Wire + Arc Additive Manufacturing and Heat Treatment of Super Martensitic Stainless Steel with a Refined Microstructure and Excellent Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Manufacturing Process

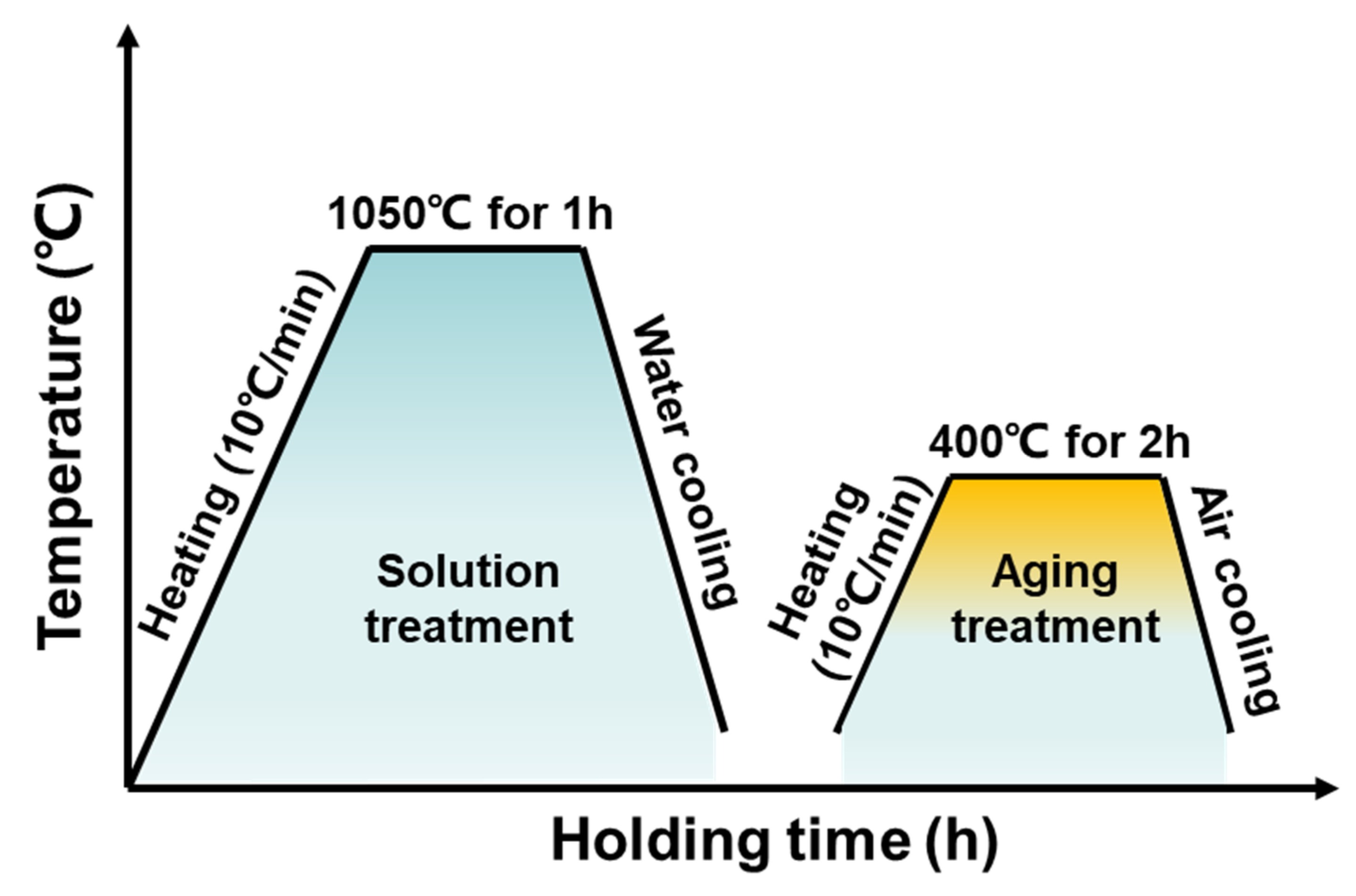

2.2. Post-Manufactured Heat Treatment Process

2.3. Microstructural Characterization

2.4. Hardness and Tensile Tests

3. Results and Discussion

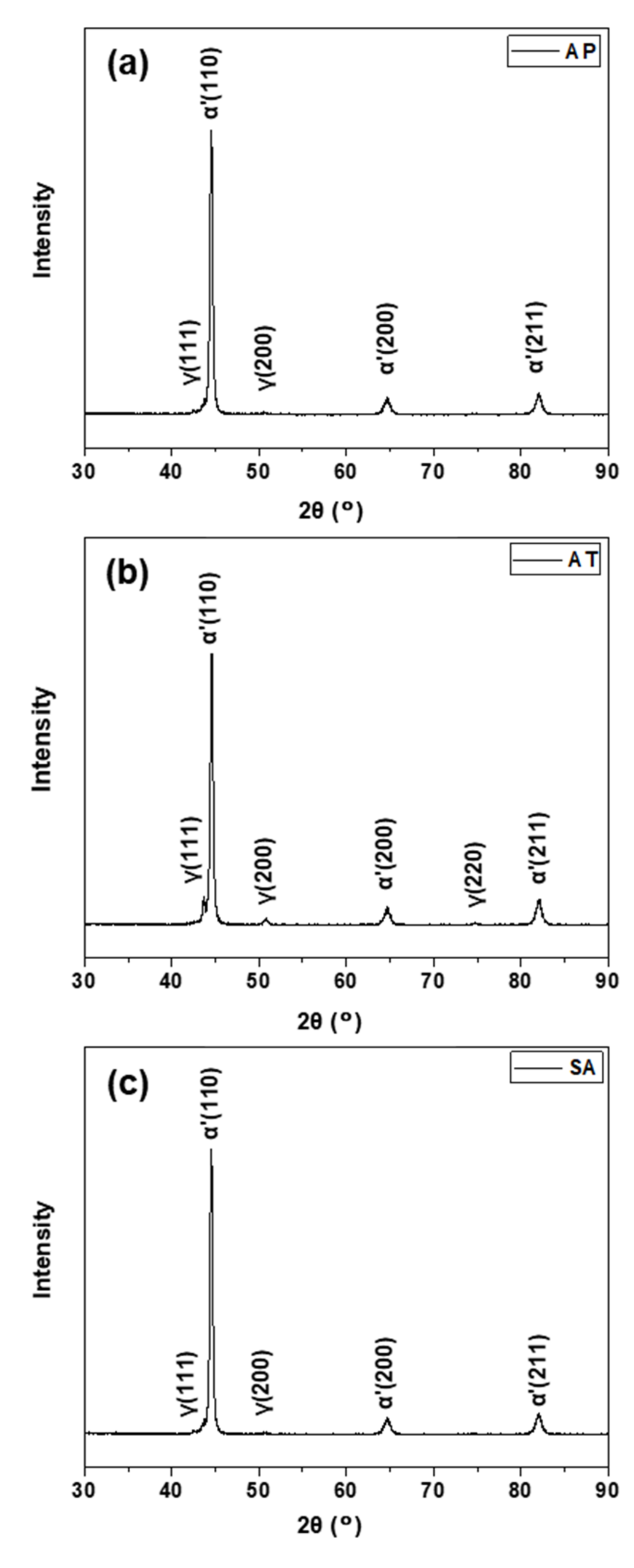

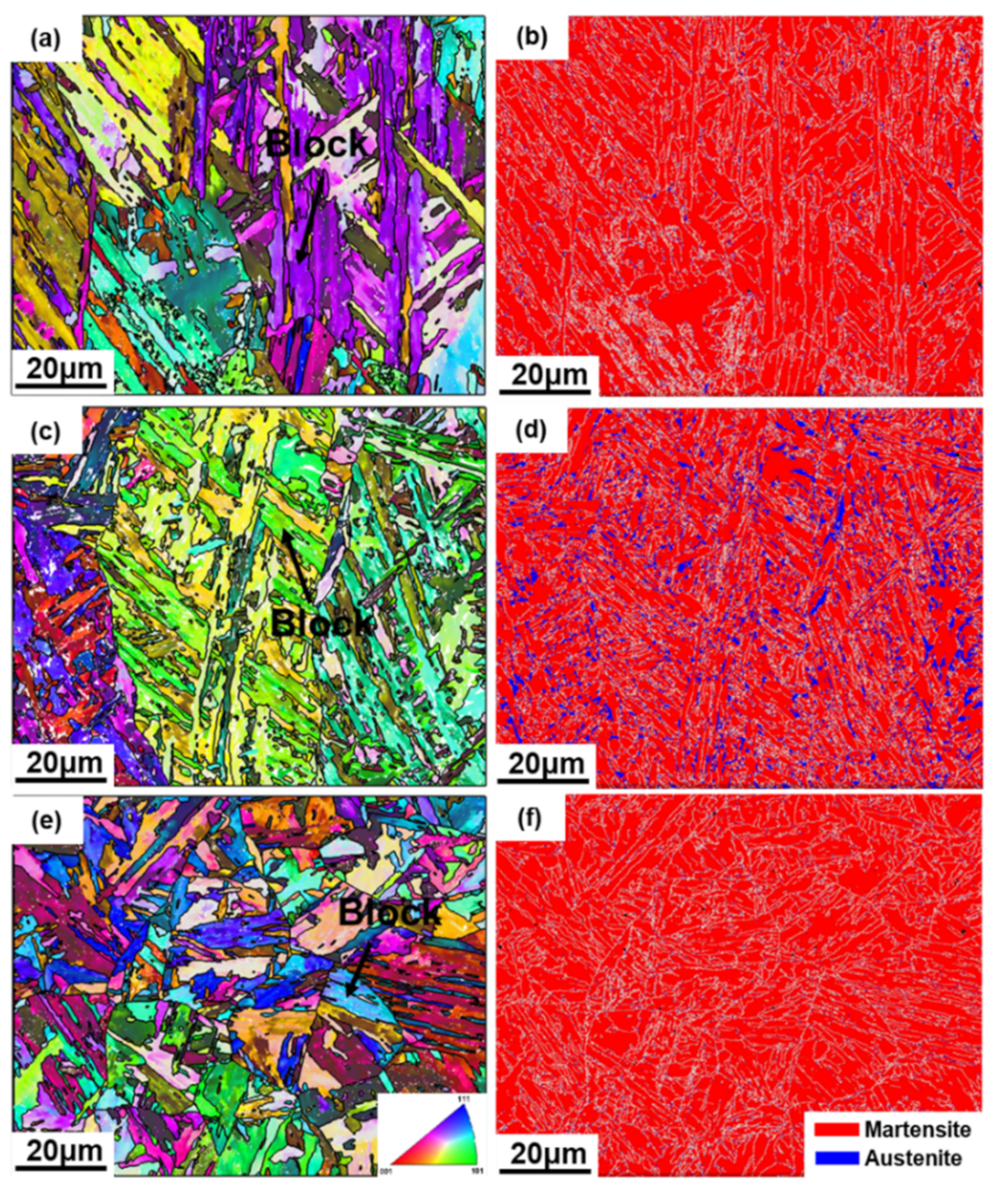

