Effectiveness of Curing Compounds for Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. FTIR Spectroscopy

2.2. Dry Mass Content

2.3. Water Retention Efficiency and Effectiveness of Curing Compounds

- It—is the curing efficiency index after time “t”

- T—is the time at which the weight of the specimens is determined (t = 0 h, 6 h, 24 h and 72 h)

- MRt—is the average of mass loss from the untreated specimens at time “t” (specimens without curing compound)

- MCt—is the average of mass loss from the treated specimens at time “t” reduced with the average of mass loss of the curing compound (solvent loss) at time “t”.

2.4. Tensile Strength by the Pull-Off Method

2.5. Scanning Microscopy

3. Results and Discussion

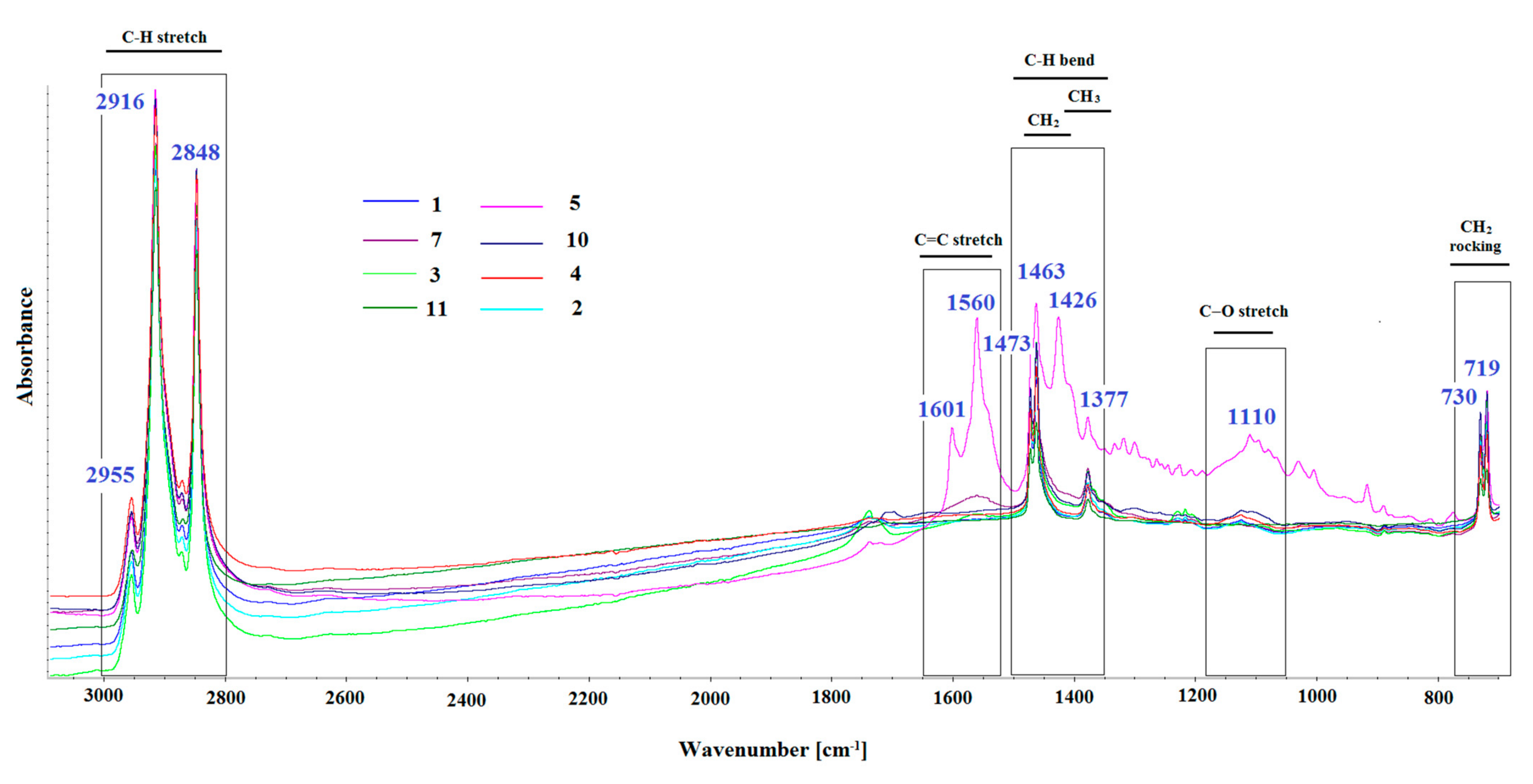

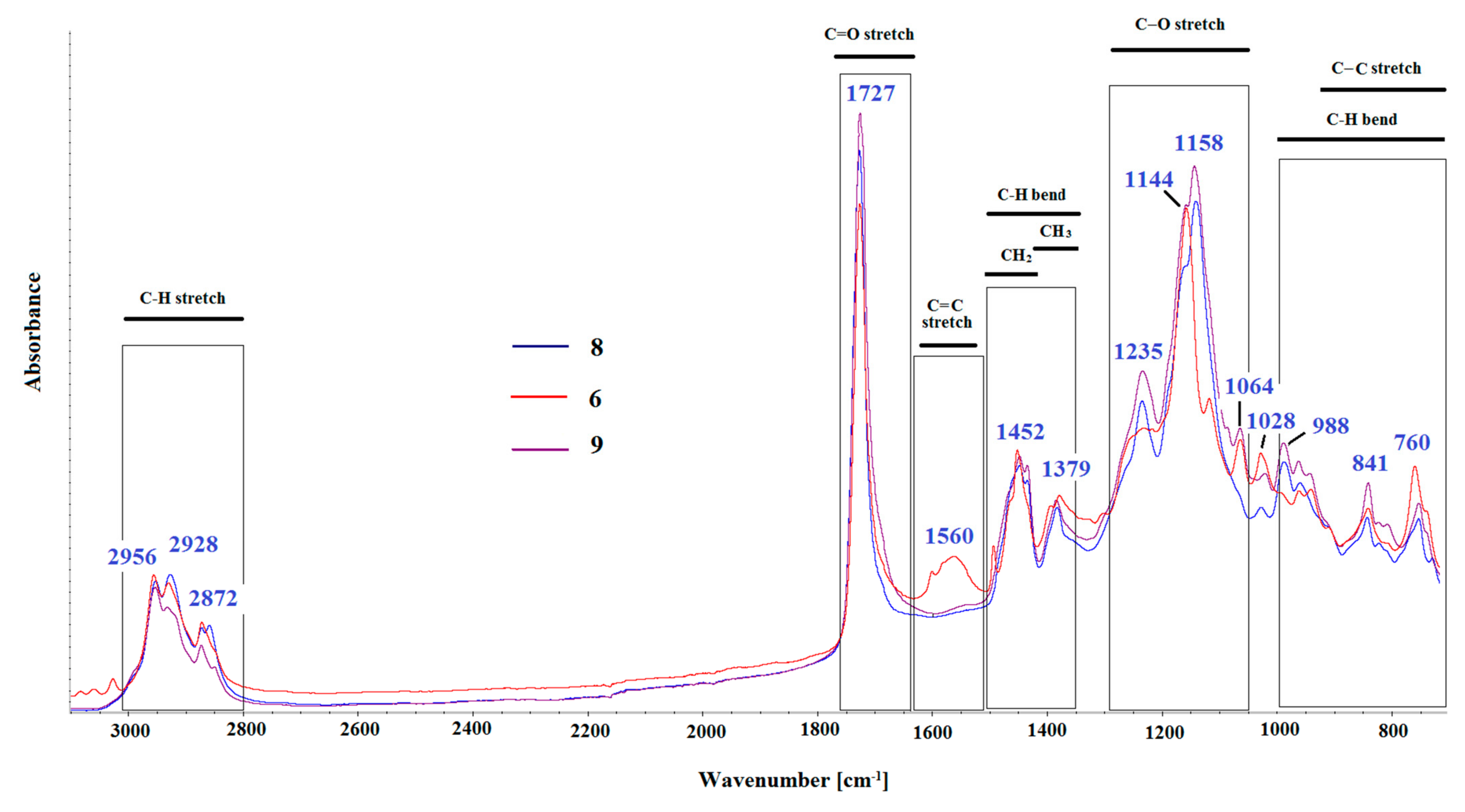

3.1. FTIR Spectroscopy

3.2. Dry Mass Content

