Impact of the Initial Phase Composition of Alloys on the Effects Manifested by Yield Sites That Occur on Sheet Aluminum Alloys Subjected to Impact-Oscillatory Loading

Abstract

:1. Introduction

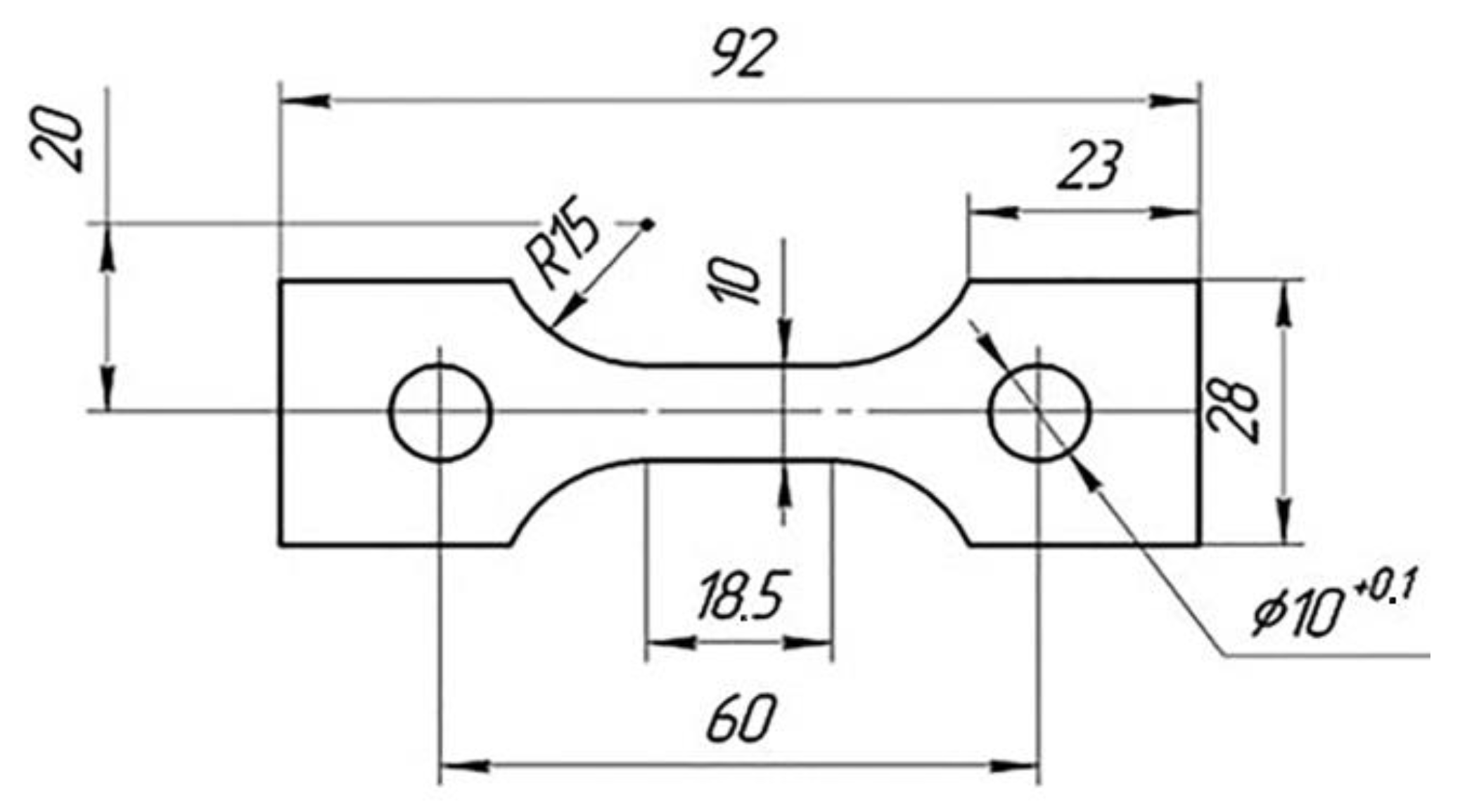

2. Materials and Methods

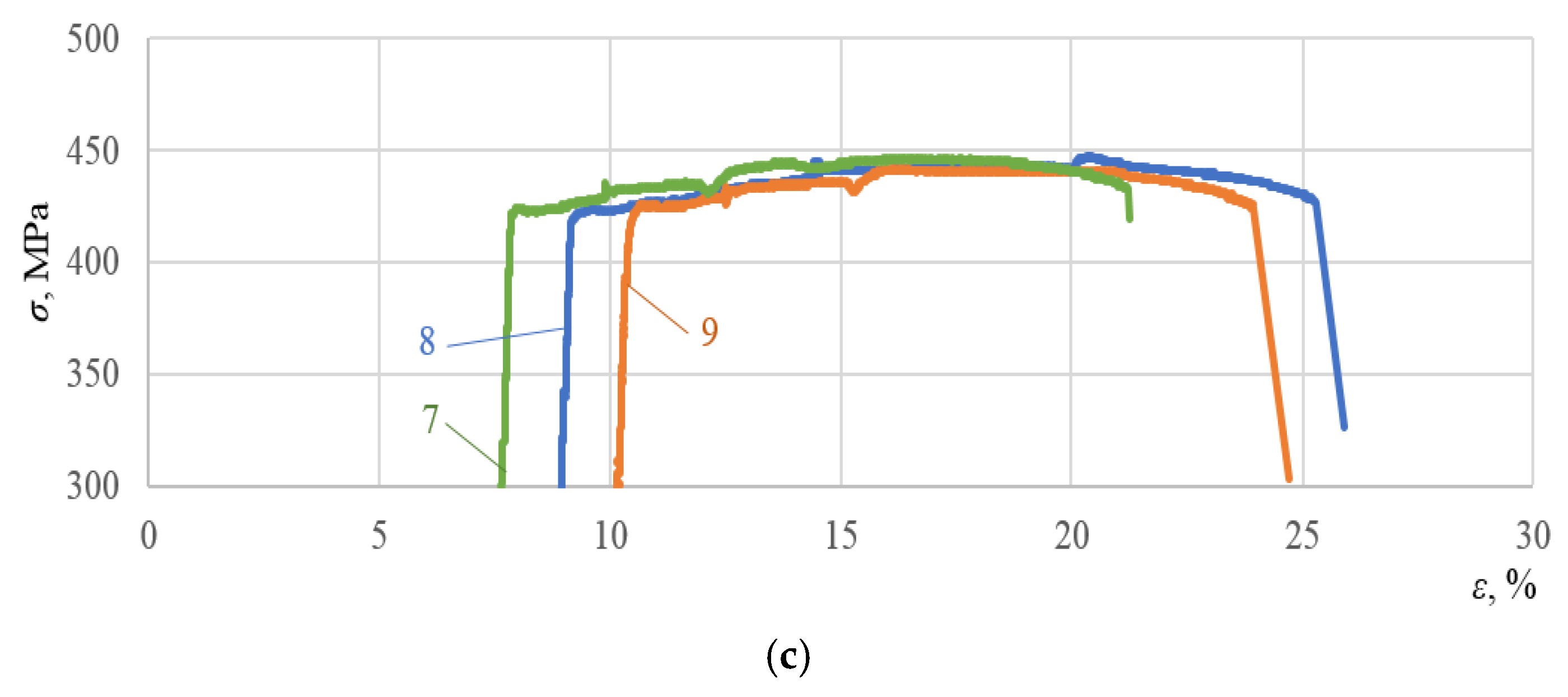

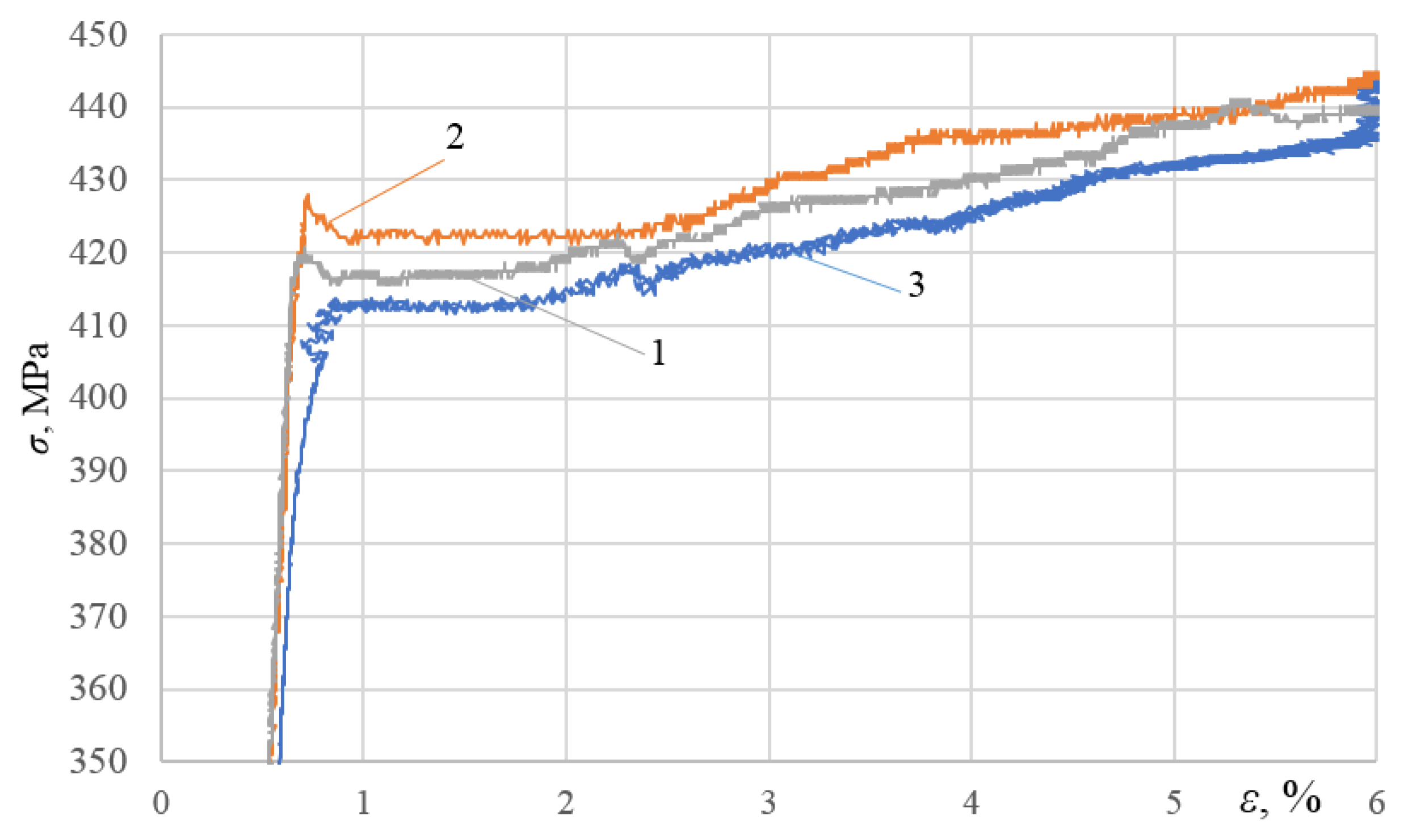

