Alteration of Structure and Characteristics of Concrete with Coconut Shell as a Substitution of a Part of Coarse Aggregate

Abstract

1. Introduction

- −

- “the composition of the conglomerate—the microstructure of the boundaries of the phases of the conglomerate”. The macrostructure of the conglomerate—the properties of concrete. The applied methodological and phenomenological approaches made it possible to provide a high degree of verification of the results. These approaches are primarily characterized by the observance of the fundamental principle of materials science “composition—structure—properties”, as well as the determination of the most characteristic, relative indicator for non-standard concretes—the coefficient of constructive quality.

2. Materials and Methods

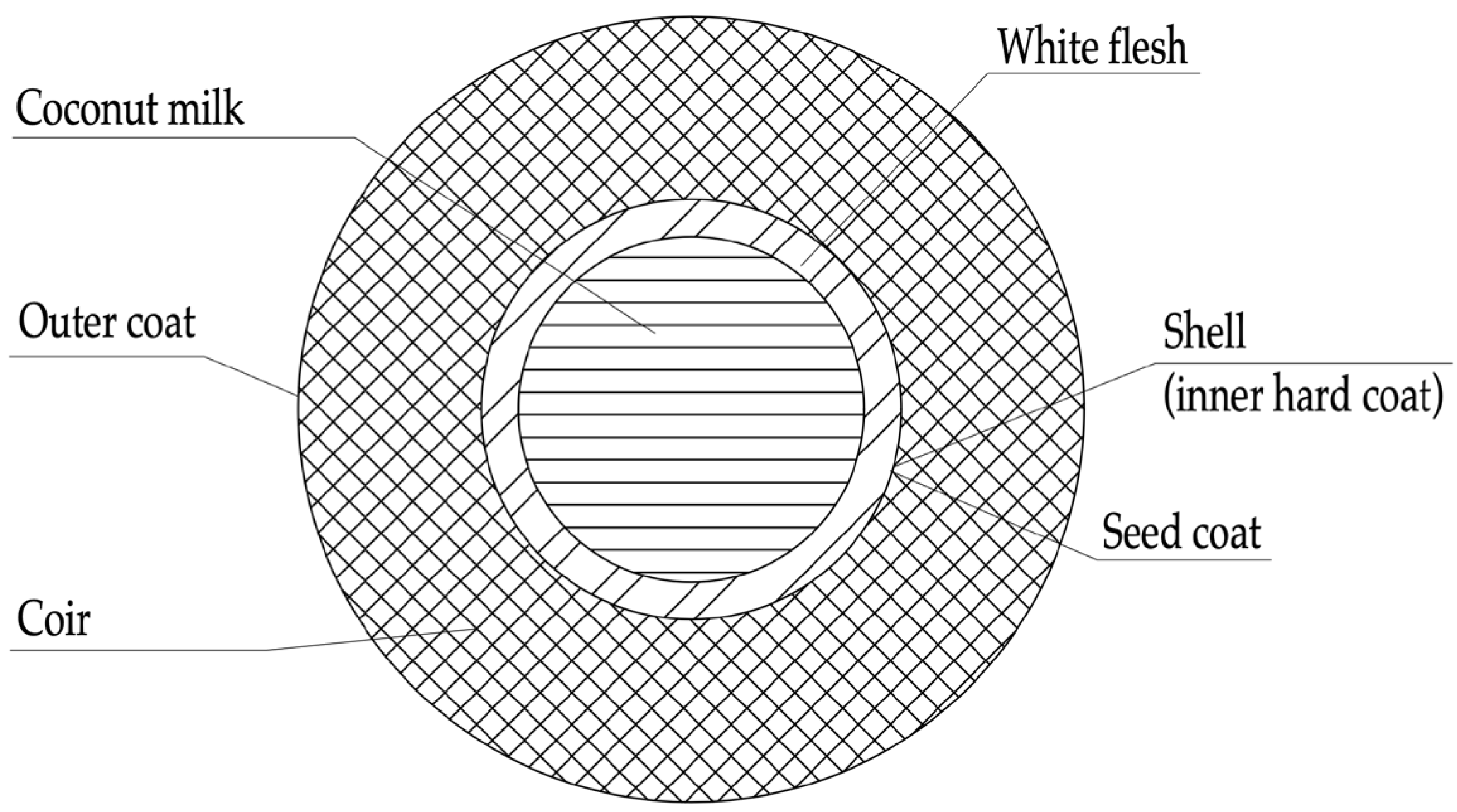

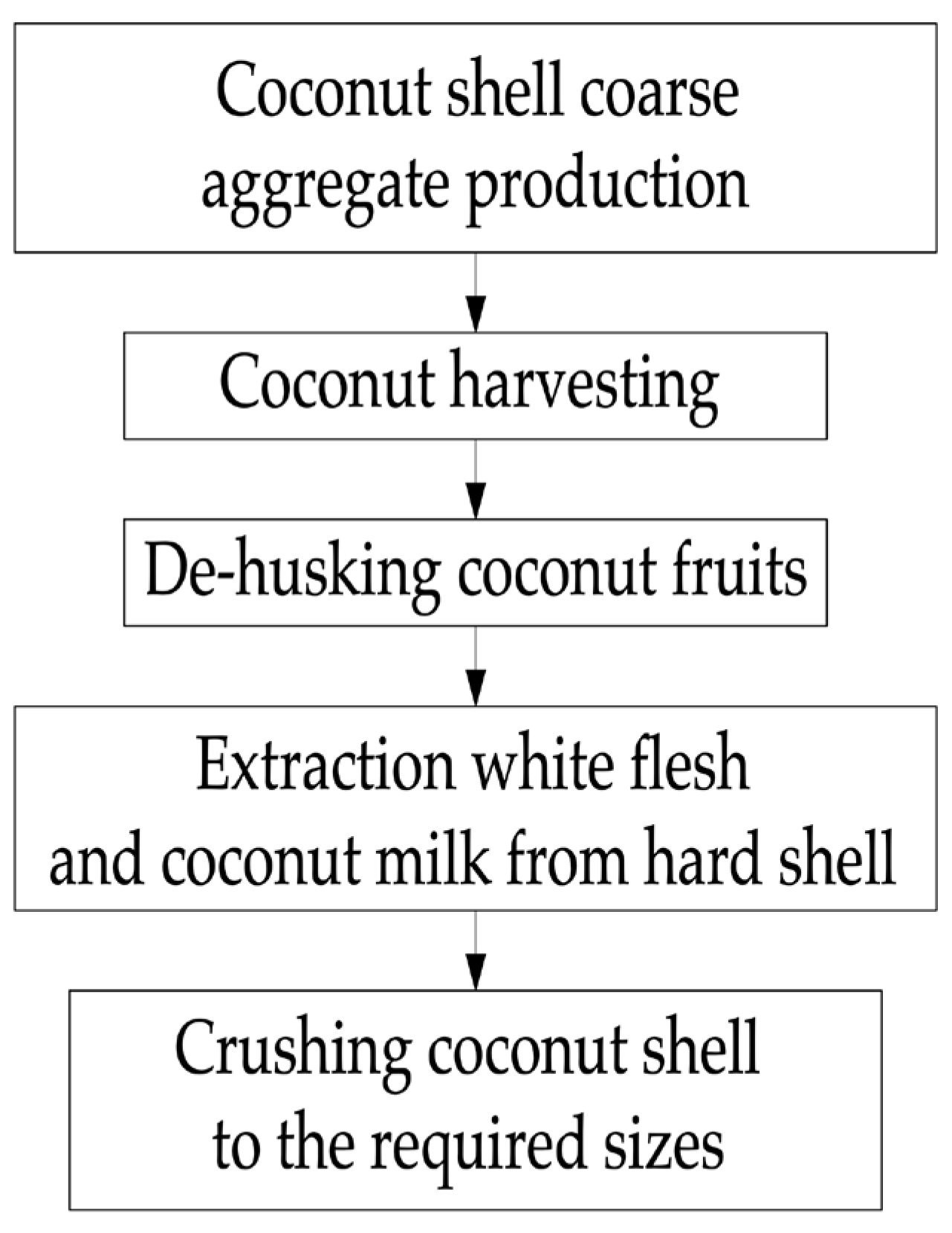

2.1. Materials

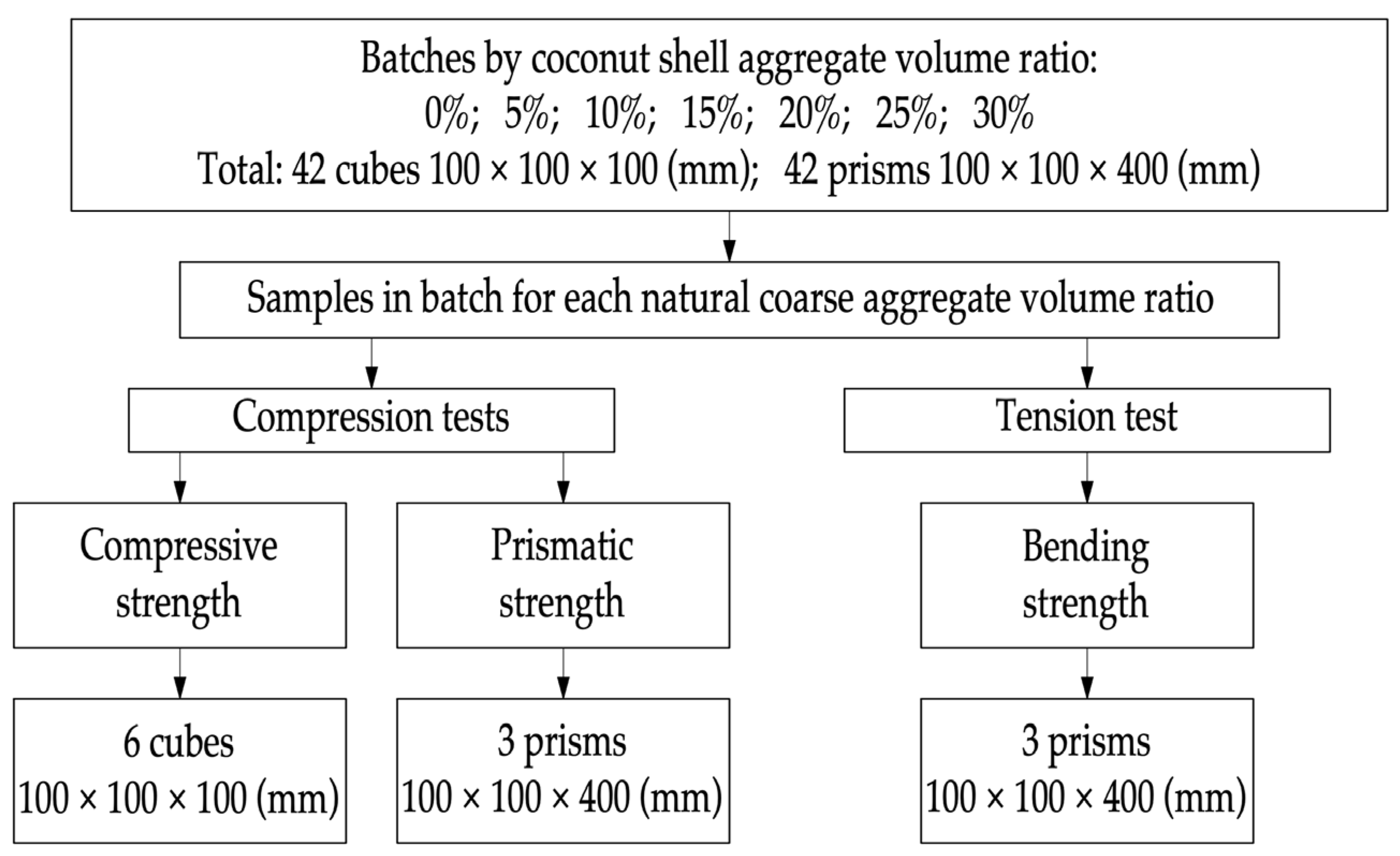

2.2. Methods

- −

- Laboratory concrete mixer BL-10 (ZZBO, Zlatoust, Russia);

- −

- Laboratory scales HT-5000 (NPP Gosmetr, St. Petersburg, Russia);

- −

- Cube shape 2FK-100 and beam shape FB-400 (RNPO RusPribor, St. Petersburg, Russia);

- −

- Normal hardening chamber KNT-1 (RNPO RusPribor, St. Petersburg, Russia).

