Fatigue Behavior of Additively Manufactured Stainless Steel 316L

Abstract

1. Introduction

2. Additive Manufacturing Technologies for Stainless Steel 316L

3. Fatigue Studies on AM 316L

- Printing parameters: i.e., Laser Energy Density (Ed) or Layer Thickness (t)

- Build orientation: Horizontal (XY), Vertical (Z), Diagonal (45°)

- Surface Finish: As-Built (AB), Machined (M), Polished (P), or Surface Treatment (ST)

- Heat Treatment: No treatment (N), Stress-Relief (SR), Annealing (ANN), Hot Isostatic Pressing (HIP), Precipitation Hardening (PH).

- Loading mode: Axial (AX), Rotating Bending (RB), Reversed Bending (RevB), Torsional (T), Multiaxial (M-AX)

- Specimen type and geometry: Cylindrical (C), Flat (F)-Dogbone (DB), Hourglass (HG)

- Test control variable: Load (Stress-based), Strain (Strain-based)

- Fatigue Load Ratio: R (Alternating R = −1, Pulsating R ≥ 0)

4. Fatigue of L-PBF 316L

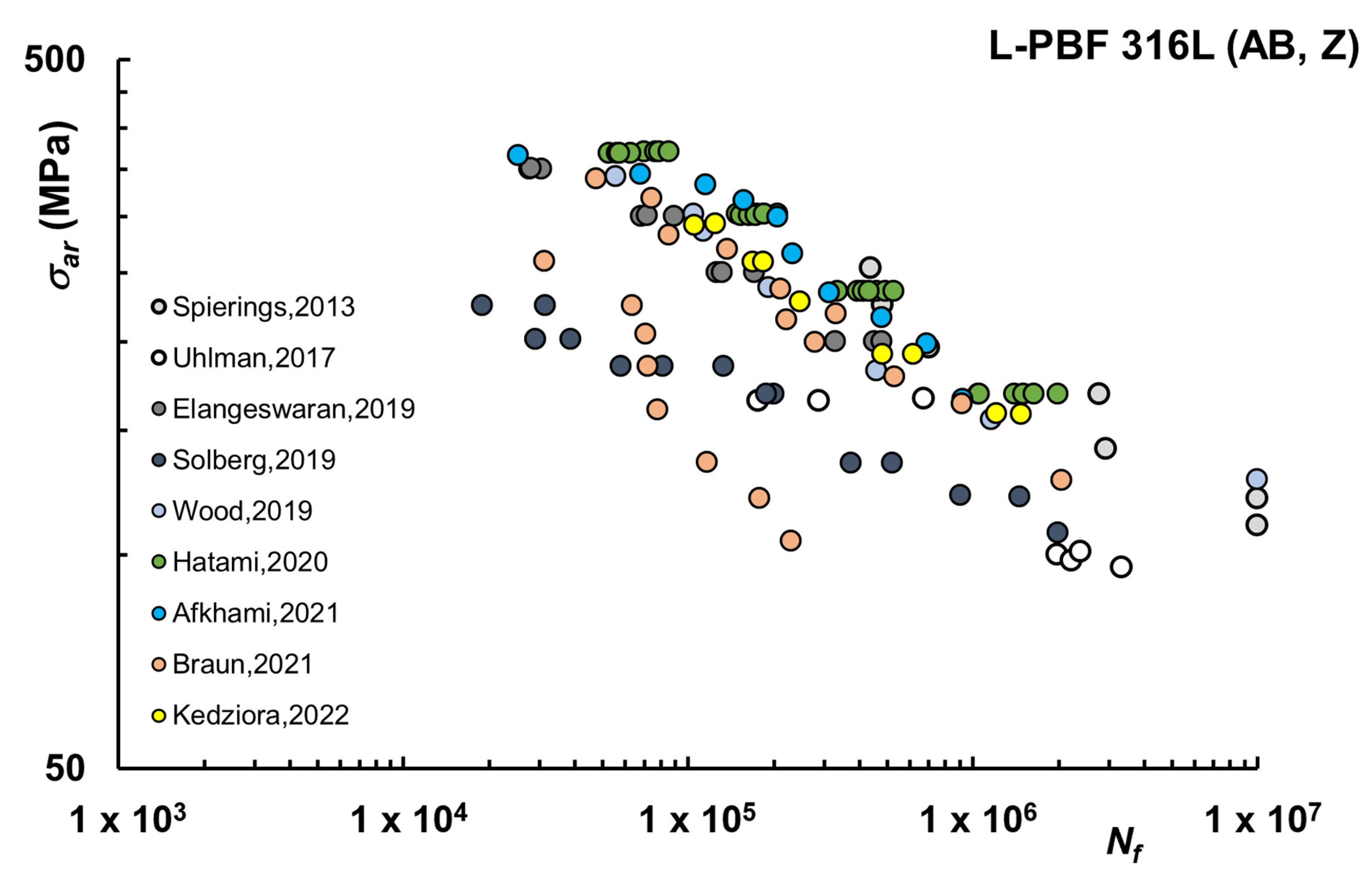

4.1. Fatigue of L-PBF 316L in AB Conditions

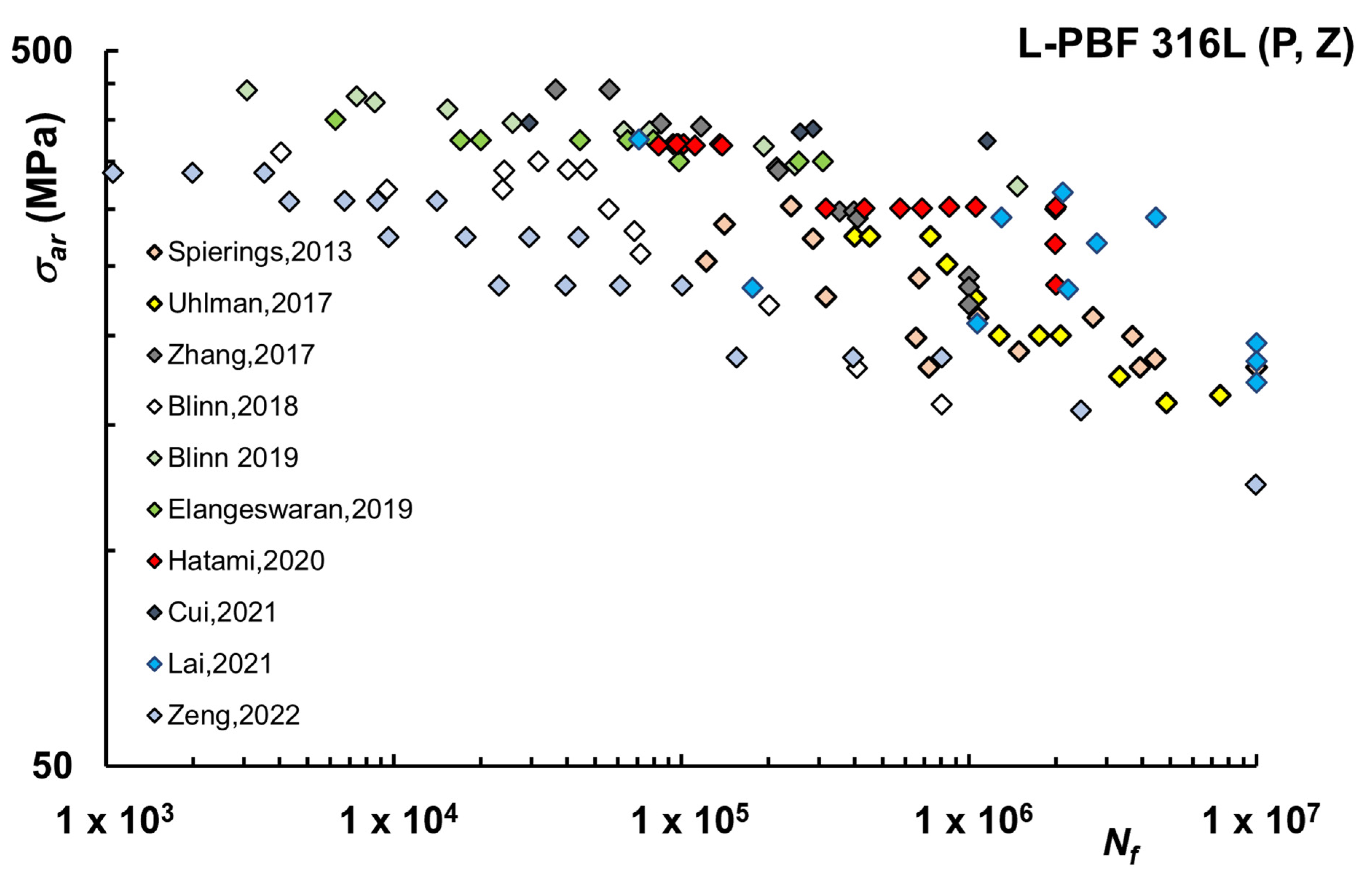

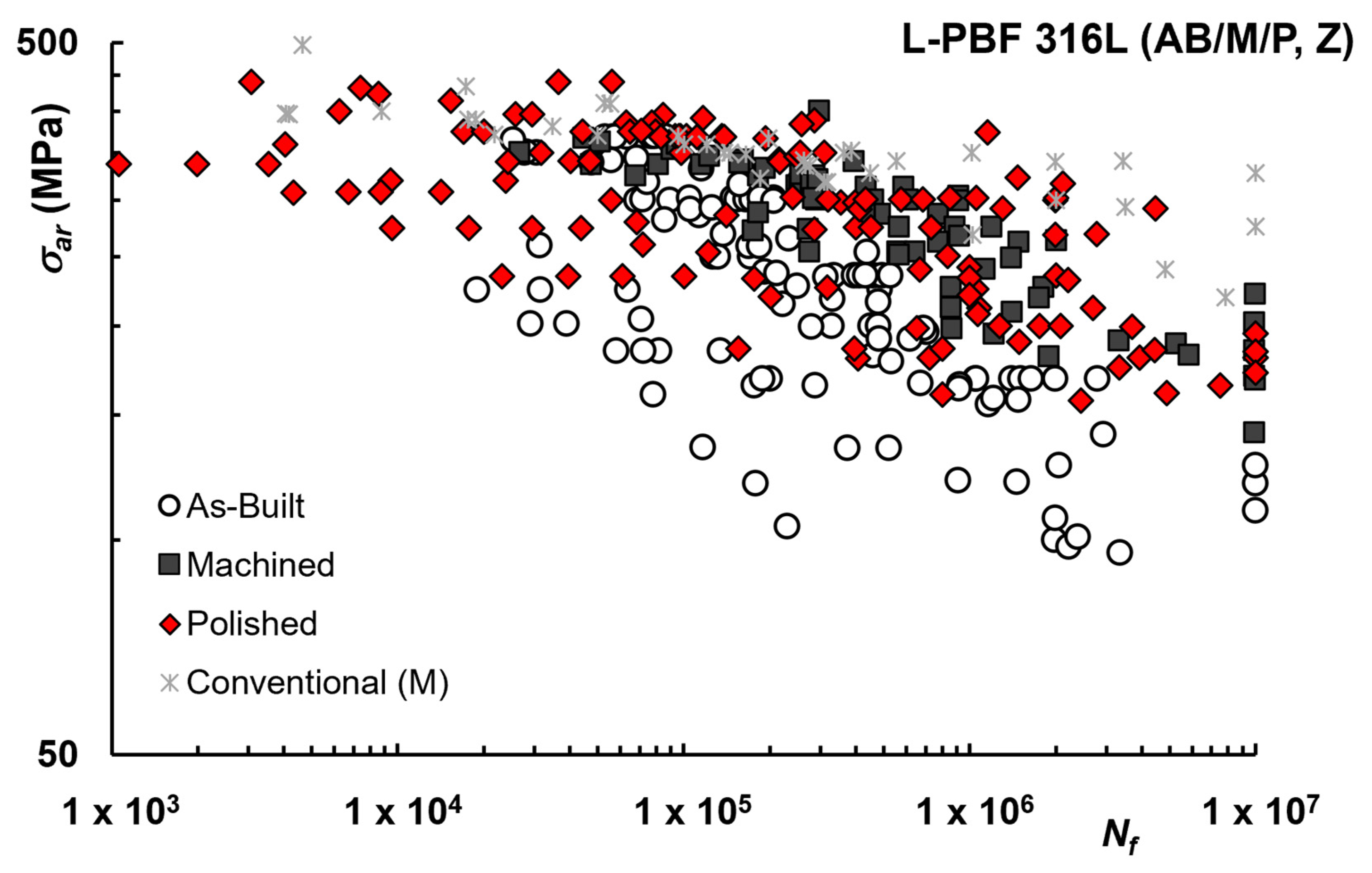

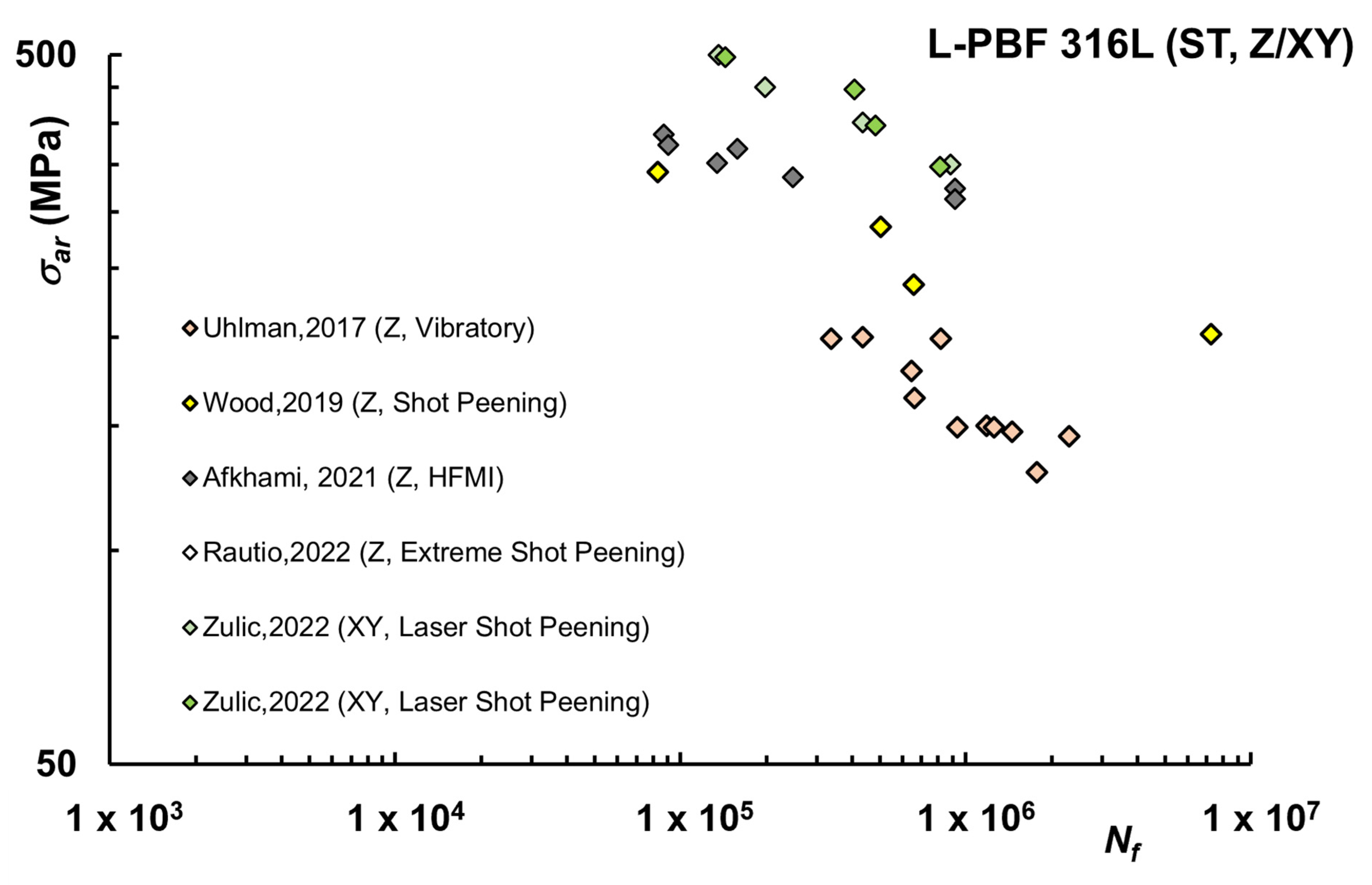

4.2. Fatigue of L-PBF 316L: Influence of Surface Finish and Treatment

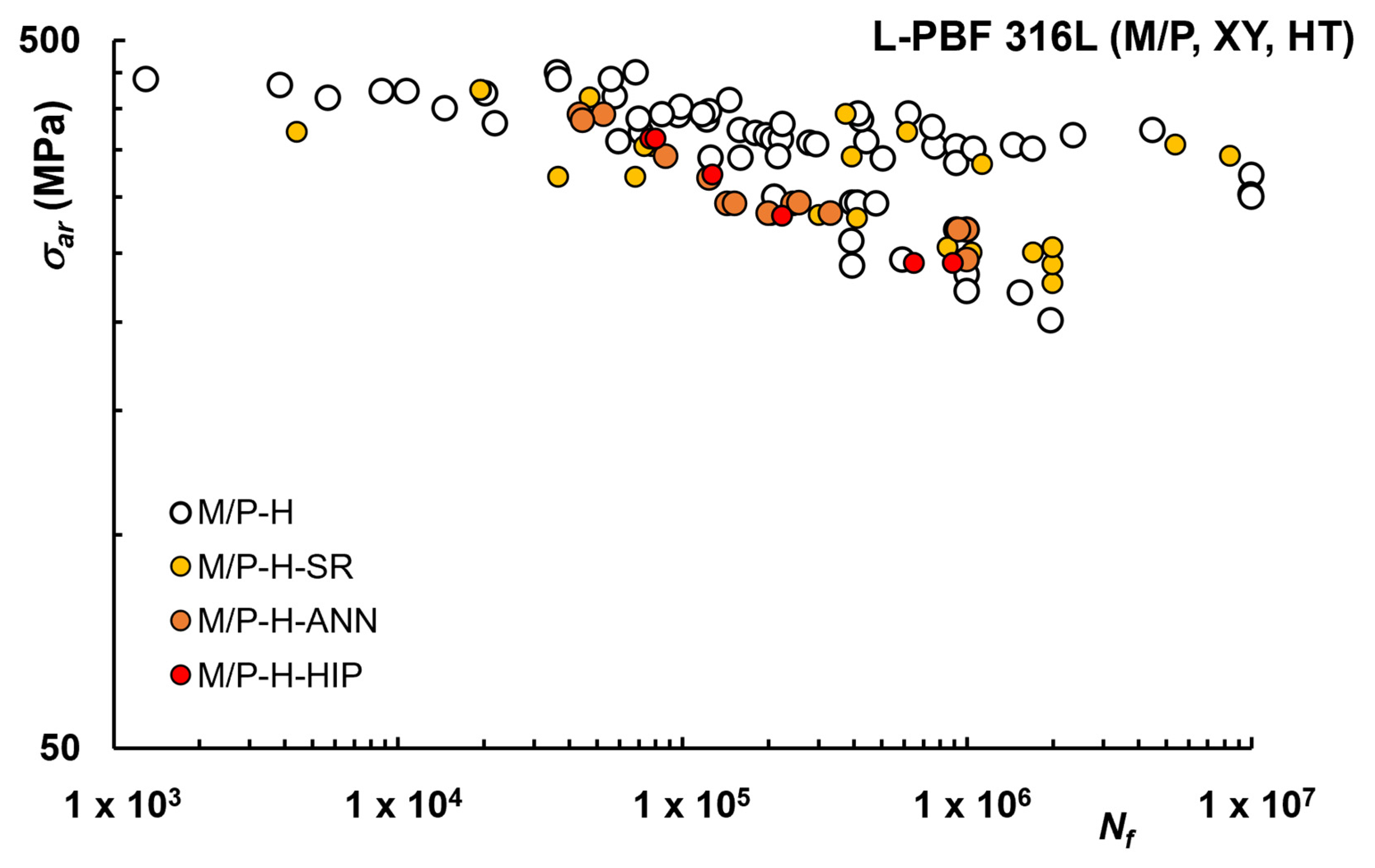

4.3. Fatigue of L-PBF 316L: Influence of Build Orientation

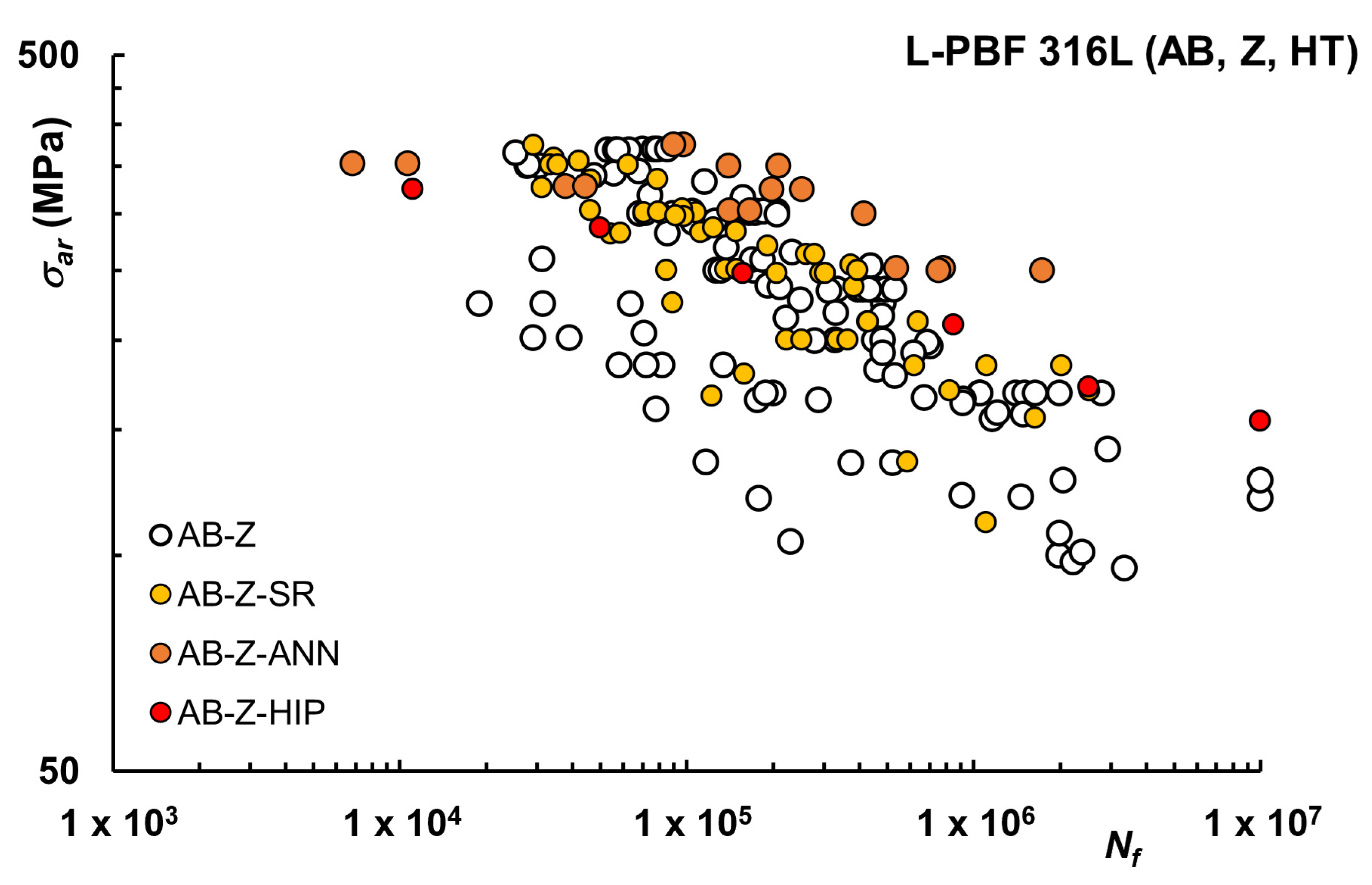

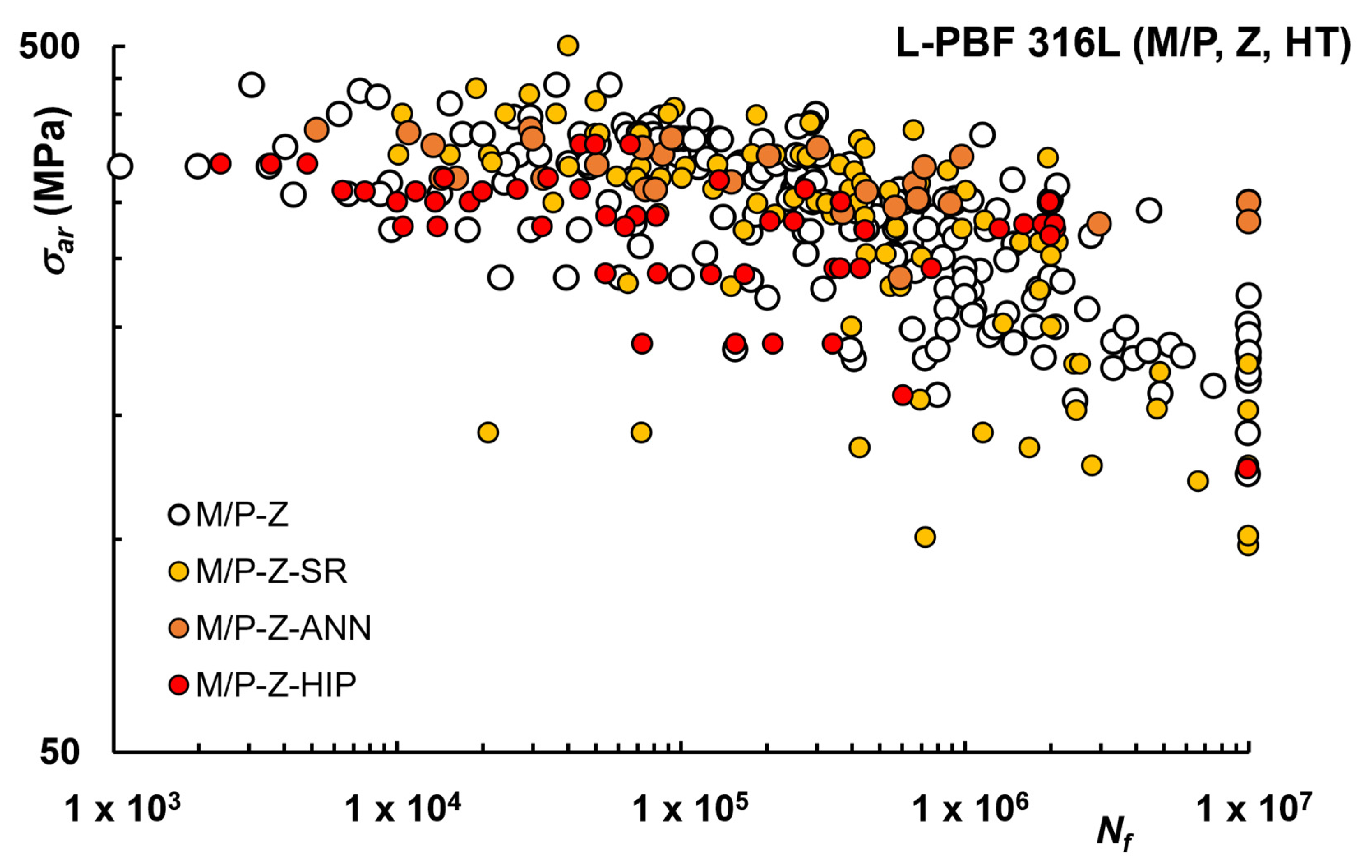

4.4. Fatigue of L-PBF 316L: Influence of Heat Treatment

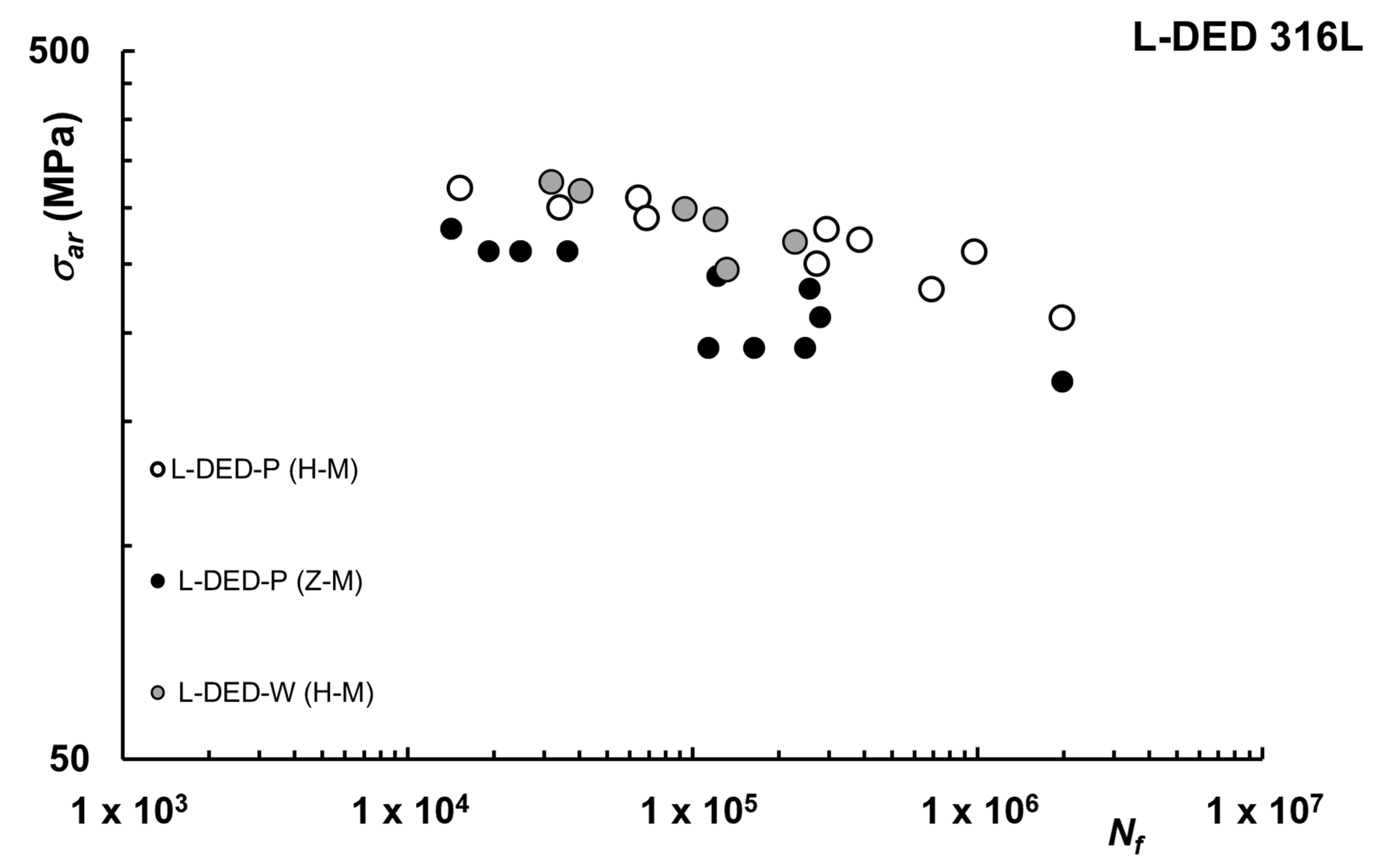

5. Fatigue of L-DED 316L

6. Fatigue of BJ and FFF 316L

7. Other Investigations on Fatigue of AM 316L

7.1. Strain-Based Approaches and LCF

7.2. Fatigue Crack Propagation (FCP)

7.3. Short Time Procedures

7.4. Predictive Models

