Corrosion Stiction in Automotive Braking Systems

Abstract

1. Introduction

2. Brake Pad Constituents

- Binder: to hold the different components together;

- Structural modifiers: typically in the form of reinforcing fibers to provide mechanical strength;

- Friction modifiers: a combination of lubricants and abrasives to adjust the friction properties of the brake pad;

- Fillers: to facilitate the production of the brake pads and reduce their cost.

- to maintain a high friction coefficient with the rotor during braking;

- to retain sufficient stability at high temperatures;

- to maintain a stable friction coefficient under different braking conditions.

2.1. Binder

2.2. Reinforcing Fibers

2.2.1. Aramid Fibers

2.2.2. Metallic Fibers

2.2.3. Ceramic Fibers

2.3. Friction Additives

2.4. Fillers

3. Environmental Impact of Corrosion on Braking Systems

- reduction of the quantity of particulate matter released by the braking system (friction material);

- greater resistance to degradation due to wear compared to vehicles without a regenerative braking system related to the downsizing of the traditional braking system with less mass of the caliper and brake pad;

- reduction of corrosive phenomena of the brake disc to avoid premature wear of the disc–pad system and the phenomenon of stiction (sticking of the pad to the disc during use of the parking brake in environmental conditions of high humidity due to the corrosion of the brake disc).

