Effects of Various Mineral Admixtures and Fibrillated Polypropylene Fibers on the Properties of Engineered Cementitious Composite (ECC) Based Mortars

Abstract

1. Introduction

2. Materials and Methods

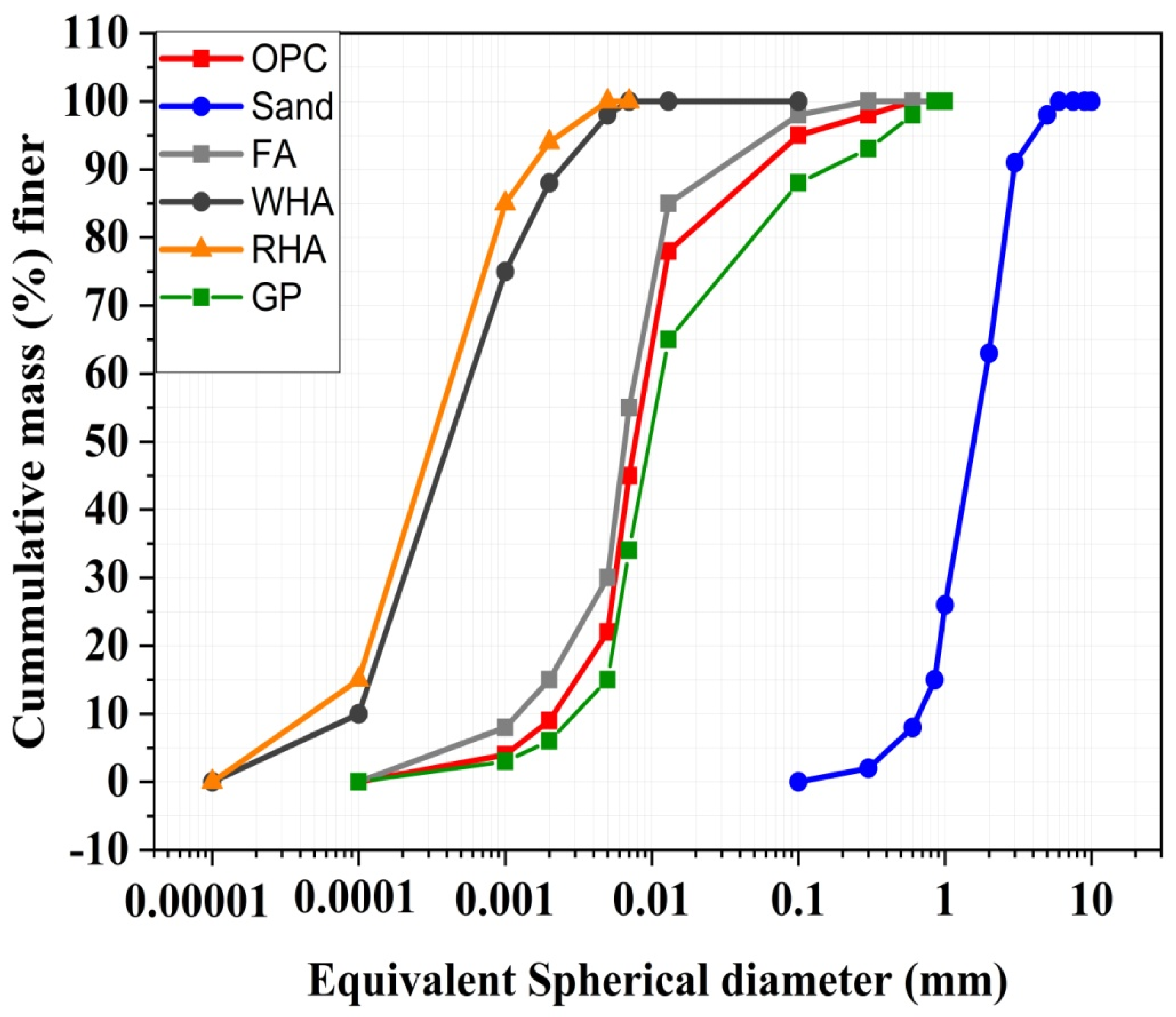

2.1. Materials

2.2. Mix Design

2.3. Methods

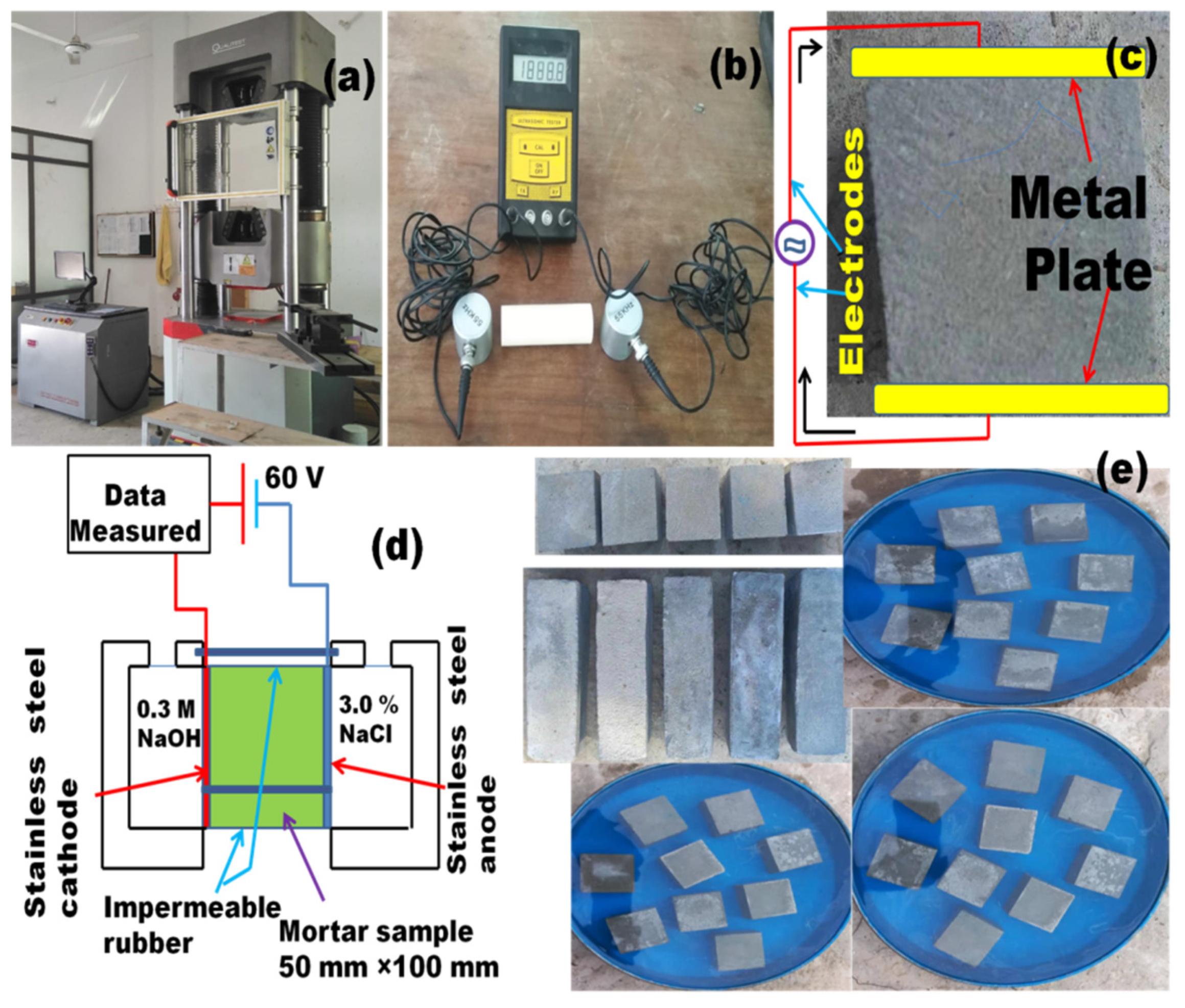

2.3.1. Mechanical Strength

2.3.2. Water Absorption and Porosity

2.3.3. Sorptivtity

2.3.4. Ultrasonic Pulse Velocity (UPV), Electric Resistivity (ER), Rapid Chloride Penetration Test (RCPT)

2.3.5. Acid and Sulfate Resistance

2.3.6. Materials Characterization

3. Results and Discussion

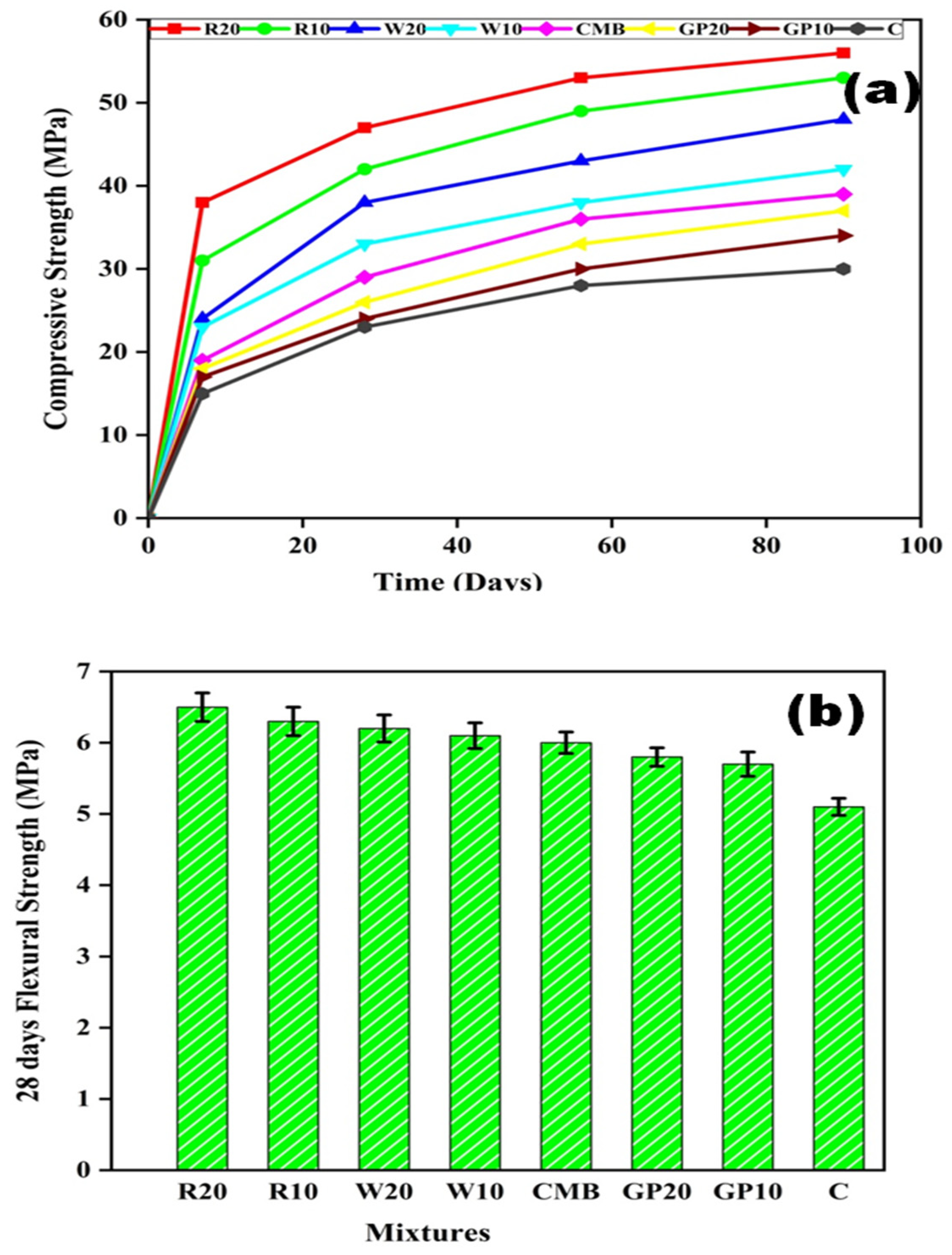

3.1. Mechanical Strength

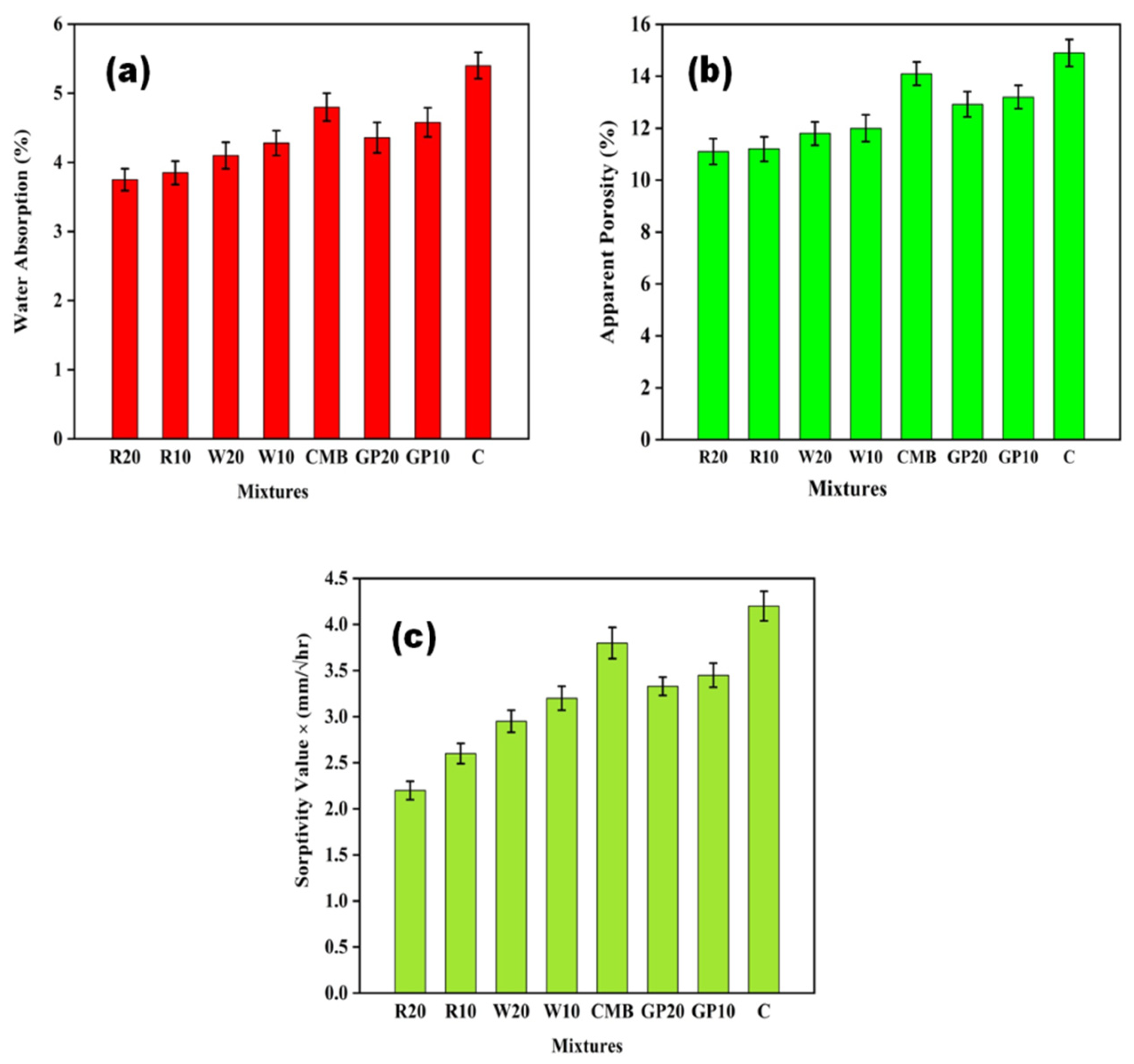

3.2. Water Absorption and Apparent Porosity

3.3. Sorptivity

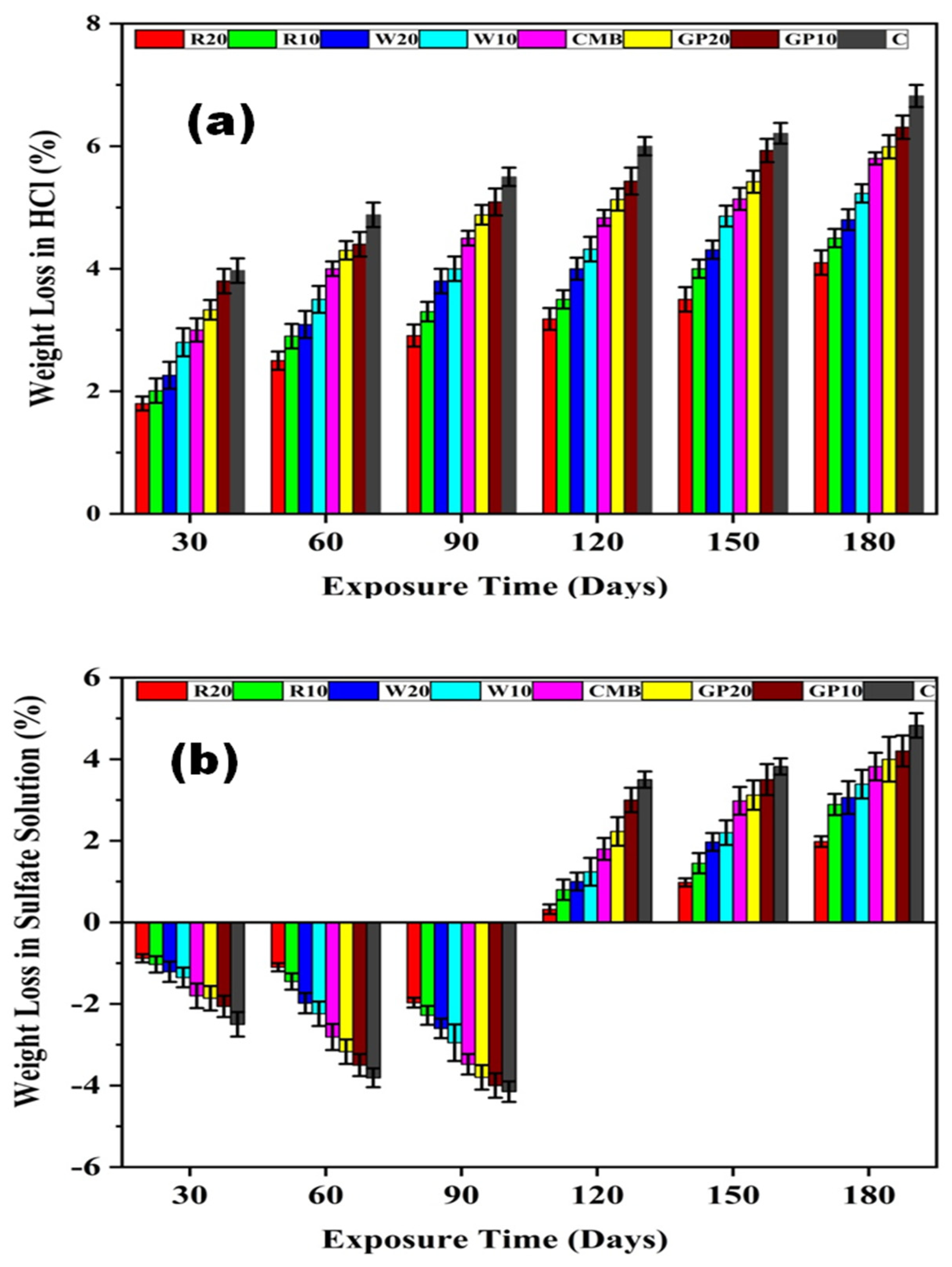

3.4. Measurement of Weight Loss

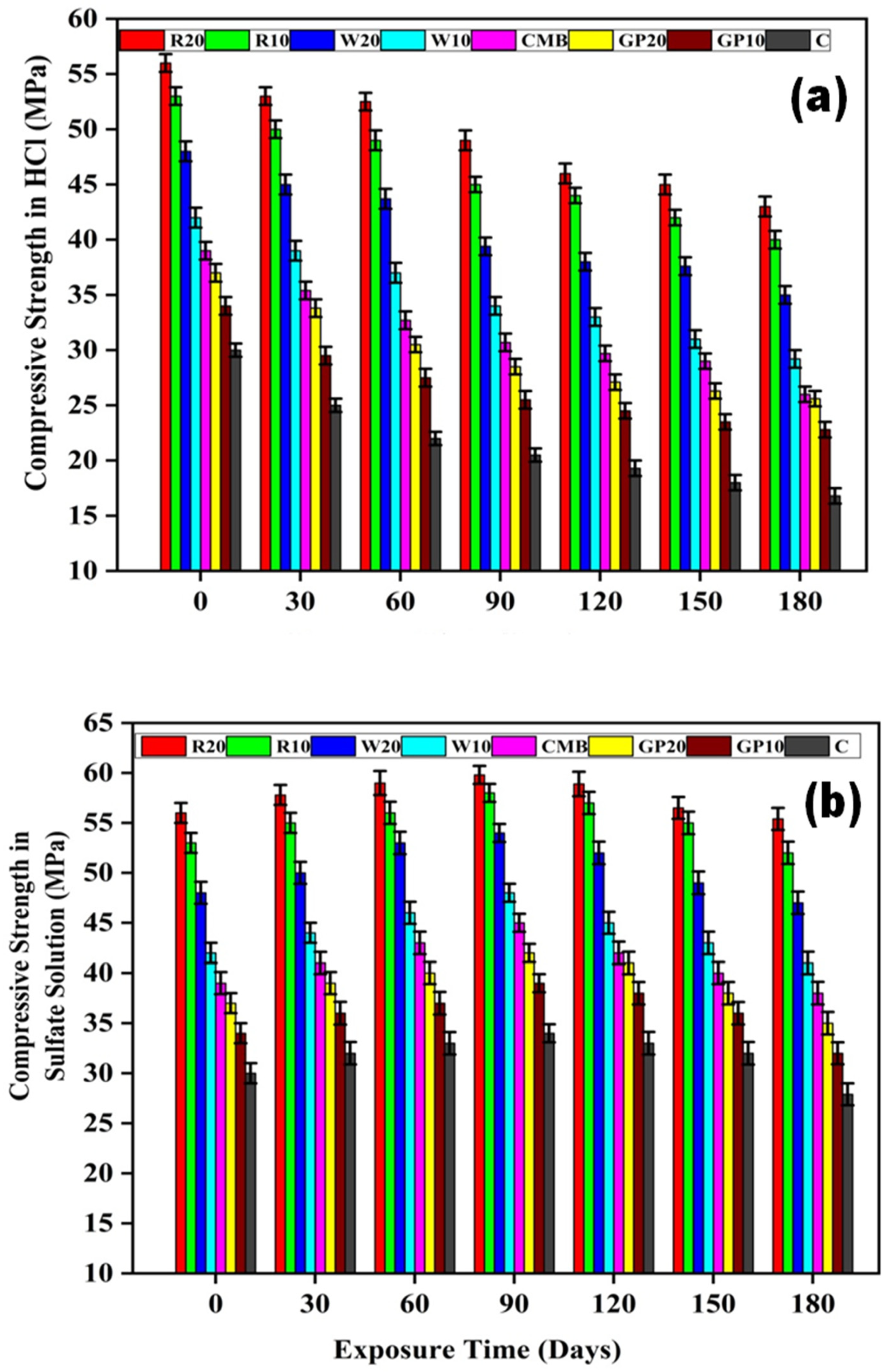

3.5. Changes in Compressive Strength after Acid and Sulfate Attack