7.5. Critical Defect Size and Role of Porosity

8. Conclusions

- Considering fatigue of L-PBF 316L, a distinct response is observed depending on whether AB or M/P condition is considered. For AB parts, run-out at 107 cycles was reported for σar up to around 130 MPa versus 330 MPa for wrought material (machined). After M/P operation, the fatigue strength of AM materials is closer (run-out at 107 cycles for σar up to around 220 MPa) to conventional parts, but still lower when considering parts printed vertically. Thus, available data show that some improvement for current technologies is still needed to make as-fabricated AM 316L competitive with its traditional counterparts. Surface treatments may improve fatigue response, but available data are limited, and more investigations are needed.

- Fatigue strength is sensitive to build orientation and for L-PBF 316L literature data confirm that samples printed flat are generally more resistant against fatigue. After machining, XY samples may reach run-out at 107 cycles for σar up to around 330 MPa, with a fatigue strength comparable with conventional 316L.

- Common HTs for 316L include SR, ANN, and HIP. For SR a more noticeable positive effect is observed for specimens with a surface in AB condition, whereas after machining the effect is limited. This supports the conclusion that relief of internal tensions is less effective on fatigue when surface layers have already been removed by some machining operation. ANN and HIP do not seem to provide distinct advantages for AB condition, while for machined conditions run-out at 107 cycles for σar up to around 300 MPa were reported. Some differences can also be noticed depending on whether low or high cyclic stress is of interest.

