Dry Friction Properties of Diamond-Coated Silicon Carbide

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Diamond Coatings

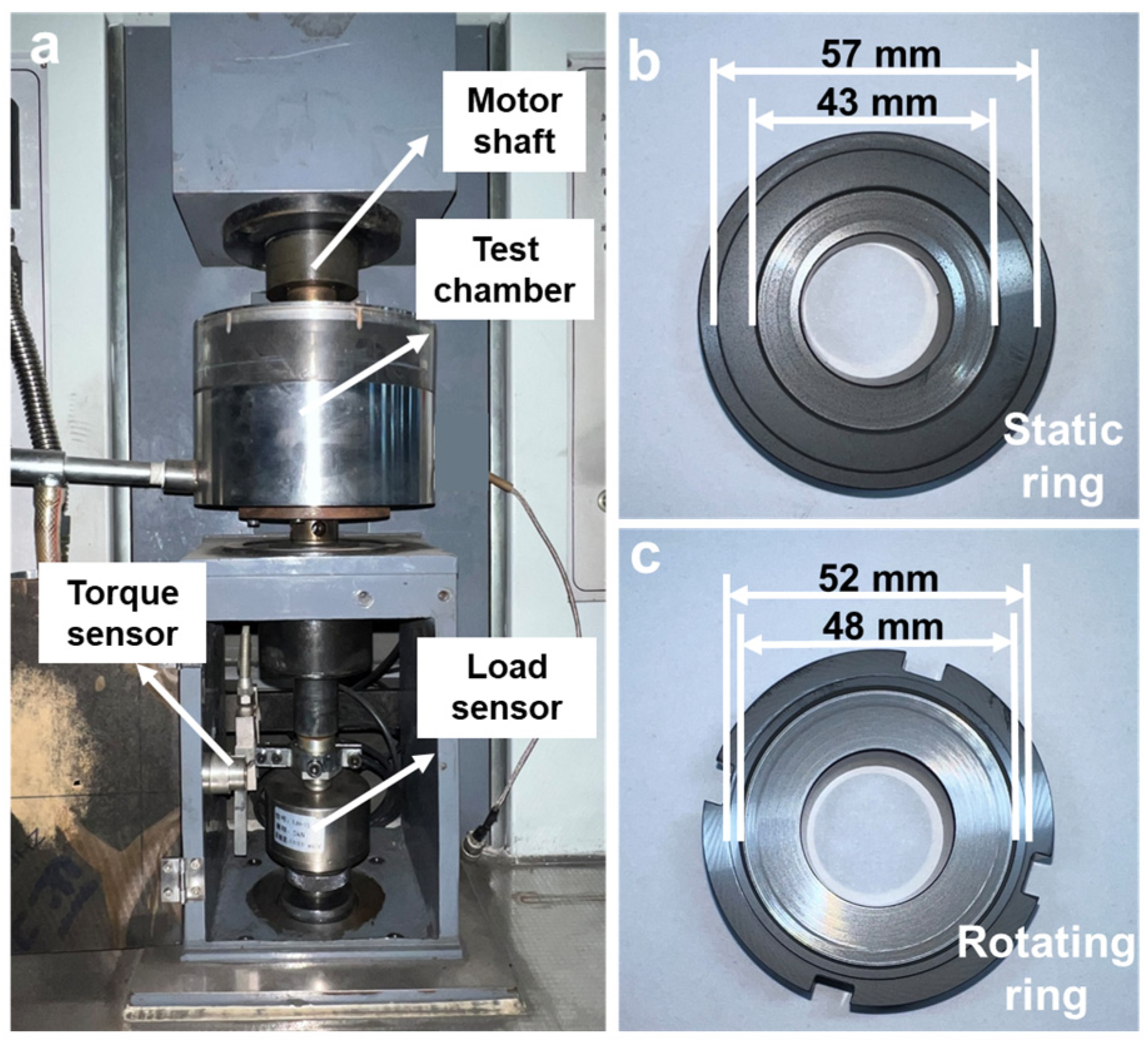

2.2. Dry Tribological Test

2.3. Characterizations

3. Results

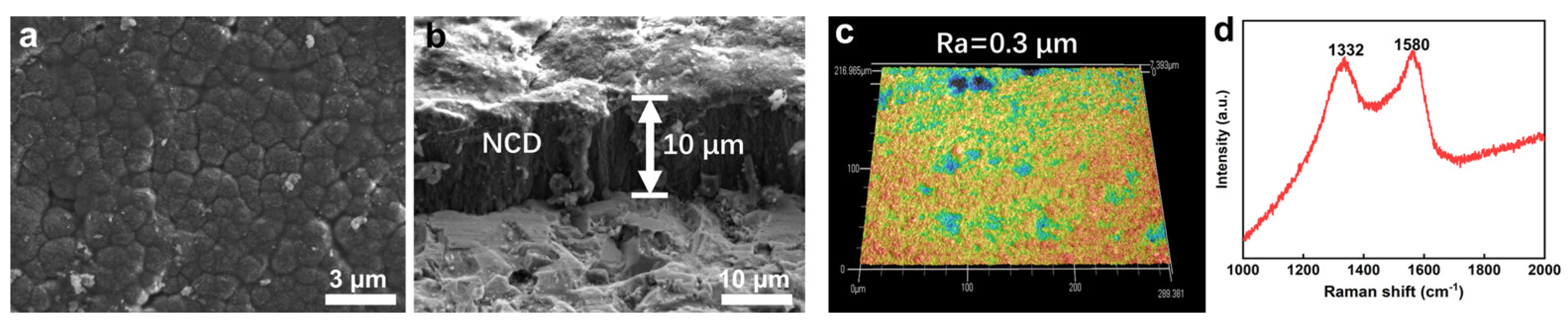

