Under the doctrine of “socialism with Chinese characteristics” implemented by the Chinese Communist Party, China’s economy has developed rapidly to become the second largest economy worldwide. Unfortunately, early steps in this historic economic development resulted in numerous problems, including ecological destruction and environmental pollution. These environmental problems have had a negative impact on development, and at various stages have affected people’s livelihoods and caused emotional and spiritual pain [

1]. One notable example is the manner in which river sand, as a traditional building material, has caused serious damage to the ecological environment of rivers and mountains owing to its excessive exploitation. In recent years, government departments have prohibited the use of river sand. Therefore, the shortage of building materials has become a major problem that is currently restricting construction. However, aeolian sand, a sand alternative, is abundant in China, given that transportation due to wind erosion is the main cause of land desertification in the areas surrounding the Gobi Desert (approximately 16% of the country’s land area). At present, the geotechnical engineering application of aeolian sand focuses on mechanical compaction and grouting. Traditional curing treatment methods are problematic, with limited reinforcement ability, construction difficulties, and environmental pollution [

2] being the current barriers to the uptake of aeolian sand for construction purposes.

Reinforcing mixed matrix materials for use in geotechnical engineering applications has been spearheaded by advances in the application of fiber reinforcement technology to soil; the latter involves the mixing of fibers with certain lengths with soil to form a new composite material that improves the tensile capacity relative to normal granular soil. Given the accessibility of numerous experimental studies on the mechanical properties of fiber-reinforced soil [

3,

4,

5,

6,

7,

8,

9,

10,

11,

12], many results exist that demonstrate an ability to control reliably material properties and responses. For example, Hongtao et al. [

13] found that the strength of cement-improved soil increases as the fiber length and content increase. However, the strength decreased when the fiber content exceeded a specific limit. Qun et al. [

14] found that the addition of fibers not only improved the ductility of cement soil, but also slowed down the crack propagation behavior. Qian [

15] found that after the addition of basalt fiber to loess, the crack development speed of the sample is delayed, and the fiber on the fracture surface is pulled out, so the tensile strength of the sample is obviously improved. Hengchao et al. [

