Effectiveness of Concrete Reinforcement with Recycled Tyre Steel Fibres

Abstract

:1. Introduction

2. Materials and Methods

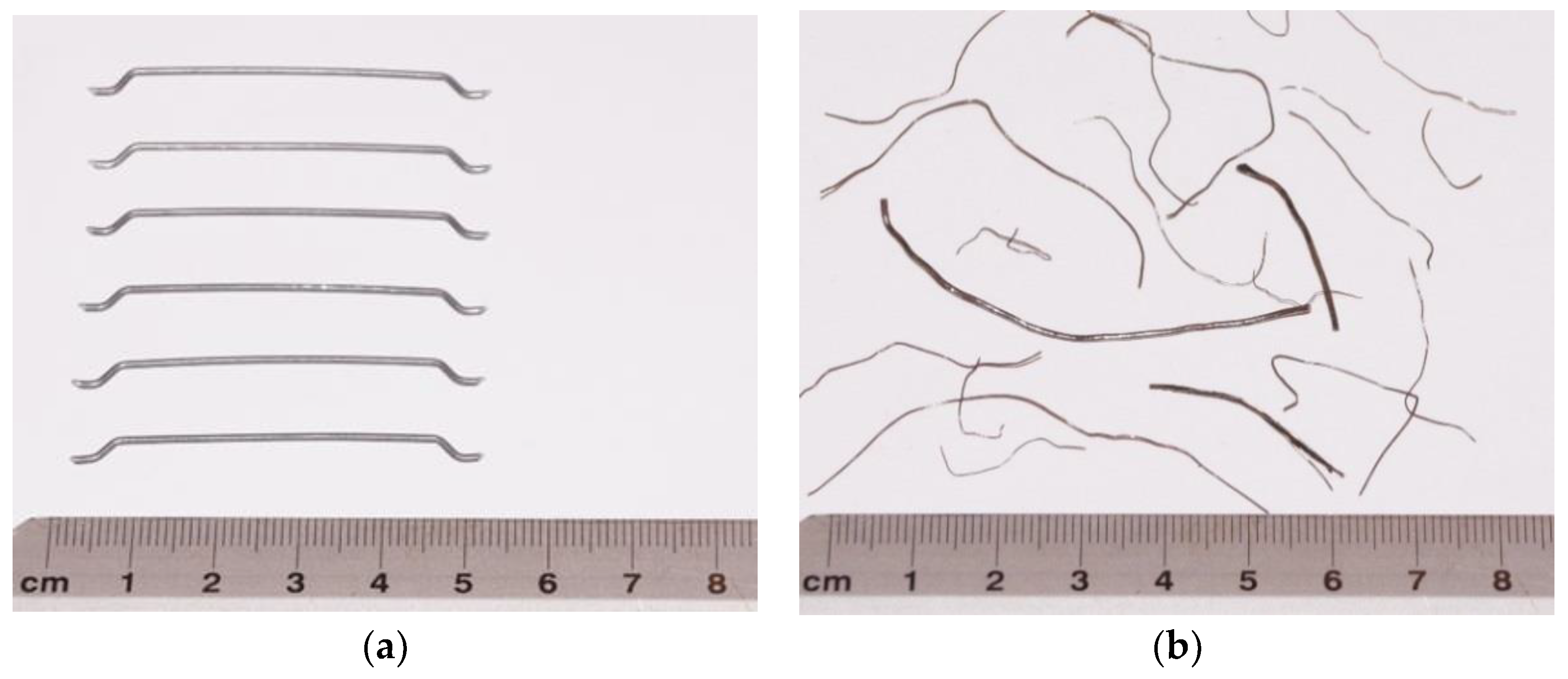

2.1. Materials

2.2. Methods

2.2.1. Composition of Concrete with Fibres

- Maximum content of cement CEM 42.5 R 350 kg/m3;

- Maximum aggregate size 16 mm, natural, uncrushed, silica-based;

- Water/cement ratio 0.55;

- Flexural tensile strength 4.3 ± 0.3 MPa (min. concrete class C25/30);

- Consistency of mix tested with the Vebe V3 method (from 6 to 10 s).