3.1. Microstructural Characteristics

3.2. Hardness

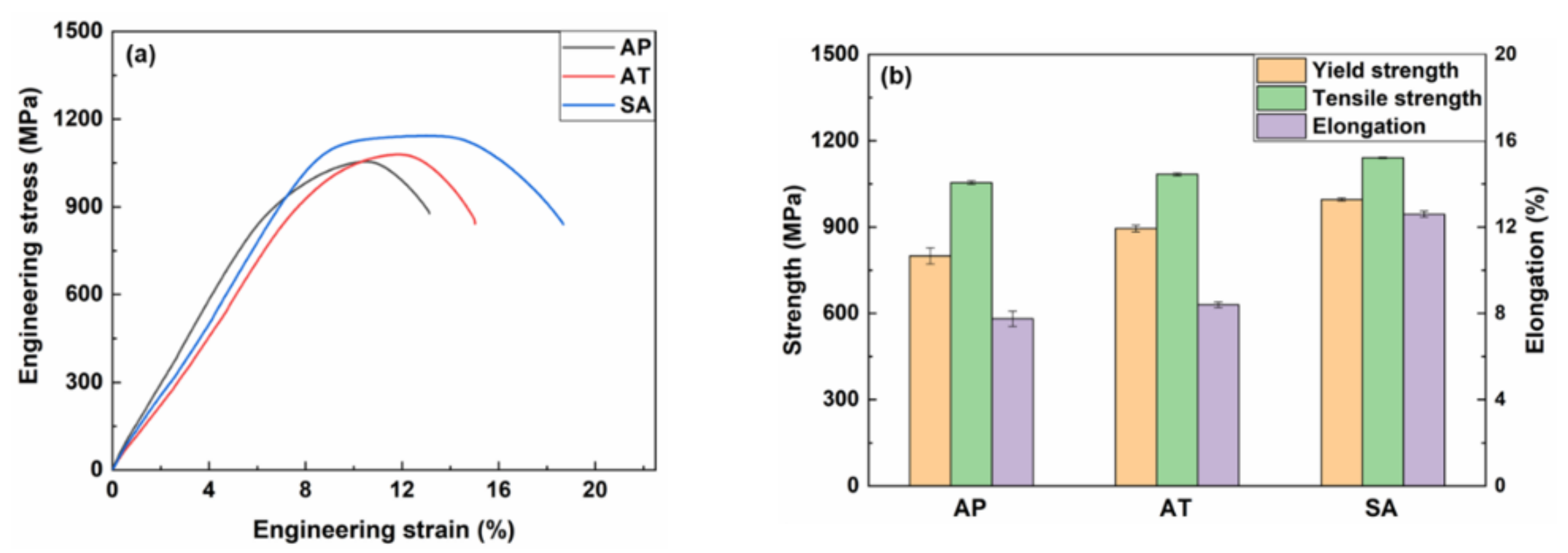

3.3. Tensile Properties

4. Conclusions

- (1)

- The microstructure of the AP sample is formed of martensite with very limited retained austenite. After direct aging treatment, the volume fraction of austenite phase grows to approximately 10% due to the complicated solute partitioning and interaction with the other microstructure. In the SA sample, the microstructure is greatly refined as a result of a mass of freshly fine grains with roughly equiaxial forms largely replacing the prior columnar microstructure during the homogenization treatment.

- (2)

- The solution + aging treatment has a beneficial effect on the hardness and strength of WAAM SMSS sample. The enhancement of strength in the SA sample can be attributed to the microstructure refinement. The hardness and ultimate tensile strength in the SA sample increase to 382 ± 4 HV0.3 and 1141 ± 3 MPa, respectively.

- (3)