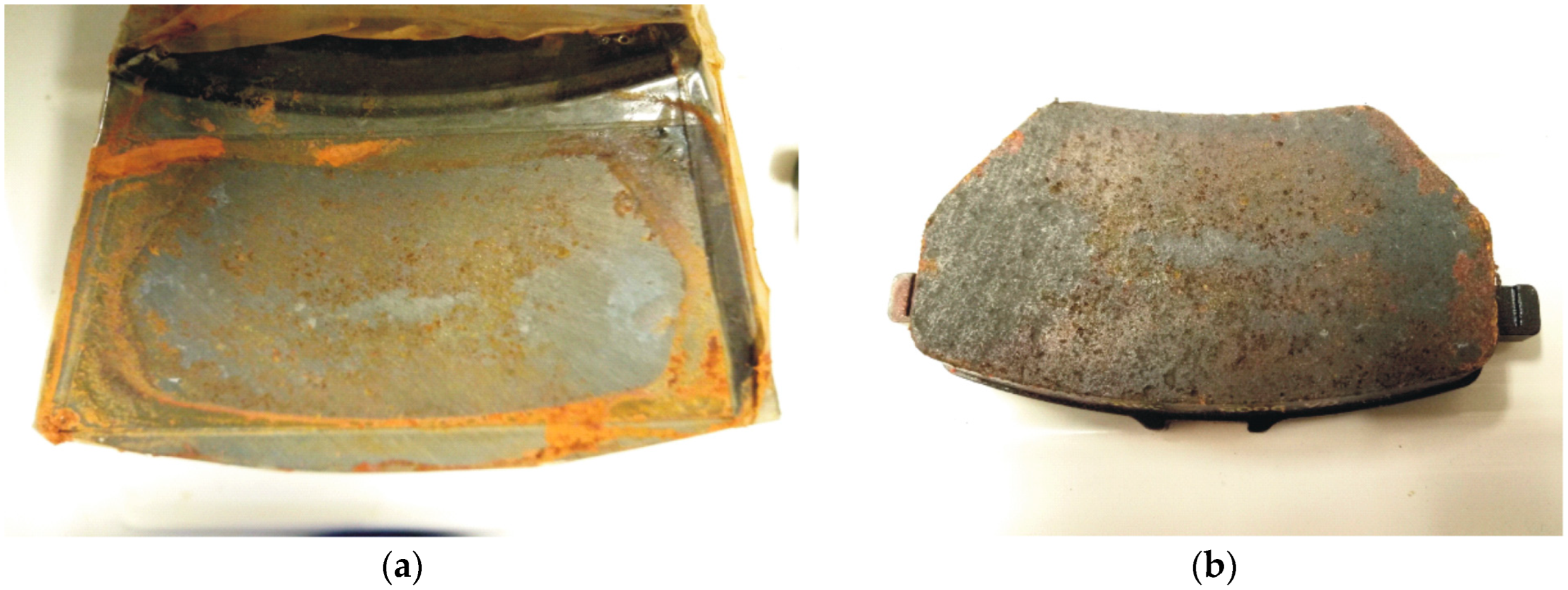

4. Corrosion-Related Phenomena in Braking Systems

4.1. Stick-Slip

4.2. Stiction

5. Effect of the Chemical and Physical Properties of the Friction Material on Stiction Behaviour

5.1. Applied Pressure and Contact Area at the Rotor–Pad Interface

5.2. pH

5.3. Porosity and Hydrophilic Behavior of the Friction Material

5.4. Mechanical Properties of the Friction Material

5.5. Local Galvanic-Coupling Effects with Metal-Based Constituents

6. Testing Methods to Investigate Stiction Phenomena

6.1. ISO 6315 Standard

- -

- Exposure in a humidity chamber at 95% ± 2% relative humidity and 50 °C ± 3 °C of the friction material for 4 h and of the brake disc for 30 min (friction materials and discs must be extracted from the chamber at the same time);

- -

- After removing surface moisture from the surfaces, the friction material must be clamped on the disc with a pressure of 2500 kPa;

- -

- The assembled friction materials and disc must be exposed in the humidity chamber for 16 h. After these are extracted from the chamber, they should dry at room temperature for 48 h;

- -

- After drying, the force to separate the friction material from the disc is measured in the radial direction.

6.2. Electrochemical Methods

6.3. Complementary Methods

7. Approaches to Control Corrosion Stiction in Braking Systems

7.1. Control of Chemical-Physical Properties of the Friction Material

- -

- Porosity of the friction material: although the effect of porosity is rather controversial in the literature, its control through proper selection of the binder and its content is very important [2,3,56,60]. Moreover, other constituents of the friction material such as vermiculite might affect the porosity of the friction material [56];

- -

- Mechanical properties of the friction material: friction materials with high stiffness and low compressibility are generally regarded as stiction-resistant materials due to their propensity to reduce the contact area at the pad–disc interface [2]. Proper tailoring of the mechanical properties of the friction material can significantly impact the stiction susceptibility and the extent of the damage of the friction material in case of stiction;

- -

- pH control: the incorporation of additives, sometimes referred to as pH boosters, that can lead to an alkalinization at the pad–disc interface, can reduce the susceptibility to stiction of gray cast-iron rotors [60]. The most employed pH booster is calcium hydroxide;

- -

- Control of local galvanic effects: it is well established that metals in the friction material can promote galvanic corrosion of the gray cast iron [58,64]. In particular, the presence of copper can be detrimental [58]. In contrast, zinc can promote the galvanic protection of the rotor and it can be considered a valid alternative to pH boosters.

7.2. Surface Treatments of the Discs and Coatings

7.3. pH Boosters and Other Additives

8. Conclusions

- -

- The corrosion-stiction phenomenon leads to a strong adhesion of the pad material to the brake disc under static conditions (parking brake activated) in aggressive environments. It is generally accepted that the stiction mechanism is controlled by the diffusion of corrosion products in the friction material under wet conditions and the successive formation of strong bonds with the brake disc during drying;

- -

- The stiction behavior highlights a complex dependency on the chemical and physical properties of the friction material due to its heterogeneous chemical composition and structure. The porosity and hydrophilic behavior of brake pads play a key role in controlling the access of aggressive electrolytes at the pad–rotor interface. Local pH variations leading to the establishment of an acid environment at the pad–disk interface can strongly increase the susceptibility to corrosion of gray cast iron. Moreover, localized galvanic coupling might occur in friction materials containing copper enhancing the corrosion attack of the brake disc. Compressibility and stiffness of the friction material can significantly affect the extension of the contact area between the pad and the rotor impacting the susceptibility to corrosion stiction;

- -

- Electrochemical techniques, including potentiodynamic polarization and electrochemical impedance spectroscopy, are useful tools for the investigation of corrosion stiction. Their combined use with surface characterization methods can lead to a better understanding of the parameters controlling this phenomenon;

- -

- Development of friction materials with a low susceptibility to corrosion stiction should follow a complementary approach targeting an accurate selection of the constituents of the friction material, a better control of local conditions established at the pad–disc interface, and also the use of specific additives or surface treatments of gray cast-iron rotors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chan, D.; Stachowiak, G.W. Review of Automotive Brake Friction Materials. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2004, 218, 953–966. [Google Scholar] [CrossRef]

- Gweon, J.; Shin, S.; Jang, H.; Lee, W.; Kim, D.; Lee, K. The Factors Governing Corrosion Stiction of Brake Friction Materials to a Gray Cast Iron Disc; SAE Technical Papers. 2018, pp. 5–12. Available online: https://saemobilus.sae.org/content/2018-01-1899/ (accessed on 27 April 2023).

