Abstract

Alkali-activated slag (AAS) has emerged as a potentially sustainable alternative to ordinary Portland cement (OPC) in various applications since OPC production contributed about 12% of global CO2 emissions in 2020. AAS offers great ecological advantages over OPC at some levels such as the utilization of industrial by-products and overcoming the issue of disposal, low energy consumption, and low greenhouse gas emission. Apart from these environmental benefits, the novel binder has shown enhanced resistance to high temperatures and chemical attacks. However, many studies have mentioned the risk of its considerably higher drying shrinkage and early-age cracking compared to OPC concrete. Despite the abundant research on the self-healing mechanism of OPC, limited work has been devoted to studying the self-healing behavior of AAS. Self-healing AAS is a revolutionary product that provides the solution for these drawbacks. This study is a critical review of the self-healing ability of AAS and its effect on the mechanical properties of AAS mortars. Several self-healing approaches, applications, and challenges of each mechanism are taken into account and compared regarding their impacts.

1. Introduction

Infrastructures are always susceptible to severe changes in durability induced through multiple cracking. These changes are often related to the influence of shrinkage, mechanical loads, and/or environmental impact. Durability has a drastic influence on the structural resiliency and sustainability of concrete structures [1,2,3,4]. Once cracking occurs an additional pathway is provided for the transportation of moisture and aggressive agents such as calcium chloride, sulfate ions, gypsum, and carbon dioxide which could lead to alkali–aggregate reactions, reinforcement corrosion, and deterioration [5]. Consequently, restoring the inherent concrete properties is not an easy process. Traditional repair and maintenance including using mortar or epoxy gels cannot be considered cost-effective and environmentally friendly procedures. In some cases, the cost of restoration could be higher than that of the initial construction. For instance, by 2021, USD 1.6 trillion was needed for the maintenance and retrofitting of highway concrete bridges in the US [6]. Thus, the development of concrete material that has the capability of self-healing and regaining any loss of performance could a promising solution for these challenges.

Biological systems such as human organs and animal bodies are capable of self-healing and restoring their original functions. Scientists are inspired by this concept and realized the ability of concrete to heal cracks. Self-healing was discovered in cementitious material where concrete was found to heal cracks under normal conditions [7,8]. Neville [9] stated that tiny concrete cracks were completely closed under wet environmental conditions because of the re-initiation of the hydration reaction of the binding material. Edvardsen [10] pointed out that calcium carbonate is the main material observed within the crack width. Based on a literature review, two primary mechanisms exist for self-healing deteriorated concrete elements: autogenous and autonomic healing. Autogenous healing seals cracks naturally with no need for any external interventions through the precipitation of CaCO3 and/or hydrating the unreacted cement particles and producing extra C-S-H in the crack flanks. Meanwhile, autonomic healing is activated through means of artificial healing materials, for instance, bacteria, chemical admixtures, or microencapsulation [1,2,11,12].

In recent years, alkali-activated composites have been considered a strong competitor to replace ordinary Portland cement (OPC) concrete in various applications. The utilization of OPC is an energy-intensive process that consumes a large number of natural resources and releases a large amount of carbon dioxide gas. It was found that for the production of 1 ton of cement, 1.5 tons of raw materials is consumed and 1 ton of carbon dioxide gas (CO2) is emitted into the atmosphere [13,14]. It is estimated that 12% of the total CO2 emissions in 2020 were due to OPC production [15].

AAS is mainly derived from the chemical reaction between aluminosilicate solid precursors with a concentrated alkaline solution. The aluminosilicate precursor could be a beneficial industrial or mining by-product such as metallurgical slag from iron production or fly ash from coal combustion. This technology has a clear influence on reducing carbon dioxide emissions and innovating a sustainable environmentally friendly infrastructure. AAS has demonstrated unconventionally superior compressive strength and appropriate resistance to high temperature and chemical attack [16]. Nevertheless, many types of research have reported many limitations on using AAS in full-scale applications, including its higher drying shrinkage and early-age cracking compared to OPC concrete which threaten structural integrity, serviceability, and safety. This shortcoming has considerably impeded its broader construction applications [17,18,19,20,21,22]. Therefore, studying the ability of these innovative materials for crack self-healing has paramount importance.

2. Concrete with Slag Basis

Alkali-activated binders are experimentally proven to exhibit excellent mechanical properties among different types of binders. Nevertheless, there are still some obstacles encountered in their large-scale applications. Volumetric instability (i.e., massive shrinkage) is one of the most important challenges of alkali-activated concrete, especially with a slag basis. It was reported that the shrinkage may reach about two to four times higher when compared to OPC [17,23,24]. This significant shrinkage induces non-uniform deformation and causes tensile stress, causing matrix cracks. The induced cracks originate open space for penetration of various corrosive substances. Hence, a serious reduction in the load-bearing capacity, along with durability problems, occurs. Previous studies [25] proposed that the shrinkage properties are more complicated in slag than in OPC due to the complex hydration process.

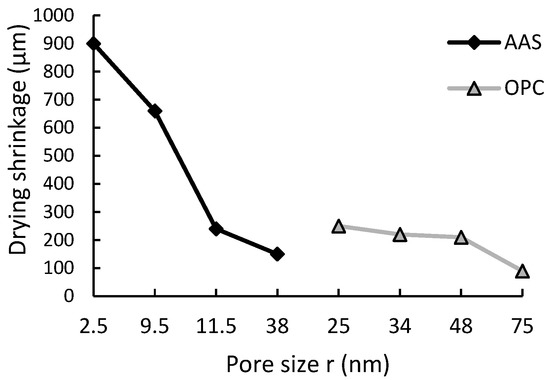

The higher shrinkage reported in AAS composites compared to OPC is associated with the finer pore structure and lower stiffness, as illustrated in Figure 1 [20]. In addition, there are larger numbers of mesopores (i.e., pore sizes between 2 nm, greater than micropores, and 50 nm, less than macropores) coupled with high capillary stress due to the pore distribution compared to OPC. The hydration reaction products (C-S-A-H and C-S-H) are also reported as a major cause of this phenomenon [7]. The presence of alkali metals in the AAS matrix (C-A-S-H gel) disrupts the regularity of the matrix layers’ arrangement, producing gels more prone to redistribution and exhibiting pronounced visco-elastic/visco-plastic characteristics [15,25].

Figure 1.

Drying shrinkage versus pore size for OPC and AAS paste [20].

Shrinkage takes place in two phases, plastic and hardening stages, and it is described as an inherent property of cementitious material. Slag paste and alkaline activators are the main materials in AAS concrete. Based on the different ways shrinkage takes place, it is classified into plastic, autogenous, drying, and carbonation shrinkages. Plastic (or young) shrinkage takes place immediately upon pouring concrete into a mold, and water evaporation is the main cause of this phenomenon. Autogenous shrinkage (chemical shrinkage) is an unavoidable reduction in volume produced by the macroscopic process of self-desiccation and the chemical reaction of concrete. Autogenous shrinkage commonly occurs when concrete has a low cement-to-water ratio [18,19]. Drying shrinkage is the change in volume due to moisture removal from the superficial gel pores that continue progressing along with the drying process of the paste component [19]. Carbonation shrinkage takes place because of the penetration of CO2 into the external surface of the binder [20].