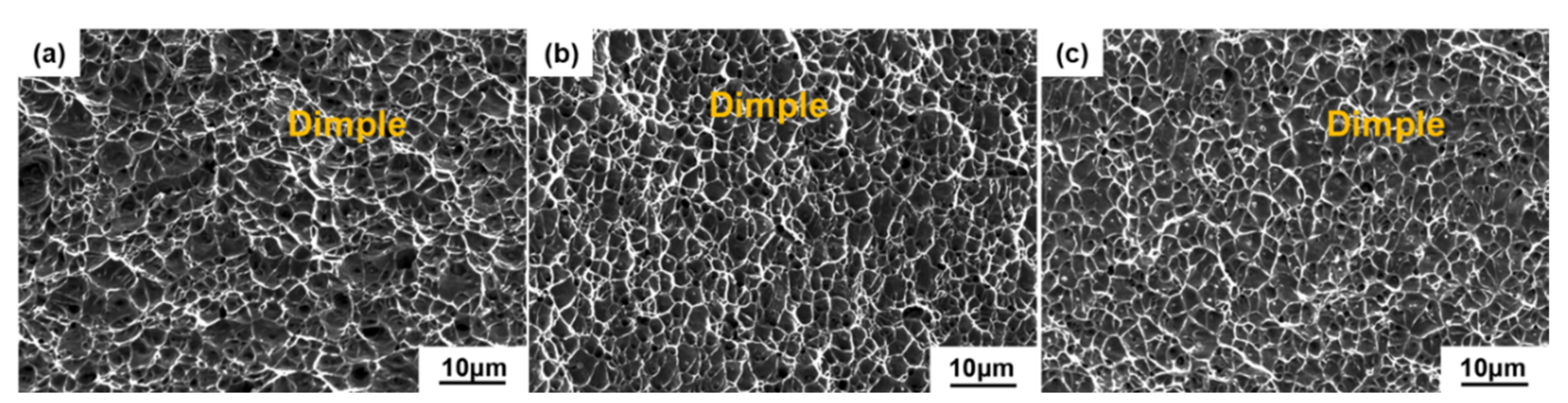

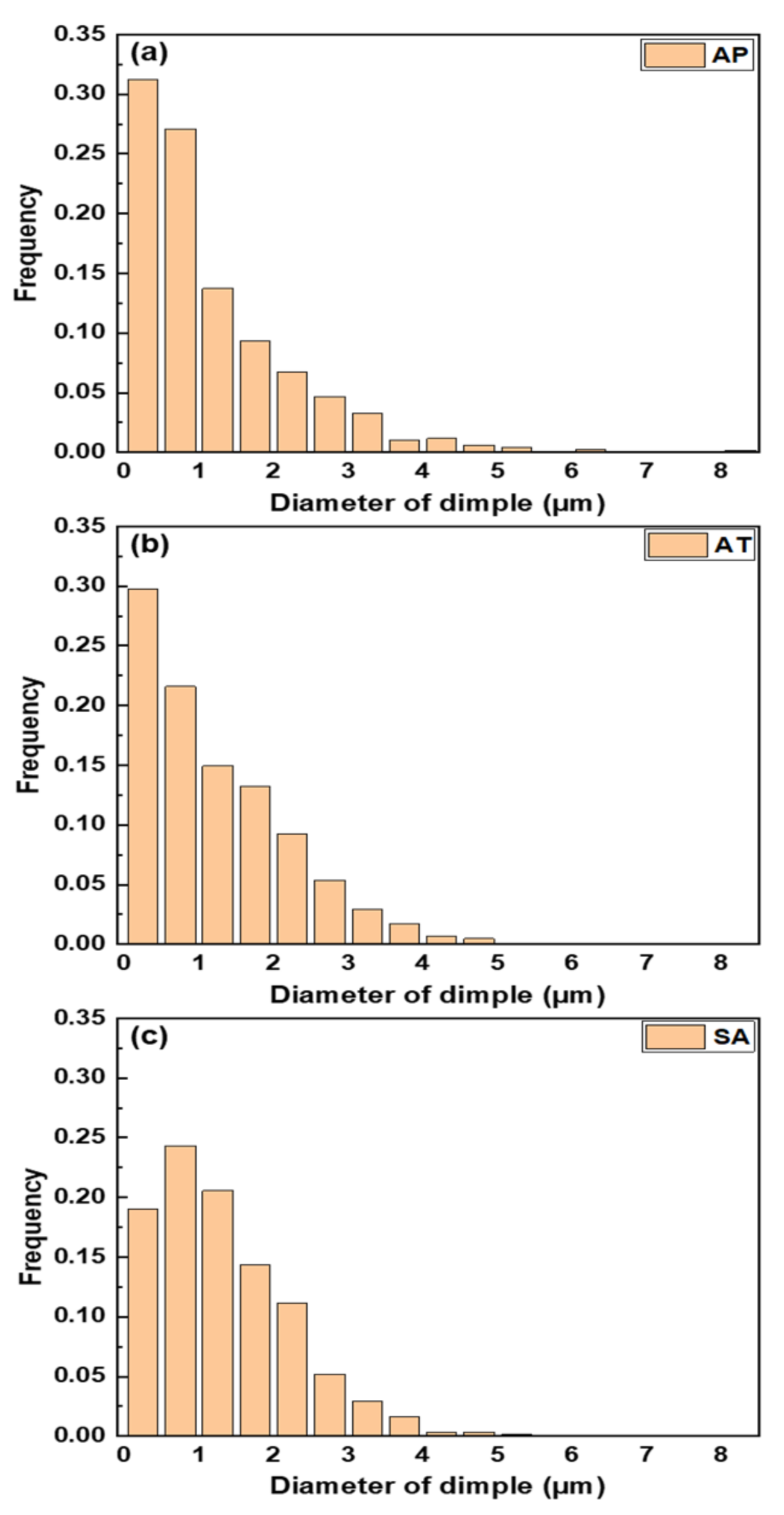

- All samples exhibit characteristic ductile fracture. In comparison to the AP sample, the fracture morphology in the SA sample exhibits a more homogeneous distribution and a larger mean size of dimples. In addition, the SA sample with a finer microstructure burns more energy during the deformation, resulting in better ductility.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Cunningham, C.; Flynn, J.M.; Shokrani, A.; Dhokia, V.; Newman, S.T. Invited review article: Strategies and processes for high quality wire arc additive manufacturing. Addit. Manuf. 2018, 22, 672–686. [Google Scholar] [CrossRef]

- Tanvir, A.N.M.; Ahsan, R.U.M.; Seo, G.; Bates, B.; Lee, C.; Liaw, P.K.; Noakes, M.; Nycz, A.; Ji, C.; Kim, D.B. Phase stability and mechanical properties of wire + arc additively manufactured H13 tool steel at elevated temperatures. J. Mater. Sci. Technol. 2020, 67, 80–94. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, D.; Wang, P.; Yan, M.; Yang, C.; Chen, Z.; Lu, J.; Lu, Z. Additive manufacturing of metals: Microstructure evolution and multistage control. J. Mater. Sci. Technol. 2022, 100, 224–236. [Google Scholar] [CrossRef]