2.2.2. Consistency of Concrete with Fibres

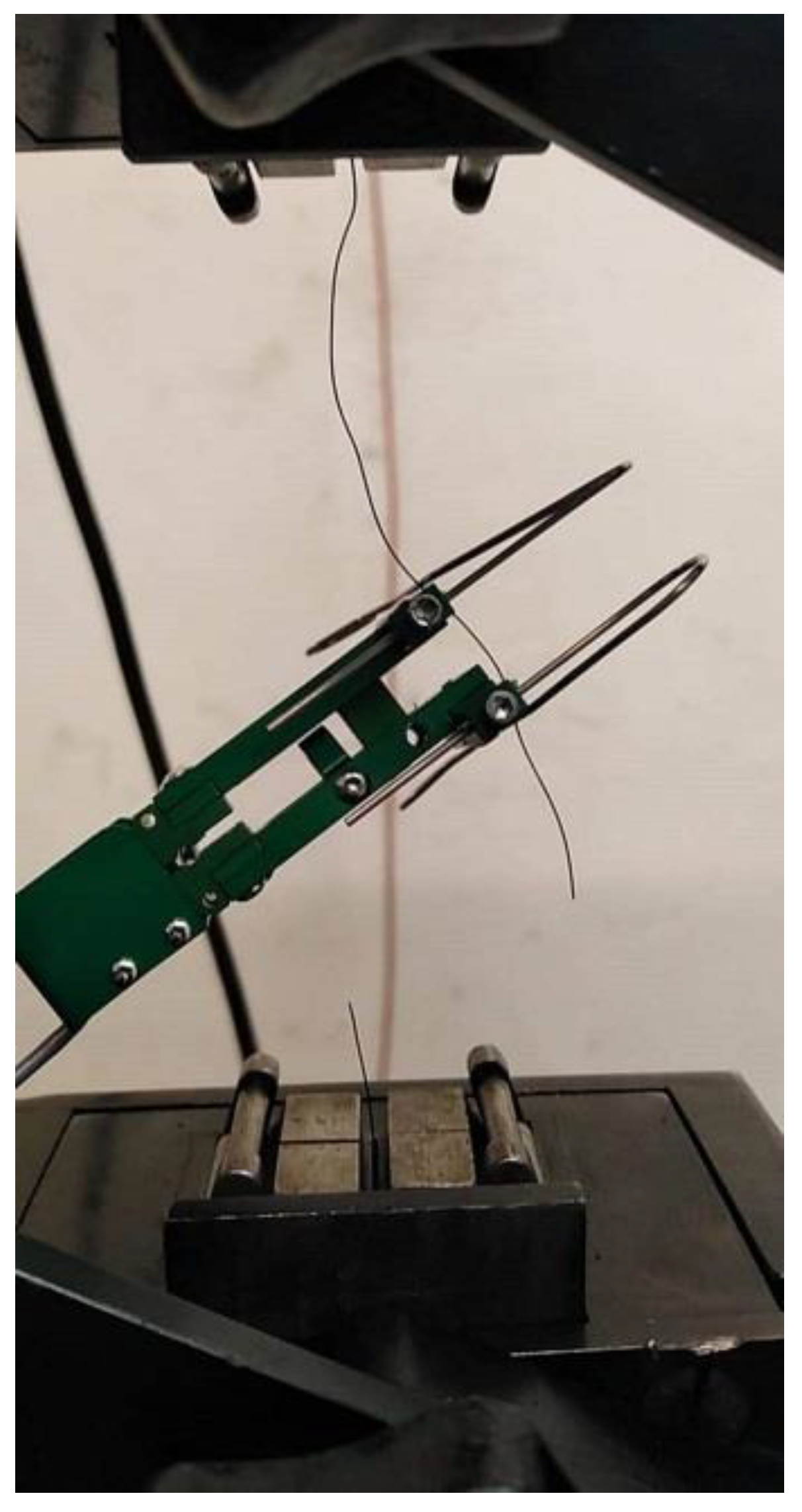

2.2.3. Residual Flexural Tensile Strength

2.2.4. Work of Fracture

2.2.5. Toughness Indices I5, I10, I20

2.2.6. Microscopic Analysis

2.2.7. Fibre Distribution Imaging with Computer Tomography

3. Results

3.1. Consistency

3.2. Residual Flexural Tensile Strength

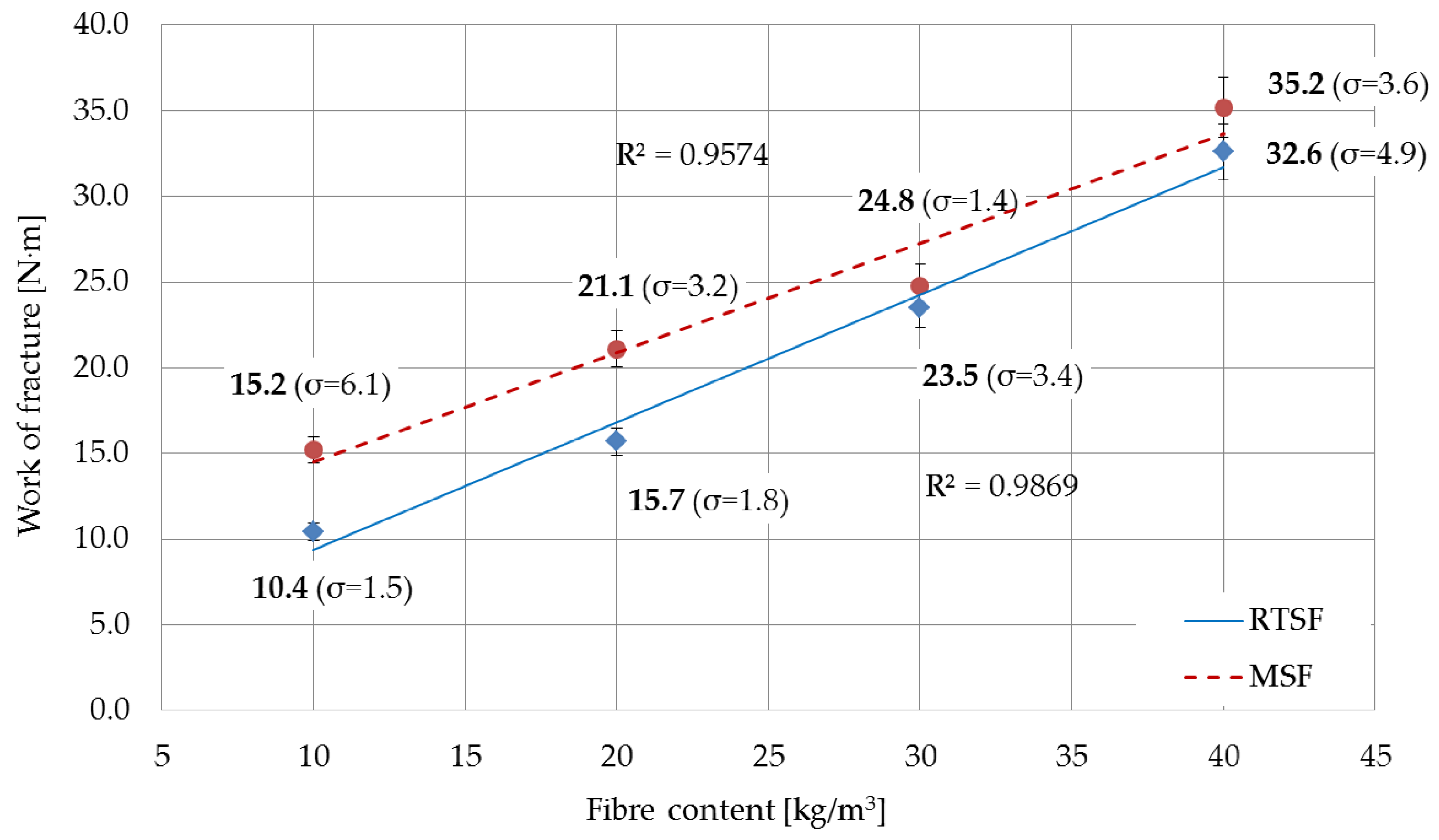

3.3. Work of Fracture

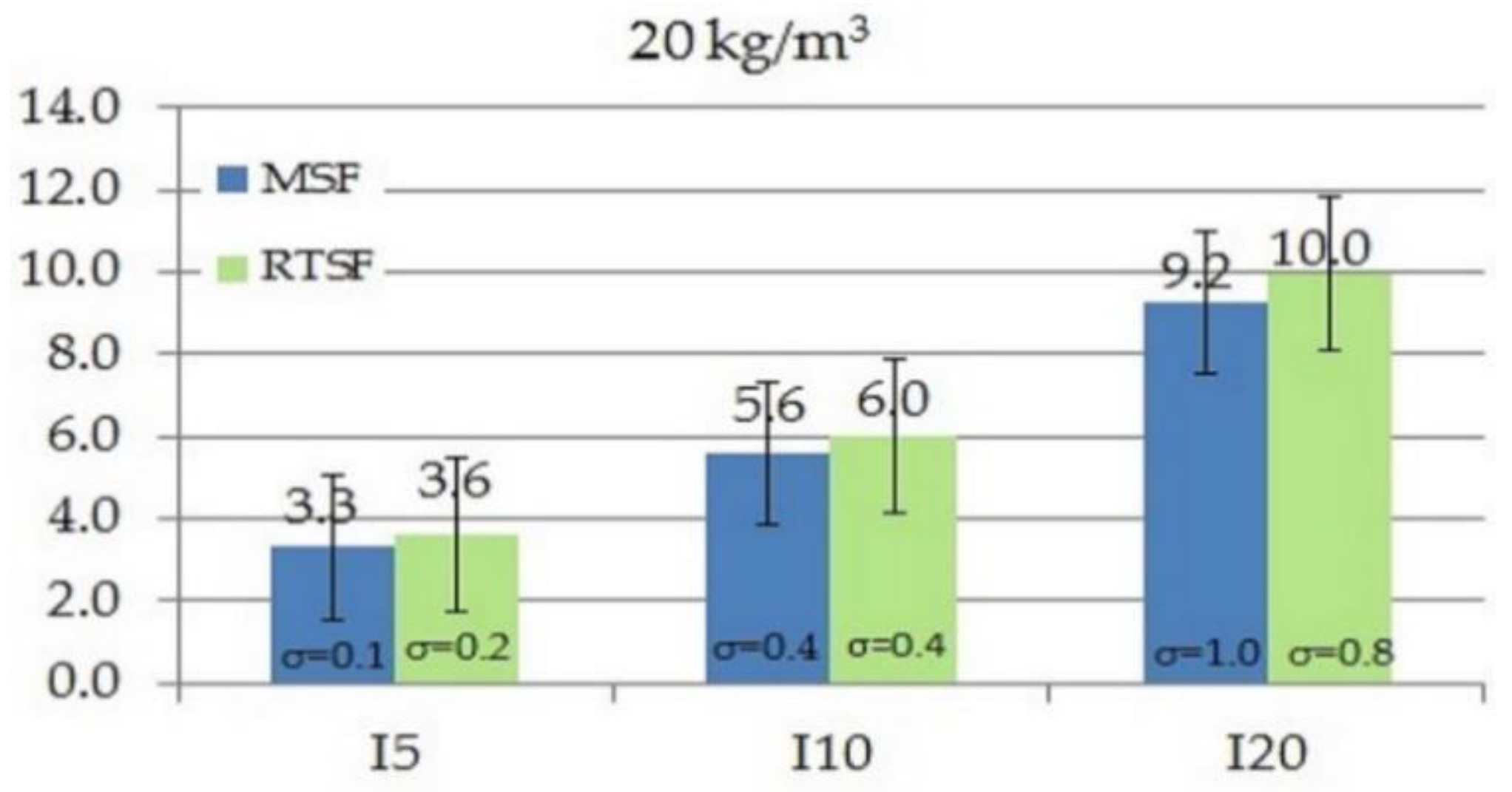

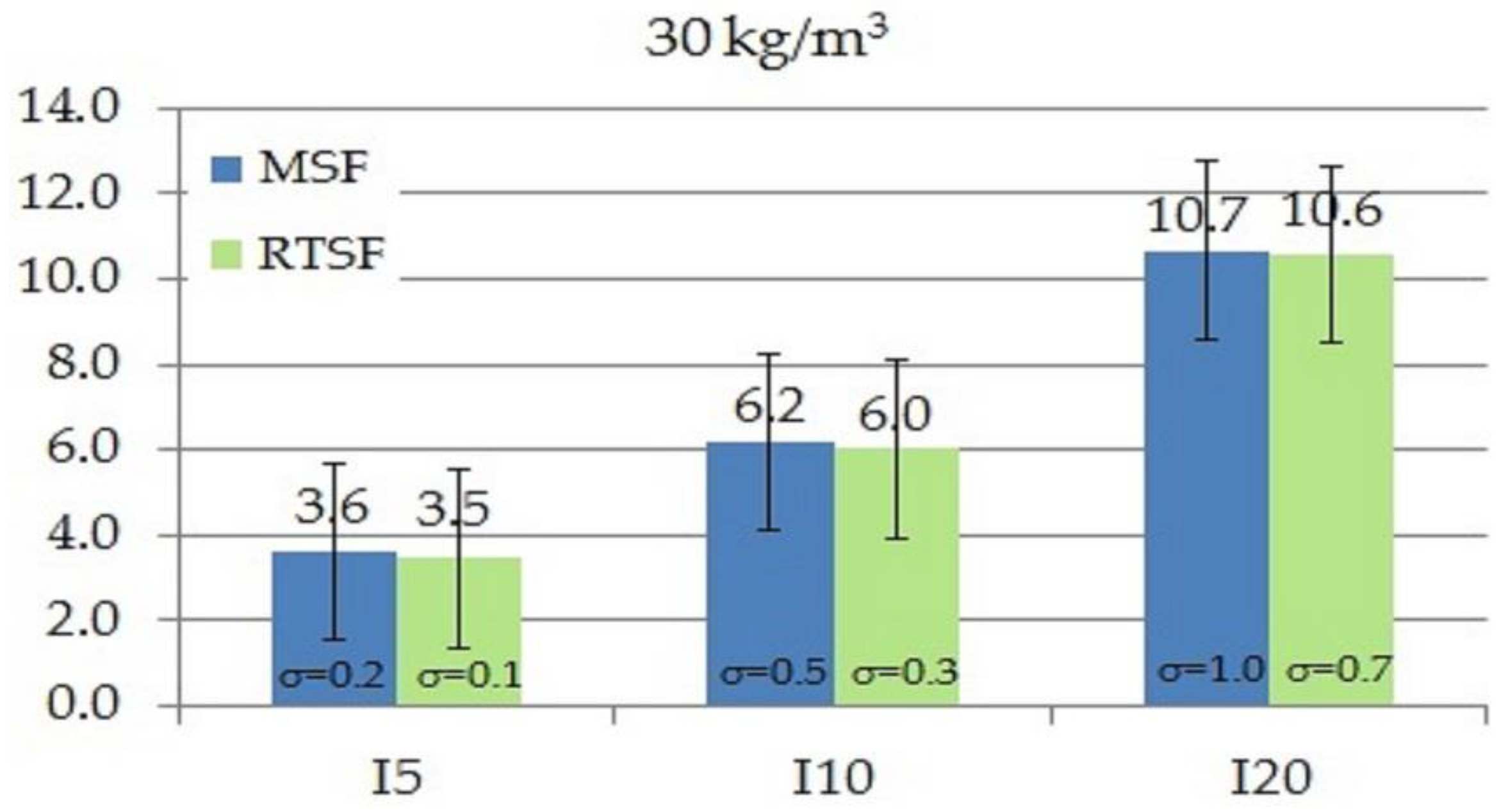

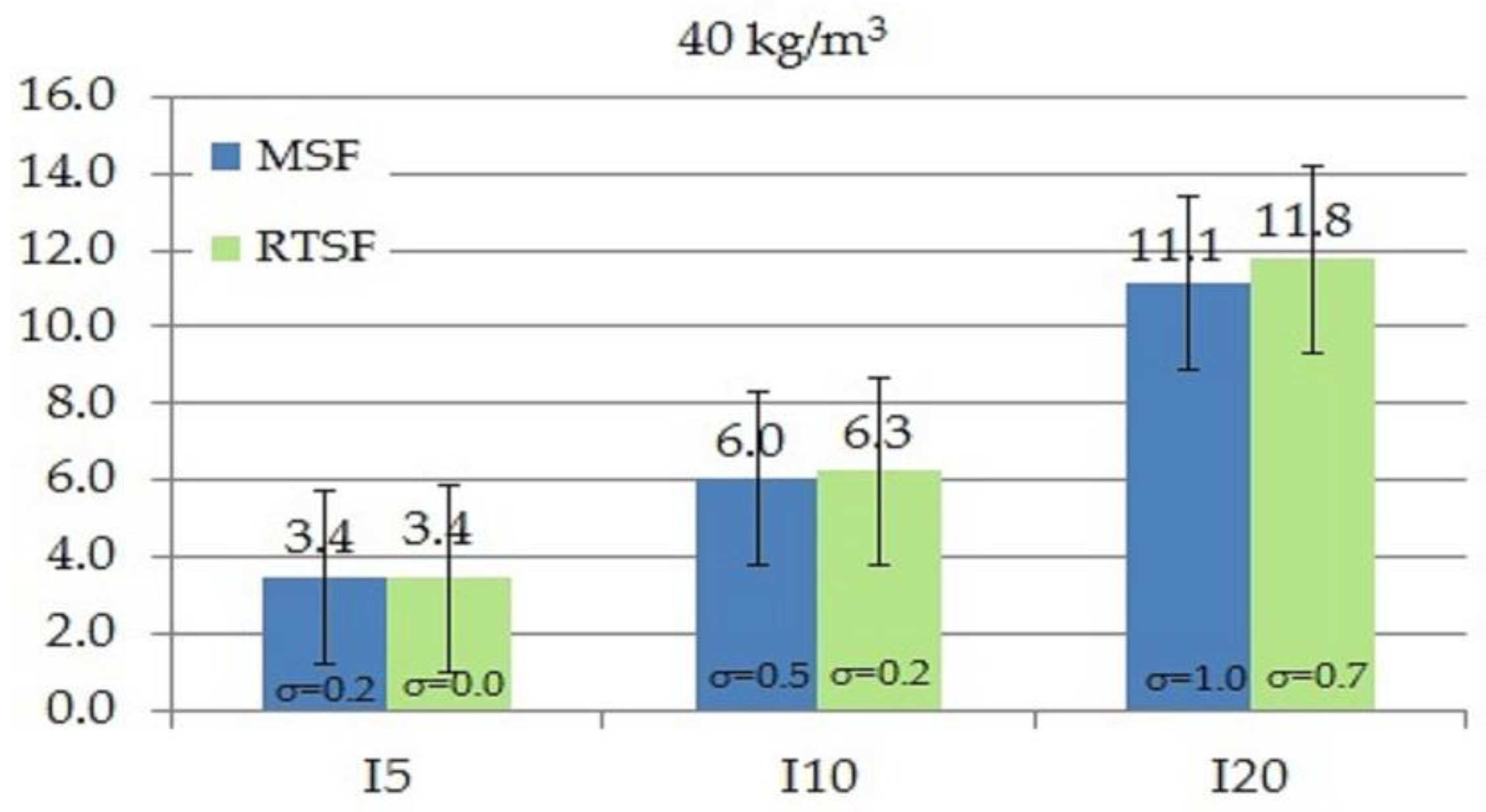

3.4. Toughness Indices

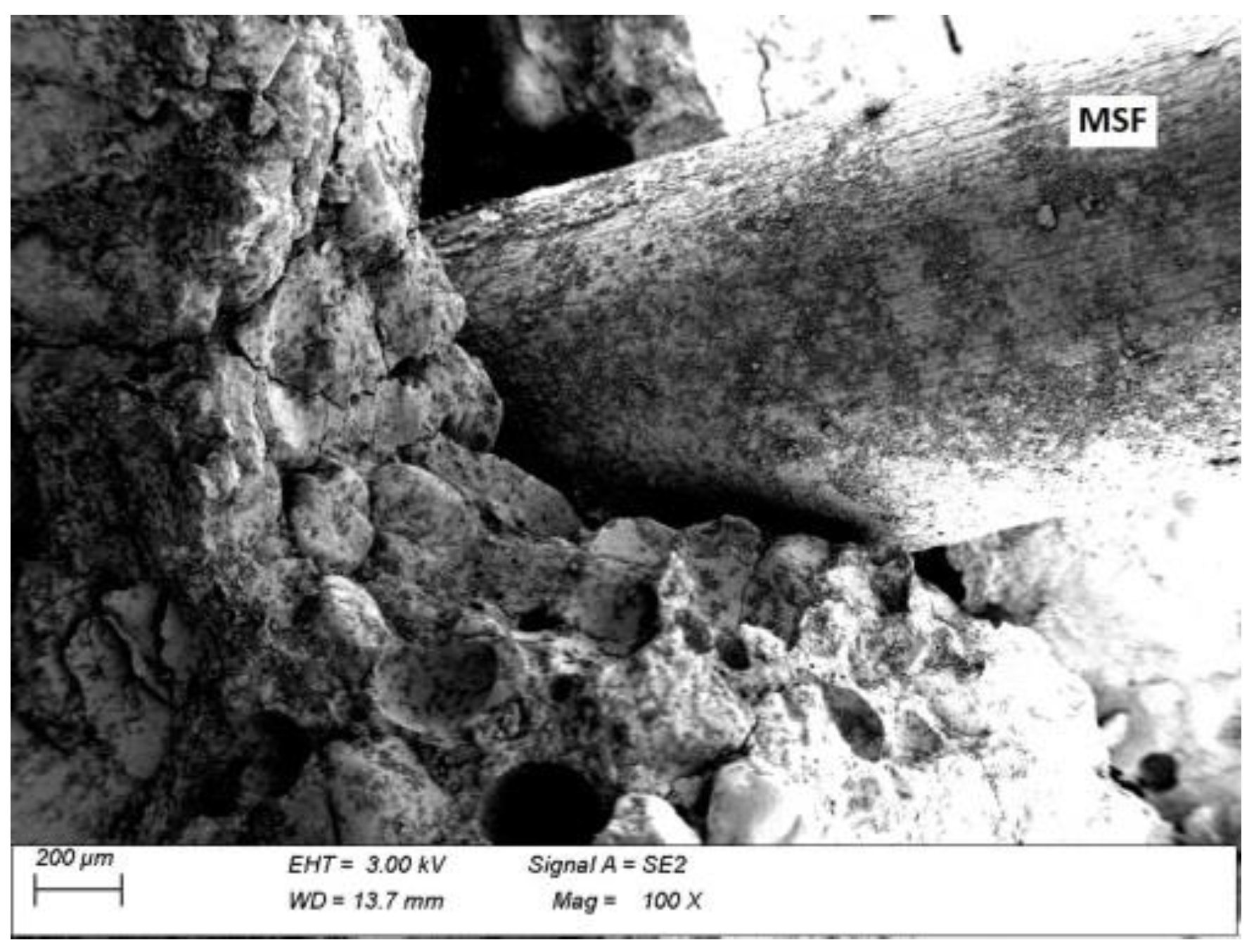

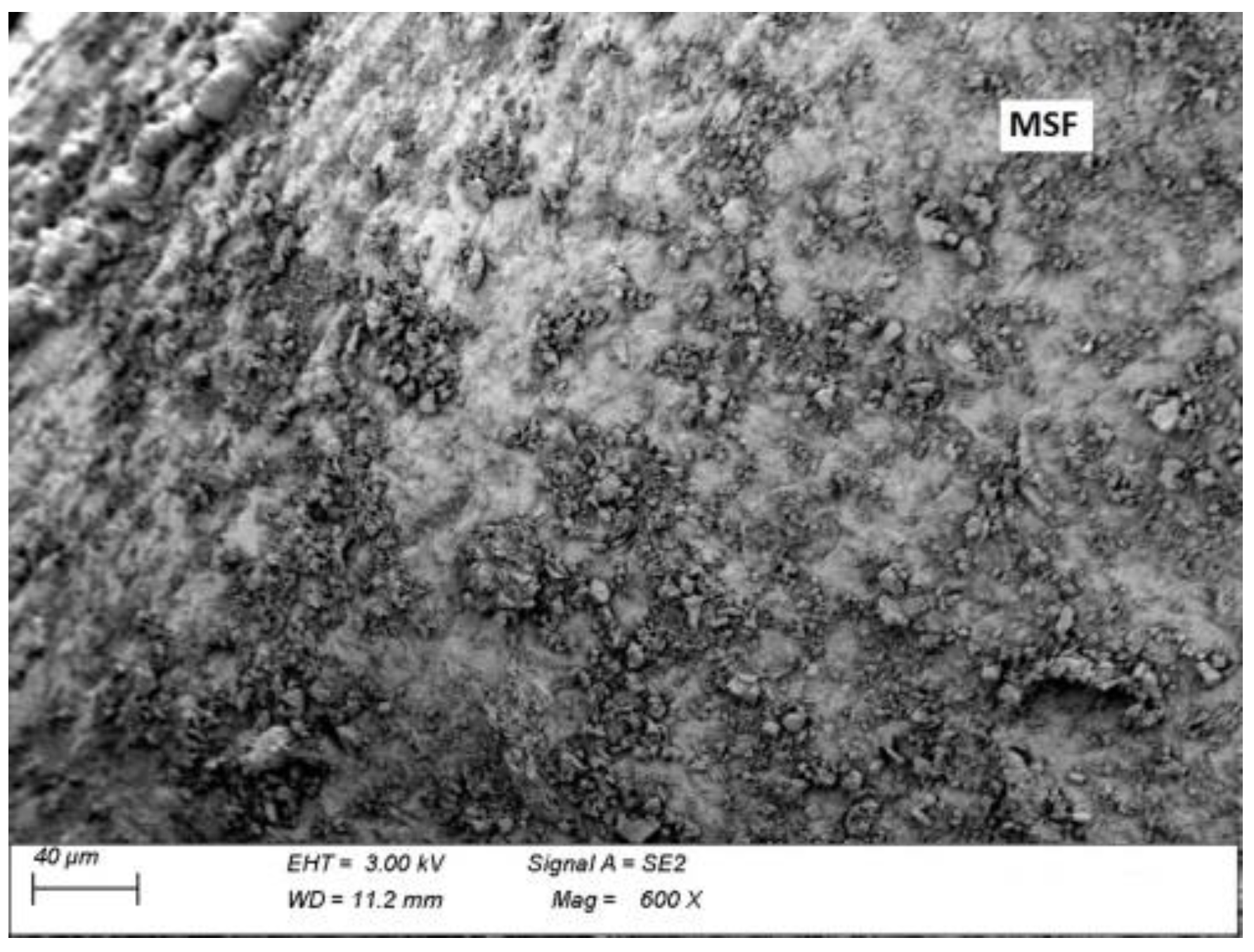

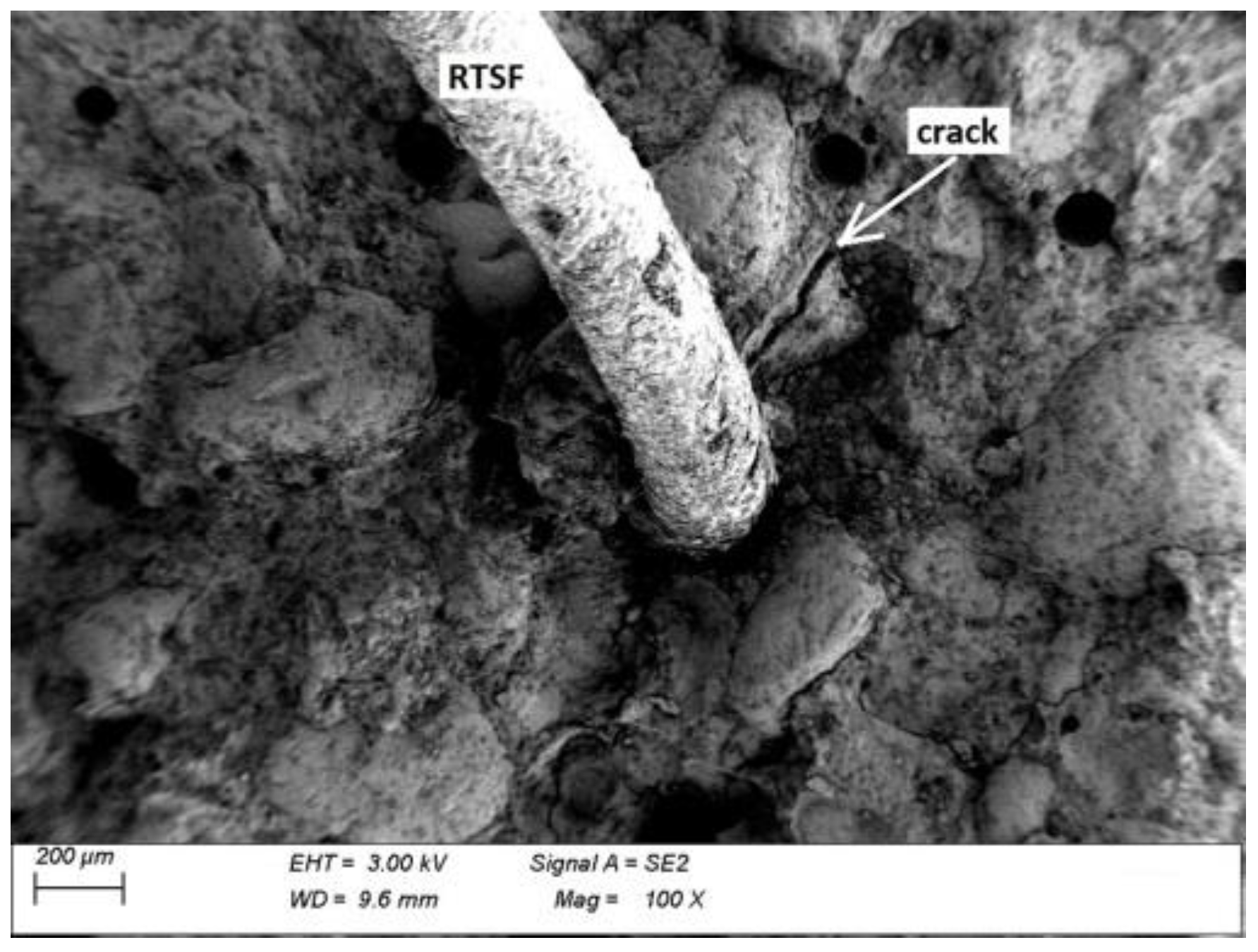

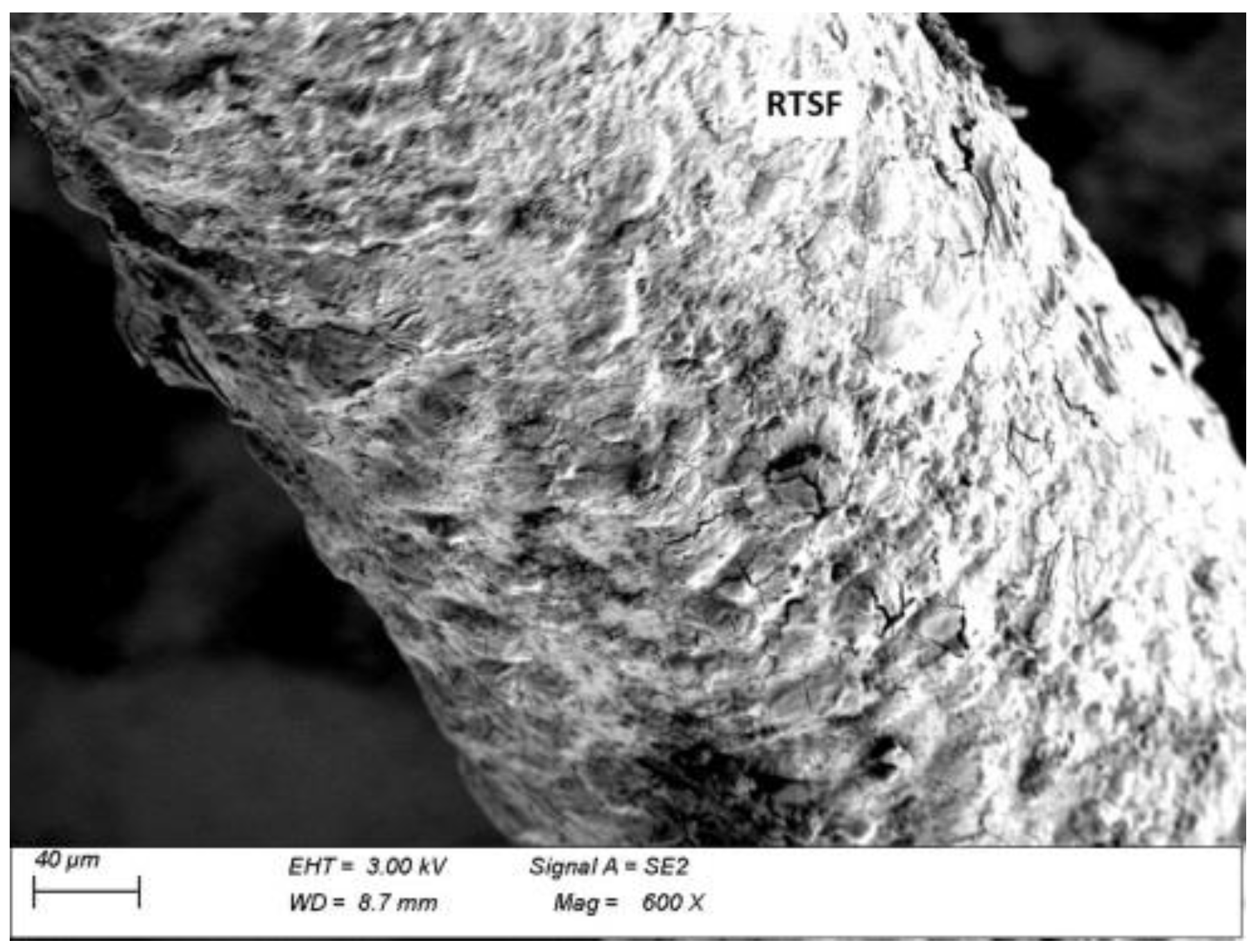

3.5. Microscopic Analysis

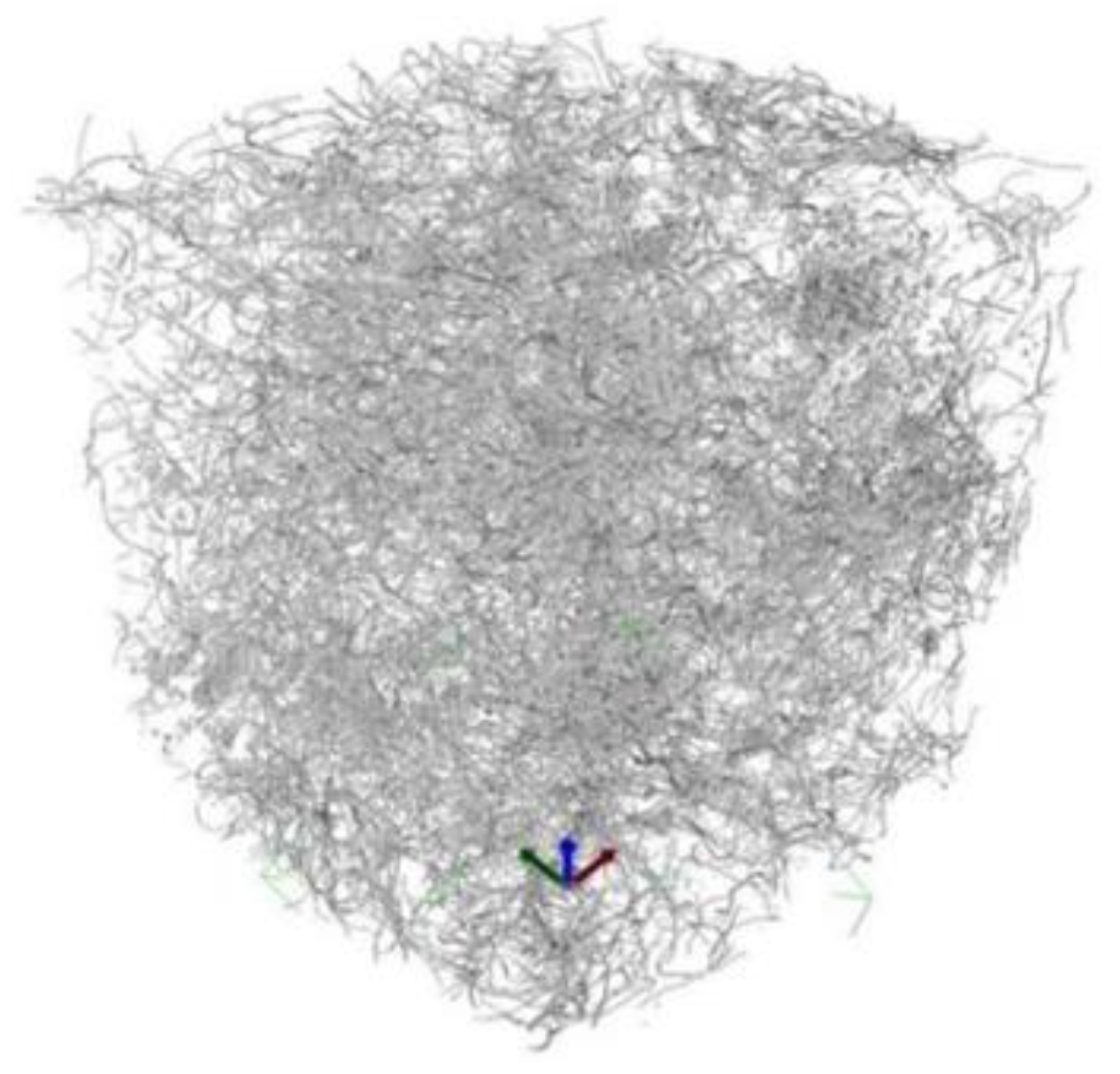

3.6. Fibre Distribution with Computer Tomography Method

4. Discussion

5. Conclusions