3. Results and Discussion

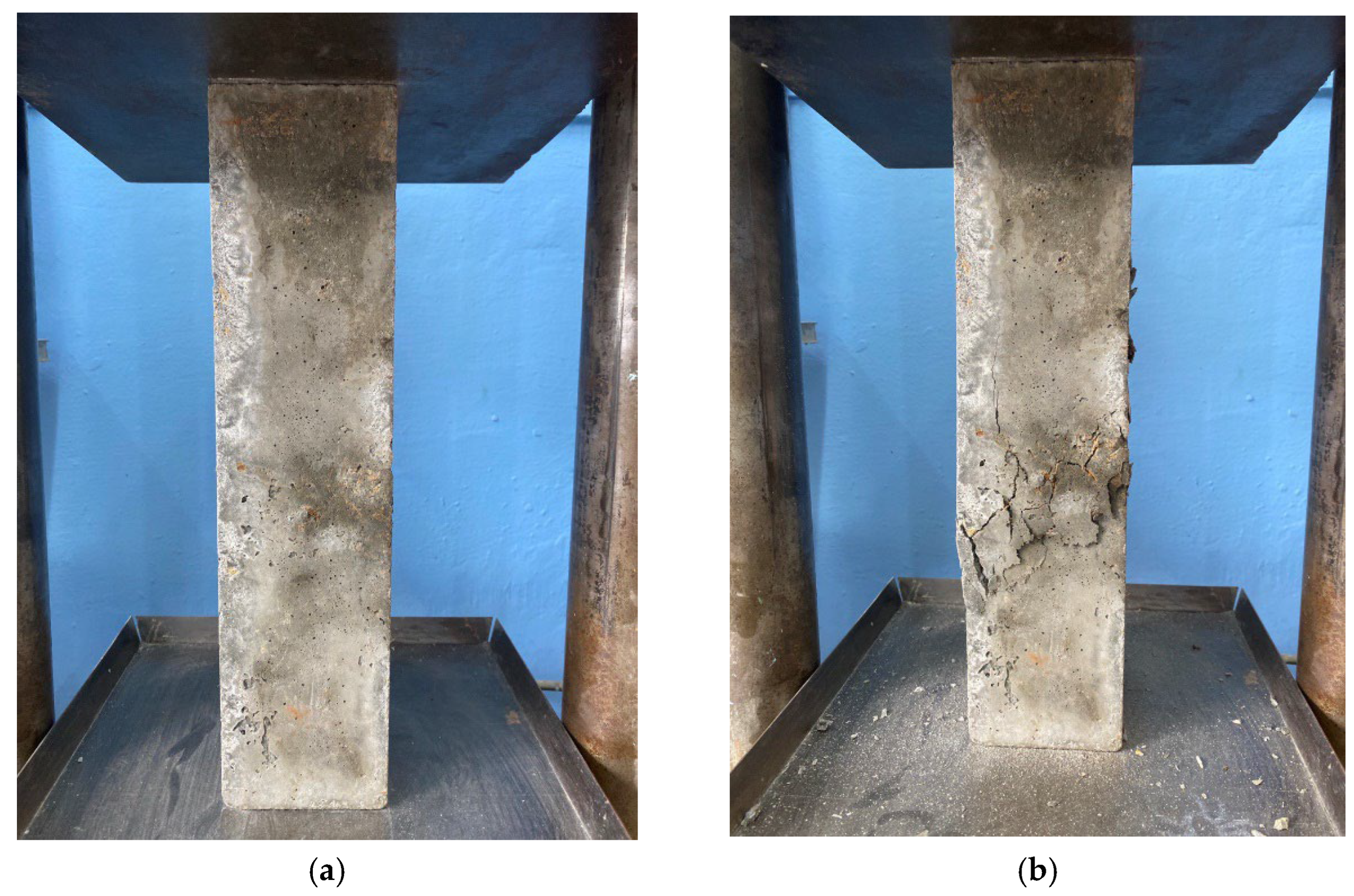

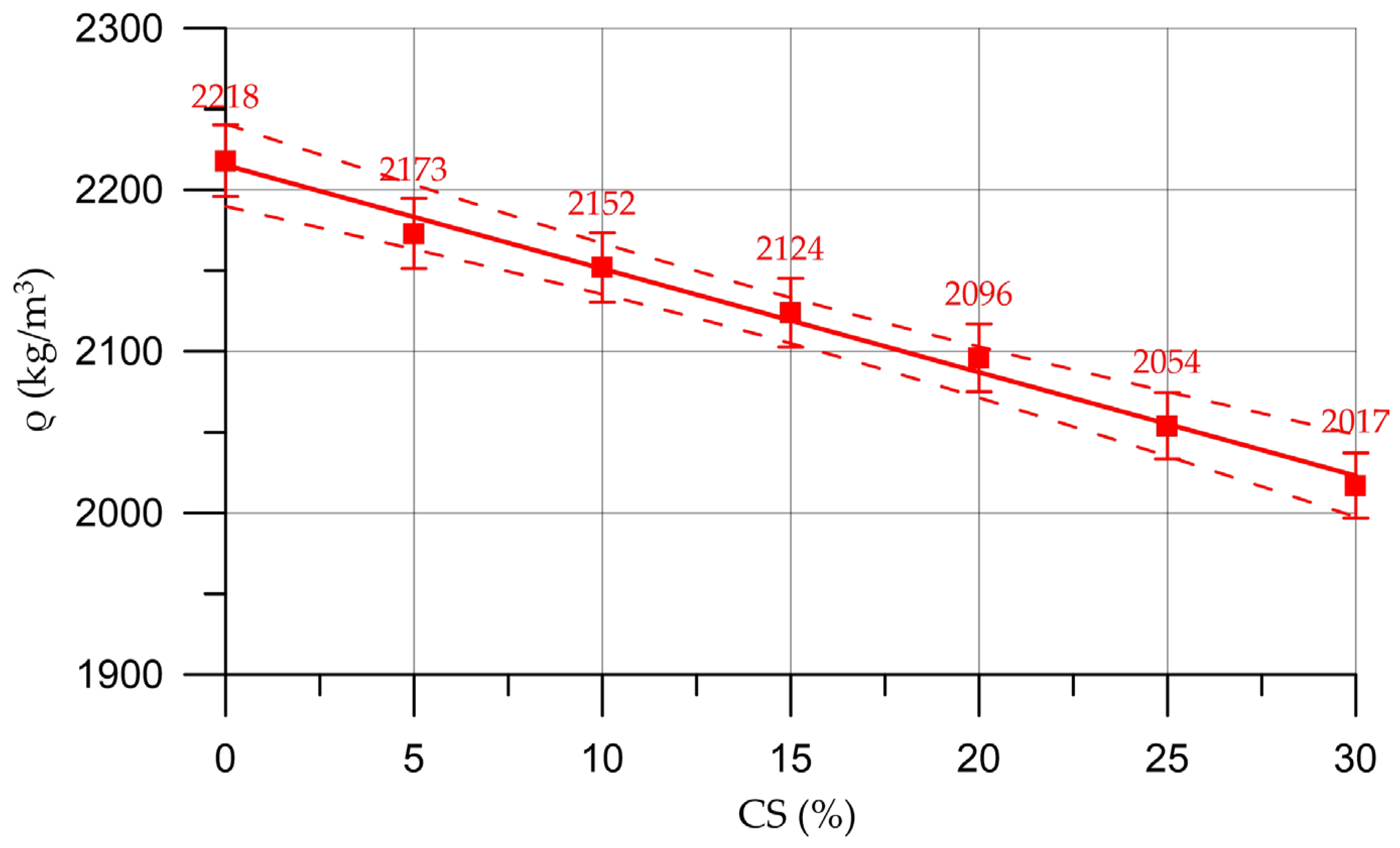

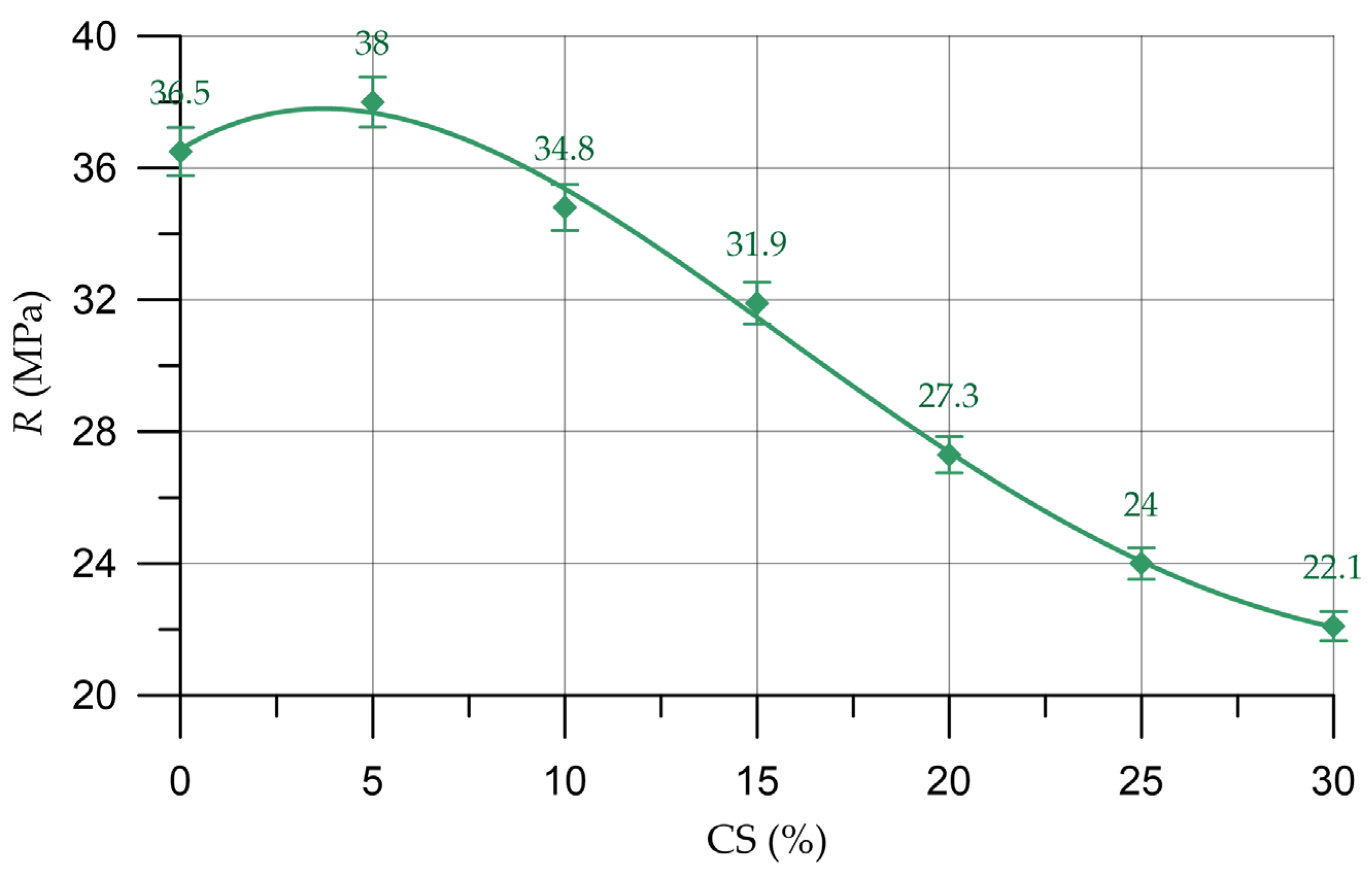

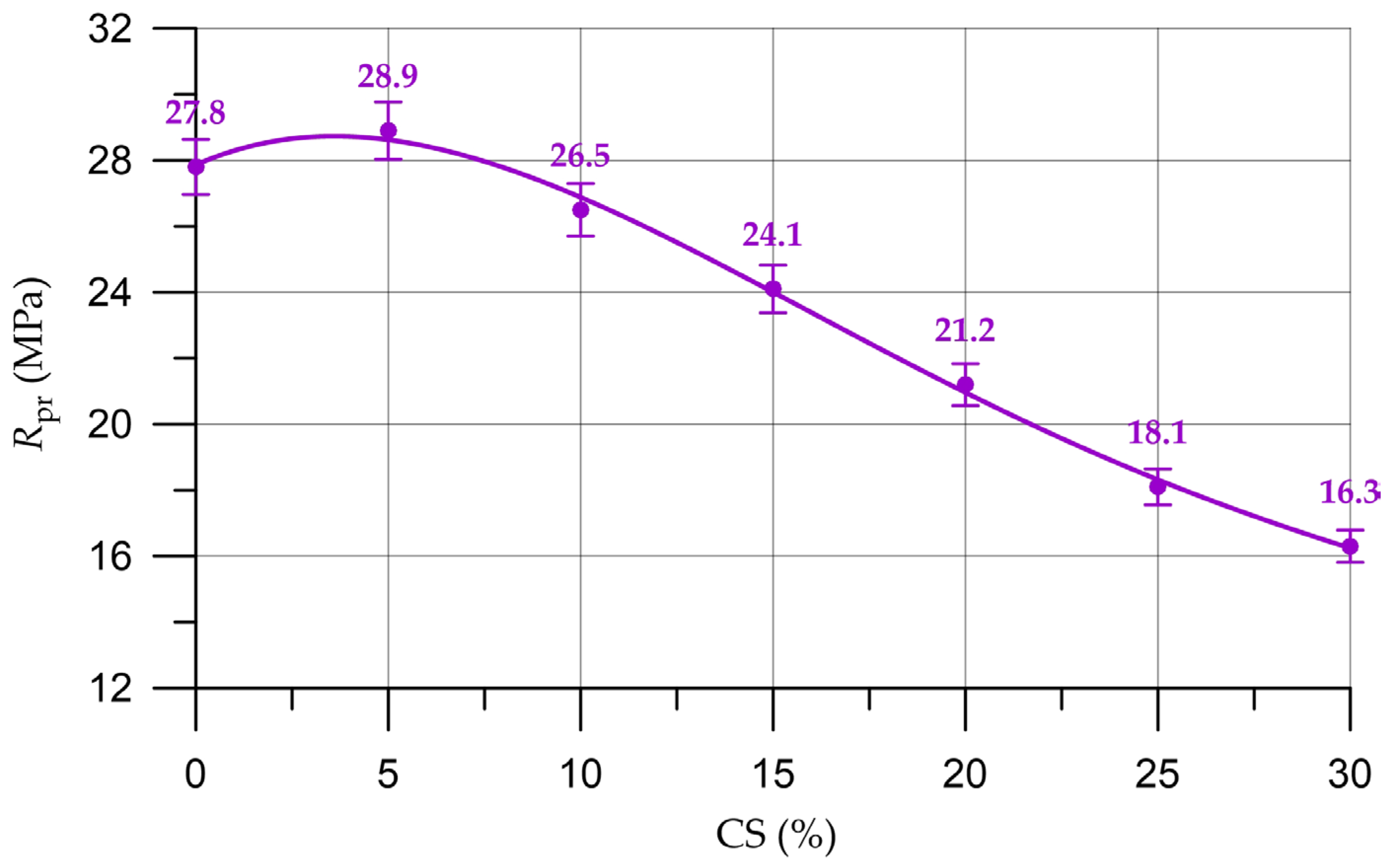

3.1. Study of the Physical and Mechanical Characteristics of Concrete

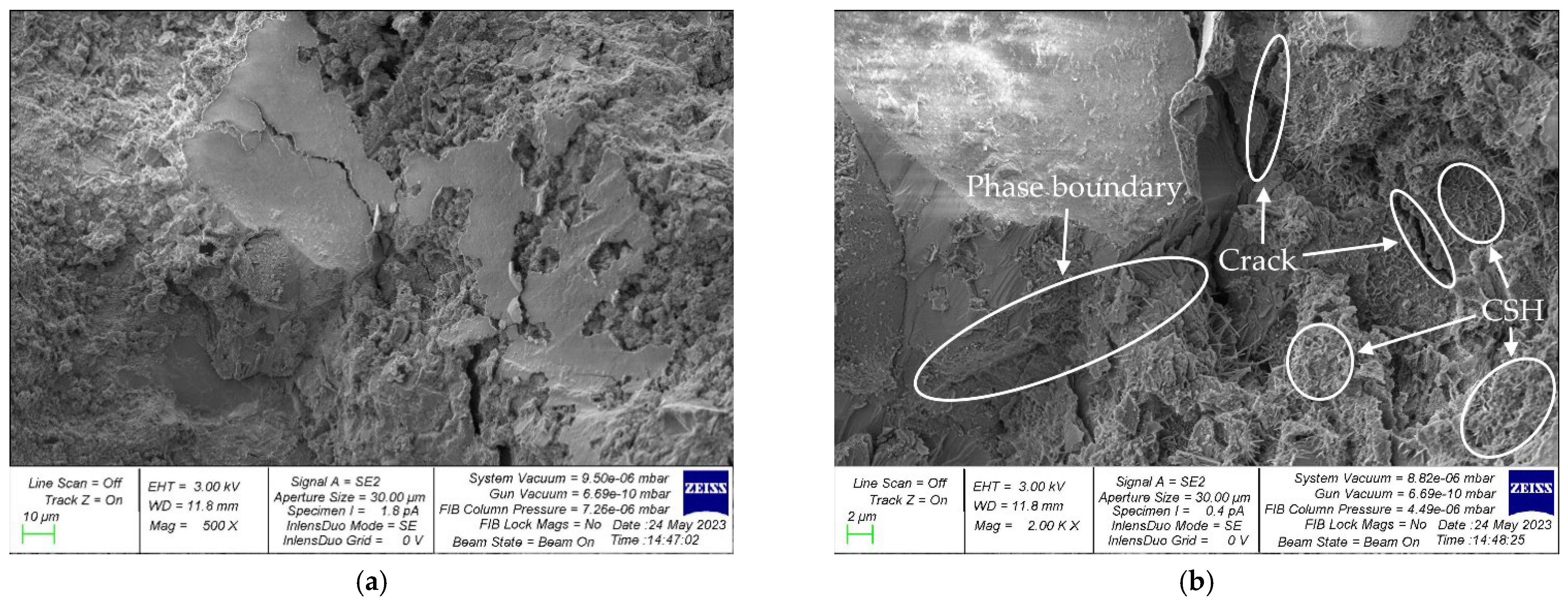

3.2. Analysis of the Microstructure of Concrete Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khan, S.S.; Ali, M. Short-Term and Long-Term Needs for Sustainable Concrete—An Overview. Eng. Proc. 2022, 22, 14. [Google Scholar] [CrossRef]

- Jang, H.-J.; Ahn, Y.-H.; Tae, S.-H. Proposal of Major Environmental Impact Categories of Construction Materials Based on Life Cycle Impact Assessments. Materials 2022, 15, 5047. [Google Scholar] [CrossRef]