- Su, C.; Chen, X.; Gao, C.; Wang, Y. Effect of heat input on microstructure and mechanical properties of Al-Mg alloys fabricated by WAAM. Appl. Surf. Sci. 2019, 486, 431–440. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, X.; Paddea, S.; Zhang, X. Fatigue crack propagation behaviour in wire + arc additive manufactured Ti-6Al-4V: Effects of microstructure and residual stress. Mater. Des. 2016, 90, 551–561. [Google Scholar] [CrossRef]

- Xu, X.; Ding, J.; Ganguly, S.; Williams, S. Investigation of process factors affecting mechanical properties of INCONEL 718 superalloy in wire + arc additive manufacture process. J. Mater. Process. Technol. 2019, 265, 201–209. [Google Scholar] [CrossRef]

- Wang, L.; Xue, J.; Wang, Q. Correlation between arc mode, microstructure, and mechanical properties during wire arc additive manufacturing of 316L stainless steel. Mater. Sci. Eng. A 2019, 751, 183–190. [Google Scholar] [CrossRef]

- Li, Y.; Yan, W.; Cotton, J.D.; Ryan, G.J.; Shen, Y.; Wang, W.; Shan, Y.; Yang, K. A new 1.9 GPa maraging stainless steel strengthened by multiple precipitating species. Mater. Des. 2015, 82, 56–63. [Google Scholar] [CrossRef]

- Tian, J.; Wang, W.; Li, H.; Yang, K.; Jiang, Z. Understanding main factors controlling high cycle fatigue crack initiation and propagation of high strength maraging stainless steels with Ti addition. Mater. Sci. Eng. A 2021, 805, 140589. [Google Scholar] [CrossRef]

- Ma, X.; Wang, L.; Liu, C.; Subramanian, S. Microstructure and properties of 13Cr5Ni1Mo0.025Nb0.09V0.06N super martensitic stainless steel. Mater. Sci. Eng. A 2012, 539, 271–279. [Google Scholar] [CrossRef]

- Liu, Y.-R.; Ye, D.; Yong, Q.-L.; Su, J.; Zhao, K.-Y.; Jiang, W. Effect of Heat Treatment on Microstructure and Property of Cr13 Super Martensitic Stainless Steel. J. Iron Steel Res. Int. 2011, 18, 60–66. [Google Scholar] [CrossRef]

- Kumar, B.R.; Sharma, S.; Munda, P.; Minz, R. Structure and microstructure evolution of a ternary Fe–Cr–Ni alloy akin to super martensitic stainless steel. Mater. Des. 2013, 50, 392–398. [Google Scholar] [CrossRef]

- Silverstein, R.; Eliezer, D. Mechanisms of hydrogen trapping in austenitic, duplex, and super martensitic stainless steels. J. Alloys Compd. 2017, 720, 451–459. [Google Scholar] [CrossRef]

- Wang, P.; Lu, S.; Xiao, N.; Li, D.; Li, Y. Effect of delta ferrite on impact properties of low carbon 13Cr–4Ni martensitic stainless steel. Mater. Sci. Eng. A 2010, 527, 3210–3216. [Google Scholar] [CrossRef]

- Monnot, M.; Roche, V.; Estevez, R.; Mantel, M.; Nogueira, R.P. Molybdenum effect on the Sulfide Stress Corrosion of a super martensitic stainless steel in sour environment highlighted by Electrochemical Impedance Spectroscopy. Electrochim. Acta 2017, 252, 58–66. [Google Scholar] [CrossRef]

- Xu, D.-K.; Liu, Y.-C.; Ma, Z.-Q.; Li, H.-J.; Yan, Z.-S. Structural refinement of 00Cr13Ni5Mo2 supermartensitic stainless steel during single-stage intercritical tempering. Int. J. Miner. Met. Mater. 2014, 21, 279–288. [Google Scholar] [CrossRef]

- Bilmes, P.; Solari, M.; Llorente, C. Characteristics and effects of austenite resulting from tempering of 13Cr–NiMo martensitic steel weld metals. Mater. Charact. 2001, 46, 285–296. [Google Scholar] [CrossRef]

- Caballero, A.; Ding, J.; Ganguly, S.; Williams, S. Wire + Arc Additive Manufacture of 17-4 PH stainless steel: Effect of different processing conditions on microstructure, hardness, and tensile strength. J. Mater. Process. Technol. 2019, 268, 54–62. [Google Scholar] [CrossRef]