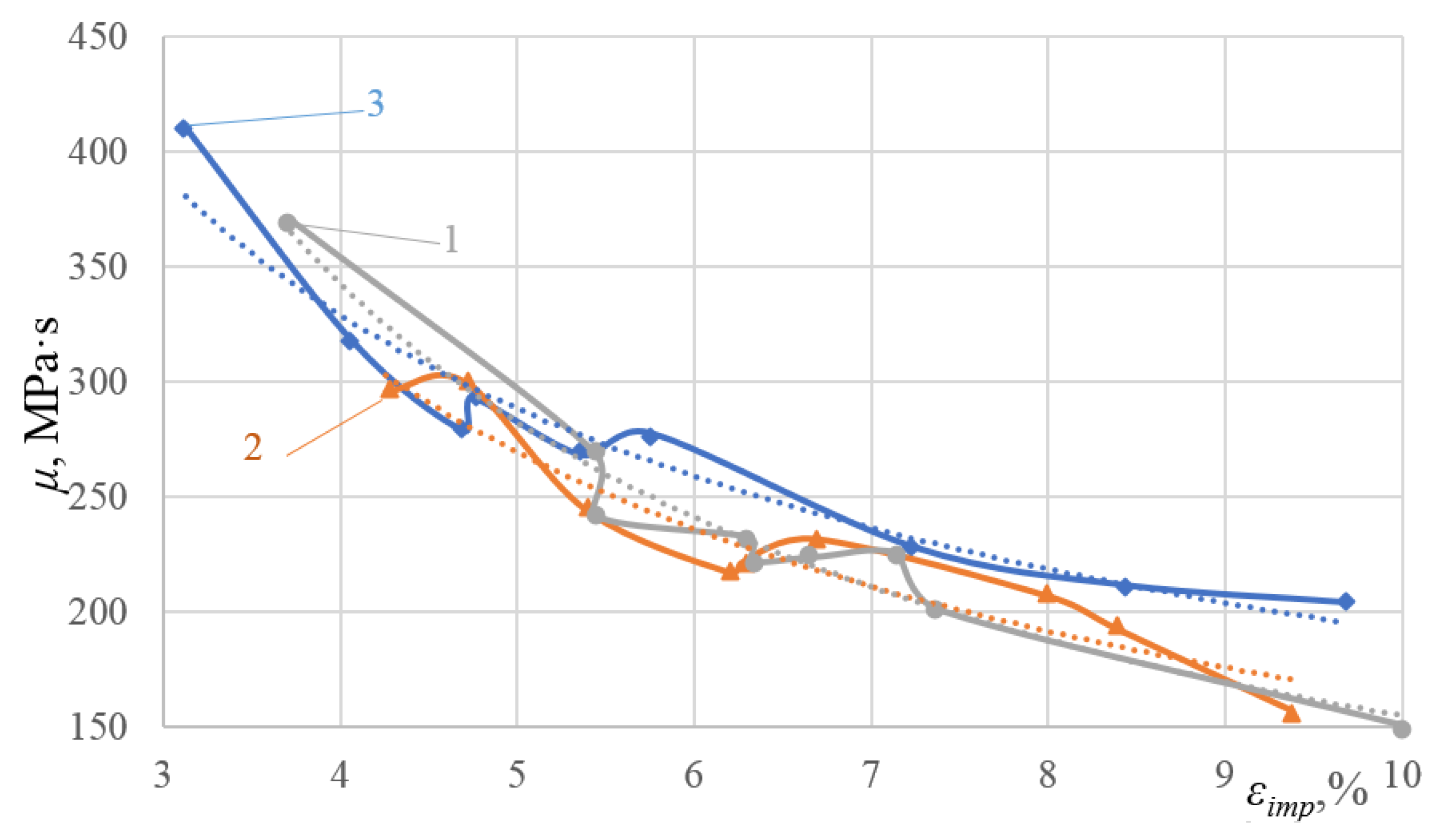

3. Results and Discussions

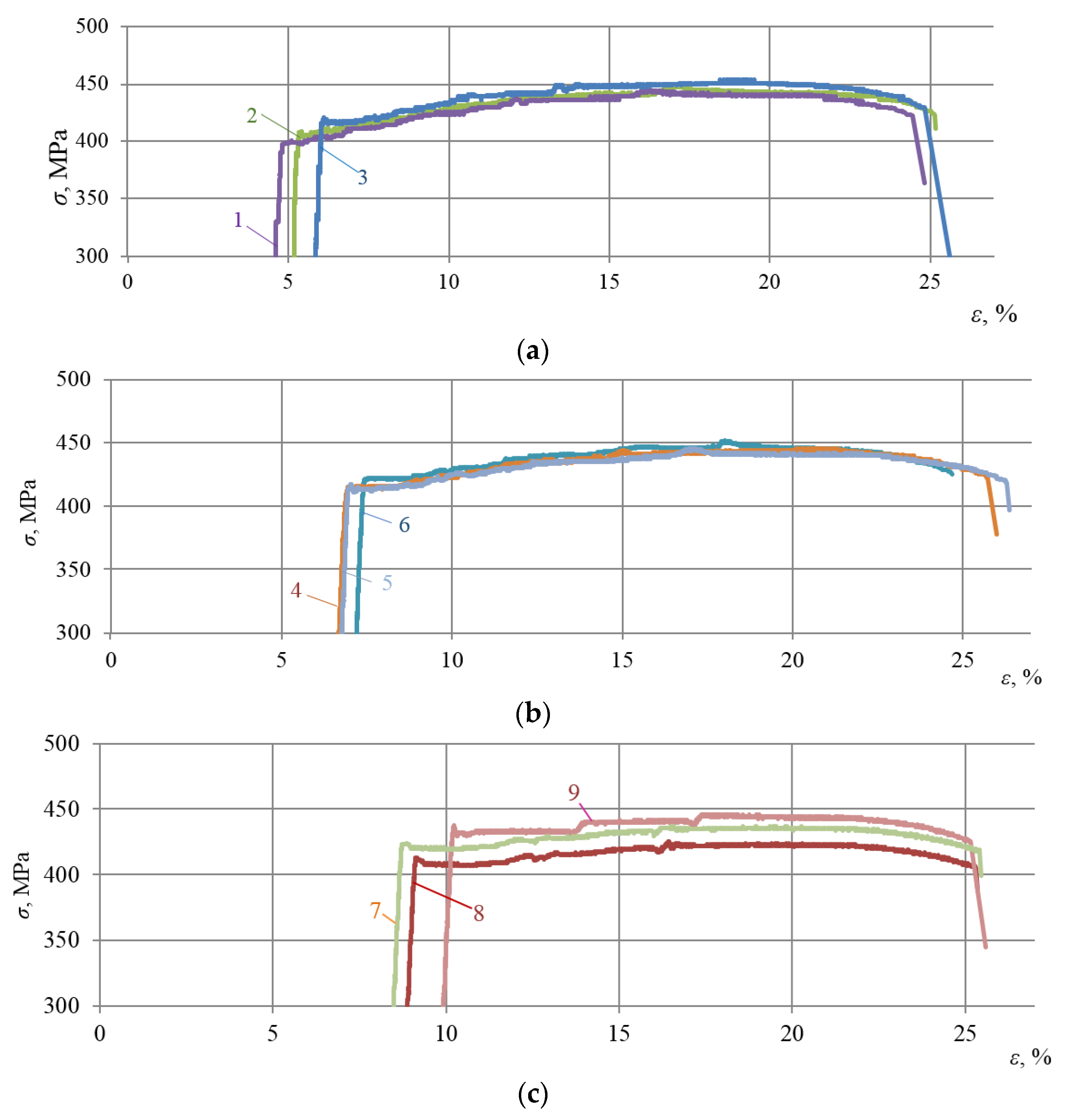

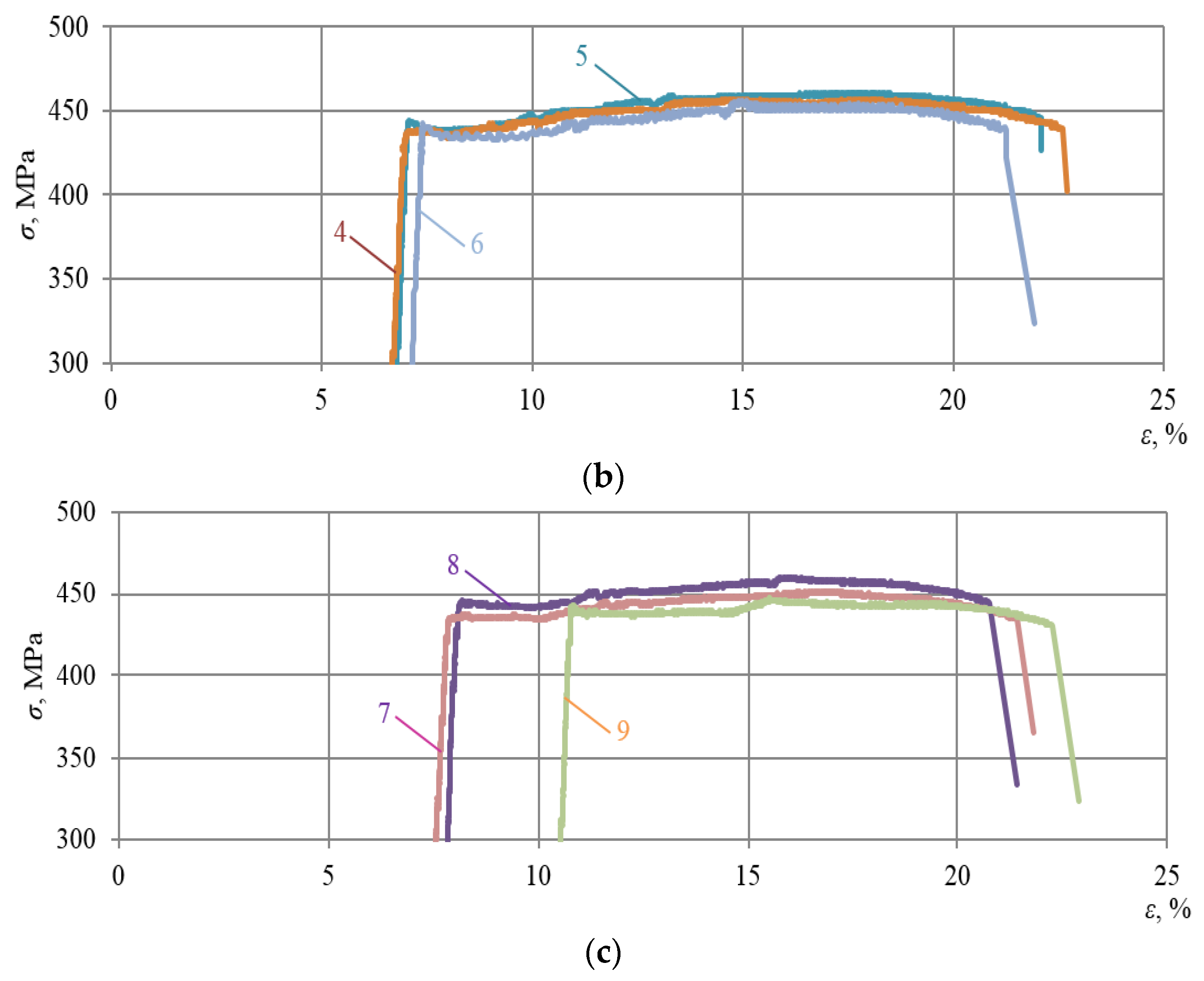