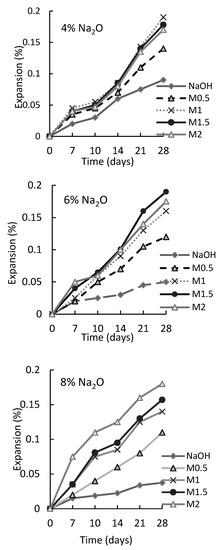

Consequently, the predominant shrinkage mechanisms in alkali-activated composites are autogenous and drying shrinkage, which are linked to losing the internal hydration water and the formation of capillary stress [18] and the capillary suction pressure that occurs due to the very fine porosity of AAS [19]. It was reported that most AASs undergo higher drying and autogenous shrinkage than OPC-based material, which progresses the cracking [26]. Autogenous shrinkage is more independent of the alkaline dosage and surroundings. The proportion of autogenous shrinkage was reported to be considerably steady compared to drying shrinkage that increased gradually with the increase in alkaline solution. The increase in the alkaline solution is represented in terms of silicate modulus and alkaline dosage, see Figure 2 [24]. However, another study [17] has highlighted that autogenous and drying shrinkage take place simultaneously under sealed conditions. Accordingly, it is not easy to determine each of them separately. The detected drying shrinking often incorporates a part of the autogenous shrinkage, however, the drying shrinkage of slag-based matrix is 1.6 times that of concrete when using traditional measures, with unrestrained shrinkage shown by 75 × 75 × 285 mm3 prisms as per Australian Standard AS1012.13 at 23 °C for 24 h followed by exposure to 23 °C and 50% relative humidity (RH). Thus, the only way to differentiate between drying and autogenous shrinkage is to use the developed ring test or the generation of restrained shrinkage prisms by modifying the Australian Standard AS1012.13 [27,28,29,30]. Another way of testing restrained shrinkage is using the ellipse ring as suggested by Kheradmand et al. [28] when studying the performance of fly ash alkali-activated mortars.

Figure 2.

Effect of different alkali dosages and silicate modulus on the expansion of the AAS mortars [24].

There are several ways mentioned in the literature to mitigate the high shrinkage in AAS. These ways include factors that might not only influence the shrinkage but might adversely affect mechanical and fresh properties of the produced concrete. Table 1 discusses these factors that might influence the shrinkage in terms of durability such as alkaline activator type, activator concentration and its ratio to the binder, mineral admixture, chemical additive, nanoparticles, curing condition, and fiber reinforcement, which could be used to mitigate the high shrinkage in AAS pastes.

Table 1.

The factors influencing the durability (i.e., shrinkage) and mechanical behavior of AAS.

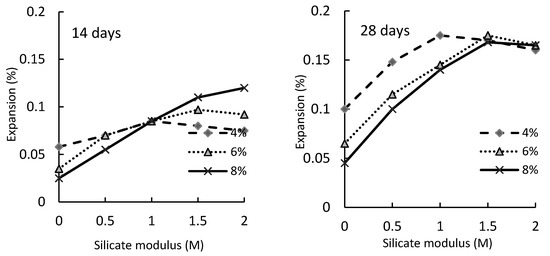

As is clear from Table 1, the alkaline activator was evaluated by many studies on the shrinkage and mechanical properties of AAS. Two factors appeared to affect the alkaline activator: type and concentration. Figure 2 illustrates that the increase in sodium silicates (0.5 M to 2 M) results in higher expansion percentage. Similarly, Figure 3 confirms that higher alkali dosage (4%, 6%, and 8%) leads to higher autogenous and drying shrinkage. The reduction of alkaline solution concentration lowers the percentage of medium capillaries and pores, which in turn increases large capillaries that reduce the capillary tensile stress.

Figure 3.

AAS expansion at different alkali dosages and silicate moduli after 14 and 28 days [24].

On the other hand, replacing the slag with mineral admixtures such as silica fume and fly ash would weaken the strength development. Several researchers [21,22] explored the use of various mineral admixtures: fly ash, silica fume, metakaolin, and lime. Seo et al. [37] reported a shrinkage improvement when incorporating lime as a partial replacement for slag due to the physical filling enhancing the paste’s compactness. However, the compressive strength results were reduced by 66% due to the formation of crystal products of Ca(OH)2 [37]. Moreover, metakaolin has been recorded to effectively alleviate the autogenous shrinkage of slag pastes. This reduction was illustrated by the existence of extra Al and Si in metakaolin, which diminished the concentration of Na+ and OH−, retarding the hydration reaction. Although there was slight variation in the studies that explored mineral admixtures’ influence on shrinkage and strength, many scholars suggested that, generally, the mineral admixtures can help in reducing shrinkage but lead to a reduction in the strength of the AAS. A few suggested researchers [7,26] that mineral admixtures’ incorporation does not affect the shrinkage. Zhang et al. [7] stressed that selecting a suitable mineral admixture proportion is of high importance to optimize the performance of AAS.

Similar to the mineral admixtures, chemical admixtures could influence the shrinkage, especially regarding the expansion and shrinkage of concrete using shrinkage-reducing admixtures, expansive agents, and superabsorbent polymers. The idea mainly relies on reducing the surface tension of the pores by increasing the coarseness of the pore structure and increasing the micropores [7,26]. Nevertheless, other researchers [20] suggested that the chemical admixture might have a negligible effect on reducing the shrinkage of AAS and this needs to be explored intensively.

Furthermore, fibers are another method that effectively controls shrinkage. The inclusion of fibers reduces shrinkage and enhances flexural strength through ties that resist tensile stresses resulting from pore capillaries. Fibers serve as a restraint in the composite, known as the fiber-bridging effect, creating composite stability and resisting any change in the paste volume. However, it should be highlighted that optimization of fiber dosage is an important aspect as it could negatively influence both shrinkage and strength. Puertas et al. [38] and Hammad et al. [13] recommended the optimized fiber range of 0.5 to 1.0%; however, this range differs based on the fiber type, silicate modulus, alkali dosage of the AAS mix, and curing condition.

As curing affects the addition of fiber, it is a factor that affects the shrinkage. Shrinkage is reduced when elevated-temperature curing occurs as reported by Awoyera and Adesina [26]. Their results showed that early elevated temperature transforms the silica gel into calcium silicate hydrates. This action improves the adhesion property found within C-A-S-H gels, accelerating the strength gain. Moreover, the overflowing products from the hydration process are redistributed and surrounded by the unreacted binder, resulting in a coarse pore structure [26]. Collin and Sanjayan [20] added that bath curing of AAS with a shrinkage admixture would create a smaller crack width than that of OPC at 3 and 7 days of curing, which indicates that usually curing has accompanying factors that affect the crack width reduction.

All these mitigation processes reduce the shrinkage up to a specific threshold; however, these processes might adversely affect the overall compressive and flexural strength or increase the embodied energy in AAS systems [26]. Furthermore, other mitigation processes involving aggregate types could be another way of reducing the shrinkage. Collin and Sanjayan [29] reported that AAS beams with slag aggregate performed better than those with natural aggregate in terms of shrinkage and tensile strength; however, these beams provided a lower elastic modulus than those of natural aggregate. Hence, a bio-green alternative could be used to reduce shrinkage and enhance compressive strength as well.

Not only would shrinkage cracking be the main issue to overcome in AAS but also its high susceptibility to cracking because of the intrinsic brittleness [35,36,37]. Generally, cracking influences the safety, serviceability, and integrity of AAS structural elements, which limits their commercial application. Moreover, Zhang et al. [39] reported that conventional maintenance techniques are typically laborious, onerous, and time- and money-consuming [3]. Thus, there is a need to develop a sustainable AAS application using the recently developed techniques of self-healing AAS, occurring autonomously without the intervention of humans, facilitating the repairing of cracks and the creation of resilient AAS. This paper reviews the most important self-healing techniques used for conventional concrete generally and applied to AAS.