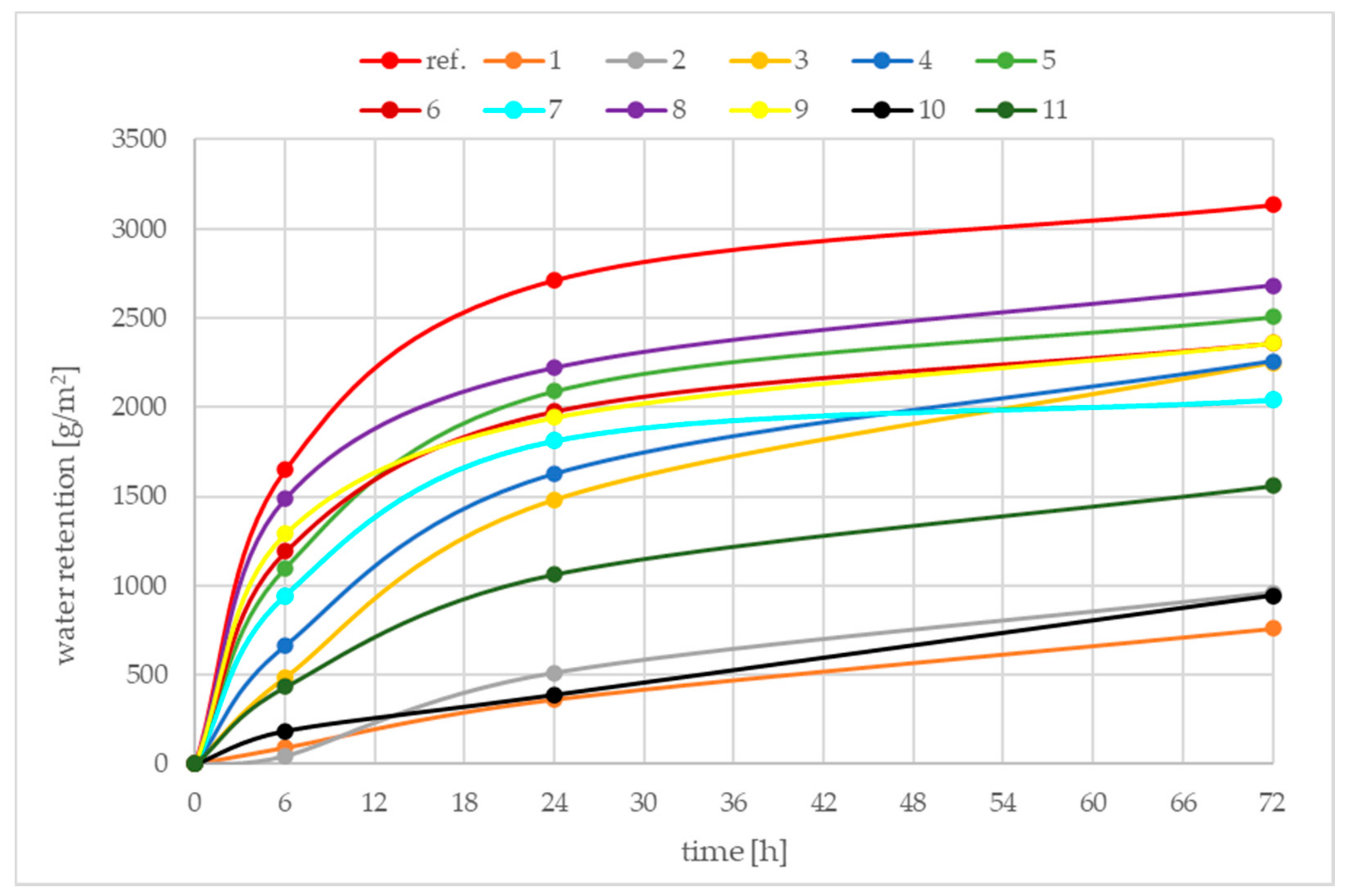

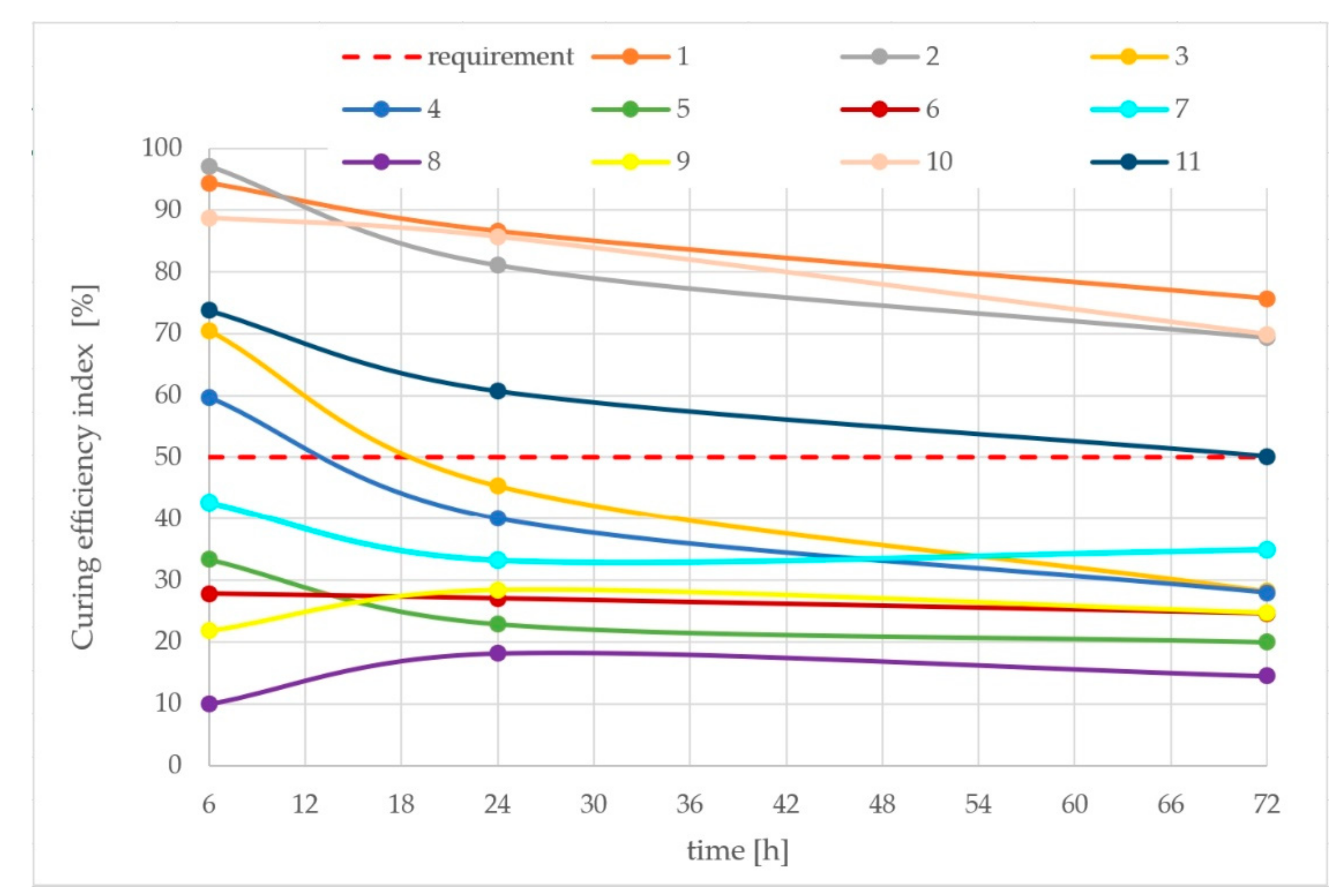

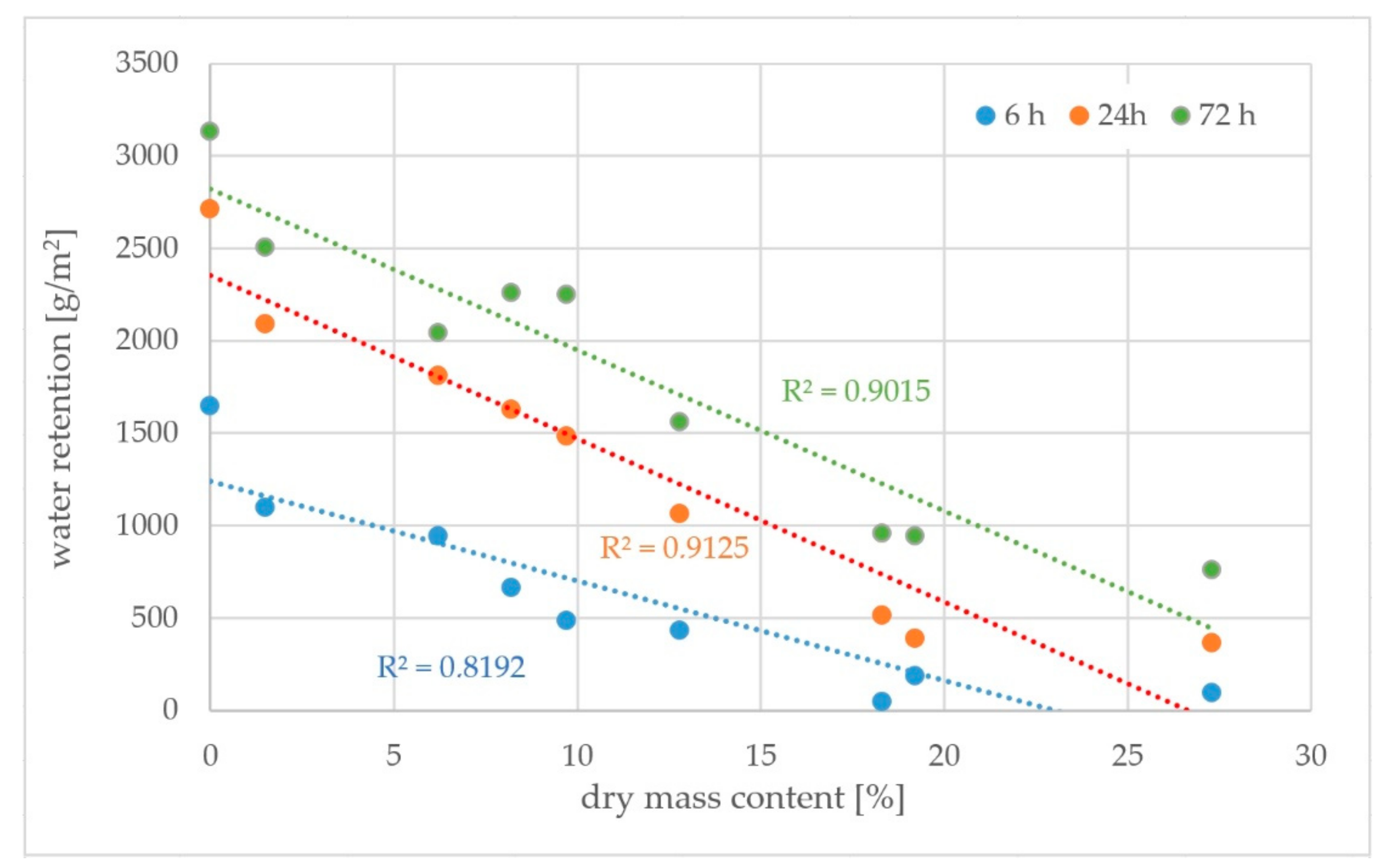

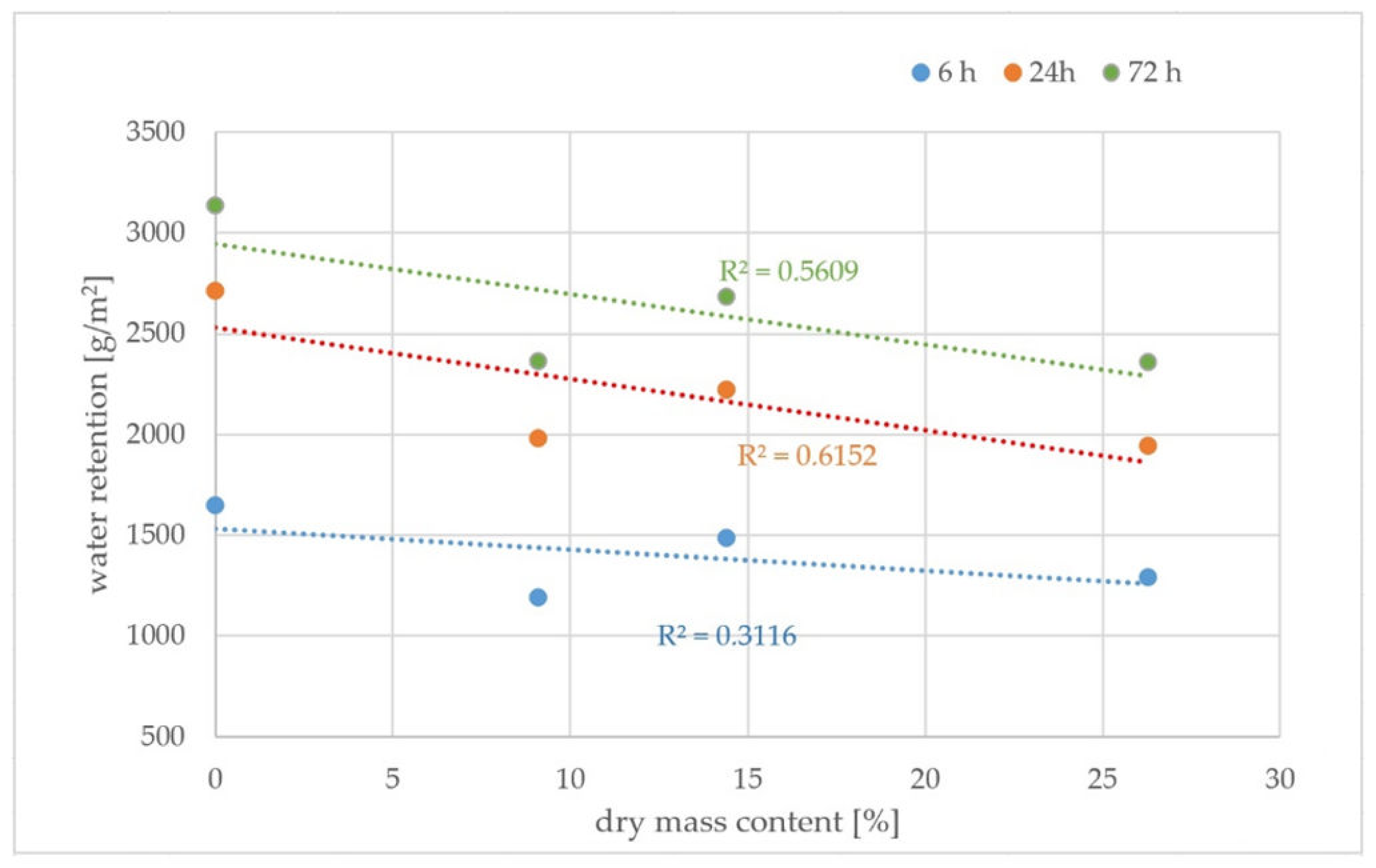

3.3. Water Retention Efficiency and Effectiveness of Curing Compounds

3.4. Tensile Strength by the Pull-Off Method

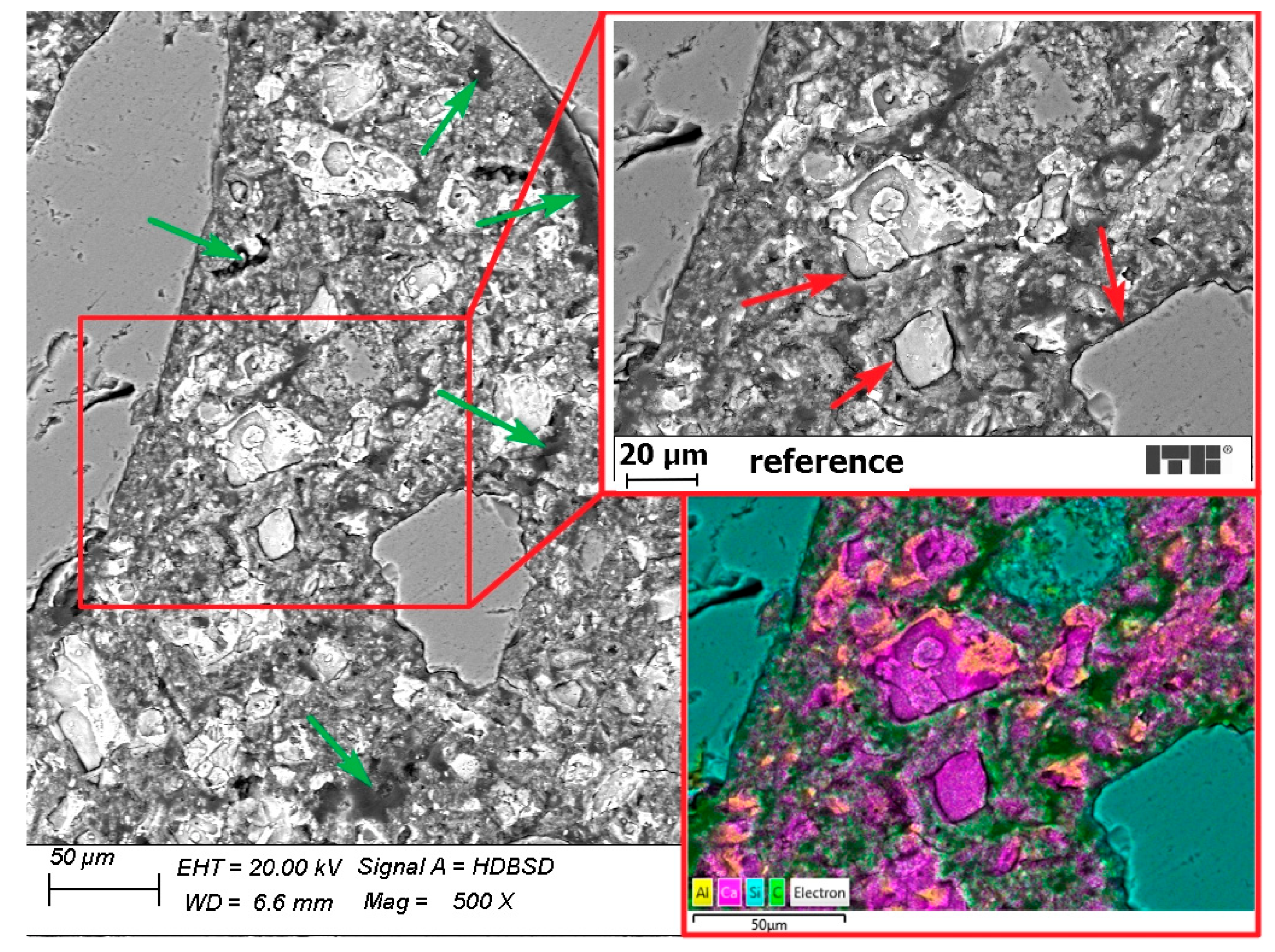

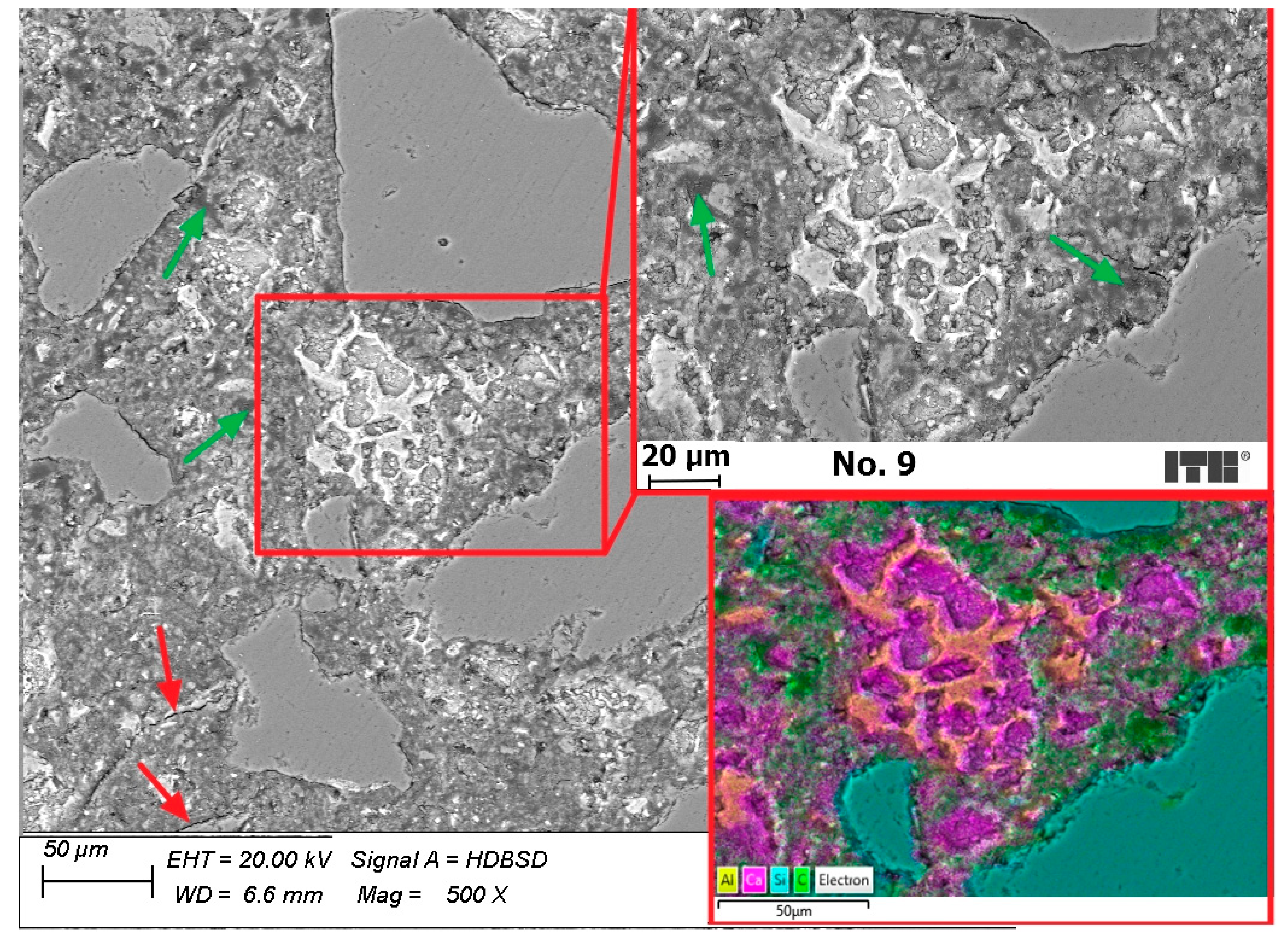

3.5. Scanning Microscopy

4. Conclusions

- Based on the functional groups’ vibrations (FTIR), it can be concluded that all tested curing compounds for concrete belong to two different groups. Both groups have different characteristic vibrations, while the fingerprint regions give unique peaks of configuration which can be used to distinguish between them. The vibrations present in the first group (samples No. 1–5, 7 and 10–11) indicate that the curing compounds are based on paraffins, while the vibrations in the second group indicate modified synthetic resins.