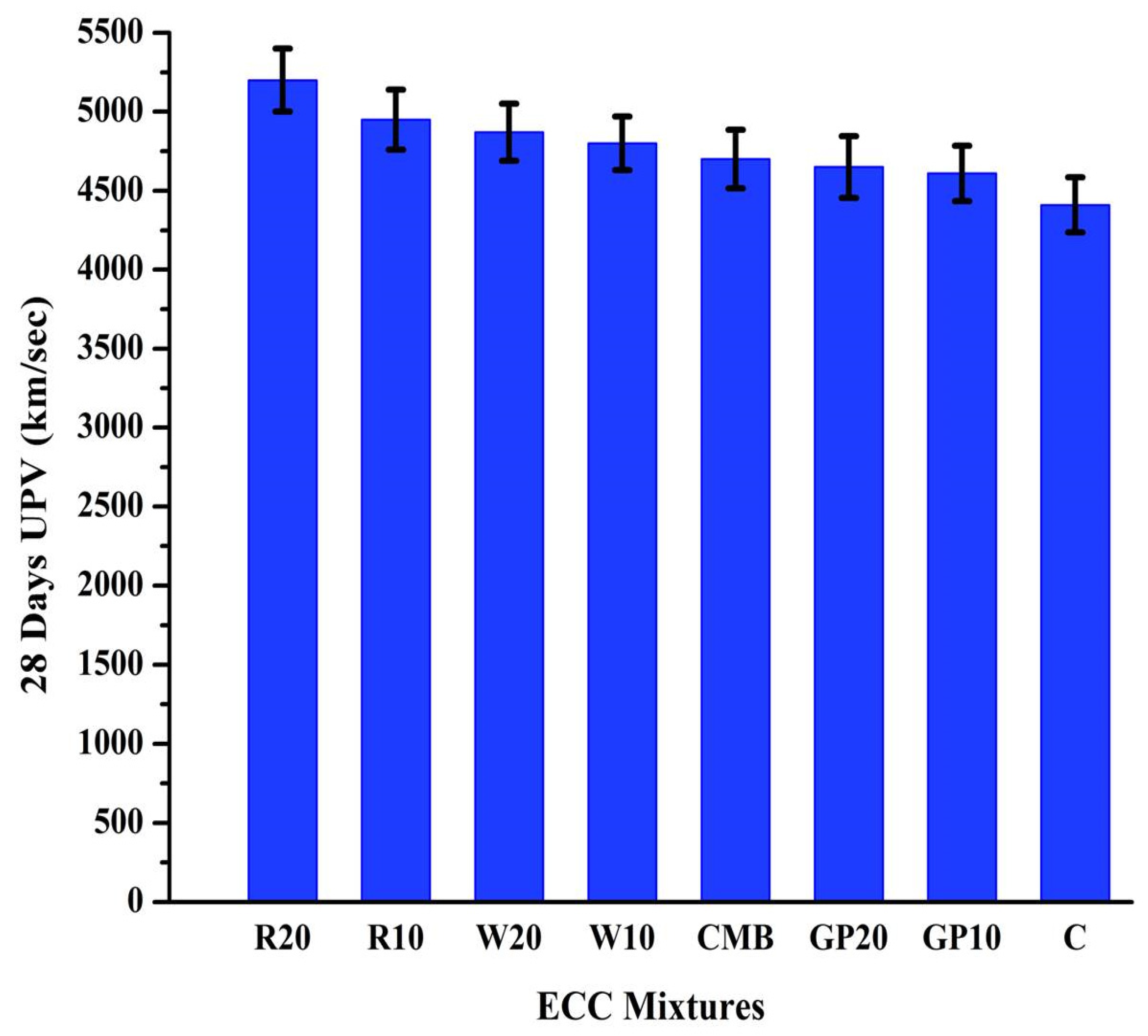

3.6. Ultrasonic Pulse Velocity (UPV) Test

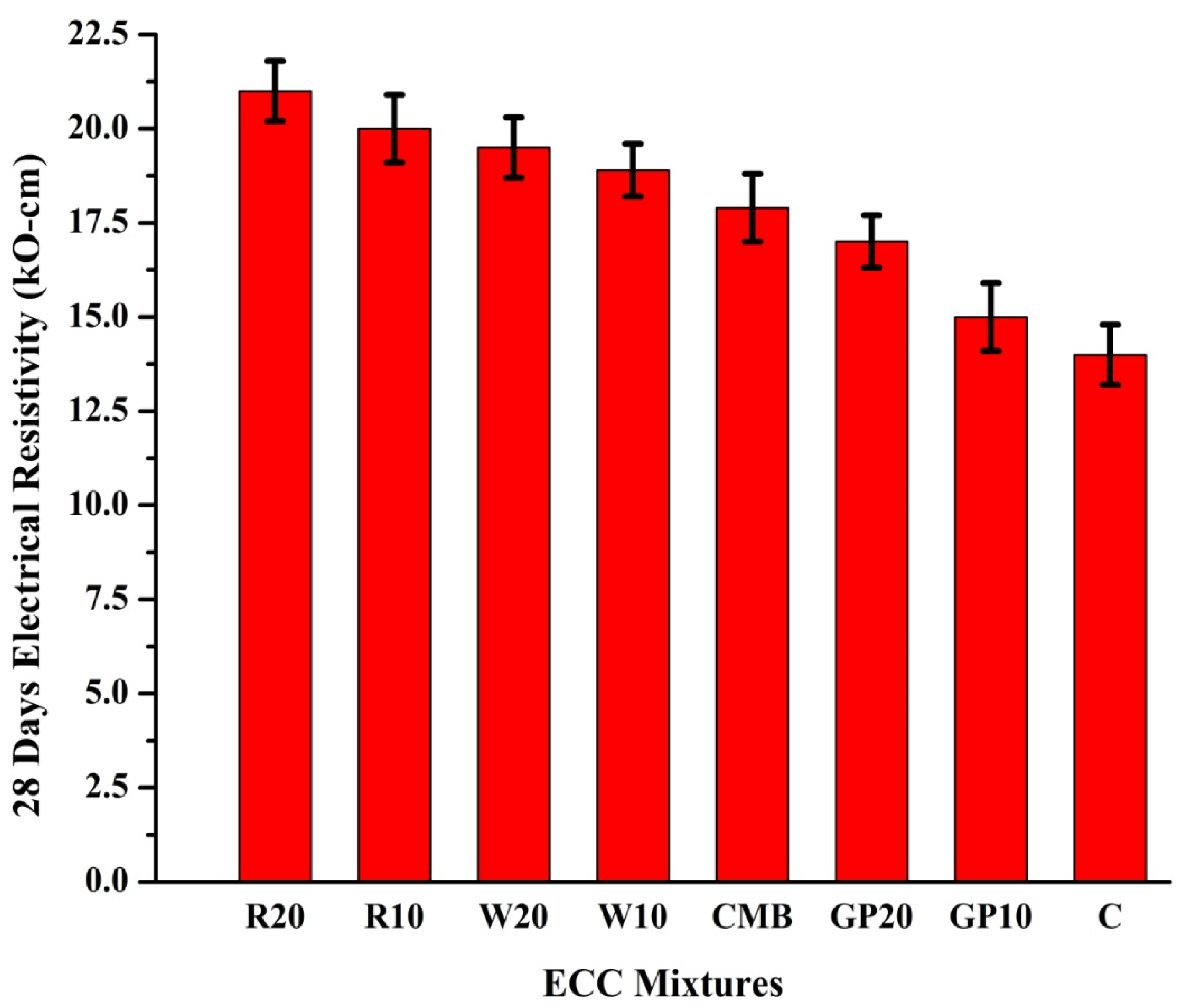

3.7. Electrical Resistivity (ER)

3.8. Rapid Chloride Penetration Test (RCPT)

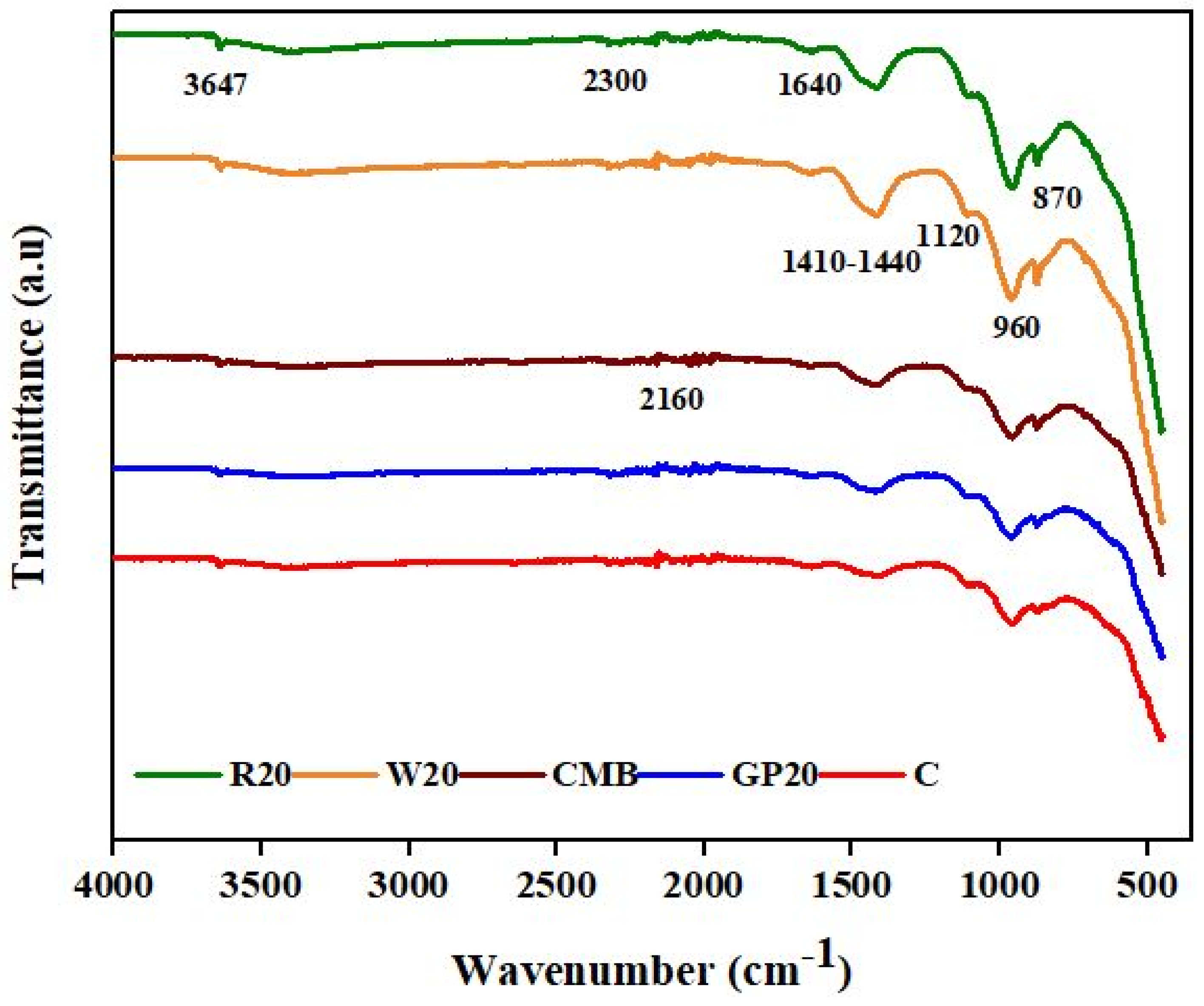

3.9. Fourier Transform Infrared Spectroscopy Analysis (FTIR)

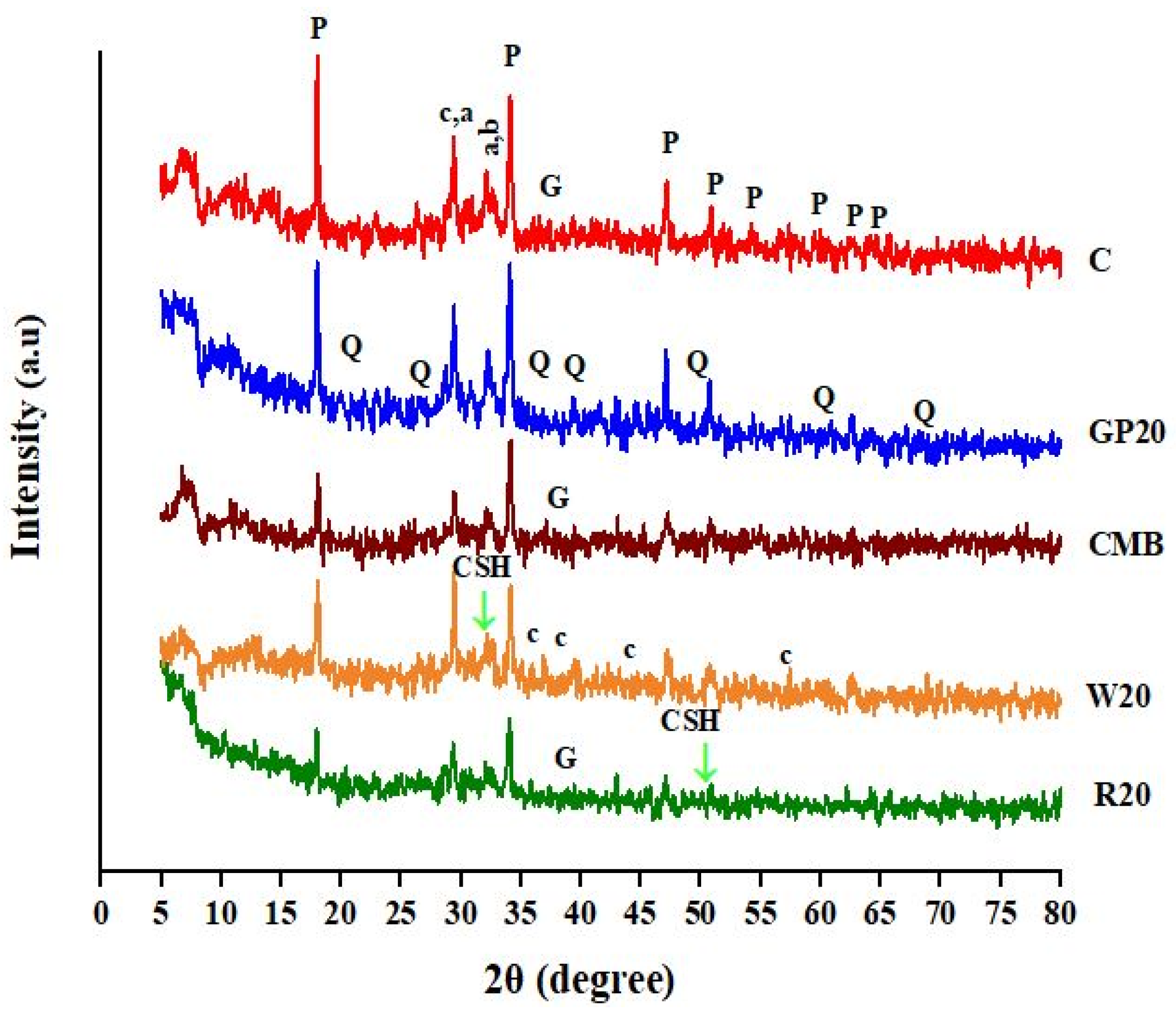

3.10. X-ray Diffraction Analysis (XRD)

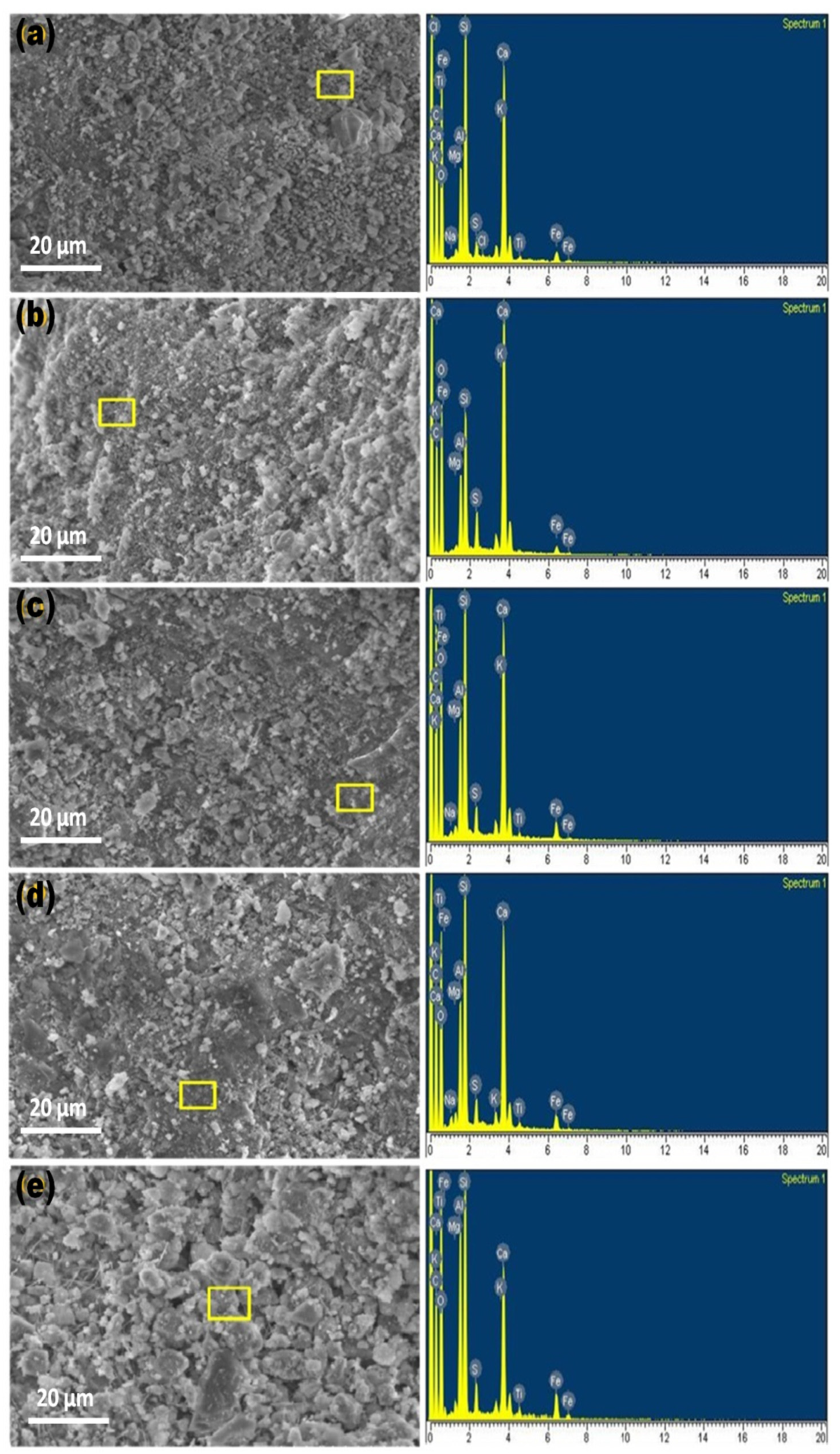

3.11. Microstructural Properties

4. Conclusions

- Using mineral admixtures such as RHA, WHA, and GP can successfully improve the mechanical performance of ECC-based mortars. RHA and WHA showed greater enhancement in mechanical strength due to their finer particles. This improvement in mechanical strength is attributed to the pozzolanic reaction and the micro filler effect of mineral admixtures. The micro-filler effect distributes the hydration products more homogeneously in the available space, resulting in a much denser matrix. Moreover, the inclusion of PP fibers improves the mechanical properties of ECC.