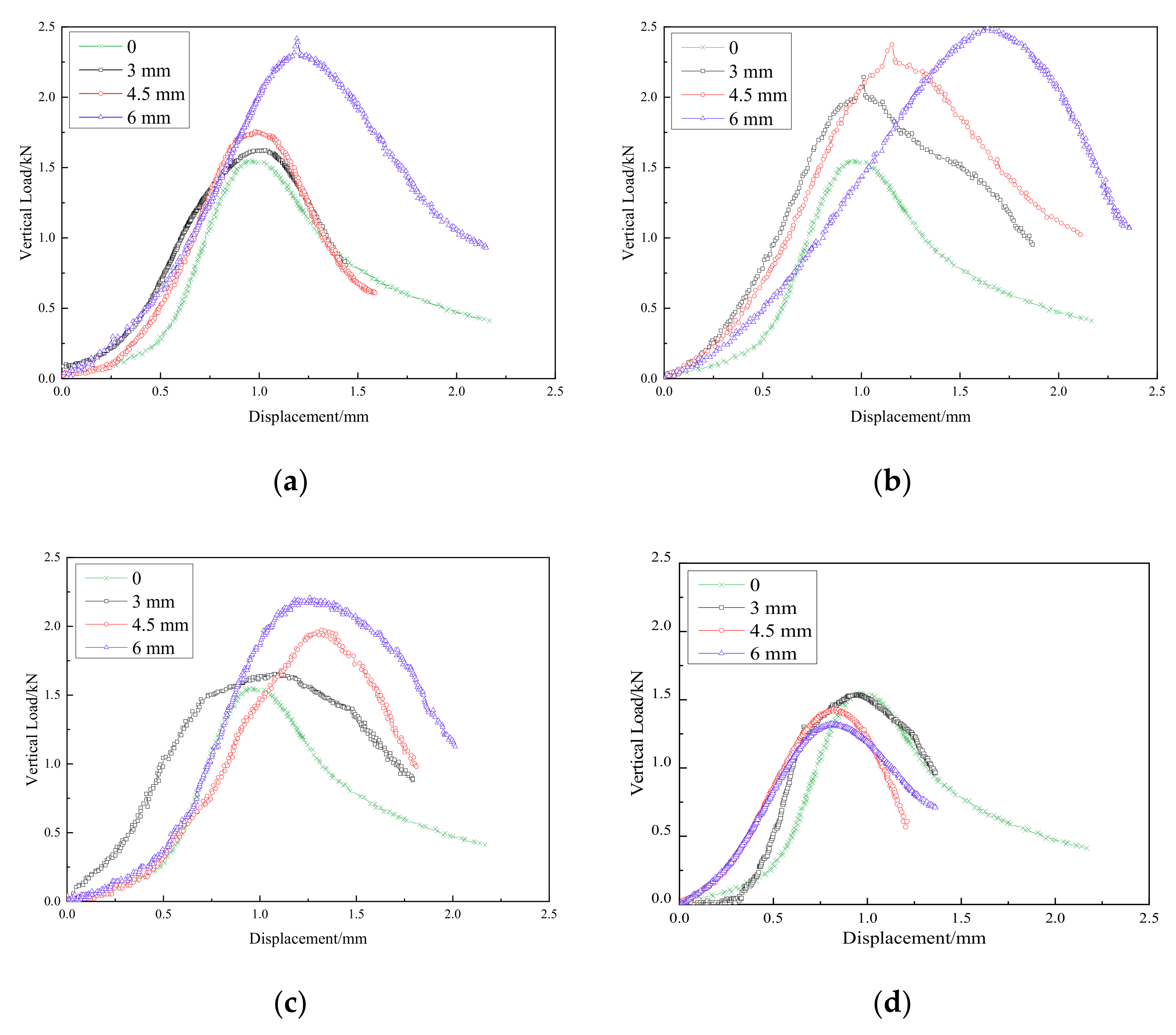

16] found that an increase in fiber content and length led to an initial increase and to a subsequent decrease in the tensile strength of glass fiber-reinforced cement soil, with an optimum fiber content of 0.2% and an optimum fiber length of 6 mm. Hong et al. [

17] obtained the variation law of the safety factor for slope stability based on consideration of parameters, such as the glass fiber length, glass fiber content, and slope height. Bo et al. [

18,

19] conducted a splitting strength test on polypropylene fiber-reinforced cement soil and found that an increase in fiber content resulted in increased splitting strength, tension–compression ratio, and ductility. Furthermore, from triaxial compression testing, it was found that adding polypropylene fibers could improve considerably the toughness of cement mortar soil. Wei et al. [

20] used glass fiber for cement–soil reinforcement and concluded that when the contents of fiber with lengths of 6 mm or 12 mm were equal to 0.3%, the reinforcement effect of cement soil was the best. To elucidate the micromechanical characteristics of fiber-reinforced soil, Chaosheng et al. [

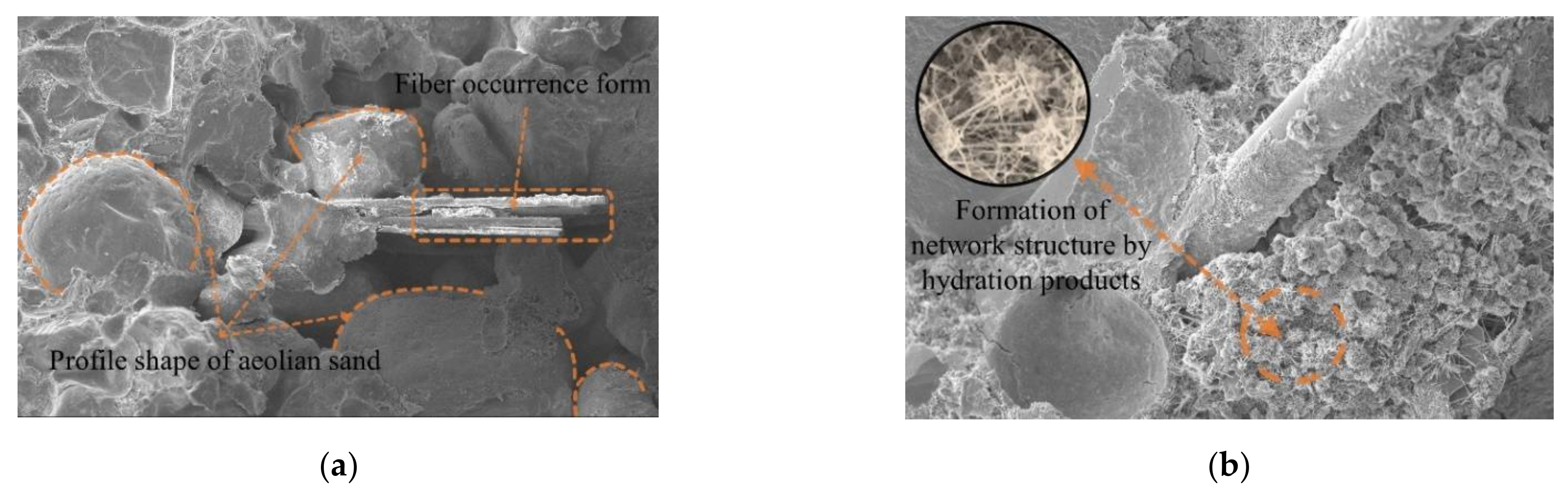

21] used an electron microscope to scan and study the interface between fiber-reinforced plain soil and fiber-reinforced cement soil, and concluded that physical friction and hydration bonding between fiber and soil were the main mechanisms of the reinforcement effect. Deyin et al. [