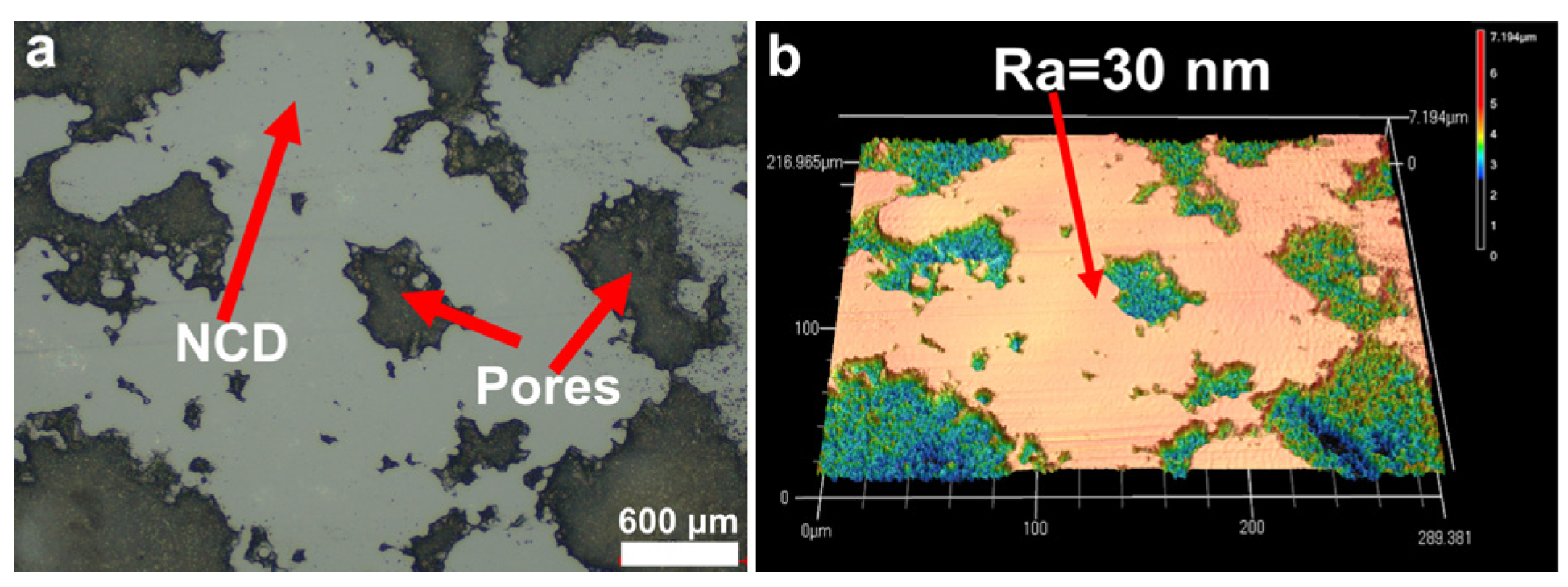

3.1. NCD Characterization

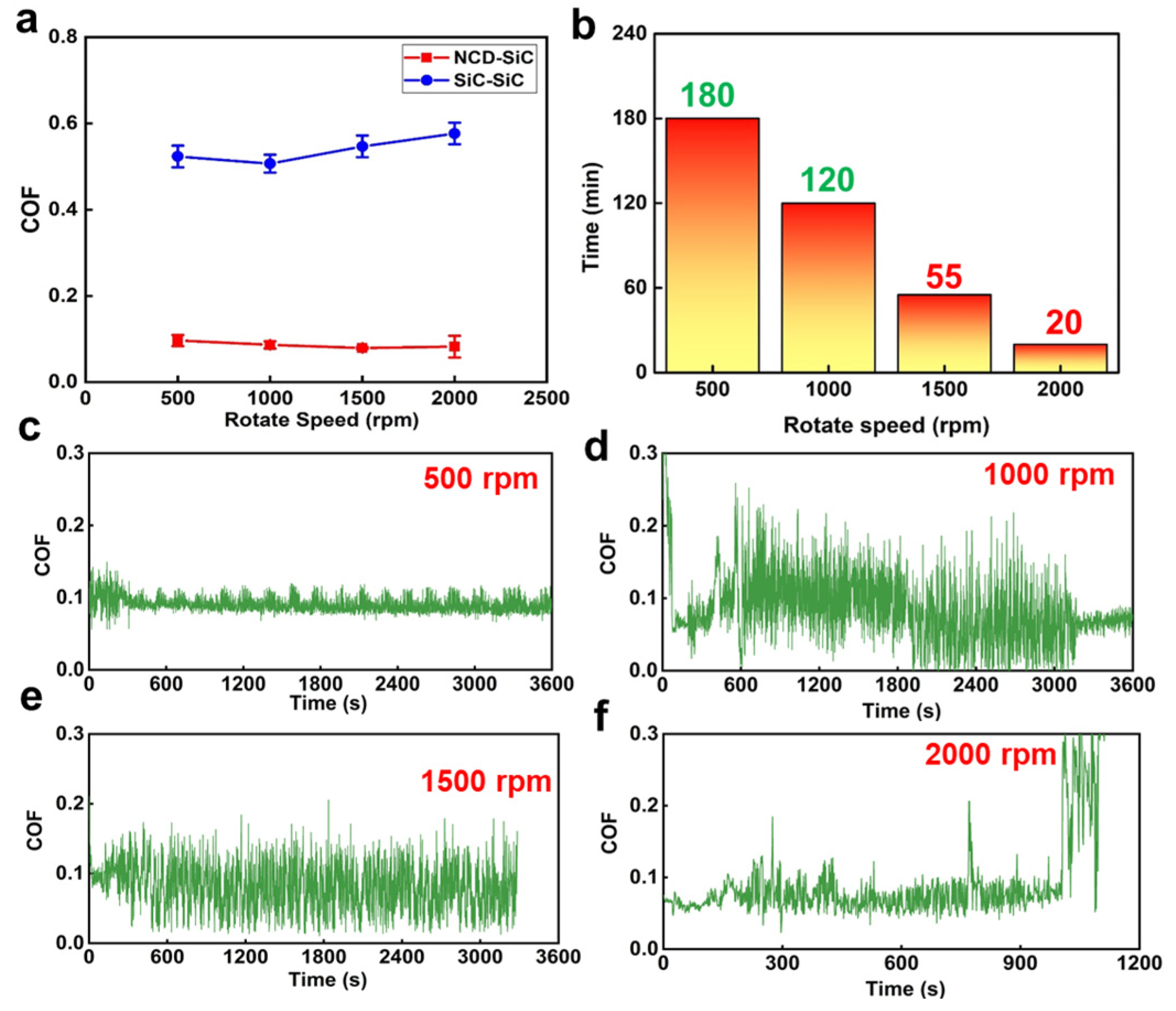

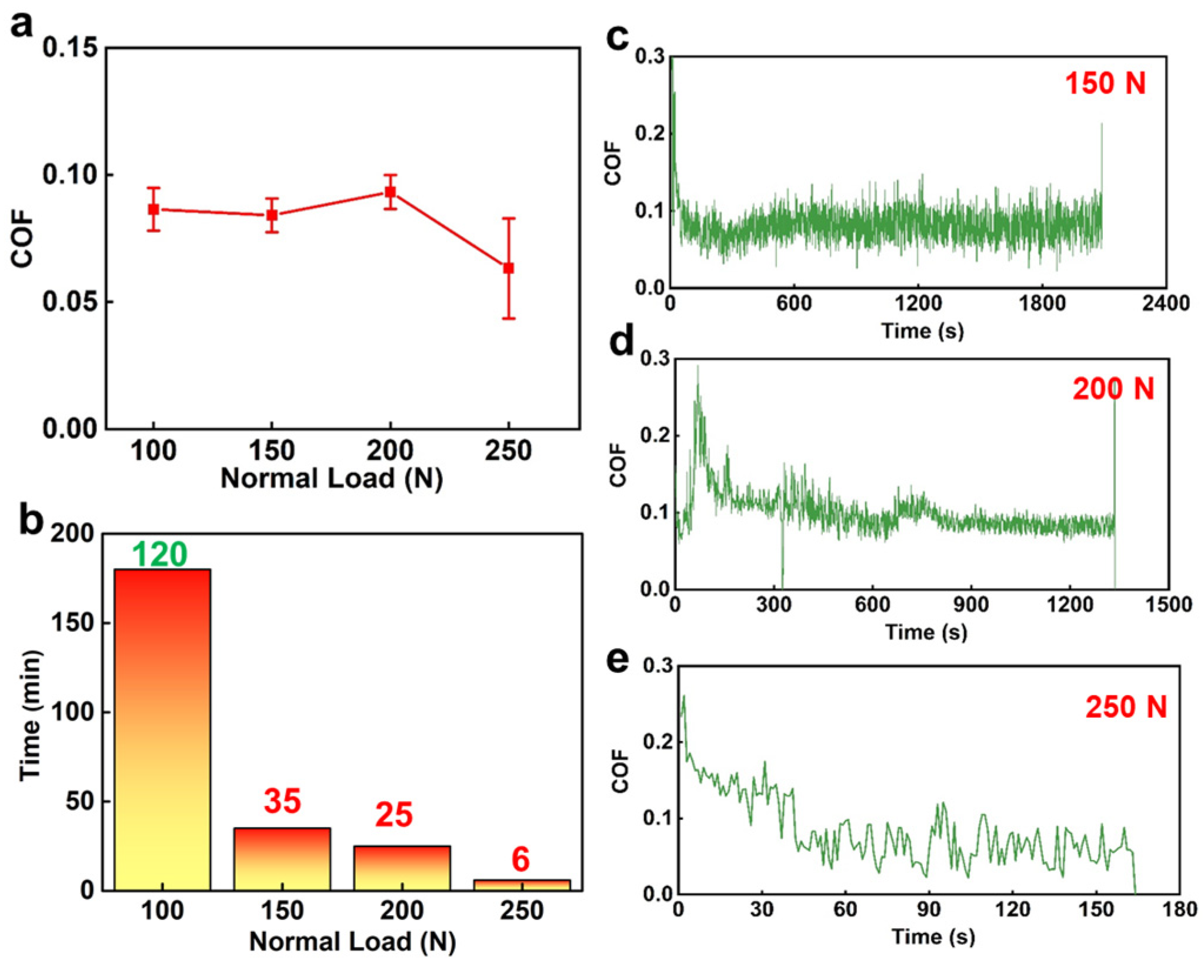

3.2. Friction Testing Results

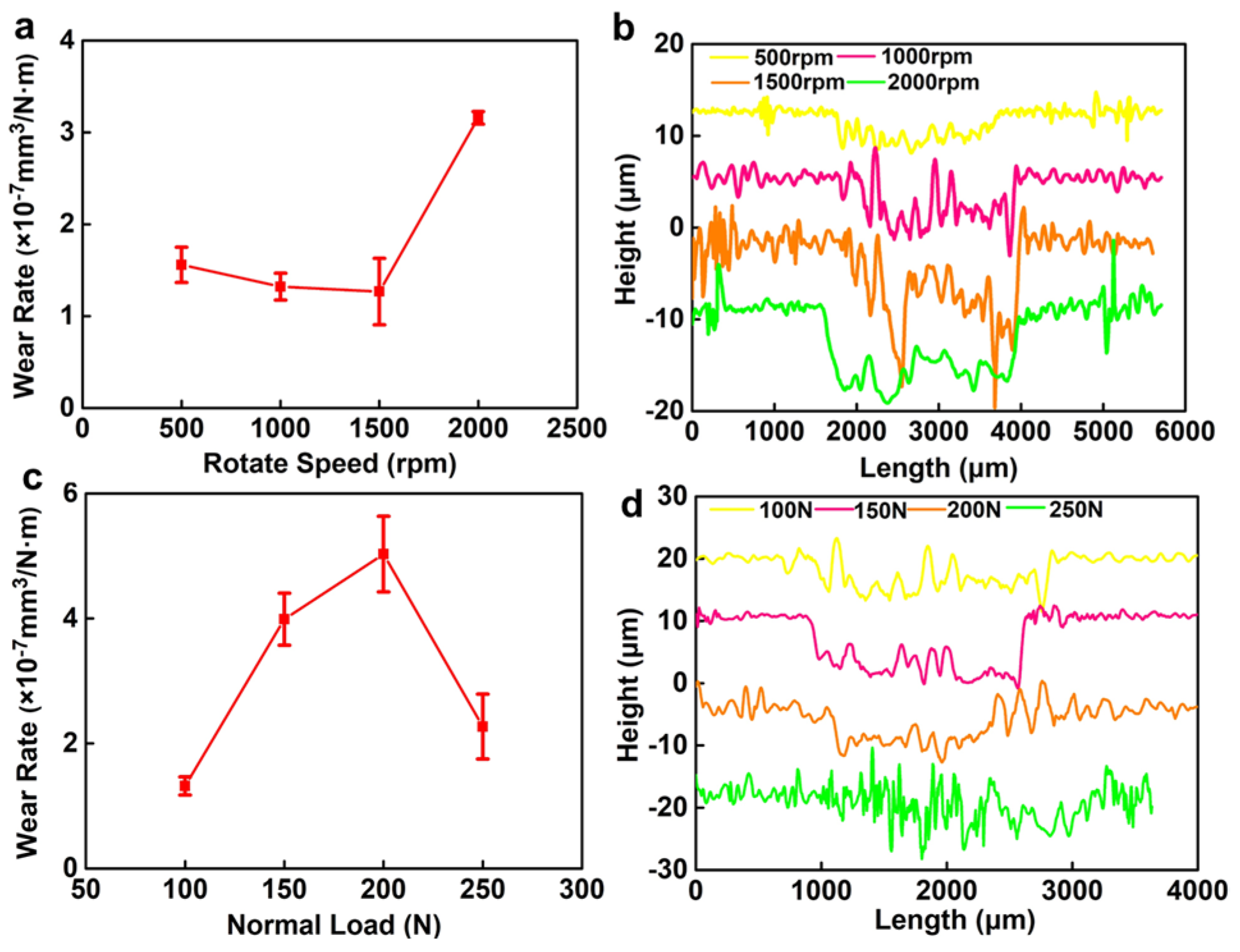

3.3. Wear Rate