- Gweon, J.; Park, J.; Lee, W.K.; Kim, D.Y.; Jang, H. Root Cause Study of Corrosion Stiction by Brake Pads on the Grey Iron Disc. Eng. Fail. Anal. 2021, 128, 105583. [Google Scholar] [CrossRef]

- Park, C.W.; Shin, M.W.; Jang, H. Friction-Induced Stick-Slip Intensified by Corrosion of Gray Iron Brake Disc. Wear 2014, 309, 89–95. [Google Scholar] [CrossRef]

- Blau, P.J. Compositions, Functions, and Testing of Friction Brake Materials and Their Additives. Energy 2001, 27, 38. [Google Scholar]

- Straffelini, G. Friction and Wear, Methodologies for Design and Control; Springer International Publishing: Berlin/Heidelberg, Germany, 2015; ISBN 9783662484630. [Google Scholar]

- Krbata, M.; Eckert, M.; Majerik, J.; Barenyi, I. Wear Behaviour of High Strength Tool Steel 90MnCrV8 in Contact with Si3N4. Metals 2020, 10, 756. [Google Scholar] [CrossRef]

- Vivier, F. Synergetic Effects inside a Simplified Friction Material: Study of the Role of Ingredients. Ph.D. Thesis, Politecnico Di Torino, Torino, Italy, 2016. [Google Scholar]

- Sathyamoorthy, G.; Vijay, R.; Lenin Singaravelu, D. Brake Friction Composite Materials: A Review on Classifications and Influences of Friction Materials in Braking Performance with Characterizations. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 1674–1706. [Google Scholar] [CrossRef]

- Dante, R.C. Types of Friction Material Formulas; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; ISBN 9780081006191. [Google Scholar]

- Cai, P.; Wang, Y.; Wang, T.; Wang, Q. Effect of Resins on Thermal, Mechanical and Tribological Properties of Friction Materials. Tribol. Int. 2015, 87, 1–10. [Google Scholar] [CrossRef]

- Rajan, B.S.; Balaji, M.A.S.; Sathickbasha, K.; Hariharasakthisudan, P. Influence of Binder on Thermomechanical and Tribological Performance in Brake Pad. Tribol. Ind. 2018, 40, 654–669. [Google Scholar] [CrossRef]

- Hong, U.S.; Jung, S.L.; Cho, K.H.; Cho, M.H.; Kim, S.J.; Jang, H. Wear Mechanism of Multiphase Friction Materials with Different Phenolic Resin Matrices. Wear 2009, 266, 739–744. [Google Scholar] [CrossRef]

- Kim, S.J.; Jang, H. Friction and Wear of Friction Materials Containing Two Different Phenolic Resins Reinforced with Aramid Pulp. Tribol. Int. 2000, 33, 477–484. [Google Scholar] [CrossRef]

- Shin, M.W.; Cho, K.H.; Lee, W.K.; Jang, H. Tribological Characteristics of Binder Resins for Brake Friction Materials at Elevated Temperatures. Tribol. Lett. 2010, 38, 161–168. [Google Scholar] [CrossRef]

- Fei, J.; Li, H.J.; Fu, Y.W.; Qi, L.H.; Zhang, Y.L. Effect of Phenolic Resin Content on Performance of Carbon Fiber Reinforced Paper-Based Friction Material. Wear 2010, 269, 534–540. [Google Scholar] [CrossRef]

- Gurunath, P.V.; Bijwe, J. Potential Exploration of Novel Green Resins as Binders for NAO Friction Composites in Severe Operating Conditions. Wear 2009, 267, 789–796. [Google Scholar] [CrossRef]