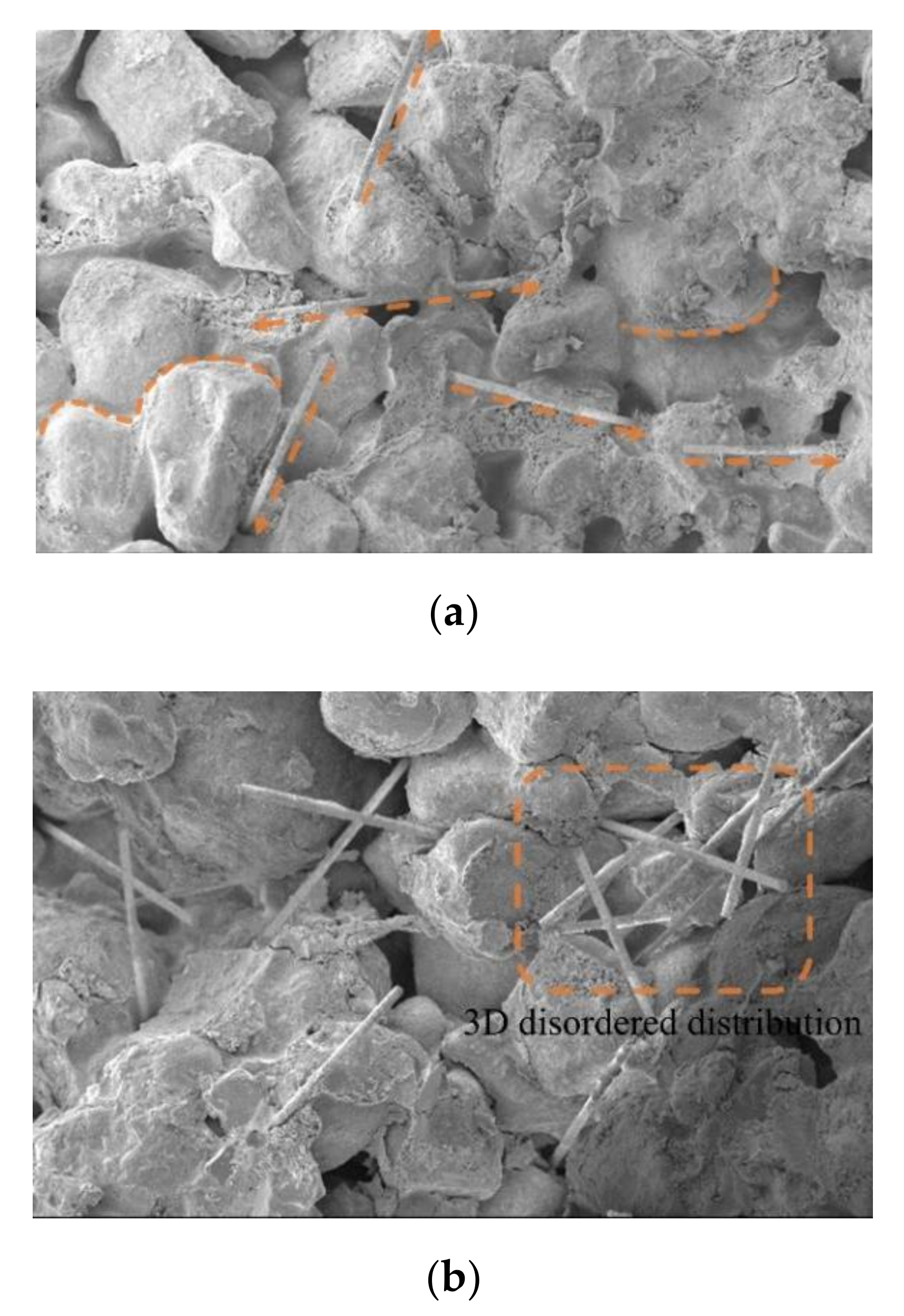

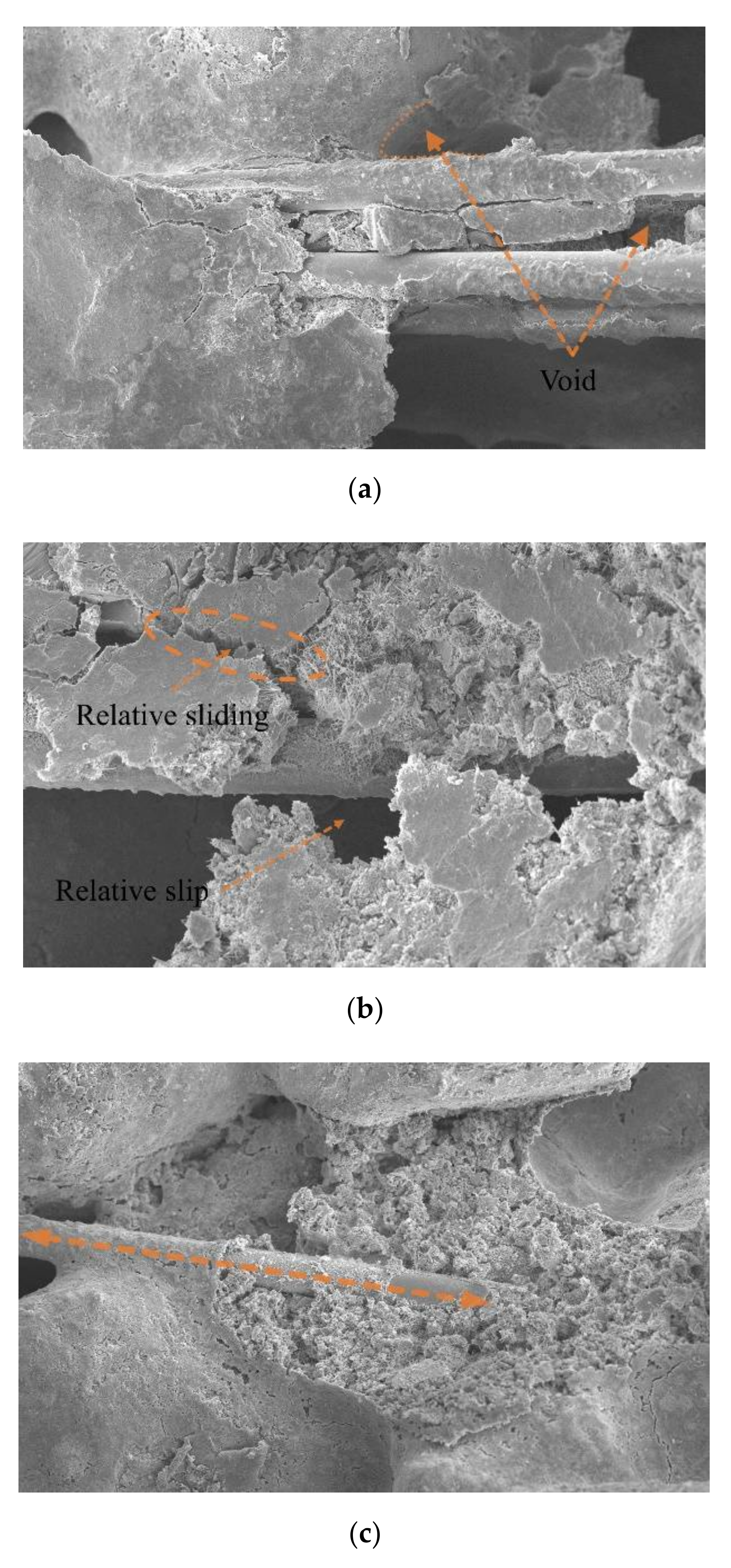

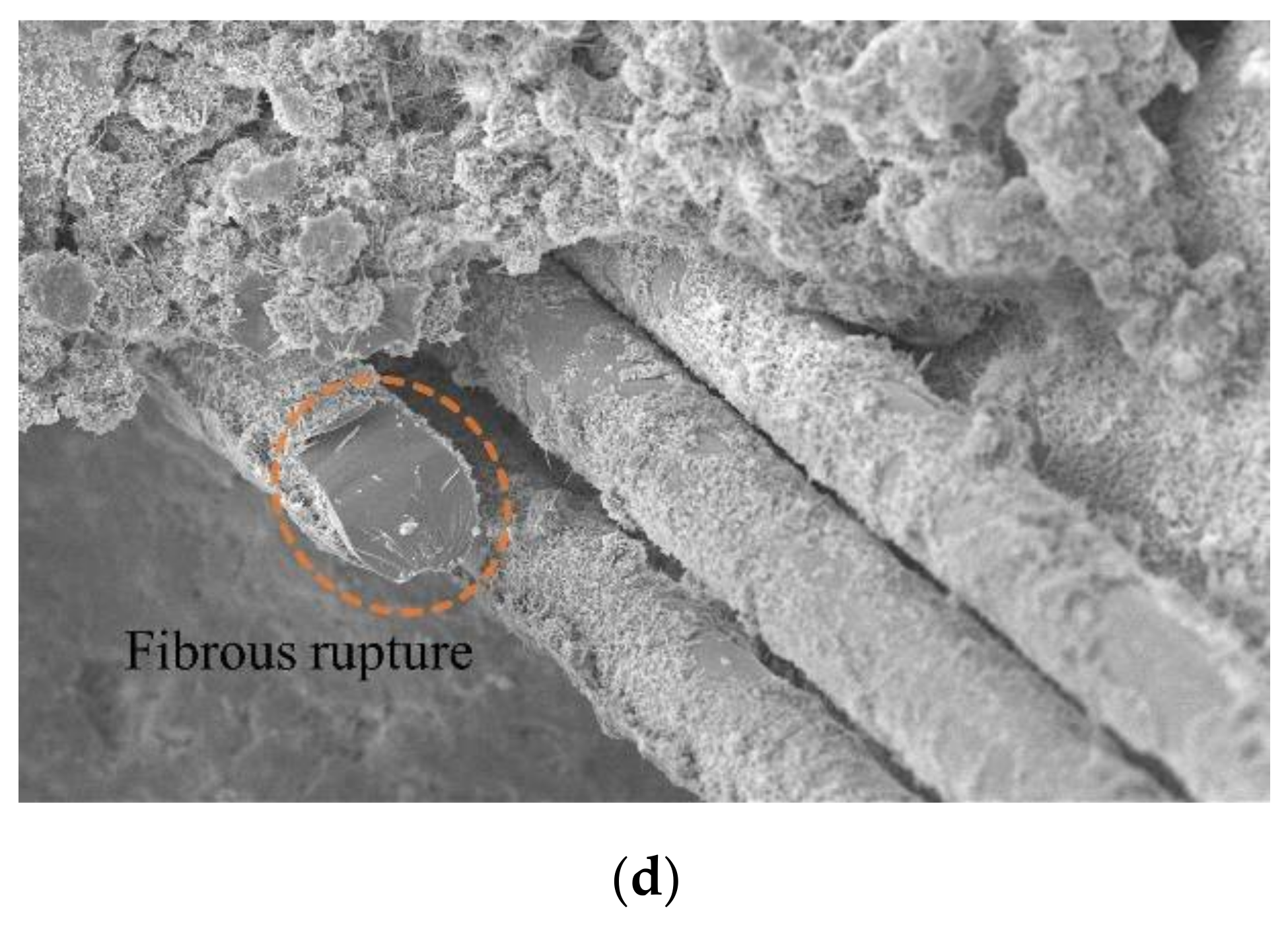

22] studied the interaction at the fiber–soil interface of unsaturated cohesive soil reinforced by polypropylene fiber using scanning electron microscopy (SEM), and concluded that fiber reinforcement was mainly achieved by the one-dimensional (1D) reinforcement of single fibers, and three-dimensional (3D) reinforcement of fiber webs. Lei et al. [