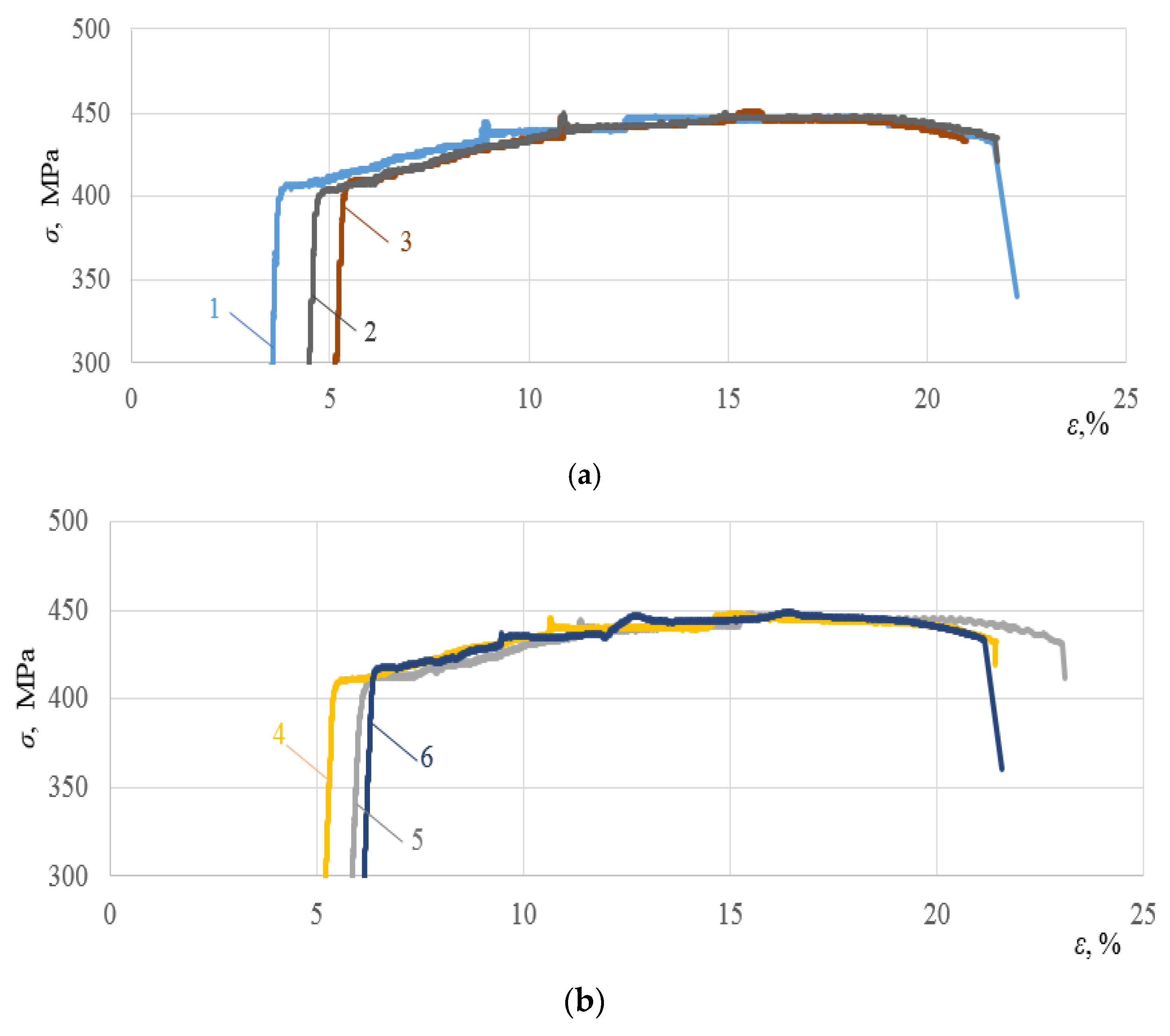

3.1. Plasticization of Aluminum Alloys Subjected to DNPs on the Elastic Part of Stress–Strain Diagrams. Mechanical Test Results