- The prerequisite for effective concrete reinforcement with recycled tyre steel fibres is their high purity, with the lowest possible amount of rubber and textile contaminants and steel dust. Such fibres may only be obtained after the purification of the original steel cord obtained from tyres.

- Recycled tyre steel fibres (RTSFs) were added to concrete in the same amount as industrial steel fibres (MSFs) used as scattered reinforcement for concrete, with all tests made and analysed comparatively.

- The geometric characteristics of recycled tyre steel fibres (RTSFs), which are a mix of hybrid fibres of different lengths, diameters, and irregular shapes, are advantageous and contribute to achieving effective microcrack bridging in the cement matrix even better than MSFs.

- The rheological properties of concrete mixes determined by a consistency test revealed that RTSFs had a slightly higher reduction in consistency than MSFs, especially at high fibre contents. Still, this reduction was not high enough to be considered a technological issue in this regard. Concrete mixes, even those containing large amounts of RTSFs and MSFs, were homogeneous in terms of fibre distribution, with no signs of segregation. The fibre distribution examination with computer tomography confirmed the homogenous and uniform distribution of fibres in concrete and no local fibre clusters.

- The properties of residual flexural tensile strength showed that at 10 and 20 kg/m3, concrete with RTSFs had lower values than that with MSFs, although concrete with the addition of 30 to 40 kg/m3 of RTSFs received higher values by about 20 and 15%, respectively. For a CMOD higher than 0.5–1.5 mm, the residual flexural strength for concrete with RTSFs was lower than that for concrete with MSFs.