- Water absorption, apparent porosity, and sorptivity were much lower for RHA, WHA than GP and control samples. These mineral admixtures increase the density of ECC-based mortars and improve the pore structure of the matrix by reducing the average pore size and sorptivity coefficient of composite microstructure.

- XRD, FTIR, SEM, and EDX results are consistent with mechanical and physical performances. Materials characterization showed that using an optimum amount of mineral admixtures imparts a dense and compact microstructure, reducing the ingress of chemicals, reducing permeability, ensuring water tightness and micro-cracks, and improving mechanical strength.

- Chemical durability results showed that RHA-based ECC specimens underwent lesser weight and compressive strength losses than other ECC mixtures when exposed to HCl and Na2SO4 solutions for 180 days. The changes in the compressive strength of ECC-based mortar exposed to acid and sulfate environments are primarily governed by the formation of expansive gypsum and salts. The porous medium governs the degradation by regulating the dissemination of ionic species of the pore solution towards the aggressive environment.

- UPV, ER, and RCPT performances of ECC mortars were enhanced due to mineral additions. SiO2 in RHA, WHA, and GP composition combined with calcium hydroxide to form additional CSH. The microstructure of ECC is affected by this reaction, which reduces the interpore connectivity, resulting in a dense and compact microstructure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Costa, F.B.P.; Righi, D.P.; Graeff, A.G.; Silva Filho, L.C.P. Experimental study of some durability properties of ECC with a more environmentally sustainable rice husk ash and high tenacity polypropylene fibers. Constr. Build. Mater. 2019, 213, 505–513. [Google Scholar] [CrossRef]