- WMO. WMO Greenhouse Gas Bulletin—The State of the Greenhouse Gases in the Atmosphere Based on Global Observations through 2018; WMO: Geneva, Switzerland, 2019; Volume 15, Available online: https://library.wmo.int/doc_num.php?explnum_id=10100 (accessed on 15 May 2023).

- Katman, H.Y.B.; Khai, W.J.; Bheel, N.; Kırgız, M.S.; Kumar, A.; Khatib, J.; Benjeddou, O. Workability, Strength, Modulus of Elasticity, and Permeability Feature of Wheat Straw Ash-Incorporated Hydraulic Cement Concrete. Buildings 2022, 12, 1363. [Google Scholar] [CrossRef]

- Ramasubramani, R.; Gunasekaran, K. Sustainable Alternate Materials for Concrete Production from Renewable Source and Waste. Sustainability 2021, 13, 1204. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’nik, A.; Özkılıç, Y.O.; Aksoylu, C. Normal-Weight Concrete with Improved Stress–Strain Characteristics Reinforced with Dispersed Coconut Fibers. Appl. Sci. 2022, 12, 11734. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Smolyanichenko, A.S.; Varavka, V.; Beskopylny, N.; Dotsenko, N. Influence of Electromagnetic Activation of Cement Paste and Nano-Modification by Rice Straw Biochar on the Structure and Characteristics of Concrete. J. Compos. Sci. 2022, 6, 268. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban, E.M.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Beskopylny, N.; Chernil’nik, A. Enhanced Performance of Concrete Dispersedly Reinforced with Sisal Fibers. Appl. Sci. 2022, 12, 9102. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Varavka, V.; Beskopylny, N.; El’shaeva, D. Enhanced Eco-Friendly Concrete Nano-Change with Eggshell Powder. Appl. Sci. 2022, 12, 6606. [Google Scholar] [CrossRef]

