming of hardening of lacquer coatings by means of UV–LED radiators. Inthercathedra 2009, 25, 75–79. Available online: http://admin-apps.isiknowledge.com/JCR/JCR?RQ=RECORD&rank=6&journal=LIBR+INFORM+SC (accessed on 17 May 2023).

- Hermann, A.; Giljean, S.; Pac, M.-J.; Marsiquet, C.; Beaufils-Marquet, M.; Burr, D.; Landry, V. Understanding indentation, scratch and wear behavior of UV-cured wood finishing products. Prog. Org. Coat. 2021, 161, 106504. [Google Scholar] [CrossRef]

- Lis, B.; Krystofiak, T. Badania adhezji powłok lakierowych do drewna. Maksymalna przyczepność. In Lakiernictwo Przem. Uszlachetnianie Powierzchni Drewna cz.2, GOLDMAN; Goldman: Tczew, Poland, 2010; pp. 44–46. [Google Scholar]

- Syka, A.; Paradowska, M. Ekologiczne lakiery niskoemisyjne. Trwała powłoka. In Lakiernictwo Przem. Uszlachetnianie Powierzchni Drewna cz.2, GOLDMAN; Goldman: Tczew, Poland, 2010; pp. 46–49. [Google Scholar]

- Budziński, A.; dla praktyków U.V. Kilka wybranych zagadnień związanych z lakierowaniem drewna. In Lakiernictwo Przem. Uszlachetnianie Powierzchni Drewna cz.1, GOLDMAN; Goldman: Tczew, Poland, 2006; pp. 58–59. [Google Scholar]

- Brewis, D.M.; Critchlow, G.W. The use of surface analytical techniques to understanding adhesion performance. Jocca 2002, 85 Pt B, 39–47. [Google Scholar]

- Scrinzi, E.; Rossi, S.; Deflorian, F.; Zanella, C. Evaluation of aesthetic durability of waterborne polyurethane coatings applied on wood for interior applications. Prog. Org. Coat. 2011, 72, 81–87. [Google Scholar] [CrossRef]

- Veigel, S.; Grüll, G.; Pinkl, S.; Obersriebnig, M.; Müller, U.; Gindl-Altmutter, W. Improving the mechanical resistance of waterborne wood coatings by adding cellulose nanofibres. React. Funct. Polym. 2014, 85, 214–220. [Google Scholar] [CrossRef]

- Pavlič, M.; Žigon, J.; Petrič, M. Wood surface finishing of selected invasive tree species. Drv. Ind. 2020, 71, 271–280. [Google Scholar] [CrossRef]

- Pavlič, M.; Petrič, M.; Žigon, J. Interactions of coating and wood flooring surface system properties. Coatings 2021, 11, 91. [Google Scholar] [CrossRef]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Hiziroglu, S. Glossiness evaluation of coated wood surfaces as function of varnish type and exposure to different conditions. Coatings 2021, 11, 558. [Google Scholar] [CrossRef]

- Nine, M.J.; Tran, D.N.H.; ElMekawy, A.; Losic, D. Interlayer growth of borates for highly adhesive graphene coatings with enhanced abrasion resistance, fire-retardant and antibacterial ability. Carbon 2017, 117, 252–262. [Google Scholar] [CrossRef]

- Kaygin, B.; Akgun, E. A nano-technological product: An innovative varnish type for wooden surfaces. Sci. Res. Essays 2008, 4, 1–7. [Google Scholar]

- Vidholdová, Z.; Slabejová, G.; Šmidriaková, M. Quality of oil-and wax-based surface finishes on thermally modified oak wood. Coatings 2021, 11, 143. [Google Scholar] [CrossRef]

- Slabejová, G.; Šmidriaková, M.; Pánis, D. Quality of silicone coating on the veneer surfaces. BioResources 2018, 13, 776–788. [Google Scholar] [CrossRef]