- Water retention and curing efficiency index for products available on the market have a wide range of values. Due to the lack of standardised test methods and requirements in European countries, the obtained values should be analysed at the place of use. It should be assumed that all of them might be used for the curing of concrete.

- Water retention efficiency correlates well with the dry mass content in curing compounds containing paraffin. That might show that the main mechanism of curing this type of product is preventing water evaporation from the concrete by creating a sealed barrier.

- Effectively cured concrete using curing compounds with low values of curing efficiency index is characterised by higher tensile strength on its surface area. That proves the importance of curing the concrete to reach projected values of performance properties.

- The effectiveness of curing compounds affects the microstructure of cement composite. When the microstructure is compact and tight, and the C-S-H phase is well developed, the effectivity of the curing compound is high. Conversely, when using low effectiveness curing compounds or none at all, the structure has numerous air voids and cracks and the C-S-H phase is weakly developed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Gowripalan, N.; Cabrera, J.G.; Cusens, A.R.; Wainwright, P.J. Effect of Curing on Durability. Concr. Int. 1990, 12, 47–54. [Google Scholar]

- Hooton, R.D.; Bickley, J.A. Design for durability: The key to improving concrete sustainability. Constr. Build. Mater. 2014, 67, 422–430. [Google Scholar] [CrossRef]