- The effectiveness of reinforcing the concrete might be measured by the fracture toughness, described as the work of fracture, referring to the total areas under the load–deflection curve, which is a new approach compared to other studies devoted to the subject matter. In the case of the work of fracture for 10 and 20 kg/m3 of the fibres, it was shown that concrete with RTSFs had lower fracture resistance than that with MSFs; however, at 30 and 40 kg/m3, the fracture resistance determined by work of fracture was similar for both types of concrete (containing RTSFs and MSFs, respectively). The efficiency of concrete reinforcement as determined by fracture mechanics parameters increases as the content of recycled tyre steel fibres in concrete increases.

- The identified fracture toughness indices, which are the measure of a fracture’s resistance at the initial stage, right after the first fracture, revealed that the higher the RTSF content in the concrete, the higher the fracture’s toughness indices. For the content of 20, 30, and 40 kg/m3, concrete with RTSFs revealed equivalent or even higher fracture toughness indicators than concrete containing MSFs.

- The microstructure of fractures of concrete with MSFs and of concrete with RTSFs was proper, with the fibres being anchored to the grout well and cement hydration products being visible on the surface of the fibres. These observations confirmed the good adhesion of the fibres to the grout. The good adhesion of RTSFs to the cement matrix resulted from the additional purifying process, which made the RTSFs’ surfaces more developed.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Chen, M.; Si, H.; Fan, X.; Xuan, Y.; Zhang, M. Dynamic compressive behaviour of recycled tyre steel fibre reinforced concrete. Constr. Build. Mater. 2021, 316, 125896. [Google Scholar] [CrossRef]

- Senesavath, S.; Salem, A.; Kashkash, S.; Zehra, B.; Orban, Z. The effect of recycled tyre steel fibers on the properties of concrete. Pollack Period. 2021, 2021, 1–7. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. A comprehensive review on the applications of waste tire rubber in cement concrete. Renew. Sustain. Energy Rev. 2016, 54, 1323–1333. [Google Scholar] [CrossRef]

- Wang, J.; Dai, Q.; Si, R.; Guo, S. Mechanical, durability, and microstructural properties of macro synthetic polypropylene (PP) fiber-reinforced rubber concrete. J. Clean. Prod. 2019, 234, 1351–1364. [Google Scholar] [CrossRef]

- Ramarad, S.; Khalid, M.; Ratnam, C.; Chuah, A.L.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission: The European Green Deal, 11.12.2019 COM (2019) 640 Final. Brussels. 2019. Available online: https://ec.europa.eu/info/sites/info/files/european-green-deal-communication_en.pdf (accessed on 21 March 2022).