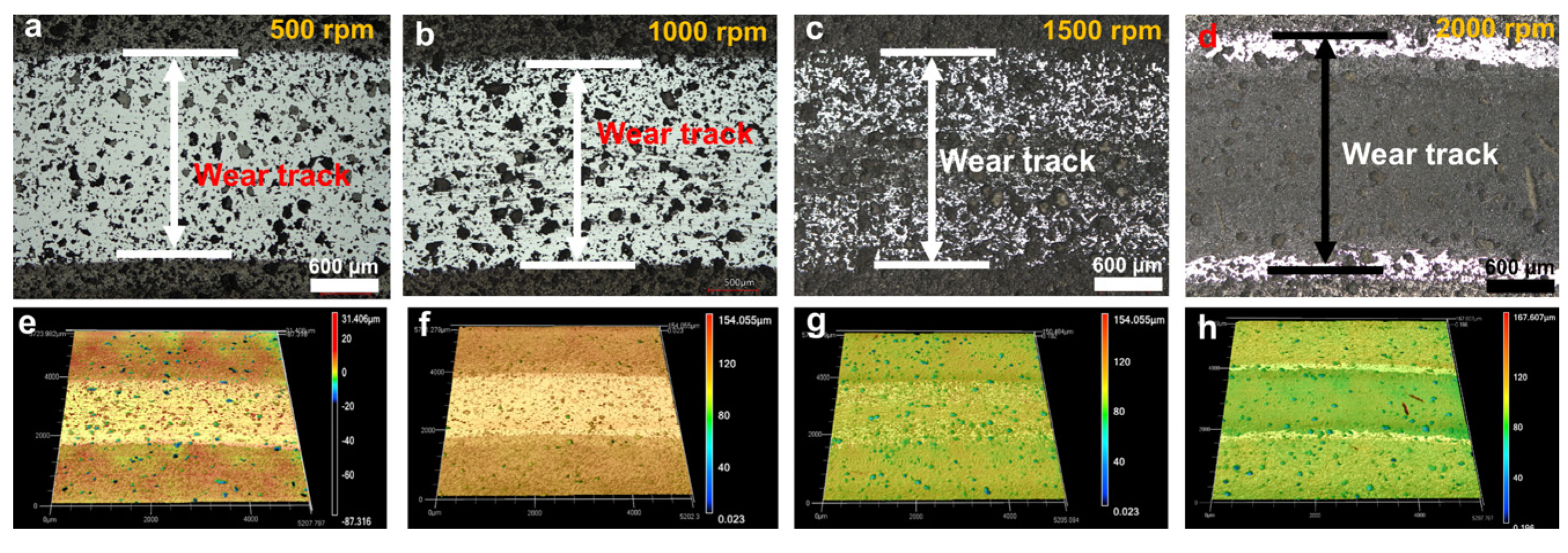

3.4. Wear Tracks Morphology

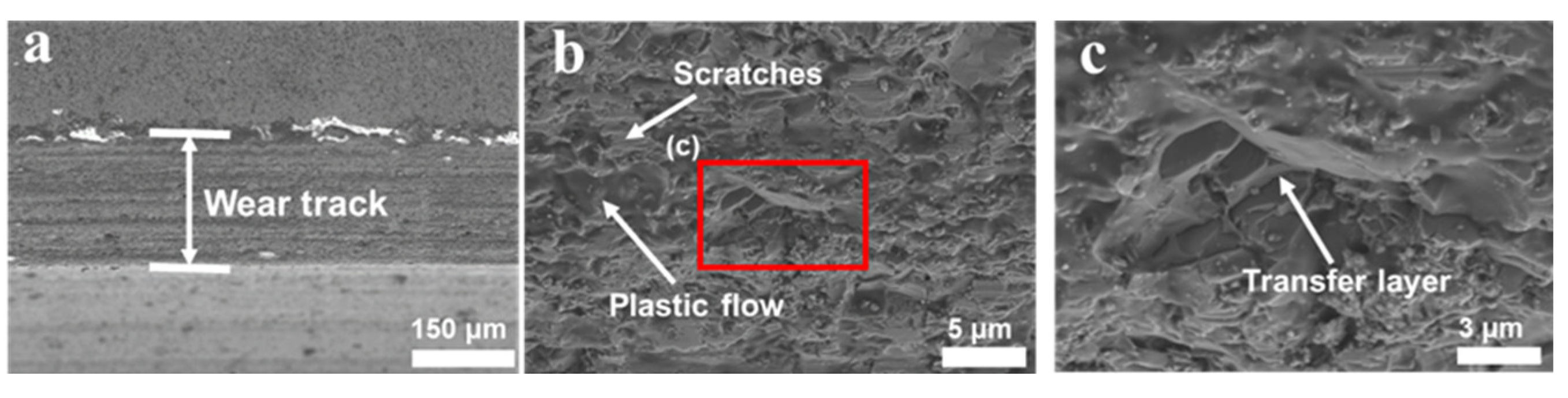

3.4.1. SiC–SiC Sealing Pairs

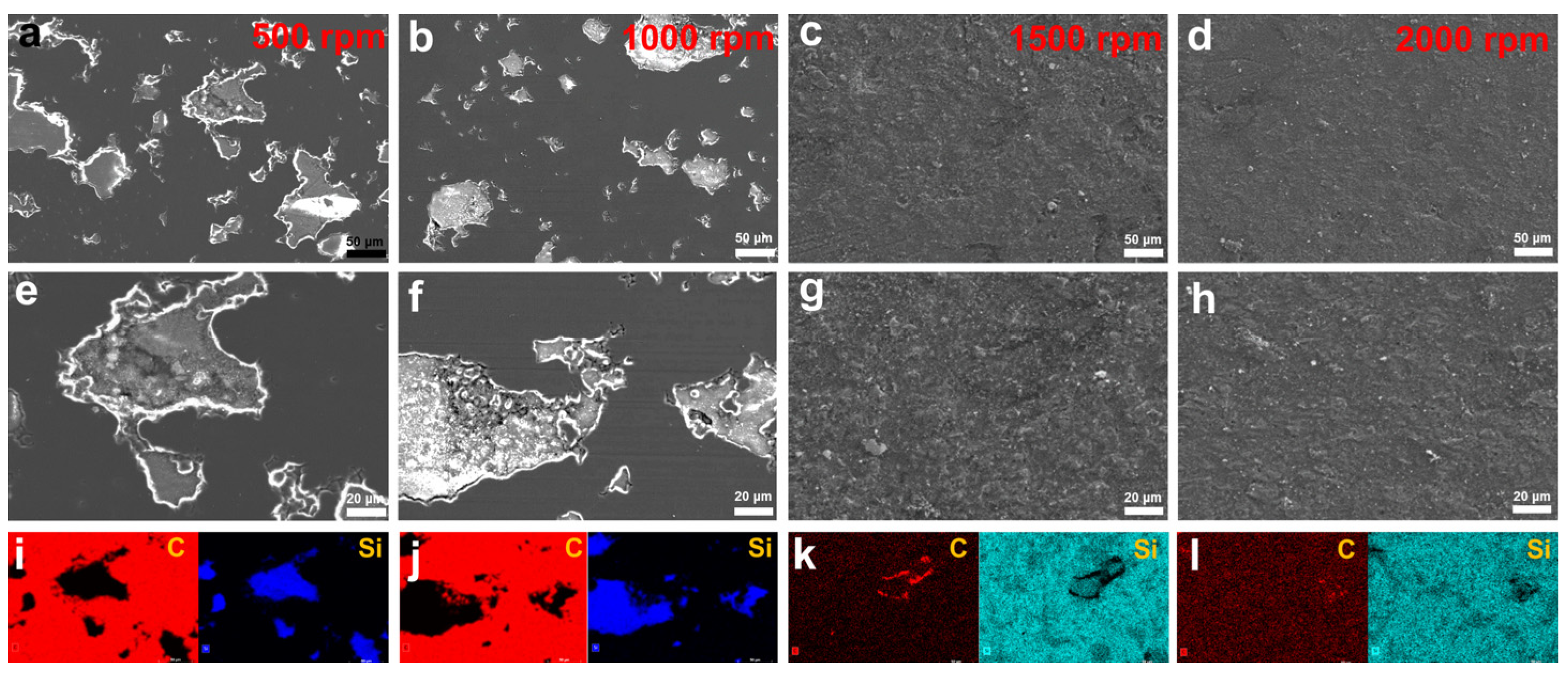

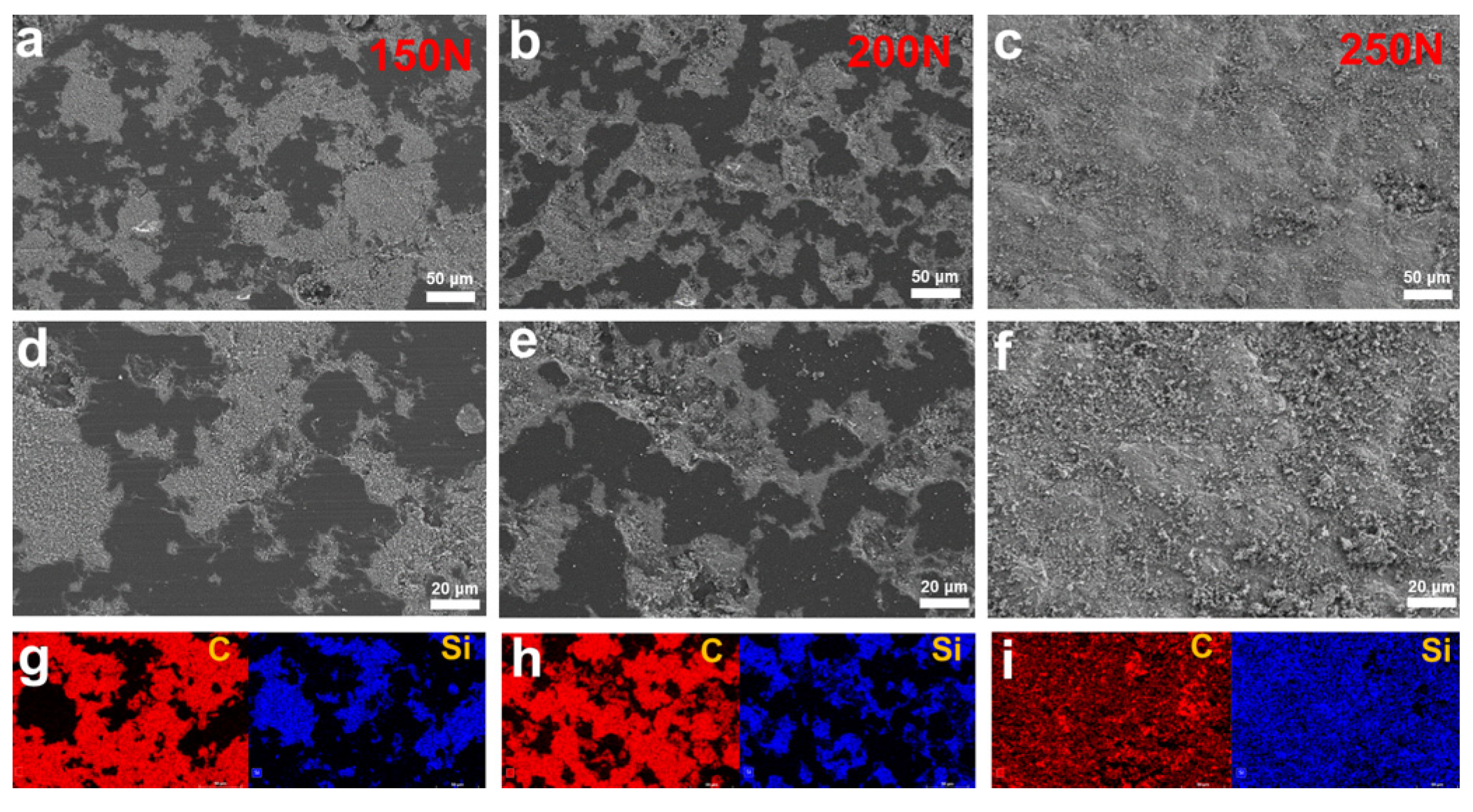

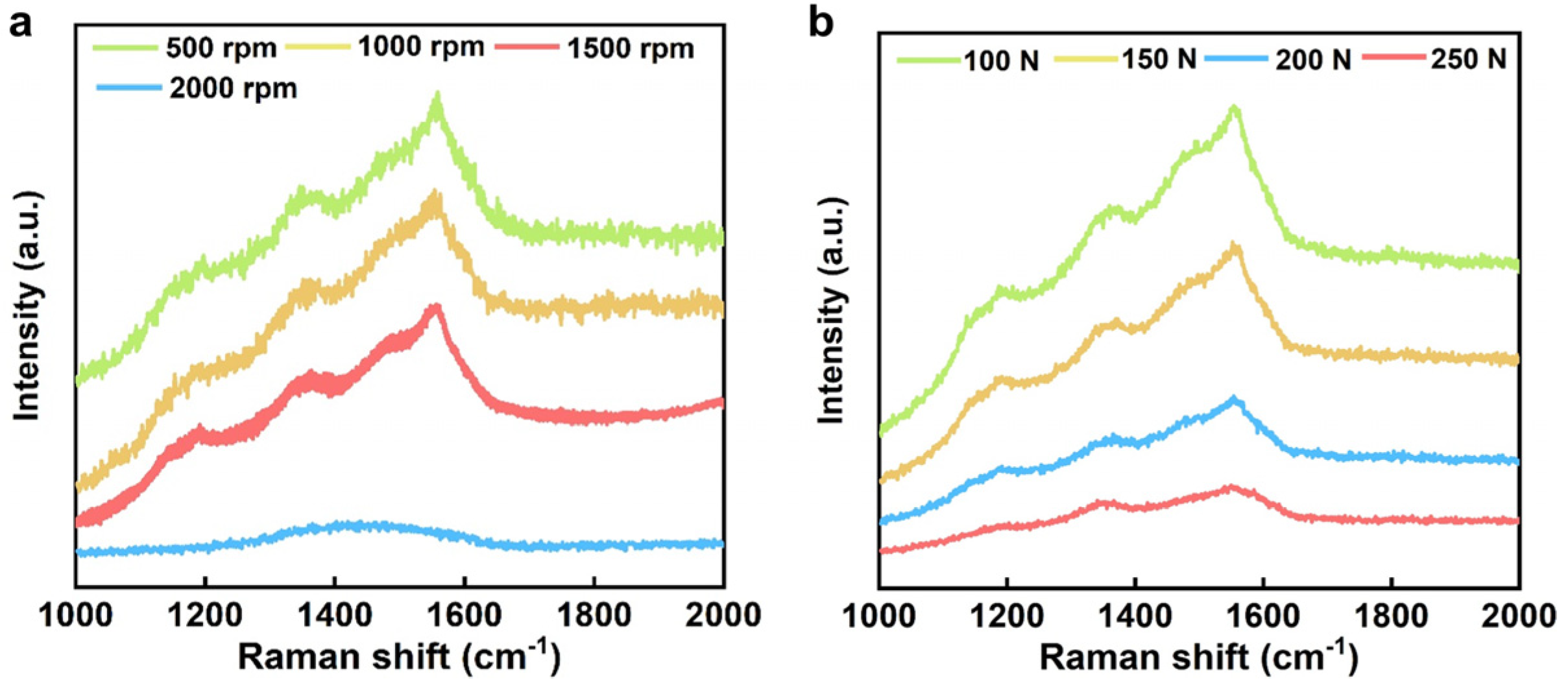