- Czarnecki, L. Sustainable concrete; is nanotechnology the future of concrete polymer composites? Adv. Mater. Res. 2013, 687, 3–11. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 13670:2011 Execution of Concrete Structures; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- Steven, C.L.J.; Gebler, H. Guide to Curing Concrete ACI 308R-16; American Concrete Institute: Farmington Hills, MI, USA, 2016. [Google Scholar]

- American Concrete Institute (ACI). Aci 306R-10; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2016; p. 24. [Google Scholar]

- American Concrete Institute (ACI). ACI Committee 305R-20; Guide to Hot Weather Concreting; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2020; p. 23. [Google Scholar]

- Gebler, S.H. The cement sustainability initiative: Recycling Concrete. World Bus. Counc. Sustain. Dev. 2008, 1, 9–11. [Google Scholar]

- Rahmatnezhad, K.; Zarastvand, M.R.; Talebitooti, R. Mechanism study and power transmission feature of acoustically stimulated and thermally loaded composite shell structures with double curvature. Compos. Struct. 2021, 276, 114557. [Google Scholar] [CrossRef]

- Woyciechowski, P. Effect of curing regime on polymer-cement concrete properties. Arch. Civ. Eng. 2020, 66, 143–160. [Google Scholar] [CrossRef]

- Pawar, Y.; Kate, S. Curing of Concrete: A Review. Int. Res. J. Eng. Technol. 2020, 7, 1820–1824. [Google Scholar] [CrossRef]

- Sun, P. A New Protocol for Evaluating Concrete Curing Effectiveness. Master’s Thesis, Texas A&M University, Department of Civil Engineering, Austin, TX, USA, August 2013. [Google Scholar]

- Mariak, A.; Chróścielewski, J.; Sabik, A.; Meronk, B.; Wilde, K. Monitoring of Concrete Curing in Extradosed Bridge Supported By Numerical Simulation. Adv. Sci. Technol. Res. J. 2016, 10, 254–262. [Google Scholar] [CrossRef] [Green Version]

- Gołaszewski, J.; Ponikiewski, T.; Cygan, T. Influence of Type of Superpalsticizers on Workability and Compressive Strength. Int. J. Adv. Eng. Technol. 2010, 17, 37–44. [Google Scholar]

- Taylor, P.C. Curing Concrete; CRC Press: Boca Raton, FL, USA, 2013; Volume 69973, pp. 1–184. [Google Scholar] [CrossRef]

- European Committee for Standardization. PKN-CEN/TS 14754-1:2007; Curing Compounds–Test Methods–Part 1: Determination of Water Retention Efficiency of Common Curing Compounds; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- ASTM C156; Standard Test Method for Water Retention by Concrete Curing Materials. ASTM International West Conshohocken: Pennsylvania, PA, USA, 2002; pp. 1–7.

- ASTM C 309; Standard Specification for Liquid Membrane-Forming Compounds for Curing Concrete 1. ASTM International West Conshohocken: Pennsylvania, PA, USA, 2015.