- Akkuş, M.; Akbulut, T.; Candan, Z. Application of electrostatic powder coating on wood composite panels using a cooling method. Part 1: Investigation of water intake, abrasion, scratch resistance, and adhesion strength. BioResources 2019, 14, 9557–9574. [Google Scholar] [CrossRef]

- Lis, B.; Krystofiak, T.; Proszyk, S. Studies of the Resistance upon Some Factors of UV Acrylic Lacquer Coatings on MDF Boards. Part II. Mechanical Factors; Forestry and Wood Technology: Warsaw, Poland, 2010; Volume 71, pp. 454–457. [Google Scholar]

- Altun, S.; Köse, D. Some of the physical properties of UV jet printed furniture surfaces. Drv. Ind. 2013, 64, 39–43. [Google Scholar] [CrossRef]

- Henke, M.; Lis, B.; Krystofiak, T. Gloss Level of HDF Finished with Different Numbers of Layers and Hardened with UV Hg-Ga Lamps of Selected Power. Coatings 2022, 12, 533. [Google Scholar] [CrossRef]

- PN-88 F-06100/11; Meble Metody badań właściwości powłok lakierowych i laminowanych Oznaczanie twardości. Polski Komitet Organizacyjny: Warszwa, Poland, 1988.

- ISO 4211-4_ISO; Furniture—Tests for Surfaces Part 4: Assesment of Resistance to Impact. International Organisation for Standardization: Geneva, Switzerland, 1988.

- DIN EN ISO 7784-3; Beschichtungsstoffe–Bestimmung des Abriebwiderstandes–Teil 3: Verfahren mit sich hin und her bewegender Probenplatte. International Organisation for Standardization: Geneva, Switzerland, 2016.

- EN 12720:2009+A1; Möbel–Bewertung der Beständigkeit von Oberflächen gegen kalte Flüssigkeiten. International Organisation for Standardization: Geneva, Switzerland, 2013.

- DIN EN ISO 11664-4; Farbmetrik–Teil 4: CIE 1976 L*a*b* Farbenraum. International Organisation for Standardization: Geneva, Switzerland, 2011.

- Wang, X.; Wang, F.; Yu, Z.; Zhang, Y.; Qi, C.; Du, L. Surface free energy and dynamic wettability of wood simultaneously treated with acidic dye and flame retardant. J. Wood Sci. 2017, 63, 271–280. [Google Scholar] [CrossRef]

- Wijekularathna, D.K.; Manage, A.B.W.; Scariano, S.M. Power analysis of several normality tests: A Monte Carlo simulation study. In Communications in Statistics-Simulation and Computation; Taylor & Francis: Abingdon, UK, 2019; Volume 51, pp. 757–773. [Google Scholar] [CrossRef]

- Sönmez, A.; Budakçı, M.; Yakın, M. Effect of application methods on the hardness gloss and adhesion strength of waterborne varnish coating on the wooden surface. J. Politek. 2004, 7, 229–235. [Google Scholar]

- Barletta, M.; Lusvarghi, L.; Mantini, F.P.; Rubino, G. Epoxy-based thermosetting powder coatings: Surface appearance, scratch adhesion and wear resistance. Surf. Coat. Technol. 2007, 201, 7479–7504. [Google Scholar] [CrossRef]

- Henke, M.; Lis, B.; Krystofiak, T. Evaluation of Surface Roughness Parameters of HDF for Finishing under Industrial Conditions. Materials 2022, 15, 6359. [Google Scholar] [CrossRef]

- Lis, B.; Krystofiak, T.; Proszyk, S. Studies of the resistance upon some factors of UV acrylic lacquer coatings on MDF boards. Part I. Resistance of heat and cold liquid action; Forestry and Wood Technology: Warsaw, Poland, 2010; Volume 71, pp. 450–453. Available online: http://annals-wuls.sggw.pl/files/files/animal/asc2019no582full.pdf#page=83 (accessed on 17 May 2023).

