Energy and Infrared Radiation Characteristics of the Sandstone Damage Evolution Process

Abstract

1. Introduction

2. Experimental Design

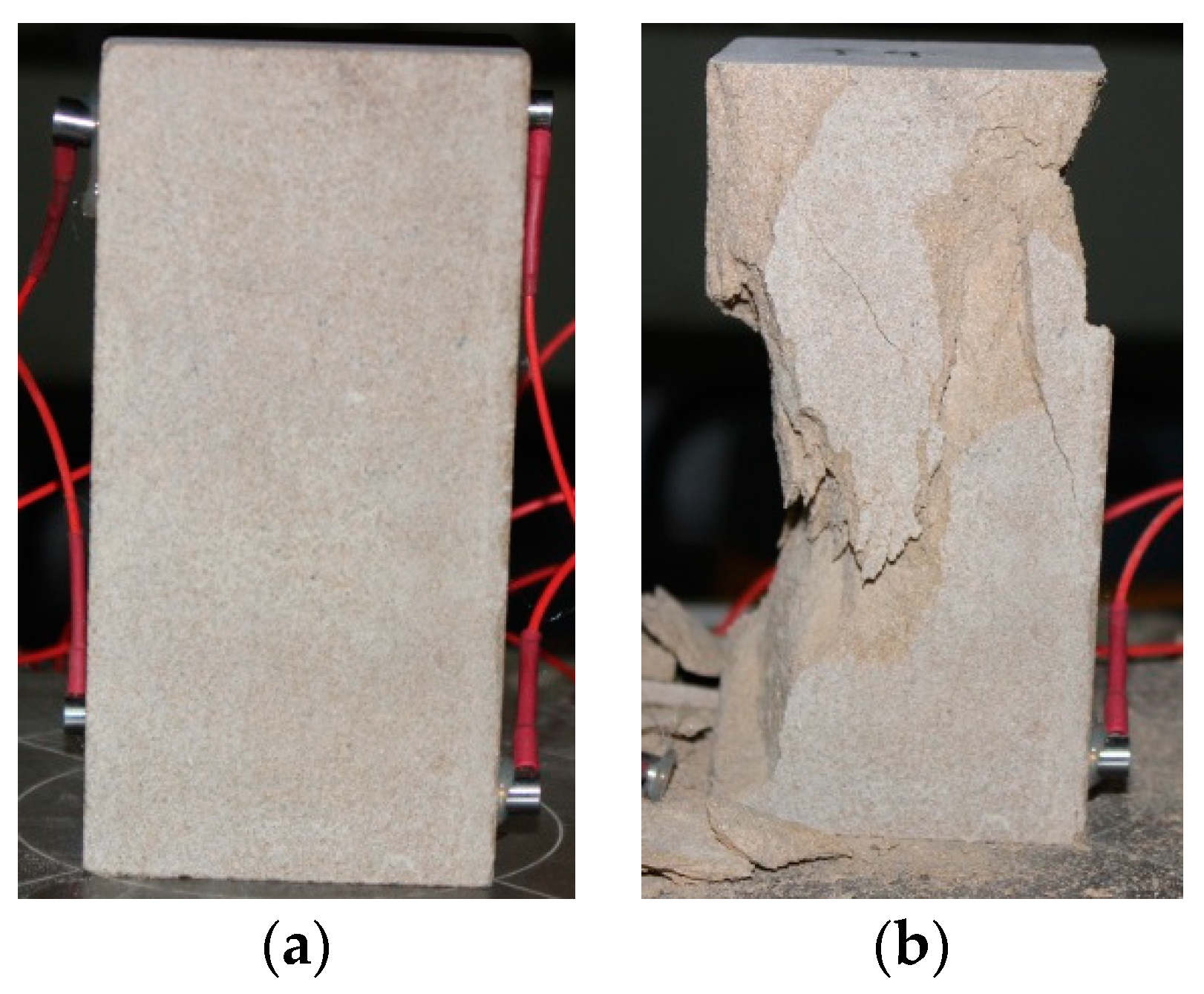

2.1. Experimental Samples

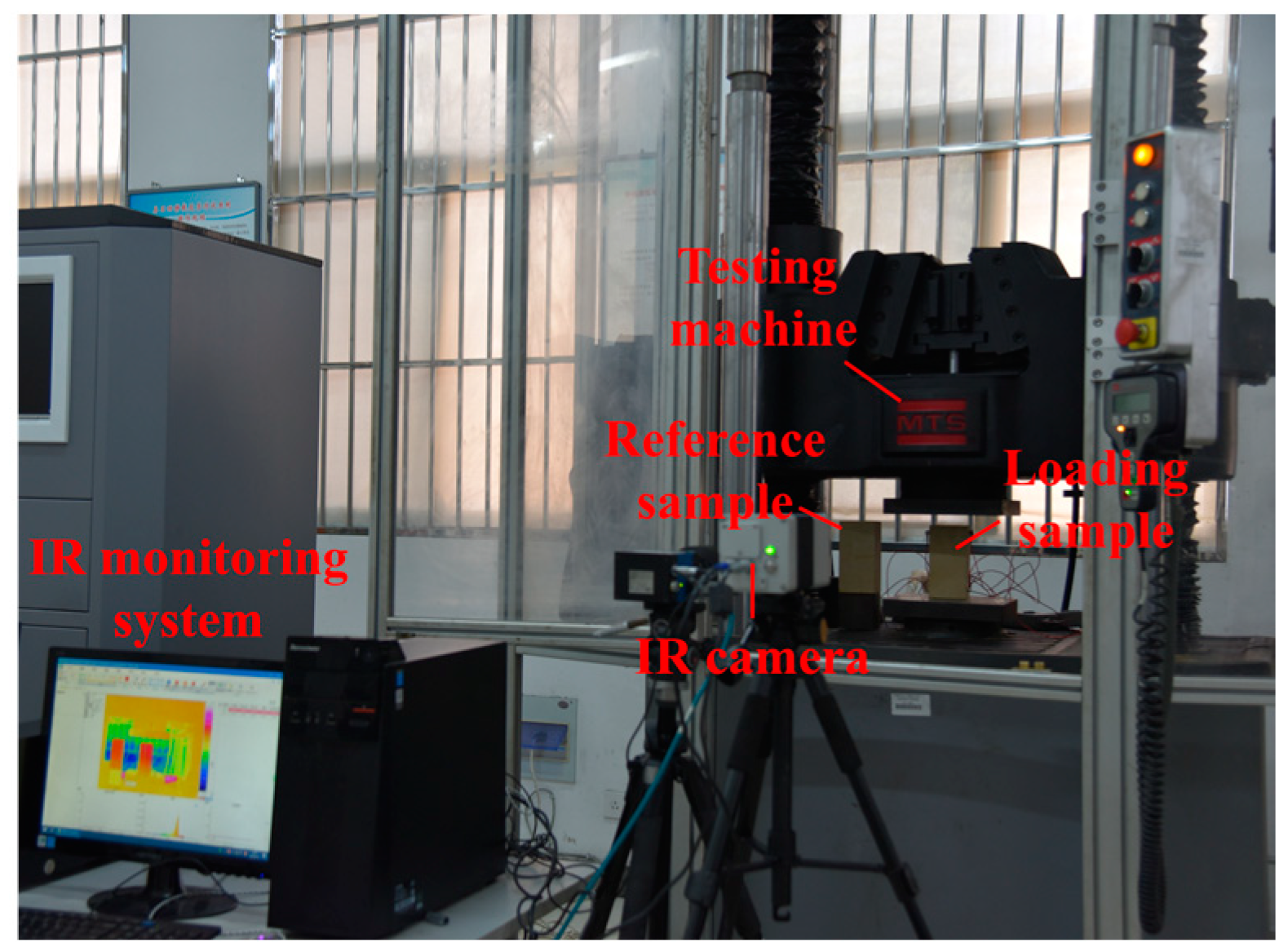

2.2. Experimental System and Method

3. Experimental Results and Analysis

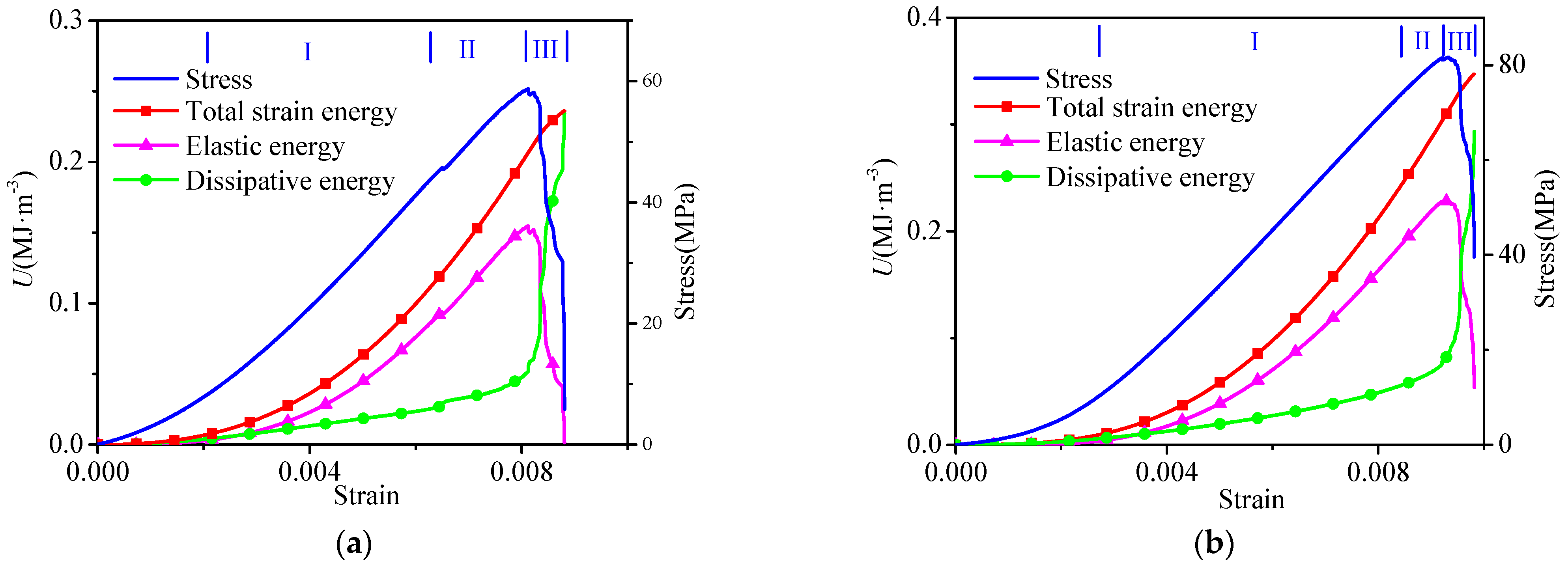

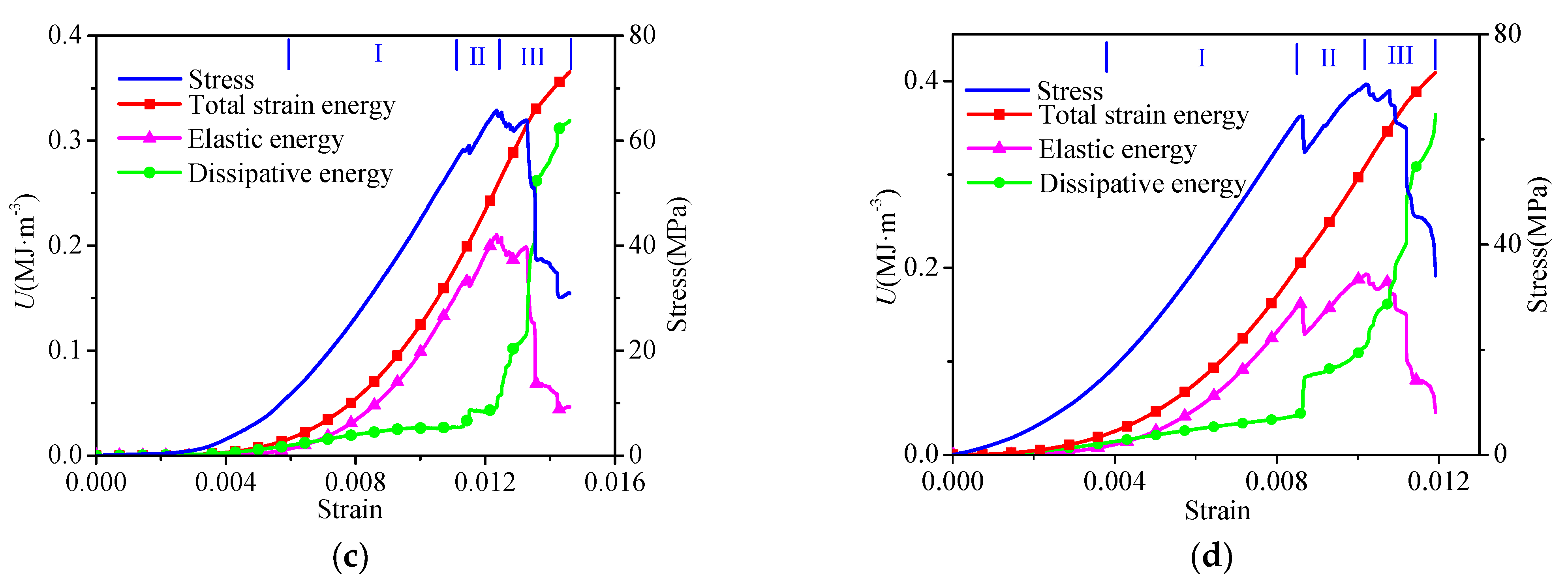

3.1. Variation Characteristics of Strain Energy in Sandstone Fracture Process

3.2. Infrared Radiation Characteristics of Sandstone Fracture Process

3.2.1. Infrared Radiation Index

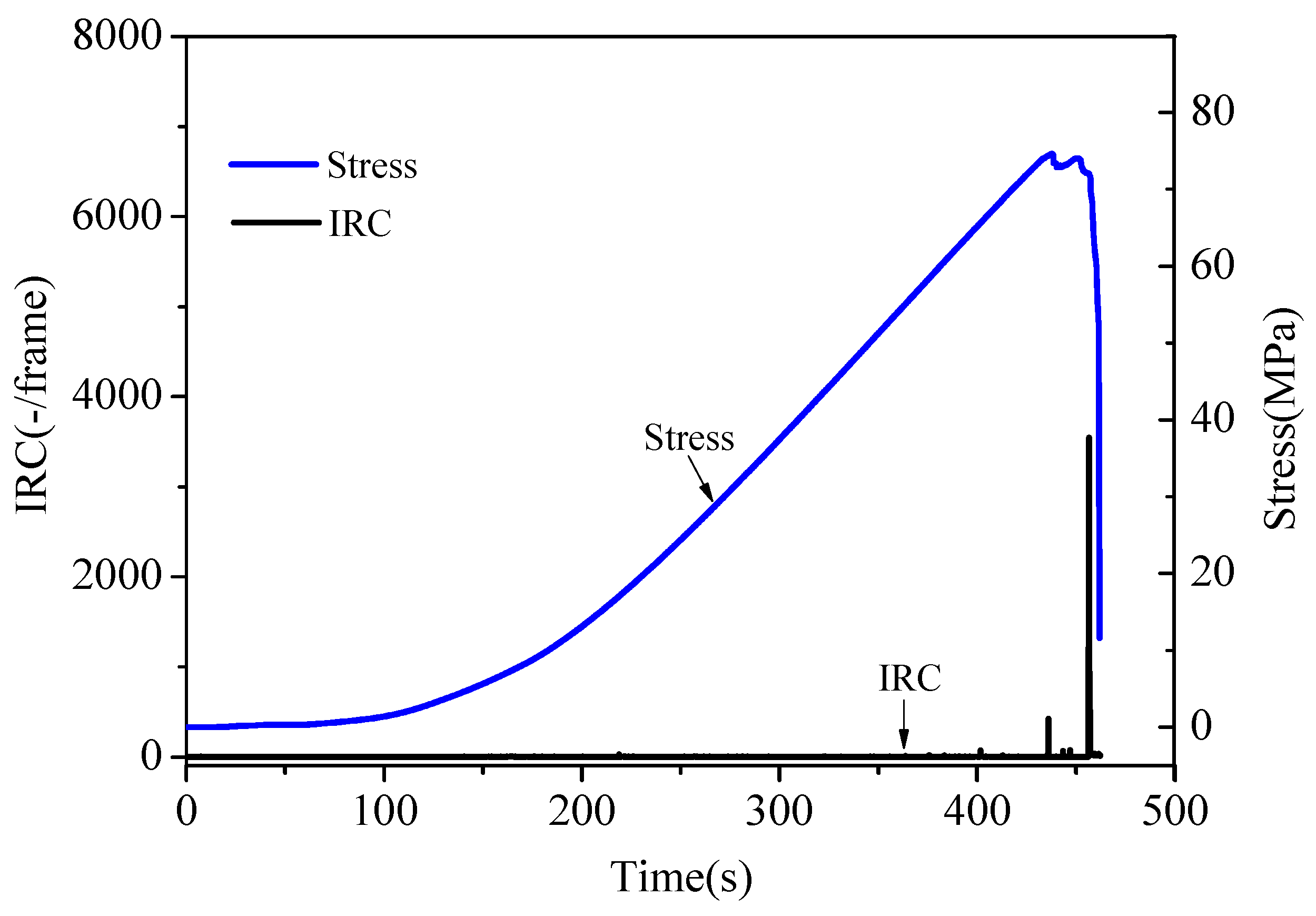