- Ghaffari, M.; Nemani, A.V.; Nasiri, A. Microstructure and mechanical behavior of PH 13–8Mo martensitic stainless steel fabricated by wire arc additive manufacturing. Addit. Manuf. 2022, 49, 102374. [Google Scholar] [CrossRef]

- Dalaee, M.; Cheaitani, F.; Arabi-Hashemi, A.; Rohrer, C.; Weisse, B.; Leinenbach, C.; Wegener, K. Feasibility study in combined direct metal deposition (DMD) and plasma transfer arc welding (PTA) additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 106, 4375–4389. [Google Scholar] [CrossRef]

- Basak, A.; Das, S. Epitaxy and Microstructure Evolution in Metal Additive Manufacturing. Annu. Rev. Mater. Res. 2016, 46, 125–149. [Google Scholar] [CrossRef]

- Spittle, J.A. Columnar to equiaxed grain transition in as solidified alloys. Int. Mater. Rev. 2006, 51, 247–269. [Google Scholar] [CrossRef]

- Conde, F.; Escobar, J.; Oliveira, J.P.; Béreš, M.; Jardini, A.L.; Bose, W.W.; Avila, J. Effect of thermal cycling and aging stages on the microstructure and bending strength of a selective laser melted 300-grade maraging steel. Mater. Sci. Eng. A 2019, 758, 192–201. [Google Scholar] [CrossRef]

- Ma, X.; Wang, L.; Liu, C.; Subramanian, S. Role of Nb in low interstitial 13Cr super martensitic stainless steel. Mater. Sci. Eng. A 2011, 528, 6812–6818. [Google Scholar] [CrossRef]

- Lu, S.-Y.; Yao, K.-F.; Chen, Y.-B.; Wang, M.-H.; Liu, X.; Ge, X. The effect of tempering temperature on the microstructure and electrochemical properties of a 13 wt.% Cr-type martensitic stainless steel. Electrochim. Acta 2015, 165, 45–55. [Google Scholar] [CrossRef]

- Nemani, A.V.; Ghaffari, M.; Salahi, S.; Nasiri, A. Effects of post-printing heat treatment on the microstructure and mechanical properties of a wire arc additive manufactured 420 martensitic stainless steel part. Mater. Sci. Eng. A 2021, 813, 141167. [Google Scholar] [CrossRef]

- Nong, X.; Zhou, X.; Li, J.; Wang, Y.; Zhao, Y.F.; Brochu, M. Selective laser melting and heat treatment of precipitation hardening stainless steel with a refined microstructure and excellent mechanical properties. Scr. Mater. 2020, 178, 7–12. [Google Scholar] [CrossRef]

- Dmitrieva, O.; Ponge, D.; Inden, G.; Millán, J.; Choi, P.; Sietsma, J.; Raabe, D. Chemical gradients across phase boundaries between martensite and austenite in steel studied by atom probe tomography and simulation. Acta Mater. 2011, 59, 364–374. [Google Scholar] [CrossRef] [Green Version]

- Liu, K.; Shan, Y.; Yang, Z.; Liang, J.; Lu, L.; Yang, K. Effect of heat treatment on prior grain size and mechanical property of a maraging stainless steel. J. Mater. Sci. Technol. 2009, 22, 769–774. [Google Scholar]

- Song, Y.; Li, X.; Rong, L.; Ping, D.; Yin, F.; Li, Y. Formation of the reversed austenite during intercritical tempering in a Fe–13% Cr–4% Ni–Mo martensitic stainless steel. Mater. Lett. 2010, 64, 1411–1414. [Google Scholar] [CrossRef]

- Luo, H.; Wang, X.; Liu, Z.; Yang, Z. Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel. J. Mater. Sci. Technol. 2020, 51, 130–136. [Google Scholar] [CrossRef]

- Kumar, P.; Jayaraj, R.; Suryawanshi, J.; Satwik, U.R.; McKinnell, J.; Ramamurty, U. Fatigue strength of additively manufactured 316 L austenitic stainless steel. Acta Mater. 2020, 199, 225–239. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Shahriari, A.; Amirkhiz, B.S.; Li, J.; Mohammadi, M. Additive manufacturing of an Fe–Cr–Ni–Al maraging stainless steel: Microstructure evolution, heat treatment, and strengthening mechanisms. Mater. Sci. Eng. A 2020, 787, 139470. [Google Scholar] [CrossRef]