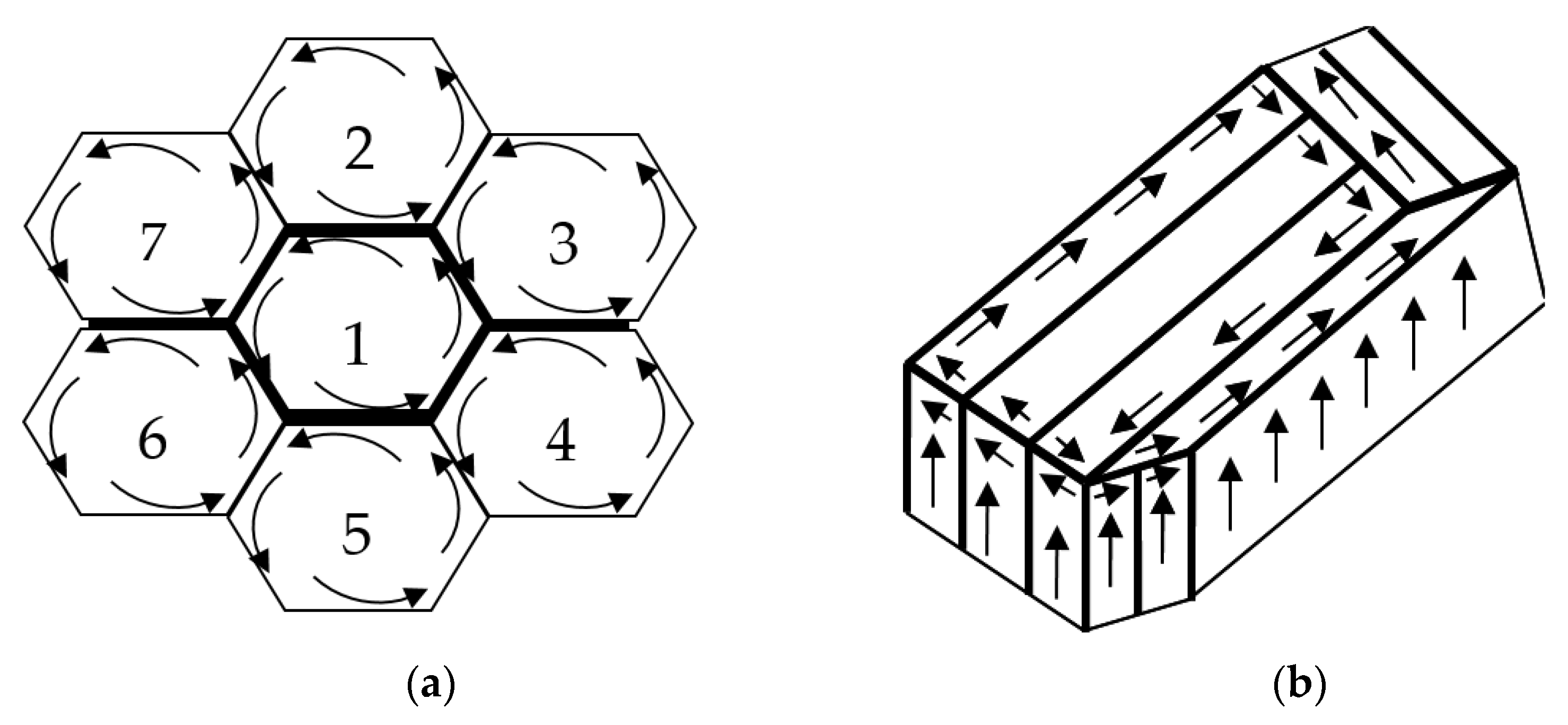

3.2. Physical Explanation of the Effect Manifested by Yield Sites That Occur in Aluminum Alloys Subjected to DNPs of Different Intensities

4. Mathematic Process Modelling

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jonson, R.H. Superplasticity. Metall. Rev. 1970, 15, 115–134. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplastisity in Metals and Ceramics; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Perevezentsev, V.N.; Rybin, V.V.; Chuvil’deev, V.N. The theory of structural superplasticity. Part I–IV. Acta Metall. Et Mater. 1992, 40, 887–923. [Google Scholar] [CrossRef]

- Kosarev, A.I.; Kudryashov, V.G. Influence of copper content on the fracture toughness of type D16 alloys. Strength Mater. 1980, 12, 716–720. [Google Scholar] [CrossRef]

- Teleshov, V.V.; Kudryashov, V.G. The use of metallographic methods for analyzing the relationships of fracture toughness of aluminum alloy semifinished products to their structure. Strength Mater. 1981, 13, 81–86. [Google Scholar] [CrossRef]

- Markushev, M.V.; Avtokratova, E.V.; Kazakulov, I.Y.; Krymsky, S.V.; Mochalova, M.Y.; Murashkin, M.Y.; Sitdikov, O.S. Microstructure and properties of an aluminum D16 alloy subjected to cryogenic rolling. Russ. Metall. 2011, 364. [Google Scholar] [CrossRef]

- Li, G.-R.; Xue, F.; Wang, H.-M.; Zheng, R.; Zhu, Y.; Chu, Q.-Z.; Cheng, J.-F. Tensile properties and microstructure of 2024 aluminum alloy subjected to the high magnetic field and external stress. Chin. Phys. B 2016, 25, 106201. [Google Scholar] [CrossRef]

- Higashi, K.; Nieh, T.G.; Mabuchi, M.; Wadsworth, J. Effect of liquid phases on the tensile elongation of superplastic aluminum alloys and composites. Scr. Metall. Et Mater. 1995, 32, 1079–1084. [Google Scholar] [CrossRef]

- Shin, D.H.; Joo, Y.J.; Kim, W.J.; Lee, C. Microstructural evolution during superplastic deformation of a 7475 Al alloy. J. Mater. Sci. 1998, 33, 3073–3078. [Google Scholar] [CrossRef]

- Shin, D.H.; Lee, C.S.; Kim, W.-J. Superplasticity of fine-grained 7475 Al alloy and a proposed new deformation mechanism. Acta Mater. 1997, 45, 5195–5202. [Google Scholar] [CrossRef]