3. Self-Healing Mechanisms

Many researchers [1,2,4,11,40,41] discussed the selection of several techniques for self-healing including the two main types, autogenic and autonomic, based on the techniques’ availability and the characteristics of cracks in terms of width and depth, as illustrated in Table 2. The values of crack width and depth listed in Table 2 were proposed by multiple researchers based on their own experience with specific materials, concrete mix, curing conditions, and experimental procedures.

Table 2.

Applicability of self-healing strategy with crack width and depth for OPC concrete.

Cracks, on either a macro or micro scale, could significantly induce a series of problems in terms of deflection and aesthetics, interfering with durability and serviceability. Consequently, crack characterization of structural elements is controlled by the serviceability limit state based on the code and guidelines required for design. The crack width and depth should be the main aspect of self-healing technology; however, as shown, self-healing could provide a reduction in crack width of nearly 1 mm (≈970 µm) which exceeds the size of most of the limited cracks under serviceability loads as per ACI 318. Thus, several techniques and mechanisms are reviewed in the next section to understand how these mechanisms and techniques would work in healing the cracks of AAS structures.

3.1. Autogenous Self-Healing

Autogenous healing is the ability of concrete or the conventional ingredients of the cementitious matrix to recover from damage. The specific chemical composition of the cementitious matrix is the main reason for this process to take place [51]. Generally, about 20 to 30% of cement in conventional concrete remains unhydrated during the process of strength gain [4,10,11]. These unhydrated cement particles react with water once cracking initiates. Thereby, the hydration process starts again, producing hydration products such as CaCO3 to seal/fill the cracks [4,10,11].

According to substantial experiments and practical application, an autogenous self-healing mechanism is a combination of complex chemical and physical processes. As stated by most of the studies in the literature [4,10,11], various causes could be responsible for the self-healing of cracks, such as (a) formation of calcium hydroxide or calcium carbonate; (b) the blocking of cracks by impurities in water; (c) hydration of unreacted cementitious materials; and (d) swelling of the hydrated cementitious matrix (C-S-H) in the crack flanks [2,4].

More than one of the proposed causes can occur simultaneously. However, most of the mechanisms can partially fill the entrance of some cracks but cannot fill the crack. This could help in preventing the development of further cracks or control the deep penetration of harmful chemicals. Crystallization of calcium carbonate is the most effective method to heal the crack naturally. This is proved by the common observation of macroscopically and microscopically precipitated calcium carbonate on the crack surfaces as a white residue. Dissolving one of the cement hydration products in water is an essential condition for calcium hydroxide to be liberated and dissipated along the cracking surfaces [4,10,11]. This means that this reaction mainly depends on the presence of water [52]. In this way, the calcium ions produced from the hydration process become able to react with the dissolved carbon dioxide, then self-healed crystals are formed and fill the gaps as described in the following Equations (1)–(5) [4,10].

H2O + CO2 ↔ H2CO3

Locations of CaCO3 crystals depend on the pH, the surrounding temperature, the partial pressure of CO2, the calcite saturation, and the concentration of Ca2+ and in the solution [10]. The other proposed mechanism of self-healing caused by further hydration of unhydrated cementitious components was recently discovered to be applicable only at the early age of concrete as the formation of calcium carbonate is the most likely reason for self-healing at later ages [9].

By observing surface cracks, calcium carbonate and calcium silicate hydrates were recognized as the main products of the self-healing process. The percentage of the formed C-S-H (<15%) was considerably lower than the percentage of the produced calcite which was 80%. It was realized that there is an obvious decline in the intensity of the self-healing efficiency after about 300 h [49]. Autogenous self-healing takes place through three processes: physical, chemical, and mechanical. The physical process causes the matrix to swell. The chemical process is responsible for initiating the ongoing hydration of the unreacted particles to precipitate CaCO3. The mechanical process comprises crack closing with the generated particles from the crushed concrete surface or impurities from water ingress [52].

Different studies were conducted to study the efficiency of the autogenous self-healing mechanism and the factors affecting it. It was found that this process is effective for small crack sizes, however, sometimes larger crack widths (between 200 µm and 300 µm) were observed [2]. Based on previous observations, the following factors (listed in Table 3) considerably affect the autogenous self-healing process [2,4,12,41,51,52].

Table 3.

Factors affecting the efficiency of autogenous self-healing mechanism and their influences.

Limited research has been devoted to studying the autogenous self-healing property of AAS [15,53,54]. The crack healing in AAS mortar specimens was inconspicuous in most of these studies, especially when the initial crack width increased from 50 µm to 100 µm, followed by a gradual decrease in any further increase in the crack width [53]. This could be explained by understanding the properties of AAS. AAS systems are commonly known for their early high strength. Hammad et al. [13] have proved that AAS composites gained about 85% of their 28th day compressive strength after only 1 day of casting. The percentage of strength gain increased to 98% and 99.5% after 7 and 14 days. The high pozzolanic activity of AAS systems and the presence of high calcium and silicon content create a reaction much faster than the reaction that occurs within OPC concrete because of the availability of highly alkaline conditions as well as the greater fineness of AAS [13,55,56]. Consequently, most of the calcium content is consumed in the gepolymerization process during the first 7 days. Some modifications have been proposed in AAS mixtures to improve the autogenous self-healing property such as partial replacement of AAS by calcium hydroxide [53,57], addition of fiber [53,54,58,59], and incorporation of an additional calcium source (i.e., calcium lactate) [15,54]. A study conducted by Provis showed that incorporating Ca(OH)2 in the AAS mix led to higher Ca2+ concentration due to the low solubility of Ca(OH)2 at a high pH level before cracking takes place. Consequently, Ca2+ was not consumed during the geopolymerization process. After the activation process of AAS, Ca(OH)2 dissolved in the curing water, providing calcium carbonate precipitation [53,60] as illustrated in Equations (6) and (7).

The addition of polyvinyl alcohol (PVA) and polyethylene (PE) fibers showed a tendency towards enhancing the healing property of AAS [53,54,57,58,59]. SEM images of AAS specimens incorporating PVA fibers revealed many crystals covering the crack surface, highlighting that PVA fibers promoted the precipitation of healing products of CaCO3 through various intermolecular forces such as ionic bonding, hydrogen bonding, and van der Waals forces [15]. Another study conducted by Nguyễn et al. [59] clarified that the addition of PE fibers bridged cracks and enhanced the precipitation of healing materials by providing nucleation sites. They stated that the healing product crystals were not only found on the external surface of the crack but also formed on the fibers. Zhang et al. [54] tested the addition of calcium lactate and urea in an AAS mix incorporating PVA fibers. The findings showed a slight improvement in crack surface healing.

3.2. Autonomous Self-Healing

Recently, autonomous self-healing has attracted considerable attention. Autonomous concrete healing is an artificial healing mechanism that occurs when an appropriate healing agent is added to concrete. Accordingly, the healing and blocking of cracks can be carried out automatically without any external aid or repair at ambient room temperature. This type of healing takes place through chemical and biological processes [2,44,45,52].

3.2.1. Chemical Self-Healing Process

One of the new approaches in autonomous self-healing uses the injection of chemical compounds into concrete cracks. This chemical process could be carried out by mixing fresh concrete with (liquid) chemical reagents such as glue. For accomplishing this process, there are several methods, for example, hollow pipette and vessel networks containing glue and encapsulated glue.