- Carlevaris, D.; Menapace, C.; Straffelini, G.; Fambri, L. Characterization of Benzoxazine Resins for Brake Pad Friction Materials Manufacturing. J. Therm. Anal. Calorim. 2022, 148, 767–787. [Google Scholar] [CrossRef]

- Gopal, P.; Dharani, L.R.; Blum, F.D. Fade and Wear Characteristics of a Glass-Fiber-Reinforced Phenolic Friction Material. Wear 1994, 174, 119–127. [Google Scholar] [CrossRef]

- Kumar, M.; Satapathy, B.K.; Patnaik, A.; Kolluri, D.K.; Tomar, B.S. Hybrid Composite Friction Materials Reinforced with Combination of Potassium Titanate Whiskers and Aramid Fibre: Assessment of Fade and Recovery Performance. Tribol. Int. 2011, 44, 359–367. [Google Scholar] [CrossRef]

- Jang, H.; Ko, K.; Kim, S.J.; Basch, R.H.; Fash, J.W. The Effect of Metal Fibers on the Friction Performance of Automotive Brake Friction Materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- Lu, Y.; Tang, C.F.; Zhao, Y.; Wright, M.A. Optimization of a Semimetallic Friction Material Formulation. J. Reinf. Plast. Compos. 2004, 23, 1537–1545. [Google Scholar] [CrossRef]

- Shibata, K.; Goto, A.; Yoshida, S.; Azuma, Y.; Nakamura, K. Development of Brake Friction Material; SAE Technical Papers; SAE: Warrendale, PA, USA, 1993. [Google Scholar]

- Han, Y.; Tian, X.; Yin, Y. Effects of Ceramic Fiber on the Friction Performance of Automotive Brake Lining Materials. Tribol. Trans. 2008, 51, 779–783. [Google Scholar] [CrossRef]

- Xin, X.; Xu, C.G.; Qing, L.F. Friction Properties of Sisal Fibre Reinforced Resin Brake Composites. Wear 2007, 262, 736–741. [Google Scholar] [CrossRef]

- Kim, S.H.; Jang, H. Friction and Vibration of Brake Friction Materials Reinforced with Chopped Glass Fibers. Tribol. Lett. 2013, 52, 341–349. [Google Scholar] [CrossRef]

- Gweon, J.H.; Joo, B.S.; Jang, H. The Effect of Short Glass Fiber Dispersion on the Friction and Vibration of Brake Friction Materials. Wear 2016, 362–363, 61–67. [Google Scholar] [CrossRef]

- Cho, M.H.; Cho, K.H.; Kim, S.J.; Kim, D.H.; Jang, H. The Role of Transfer Layers on Friction Characteristics in the Sliding Interface between Friction Materials against Gray Iron Brake Disks. Tribol. Lett. 2005, 20, 101–108. [Google Scholar] [CrossRef]

- Xiao, X.; Yin, Y.; Bao, J.; Lu, L.; Feng, X. Review on the Friction and Wear of Brake Materials. Adv. Mech. Eng. 2016, 8, 1687814016647300. [Google Scholar] [CrossRef]

- Marin, E.; Daimon, E.; Boschetto, F.; Rondinella, A.; Inada, K.; Zhu, W.; Pezzotti, G. Diagnostic Spectroscopic Tools for Worn Brake Pad Materials: A Case Study. Wear 2019, 432–433, 202969. [Google Scholar] [CrossRef]

- Cho, K.H.; Cho, M.H.; Kim, S.J.; Jang, H. Tribological Properties of Potassium Titanate in the Brake Friction Material; Morphological Effects. Tribol. Lett. 2008, 32, 59–66. [Google Scholar] [CrossRef]

- Lu, Y. A Combinatorial Approach for Automotive Friction Materials: Effects of Ingredients on Friction Performance. Compos. Sci. Technol. 2006, 66, 591–598. [Google Scholar] [CrossRef]

- Hulskotte, J.H.J.; Roskam, G.D.; Van Der Gon, H.A. Elemental Composition of Current Automotive Braking Materials and Derived Air Emission Factors. Atmos. Environ. 2014, 99, 436–445. [Google Scholar] [CrossRef]