- A Brief Introduction to ECC and ECC Technology Network. Available online: www.engineeredcomposites.com/ (accessed on 3 November 2007).

- Li, V.C.; Wang, S. Microstructure variability and macroscopic composite properties of high performance fiber reinforced cementitious composites. Probabilistic Eng. Mech. 2006, 21, 201–206. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of PVA-ECC. ACI Mater. J. 2001, 98, 483–492. [Google Scholar]

- Li, V.C. On engineered cementitious composites (ECC)—A review of the material and its applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Li, V.C. Engineered cementitious composites. In Construction Materials, Proceedings of the Third International Conference on Construction Materials: Performance, Innovations and Structural Implications and Mindess Symposium, Vancouver, BC, Canada, 22–24 August 2005; Banthia, N., Uomoto, T., Bentur, A., Shah, S.P., Eds.; University of British Columbia: Vancouver, BC, Canada, 2005. [Google Scholar]

- Li, V.C.; Stang, H. Elevating FRC material ductility to infrastructure durability. In Proceedings of the 6th RILEM Symposium on Fiber-Reinforced Concretes (FRC)—BEFIB 2004, Varenna, Italy, 20–22 September 2004; Prisco, M., Felicetti, R., Plizzari, G.A., Eds.; RILEM Publications: Bagneux, France, 2004; Volume 1, pp. 171–186. [Google Scholar]

- Yang, E.H.; Yang, Y.Z.; Li, V.C. Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater. J. 2007, 104, 620–628. [Google Scholar]

- Wang, S.; Li, V.C. Engineered cementitious composites with high-volume fly ash. ACI Mater. J. 2007, 104, 233–241. [Google Scholar]

- Termkhajornkit, P.; Nawa, T.; Yamashiro, Y.; Saito, T. Self-healing ability of fly ash–cement systems. Cem. Concr. Compos. 2009, 31, 195–203. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yildirim, G.; Erdem, T.K. Self-healing capability of cementitious composites incorporating different supplementary cementitious materials. Cem. Concr. Compos. 2013, 35, 89–101. [Google Scholar] [CrossRef]