Hollow Pipette and Vessel Networks Containing Glue

The hollow pipette concept is inspired by blood vessels in animals. These pipettes or vessels (classified by diameter size) provide a medium for storing functional components or healing agents. Pipettes are embedded within the composite matrix. When concrete is subjected to damage or cracking occurs, the healing material will flow out to start the healing process. Either the hollow pipettes or the vessel networks can be used to design a self-healing concrete based on passive or active mode. The passive mode uses hollow vessels that are not linked to an external glue source, while the active mode needs an external supply of glue for distribution [11]. Systems of hollow vessels have been investigated at different length scales through several studies on the design of different healing materials such as polymers and polymeric composites. The applicability of hollow vessels in allowing the flow of healing agents was proven in many cases [4]. This method has been applied to cementitious materials and demonstrated as a feasible approach by various researchers. Experiments have been carried out on concrete specimens containing distributed brittle vessels of healing materials inside. Then, the pattern of glue distribution within cracks was monitored upon concrete damage. For accurate monitoring, vessels were sometimes filled with healing agents mixed with fluorescent dye for detecting the rupture details and sequence [61].

Methyl methacrylate, ethyl cranoacrylate, acrylic resin, and epoxy are different examples of healing materials (glue) that are suitable for filling the hollow pipettes. A network of vessels was applied within a concrete specimen for the distribution of glue. This brittle vessel network inside concrete was connected at one end to a glue supply, whereas the other end was sealed inside concrete. Another study proved that this technique used in a concrete specimen resulted in a 20% increase in the loading capacity under a subsequent flexural test [11]. Despite there having been several studies on using this procedure, there are no available data on applying this mechanism in AAS concrete. Hence, this method is considered a complicated method that is subject to a lack of constructability using the current technology. Therefore, it needs verification for use in actual projects [61,62].

Encapsulated Glue

The encapsulation technique was inspired by examples in nature, ranging from the macro scale (bird’s egg or seeds) to the micro scale (cells). Microencapsulation involves the development and preparation of capsules containing dyes that were originally for paper copying and eventually replaced with carbon paper. White et al. [63] developed the idea and introduced the applicability of using microcapsules containing glue for designing self-healing concrete. Concrete cracks would cause a rupture in the embedded microcapsules, causing release of the glue into the crack faces through capillary action [1,11].

Many researchers believed that this technique is versatile due to its efficiency in regaining the mechanical properties and the durability of concrete [2,64]. This method was initially applied to structural polymers [63]. The proposed capsules contain the healing agent and a catalyst for chemical triggering. There are three main components in the mechanism of capsule-based self-healing: (a) the trigger that initiates the process of activation by damaging the capsule, (b) the healing agent which is the core that is released upon activation into the crack, and (c) the capsule shell (coating for protection) to prevent the direct contact of the healing agent and the surrounding matrix. The compatibility of these materials with the concrete matrix is a crucial factor for a successful self-healing process [52]. There are two mechanisms for activating the capsules. The first and the most popular procedure is the mechanical activator where the stresses resulting from the crack formation lead to the breakage of the brittle capsule and releasing of the agent. The second mechanism depends on adding chemical triggers for penetrating the matrix via nanocracks before microcracks occur. The sensitivity of the chemical trigger was deduced to be higher [65].

Different types of healing agents are used for the self-healing process as listed in Table 4. They are categorized into three groups: one, two, and multiple healing agent components. There is no need for more chemical components or catalysts (such as sodium silica (Na2SiO3)) in the case of using one component as a healing agent for activation due to its ability to act individually. For the other two types, another substance, for example, dicyclopentadiene (DCPD), is required to achieve maximum efficiency. Practically, two or more component systems are found to be more complicated and have a high risk of inappropriate mixing that may cause inefficient crack healing. Moreover, optimum fluid with low viscosity is a vital factor for controlling the healing material transportation and penetration through the crack as well as solidifying in the desired locations [66]. Basically, after conducting many studies using this approach, it was elaborated that there were many technical problems, including: (a) mixing two healing components is difficult, (b) the required quantity of agent for filling one microcapsule is limited, (c) the capsule shell should be strong enough to protect the healing agent during the mixing and hydration process (different types of applicable shells are illustrated in Table 5), (d) the bond between the capsule shell and the concrete matrix has to be improved and be stronger than the microcapsules [11,64].

Table 4.

Different types of healing agents used in the encapsulation technique.

Table 5.

Different types of capsule shells used in the encapsulation technique.

Despite the remarkable progress accomplished in adopting this technique in OPC-based systems, no studies have introduced microcapsules in AAS-based composites and evaluated their performance.

3.2.2. Biological Self-Healing Process

This process is an environment-friendly mechanism that takes place by adding microorganisms to concrete. For that, it has been categorized as a biological strategy. The reason for choosing microorganisms is their wide availability (i.e., in soil, water, acidic springs, industrial wastewater, oil reservoirs, etc.). There are several types of microorganisms, for instance, bacteria, fungi, and viruses. Among these types, it was found that a certain strain of bacteria could be considered due to its ability to precipitate certain useful chemicals used in the design of biological self-healing concrete. These useful precipitation chemicals are polymorphic iron aluminum silicate ((Fe5Al3)(SiAl)O10(OH)5) and calcium carbonate (CaCO3) [40,41].

For governing bacterial self-healing, there are two processes: (a) bacterial metabolism, and (b) enzymatic ureolysis. In the first mechanism, bacteria are present as a catalyst that converts the precursor compound into a filler material. The produced filler material is a calcium carbonate-based mineral that acts as a type of bio-cement and seals cracks [77]. The reaction taking place can be formulated as follows:

Ca(C3H5O2)2 + 7O2 → CaCO3 + 5CO2 + 5H2O

This type of reaction is six times more effective compared to autogenous self-healing as the produced CO2 starts a localized reaction with Ca(OH)2 within the crack mouth. As a result, five more CaCO3 molecules are produced [78].

The second process is known as ureolysis which is one of the most popular ways to design self-healing concrete. In this process, bacteria can produce urease, an enzyme that catalyzes urea (CO(NH2)2) into ammonium ( and carbonate (). The hydrolyzed ammonia and carbon dioxide help in increasing the pH and carbonate concentration in the presence of a bacterial environment. A series of biochemical reactions occur to produce calcium carbonate as described in the following Equations (9)–(15). The primary role of bacteria is to form the precipitate calcium carbonate which is attributed to their effect in elevating the pH of the environment through their metabolism [11,79,80]:

Urea is hydrolyzed into carbonate and ammonia in the presence of urease as shown in Equation (9):

CO(NH2)2 + H2O → NH2COOH + NH3

Carbonate is simultaneously hydrolyzed to produce ammonia and carbonic acid:

NH2COOH + H2O → NH3 + H2CO3

Carbonic acid is hydrolyzed into carbonate ions and hydrogen ions:

Ammonia is spontaneously hydrolyzed to produce ammonium and hydroxide ions:

The production of hydroxide ions increases the pH value and causes the overall equilibrium to form carbonate ions:

The negative charge of the produced carbonate ions attracts the positively charged calcium ions (Ca2+) to form the precipitation of calcium carbonate (CaCO3) at the cell surface:

Ca2+ + Cell → Cell-Ca2+

A large number of bacteria have been tested to produce self-healing concrete, however, the survival of most of them is in still in question due to the high pH of the fresh concrete (between (10) and (13)). This high-alkalinity solution is considered to be harsh for the bacteria’s survival. Furthermore, the fresh concrete’s temperature, which is around 70 °C, is too high for cell growth. Not only is temperature one of the drawbacks but so is water scarcity for cell growth once fresh concrete hardens. As a result, the chosen type of bacteria has to show high resistance against the high pH, temperature, and massive limitation of water [81]. The bacteria must have the ability to withstand the pressure caused by the hydration and densification of the mix. Over time, the pores in the matrix will reduce due to the ongoing hydration that leads to exposing the bacteria to considerable compressive stress. Consequently, the chosen bacterial strain must be an obligate alkaliphile as well as spore-forming. These strains are fully functional vegetative cells that become dormant and produce spores under adverse conditions. Spores are much tougher than vegetative cells and can resist harsh conditions. Once the environmental conditions improve, these spores return to their vegetative state. Hence, these spores remain dormant until cracks start and, once exposed to water, they will germinate back into vegetative cells and metabolize the available growth substrate, producing the precipitation of healing products [39]. Bacillus species are specifically highlighted to have the potential for application in cement materials and are known for their ability to precipitate CaCO3 in different ways, closing pores and cracks in concrete and cementitious materials [12,46,77,81,82].