- Olanipekun, E.A.; Olusola, K.O.; Ata, O. A comparative study of concrete properties using coconut shell and palm kernel shell as coarse aggregates. Build. Environ. 2006, 41, 297–301. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Evtushenko, A.; El’shaeva, D.; Chernil’nik, A. Improving the Physical and Mechanical Characteristics of Modified Aerated Concrete by Reinforcing with Plant Fibers. Fibers 2023, 11, 33. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. A study on some durability properties of coconut shell aggregate concrete. Mater. Struct. 2015, 48, 1253–1264. [Google Scholar] [CrossRef]

- Tomar, R.; Kishore, K.; Parihar, H.S.; Gupta, N. A comprehensive study of waste coconut shell aggregate as raw material in concrete. Mater. Today Proc. 2021, 44, 437–443. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; Chernil’nik, A.; El’shaeva, D. Effect of Walnut-Shell Additive on the Structure and Characteristics of Concrete. Materials 2023, 16, 1752. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Meskhi, B.; Shilov, A.A.; Varavka, V.; Evtushenko, A.; Özkılıç, Y.O.; Aksoylu, C.; Karalar, M. Composition Component Influence on Concrete Properties with the Additive of Rubber Tree Seed Shells. Appl. Sci. 2022, 12, 11744. [Google Scholar] [CrossRef]

- Coffetti, D.; Crotti, E.; Gazzaniga, G.; Carrara, M.; Pastore, T.; Coppola, L. Pathways towards sustainable concrete. Cem. Concr. Res. 2022, 154, 106718. [Google Scholar] [CrossRef]

- Khan, K.; Salami, B.A.; Jamal, A.; Amin, M.N.; Usman, M.; Al-Faiad, M.A.; Abu-Arab, A.M.; Iqbal, M. Prediction Models for Estimating Compressive Strength of Concrete Made of Manufactured Sand Using Gene Expression Programming Model. Materials 2022, 15, 5823. [Google Scholar] [CrossRef]

- Almadani, M.; Razak, R.A.; Abdullah, M.M.A.B.; Mohamed, R. Geopolymer-Based Artificial Aggregates: A Review on Methods of Producing, Properties, and Improving Techniques. Materials 2022, 15, 5516. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Sleiman, E.; Aintrazi, S.; Saadeddine, J.; Abboud, R.; Antoun, M. Eco-Friendly Optimum Structural Concrete Mix Design. Sustainability 2022, 14, 8660. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Quan, H.; Xu, X.; Wang, Q.; Ni, S. Assessment on the Properties of Biomass-Aggregate Geopolymer Concrete. Appl. Sci. 2022, 12, 3561. [Google Scholar] [CrossRef]

- Marey, H.; Kozma, G.; Szabó, G. Effects of Using Green Concrete Materials on the CO2 Emissions of the Residential Building Sector in Egypt. Sustainability 2022, 14, 3592. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Ni, S. Assessment of the engineering properties of biomass recycled aggregate concrete developed from coconut shells. Constr. Build. Mater. 2022, 342, 128015. [Google Scholar] [CrossRef]

- Nunes, L.A.; Silva, M.L.S.; Gerber, J.Z.; Kalid, R.A. Waste green coconut shells: Diagnosis of the disposal and applications for use in other products. J. Clean. Prod. 2020, 255, 120169. [Google Scholar] [CrossRef]

- Srivani, G.; Vamsi Mohan, U. Study on strength properties of concrete by partial replacement of cement with sugarcane bagasse ash and coarse aggregate with coconut shells. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Bari, H.; Salam, M.A.; Safiuddin, M. Fresh and hardened properties of brick aggregate concrete including coconut shell as a partial replacement of coarse aggregate. Constr. Build. Mater. 2021, 297, 123745. [Google Scholar] [CrossRef]

- Prithika, A.J.; Sekar, S.K. Mechanical and fracture characteristics of Eco-friendly concrete produced using coconut shell, ground granulated blast furnace slag and manufactured sand. Constr. Build. Mater. 2016, 103, 1–7. [Google Scholar] [CrossRef]

- Janani, S.; Kulanthaivel, P.; Sowndarya, G.; Srivishnu, H.; Shanjayvel, P.G. Study of coconut shell as coarse aggregate in light weight concrete- a review. Mater. Today Proc. 2022, 65, 2003–2006. [Google Scholar] [CrossRef]

- Prakash, R.; Divyah, N.; Srividhya, S.; Avudaiappan, S.; Amran, M.; Naidu Raman, S.; Guindos, P.; Vatin, N.I.; Fediuk, R. Effect of Steel Fiber on the Strength and Flexural Characteristics of Coconut Shell Concrete Partially Blended with Fly Ash. Materials 2022, 15, 4272. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Shahidan, S.; Algaifi, H.A.; Zuki, S.S.M.; Benjeddou, O.; Ibrahim, M.H.W.; Huseien, G.F. Thermal Conductivity of Coconut Shell-Incorporated Concrete: A Systematic Assessment via Theory and Experiment. Sustainability 2022, 14, 16167. [Google Scholar] [CrossRef]

- Mhaya, A.M.; Algaifi, H.A.; Shahidan, S.; Zuki, S.S.M.; Azmi, M.A.M.; Ibrahim, M.H.W.; Huseien, G.F. Systematic Evaluation of Permeability of Concrete Incorporating Coconut Shell as Replacement of Fine Aggregate. Materials 2022, 15, 7944. [Google Scholar] [CrossRef]

- Raja, K.C.P.; Thaniarasu, I.; Elkotb, M.A.; Ansari, K.; Saleel, C.A. Shrinkage Study and Strength Aspects of Concrete with Foundry Sand and Coconut Shell as a Partial Replacement for Coarse and Fine Aggregate. Materials 2021, 14, 7420. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Study on Durability Properties of Coconut Shell Concrete with Coconut Fiber. Buildings 2019, 9, 107. [Google Scholar] [CrossRef]

- Kanojia, A.; Jain, S.K. Performance of coconut shell as coarse aggregate in concrete. Constr. Build. Mater. 2017, 140, 150–156. [Google Scholar] [CrossRef]