- Kukutschová, J.; Moravec, P.; Tomášek, V.; Matějka, V.; Smolík, J.; Schwarz, J.; Seidlerová, J.; Šafářová, K.; Filip, P. On Airborne Nano/Micro-Sized Wear Particles Released from Low-Metallic Automotive Brakes. Environ. Pollut. 2011, 159, 998–1006. [Google Scholar] [CrossRef]

- Gilardi, R.; Alzati, L.; Thiam, M.; Brunel, J.F.; Desplanques, Y.; Dufrénoy, P.; Sharma, S.; Bijwe, J. Copper Substitution and Noise Reduction in Brake Pads: Graphite Type Selection. Materials 2012, 5, 2258–2269. [Google Scholar] [CrossRef]

- Aranganathan, N.; Bijwe, J. Special Grade of Graphite in NAO Friction Materials for Possible Replacement of Copper. Wear 2015, 330–331, 515–523. [Google Scholar] [CrossRef]

- Aranganathan, N.; Bijwe, J. Development of Copper-Free Eco-Friendly Brake-Friction Material Using Novel Ingredients. Wear 2016, 352–353, 79–91. [Google Scholar] [CrossRef]

- Venkatesh, S.; Murugapoopathiraja, K. Scoping Review of Brake Friction Material for Automotive. Mater. Today Proc. 2019, 16, 927–933. [Google Scholar] [CrossRef]

- Komori, T.; Miyake, S.; Senoo, Y. Brake-Friction Material. U.S. Patent 4954536, 4 September 1990. [Google Scholar]

- Satapathy, B.K.; Patnaik, A.; Dadkar, N.; Kolluri, D.K.; Tomar, B.S. Influence of Vermiculite on Performance of Flyash-Based Fibre-Reinforced Hybrid Composites as Friction Materials. Mater. Des. 2011, 32, 4354–4361. [Google Scholar] [CrossRef]

- Křístková, M.; Weiss, Z.; Filip, P. Hydration Properties of Vermiculite in Phenolic Resin Friction Composites. Appl. Clay Sci. 2004, 25, 229–236. [Google Scholar] [CrossRef]

- Saffar, A.; Shojaei, A. Effect of Rubber Component on the Performance of Brake Friction Materials. Wear 2012, 274–275, 286–297. [Google Scholar] [CrossRef]

- Zum Hagen, F.H.F.; Mathissen, M.; Grabiec, T.; Hennicke, T.; Rettig, M.; Grochowicz, J.; Vogt, R.; Benter, T. Study of Brake Wear Particle Emissions: Impact of Braking and Cruising Conditions. Environ. Sci. Technol. 2019, 53, 5143–5150. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G. Brake Wear Particle Emissions: A Review. Environ. Sci. Pollut. Res. 2015, 22, 2491–2504. [Google Scholar] [CrossRef]

- Oroumiyeh, F.; Zhu, Y. Brake and Tire Particles Measured from On-Road Vehicles: Effects of Vehicle Mass and Braking Intensity. Atmos. Environ. X 2021, 12, 100121. [Google Scholar] [CrossRef]

- Amato, F.; Pandolfi, M.; Escrig, A.; Querol, X.; Alastuey, A.; Pey, J.; Perez, N.; Hopke, P.K. Quantifying Road Dust Resuspension in Urban Environment by Multilinear Engine: A Comparison with PMF2. Atmos. Environ. 2009, 43, 2770–2780. [Google Scholar] [CrossRef]

- Garg, B.D.; Cadle, S.H.; Mulawa, P.A.; Groblicki, P.J.; Laroo, C.; Parr, G.A. Brake Wear Particulate Matter Emissions. Environ. Sci. Technol. 2000, 34, 4463–4469. [Google Scholar] [CrossRef]

- Han, L.; Zhuang, G.; Cheng, S.; Wang, Y.; Li, J. Characteristics of Re-Suspended Road Dust and Its Impact on the Atmospheric Environment in Beijing. Atmos. Environ. 2007, 41, 7485–7499. [Google Scholar] [CrossRef]

- Apeagyei, E.; Bank, M.S.; Spengler, J.D. Distribution of Heavy Metals in Road Dust along an Urban-Rural Gradient in Massachusetts. Atmos. Environ. 2011, 45, 2310–2323. [Google Scholar] [CrossRef]