- Considering fatigue of L-DED 316L, results seem promising, with run-out at 107 cycles for σar up to around 210 MPa but current knowledge at the microstructural level is still limited. For BJ 316L, despite higher porosity levels, fatigue strength seems comparable with L-PBF under AB condition (run-out at 107 cycles for σar up to around 150 MPa), thanks to a peculiar fatigue failure mechanism. FFF 316L exhibited the lowest fatigue strength, as a consequence of higher porosity and lower internal cohesion between layers and fused filaments, requiring optimization of processing conditions.

- Taken as a whole, available fatigue data are highly scattered, and even if some general trends emerge, it is clear that a common and shared base for optimal selection of processing and post-processing parameters is still lacking, even for more mature processes like L-PBF. This is a consequence of the high number of processing parameters involved, combined with the availability on the market of different commercial systems that may require different settings or whose parameters selection is not disclosed or available for the end user.

- The microstructure of AM 316L is different from conventional manufacturing and plays a major role in fatigue crack initiation and propagation. For L-PBF the microstructure of 316L is generally fully austenitic with elongated grains, resulting in anisotropic resistance to crack propagation, with more tortuous paths and slower growth when the load is applied parallel to the direction of grain growth. Fine cellular microstructures, typical of AB condition, are deemed to be more favorable for higher stress levels. Annealing or HIP at high temperatures causing recrystallization may lead to more isotropic crack propagation and coarser-grained microstructure that can be preferred when higher ductility and lower cyclic stresses are needed.

- For other AM technologies less information is available, but studies indicate that in DED, the microstructure consists of both columnar and equiaxed grains, with δ-ferritic phase up to 4–5% and oxides or non-metallic inclusions that may favor crack initiation. In BJ, the δ-ferritic phase may also be present, but the microstructure is not elongated in the building direction and microstructural features such as high-angle grain boundaries and annealing twin boundaries may positively affect fatigue behavior, by making it more difficult for the fatigue cracks to grow. In FFF the higher porosity hinders other microstructure-related effects.

- While fatigue is an inherently complex phenomenon, especially for AM metal in which internal defects and surface roughness may play a crucial role, the variability observed for fatigue data may also be the consequence of the different testing protocols adopted, in which load ratio R, shape (flat or cylindrical) and size of the specimens may change considerably. A shared standardized approach among researchers would certainly be beneficial to better isolate contributions from process-related factors.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AB | As-Built | ME | Metal Extrusion |

| AD | Artificial Defects | N | No Heat Treatment |

| AM | Additive Manufacturing | Nf | Number of cycles to failure |

| ANN | Annealing | P | Polished |

| AX | Axial | PBF | Powder Bed Fusion |

| BJ | Binder Jetting | Pd | Total Laser Energy in unit time |

| C | Cylindrical specimen | PH | Precipitation Hardening |

| CC | Continuous Casting | ||

| CT | Compact Tension specimen | PhyBaLCHT | Short-time procedure based on cyclic indentation test |

| DB | Dogbone specimen | R | Fatigue Load Ratio |

| DED | Directed Energy Deposition | Ra | Surface roughness Ra |

| Δ Kth | Threshold value of stress intensity factor | RB | Rotating Bending |

| DMLS | Direct Metal Laser Sintering | RevB | Reversed Bending |

| DMS-PSO | Dynamic multiswarm particle swarm optimizer algorithm | Rz | Surface roughness Rz |

| δ-phase | Ferritic phase | SR | Stress Relief |

| E | Elastic Modulus | ST | Surface Treatment |

| EBSD | Electron Backscatter Diffraction | SS | Stainless Steel |

| Ed | Laser Energy Density | σa | Alternating stress in a fatigue cycle |

| εR | Strain at failure | σar | Equivalent alternating stress |

| F | Flat specimen | SLM | Selective Laser Melting |

| FCI | Fatigue Crack Initiation | σm | Mean stress in a fatigue cycle |

| FCP | Fatigue Crack Propagation | σmax | Maximum stress in a fatigue cycle |

| FFF | Fused Filament Fabrication | σmin | Minimum stress in a fatigue cycle |

| γ-phase | Austenitic phase | σ-phase | Chromium/molybdenum-rich intermetallic phase |

| h | hatch spacing | SP | Shot Peening |

| HAGB | High Angle Grain Boundaries | STP | Stepped Test Protocol |

| HCF | High Cycle Fatigue | SWT | Smith-Watson-Topper parameter |

| HFMI | High-Frequency Mechanical Impact finishing | t | Layer Thickness |

| HG | Hourglass specimen | T | Torsional load |

| HIP | Hot Isostatic Pressing | UTS | Ultimate Tensile Strength |

| HT | Heat Treatment | v | Scanning speed |

| LCF | Low Cycle Fatigue | VF | Vibratory Finishing |

| L-PBF | Laser Powder Bed Fusion | VHCF | Very High Cycle Fatigue |

| L-DED-P | Directed Laser Deposition (Powder form) | WAAM | Wire Arc Additive Manufacturing |

| L-DED-W | Directed Laser Deposition (Wire form) | XCT | X-ray Computed Tomography |

| LENS | Laser engineered net shaping | XRD | X-ray Diffraction |

| LIT | Load Increase Tests | XY | Horizontal Building Orientation |

| LOF | Lack of Fusion | YS | Yield Strength |

| LSP | Laser Shot Peening | Z | Vertical Building Orientation |

| M | Machined | 2Nf | Number of reversals to failure |

| M-AX | Multiaxial load | 45° | Diagonal Building Orientation |

References

- Zhang, M.; Sun, C.N.; Zhang, X.; Goh, P.C.; Wei, J.; Hardacre, D.; Li, H. Fatigue and fracture behaviour of laser powder bed fusion stainless steel 316L: Influence of processing parameters. Mater. Sci. Eng. A 2017, 703, 251–261. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Fatigue life improvement through surface nanostructuring of stainless steel by means of surface mechanical attrition treatment. Scr. Mater. 2006, 54, 1949–1954. [Google Scholar] [CrossRef]

- Bedmar, J.; Riquelme, A.; Rodrigo, P.; Torres, B.; Rams, J. Comparison of different additive manufacturing methods for 316l stainless steel. Materials 2021, 14, 6504. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Mirzababaei, S.; Pasebani, S. A Review on Binder Jet Additive Manufacturing of 316L Stainless Steel. J. Manuf. Mater. Process. 2019, 3, 82. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Lores, A.; Azurmendi, N.; Agote, I.; Zuza, E. A review on recent developments in binder jetting metal additive manufacturing: Materials and process characteristics. Powder Metall. 2019, 62, 267–296. [Google Scholar] [CrossRef]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal binder jetting additive manufacturing: A literature review. J. Manuf. Sci. Eng. Trans. ASME 2020, 142, 090801. [Google Scholar] [CrossRef]

- Suwanpreecha, C.; Manonukul, A. A Review on Material Extrusion Additive Manufacturing of Metal and How It Compares with Metal Injection Moulding. Metals 2022, 12, 429. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Microstructure and mechanical properties of AISI 316L produced by directed energy deposition-based additive manufacturing: A review. Appl. Sci. 2020, 10, 3310. [Google Scholar] [CrossRef]

- Zitelli, C.; Folgarait, P.; di Schino, A. Laser powder bed fusion of stainless steel grades: A review. Metals 2019, 9, 731. [Google Scholar] [CrossRef]

- Ahmed, N.; Barsoum, I.; Haidemenopoulos, G.; Al-Rub, R.K.A. Process parameter selection and optimization of laser powder bed fusion for 316L stainless steel: A review. J. Manuf. Process. 2022, 75, 415–434. [Google Scholar] [CrossRef]

- Santamaria, R.; Salasi, M.; Bakhtiari, S.; Leadbeater, G.; Iannuzzi, M.; Quadir, M.Z. Microstructure and mechanical behaviour of 316L stainless steel produced using sinter-based extrusion additive manufacturing. J. Mater. Sci. 2022, 57, 9646–9662. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Simsiriwong, J.; Sanaei, N.; Pegues, J.; Torries, B.; Phan, N.; Shamsaei, N. Fatigue behaviour of additive manufactured materials: An overview of some recent experimental studies on Ti-6Al-4V considering various processing and loading direction effects. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 991–1009. [Google Scholar] [CrossRef]

- Afkhami, S.; Dabiri, M.; Alavi, S.H.; Björk, T.; Salminen, A. Fatigue characteristics of steels manufactured by selective laser melting. Int. J. Fatigue. 2019, 122, 72–83. [Google Scholar] [CrossRef]

- Pegues, J.W.; Roach, M.D.; Shamsaei, N. Additive manufacturing of fatigue resistant austenitic stainless steels by understanding process-structure–property relationships. Mater. Res. Lett. 2020, 8, 8–15. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A. Fatigue Design with Additive Manufactured Metals: Issues to Consider and Perspective for Future Research. Procedia Eng. 2018, 213, 5–16. [Google Scholar] [CrossRef]