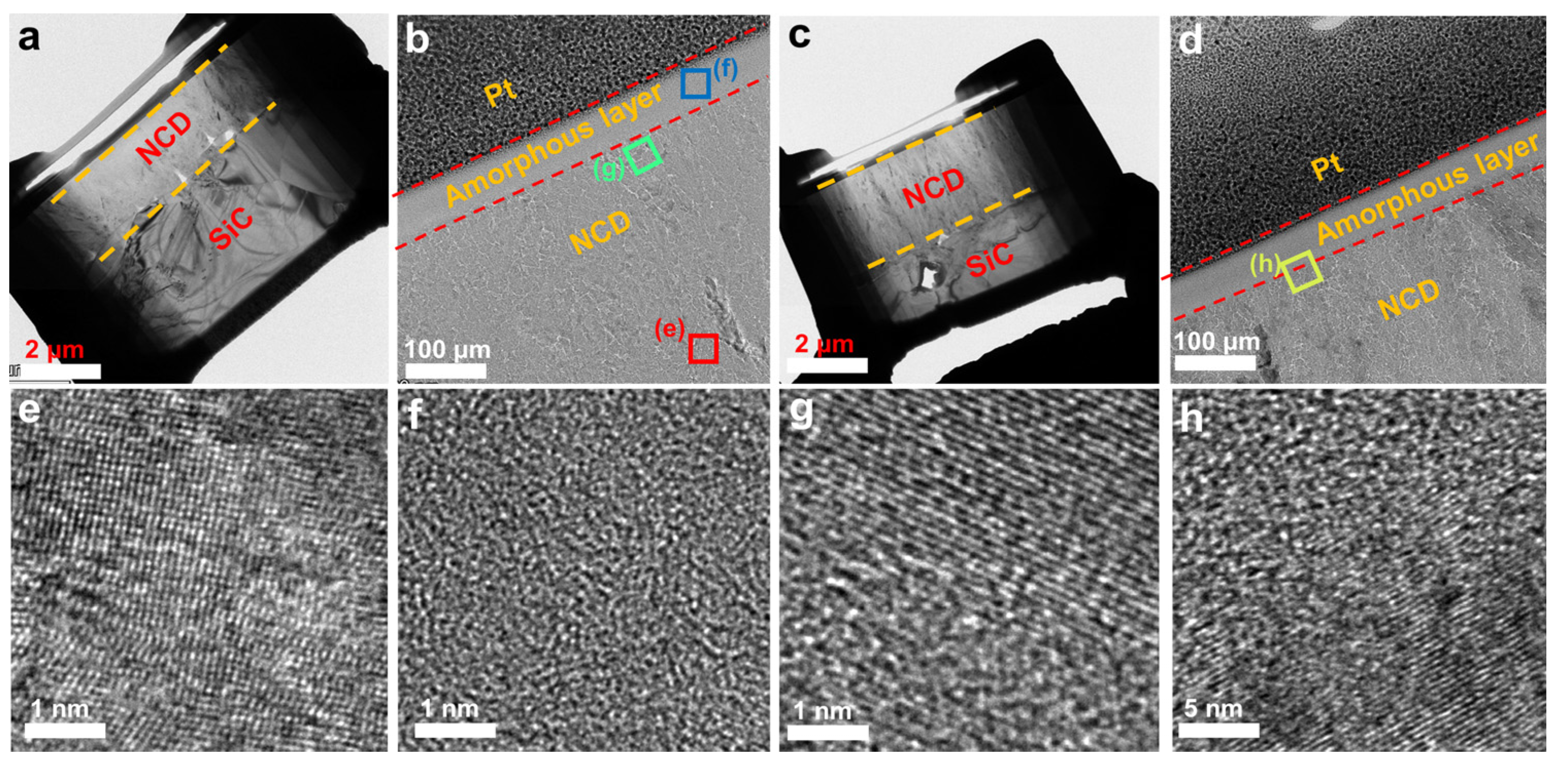

3.4.2. SiC–NCD Sealing Pairs

4. Discussion

5. Conclusions

- (1)

- NCD coatings with thickness of 10 μm and surface roughness of 0.3 μm were successfully deposited on the surface of SiC static seal rings. The COF of SiC–NCD seal pairs was about 0.07–0.09, which was reduced by 83–86% compared to SiC–SiC seal pairs. The wear rate of NCD–SiC ranged from 1.13 × 10−7 mm3/N·m to 3.26 × 10−7 mm3/N·m at various normal loads and speeds.

- (2)

- The observations of wear tracks indicate that the presence of NCD coatings prevent serous adhesive wear and abrasive wear between SiC seal rings. The main reasons for limiting the service life of NCD–SiC seal pairs are the failure of the NCD coatings and the accumulation of wear debris.