- Bhoj, S.; Manoj, A.; Bhaskar, S. Usage potential and benefits of processed coconut shells in concrete as coarse aggregates. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Itam, Z.; Johar, A.D.; Syamsir, A.; Zainoodin, M.; Shaikh Ahmad Fadzil, S.M.M.; Beddu, S. Utilization of coconut shell as a supplementary cementitious material in concrete. Mater. Today Proc. 2022, 66, 2818–2823. [Google Scholar] [CrossRef]

- Bari, H.; Safiuddin, M.; Salam, M.A. Microstructure of Structural Lightweight Concrete Incorporating Coconut Shell as a Partial Replacement of Brick Aggregate and Its Influence on Compressive Strength. Sustainability 2021, 13, 7157. [Google Scholar] [CrossRef]

- Sujatha, A.; Deepa Balakrishnan, S. Properties of high strength lightweight concrete incorporating crushed coconut shells as coarse aggregate. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Palanisamy, M.; Kolandasamy, P.; Awoyera, P.; Gobinath, R.; Muthusamy, S.; Krishnasamy, T.R.; Viloria, A. Permeability properties of lightweight self-consolidating concrete made with coconut shell aggregate. J. Mater. Res. Technol. 2020, 9, 3547–3557. [Google Scholar] [CrossRef]

- Aziz, W.; Aslam, M.; Ejaz, M.F.; Ali, M.J.; Ahmad, R.; Wajeeh-ul-Hassan Raza, M.; Khan, A. Mechanical properties, drying shrinkage and structural performance of coconut shell lightweight concrete. Structures 2022, 35, 26–35. [Google Scholar] [CrossRef]

- Krishnaswami, N.; Velusamy, S.; Palanisamy, C.; Prakash, G.; Loganathan, K.K.; Moorthy, J. Experimental studies on light weight concrete using gib & coconut shell in concrete. Mater. Today Proc. 2022, 65, 1307–1314. [Google Scholar] [CrossRef]

- Soumya, S.; Pennarasi, G.; Gunasekaran, K. Study on the reinforced manhole cover slab using coconut shell aggregate concrete. Mater. Today Proc. 2019, 14, 386–394. [Google Scholar] [CrossRef]

- Herring, T.C.; Nyomboi, T.; Thuo, J.N. Ductility and cracking behavior of reinforced coconut shell concrete beams incorporated with coconut shell ash. Results Eng. 2022, 14, 100401. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. Plastic shrinkage and deflection characteristics of coconut shell concrete slab. Constr. Build. Mater. 2013, 43, 203–207. [Google Scholar] [CrossRef]

- Sekar, A.; Kandasamy, G. Optimization of Coconut Fiber in Coconut Shell Concrete and Its Mechanical and Bond Properties. Materials 2018, 11, 1726. [Google Scholar] [CrossRef] [PubMed]

- Thangasamy, L.; Kandasamy, G. Behavior of Steel–Coconut Shell Concrete–Steel Composite Beam without and with Shear Studs under Flexural Load. Materials 2020, 13, 2444. [Google Scholar] [CrossRef] [PubMed]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. Study on reinforced lightweight coconut shell concrete beam behavior under shear. Mater. Des. 2013, 50, 293–301. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Annadurai, R.; Chandar, S.P.; Anandh, S. Study for the relevance of coconut shell aggregate concrete non-pressure pipe. Ain Shams Eng. J. 2017, 8, 523–530. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Kumar, P.S.; Lakshmipathy, M. Mechanical and bond properties of coconut shell concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- GOST R 57813-2017/EN 12350-6:2009; Testing Fresh Concrete. Part 6. Density. National Standard of the Russian Federation: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200157335 (accessed on 15 May 2023).

- GOST R 57809-2017/EN 12350-2:2009; Testing Fresh Concrete. Part 2. Slump Test. National Standard of the Russian Federation: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200157288 (accessed on 15 May 2023).

- GOST R 57345-2016/EN 206-1:2013; Concrete. General Specifications. National Standard of the Russian Federation: Moscow, Russia, 2017. Available online: https://docs.cntd.ru/document/1200142845 (accessed on 8 June 2023).

- Thilagashanthi, T.; Gunasekaran, K.; Satyanarayanan, K.S. Microstructural pore analysis using SEM and ImageJ on the absorption of treated coconut shell aggregate. J. Clean. Prod. 2021, 324, 129217. [Google Scholar] [CrossRef]

- GOST 10180-2012; Concretes. Methods for Strength Determination Using Reference Specimens. Interstate Standard: Moscow, Russia, 2018. Available online: http://docs.cntd.ru/document/1200100908 (accessed on 15 May 2023).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and other Requirements of Specimens and Moulds. CEN-CENELEC Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 7 June 2023).

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. CEN-CENELEC Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 7 June 2023).

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. CEN-CENELEC Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 7 June 2023).

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. CEN-CENELEC Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/10b1c613-819b-42d7-8f94-480cd37a666a/en-12390-4-2019 (accessed on 7 June 2023).

- EN 12390-5:2019; Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens. CEN-CENELEC Management Centre: Brussels, Belgium, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/5653c2c7-55a9-4bcb-8e13-5b1dfb0e3baf/en-12390-5-2019 (accessed on 7 June 2023).

- GOST 24452; Concretes. Methods of Prismatic, Compressive Strength, Modulus of Elasticity and Poisson’s Ratio Determination. Interstate Standard: Moscow, Russia, 2005. Available online: https://docs.cntd.ru/document/9056198 (accessed on 15 May 2022).

- GOST 12730.1-2020; Concretes. Methods of Determination of Density. Interstate Standard: Moscow, Russia, 2021. Available online: https://docs.cntd.ru/document/1200177299 (accessed on 15 May 2023).