23] used SEM and showed that when the fiber content was 0.25%, the fiber dispersed evenly in the soil. This even dispersion played a key role in enabling a 3D fiber web to be formed. The soil produced a gripping effect on the fiber, and the main failure modes of the fiber were slip and wear. Tang et al. [

24,

25] found that after the fiber was added to the soil, friction and cohesive force were generated at the interface between the fiber and the soil, and the magnitude of this net interfacial force directly affected the improvement effect of the fiber on the soil owing to the generated interfacial shear strength. Shizong [

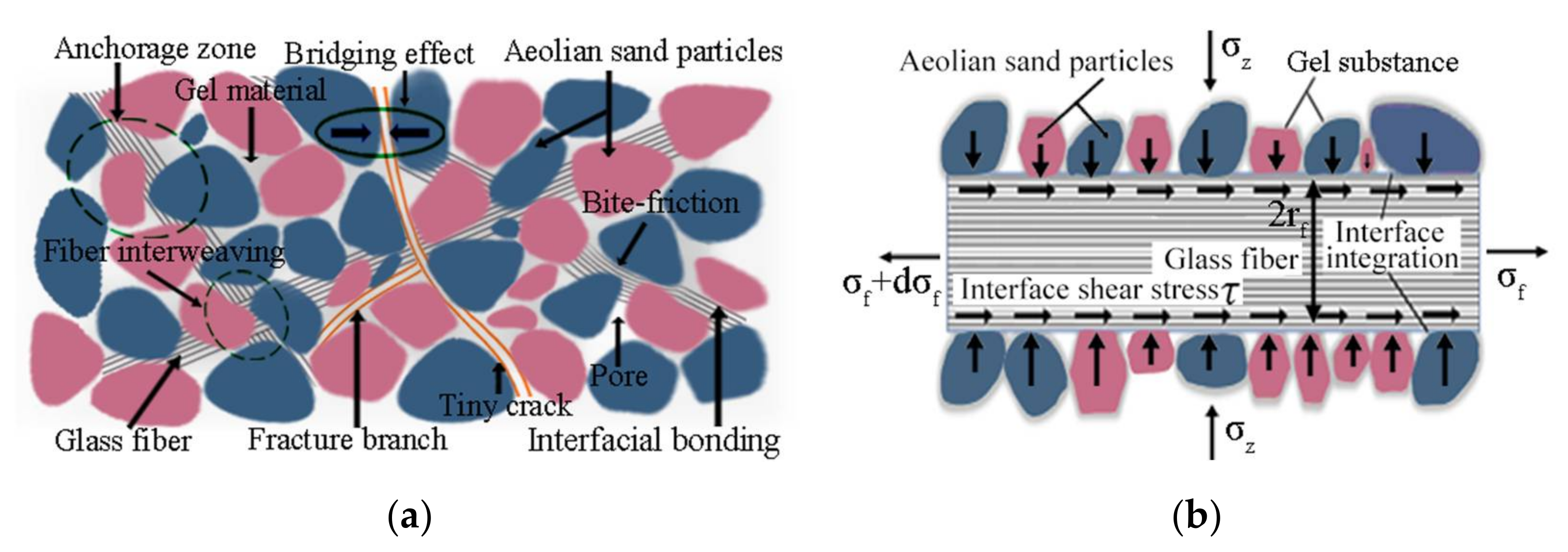

26] analyzed the principle of cement soil strength enhancement by the fiber, and asserted that the possible mechanisms can be summarized according to the “bending mechanism” and “interweaving mechanism” concepts. To date, studies of the microscopic properties of fiber-reinforced soil have been limited because the soil types considered were loess, clay, soft soil, or expansive soil. Only a few research studies have been conducted on aeolian sand, especially curing aeolian sand with glass fiber and cement as reinforcing materials. Given the complex interaction between geosynthetics, findings of fiber reinforcement using other soils cannot be extended to aeolian sand. Therefore, conducting experimental studies to establish an evidence base specific to the reinforcement of aeolian sand with cement and fiber is necessary.