- Sahmaran, M.; Li, M.; Li, V.C. Transport properties of engineered cementitious composites under chloride exposure. ACI Mater. J. 2007, 104, 604–611. [Google Scholar]

- Li, M.; Li, V.C. Cracking and healing of engineered cementitious composites under chloride environment. ACI Mater. J. 2011, 108, 333–340. [Google Scholar]

- Qudoos, A.; Ullah, Z.; Rehman, A.; Baloch, Z. Performance Evaluation of the Fiber—Reinforced Cement Composite Blended with Wheat Straw Ash. Adv. Mater. Sci. Eng. 2019, 2019, 1835764. [Google Scholar] [CrossRef]

- Righi, D.P.; Costa, F.B.P.; Graeff, A.G.; Silva Filho, L.C.P. Tensile Behaviour and Durability Issues of Engineered Cementitious Composites with Rice Husk Ash. Rev. Matéria 2017, 22, 1–9. [Google Scholar] [CrossRef]

- Qudoos, A.; Kakar, E.; Rehman, A.; Jeon, I.K.; Kim, H.G. Influence of Miling Techniques on the performance of wheat Straw Ash in Cement Composites. Appl. Sci. 2020, 10, 3511. [Google Scholar] [CrossRef]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Hossain, K.M.A. Effect of glass powder on sulfuric acid resistance of cementitious materials. Constr. Build. Mater. 2016, 113, 163–173. [Google Scholar] [CrossRef]

- Liu, S.; Wang, S.; Tang, W.; Hu, N.; Wei, J. Inhibitory effect of waste glass powder on ASR expansion induced by waste glass aggregate. Materials 2015, 8, 6849–6862. [Google Scholar] [CrossRef] [PubMed]

- Siad, H.; Lachemi, M.; Sahmaran, M.; Mesbah, H.A.; Hossain, K.M.A. Use of recycled glass powder to improve the performance properties of high volume fly ash-engineered cementitious composites. Constr. Build. Mater. 2018, 163, 53–62. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Zi, G.; Meyer, C. Fracture mechanics of ASR in concretes with waste glass particles of different sizes. J. Eng. Mech. 2000, 126, 226–232. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Use of waste glass as sand in mortar: Part II. Alkali–silica reaction and mitigation methods. Cem. Concr. Compos. 2013, 35, 118–126. [Google Scholar] [CrossRef]

- Shang, X.; Yu, J.; Li, L.; Lu, Z. Strengthening of RC Structures by Using Engineered Cementitious Composites: A Review. Sustainability 2019, 11, 3384. [Google Scholar] [CrossRef]

- Latifi, M.R.; Biricik, O.; Aghabaglou, A.M. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2021, 36, 345–369. [Google Scholar] [CrossRef]

- Yang, E.H.; Li, V.C. Strainhardening fiber cement optimization and component tailoring by means of a micromechanical model. Constr. Build. Mater. 2010, 24, 130–139. [Google Scholar] [CrossRef]

- Li, V.C.; Horikoshi, T.; Ogawa, A.S.; Torigoe, S.; Saito, T. Micromechanics-Based Durability Study of Polyvinyl Alcohol-Engineered Cementitious Composite. ACI Mater. J. 2004, 101, 242–248. [Google Scholar]

- ChiaHwan, Y.; JianBo, H. The Mechanical Behavior of Fiber Reinforced PP ECC Beams under Reverse Cyclic Loading. Adv. Mater. Sci. Eng. 2014, 2014, 159790. [Google Scholar] [CrossRef][Green Version]

- Karahan, O.; Atis, C.D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- ASTM C150/C150M-16; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C128-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C618-12a; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C192/C192M-19; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in or (50-mm) Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM C348-20; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C642-13; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C1585-13; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM C597-16; Standard Test Method for Pulse Velocity through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- Tran, N.T.; Pyo, S.; Kim, D.J. Corrosion resistance of strain-hardening steel-fiber-reinforced cementitious composites. Cem. Concr. Compos. 2015, 63, 17–29. [Google Scholar] [CrossRef]

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C267-01; Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2012.

- Jamil, M.; Khan, M.N.N.; Karim, M.R.; Kaish, A.B.M.A.; Zain, M.F.M. Physical and chemical contributions of Rice Husk Ash on the properties of mortar. Constr. Build. Mater. 2016, 128, 185–198. [Google Scholar] [CrossRef]

- Qudoos, A.; Kim, H.G.; Rehman, A.; Ryou, J.S. Effect of mechanical processing on the pozzolanic efficiency and the microstructure development of wheat straw ash blended cement composites. Constr. Build. Mater. 2018, 193, 481–490. [Google Scholar] [CrossRef]

- Ramasamy, V. Compressive Strength and Durability Properties of Rice Husk Ash Concrete. KSCE J. Civ. Eng. 2012, 16, 93–102. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M.; Filho, A.C. Concreto: Estrutura, Propriedades e Materials; Pini: São Paulo, SP, Brazil, 1994. [Google Scholar]

- Omran, A.; Hamou, A.T. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- Hesami, S.; Ahmadi, S.; Nematzadeh, M. Effects of rice husk ash and fiber on mechanical properties of pervious concrete pavement. Constr. Build. Mater. 2014, 53, 680–691. [Google Scholar] [CrossRef]

- Adesina, A.; Das, S. Influence of glass powder on the durability properties of engineered cementitious composites. Constr. Build. Mater. 2020, 242, 118199. [Google Scholar] [CrossRef]

- Schwarz, N.; Neithalath, N. Influence of a fine glass powder on cement hydration: Comparison to fly ash and modeling the degree of hydration. Cem. Concr. Res. 2008, 38, 429–436. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Isaia, G.C.; Gastaldini, A.L.G. Effects on durability of HPC with very high levels of mineral additions and hydrated lime. In Proceedings of the IV International ACI/CANMET Conference on Quality of Concrete Structures and Recent Advances in Concrete Materials and Testing, Coimbra, Portugal, 6–7 September 2005; pp. 741–760. [Google Scholar]

- Letelier, V.; Jara, B.I.H.; Manosalva, M.; Parodi, C.; Ortega, J.M. Use of waste glass as a replacement for raw materials in mortars with a lower environmental impact. Energies 2019, 12, 1974. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Rizwan, S.A.; Memon, S.A.; Tulliani, J.M.; Ferro, G.A. Experimental Investigation on Use of Wheat Straw Ash and Bentonite in Self-Compacting Cementitious System. Adv. Mater. Sci. Eng. 2014, 2014, 832508. [Google Scholar] [CrossRef]

- Matos, A.M.; Coutinho, J.S. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos. Part B Eng. 2013, 45, 1587–1594. [Google Scholar] [CrossRef]

- Jo, B.W.; Sikandar, M.A.; Chakraborty, S.; Baloch, Z. Investigation of the acid and sulfate resistance performances of hydrogen-rich water based mortars. Constr. Build. Mater. 2017, 137, 1–11. [Google Scholar] [CrossRef]

- Munoz-Sanchez, B.; Arevalo-Caballero, M.J.; Pacheco-Menor, M.C. Influence of acetic acid and calcium hydroxide treatments of rubber waste on the properties of rubberized mortars. Mater. Struct. 2017, 50, 75. [Google Scholar] [CrossRef]

- Khan, M.H.; Sikandar, M.A.; Jamal, Q. Properties of Mortars Formulated from Self-Compacting High-Performance Concrete Containing Various Mineral Additions. Iran. J. Sci. Technol. Trans. Civ. Eng. 2021, 45, 779–793. [Google Scholar] [CrossRef]

- Ozbay, E.; Sahmaran, M.; Lachemi, M.; Yucel, H.E. Self-healing of micro cracks in high-volume fly-ash-incorporated engineered cementitious composites. ACI Mater. J. 2013, 110, 33–44. [Google Scholar]