- Ghouri, I.; Barker, R.; Brooks, P.; Kosarieh, S.; Barton, D. The Effects of Corrosion on Particle Emissions from a Grey Cast Iron; SAE Technical Papers; SAE: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Motta, M.; Zanocco, M.; Rondinella, A.; Iodice, V.; Sin, A.; Fedrizzi, L.; Andreatta, F. Inhibitive Effect of 8-Hydroxyquinoline on Corrosion of Gray Cast Iron in Automotive Braking Systems. Electrochim. Acta 2023, 449, 142221. [Google Scholar] [CrossRef]

- Shin, M.W.; Cho, K.H.; Kim, S.J.; Jang, H. Friction Instability Induced by Corrosion of Gray Iron Brake Discs. Tribol. Lett. 2010, 37, 149–157. [Google Scholar] [CrossRef]

- Gao, C.; Kuhlmann-Wilsdorf, D. Adsorption Films, Humidity, Stick-Slip, and Resistance of Sliding Contacts. IEEE Trans. Compon. Hybrids Manuf. Technol. 1991, 14, 37–44. [Google Scholar] [CrossRef]

- Djafri, M.; Bouchetara, M.; Busch, C.; Weber, S. Effects of Humidity and Corrosion on the Tribological Behaviour of the Brake Disc Materials. Wear 2014, 321, 8–15. [Google Scholar] [CrossRef]

- Blau, P.J.; Truhan, J.J.; Kenik, E.A. Effects of the Exposure to Corrosive Salts on the Frictional Behavior of Gray Cast Iron and a Titanium-Based Metal Matrix Composite. Tribol. Int. 2007, 40, 1335–1343. [Google Scholar] [CrossRef]

- Passarelli, U.P.; Merlo, F.; Pellerej, D.; Buonfico, P. Influence of Brake Pad Porosity and Hydrophilicity on Stiction by Corrosion of Friction Material against Gray Cast Iron Rotor; SAE Technical Papers; SAE: Warrendale, PA, USA, 2012; Volume 7. [Google Scholar] [CrossRef]

- ISO Standard No. 6315; Road Vehicles—Brake Linings—Seizure to Ferrous Mating Surface Due to Corrosion—Test Procedure. International Organization for Standardization: Geneva, Switzerland, 1980.

- Tigane, R.; Bauwens, D.; Hude, O.; Joiret, S.; Keddam, M.; Turmine, M.; Vivier, V. On the Local Corrosion in a Thin Layer of Electrolyte Separating Two Materials: Specific Aspects and Their Contribution to Pad-to-Disk Stiction in Automobile Brake System. J. Solid State Electrochem. 2021, 25, 895–904. [Google Scholar] [CrossRef]

- Merlo, F.; Passarelli, U.; Pellerej, D.; Buonfico, P. Effect of Gray Cast-Iron Microstructure and Brake Pad Formula on Wear Behavior and Corrosion Sticking Influenced by Thermal Preconditioning: The Copper Role; SAE Technical Papers; SAE: Warrendale, PA, USA, 2012; Volume 7. [Google Scholar] [CrossRef]

- Robere, M. Disc Brake Pad Corrosion Adhesion: Test-to-Field Issue Correlation, and Exploration of Friction Physical Properties Influence to Adhesion Break-Away Force; SAE Technical Papers; SAE: Warrendale, PA, USA, 2016; Volume 2016. [Google Scholar] [CrossRef]

- Bertasi, F.; Mancini, A.; Bandiera, M.; Pin, S.; Casini, A.; Bonfanti, A. Interplay between Composition and Electrochemical Performance at the Pad-Disc Interface. pp. 1–10. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-85140983240&origin=resultslist&sort=plf-f&src=s&st1=bertasi&st2=federico&nlo=1&nlr=20&nls=count-f&sid=093185955474dcf14eff3fa5fbe9c675&sot=anl&sdt=aut&sl=38&s=AU-ID%28%22Bertasi%2c+Federico%22+48161103700%29&relpos=1&citeCnt=0&searchTerm (accessed on 27 April 2023).