The effects of bacteria on the compressive strength and transport properties of concrete are listed in Table 6. Nevertheless, the variation in concrete porosity during maturing may cause a decrease in the viability of spores as well as their survival time which may only reach 4 months [83]. Consequently, so-called protection solutions and organic precursors have been introduced [41,77,84]. Finally, the process of microbial-induced calcite precipitation (MICP) can be used in a cementitious matrix composed of three main elements: (a) an alkali-resisting, spore-forming, Gram-positive bacterium, in an inactive form, which can be activated upon exposure to water, (b) a nutrient or precursor compound, and (c) a carrier compound for protection of bacteria from the external pressure applied by concrete [85]. However, the incorporation of bacteria is not limited to the spore form only. Bacteria could be added by encapsulation or through using the vascular network method [2,11]. However, the encapsulation technique and vascular network method are difficult to prepare in small or large amounts which makes the processes not cost-effective choices. Moreover, the spores of bacteria cannot break the encapsulation shell easily until they encounter major cracks or deterioration. Additionally, the spore form of bacteria shows the fastest healing reaction [86]. The main advantage of this mechanism is that it is a natural, environmentally friendly method and compatible with the cement matrix. Its main disadvantage is the required measures for the protection of bacteria [87]. A summarized comparison between different self-healing mechanisms is provided in Table 7.

Table 6.

The influence of various bacterial types on the compressive strength and transport properties of concrete.

Table 7.

The advantages and disadvantages of different self-healing mechanisms.

4. Self-Healing Alkali-Activated Concrete

According to the literature, few studies have investigated the self-healing property of alkali-activated concrete. Zhang et al. [92] explored the potential of self-healing in AAS mortars using PVA fibers and compared it with the behavior of cement-based materials. Based on optical microscopy and scanning electron microscopy (SEM), both composites exhibited self-healing properties, producing calcium carbonate as the main healing product. Another study showed that the addition of PVA fibers within AAS mortar specimens achieved a maximum healing ratio of 65% for the narrowest crack width of 50 μm and the lowest healing ratio of 18% for the original crack width of 150 μm. This efficiency could be improved by incorporating crystalline additives to reach 100% and 25% for crack widths of 50 μm and 150 μm, respectively [97]. Similarly, AAS composites incorporating PE fibers were revealed to have a superior reduction in crack width concerning cement-based composites. SEM observations have confirmed that the prominent healing material of both OPC and AAS-based composites is CaCO3 as previously stated by different researchers. Moreover, the tensile strength along with the tensile strain increased significantly by 150% and 234% during the reloading tests after crack healing [57,59]. The effect of the partial replacement of slag by calcium hydroxide on the healing process has shown higher levels of crack healing compared with specimens without calcium hydroxide because of the availability of higher concentrations of Ca2+ ions in the AAS matrix. This led to reducing the diameters of capillary pores by about 37% and 23% in calcium hydroxide and zero calcium hydroxide specimens [53]. The potential of the bacterium Sporosarcina pasteuri in the crack healing property of AAS mortar was investigated using porous expanded recycled glass granules as bacterial carriers. Most of the crack surfaces under 100 μm were entirely healed after 5 months of curing. Bio-based samples showed enhanced crack healing with a maximum width of 140 μm. Increases in compressive strength of 7% and 14% have been observed for bacterial-based specimens incorporating calcium lactate and calcium chloride, respectively. The usage of a combination of bacterial nutrients (calcium lactate and urea) and porous expanded recycled glass granules led to a decrease in mechanical properties. However, the final strength increased by 7% due to the positive effect of the immobilized bacteria [15,54]. Consequently, the incorporation of bacteria in AAS seemed to be a promising technology for widening full-scale production and overcoming the problem of early cracking in AAS systems [15,53,54,98].

5. Conclusions

The innovative technology of alkali-activated composites is known for its small carbon footprint and energy savings. These smart sustainable composites offer an eye-catching combination of good-quality mechanical properties and durability. However, degradation initiated at a very early stage may put a limitation on their usage as construction materials. The volumetric instability of AAS is two to four times higher than that of OPC composites. The finer pore structure of AAS, the lower stiffness, and the presence of alkali metals in the hydration products (C-S-A-H) are reported to be the main causes of this higher shrinkage. Based on this critical review, this research suggests producing smart alkali-activated composites with self-healing properties, which would provide a self-repairing structure with the minimal help of external maintenance.

- The natural self-healing mechanism could occur due to any of the following reasons: formation of calcium hydroxide or calcium carbonate, further hydration of the unreacted particles of cement, swelling of the hydrated cementitious matrix (C-S-H) in the crack flanks, or blocking of cracks by impurities in the curing water. More than one of the mentioned causes may occur.

- Clinker content in cement, hydration age, crack geometry, exposure condition, and addition of fiber or additives could enhance the efficiency of autogenous crack healing.

- Innovative techniques of chemical and biological self-healing have been proposed. The mentioned strategies are hollow vessels, encapsulation, and immobilization of bacteria. The idea of these methods is to prompt the intrinsic self-healing property of concrete to produce calcium ions and supply the cementitious matrix with external chemical or functional materials to provide better healing capacity.

- Bacterial-based bio-concrete is a remarkable solution because it showed enhanced results and an eco-friendly practical process. Nevertheless, the efficiency of the healing process depends on the proportion of the unreacted matrix that will respond to the introduced healing agent, and crack geometry and size play a vital role in predicting effective healing.

- From the available limited literature, it seems feasible to prompt the production of alkali-activated self-healing composites with a good crack-healing ratio and improved mechanical properties.

6. Future Research and Recommendation

As discussed earlier, several parameters could influence the shrinkage of AAS and there are several solutions to overcome this shrinkage. The most commonly suggested is an autonomic healing solution. However, very few researchers work in this area, and the following points still need to be discussed:

- Curing methods, including cycling air and wet methods, wetting and drying for just 24 h, wetting and air drying for 3 h, air drying, and oven drying. To date it is not clear which curing method would be suitable.