| Parameter | Board Label | |

|---|---|---|

| A | B | |

| Density [kg/m3] according to DIN EN 323:1993 | 850 | 830 |

| Modulus of elasticity [MPa] according to DIN EN 310:1993 | 4300 | 4500 |

| Humidity [%] according to DIN EN 322:1993 | 7 | 7 |

| Swelling resistance [%] according to DIN EN 317:1999 | 45 | 45 |

| Parameter | UV Primer | UV Basecoat | UV Topcoat |

|---|---|---|---|

| Density [g/cm3] | 1.63 ± 0.15 | 1.73 | 1.30 ± 0.15 |

| Solid content [%] according to PN-EN ISO 3251:2019 | 95.3 ± 0.5 | 98.3 ± 0.5 | 97.8 ± 0.5 |

| Viscosity [mPa.s] (Brookfield, Thermosel 35 °C, 20 rpm, spindle 27) | 7700 | 400 | 1475 |

| Variants of Application | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type of Varnish Product | Number of Layers | Amount of Varnish Applied [g/m2] | |||||||

| UV acrylic primer | 1 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| 2 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| UV acrylic basecoat | 1 | 15 | 7.5 | 7.5 | 10 | 5 | 10 | 15 | 20 |

| 2 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

| 3 | 7.5 | 7.5 | 10 | 5 | |||||

| UV acrylic topcoat | 1 | 10 | 10 | 3 | 3 | 3 | 3 | 3 | 3 |

| Rating | Criteria |

|---|---|

| 5 | No visible marks on the surface |

| 4 | No cracks on the surface, but an impact mark is visible only when the light from a light source is reflected off the test surface at or quite close to the test point back to the observer’s eyes |

| 3 | Slightly cracked surface, generally one or two circular cracks around the impact mark |

| 2 | Moderate to heavy crack formation within the limits of the impact mark |

| 1 | Crack formation beyond the impact mark and/or flaking of the surface finish or surface covering material |

| Cold Liquid | Characteristic |

|---|---|

| Distilled water | - |

| Acetone | - |

| Paraffin | Paraffinum liquidum |

| Ethylene | 48% (v/v) aqueous solution |

| Wine | Merlot Trevenezie IGT 2021 |

| Tea | 1.75 g of tea leaves infused in 175 mL of boiling water, leached for 5 min without stirring, and then carefully decanted |

| Coffee | 40 g of instant, freeze-dried coffee dissolved in 1 L ofboiling water |

| Beetroot juice | 100% beetroot juice (Biurkom Flampol Sp. z o.o., Poland) |

| Blackcurrant juice | Pasteurized nectar, blackcurrant juice from concentrated juice (26%), fruit content minimum 26%, (Tymbark-MWS Sp. z o.o., Poland) |

| Condensed milk | 8% fat content, sweetened (Milk Company in Gostyn, Poland) |

| Degree | Description |

|---|---|

| 5 | No visible changes (no damage) |

| 4 | Slight change in gloss—visible only in the reflection of a light source, e.g., discoloration or change in color or gloss; no change in the surface structure, e.g., swelling, fiber elevation, cracking, or blistering |

| 3 | Slight traces of damage (gloss)—visible from multiple perspectives, e.g., discoloration or change in color or gloss; no change in the surface structure, e.g., swelling, fiber elevation, cracking, or blistering |

| 2 | Strong traces of damage—visible in all viewing directions, e.g., discoloration, change in color or gloss, and/or the surface structure has changed slightly, e.g., swelling, fiber elevation, cracking, or blistering |

| 1 | Strong damage—the surface structure has changed noticeably and/or discoloration or change in color or gloss, and/or the surface material has partially or completely come off, and/or the filter paper sticks to the surface |

| One-Way ANOVA Response | Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| UV Lamp power [W/cm] | 2 | 115,289 | 57,645 | 4.89 | 0.012 | |