- Ashby, M.F.; Verrall, R.A. Diffusion-accommodated flow and superplasticity. Acta Metall. 1973, 21, 149–163. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Salimonenko, D.A.; Tsenev, N.K.; Berbon, P.B.; Langdon, T.G. Observations of high strain rate superplasticity in commercial aluminum alloys with ultrafine grain sizes. Scr. Mater. 1997, 37, 1945–1950. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Yunusova, N.F.; Valiev, R.Z.; Tsenev, N.; Perevezentsev, V.; Langdon, T. Characteristics of superplasticity in an ultrafinegrained aluminum alloy processed by ECA pressing. Scr. Mater. 2003, 49, 467–472. [Google Scholar] [CrossRef]

- Padmanabhan, K.A.; Basariya, M.R. A theory of steady state structural superplasticity in different classes of materials: A materials-agnostic analysis. Mater. Sci. Eng. A 2019, 744, 704–715. [Google Scholar] [CrossRef]

- Lanjewar, H.; Naghdy, S.; Vercruysse, F.; Kestens, L.A.I.; Verleysen, P. Severe plastically deformed commercially pure aluminum: Substructure, micro-texture and associated mechanical response during uniaxial tension. Mater. Sci. Eng. A 2019, 764, 138195. [Google Scholar] [CrossRef]

- Yakovtseva, O.A.; Sitkina, M.N.; Kotov, A.D.; Rofman, O.V.; Mikhaylovskaya, A.V. Experimental study of the superplastic deformation mechanisms of high-strength aluminum-based alloy. Mater. Sci. Eng. A 2020, 788, 139639. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Yakovtseva, O.A.; Sitkina, M.N.; Kotov, A.D.; Irzhak, A.V.; Krymskiy, S.V.; Portnoy, V.K. Comparison between superplastic deformation mechanisms at primary and steady stages of the fine grain AA7475 aluminium alloy. Mater. Sci. Eng. A 2018, 718, 277–286. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Musin, F.; Gromov, D.; Nieh, T.G.; Lesuer, D.R. Grain refinement and superplastic behaviour of a modified 6061 aluminium alloy. Mater. Sci. Technol. 2003, 19, 483–490. [Google Scholar] [CrossRef]

- Bae, D.H.; Ghosh, A.K. Grain size and temperature dependence of superplastic deformation in an Al-Mg alloy under isostructural condition. Acta Mater. 2000, 48, 1207–1224. [Google Scholar] [CrossRef]

- Harisankar, K.R.; Sripathi, S.; Padmanabhan, K.A. On a unique constitutive equation for steady state isotropic optimal structural superplastic deformation in all classes of materials. Lett. Mater. 2022, 12, 5–14. [Google Scholar] [CrossRef]

- Bieler, T.R.; Mukherjee, A.K. The high strain rate superplastic deformation mechanisms of mechanically alloyed aluminum IN90211. Mater. Sci. Eng. A 1990, 128, 171–182. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.; Sun, Q.; Ye, L.; Zhang, X. Superplastic Deformation Mechanisms in Fine-Grained 2050 Al-Cu-Li Alloys. Materials 2020, 13, 2705. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.Y.; Liu, F.C.; Mishra, R.S. Superplastic deformation mechanism of an ultrafine-grained aluminum alloy produced by friction stir processing. Acta Mater. 2010, 58, 4693–4704. [Google Scholar] [CrossRef]

- Aryshensky, E.V.; Konovalov, S.V.; Latushkin, I.A.; Lapshov, M.A. Study of the evolution of crystallographic texture during the drawing of a low-alloyed aluminum alloy. Tsvetnye Met. 2022, 2022, 60–66. [Google Scholar] [CrossRef]

- Smirnov, O.M.; Seung, J.; Poustovalova, I.V. Superplasticity of Mechanically Alloyed Nanocrystalline and Amorphous Materials. In Investigations and Applications of Severe Plastic Deformation; Lowe, T.C., Valiev, R.Z., Eds.; NATO Science Series; Springer: Dordrecht, The Netherlands, 2000; p. 80. [Google Scholar] [CrossRef]

- Nieh, T.G.; Wadsworth, J.; Imai, T. A Rheological view of High Strain Rate Superplasticity in Alloys and Metal Matrix Composites. Scr. Metall. 1992, 26, 703–708. [Google Scholar] [CrossRef]

- Mabuchi, M.; Higashi, K.; Langdon, T.G. An investigation of the role of a liquid phase in AlCuMg metal matrix composites exhibiting high strain rate superplasticity. Acta Metall. Et Mater. 1994, 42, 1739–1745. [Google Scholar] [CrossRef]

- Chausov., M.; Brezinova, J.; Zasimchuk, E.; Maruschak, P.; Khyzhun, O.; Pylypenko, A.; Bazarnik, P.; Brezina, J. Effect of Structure Self-Organization of Aluminum Alloy D16ChATW under Impact-Oscillatory Loading on Its Fatigue Life. J. Mater. Eng. Perform. 2021, 30, 6235–6242. [Google Scholar] [CrossRef]

- Chausov, M.; Zasimchuk, E.; Maruschak, P.; Khyzhun, O.; Pylypenko, A.; Prentkovskis, O.; Brezinová, J. Influence of impact-oscillatory loading on fatigue life of aluminium alloy 2024-T351. Iran J. Sci. Technol. Trans. Mech. Eng. 2021, 46, 875–884. [Google Scholar] [CrossRef]

- Chausov, M.; Zasimchuck, Y.; Markashova, L.; Vildeman, V.; Turchuk, T.; Pylypenko, A. Specialty deformation of plastics materials under dynamic non-equilibrium. Zavod. Laboratorlya. Diagn. Mater. 2009, 75, 52–59. [Google Scholar]

- Zasimchuk, E.; Turchak, T.; Chausov, N. Hydrodynamic plastic flow in metal materials. Results Mater. 2020, 6, 100090. [Google Scholar] [CrossRef]

- Chausov, N.G.; Voityuk, D.G.; Pilipenko, A.P.; Kuz’menko, A.M. Setup for testing materials with plotting complete stress–strain diagrams. Strength Mater. 2004, 36, 532–537. [Google Scholar] [CrossRef]

- Chausov, M.G.; Berezin, V.B.; Pylypenko, A.P.; Hutsaylyuk, V.B. Strain field evolution on the surface of aluminum sheet alloys exposed to specific impact with oscillation loading. J. Strain. Anal. 2014, 50, 61–72. [Google Scholar] [CrossRef]

- Chumachenko, E.N.; Smipnov, O.M.; Tsepin, M.A. Superplasticity: Materials, Theory, Technologies, 2nd ed.; Book House “LIBROKOM”: Moscow, Russia, 2009; 320p. (In Russian) [Google Scholar]

- Liao, Y. Practical Electron Microscopy and Database. 2006. Available online: www.globalsino.com/EM/ (accessed on 24 December 2022).