- Although it was stated that sodium concentration is a parameter, limited studies have mentioned the possibility for bacteria to die before activation; however, none of them mentioned the concentration percentage at which the bacteria will not be influenced.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No data, models, or code were generated or used during the study.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| AAS | Alkali-activated slag |

| OPC | Ordinary Portland cement |

| CO2 | Carbon dioxide gas |

| CaCO3 | Calcium carbonate |

| C-S-H | Calcium silicate hydrates |

| C-S-A-H | Calcium silicate aluminate hydrates |

| RH | Relative humidity |

| CSA | Calcium sulfoaluminate |

| CA | Crystalline additive |

| Ca(OH)2 | Calcium hydroxide |

| PVA | Polyvinyl alcohol |

| PE | Polyethylene |

| MICP | Microbial-induced calcite precipitation |

| SEM | Scanning electron microscopy |

References

- Luhar, S.; Luhar, I.; Shaikh, F.U.A. Review on Performance Evaluation of Autonomous Healing of Geopolymer Composites. Infrastructures 2021, 6, 94. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U. Past and present techniques of self-healing in cementitious materials: A critical review on the efficiency of implemented treatments. J. Mater. Res. Technol. 2020, 9, 6883–6899. [Google Scholar] [CrossRef]

- Jogi, P.K.; Vara Lakshmi, T.V.S. Self-healing concrete based on different bacteria: A review. In Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; pp. 1246–1252. [Google Scholar] [CrossRef]

- Wu, M.; Johannesson, B.; Geiker, M. A review: Self-healing in cementitious materials and engineered cementitious composite as a self-healing material. Constr. Build. Mater. 2012, 28, 571–583. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Nelson, A.J.; Nehdi, M.L. Visualization and quantification of crack self-healing in cement-based materials incorporating different minerals. Cem. Concr. Compos. 2019, 103, 49–58. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Shah, K.W.; Dong, Z.; Wu, J. Performance evaluation and microstructure characterization of seawater and coral/sea sand alkali-activated mortars. Constr. Build. Mater. 2020, 259, 120403. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Cheng, Y.; Huseien, G.F.; Shah, K.W. Shrinkage mechanisms and shrinkage-mitigating strategies of alkali-activated slag composites: A critical review. Constr. Build. Mater. 2022, 318, 125993. [Google Scholar] [CrossRef]

- Hager, M.D.; Greil, P.; Leyens, C.; van der Zwaag, S.; Schubert, U.S. Self-Healing Materials. Adv. Mater. 2010, 22, 5424–5430. [Google Scholar] [CrossRef]

- Neville, A. Autogenous Healing—A Concrete Miracle? Concr. Int. 2002, 24, 76–82. [Google Scholar]

- Edvardsen, C. Water Permeability and Autogenous Healing of Cracks in Concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar] [CrossRef]

- Talaiekhozani, A.; Keyvanfar, A.; Shafaghat, A.; Andalib, R.; Abd Majid, M.; Fulazzaky, M.A.; Mohamad Zin, R.; Lee, C.T.; Hussin, M.; Hamzah, N.; et al. A Review of Self-healing Concrete Research Development. J. Environ. Treat. Tech. 2014, 2, 1–11. [Google Scholar]

- Van Tittelboom, K.; de Belie, N. Self-Healing in Cementitious Materials—A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [PubMed]

- Hammad, N.; El-Nemr, A.; El-Deen Hasan, H. The performance of fiber GGBS based alkali-activated concrete. J. Build. Eng. 2021, 42, 102464. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Karunasena, W.M.; Benmokrane, B.; Mendis, P.A. Comparison of the Shear Behaviour of Geopolymer Concrete Beams with Gfrp and Steel Transverse Reinforcements. In Proceedings of the Joint Conference of the 12th International Symposium on Fiber Reinforced Polymers for Reinforced Concrete Structures (FRPRCS-12) & the 5th Asia-Pacific Conference on Fiber Reinforced Polymers in Structures (APFIS-2015), Nanjing, China, 14–16 December 2015. [Google Scholar]

- Zhang, L.V.; Suleiman, A.R.; Mehdizadeh Allaf, M.; Marani, A.; Tuyan, M.; Nehdi, M.L. Crack self-healing in alkali-activated slag composites incorporating immobilized bacteria. Constr. Build. Mater. 2022, 326, 126842. [Google Scholar] [CrossRef]

- Hammad, N.; El Nemr, A.M.; Hassan, H.E.D. Flexural performance of reinforced Alkali-activated concrete beams incorporating steel and structural Macro synthetic polypropylene fiber. Constr. Build. Mater. 2022, 324, 126634. [Google Scholar] [CrossRef]

- Cartwright, C.; Rajabipour, F.; Radlińska, A. Shrinkage Characteristics of Alkali-Activated Slag Cements. J. Mater. Civ. Eng. 2015, 27, B4014007. [Google Scholar] [CrossRef]

- Mastali, M.; Kinnunen, P.; Dalvand, A.; Mohammadi Firouz, R.; Illikainen, M. Drying shrinkage in alkali-activated binders—A critical review. Constr. Build. Mater. 2018, 190, 533–550. [Google Scholar] [CrossRef]

- Amin, M.N.; Kim, J.-S.; Dat, T.T.; Kim, J.-K. Improving test methods to measure early age autogenous shrinkage in concrete based on air cooling. IES J. A Civ. Struct. Eng. 2010, 3, 244–256. [Google Scholar] [CrossRef]

- Collins, F.; Sanjayan, J.G. Effect of pore size distribution on drying shrinking of alkali-activated slag concrete. Cem. Concr. Res. 2000, 30, 1401–1406. [Google Scholar] [CrossRef]

- Humad, A.M.; Habermehl-Cwirzen, K.; Cwirzen, A. Effects of fineness and chemical composition of blast furnace slag on properties of Alkali-Activated Binder. Materials 2019, 12, 3447. [Google Scholar] [CrossRef]

- Li, Z.; Lu, T.; Chen, Y.; Wu, B.; Ye, G. Prediction of the autogenous shrinkage and microcracking of alkali-activated slag and fly ash concrete. Cem. Concr. Compos. 2021, 117, 103913. [Google Scholar] [CrossRef]

- Zhang, L.v.; Marani, A.; Nehdi, M.L. Chemistry-informed machine learning prediction of compressive strength for alkali-activated materials. Constr. Build. Mater. 2022, 316, 126103. [Google Scholar] [CrossRef]

- Shi, Z.; Shi, C.; Wan, S.; Zhang, Z. Effects of alkali dosage and silicate modulus on alkali-silica reaction in alkali-activated slag mortars. Cem. Concr. Res. 2018, 111, 104–115. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali-activated geopolymer concrete with recycled aggregate. Compos. B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Awoyera, P.; Adesina, A. A critical review on application of alkali-activated slag as a sustainable composite binder. Case Stud. Constr. Mater. 2019, 11, e00268. [Google Scholar] [CrossRef]

- Khan, I.; Xu, T.; Castel, A.; Gilbert, R.I.; Babaee, M. Risk of early age cracking in geopolymer concrete due to restrained shrinkage. Constr. Build. Mater. 2019, 229, 116840. [Google Scholar] [CrossRef]

- Kheradmand, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Shrinkage Performance of Fly Ash Alkali-activated Cement Based Binder Mortars. KSCE J. Civ. Eng. 2018, 22, 1854–1864. [Google Scholar] [CrossRef]

- Collins, F.; Sanjayan, J.G. Cracking tendency of alkali-activated slag concrete subjected to restrained shrinkage. Cem. Concr. Res. 2000, 30, 791–798. [Google Scholar] [CrossRef]

- AS 1012.13:2015; Methods of Testing Concrete Determination of the Drying Shrinkage of Concrete for Samples Prepared in the Field or the Laboratory. Standards Australia: Sydney, Australia, 2015.