| Amount of topcoat [g/m2] | 1 | 261,235 | 261,235 | 31.24 | 0.000 | |

| Scratch resistance | Application of basecoat [g/m2] | 2 | 115,833 | 57,917 | 4.92 | 0.012 |

| Number of applications | 1 | 2552 | 2552 | 0.18 | 0.671 | |

| Type of board | 1 | 12,245 | 12,245 | 0.89 | 0.351 |

| Type of Varnish Product | Number of Layers | UV Lamp Power 60 W/cm | UV Lamp Power 90 W/cm | UV Lamp Power 120 W/cm | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Amount of Varnish Applied, in g/m2 | Amount of Varnish Applied, in g/m2 | Amount of Varnish Applied, in g/m2 | |||||||||||||||||||||||

| UV acrylic primer | 1 | 30 | 30 | 30 | |||||||||||||||||||||

| 2 | 20 | 20 | 20 | ||||||||||||||||||||||

| UV acrylic basecoat | 1 | 15 | 7.5 | 7.5 | 10 | 5 | 10 | 15 | 20 | 15 | 7.5 | 7.5 | 10 | 5 | 10 | 15 | 20 | 15 | 7.5 | 7.5 | 10 | 5 | 10 | 15 | 20 |

| 2 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | 30 | |

| 3 | 7.5 | 7.5 | 10 | 5 | 7.5 | 7.5 | 10 | 5 | 7.5 | 7.5 | 10 | 5 | |||||||||||||

| Sumaric | 45 | 45 | 45 | 50 | 40 | 40 | 45 | 50 | 45 | 45 | 45 | 50 | 40 | 40 | 45 | 50 | 45 | 45 | 45 | 50 | 40 | 40 | 45 | 50 | |

| UV acrylic topcoat | 1 | 10 | 10 | 3 | 3 | 3 | 3 | 3 | 3 | 10 | 10 | 3 | 3 | 3 | 3 | 3 | 3 | 10 | 10 | 3 | 3 | 3 | 3 | 3 | 3 |

| Evaluation of surface resistance to cold liquids | Acetone 16 h | X | X | • | • | • | • | • | • | • | • | • | • | • | • | • | • | X | X | • | • | • | • | • | • |

| Wine 16 h | X | • | X | • | X | X | X | X | • | • | • | • | • | • | • | • | • | • | • | • | • | • | • | • | |

| Coffee 16 h | X | • | X | • | X | X | X | X | • | • | • | • | • | • | • | • | • | • | • | • | • | • | • | • | |

| Acetone 24 h | X | X | • | • | • | • | • | • | • | • | • | • | • | • | • | • | X | X | • | • | • | • | • | • | |

| Wine 24 h | X | X | X | X | X | X | X | X | • | • | X | X | X | X | X | X | • | • | X | X | X | X | X | X | |

| Coffee 24 h | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | X | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Henke, M.; Lis, B.; Krystofiak, T. Mechanical and Chemical Resistance of UV Coating Systems Prepared under Industrial Conditions. Materials 2023, 16, 4468. https://doi.org/10.3390/ma16124468

Henke M, Lis B, Krystofiak T. Mechanical and Chemical Resistance of UV Coating Systems Prepared under Industrial Conditions. Materials. 2023; 16(12):4468. https://doi.org/10.3390/ma16124468

Chicago/Turabian StyleHenke, Milena, Barbara Lis, and Tomasz Krystofiak. 2023. "Mechanical and Chemical Resistance of UV Coating Systems Prepared under Industrial Conditions" Materials 16, no. 12: 4468. https://doi.org/10.3390/ma16124468

APA StyleHenke, M., Lis, B., & Krystofiak, T. (2023). Mechanical and Chemical Resistance of UV Coating Systems Prepared under Industrial Conditions. Materials, 16(12), 4468. https://doi.org/10.3390/ma16124468