- (3)

- Wear tracks analysis shows that a self-lubricating amorphous layer was formed by the amorphous transformation of NCD during friction testing due to the sliding-induced graphitization or rehybridization of diamond. This phase transition phenomenon is the reason for the excellent tribological performances of NCD–SiC seal pairs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, J.; Wang, T.; Ding, X.; Song, H.; Li, H. Tribological Performance of Friction Pairs with Different Materials and Bi-Composite Surface Texture Configurations. Appl. Sci. 2021, 11, 4738. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, X.; Huang, W.; Liu, Y.; Hu, S. Gas Face Seal Status Estimation Based on Acoustic Emission Monitoring and Support Vector Machine Regression. Adv. Mech. Eng. 2020, 12, 1–14. [Google Scholar] [CrossRef]

- Hong, W.; Baoshan, Z.; Jianshu, L.; Changliu, Y. A Thermohydrodynamic Analysis of Dry Gas Seals for High-Temperature Gas-Cooled Reactor. J. Tribol. 2013, 135, 021701–021709. [Google Scholar] [CrossRef]

- Tacon, K.; Twiss, C.; Mammadov, V.; Aslan-Zada, F. Dry Gas Sealing Solutions for High-Pressure Compressor Applications. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2013, 228, 238–252. [Google Scholar] [CrossRef]

- Yin, Y.; Huang, W.; Li, D.; Hu, S.; Liu, X.; Liu, Y. Discriminative Features of Abnormities in a Spiral Groove Gas Face Seal Based on Dynamic Model Considering Contact. Chin. J. Mech. Eng. 2022, 35, 22. [Google Scholar] [CrossRef]

- Straffelini, G.; Scardi, P.; Molinari, A.; Polini, R. Characterization and Sliding Behavior of Hfcvd Diamond Coatings on Wc–Co. Wear 2001, 249, 461–472. [Google Scholar] [CrossRef]

- Zhang, H.; Song, H.; Pang, M.; Yang, G.; Ji, F.; Jiang, N.; Nishimura, K. Tribological Performance of Microcrystalline Diamond (Mcd) and Nanocrystalline Diamond (Ncd) Coating in Dry and Seawater Environment. Crystals 2022, 12, 1345. [Google Scholar] [CrossRef]

- Guo, Z.; Deng, F.; Zhang, L.; Hao, C.; Zhao, X.; Xiang, D. Fabrication and Tribological Properties of Textured Diamond Coatings on Wc-Co Cemented Carbide Surfaces. Ceram. Int. 2021, 47, 5423–5431. [Google Scholar] [CrossRef]

- Takeno, T.; Komoriya, T.; Nakamori, I.; Miki, H.; Abe, T.; Uchimoto, T.; Takagi, T. Tribological Properties of Partly Polished Diamond Coatings. Diam. Relat. Mater. 2005, 14, 2118–2121. [Google Scholar] [CrossRef]

- Barros, M.I.D.; Vandenbulcke, L.; Bléchet, J.J. Influence of Diamond Characteristics on the Tribological Behaviour of Metals against Diamond-Coated Ti–6al–4v Alloy. Wear 2001, 249, 67–77. [Google Scholar] [CrossRef]

- Hollman, P.; Bjorkman, H.; Alahelisten, A.; Hogmark, S. Diamond Coatings Applied to Mechanical Face Seals. Surf. Coat. Technol. 1998, 105, 169–174. [Google Scholar] [CrossRef]

- Schade, A.; Rosiwal, S.M.; Singer, R.F. Influence of Surface Topography of Hf-Cvd Diamond Films on Self-Mated Planar Sliding Contacts in Dry Environments. Surf. Coat. Technol. 2007, 201, 6197–6205. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Elam, J.W.; Erdemir, A.; Carlisle, J.A.; Auciello, O.; Libera, J.A.; Pellin, M.J.; Gruen, D.M.; Hryn, J.N. Development of Ultrananocrystalline Diamond (Uncd) Coatings for Multipurpose Mechanical Pump Seals. Wear 2011, 270, 325–331. [Google Scholar] [CrossRef]

- Xu, T.; Yang, S.; Chen, M.; Tian, J.; Xue, Q.; Li, J.; Guo, W. Influence of Nitrogen Ion Implantation on Tribological Properties of Nanocrystalline Diamond Films. J. Phys. D Appl. Phys. 2002, 35, 788–793. [Google Scholar] [CrossRef]

- Schneider, A.; Steinmueller-Nethl, D.; Roy, M.; Franek, F. Enhanced Tribological Performances of Nanocrystalline Diamond Film. Int. J. Refract. Met. Hard Mater. 2010, 28, 40–50. [Google Scholar] [CrossRef]

- Panda, K.; Kumar, N.; Sankaran, K.J.; Panigrahi, B.K.; Dash, S.; Chen, H.C.; Lin, I.N.; Tai, N.H.; Tyagi, A.K. Tribological Properties of Ultrananocrystalline Diamond and Diamond Nanorod Films. Surf. Coat. Technol. 2012, 207, 535–545. [Google Scholar] [CrossRef]

- Sharma, N.; Kumar, N.; Dhara, S.; Dash, S.; Bahuguna, A.; Kamruddin, M.; Tyagi, A.K.; Raj, B. Tribological Properties of Ultra Nanocrystalline Diamond Film-Effect of Sliding Counterbodies. Tribol. Int. 2012, 53, 167–178. [Google Scholar] [CrossRef]

- Schneider, A.; Brenner, J.; Steinmüller-Nethl, D.; Roy, M.; Franek, F. Tribological Properties of Lubricated Nanocrystalline Diamond Surfaces for Various Loads and Geometries. Tribol. Mater. Surf. Interfaces 2013, 3, 175–181. [Google Scholar] [CrossRef]

- Panda, K.; Kumar, N.; Polaki, S.R.; Panigrahi, B.K.; Dash, S.; Tyagi, A.K.; Lin, I.N. Microstructure and Friction Behaviour in Nanocrystalline Diamond Films. Philos. Mag. 2015, 95, 886–905. [Google Scholar] [CrossRef]

- Yan, Y.; Lei, X.; He, Y. Experimental Study on the Effect of Surface Texture on Tribological Properties of Nanodiamond Films under Water Lubrication. Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol. 2021, 236, 995–1007. [Google Scholar] [CrossRef]

- Abreu, C.S.; Amaral, M.; Fernandes, A.J.S.; Oliveira, F.J.; Silva, R.F.; Gomes, J.R. Friction and Wear Performance of Hfcvd Nanocrystalline Diamond Coated Silicon Nitride Ceramics. Diam. Relat. Mater. 2006, 15, 739–744. [Google Scholar] [CrossRef]

- Shabani, M.; Carrapichano, J.M.; Oliveira, F.J.; Silva, R.F. Multilayered Diamond Mechanical Seal Rings under Biodiesel Lubrication and the Full Sealing Conditions of Pressurized Water. Wear 2017, 384–385, 178–184. [Google Scholar] [CrossRef]