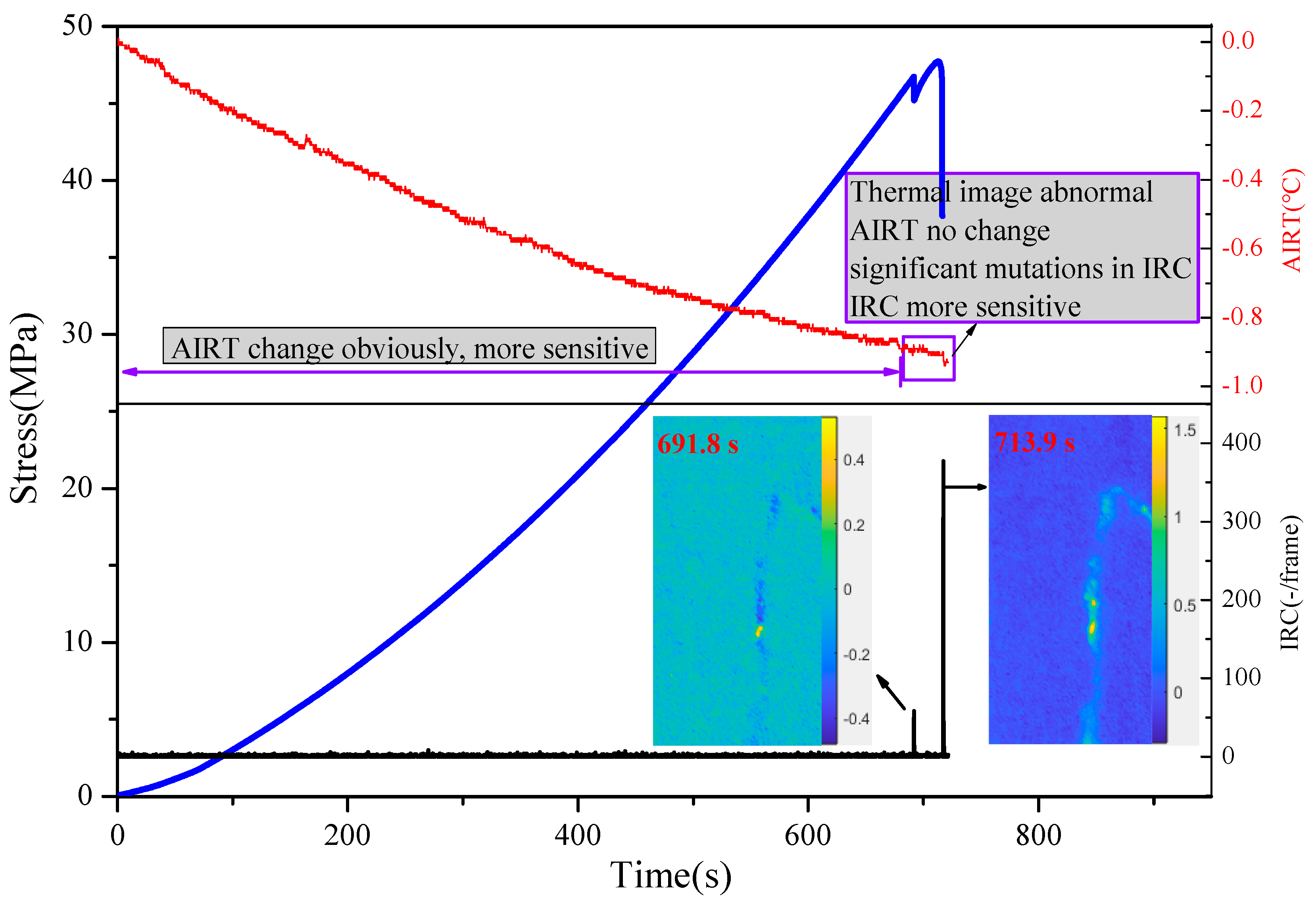

3.2.2. Characteristics of Infrared Radiation Time Sequence Change

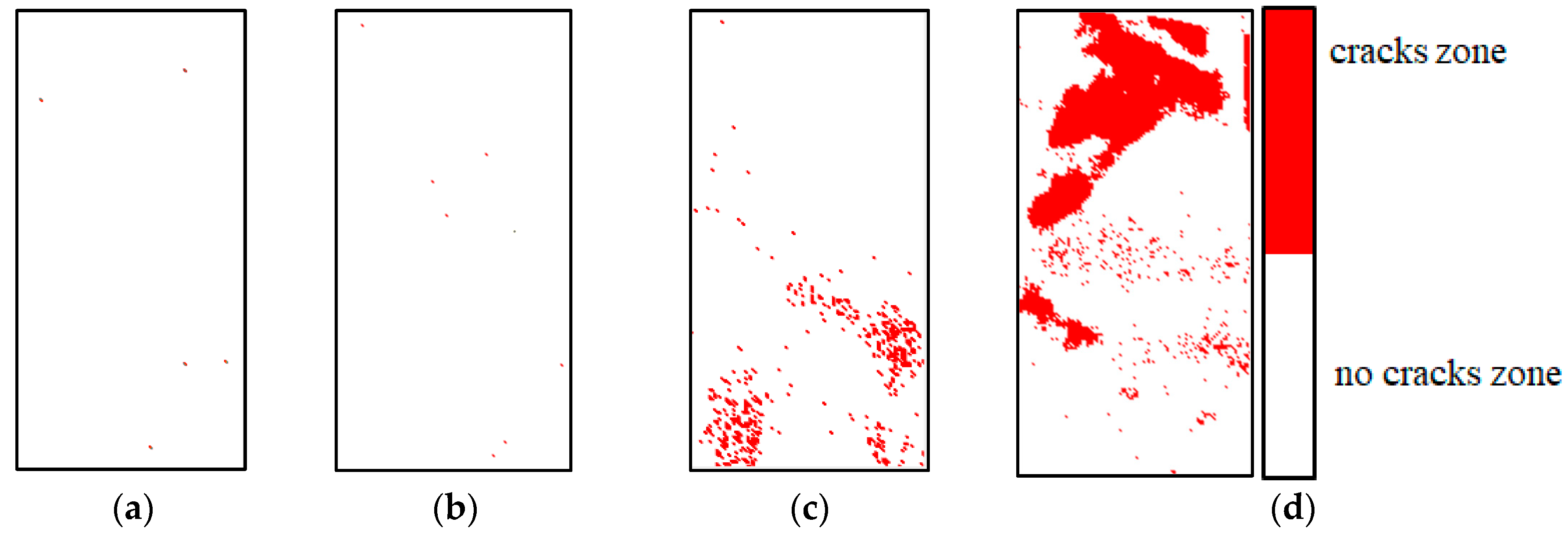

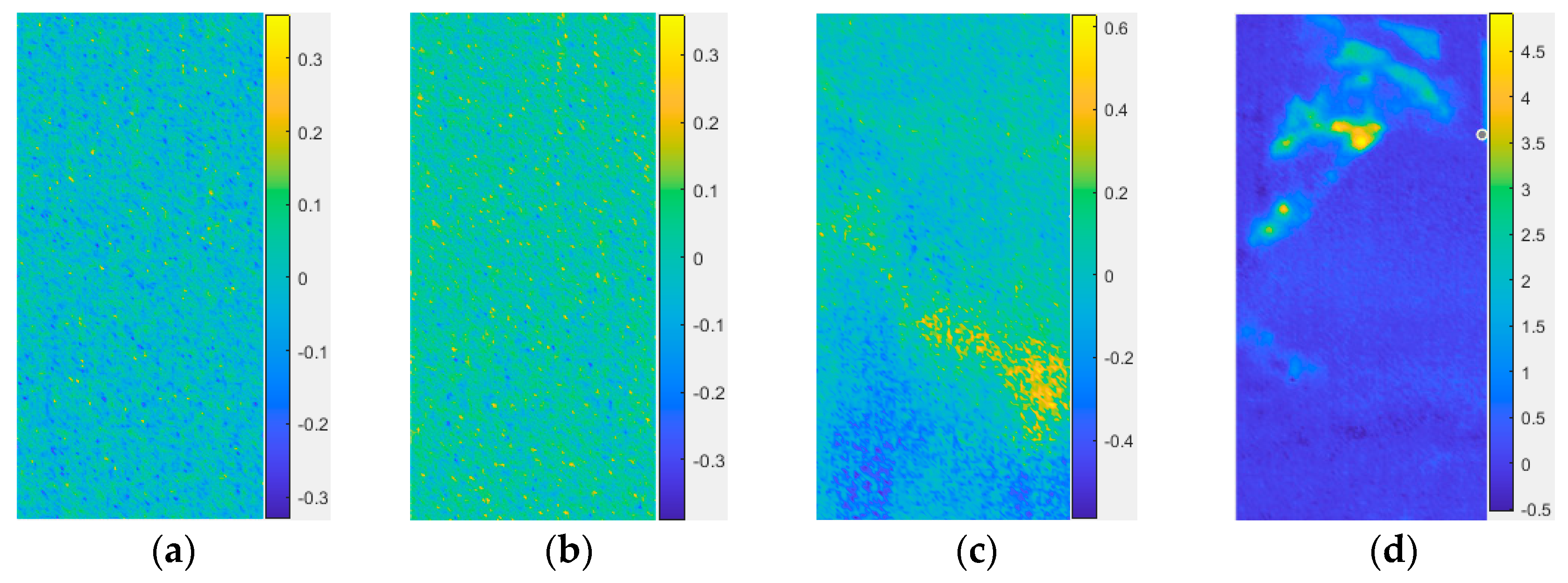

3.2.3. Spatial Variation Characteristics of Infrared Radiation

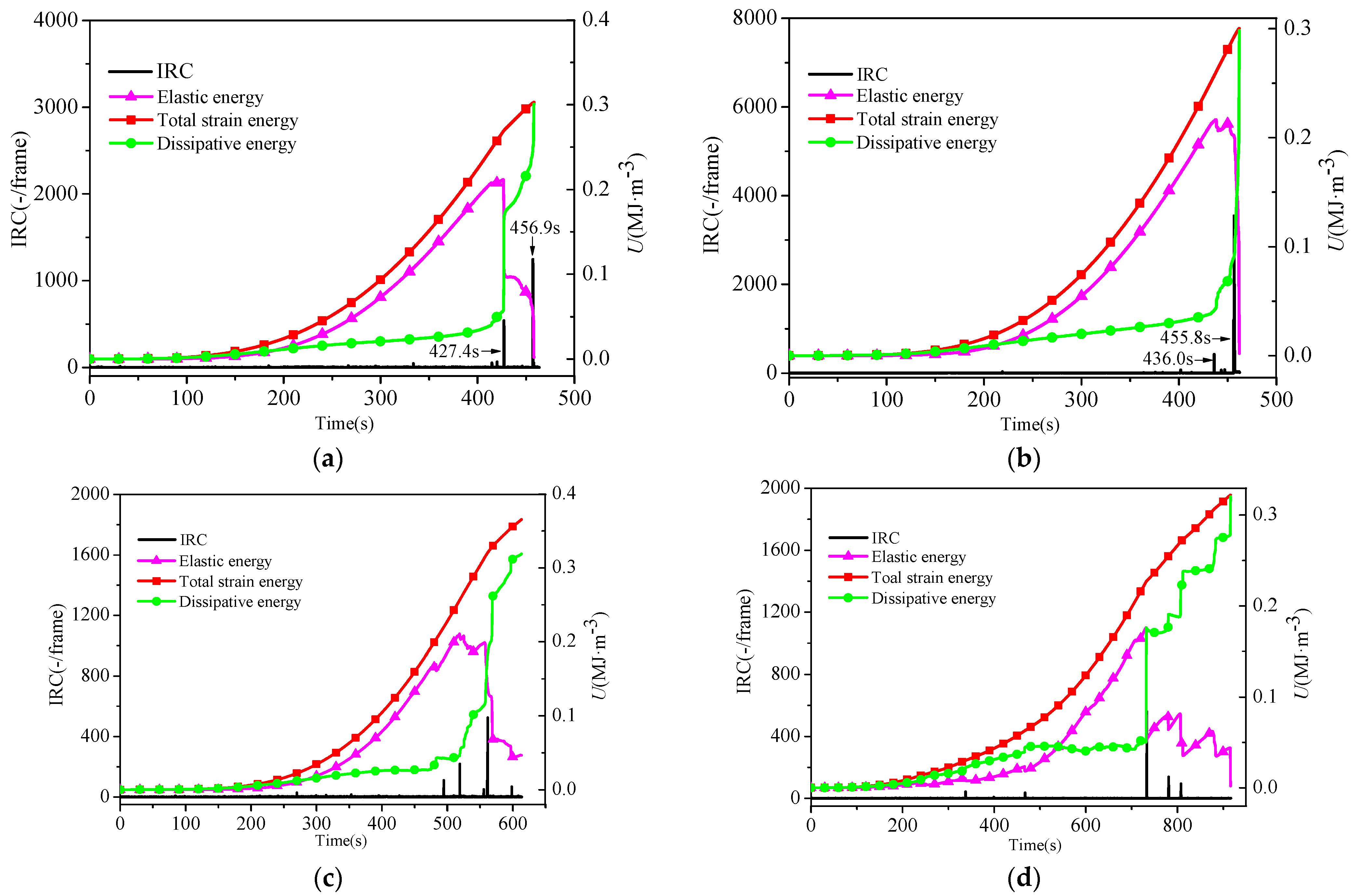

3.3. Correlation between Infrared Radiation and Strain Energy in Sandstone Loading Process

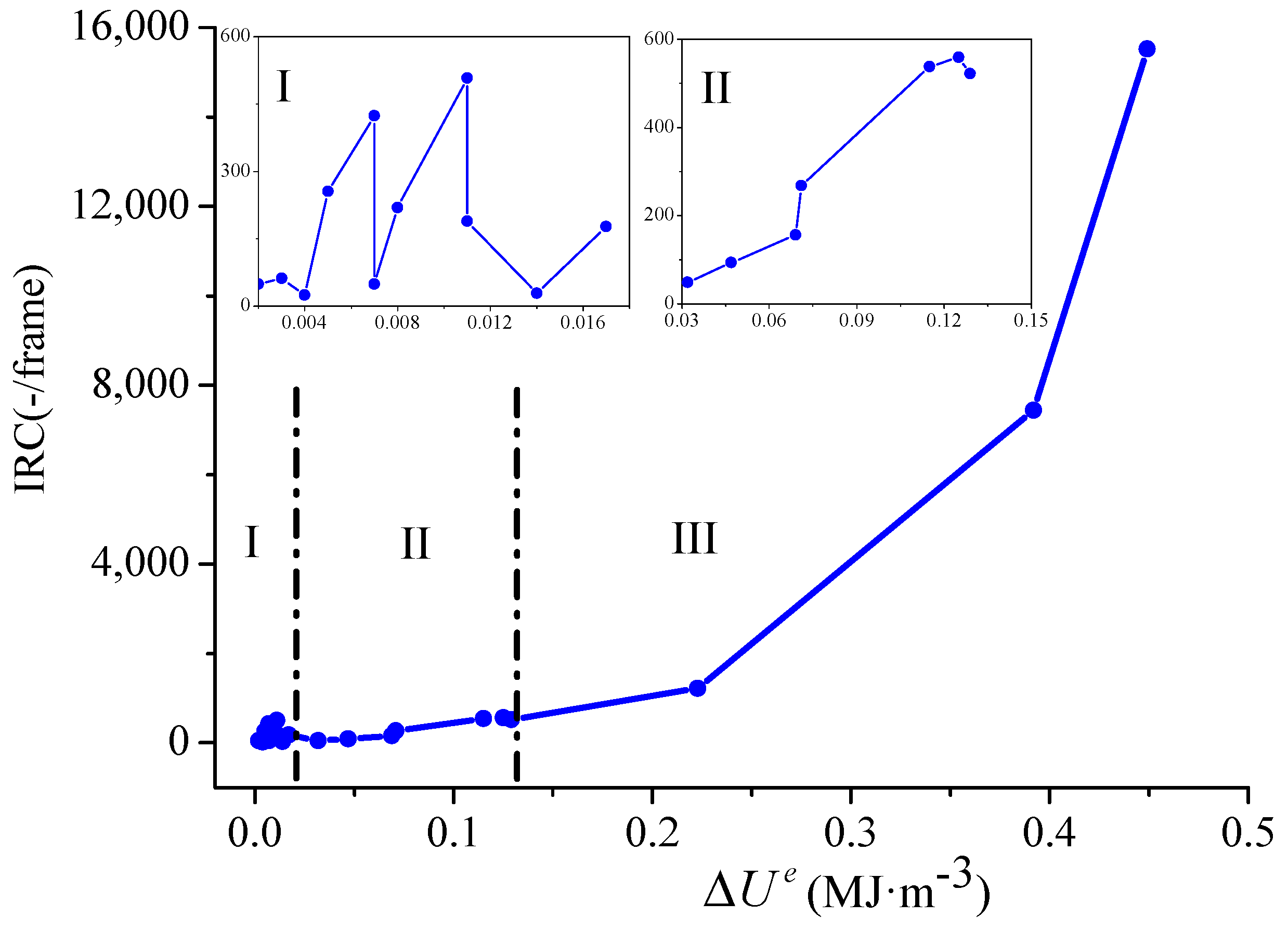

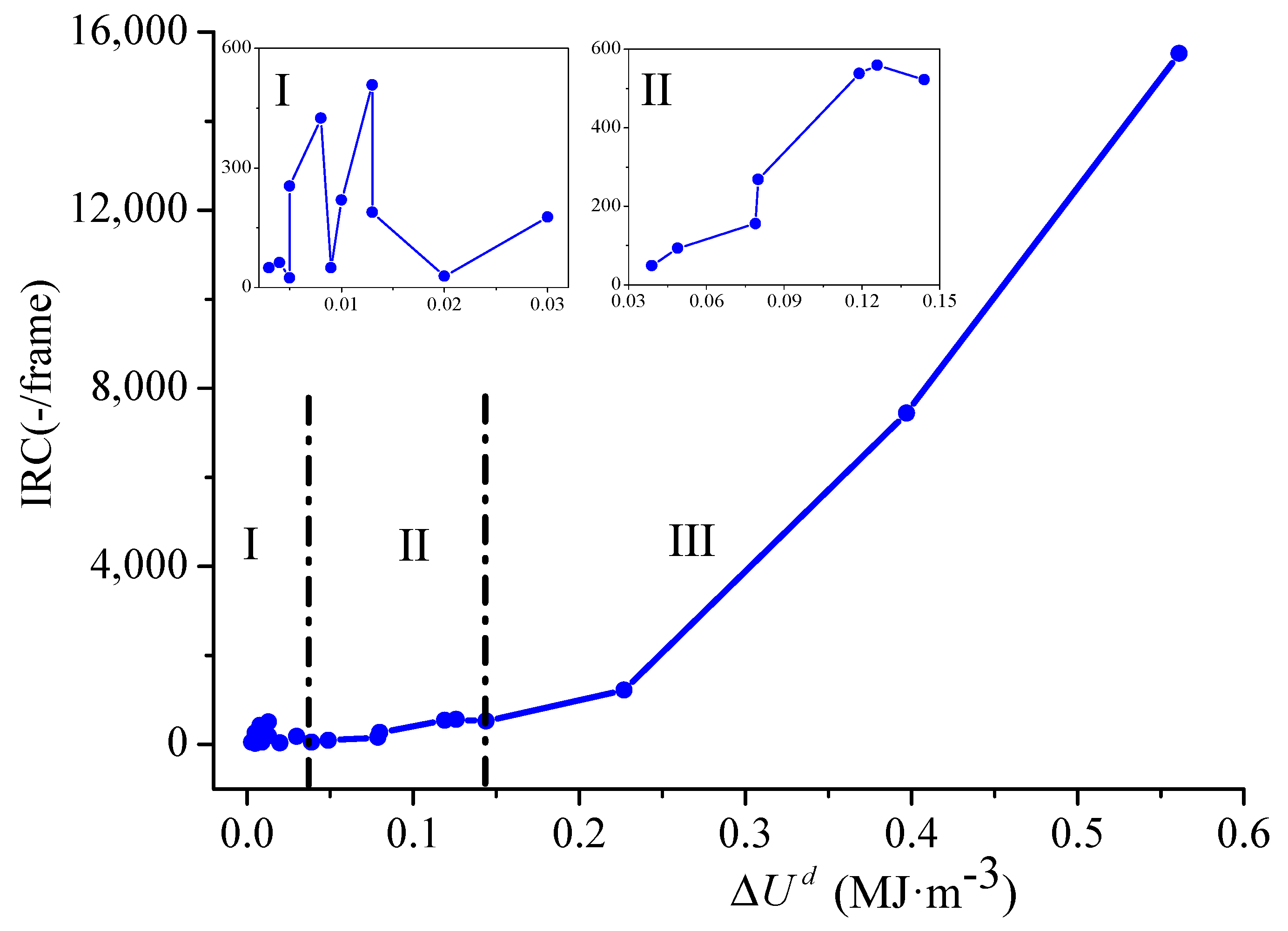

3.4. Quantitative Relationship between Infrared Radiation and Strain Energy in Sandstone Stress Drop

4. Discussion

4.1. Sensitivity Analysis of Infrared Radiation Index