- Huerta, E.; Oliva, A.I.; Aviles, F.; González-Hernández, J.; Corona, J.E. Elastic modulus determination of Al-Cu film alloys prepared by thermal diffusion. J. Nanomater. 2012, 2012, 895131. [Google Scholar] [CrossRef]

| Alloys | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|

| D16ChATW | 0.18 | 4.4 | 0.63 | 1.4 | 0.01 | 0.01 | 0.07 | - |

| 2024-T351 | 0.05 | 0.13 | 4.7 | 0.70 | 1.5 | 0.01 | 0.02 | 0.04 |

| T | 0.08 | 0.255 | 0.825 | 0.024 | 0.03 | 0.002 | 0.012 | 0.018 |

| Alloys | σys, MPa | σus, MPa | δ, % |

|---|---|---|---|

| D16ChATW | 322 | 448 | 25.2 |

| 2024-T351 | 372 | 462 | 20.5 |

| T | 330 | 450 | 21.1 |

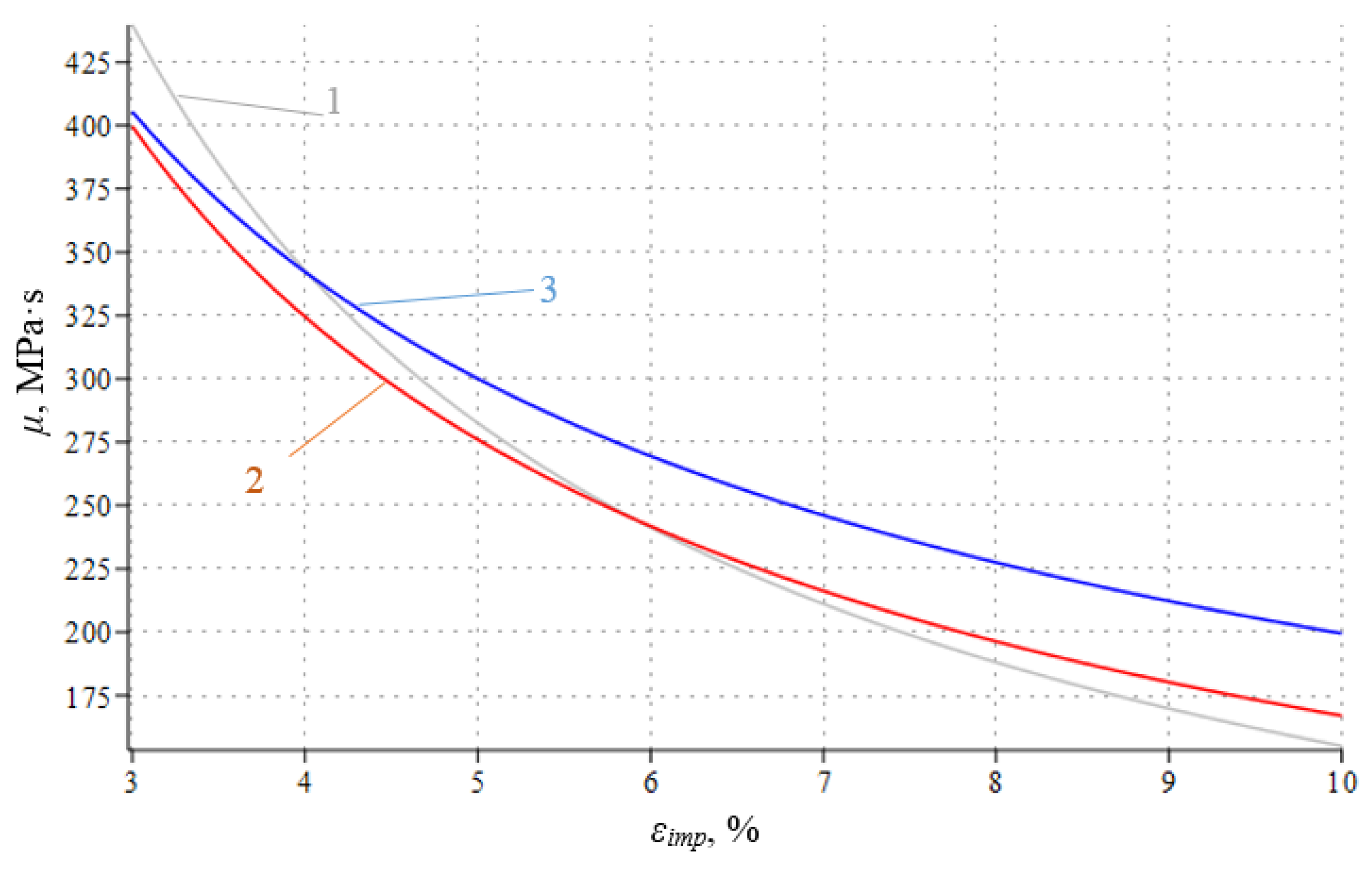

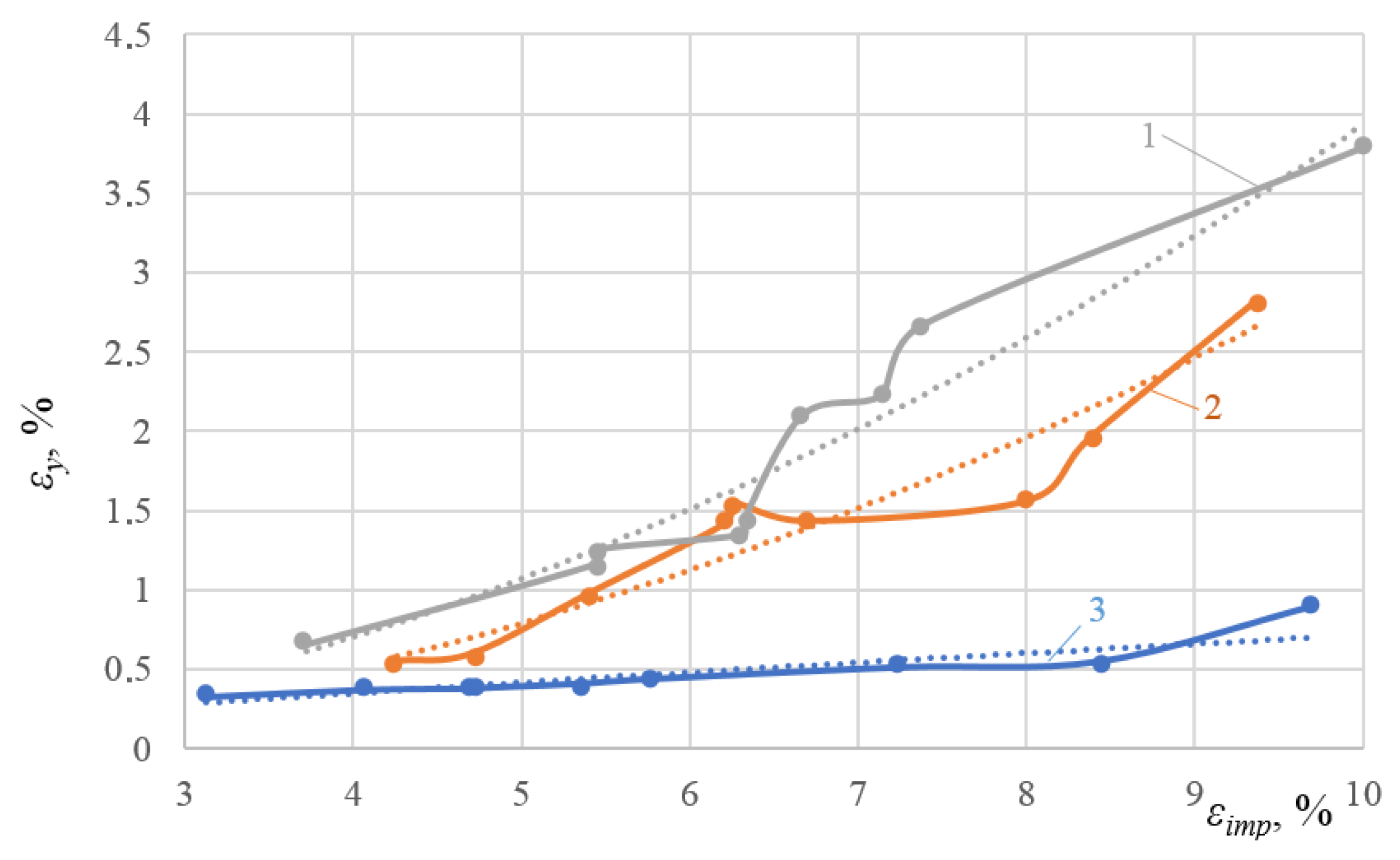

| Alloy | Number of Specimens | εimp, % | σimp, MPa | , s−1 | μ, MPa·s | Yield Site, εy, % |

|---|---|---|---|---|---|---|

| T | 1 | 3.13 | 300.76 | 0.73 | 412.0 | 0.33 |

| 2 | 4.06 | 295.74 | 0.93 | 318.0 | 0.37 | |

| 3 | 4.69 | 306.36 | 1.05 | 291.77 | 0.38 | |

| 4 | 4.75 | 316.02 | 1.13 | 279.66 | 0.38 | |

| 5 | 5.37 | 344.40 | 1.29 | 266.98 | 0.41 | |

| 6 | 5.75 | 354.34 | 1.28 | 276.83 | 0.44 | |

| 7 | 7.25 | 343.81 | 1.51 | 227.69 | 0.52 | |

| 8 | 8.44 | 380.94 | 1.80 | 211.63 | 0.55 | |

| 9 | 9.69 | 393.28 | 1.93 | 203.77 | 0.90 | |

| D16ChATW | 1 | 4.26 | 374.75 | 1.27 | 295.08 | 0.55 |

| 2 | 4.71 | 401.54 | 1.34 | 299.66 | 0.60 | |

| 3 | 5.40 | 392.70 | 1.61 | 243.91 | 0.97 | |

| 4 | 6.21 | 402.35 | 1.85 | 217.49 | 1.41 | |

| 5 | 6.27 | 410.65 | 1.85 | 221.97 | 1.54 | |

| 6 | 6.69 | 413.75 | 1.78 | 232.44 | 1.43 | |

| 7 | 8.0 | 404.74 | 1.95 | 207.56 | 1.56 | |

| 8 | 8.39 | 396.46 | 2.06 | 192.46 | 1.96 | |

| 9 | 9.38 | 395.94 | 2.52 | 157.12 | 2.83 | |

| 2024-T351 | 1 | 3.72 | 398.15 | 1.08 | 368.66 | 0.66 |