- Abreu, C.S.; Amaral, M.S.; Oliveira, F.J.; Tallaire, A.; Bénédic, F.; Syll, O.; Cicala, G.; Gomes, J.R.; Silva, R.F. Tribological Testing of Self-Mated Nanocrystalline Diamond Coatings on Si3n4 Ceramics. Surf. Coat. Technol. 2006, 200, 6235–6239. [Google Scholar] [CrossRef]

- Silva, W.M.; Ferreira, N.G.; Travello, J.; Almeida, E.C.; Azevedo, A.F.; Baldan, M.R. Dependence of Diamond Nucleation and Growth through Graphite Etching at Different Temperatures. Diam. Relat. Mater. 2007, 16, 1705–1710. [Google Scholar] [CrossRef]

- Salgueiredo, E.; Abreu, C.S.; Amaral, M.; Oliveira, F.J.; Gomes, J.R.; Silva, R.F. Self-Mated Tribological Systems Based on Multilayer Micro/Nanocrystalline Cvd Diamond Coatings. Wear 2013, 303, 225–234. [Google Scholar] [CrossRef]

- Ferreira, S.; Duarte, P.; Almeida, F.A.; Silva, R.F. Bilayered Coatings of Bn/Diamond Grown on Si3n4 Ceramic Substrates. Diam. Relat. Mater. 2011, 20, 464–467. [Google Scholar] [CrossRef]

- Abreu, C.S.; Amaral, M.; Oliveira, F.J.; Fernandes, A.J.S.; Gomes, J.R.; Silva, R.F. Enhanced Performance of Hfcvd Nanocrystalline Diamond Self-Mated Tribosystems by Plasma Pretreatments on Silicon Nitride Substrates. Diam. Relat. Mater. 2006, 15, 2024–2028. [Google Scholar] [CrossRef]

- Guo, D.; Cai, N.; Wu, G.; Xie, F.; Tan, S.; Jiang, N.; Li, H. Improving Pressure–Velocity Limit of Mechanical Seal with Polycrystalline Diamond Coating. Appl. Sci. 2020, 10, 6090. [Google Scholar] [CrossRef]

- Schade, A.; Rosiwal, S.M.; Singer, R.F. Tribological Behaviour of <100> and <111> Fibre Textured Cvd Diamond Films under Dry Planar Sliding Contact. Diam. Relat. Mater. 2006, 15, 1682–1688. [Google Scholar]

- Simões, R.; Martins, B.; Santos, J.; Neto, V. Hfcvd Diamond-Coated Mechanical Seals. Coatings 2018, 8, 172. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, J.R.; Lau, B.K.T.P. Uv Raman Characteristics of Nanocrystalline Diamond Films with Different Grain Size. Diam. Relat. Mater. 2000, 9, 1979–1983. [Google Scholar] [CrossRef]

- Kromka, A.; Breza, J.; Kadlečíková, M.; Janík, J.; Balon, F. Identification of Carbon Phases and Analysis of Diamond/Substrate Interfaces by Raman Spectroscopy. Carbon 2005, 43, 425–429. [Google Scholar] [CrossRef]

- Tang, C.J.; Neves, A.J.; Carmo, M.C. Infrared Absorption Study of Hydrogen Incorporation in Thick Nanocrystalline Diamond Films. Appl. Phys. Lett. 2005, 86, 223107. [Google Scholar] [CrossRef]

- Dychalska, A.; Popielarski, P.; Franków, W.; Fabisiak, K.; Paprocki, K.; Szybowicz, M. Study of Cvd Diamond Layers with Amorphous Carbon Admixture by Raman Scattering Spectroscopy. Mater. Sci. Pol. 2015, 33, 799–805. [Google Scholar] [CrossRef]

- May, P.W.; Smith, J.A.; Rosser, K.N. 785 nm Raman Spectroscopy of Cvd Diamond Films. Diam. Relat. Mater. 2008, 17, 199–203. [Google Scholar] [CrossRef]

- Knight, D.S.; White, W.B. Characterization of Diamond Films by Raman Spectroscopy. J. Mater. Res. 1988, 4, 385–393. [Google Scholar] [CrossRef]

- Yoshikawa, M.; Katagiri, G.; Ishida, H.; Ishitani, A. Characterization of Crystamne Quality of Diamond Fums by Raman Spectroscopy. Appl. Phys. Lett. 1989, 55, 2608–2610. [Google Scholar] [CrossRef]

- Erdemir, A.; Fenske, G.R.; Krauss, A.R.; Gruen, D.M.; McCauley, T.; Csencsit, R.T. Tribological Properties of Nanocrystalline Diamond Films. Surf. Coat. Technol. 1999, 120, 565–572. [Google Scholar] [CrossRef]

- Wang, C.; Song, X.; Shen, X.; Sun, F. Molecular Dynamics Simulation and Experimental Investigation of Structural Transformation and Graphitization in Diamond During Friction. Comput. Mater. Sci. 2020, 184, 109862. [Google Scholar] [CrossRef]

- Konicek, A.R.; Grierson, D.S.; Gilbert, P.U.; Sawyer, W.G.; Sumant, A.V.; Carpick, R.W. Origin of Ultralow Friction and Wear in Ultrananocrystalline Diamond. Phys. Rev. Lett. 2008, 100, 235502. [Google Scholar] [CrossRef]

| Number | Rotating Speed (rpm) | Normal Load (N) |

|---|---|---|

| Group 1 | 500, 1000, 1500 and 2000 | 100 |

| Group 2 | 1000 | 100, 150, 200 and 250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, Y.; Xie, F.; Wang, J.; Xu, B.; Chen, H.; Yan, B.; Wu, Y.; Huang, W.; Li, H. Dry Friction Properties of Diamond-Coated Silicon Carbide. Materials 2023, 16, 3640. https://doi.org/10.3390/ma16103640

Du Y, Xie F, Wang J, Xu B, Chen H, Yan B, Wu Y, Huang W, Li H. Dry Friction Properties of Diamond-Coated Silicon Carbide. Materials. 2023; 16(10):3640. https://doi.org/10.3390/ma16103640

Chicago/Turabian StyleDu, Yuefeng, Fangmin Xie, Jian Wang, Bin Xu, Huanyi Chen, Bineng Yan, Yanjiao Wu, Weifeng Huang, and He Li. 2023. "Dry Friction Properties of Diamond-Coated Silicon Carbide" Materials 16, no. 10: 3640. https://doi.org/10.3390/ma16103640

APA StyleDu, Y., Xie, F., Wang, J., Xu, B., Chen, H., Yan, B., Wu, Y., Huang, W., & Li, H. (2023). Dry Friction Properties of Diamond-Coated Silicon Carbide. Materials, 16(10), 3640. https://doi.org/10.3390/ma16103640