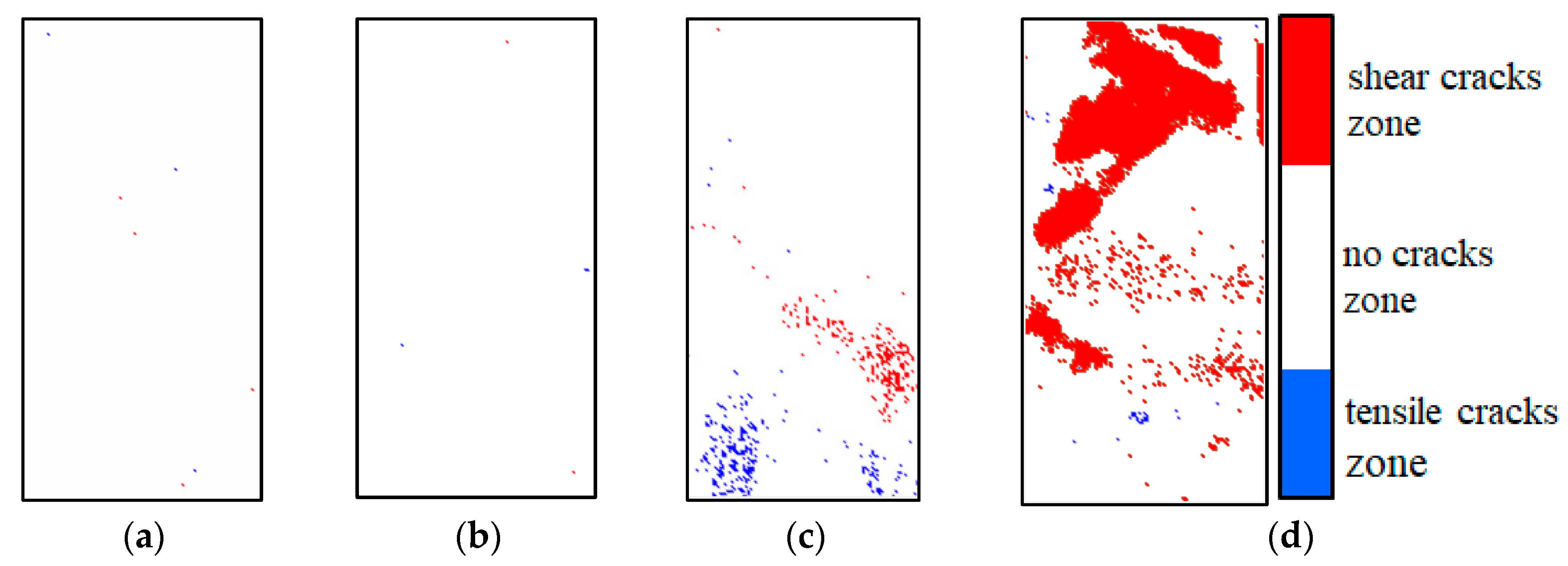

4.2. Identification of Location and Propagation Pattern of Sandstone Microcracks

4.3. Engineering Value and Practical Significance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| IRC | Infrared radiation counts |

| Variation in elastic energy | |

| Variation in dissipation energy | |

| Variation in IRC | |

| AIRT | Average infrared radiation temperature |

References

- Yang, T.H.; Tang, C.A.; Tan, Z.H.; Zhu, W.C.; Feng, Q.Y. State of the art of inrush models in rock mass failure and developing trend for prediction and forecast of grounwater inrush. Chin. J. Rock Mech. Eng. 2007, 26, 268–277. [Google Scholar]