- Sikandar, M.A.; Ahmad, W.; Khan, M.H.; Ali, F.; Waseem, M. Effect of water resistant SiO2 coated SrAl2O4: Eu2+ Dy3+ persistent luminescence phosphor on the properties of Portland cement pastes. Constr. Build. Mater. 2019, 228, 116823. [Google Scholar] [CrossRef]

- Horgnies, M.; Chen, J.J.; Bouillon, C. Overview about the use of Fourier Transform Infrared spectroscopy to study cementitious Materials. WIT Trans. Eng. Sci. 2013, 77, 251–262. [Google Scholar] [CrossRef]

- Ylmén, R.; Jäglid, U.; Steenari, B.M.; Panas, I. Early hydration and setting of Portland cement monitored by IR, SEM and Vicat techniques. Cem. Concr. Res. 2009, 39, 433–439. [Google Scholar] [CrossRef]

- Habeeb, G.A.; Mahmud, B.H. Study on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Hamid, R.; Ibrahim, N.; Jamadin, A. Influence of grinding of rice husk ash to the workability and strength of concrete. Int. Refereed J. Eng. Sci. IRJES 2013, 2, 50–54. [Google Scholar]

- Mollah, M.Y.A.; Lu, F.; Cocke, D.L. An X-ray diffraction (XRD) and Fourier transform infrared spectroscopic (FT-IR) characterization of the speciation of arsenic (V) in Portland cement type-V. Sci. Total Environ. 1998, 224, 57–68. [Google Scholar] [CrossRef]

- Rupasinghe, M.; San Nicolas, R.; Mendis, P.; Sofi, M.; Ngo, T. Investigation of strength and hydration characteristics in nano-silica incorporated cement paste. Cem. Concr. Compos. 2017, 80, 17–30. [Google Scholar] [CrossRef]

- Li, F.; Liu, J.S. An experimental investigation of hydration mechanism of cement with silicane. Constr. Build. Mater. 2018, 166, 684–693. [Google Scholar] [CrossRef]

- Stutzman, P.E. Guide for X-ray Powder Diffraction Analysis of Portland Cement and Clinker; U.S. Department of Commerce, Technology Administration, National Institute of Standards and Technology, Office of Applied Economics, Building and Fire Research Laboratory: Baltimore, MD, USA, 1996. [Google Scholar]

- Habib, A.; Aiad, I.; Youssef, T.A.; El-Aziz, A.A. Effect of some chemical admixtures on the physicochemical and rheological properties of oil well cement pastes. Constr. Build. Mater. 2016, 120, 80–88. [Google Scholar] [CrossRef]

- Kunther, W.; Ferreiro, S.; Skibsted, J. Influence of the Ca/Si Ratio on the Compressive Strength of Cementitious Calcium-Silicate-Hydrate Binders. J. Mater. Chem. A 2017, 5, 17401–17412. [Google Scholar] [CrossRef]

| Chemical Composition (%) | OPC | FA | RHA | WHA | GP |

|---|---|---|---|---|---|

| SiO2 | 20.78 | 58 | 93.2 | 72.7 | 68.1 |

| Fe2O3 | 2.99 | 3.58 | 0.1 | - | 0.4 |

| Al2O3 | 5.81 | 29.08 | 0.4 | 0.48 | 2.0 |

| CaO | 62.18 | 3.6 | 1.1 | 10.6 | 13.6 |

| SO3 | 1.89 | 1.8 | 0.9 | 6.13 | - |

| MgO | 1.52 | 1.91 | 0.1 | 2.20 | 1.3 |

| TiO2 | - | 1.75 | - | - | - |

| Na2O | - | 2.00 | 0.1 | 5.41 | 7.2 |

| P2O5 | - | - | - | 4.68 | - |

| K2O | - | 0.73 | 1.3 | 11.4 | 0.6 |

| Free Lime | 0.68 | - | - | - | - |

| IR | 0.3 | - | - | - | - |

| LOI | 2.00 | 2.00 | 3.7 | 5.5 | 0.49 |

| Properties | Value |

|---|---|

| Length (mm) | 13 |

| Diameter (µm) | 32 |

| Tensile Strength (MPa) | 520 |

| Elastic Modulus (GPa) | 4.2 |

| Elongation (%) | 4 |

| Mix ID | Controlled (C) | RHA 10% (R10) | RHA 20% (R20) | WHA 10% (W10) | WHA 20% (W20) | GP 10% (GP10) | GP 20% (GP20) | Combined 20% (CMB) |

|---|---|---|---|---|---|---|---|---|

| OPC | 381.6 | 381.6 | 381.6 | 381.6 | 381.6 | 381.6 | 381.6 | 381.6 |

| FA | 890.4 | 763.2 | 636.0 | 763.2 | 636.0 | 763.2 | 636.0 | 636.0 |

| RHA | 0 | 127.2 | 254.4 | 0 | 0 | 0 | 0 | 84.8 |

| WHA | 0 | 0 | 0 | 127.2 | 254.4 | 0 | 0 | 84.8 |

| GP | 0 | 0 | 0 | 0 | 0 | 127.2 | 254.4 | 84.8 |

| Sand | 462 | 462 | 462 | 462 | 462 | 462 | 462 | 462 |

| Water | 318 | 318 | 318 | 318 | 318 | 318 | 318 | 318 |

| HRWR | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 | 15.3 |

| Fiber | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 |

| Sample Code | Hydration Time (Days) | Wt. % of Elements Measured from EDX Analysis | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Na | Mg | Al | Si | S | K | Ca | Ti | Fe | Cl | ||

| CMB | 28 | 34.56 | 30.97 | 0.20 | 0.31 | 3.53 | 8.50 | 1.28 | 0.93 | 15.00 | 0.49 | 4.15 | - |

| R20 | 28 | 28.59 | 35.96 | 0.10 | 0.31 | 3.28 | 9.72 | 1.08 | 1.03 | 11.80 | 0.39 | 2.97 | 0.18 |

| W20 | 28 | 24.74 | 34.88 | - | 0.24 | 3.23 | 9.10 | 2.25 | 1.37 | 15.00 | - | 2.56 | - |

| GP20 | 28 | 30.94 | 33.17 | 0.47 | 0.48 | 4.04 | 8.40 | 1.28 | 0.83 | 15.20 | 0.54 | 4.27 | - |

| C | 28 | 26.45 | 35.06 | - | 0.53 | 6.18 | 7.53 | 1.53 | 0.76 | 18.10 | 0.82 | 7.61 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hanif Khan, M.; Zhu, H.; Ali Sikandar, M.; Zamin, B.; Ahmad, M.; Muayad Sabri Sabri, M. Effects of Various Mineral Admixtures and Fibrillated Polypropylene Fibers on the Properties of Engineered Cementitious Composite (ECC) Based Mortars. Materials 2022, 15, 2880. https://doi.org/10.3390/ma15082880

Hanif Khan M, Zhu H, Ali Sikandar M, Zamin B, Ahmad M, Muayad Sabri Sabri M. Effects of Various Mineral Admixtures and Fibrillated Polypropylene Fibers on the Properties of Engineered Cementitious Composite (ECC) Based Mortars. Materials. 2022; 15(8):2880. https://doi.org/10.3390/ma15082880

Chicago/Turabian StyleHanif Khan, Muhammad, Han Zhu, Muhammad Ali Sikandar, Bakht Zamin, Mahmood Ahmad, and Mohanad Muayad Sabri Sabri. 2022. "Effects of Various Mineral Admixtures and Fibrillated Polypropylene Fibers on the Properties of Engineered Cementitious Composite (ECC) Based Mortars" Materials 15, no. 8: 2880. https://doi.org/10.3390/ma15082880

APA StyleHanif Khan, M., Zhu, H., Ali Sikandar, M., Zamin, B., Ahmad, M., & Muayad Sabri Sabri, M. (2022). Effects of Various Mineral Admixtures and Fibrillated Polypropylene Fibers on the Properties of Engineered Cementitious Composite (ECC) Based Mortars. Materials, 15(8), 2880. https://doi.org/10.3390/ma15082880