- Astafurov, S.; Astafurova, E. Phase composition of austenitic stainless steels in additive manufacturing: A review. Metals 2021, 11, 1052. [Google Scholar] [CrossRef]

- Adeyemi, A.; Akinlabi, E.T.; Mahamood, R.M. Powder bed based laser additive manufacturing process of stainless steel: A review. Mater. Today Proc. 2018, 5, 18510–18517. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Bassini, E. Directed energy deposition of aisi 316l stainless steel powder: Effect of process parameters. Metals 2021, 11, 932. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition. J. Mater. Process. Technol. 2017, 240, 12–22. [Google Scholar] [CrossRef]

- Blinn, B.; Lion, P.; Jordan, O.; Meiniger, S.; Mischliwski, S.; Tepper, C.; Gläßner, C.; Aurich, J.C.; Weigold, M.; Beck, T. Process-influenced fatigue behavior of AISI 316L manufactured by powder- and wire-based Laser Direct Energy Deposition. Mater. Sci. Eng. A 2021, 818, 141383. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316 L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A. 2016, 677, 1–10. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Wang, J.; Dhokia, V.; Shrokani, A.; Newman, S.T. Characterisation of austenitic 316LSi stainless steel produced by wire arc additive manufacturing with interlayer cooling. In Proceedings of the 2019 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019; pp. 426–439. [Google Scholar]

- Vinoth, V.; Sathiyamurthy, S.; Natarajan, U.; Venkatkumar, D.; Prabhakaran, J.; Prakash, K.S. Examination of microstructure properties of AISI 316L stainless steel fabricated by wire arc additive manufacturing. Mater. Today Proc. 2022, 66, 702–706. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef]

- Lecis, N.; Beltrami, R.; Mariani, M. Binder jetting 3D printing of 316 stainless steel: Influence of process parameters on microstructural and mechanical properties. Metall. Ital. 2021, 113, 31–41. [Google Scholar]

- Mirzababaei, S.; Paul, B.K.; Pasebani, S. Microstructure-property relationship in binder jet produced and vacuum sintered 316 L. Addit. Manuf. 2022, 53, 102720. [Google Scholar] [CrossRef]

- Zwiren, A.; Murphy, T.F. Comparison of Binder Jetting Additive Manufacturing to Press and Sinter 316L Stainless Steel. Int. J. Powder Metall. 2018, 54, 39–50. [Google Scholar]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Wagner, M.A.; Engel, J.; Hadian, A.; Clemens, F.; Rodriguez-Arbaizar, M.; Carreño-Morelli, E.; Wheeler, J.M.; Spolenak, R. Filament extrusion-based additive manufacturing of 316L stainless steel: Effects of sintering conditions on the microstructure and mechanical properties. Addit. Manuf. 2022, 59, 103147. [Google Scholar] [CrossRef]

- Jiang, D.; Ning, F. Additive Manufacturing of 316L Stainless Steel by a Printing-Debinding-Sintering Method: Effects of Microstructure on Fatigue Property, J. Manuf. Sci. Eng. 2021, 143. [Google Scholar] [CrossRef]

- Budynas, R.G.; Nysbett, J.K. (Eds.) Shigley’s Mechanical Engineering Design, 9th ed.; McGraw-Hill: New Nork, NY, USA, 2011. [Google Scholar]

- Voloskov, B.; Evlashin, S.; Dagesyan, S.; Abaimov, S.; Akhatov, I.; Sergeichev, I. Very high cycle fatigue behavior of additively manufactured 316L stainless steel. Materials 2020, 13, 3293. [Google Scholar] [CrossRef]

- Voloskov, B.; Mishurova, T.; Evlashin, S.; Akhatov, I.; Bruno, G.; Sergeichev, I. Artificial Defects in 316L Stainless Steel Produced by Laser Powder Bed Fusion: Printability, Microstructure, and Effects on the Very-High-Cycle Fatigue Behavior. Adv. Eng. Mater. 2022, 2200831. [Google Scholar] [CrossRef]

- Spierings, A.B.B.; Starr, T.L.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Leuders, S.; Lieneke, T.; Lammers, S.; Tröster, T.; Niendorf, T. On the fatigue properties of metals manufactured by selective laser melting—The role of ductility. J. Mater. Res. 2014, 29, 1911–1919. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Uhlmann, E.; Fleck, C.; Gerlitzky, G.; Faltin, F. Dynamical Fatigue Behavior of Additive Manufactured Products For a Fundamental Life cycle Approach. Procedia CIRP 2017, 61, 588–593. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Goh, P.C.; Wei, J.; Li, H.; Hardacre, D. Elucidating the Relations Between Monotonic and Fatigue Properties of Laser Powder Bed Fusion Stainless Steel 316L. JOM 2018, 70, 390–395. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Goh, P.C.; Wei, J.; Hardacre, D.; Li, H. Effect of heat treatment on fatigue crack initiation of laser powder bed fusion stainless steel 316L. MATEC Web Conf. 2018, 165, 1–6. [Google Scholar] [CrossRef]

- Blinn, B.; Klein, M.; Gläßner, C.; Smaga, M.; Aurich, J.C.; Beck, T. An investigation of the microstructure and fatigue behavior of additively manufactured AISI 316L stainless steel with regard to the influence of heat treatment. Metals 2018, 8, 220. [Google Scholar] [CrossRef]

- Blinn, B.; Ley, M.; Buschhorn, N.; Teutsch, R.; Beck, T. Investigation of the anisotropic fatigue behavior of additively manufactured structures made of AISI 316L with short-time procedures PhyBaL LIT and PhyBaL CHT. Int. J. Fatigue 2019, 124, 389–399. [Google Scholar] [CrossRef]

- Elangeswaran, C.; Cutolo, A.; Muralidharan, G.K.; de Formanoir, C.; Berto, F.; Vanmeensel, K.; van Hooreweder, B. Effect of post-treatments on the fatigue behaviour of 316L stainless steel manufactured by laser powder bed fusion. Int. J. Fatigue 2019, 123, 31–39. [Google Scholar] [CrossRef]

- Shrestha, R.; Simsiriwong, J.; Shamsaei, N. Comparison of rotating-bending and axial fatigue behaviors of LB-PBF 316L stainless steel. In Proceedings of the 2019 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 12–14 August 2019; pp. 515–521. [Google Scholar]

- Solberg, K.; Guan, S.; Razavi, S.M.J.; Welo, T.; Chan, K.C.; Berto, F. Fatigue of additively manufactured 316L stainless steel: The influence of porosity and surface roughness. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2043–2052. [Google Scholar] [CrossRef]

- Wood, P.; Libura, T.; Kowalewski, Z.L.; Williams, G.; Serjouei, A. Influences of horizontal and vertical build orientations and post-fabrication processes on the fatigue behavior of stainless steel 316l produced by selective laser melting. Materials 2019, 12, 4203. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Goh, P.C.; Wei, J.; Hardacre, D.; Li, H. High cycle fatigue life prediction of laser additive manufactured stainless steel: A machine learning approach. Int. J. Fatigue 2019, 128, 105194. [Google Scholar] [CrossRef]

- Blinn, B.; Krebs, F.; Ley, M.; Teutsch, R.; Beck, T. Determination of the influence of a stress-relief heat treatment and additively manufactured surface on the fatigue behavior of selectively laser melted AISI 316L by using efficient short-time procedures. Int. J. Fatigue 2020, 131, 105301. [Google Scholar] [CrossRef]

- Elangeswaran, C.; Cutolo, A.; Muralidharan, G.K.; Vanmeensel, K.; van Hooreweder, B. Microstructural analysis and fatigue crack initiation modelling of additively manufactured 316L after different heat treatments. Mater. Des. 2020, 194, 108962. [Google Scholar] [CrossRef]

- Hatami, S.; Ma, T.; Vuoristo, T.; Bertilsson, J.; Lyckfeldt, O. Fatigue Strength of 316 L Stainless Steel Manufactured by Selective Laser Melting. J. Mater. Eng. Perform. 2020, 29, 3183–3194. [Google Scholar] [CrossRef]

- Kumar, P.; Jayaraj, R.; Suryawanshi, J.; Satwik, U.R.; McKinnell, J.; Ramamurty, U. Fatigue strength of additively manufactured 316L austenitic stainless steel. Acta Mater. 2020, 199, 225–239. [Google Scholar] [CrossRef]