- Chen, W.; Li, B.; Wang, J.; Thom, N. Effects of alkali dosage and silicate modulus on autogenous shrinkage of alkali-activated slag cement paste. Cem. Concr. Res. 2021, 141, 106322. [Google Scholar] [CrossRef]

- He, J.; Bai, W.; Zheng, W.; He, J.; Sang, G. Influence of hydrated lime on mechanical and shrinkage properties of alkali-activated slag cement. Constr. Build. Mater. 2021, 289, 123201. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A. Shrinkage mitigation strategies in alkali-activated slag. Cem. Concr. Res. 2017, 101, 131–143. [Google Scholar] [CrossRef]

- Ma, Y.; Yang, X.; Hu, J.; Zhang, Z.; Wang, H. Accurate determination of the ‘time-zero’ of autogenous shrinkage in alkali-activated fly ash/slag system. Compos. B Eng. 2019, 177, 107367. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Effect of activator type and content on properties of alkali-activated slag mortars. Compos. B Eng. 2014, 57, 166–172. [Google Scholar] [CrossRef]

- Li, Z.; Nedeljković, M.; Chen, B.; Ye, G. Mitigating the autogenous shrinkage of alkali-activated slag by metakaolin. Cem. Concr. Res. 2019, 122, 30–41. [Google Scholar] [CrossRef]

- Seo, J.; Kim, S.; Park, S.; Bae, S.J.; Lee, H.K. Microstructural evolution and carbonation behavior of lime-slag binary binders. Cem. Concr. Compos. 2021, 119, 104000. [Google Scholar] [CrossRef]

- Puertas, F.; González-Fonteboa, B.; González-Taboada, I.; Alonso, M.M.; Torres-Carrasco, M.; Rojo, G.; Martínez-Abella, F. Alkali-activated slag concrete: Fresh and hardened behavior. Cem. Concr. Compos. 2018, 85, 22–31. [Google Scholar] [CrossRef]

- Herbert, E.N. Development and Application of Self-Healing Engineered Cementitious Composites (ECC) for Durable and Sustainable Infrastructure. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2016. [Google Scholar]

- Han, N.-X.; Xing, F. A Comprehensive Review of the Study and Development of Microcapsule Based Self-Resilience Systems for Concrete Structures at Shenzhen University. Materials 2016, 10, 2. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Parks, J.; Edwards, M.; Vikesland, P.; Dudi, A. Effects of Bulk Water Chemistry on Autogenous Healing of Concrete. J. Mater. Civ. Eng. 2010, 22, 515–524. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, E.-H.; Li, V.C. Autogenous healing of engineered cementitious composites at an early age. Cem. Concr. Res. 2011, 41, 176–183. [Google Scholar] [CrossRef]

- Qian, C.X.; Luo, M.; Ren, L.F.; Wang, R.X.; Li, R.Y.; Pan, Q.F.; Chen, H.C. Self-Healing and Repairing Concrete Cracks Based on Bio-Mineralization. Key Eng. Mater. 2014, 629, 494–503. [Google Scholar] [CrossRef]

- Wang, J.Y.; de Belie, N.; Verstraete, W. Diatomaceous earth as a protective vehicle for bacteria applied for self-healing concrete. J. Ind. Microbiol. Biotechnol. 2012, 39, 567–577. [Google Scholar] [CrossRef]

- Achal, V.; Mukerjee, A.; Sudhakara Reddy, M. Biogenic treatment improves the durability and remediates the cracks of concrete structures. Constr. Build. Mater. 2013, 48, 1–5. [Google Scholar] [CrossRef]

- Dong, B.; Han, N.; Zhang, M.; Wang, X.; Cui, H.; Xing, F. A Microcapsule Technology Based Self-Healing System for Concrete Structures. J. Earthq. Tsunami 2013, 7, 1350014. [Google Scholar] [CrossRef]

- Mostavi, E.; Asadi, S.; Hassan, M.M.; Alansari, M. Evaluation of Self-Healing Mechanisms in Concrete with Double-Walled Sodium Silicate Microcapsules. J. Mater. Civ. Eng. 2015, 27, 04015035. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G.; Damidot, D. Effect of blast furnace slag on self-healing of microcracks in cementitious materials. Cem. Concr. Res. 2014, 60, 68–82. [Google Scholar] [CrossRef]

- Stuckrath, C.; Serpell, R.; Valenzuela, L.M.; Lopez, M. Quantification of chemical and biological calcium carbonate precipitation: Performance of self-healing in a reinforced mortar containing chemical admixtures. Cem. Concr. Compos. 2014, 50, 10–15. [Google Scholar] [CrossRef]

- De Rooij, M.; van Tittelboom, K.; de Belie, N.; Schlangen, E. Self-Healing Phenomena in Cement-Based Materials; Springer: Dordrecht, The Netherlands, 2013; Volume 11. [Google Scholar] [CrossRef]

- Rajczakowska, M. Self-Healing Concrete. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2019. [Google Scholar]

- Zhang, L.V.; Suleiman, A.R.; Nehdi, M.L. Crack Self-Healing in NaOH-Activated Slag-Based Composites Incorporating Calcium Hydroxide. J. Mater. Civ. Eng. 2021, 33, 04021012. [Google Scholar] [CrossRef]

- Zhang, L.V.; Nehdi, M.L.; Suleiman, A.R.; Allaf, M.M.; Gan, M.; Marani, A.; Tuyan, M. Crack self-healing in bio-green concrete. Compos. B Eng. 2021, 227, 109397. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Kim, T. Assessment of Construction Cost Saving by Concrete Mixing the Activator Material. Sustainability 2016, 8, 403. [Google Scholar] [CrossRef]

- Nguy, H.H.; Choi, J.I.; Kim, H.K.; Lee, B.Y. Effects of the type of activator on the self-healing ability of fiber-reinforced alkali-activated slag-based composites at an early age. Constr. Build. Mater. 2019, 224, 980–994. [Google Scholar] [CrossRef]

- Zhang, L.V.; Suleiman, A.R.; Nehdi, M.L. Self-healing in fiber-reinforced alkali-activated slag composites incorporating different additives. Constr. Build. Mater. 2020, 262, 120059. [Google Scholar] [CrossRef]

- Nguy, H.H.; Choi, J.I.; Song, K.I.; Song, J.K.; Huh, J.; Lee, B.Y. Self-healing properties of cement-based and alkali-activated slag-based fiber-reinforced composites. Constr. Build. Mater. 2018, 165, 801–811. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Pang, J.W.C.; Bond, I.P. ‘Bleeding composites’—Damage detection and self-repair using a biomimetic approach. Compos. Part A Appl. Sci. Manuf. 2005, 36, 183–188. [Google Scholar] [CrossRef]

- Joseph, C.; Jefferson, A.D.; Cantoni, M. Issues relating to the autonomic healing of cementitious materials. In Proceedings of the First International Conference on Self Healing Materials, Noordwijk aan Zee, The Netherlands, 18–20 April 2007. [Google Scholar]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797. [Google Scholar] [CrossRef]

- Wang, X.; Sun, P.; Han, N.; Xing, F. Experimental Study on Mechanical Properties and Porosity of Organic Microcapsules Based Self-Healing Cementitious Composite. Materials 2017, 10, 20. [Google Scholar] [CrossRef]

- Xiong, W.; Tang, J.; Zhu, G.; Han, N.; Schlangen, E.; Dong, B.; Wang, X.; Xing, F. A novel capsule-based self-recovery system with a chloride ion trigger. Sci. Rep. 2015, 5, 10866. [Google Scholar] [CrossRef]

- Gilford, J.; Hassan, M.M.; Rupnow, T.; Barbato, M.; Okeil, A.; Asadi, S. Dicyclopentadiene and Sodium Silicate Microencapsulation for Self-Healing of Concrete. J. Mater. Civ. Eng. 2014, 26, 886–896. [Google Scholar] [CrossRef]