- Kučerová, L.; Zetková, I.; Jandová, A.; Bystrianský, M. Microstructural characterisation and in-situ straining of additive-manufactured X3NiCoMoTi 18-9-5 maraging steel. Mater. Sci. Eng. A 2019, 750, 70–80. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Elwany, A.; Bian, L. Effects of building orientation and heat treatment on fatigue behavior of selective laser melted 17-4 PH stainless steel. Int. J. Fatigue 2017, 94, 218–235. [Google Scholar] [CrossRef]

- Ye, D.; Li, J.; Jiang, W.; Su, J.; Zhao, K. Effect of Cu addition on microstructure and mechanical properties of 15%Cr super martensitic stainless steel. Mater. Des. 2012, 41, 16–22. [Google Scholar] [CrossRef]

- Sugimoto, K.-I.; Usui, N.; Kobayashi, M.; Hashimoto, S.-I. Effects of Volume Fraction and Stability of Retained Austenite on Ductility of TRIP-aided Dual-phase Steels. ISIJ Int. 1992, 32, 1311–1318. [Google Scholar] [CrossRef]

- Li, X.; Song, R.; Zhou, N.; Li, J. An ultrahigh strength and enhanced ductility cold-rolled medium-Mn steel treated by intercritical annealing. Scr. Mater. 2018, 154, 30–33. [Google Scholar] [CrossRef]

- Zhou, J.; Shen, Y.; Xue, W.; Jia, N.; Misra, R. Improving strength and ductility of low activation martensitic (LAM) steel by alloying with titanium and tempering. Mater. Sci. Eng. A 2021, 799, 140152. [Google Scholar] [CrossRef]

- Zhou, Q.; Qian, L.; Tan, J.; Meng, J.; Zhang, F. Inconsistent effects of mechanical stability of retained austenite on ductility and toughness of transformation-induced plasticity steels. Mater. Sci. Eng. A 2013, 578, 370–376. [Google Scholar] [CrossRef]

- Benzerga, A.; Besson, J.; Pineau, A. Anisotropic ductile fracture: Part I: Experiments. Acta Mater. 2004, 52, 4623–4638. [Google Scholar] [CrossRef]

- Asadi, M.; De Cooman, B.C.; Palkowski, H. Influence of martensite volume fraction and cooling rate on the properties of thermomechanically processed dual phase steel. Mater. Sci. Eng. A 2012, 538, 42–52. [Google Scholar] [CrossRef]

- Srinivasan, K.; Huang, Y.; Kolednik, O.; Siegmund, T. The size dependence of micro-toughness in ductile fracture. J. Mech. Phys. Solids 2008, 56, 2707–2726. [Google Scholar] [CrossRef]

| Arc Current | Arc Voltage | Traveling Speed | Gas Flow Rate | Deposition Strategy |

|---|---|---|---|---|

| 220 A | 23.5 V | 0.5 m/min | 18 L/min | Oscillated pass |

| C | Si | Mn | Cr | Ni | Mo | Cu | Fe |

|---|---|---|---|---|---|---|---|

| ≤0.04 | 0.42 | 0.84 | 13.23 | 5.55 | 0.81 | 0.32 | Bal. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Niu, B.; Pan, L.; Yi, J. Wire + Arc Additive Manufacturing and Heat Treatment of Super Martensitic Stainless Steel with a Refined Microstructure and Excellent Mechanical Properties. Materials 2022, 15, 2624. https://doi.org/10.3390/ma15072624

Zou X, Niu B, Pan L, Yi J. Wire + Arc Additive Manufacturing and Heat Treatment of Super Martensitic Stainless Steel with a Refined Microstructure and Excellent Mechanical Properties. Materials. 2022; 15(7):2624. https://doi.org/10.3390/ma15072624

Chicago/Turabian StyleZou, Xiaodong, Ben Niu, Linlin Pan, and Jianglong Yi. 2022. "Wire + Arc Additive Manufacturing and Heat Treatment of Super Martensitic Stainless Steel with a Refined Microstructure and Excellent Mechanical Properties" Materials 15, no. 7: 2624. https://doi.org/10.3390/ma15072624

APA StyleZou, X., Niu, B., Pan, L., & Yi, J. (2022). Wire + Arc Additive Manufacturing and Heat Treatment of Super Martensitic Stainless Steel with a Refined Microstructure and Excellent Mechanical Properties. Materials, 15(7), 2624. https://doi.org/10.3390/ma15072624