- Afkhami, S.; Dabiri, M.; Piili, H.; Björk, T. Effects of manufacturing parameters and mechanical post-processing on stainless steel 316L processed by laser powder bed fusion. Mater. Sci. Eng. A 2021, 802, 140660. [Google Scholar] [CrossRef]

- Braun, M.; Mayer, E.; Kryukov, I.; Wolf, C.; Böhm, S.; Taghipour, A.; Wu, R.E.; Ehlers, S.; Sheikhi, S. Fatigue strength of PBF-LB/M and wrought 316L stainless steel: Effect of post-treatment and cyclic mean stress. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 3077–3093. [Google Scholar] [CrossRef]

- Gnanasekaran, B.; Song, J.; Vasudevan, V.; Fu, Y. Corrosion Fatigue Characteristics of 316L Stainless Steel. Metals 2021, 11, 1046. [Google Scholar] [CrossRef]

- Kotzem, D.; Kleszczynski, S.; Stern, F.; Elspaß, A.; Tenkamp, J.; Witt, G.; Walther, F. Impact of single structural voids on fatigue properties of AISI 316L manufactured by laser powder bed fusion. Int. J. Fatigue 2021, 148, 106207. [Google Scholar] [CrossRef]

- Lai, W.J.; Ojha, A.; Li, Z.; Engler-Pinto, C.; Su, X. Effect of residual stress on fatigue strength of 316L stainless steel produced by laser powder bed fusion process. Prog. Addit. Manuf. 2021, 6, 375–383. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Susmel, L. Constant/variable amplitude multiaxial notch fatigue of additively manufactured AISI 316L. Int. J. Fatigue 2021, 152, 106412. [Google Scholar] [CrossRef]

- Wang, Y.; Su, Z. Effect of micro-defects on fatigue lifetime of additive manufactured 316L stainless steel under multiaxial loading. Theor. Appl. Fract. Mech. 2021, 111, 102849. [Google Scholar] [CrossRef]

- Werner, T.; Madia, M.; Zerbst, U. Comparison of the fatigue behavior of wrought and additively manufactured AISI 316L. Procedia Struct. Integr. 2021, 38, 554–563. [Google Scholar] [CrossRef]

- Cui, L.; Jiang, F.; Deng, D.; Xin, T.; Sun, X.; Mousavian, R.T.; Peng, R.L.; Yang, Z.; Moverare, J. Cyclic response of additive manufactured 316L stainless steel: The role of cell structures. Scr. Mater. 2021, 205, 114190. [Google Scholar] [CrossRef]

- Kedziora, S.; Decker, T.; Museyibov, E.; Morbach, J.; Hohmann, S.; Huwer, A.; Wahl, M. Strength Properties of 316L and 17-4 PH Stainless Steel Produced with Additive Manufacturing. Materials 2022, 15, 6278. [Google Scholar] [CrossRef] [PubMed]

- Rautio, T.; Jaskari, M.; Gundgire, T.; Iso-Junno, T.; Vippola, M.; Järvenpää, A. The Effect of Severe Shot Peening on Fatigue Life of Laser Powder Bed Fusion Manufactured 316L Stainless Steel. Materials 2022, 15, 3517. [Google Scholar] [CrossRef]

- Zulić, S.; Rostohar, D.; Kaufman, J.; Pathak, S.; Kopeček, J.; Böhm, M.; Brajer, J.; Mocek, T. Fatigue life enhancement of additive manufactured 316l stainless steel by LSP using a DPSS laser system. Surf. Eng. 2022, 38, 183–190. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, H.A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Andreau, O.; Pessard, E.; Koutiri, I.; Penot, J.D.; Dupuy, C.; Saintier, N.; Peyre, P. A competition between the contour and hatching zones on the high cycle fatigue behaviour of a 316L stainless steel: Analyzed using X-ray computed tomography. Mater. Sci. Eng. A 2019, 757, 146–159. [Google Scholar] [CrossRef]

- Cao, Y.; Moumni, Z.; Zhu, J.; Zhang, Y.; You, Y.; Zhang, W. Comparative investigation of the fatigue limit of additive-manufactured and rolled 316 steel based on self-heating approach. Eng. Fract. Mech. 2020, 223, 106746. [Google Scholar] [CrossRef]

- Andreau, O.; Pessard, E.; Koutiri, I.; Peyre, P.; Saintier, N. Influence of the position and size of various deterministic defects on the high cycle fatigue resistance of a 316L steel manufactured by laser powder bed fusion. Int. J. Fatigue 2021, 143, 105930. [Google Scholar] [CrossRef]

- Fergani, O.; Wold, A.B.; Berto, F.; Brotan, V.; Bambach, M. Study of the effect of heat treatment on fatigue crack growth behaviour of 316L stainless steel produced by selective laser melting. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1102–1119. [Google Scholar] [CrossRef]

- Zeng, F.; Yang, Y.; Qian, G. Fatigue properties and S-N curve estimating of 316L stainless steel prepared by SLM. Int. J. Fatigue 2022, 162, 106946. [Google Scholar] [CrossRef]

- Shrestha, R.; Shamsaei, N.; Thompson, S.; Bian, L. Effect of Build Orientation on the Fatigue Behavior of Stainless Steel 316L via a Laser-based Power Bed Fusion Process. In Proceedings of the 2016 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016; pp. 605–616. [Google Scholar]

- Shrestha, R.; Simsiriwong, J.; Shamsaei, N. Fatigue behavior of additive manufactured 316L stainless steel parts: Effects of layer orientation and surface roughness. Addit. Manuf. 2019, 28, 23–38. [Google Scholar] [CrossRef]

- Kluczyński, J.; Śnieżek, L.; Grzelak, K.; Torzewski, J.; Szachogłuchowicz, I.; Oziębło, A.; Perkowski, K.; Wachowski, M.; Małek, M. The influence of heat treatment on low cycle fatigue properties of selectively laser melted 316l steel. Materials 2020, 13, 5737. [Google Scholar] [CrossRef] [PubMed]

- Kimes, K.; Myers, K.; Klein, A.; Ahlfors, M.; Stevens, E.; Chmielus, M. Binder Jet 3D Printing of 316L Stainless Steel: Effects of HIP on Fatigue. Microsc. Microanal. 2019, 25, 2600–2601. [Google Scholar] [CrossRef]

- Muhammad, W.; Batmaz, R.; Natarajan, A.; Martin, E. Effect of binder jetting microstructure variability on low cycle fatigue behavior of 316L. Mater. Sci. Eng. A 2022, 839, 142820. [Google Scholar] [CrossRef]

- Rohatgi, A. Webplotdigitizer: Version 4.6. 2022. Available online: https://automeris.io/WebPlotDigitize (accessed on 21 September 2022).

- Solberg, K.; Berto, F. What is going on with fatigue of additively manufactured metals? Mater. Des. Process. Commun. 2019, 1, 21–24. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Wei, J.; Hardacre, D.; Li, H. High cycle fatigue and ratcheting interaction of laser powder bed fusion stainless steel 316L: Fracture behaviour and stress-based modelling. Int. J. Fatigue 2019, 121, 252–264. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; Schoenung, J.M.; Marchi, C.S. Relationship between manufacturing defects and fatigue properties of additive manufactured austenitic stainless steel. Mater. Sci. Eng. A 2019, 765, 138268. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.P. Microstructural investigation of selective laser melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Röttger, A.; Geenen, K.; Windmann, M.; Binner, F.; Theisen, W. Comparison of microstructure and mechanical properties of 316 L austenitic steel processed by selective laser melting with hot-isostatic pressed and cast material. Mater. Sci. Eng. A 2016, 678, 365–376. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly anisotropic steel processed by selective laser melting. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Tor, S.B.; Chua, C.K. Simultaneously enhanced strength and ductility for 3D-printed stainless steel 316L by selective laser melting. NPG Asia Mater. 2018, 10, 127–136. [Google Scholar] [CrossRef]

- Pegues, J.W.; Roach, M.D.; Shamsaei, N. Influence of microstructure on fatigue crack nucleation and microstructurally short crack growth of an austenitic stainless steel. Mater. Sci. Eng. A 2017, 707, 657–667. [Google Scholar] [CrossRef]

- Levy, A.B.; Spierings, G. Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades. In SFF Symp.; University of Texas: Austin, TX, USA, 2009; pp. 342–353. [Google Scholar]

- ASTM E466-21 Standard Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials, (n.d.). Available online: https://www.astm.org/e0466-21.html (accessed on 20 October 2022).

- ASTM E606/E606M-21 Standard Practice for Strain-Controlled Fatigue Testing. 2021. Available online: https://www.astm.org/standards/e606 (accessed on 20 October 2022).