- Shan, P.F.; Lai, X.P.; Cui, F.; Cao, J.T. Energy dissipation properties and mechanisms of fractured coal-rock mass failure under mining condition. J. Min. Saf. Eng. 2018, 35, 834–842. [Google Scholar]

- Xie, H.P.; Peng, R.D.; Ju, Y.; Zhou, H.W. On energy analysis of rock failure. Chin. J. Rock Mech. Eng. 2005, 24, 2603–2608. [Google Scholar]

- Zhao, Y.S.; Feng, Z.C.; Wan, Z.J. Least energy priciple of dynamical failure of rock mass. Chin. J. Rock Mech. Eng. 2003, 22, 1781–1783. [Google Scholar]

- Xie, H.; Ju, Y.; Li, L.; Peng, R. Energy mechanism of deformation and failure of rock masses. Chin. J. Rock Mech. Eng. 2008, 27, 1729–1740. [Google Scholar]

- Xie, H.P.; Ju, Y.; Li, L.Y. Citeria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin. J. Rock Mech. Eng. 2005, 24, 3003–3010. [Google Scholar]

- Liang, C.Y.; Li, X.; Wu, S.R. Research on energy characteristics of size effect of granite under low/intermediate strain rates. Rock Soil Mech. 2016, 37, 3472–3480. [Google Scholar]

- Chen, Z.Q.; He, C.; Ma, G.Y.; Xu, G.W.; Ma, C.C. Energy damage evolution mechanism of rock and its application to brittleness evaluation. Rock Mech. Rock Eng. 2019, 52, 1265–1274. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Gao, F. Experimental investigations on energy evolution characteristics of coal, sandstone and granite during loading process. J. China Univ. Min. Technol. 2015, 44, 416–422. [Google Scholar]

- Kong, C.Z.; Zhou, Z.Q.; Sun, T.; Jiang, Y.J.; Nan, X.C.; Zhu, X.; Zeng, P. Energy release and precursory characteristics during sandstone failure process. Water Res. Hydropower Eng. 2022, 53, 163–172. [Google Scholar]

- Salami, Y.Z.; Dano, C.; Hicher, P.Y. Infrared thermography of rock fracture. Géotech. Lett. 2017, 7, 36–40. [Google Scholar] [CrossRef]

- Hao, J.W.; Qiao, L.; Li, Z.J.; Li, Q.W. Analysis on rock fracture signals and exploration of infrared advance prediction under true triaxial loading. J. Mater. Civil. Eng. 2022, 34, 04022058. [Google Scholar] [CrossRef]

- Huang, J.W.; Liu, S.J.; Liu, W.F.; Zhang, C.J.; Li, S.P.; Yu, M.; Wu, L.X. Experimental study on the thermal infrared spectral variation of fractured rock. Remote Sens. 2021, 13, 1191. [Google Scholar] [CrossRef]

- Shen, R.; Li, H.; Wang, E.; Chen, T.; Li, T.; Tian, H.; Hou, Z. Infrared radiation characteristics and fracture precursor information extraction of loaded sandstone samples with varying moisture contents. Int. J. Rock Mech. Min. Sci. 2020, 130, 104344. [Google Scholar] [CrossRef]