- Grantham, M.; Basheer, P.A.M.; Magee, B.; Soutsos, M. Concrete Solutions 2014; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Giannaros, P.; Kanellopoulos, A.; Al-Tabbaa, A. Sealing of cracks in cement using microencapsulated sodium silicate. Smart Mater. Struct. 2016, 25, 84005. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Giannaros, P.; Al-Tabbaa, A. The effect of varying volume fraction of microcapsules on fresh, mechanical and self-healing properties of mortars. Constr. Build. Mater. 2016, 122, 577–593. [Google Scholar] [CrossRef]

- Milla, J.; Hassan, M.M.; Rupnow, T.; Al-Ansari, M.; Arce, G. Effect of Self-Healing Calcium Nitrate Microcapsules on Concrete Properties. Transp. Res. Rec. J. Transp. Res. Board 2016, 2577, 69–77. [Google Scholar] [CrossRef]

- Hassan, M.M.; Milla, J.; Rupnow, T.; Al-Ansari, M.; Daly, W.H. Microencapsulation of Calcium Nitrate for Concrete Applications. Transp. Res. Rec. J. Transp. Res. Board 2016, 2577, 8–16. [Google Scholar] [CrossRef]

- Al-Ansari, M.; Abu-Taqa, A.G.; Hassan, M.M.; Senouci, A.; Milla, J. Performance of modified self-healing concrete with calcium nitrate microencapsulation. Constr. Build. Mater. 2017, 149, 525–534. [Google Scholar] [CrossRef]

- Wang, J.Y.; Snoeck, D.; van Vlierberghe, S.; Verstraete, W.; de Belie, N. Application of hydrogel encapsulated carbonate precipitating bacteria for approaching a realistic self-healing in concrete. Constr. Build. Mater. 2014, 68, 110–119. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Ryou, J.-S. Self-healing behavior for crack closing of the expansive agent via granulation/film coating method. Constr. Build. Mater. 2014, 71, 188–193. [Google Scholar] [CrossRef]

- Tan, N.P.B.; Keung, L.H.; Choi, W.H.; Lam, W.C.; Leung, H.N. Silica-based self-healing microcapsules for self-repair in concrete. J. Appl. Polym. Sci. 2016, 133, 43090. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Kanellopoulos, A.; Al-Tabbaa, A. Encapsulation of expansive powder minerals within a concentric glass capsule system for self-healing concrete. Constr. Build. Mater. 2016, 121, 629–643. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of bacteria as self-healing agent for the development of sustainable concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Jonkers, H.M. Self Healing Concrete: A Biological Approach. In Self Healing Materials: An Alternative Approach to 20 Centuries of Materials Science; Springer: Dordrecht, The Netherlands, 2007. [Google Scholar]

- Luhar, S.; Gourav, S. A review paper on self-healing concrete Solid Waste Management View project Development of an Innovative Insulation Fire Resistant Facade from the Construction and Demolition Wastes (DEFEAT) View project Salmabanu Luhar A Review Paper on Self Healing Concrete. J. Civ. Eng. Res. 2015, 2015, 53–58. [Google Scholar]

- Reinhardt, H.-W.; Jooss, M. Permeability and self-healing of cracked concrete as a function of temperature and crack width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- De Muynck, W.; Cox, K.; de Belie, N.; Verstraete, W. Bacterial carbonate precipitation as an alternative surface treatment for concrete. Constr. Build. Mater. 2008, 22, 875–885. [Google Scholar] [CrossRef]

- De Koster, S.A.L.; Mors, R.M.; Nugteren, H.W.; Jonkers, H.M.; Meesters, G.M.H.; van Ommen, J.R. Geopolymer Coating of Bacteria-containing Granules for Use in Self-healing Concrete. Procedia Eng. 2015, 102, 475–484. [Google Scholar] [CrossRef]

- Paine, K. Bacteria-based self-healing concrete: Effects of environment, exposure, and crack size. In Proceedings of the RILEM Conference on Microorganisms-Cementitious Materials Interactions, Delft, The Netherlands, 23 June 2016; RILEM Publications: Champs-sur-Marne, France, 2016. [Google Scholar]

- Palin, D. A Cost-Effective Bacteria-Based Self-Healing Cementitious Composite for Low-Temperature Marine Applications. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Khan, M.B.E. Self-Healing Performance of Bacteria-Based Mortar in Marine Environment Originality Statement. Ph.D. Thesis, The University of Sydney, Sydney, Australia, 2020. [Google Scholar]

- Pal, S.; Mohanty, I.; Panda, I. Self-healing Conventional Concrete Using Bacteria. In Recent Developments in Sustainable Infrastructure: Select Proceedings of ICRDSI 2019; Springer: Singapore, 2021; pp. 441–451. [Google Scholar] [CrossRef]

- Vijay, K.; Murmu, M.; Deo, S.v. Bacteria based self-healing concrete—A review. Constr. Build. Mater. 2017, 152, 1008–1014. [Google Scholar] [CrossRef]

- Bang, S.S.; Galinat, J.K.; Ramakrishnan, V. Calcite precipitation induced by polyurethane-immobilized Bacillus pasteurii. Enzym. Microb. Technol. 2001, 28, 404–409. [Google Scholar] [CrossRef]

- Chahal, N.; Siddique, R.; Rajor, A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Constr. Build. Mater. 2012, 28, 351–356. [Google Scholar] [CrossRef]

- Bayati, M.; Saadabadi, L.A. Efficiency of bacteria-based self-healing method in alkali-activated slag (AAS) mortars. J. Build. Eng. 2021, 42, 102492. [Google Scholar] [CrossRef]

- De Muynck, W.; de Belie, N.; Verstraete, W. Improvement of concrete durability with the aid of bacteria. In Proceedings of the First International Conference on Self Healing Materials, Noordwijk aan Zee, The Netherlands, 18–20 April 2007. [Google Scholar]

- Zhang, L.V.; Suleiman, A.R.; Marani, A. Comparative Study on Self-Healing Behavior of Alkali-Activated Composites and Cement-Based Materials. Available online: https://www.researchgate.net/publication/352552683 (accessed on 12 June 2023).

- Nosouhian, F.; Mostofinejad, D.; Hasheminejad, H. Concrete Durability Improvement in a Sulfate Environment Using Bacteria. J. Mater. Civ. Eng. 2016, 28, 04015064. [Google Scholar] [CrossRef]

- Burne, R.A.; Chen, Y.-Y.M. Bacterial ureases in infectious diseases. Microbes Infect. 2000, 2, 533–542. [Google Scholar] [CrossRef]

- Siddique, R.; Singh, K.; Kunal; Singh, M.; Corinaldesi, V.; Rajor, A. Properties of bacterial rice husk ash concrete. Constr. Build. Mater. 2016, 121, 112–119. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; da Silva, F.B.; Boon, N.; Verstraete, W.; de Belie, N. Screening of bacteria and concrete compatible protection materials. Constr. Build. Mater. 2015, 88, 196–203. [Google Scholar] [CrossRef]

- Zhang, L.V.; Suleiman, A.R.; Marani, A. Effect of Various Temperatures and Relative Humidity on Crack Self-Healing in Fiber-Reinforced Mortars Incorporating Crystalline Additives Application of Phase Change Materials in Concrete Walls for Energy Saving View project Novel Hybrid Firefly-ANN Model for Predicting Embodied Carbon and Cost of Post-Tensioned Slabs View Project. 2020. Available online: https://www.researchgate.net/publication/352552796 (accessed on 12 June 2023).

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).