- Fuchs, O.; Fatemi, A.; Stephens, R.R.; Stephens, R.I. Metal Fatigue in Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2000. [Google Scholar]

- Mohammad, K.A.; Zainudin, E.S.; Sapuan, S.M.; Zahari, N.I.; Aidy, A. Fatigue Life for Type 316L Stainless Steel under Cyclic Loading. Adv. Mater. Res. 2013, 701, 77–81. [Google Scholar] [CrossRef]

- Pola, A.; Battini, D.; Tocci, M.; Avanzini, A.; Girelli, L.; Petrogalli, C.; Gelfi, M. Evaluation on the fatigue behavior of sand-blasted AlSi10Mg obtained by DMLS. Frat. Ed Integrita Strutt. 2019, 13, 775–790. [Google Scholar] [CrossRef]

- Avanzini, A.; Battini, D.; Gelfi, M.; Girelli, L.; Petrogalli, C.; Pola, A.; Tocci, M. Investigation on fatigue strength of sand-blasted DMLS-AlSi10Mg alloy. Procedia Struct. Integr. 2019, 18, 119–128. [Google Scholar] [CrossRef]

- Beretta, S.; Romano, S. A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int. J. Fatigue 2017, 94, 178–191. [Google Scholar] [CrossRef]

- Kurgan, N.; Varol, R. Mechanical properties of P/M 316L stainless steel materials. Powder Technol. 2010, 201, 242–247. [Google Scholar] [CrossRef]

- Benarji, K.; Kumar, Y.R.; Jinoop, A.N.; Paul, C.P.; Bindra, K.S. Effect of Heat-Treatment on the Microstructure, Mechanical Properties and Corrosion Behaviour of SS 316 Structures Built by Laser Directed Energy Deposition Based Additive Manufacturing. Met. Mater. Int. 2021, 27, 488–499. [Google Scholar] [CrossRef]

- Cui, L.; Jiang, F.; Peng, R.L.; Mousavian, R.T.; Yang, Z.; Moverare, J. Dependence of microstructures on fatigue performance of polycrystals: A comparative study of conventional and additively manufactured 316L stainless steel. Int. J. Plast. 2022, 149, 103172. [Google Scholar] [CrossRef]

- Cutolo, A.; Elangeswaran, C.; de Formanoir, C.; Muralidharan, G.K.; van Hooreweder, B. Effect of Heat Treatments on Fatigue Properties of Ti–6Al–4V and 316L Produced by Laser Powder Bed Fusion in As-Built Surface Condition; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 395–405. [Google Scholar] [CrossRef]

- Zheng, B.; Haley, J.C.; Yang, N.; Yee, J.; Terrassa, K.W.; Zhou, Y.; Lavernia, E.J.; Schoenung, J.M. On the evolution of microstructure and defect control in 316L SS components fabricated via directed energy deposition. Mater. Sci. Eng. A 2019, 764, 138243. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- De Lima, M.S.F.; Sankaré, S. Microstructure and mechanical behavior of laser additive manufactured AISI 316 stainless steel stringers. Mater. Des. 2014, 55, 526–532. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Kurose, T.; Abe, Y.; Santos, M.V.A.; Kanaya, Y.; Ishigami, A.; Tanaka, S.; Ito, H. Influence of the layer directions on the properties of 316l stainless steel parts fabricated through fused deposition of metals. Materials 2020, 13, 2493. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Wei, J.; Hardacre, D.; Li, H. Predictive models for fatigue property of laser powder bed fusion stainless steel 316L. Mater. Des. 2018, 145, 42–54. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Goh, P.C.; Wei, J.; Hardacre, D.; Li, H. Application of Data Science Approach to Fatigue Property Assessment of Laser Powder Bed Fusion Stainless Steel 316L. In Mechanical Fatigue of Metals; Structural Integrity Vol.7; Springer: Cham, Switzerland, 2019; pp. 99–105. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, C.N.; Zhang, X.; Goh, P.C.; Wei, J.; Li, H.; Hardacre, D. Competing influence of porosity and microstructure on the fatigue property of laser powder bed fusion stainless steel 316L. In Proceedings of the 2017 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017; pp. 365–376. [Google Scholar]

- Macek, W.; Martins, R.F.; Branco, R.; Marciniak, Z.; Szala, M.; Wroński, S. Fatigue fracture morphology of AISI H13 steel obtained by additive manufacturing. Int. J. Fract. 2022, 235, 79–98. [Google Scholar] [CrossRef]

- Macek, W.; Branco, R.; Trembacz, J.; Costa, J.D.; Ferreira, J.A.M.; Capela, C. Effect of multiaxial bending-torsion loading on fracture surface parameters in high-strength steels processed by conventional and additive manufacturing. Eng. Fail. Anal. 2020, 118, 104784. [Google Scholar] [CrossRef]

| Ref. | Build Orientation | Surface Finish | Heat Treatment | Specimen | Test Type | R | |

|---|---|---|---|---|---|---|---|

| [40] | Z | AB/M | N | C | HG | AX | 0.1 |

| [41] | Z | AB/M | N/SR/HIP | C | HG | AX | −1 |

| [42] | XY/Z | AB | SR/HIP | C | HG | AX | −1 |

| [43] | Z | AB/M/ST | N | C | DB | AX | −1 |

| [1] | XY | M | N | F | DB | AX | 0.1 |

| [44] | XY | M | N/ANN | F | DB | AX | 0.1 |

| [45] | XY | M | N/ANN | F | DB | AX | 0.1 |

| [46] | XY/Z | M | N | C | DB | AX | −1 |

| [47] | XY/Z/45° | M | N | C | DB | AX | −1 |

| [48] | Z | AB/M | N/SR | C | HG | AX | −1 |

| [49] | Z | AB | ANN | C | HG/DB | AX/RB | −1 |

| [50] | Z | AB | N | C | DB | AX | 0.1 |

| [51] | XY/Z | AB/M/ST | N/SR | C | HG | AX | 0.1 |

| [52] | XY/Z | M | N/ANN/HIP | F | DB | AX | 0.1/0.7/−1 |

| [53] | XY/Z | M | SR | C | DB | AX | −1 |

| [54] | Z | M | ANN, HIP | C | HG | AX | −1 |

| [55] | Z | AB/M | N | C | DB | AX | 0.1 |

| [56] | Z | M | SR | C | HG | RB | −1 |

| [57] | XY/Z | AB/M/ST | N | C | DB | AX | 0.1 |

| [58] | Z | AB/M | SR | C | HG | AX | 0/−1 |

| [59] | XY | N/D | N | F | DB | AX | 0.1 |

| [60] | XY | M | N | C | HG | AX | −1 |

| [61] | Z | M | ANN | C | HG | AX | −1 |

| [62] | XY | M | SR | C | DB | M-AX | N/A |

| [63] | XY | M | N/D | C | DB | M-AX | N/A |

| [64] | Z | M | ANN | C | DB | AX | −1 |

| [65] | Z | M | ANN | C | DB | AX | −1 |

| [66] | Z | AB | SR | F | DB | AX | 0.1 |

| [67] | Z | M/ST | SR | C | HG | RevB | −1 |

| [68] | XY | AB/ST | SR | F | - | RevB | −1 |

| [69] | XY/Z | - | SR | F | CT | FCP | 0.1 |

| [70] | Z | M | N | C | DB | AX/STP | 0.1 |

| [71] | - | M | N | C | HG | AX/STP | 0.1 |

| [72] | Z | M | SR | C | DB | AX/STP/AD | 0.1 |

| [73] | Z/45° | - | SR/ANN | F | CT | FCP | 0.1 |

| [74] | Z | M | N/HIP | F | DB | AX | 0 |

| [38] | Z | M | N | C | DB/HG | AX | 0.1 |

| [39] | Z | M | N | C | HG | AX/AD | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avanzini, A. Fatigue Behavior of Additively Manufactured Stainless Steel 316L. Materials 2023, 16, 65. https://doi.org/10.3390/ma16010065

Avanzini A. Fatigue Behavior of Additively Manufactured Stainless Steel 316L. Materials. 2023; 16(1):65. https://doi.org/10.3390/ma16010065

Chicago/Turabian StyleAvanzini, Andrea. 2023. "Fatigue Behavior of Additively Manufactured Stainless Steel 316L" Materials 16, no. 1: 65. https://doi.org/10.3390/ma16010065

APA StyleAvanzini, A. (2023). Fatigue Behavior of Additively Manufactured Stainless Steel 316L. Materials, 16(1), 65. https://doi.org/10.3390/ma16010065