- Construction Products Regulation (CPR) Regulation (EU) No 305/2011; European Commission: Brussels, Belgium, 2011.

- Godek, J.; Duczek, S. Initial Suitability Assessment Guideline the Properties of Coating Preparations and Coatings for the Care of Cement Concrete Surfaces; Road and Bridge Research Institute: Warsaw, Poland, 1983. (In Polish) [Google Scholar]

- Kozicki, M.; Creek, D.J.; Sexton, A.E.; Morahan, A.; Wesełucha-Birczyńska, B.J.; Wood, B.R. An attenuated total reflection (ATR) and Raman spectroscopic in-vestigation into the effects of chloroquine on Plasmodium falciparum-infected red blood cells. Analyst 2015, 140, 2236–2246. [Google Scholar] [CrossRef] [PubMed]

- European Committee for Standardization. PN-EN 480-8:2012; Admixtures for Concrete, Mortar and Grout–Test Methods–Part 8: Determination of the Conventional dry Material Content; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- AASHTO T 155; Standard Method of Test for Water Retention by Liquid Membrane-Forming Curing Compounds for Concrete. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2013.

- Vandenbossche, J.M. A Review of the Curing Compounds and Application Techniques Used by the Minnesota Department of Transportation for Concrete Pavements; Minnesota Department of Transportation Office of Research Services: Maplewood, MN, USA, 1999. [Google Scholar]

- European Committee for Standardization. EN 197-1:2012; Cement–Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization. EN 12620:2002+A1:2008; Aggregates for Concrete; European Committee for Standardization: Brussels, Belgium, 2008. [Google Scholar]

- European Committee for Standardization. EN 206+A1:2016-12; Concrete–Specification, Performance, Production and Conformity; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- European Committee for Standardization. EN 12350-2:2011; Testing Fresh Concrete–Part 2: Slump Test; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- European Committee for Standardization. EN 12350-7:2019-08; Testing Fresh Concrete–Part 7: Air Content–Pressure Methods; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- European Committee for Standardization. EN 1542:1999; Products and Systems for the Protection and Repair of Concrete Structures–Test Methods–Measurement of Bond Strength by Pull-Off; European Committee for Standardization: Brussels, Belgium, 1999. [Google Scholar]

- European Committee for Standardization. EN 196-1:2016-07; Methods of Testing Cement–Part 1: Determination of Strength; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Farber, C. Complementarity of Raman and Infrared Spectroscopy for Structural Characterization of Plant Epicuticular Waxes. ACS Omega 2019, 4, 3700–3707. [Google Scholar] [CrossRef] [Green Version]

- Robertson, D.; Reenen, A.; Duveskog, H. A comprehensive investigation into the structure-property relationship of wax and how it influences the properties of hot melt adhesives. Int. J. Adhes. Adhes. 2020, 99, 102559. [Google Scholar] [CrossRef]

- Duan, G.; Zhang, C.; Li, A.; Yang, X.; Lu, L.; Wang, X. Preparation and Characterization of Mesoporous Zirconia Made by Using a Poly (methyl methacrylate) Template. Nanoscale Res. Lett. 2008, 3, 118. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Constituent | Content (kg/m3) |

|---|---|

| Portland cement CEM I 42,5 R | 520 |

| melaphyre fines 0–0.25 | 182 |

| fine aggregate–river sand 0/2 mm | 589 |

| coarse aggregate–natural 2/8 mm | 846 |

| tap water | 220 |

| water–cement ratio | w/c = 0.42 |

| consistency of the fresh mix | S1 |

| Sample | Dry MASS Content (%) |

|---|---|

| 1 | 27.3 |

| 2 | 18.3 |

| 3 | 9.7 |

| 4 | 8.2 |

| 5 | 1.5 |

| 6 | 9.1 |

| 7 | 6.2 |

| 8 | 14.4 |

| 9 | 26.3 |

| 10 | 19.2 |

| 11 | 12.8 |

| Sample | Tensile Strength (Standard Deviation) (MPa) | Minimum Value (MPa) |

|---|---|---|

| ref. | 1.82 (0.16) | 1.56 |

| 1 | 2.63 (0.30) | 2.22 |

| 2 | 2.53 (0.28) | 2.26 |

| 3 | 1.95 (0.19) | 1.70 |

| 4 | 2.51 (0.12) | 2.37 |

| 7 | 1.87 (0.16) | 1.67 |

| 9 | 2.11 (0.17) | 2.03 |

| 10 | 1.87 (0.17) | 1.80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chyliński, F.; Michalik, A.; Kozicki, M. Effectiveness of Curing Compounds for Concrete. Materials 2022, 15, 2699. https://doi.org/10.3390/ma15072699

Chyliński F, Michalik A, Kozicki M. Effectiveness of Curing Compounds for Concrete. Materials. 2022; 15(7):2699. https://doi.org/10.3390/ma15072699

Chicago/Turabian StyleChyliński, Filip, Agnieszka Michalik, and Mateusz Kozicki. 2022. "Effectiveness of Curing Compounds for Concrete" Materials 15, no. 7: 2699. https://doi.org/10.3390/ma15072699

APA StyleChyliński, F., Michalik, A., & Kozicki, M. (2022). Effectiveness of Curing Compounds for Concrete. Materials, 15(7), 2699. https://doi.org/10.3390/ma15072699