| 2 | 5.43 | 437.30 | 1.62 | 269.94 | 1.16 | |

| 3 | 5.44 | 398.20 | 1.65 | 241.33 | 1.26 | |

| 4 | 6.31 | 427.38 | 1.84 | 232.27 | 1.35 | |

| 5 | 6.32 | 417.18 | 1.88 | 221.90 | 1.45 | |

| 6 | 6.67 | 422.86 | 1.89 | 223.74 | 2.11 | |

| 7 | 7.14 | 425.19 | 1.89 | 224.97 | 2.23 | |

| 8 | 7.38 | 428.06 | 2.13 | 200.97 | 2.67 | |

| 9 | 10.0 | 413.06 | 2.74 | 150.75 | 3.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chausov, M.; Pylypenko, A.; Maruschak, P.; Zasimchuk, V.; Brezinová, J.; Brezina, J.; Viňáš, J. Impact of the Initial Phase Composition of Alloys on the Effects Manifested by Yield Sites That Occur on Sheet Aluminum Alloys Subjected to Impact-Oscillatory Loading. Materials 2023, 16, 249. https://doi.org/10.3390/ma16010249

Chausov M, Pylypenko A, Maruschak P, Zasimchuk V, Brezinová J, Brezina J, Viňáš J. Impact of the Initial Phase Composition of Alloys on the Effects Manifested by Yield Sites That Occur on Sheet Aluminum Alloys Subjected to Impact-Oscillatory Loading. Materials. 2023; 16(1):249. https://doi.org/10.3390/ma16010249

Chicago/Turabian StyleChausov, Mykola, Andrii Pylypenko, Pavlo Maruschak, Vira Zasimchuk, Janette Brezinová, Jakub Brezina, and Ján Viňáš. 2023. "Impact of the Initial Phase Composition of Alloys on the Effects Manifested by Yield Sites That Occur on Sheet Aluminum Alloys Subjected to Impact-Oscillatory Loading" Materials 16, no. 1: 249. https://doi.org/10.3390/ma16010249

APA StyleChausov, M., Pylypenko, A., Maruschak, P., Zasimchuk, V., Brezinová, J., Brezina, J., & Viňáš, J. (2023). Impact of the Initial Phase Composition of Alloys on the Effects Manifested by Yield Sites That Occur on Sheet Aluminum Alloys Subjected to Impact-Oscillatory Loading. Materials, 16(1), 249. https://doi.org/10.3390/ma16010249