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; Dotsenko, N.; Kotenko, M. Influence of Recipe Factors on the Structure and Properties of Non-Autoclaved Aerated Concrete of Increased Strength. Appl. Sci. 2022, 12, 6984. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Varavka, V. Nanomodification of Lightweight Fiber Reinforced Concrete with Micro Silica and Its Influence on the Constructive Quality Coefficient. Materials 2021, 14, 7347. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C.; Divyah, N. An investigation of key mechanical and durability properties of coconut shell concrete with partial replacement of fly ash. Struct. Concr. 2021, 22, E985–E996. [Google Scholar] [CrossRef]

- Tangadagi, R.B.; Manjunatha, M.; Preethi, S.; Bharath, A.; Reshma, T.V. Strength characteristics of concrete using coconut shell as a coarse aggregate—A sustainable approach. Mater. Today Proc. 2021, 47, 3845–3851. [Google Scholar] [CrossRef]

- Baranova, A.A.; Yazina, O.I.; Bobrova, A.A.; Rudykh, K.N. Effect of quantity of silica fume on the coefficients of constructive quality fine-grained concrete and structural foam concrete. Mod. Technol. Sci. Technol. Prog. 2018, 1, 95–96. [Google Scholar]

- Rylova, T.; Lakhtaryna, S.; Yegorova, O. Lightweight structural concrete with an increased coefficient of structural quality. Proc. DonNACEA 2018, 4–2, 221–226. [Google Scholar]

- Gunasekaran, K.; Annadurai, R.; Kumar, P.S. Study on reinforced lightweight coconut shell concrete beam behavior under flexure. Mater. Des. 2013, 46, 157–167. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Wang, P. Assessment of the engineering properties and economic advantage of recycled aggregate concrete developed from waste clay bricks and coconut shells. J. Build. Eng. 2023, 68, 106071. [Google Scholar] [CrossRef]

- Ni, S.; Liu, H.; Li, Q.; Quan, H.; Gheibi, M.; Fathollahi-Fard, A.M.; Tian, G. Assessment of the engineering properties, carbon dioxide emission and economic of biomass recycled aggregate concrete: A novel approach for building green concretes. J. Clean. Prod. 2022, 365, 132780. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Specific surface area (m2/kg) | 338 |

| Soundness (mm) | 0.5 |

| Fineness, passage through a sieve No 008 (%) | 98.1 |

| Setting times (min) | |

| -start | 165 |

| -end | 230 |

| Compressive strength (MPa): | |

| -2 days | 18.5 |

| -28 days | 49.2 |

| Mineral | Content (%) |

|---|---|

| C3S (alite) | 66 |

| C2S (belite) | 14 |

| C3A (tricalcium aluminate) | 8 |

| C4AF (tetracalcium aluminoferrite) | 12 |

| Residues on Sieves (%) | Sieve Diameter (mm) | Fineness Modulus | |||||

|---|---|---|---|---|---|---|---|

| 2.5 | 1.25 | 0.63 | 0.315 | 0.16 | <0.16 | ||

| Partial | 1.5 | 2.0 | 10.5 | 50.5 | 34.0 | 1.5 | 1.82 |

| Total | 1.5 | 3.5 | 14.0 | 64.5 | 98.5 | ||

| Bulk density (kg/m3) | 1464 | ||||||

| The content of dust and clay particles (%) | 0.3 | ||||||

| Content of clay in lumps (%) | 0.1 | ||||||

| Organic and contaminant content | No | ||||||

| Indicator Title | Actual Value |

| Particle size (mm) | 5–10 |

| Bulk density (kg/m3) | 1397 |

| Apparent density (kg/m3) | 2548 |

| Resistance to fragmentation (wt.%) | 12.6 |

| The content of lamellar and acicular grains (wt.%) | 9.1 |

| Voids (%) | 45 |

| Indicator Title | Actual Value |

|---|---|

| Particle size (mm) | 5–10 |

| Moisture content (%) | 4.6 |

| Water absorption (%) | 26.1 |

| Bulk density (kg/m3) | 592 |

| Apparent density (kg/m3) | 1082 |

| Composition Type | Concrete Mixture Proportion per 1 m3 | |||||||

|---|---|---|---|---|---|---|---|---|

| Portland Cement (kg/m3) | Water (L/m3) | Crushed Stone (kg/m3) | Coconut Shell (kg/m3) | Sand (kg/m3) | Poly-Plast-SP1 (%) | Density (kg/m3) [49] | Slump (cm) [50] | |

| 0 CS | 340 | 195 | 1002 | 0 | 690 | 0 | 2227 | 8.4 |

| 5 CS | 340 | 195 | 952 | 21 | 690 | 0 | 2198 | 8.3 |

| 10 CS | 340 | 195 | 901 | 43 | 690 | 0.5 | 2169 | 7.9 |

| 15 CS | 340 | 195 | 851 | 64 | 690 | 1.0 | 2140 | 7.7 |

| 20 CS | 340 | 195 | 801 | 85 | 690 | 1.0 | 2111 | 7.6 |

| 25 CS | 340 | 195 | 751 | 106 | 690 | 1.0 | 2082 | 6.8 |

| 30 CS | 340 | 195 | 701 | 128 | 690 | 1.5 | 2053 | 6.7 |

| Characteristics of Concrete | ∆ in % with Coarse Aggregate from Coconut Shell; % by Volume of Coarse Aggregate | ||||||

|---|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | 25 | 30 | |

| Density (kg/m3) | 0 | −2.0 | −3.0 | −4.2 | −5.5 | −7.4 | −9.1 |

| Compressive strength (MPa) | 0 | 4.1 | −4.7 | −12.6 | −25.2 | −34.2 | −39.5 |

| Prism strength (MPa) | 0 | 4.0 | −4.7 | −13.3 | −23.7 | −34.9 | −41.4 |

| Bending strength (MPa) | 0 | 3.4 | −3.4 | −15.3 | −23.7 | −33.9 | −40.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stel’makh, S.A.; Beskopylny, A.N.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Shilov, A.A.; El’shaeva, D.; Chernil’nik, A.; Kurilova, S. Alteration of Structure and Characteristics of Concrete with Coconut Shell as a Substitution of a Part of Coarse Aggregate. Materials 2023, 16, 4422. https://doi.org/10.3390/ma16124422

Stel’makh SA, Beskopylny AN, Shcherban’ EM, Mailyan LR, Meskhi B, Shilov AA, El’shaeva D, Chernil’nik A, Kurilova S. Alteration of Structure and Characteristics of Concrete with Coconut Shell as a Substitution of a Part of Coarse Aggregate. Materials. 2023; 16(12):4422. https://doi.org/10.3390/ma16124422

Chicago/Turabian StyleStel’makh, Sergey A., Alexey N. Beskopylny, Evgenii M. Shcherban’, Levon R. Mailyan, Besarion Meskhi, Alexandr A. Shilov, Diana El’shaeva, Andrei Chernil’nik, and Svetlana Kurilova. 2023. "Alteration of Structure and Characteristics of Concrete with Coconut Shell as a Substitution of a Part of Coarse Aggregate" Materials 16, no. 12: 4422. https://doi.org/10.3390/ma16124422

APA StyleStel’makh, S. A., Beskopylny, A. N., Shcherban’, E. M., Mailyan, L. R., Meskhi, B., Shilov, A. A., El’shaeva, D., Chernil’nik, A., & Kurilova, S. (2023). Alteration of Structure and Characteristics of Concrete with Coconut Shell as a Substitution of a Part of Coarse Aggregate. Materials, 16(12), 4422. https://doi.org/10.3390/ma16124422