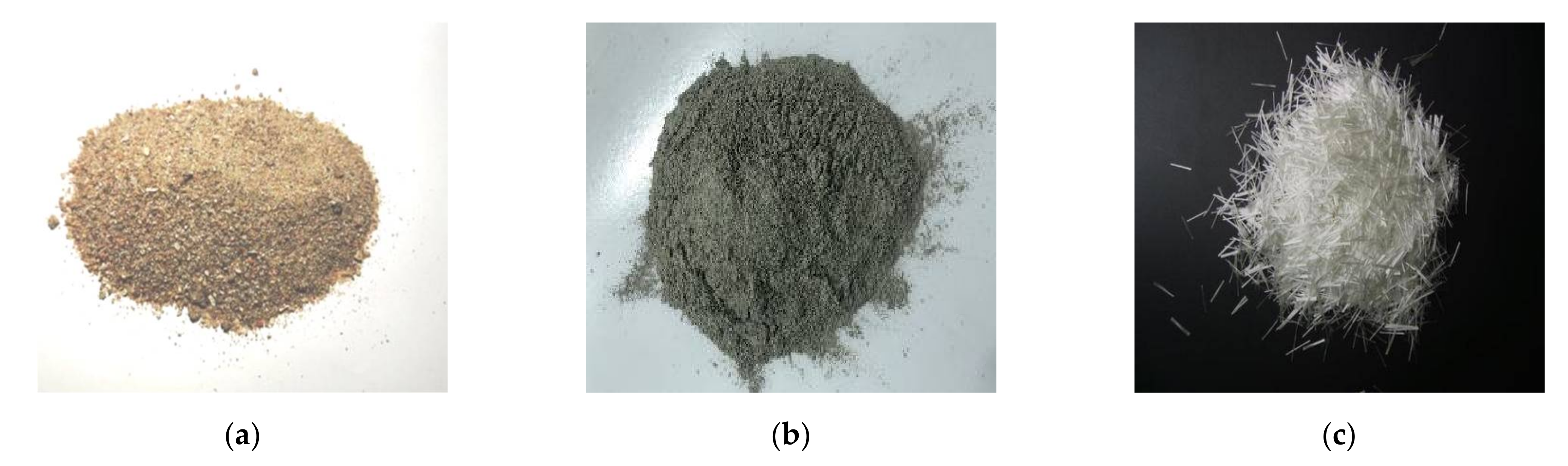

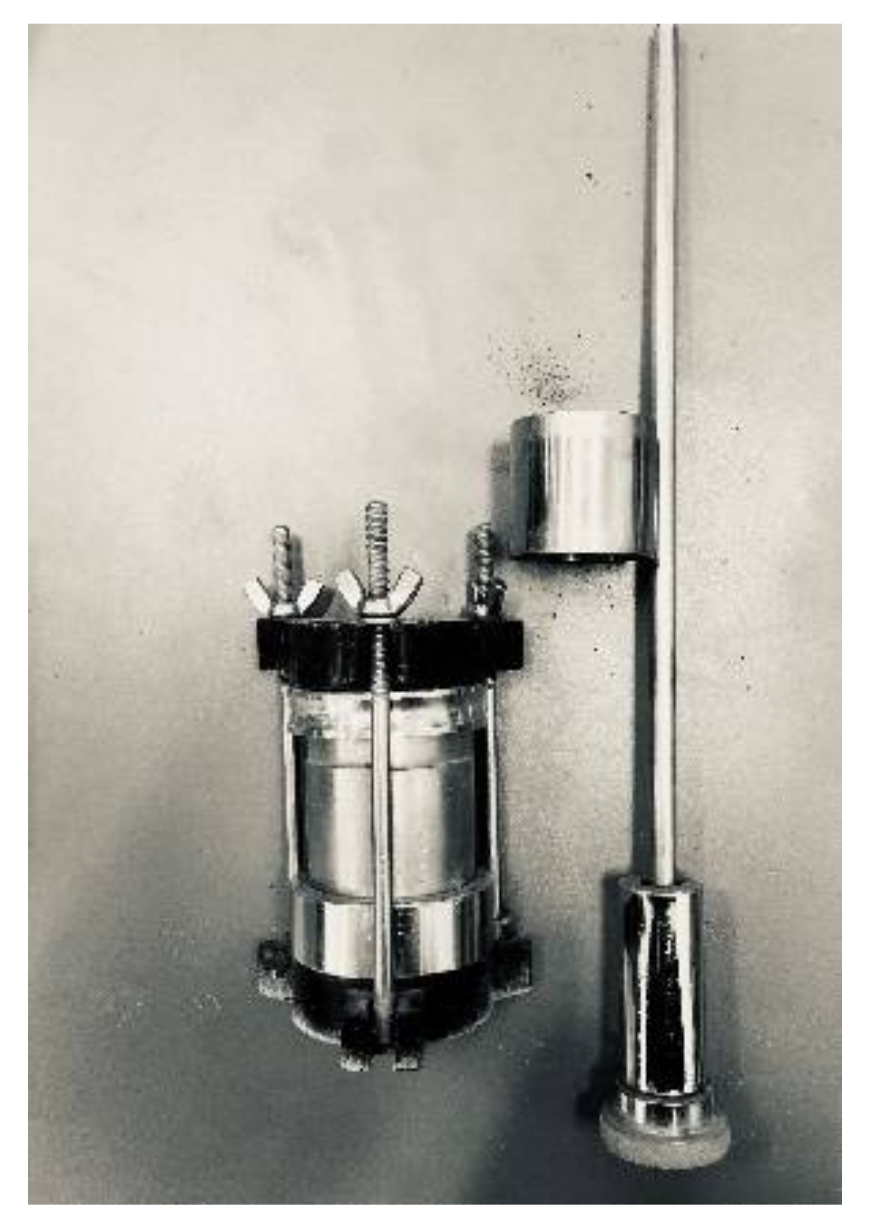

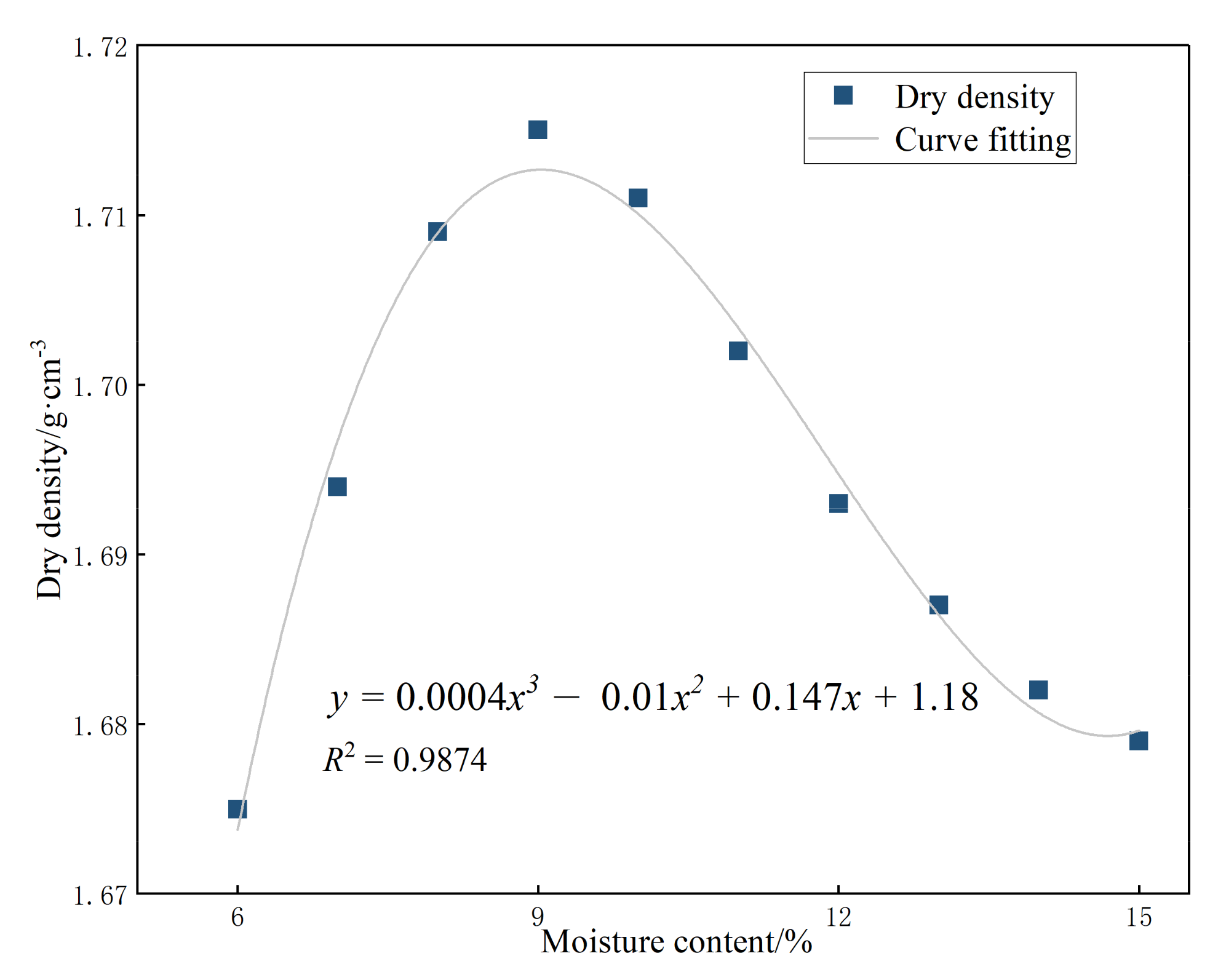

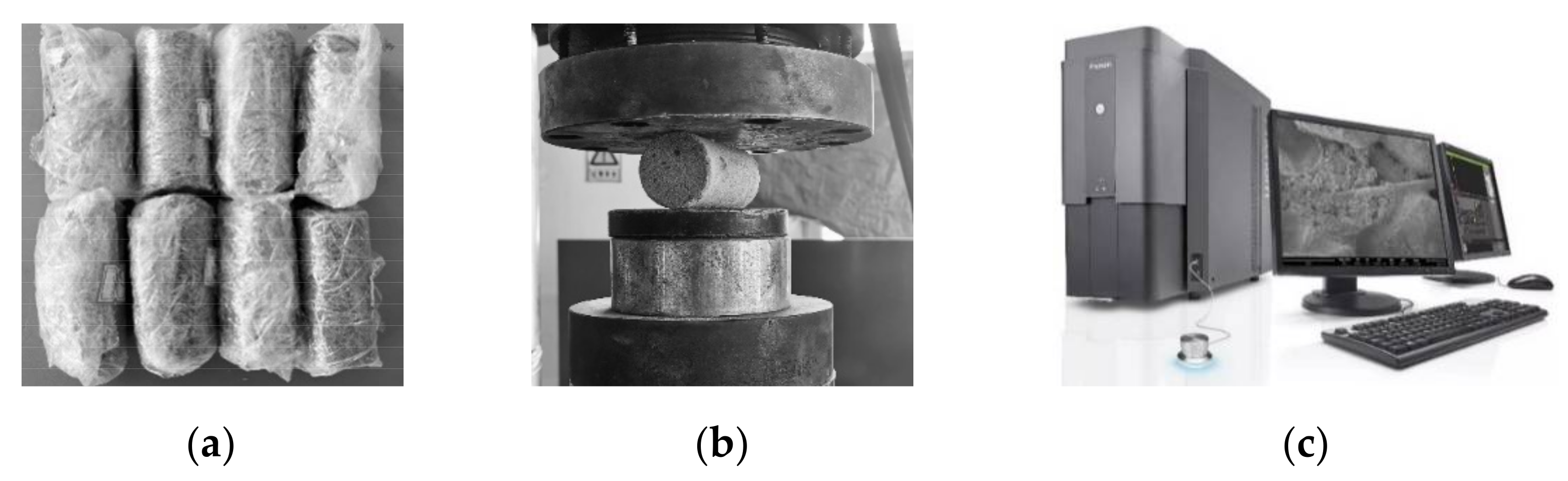

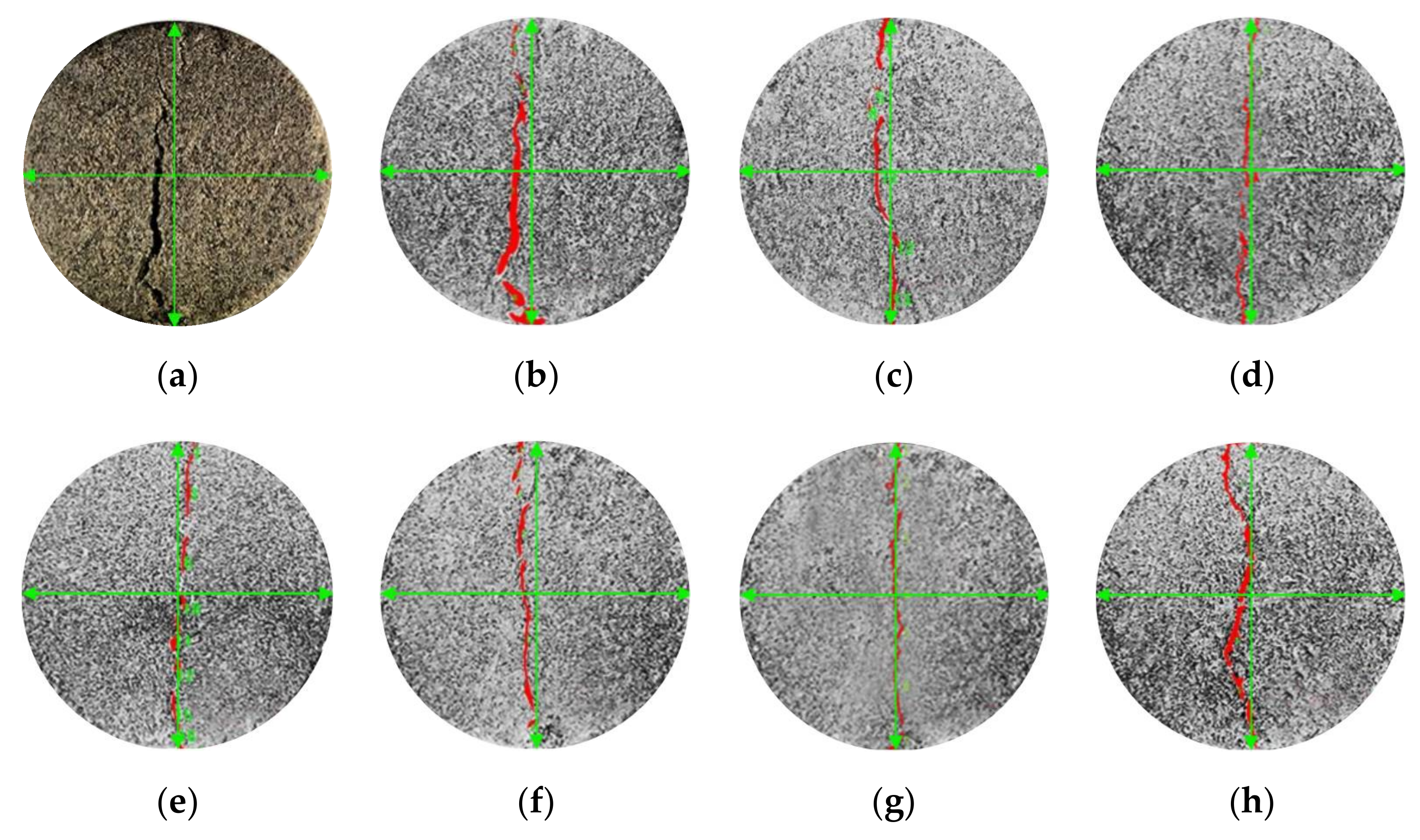

In this study, aeolian sand is adopted to fill roadbeds in desert areas as the engineering application of interest, and aeolian sand in the Zhangwu area of Liaoning province is the base material with research interest. A cross-scale research method that combines macroscopic splitting mechanical tests with SEM technology has been adopted for this study to explore the influence of different fiber blending schemes on the splitting strength of cement-fiber-solidified aeolian sand. Based on the basic theory of interface mechanics [

27], The effect of additive (glass fiber, cement) content and fiber length on the splitting strength and fiber morphology of cement-fiber solidified aeolian sand under splitting condition and the mechanisms of the cement–fiber solidified aeolian sand reinforcement–soil interface are revealed. The research shows that the engineering mechanical properties of aeolian sand can be improved by adding appropriate amounts of cement and fiber, and the research results can provide a scientific basis for the prevention and treatment of subgrade diseases of cement-fiber solidified aeolian sand.