- Cao, K.W.; Ma, L.Q.; Wu, Y.; Muhammad, K.N.; Spearing, A.J.S.; Sajjad, H.; Yang, J. Cyclic fatigue characteristics of rock failure using infrared radiation as precursor to violent failure: Experimental insights from loading and unloading response. Fatigue Fract. Eng. Mater. Struct. 2020, 44, 584–594. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Z.; Liu, L.; Chuai, X.; Lu, H. Predicting points of the infrared precursor for limestone failure under uniaxial compression. Int. J. Rock Min. Sci. 2016, 88, 34–43. [Google Scholar] [CrossRef]

- Lai, X.P.; Liu, X.M.; Shan, P.F.; Zhang, S.; Fang, X.W.; Xu, H.D. Study on thermal infrared radiation variation of fractured coal-rock mass failure during mining. J. Min. Saf. Eng. 2019, 36, 777–785. [Google Scholar]

- Cai, X.; Zhou, Z.L.; Tan, L.H.; Zhi, Z.H.; Song, Z.Y. Water saturation effects on thermal infrared radiation features of rock materials during deformation and fracturing. Rock Mech. Rock Eng. 2020, 53, 4839–4856. [Google Scholar] [CrossRef]

- Zhou, Z.L.; Liu, Y.; Cai, X.; Chang, Y.; Gao, S. Infrared radiation characteristics of sandstone exposed to impact loading. J. Cent. South Univ. (Sci. Technol.) 2022, 53, 2555–2562. [Google Scholar]

- Liu, S.J.; Wei, J.L.; Huang, J.W.; Wu, L.X.; Zhang, Y.B.; Tian, B.Z. Quantitative analysis methods of infrared radiation tempeature field variation in rock loading process. Chin. J. Rock Mech. Eng. 2015, 34, 2968–2976. [Google Scholar]

- Ma, L.Q.; Sun, H.; Zhang, Y.; Zhou, T.; Li, K. Characteristics of infrared radiation of coal specimens under uniaxial loading. Rock Mech. Rock Eng. 2016, 49, 1567–1572. [Google Scholar] [CrossRef]

- Wu, X.Z.; Gao, X.; Zhao, K.; Liu, J.W.; Liu, X.X. Abnormality of transient infrared temperature field (ITF) in the process of rock failure. Chin. J. Rock Mec. Eng. 2016, 35, 1578–1594. [Google Scholar]

- Sun, H.; Ma, L.Q.; Konietzky, H.; Du, Y.Y.; Wang, F. Characteristics and generation mechanisms of key infrared radiation signals during damage evolution in sandstone. Acta Geotech. 2022, 17, 1753–1763. [Google Scholar] [CrossRef]

- Huang, J.W.; Song, L.A.; Yu, M.; Zhang, C.J.; Li, S.P.; Li, Z.X.; Geng, J.; Zhang, C. Quantitative spatial analysis of thermal infrared radiation temperature fields by the standard deviational ellipse method for the uniaxial loading of sandstone. Infrared Phys. Technol. 2022, 234, 104150. [Google Scholar] [CrossRef]

- Sun, H.; Ma, L.Q.; Adeleke, N.; Zhang, Y. Background thermal noise correction methodology for average infrared radiation temperature of coal under uniaxial loading. Infrared Phys. Technol. 2017, 81, 157–165. [Google Scholar] [CrossRef]

- Shi, D.P.; Wang, J.M.; Xiong, L.C. Study on noise correction algorithm of infrared emissivity of rock under uniaxial compression. Sustainability 2022, 14, 12769. [Google Scholar] [CrossRef]

| Specimen No. | Peak Stress (MPa) | Elastic Modulus (104 MPa) |

|---|---|---|

| A1 | 71.27 | 1.2 |

| A2 | 74.62 | 1.3 |

| A3 | 58.92 | 1.4 |

| A4 | 43.64 | 1.1 |

| A5 | 81.80 | 1.1 |

| A6 | 53.08 | 1.1 |

| A7 | 47.77 | 1.0 |

| A8 | 58.56 | 0.4 |

| A9 | 62.94 | 1.3 |

| A10 | 70.52 | 1.3 |

| A11 | 96.31 | 1.4 |

| A12 | 106.56 | 1.4 |

| A13 | 65.69 | 1.5 |

| Sample No. | Stress Drop/Peak Stress | |||

|---|---|---|---|---|

| A1 | 0.002 | 0.003 | 49 | 99.09% |

| 0.003 | 0.004 | 62 | 99.67% | |

| 0.115 | 0.119 | 538 | 100.00% | |

| A2 | 0.007 | 0.008 | 424 | 100.00% |

| A3 | 0.223 | 0.227 | 1223 | 97.76% |

| A4 | 0.071 | 0.080 | 268 | 100.00% |

| 0.004 | 0.005 | 24 | 43.76% | |

| 0.007 | 0.009 | 49 | 34.63% | |

| A5 | 0.005 | 0.005 | 255 | 100.00% |

| A6 | 0.011 | 0.013 | 508 | 100.00% |

| A7 | 0.008 | 0.010 | 219 | 100.00% |

| 0.129 | 0.144 | 522 | 96.98% | |

| A8 | 0.125 | 0.126 | 559 | 100.00% |

| 0.047 | 0.049 | 94 | 68.01% | |

| A9 | 0.011 | 0.013 | 189 | 100.00% |

| A10 | 0.032 | 0.039 | 49 | 91.29% |

| 0.014 | 0.030 | 28 | 99.89% | |

| 0.069 | 0.079 | 156 | 88.51% | |

| A11 | 0.017 | 0.020 | 177 | 91.33% |

| A12 | 0.392 | 0.397 | 7442 | 100.00% |

| A13 | 0.449 | 0.561 | 15519 | 100.00% |

| Average | 0.083 | 0.092 | 1350.19 | 91% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Zhu, H.-Y.; Han, J.; Fu, C.; Chen, M.-M.; Wang, K. Energy and Infrared Radiation Characteristics of the Sandstone Damage Evolution Process. Materials 2023, 16, 4342. https://doi.org/10.3390/ma16124342

Sun H, Zhu H-Y, Han J, Fu C, Chen M-M, Wang K. Energy and Infrared Radiation Characteristics of the Sandstone Damage Evolution Process. Materials. 2023; 16(12):4342. https://doi.org/10.3390/ma16124342

Chicago/Turabian StyleSun, Hai, Hong-Yan Zhu, Jie Han, Chun Fu, Mi-Mi Chen, and Kun Wang. 2023. "Energy and Infrared Radiation Characteristics of the Sandstone Damage Evolution Process" Materials 16, no. 12: 4342. https://doi.org/10.3390/ma16124342

APA StyleSun, H., Zhu, H.-Y., Han, J., Fu, C., Chen, M.-M., & Wang, K. (2023). Energy and Infrared Radiation Characteristics of the Sandstone Damage Evolution Process. Materials, 16(12), 4342. https://doi.org/10.3390/ma16124342