- Sathickbasha, K.; Selvakumar, A.S.; Sai Balaji, M.A.; Surya Rajan, B. Effect of Steel Family Fibers on Friction and Stiction Behavior of Brake Pads. FME Trans. 2019, 47, 856–864. [Google Scholar] [CrossRef]

- Bertasi, F.; Bandiera, M.; Pavesi, A.; Bonfanti, A.; Mancini, A. Friction Materials: Best Practices for the Evaluation of Corrodibility and Corrosion Mechanism. 2022, pp. 1–5. Available online: https://www.fisita.com/library/eurobrake/2021/1482eb2021-mds-007 (accessed on 27 April 2023).

- Bandiera, M.; Mauri, A.; Bestetti, M.; Bonfanti, A.; Mancini, A.; Bertasi, F. Corrosion Phenomena in Braking Systems; International Corrosion Conference Series; National Association of Corrosion Engineers International: Houston, TX, USA, 2020; p. 14550. [Google Scholar]

- Bandiera, M.; Mancini, A.; Pavesi, A.; Bonfanti, A.; Pin, A.; Bertasi, F. Sticking Phenomena at the Brake Pad-Disc Interface: An Open Call for Electrochemists. NACE International Corrosion Conference Series; National Association of Corrosion Engineers International: Houston, TX, USA, 2021; p. 16429. [Google Scholar]

- Sin, X.A.; Fedrizzi, L.; Andreatta, F.; De Nicolo’, A. A1 Method and Equipment for Studying and Establishing the Physico-Chemical Conditions of Stiction between a Braking Element and an Element to Be Braked. U.S. Patent 2022/0317022, 6 October 2022. [Google Scholar]

- Bandiera, M.; Bonfanti, A.; Mancini, A.; Pin, S.; Bertasi, F. Physico-Chemical Characterization of Corrosion Scales in Braking Systems; NACE International Corrosion Conference Series; National Association of Corrosion Engineers International: Houston, TX, USA, 2020; Volume 2020, pp. 1–15. [Google Scholar]

- Aranke, O.; Algenaid, W.; Awe, S.; Joshi, S. Coatings for Automotive Gray Cast Iron Brake Discs: A Review. Coatings 2019, 9, 552. [Google Scholar] [CrossRef]

- Holly, M.L.; Devoe, L.; Webster, J. Ferritic Nitrocarburized Brake Rotors. In Proceedings of the SAE 2011 World Congress & Exhibition, Detroit, MI, USA, 12–14 April 2011. [Google Scholar] [CrossRef]

- Chioibasu, D.; Mihai, S.; Cotrut, C.M.; Voiculescu, I.; Popescu, A.C. Tribology and Corrosion Behavior of Gray Cast Iron Brake Discs Coated with Inconel 718 by Direct Energy Deposition. Int. J. Adv. Manuf. Technol. 2022, 121, 5091–5107. [Google Scholar] [CrossRef]

- Kiehl, M.; Scheid, A.; Graf, K.; Ernst, B.; Tetzlaff, U. Coaxial Laser Cladding of Cobalt-Base Alloy StelliteTM 6 on Gray Cast Iron/Investigations on Friction, Wear versus Commercial Brake Pad, and Corrosion Characteristics. Proc. Inst. Mech. Eng. Part D J. Automob Eng. 2023, 32, 3821. [Google Scholar] [CrossRef]

- Atkinson, A. Friction Material. WO Patent 93/22580, 27 October 1993. [Google Scholar]

- Lamport, R. A1 Brake Assembly and Additive. U.S. Patent 2006/0283673, 21 December 2006. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motta, M.; Fedrizzi, L.; Andreatta, F. Corrosion Stiction in Automotive Braking Systems. Materials 2023, 16, 3710. https://doi.org/10.3390/ma16103710

Motta M, Fedrizzi L, Andreatta F. Corrosion Stiction in Automotive Braking Systems. Materials. 2023; 16(10):3710. https://doi.org/10.3390/ma16103710

Chicago/Turabian StyleMotta, Michele, Lorenzo Fedrizzi, and Francesco Andreatta. 2023. "Corrosion Stiction in Automotive Braking Systems" Materials 16, no. 10: 3710. https://doi.org/10.3390/ma16103710

APA StyleMotta, M., Fedrizzi, L., & Andreatta, F. (2023). Corrosion Stiction in Automotive Braking Systems. Materials, 16(10), 3710. https://doi.org/10.3390/ma16103710