- Sathiskumar, C.; Karthikeyan, S. Recycling of waste tires and its energy storage application of by-products—A review. Sustain. Mater. Technol. 2019, 22, e00125. [Google Scholar] [CrossRef]

- ETRMA European Tyre & Rubber Manufacturers Association. End of Life Tyres Management—Europe 2018 Status; ETRMA: Brussels, Belgium, 2020. [Google Scholar]

- Bowles, A.; Fowler, G.; O’Sullivan, C.; Parker, K. Sustainable rubber recycling from waste tyres by waterjet: A novel mechanistic and practical analysis. Sustain. Mater. Technol. 2020, 25, e00173. [Google Scholar] [CrossRef]

- Strukar, K.; Šipoš, T.K.; Miličević, I.; Bušić, R. Potential use of rubber as aggregate in structural reinforced concrete element—A review. Eng. Struct. 2019, 188, 452–468. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J.; Chen, G.; Xie, Z. Fracture behaviors of a new steel fiber reinforced recycled aggregate concrete with crumb rubber. Constr. Build. Mater. 2013, 53, 32–39. [Google Scholar] [CrossRef]

- Thomas, B.S.; Gupta, R.C. Long term behaviour of cement concrete containing discarded tire rubber. J. Clean. Prod. 2015, 102, 78–87. [Google Scholar] [CrossRef]

- Bušić, R.; Benšić, M.; Miličević, I.; Strukar, K. Prediction Models for the Mechanical Properties of Self-Compacting Concrete with Recycled Rubber and Silica Fume. Materials 2020, 13, 1821. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.; Papastergiou, P.; Angelakopoulos, H.; Guadagnini, M.; Pilakoutas, K. Mechanical properties of SFRC using blended manufactured and recycled tyre steel fibres. Constr. Build. Mater. 2018, 163, 376–389. [Google Scholar] [CrossRef]

- Tlemat, H. Steel Fibres from Waste Tyres to Concrete: Testing, Modelling and Design; The University of Sheffield: Sheffield, UK, 2004. [Google Scholar]

- Graeff, A.G. Long-Term Performance of Recycled Steel Fibre Reinforced Concrete for Pavement Applications; The University of Sheffield: Sheffield, UK, 2011. [Google Scholar]

- Hu, H. Mechanical Properties of Blended Steel Fibre Reinforced Concrete Using Manufactured and Recycled Fibres from Tyres; The University of Sheffield: Sheffield, UK, 2018. [Google Scholar]

- Al-Musawi, H.; Figueiredo, F.; Bernal, S.A.; Guadagnini, M.; Pilakoutas, K. Performance of rapid hardening recycled clean steel fibre materials. Constr. Build. Mater. 2018, 195, 483–496. [Google Scholar] [CrossRef]

- Kundak, M.; Lazić, L.; Črnko, J. CO2 emissions in the steel industry. Metalurgija 2009, 48, 193–197. [Google Scholar]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Gigli, S.; Landi, D.; Germani, M. Cost-benefit analysis of a circular economy project: A study on a recycling system for end-of-life tyres. J. Clean. Prod. 2019, 229, 680–694. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.; Abdollahnejad, Z.; Illikainen, M. Characterization and optimization of hardened properties of self-consolidating concrete incorporating recycled steel, industrial steel, polypropylene and hybrid fibers. Compos. Part B Eng. 2018, 151, 186–200. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A.; Illikainen, M. Development of eco-efficient and cost-effective reinforced self-consolidation concretes with hybrid industrial/recycled steel fibers. Constr. Build. Mater. 2018, 166, 214–226. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Banthia, N. Scrap tire steel fiber as a substitute for commercial steel fiber in cement mortar: Engineering properties and cost-benefit analyses. Resour. Conserv. Recycl. 2018, 134, 248–256. [Google Scholar] [CrossRef]

- Aiello, M.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Frazão, C.; Díaz, B.; Barros, J.; Bogas, J.A.; Toptan, F. An experimental study on the corrosion susceptibility of Recycled Steel Fiber Reinforced Concrete. Cem. Concr. Compos. 2018, 96, 138–153. [Google Scholar] [CrossRef]

- Grzymski, F.; Musiał, M.; Trapko, T. Mechanical properties of fibre reinforced concrete with recycled fibres. Constr. Build. Mater. 2018, 198, 323–331. [Google Scholar] [CrossRef]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Constr. Build. Mater. 2018, 161, 141–155. [Google Scholar] [CrossRef]

- Skarżyński, Ł.; Suchorzewski, J. Mechanical and fracture properties of concrete reinforced with recycled and industrial steel fibers using Digital Image Correlation technique and X-ray micro computed tomography. Constr. Build. Mater. 2018, 183, 283–299. [Google Scholar] [CrossRef]

- Zamanzadeh, Z.; Lourenço, L.; Barros, J. Recycled Steel Fibre Reinforced Concrete failing in bending and in shear. Constr. Build. Mater. 2015, 85, 195–207. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Gao, L. Influence of Tire-Recycled Steel Fibers on Strength and Flexural Behavior of Reinforced Concrete. Adv. Mater. Sci. Eng. 2020, 2020, 6363105. [Google Scholar] [CrossRef] [Green Version]

- Al-Musawi, H.; Figueiredo, F.; Guadagnini, M.; Pilakoutas, K. Shrinkage properties of plain and recycled steel-fibre-reinforced rapid hardening mortars for repairs. Constr. Build. Mater. 2018, 197, 369–384. [Google Scholar] [CrossRef] [Green Version]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Caggiano, A.; Gambarelli, S.; Martinelli, E.; Nisticò, N.; Pepe, M. Experimental characterization of the post-cracking response in Hybrid Steel/Polypropylene Fiber-Reinforced Concrete. Constr. Build. Mater. 2016, 125, 1035–1043. [Google Scholar] [CrossRef]

- Bjegovic, D.; Baricevic, A.; Lakusic, S.; Damjanovic, D.; Duvnjak, I. Positive Interaction of Industrial and Recycled Steel FIBRES in Fibre Reinforced Concrete. J. Civ. Eng. Manag. 2014, 19, S50–S60. [Google Scholar] [CrossRef] [Green Version]

- Baricevic, A.; Bjegovic, D.; Skazlic, M.; Baricevic, A.; Bjegovic, D.; Skazlic, M. Hybrid Fiber–Reinforced Concrete with Unsorted Recycled-Tire Steel Fibers. J. Mater. Civ. Eng. 2017, 29, 06017005. [Google Scholar] [CrossRef]

- Isa, M.N.; Pilakoutas, K.; Guadagnini, M.; Angelakopoulos, H. Mechanical performance of affordable and eco-efficient ultra-high performance concrete (UHPC) containing recycled tyre steel fibres. Constr. Build. Mater. 2020, 255, 119272. [Google Scholar] [CrossRef]

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Proc. Inst. Civ. Eng. Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- Colombo, M.; di Prisco, M.; Mazzoleni, L. Sprayed tunnel linings: A comparison between several reinforcement solutions. Mater. Struct. 2009, 42, 1295–1311. [Google Scholar] [CrossRef]

- Naaman, A.E. Engineered Steel Fibers with Optimal Properties for Reinforcement of Cement Composites. J. Adv. Concr. Technol. 2003, 1, 241–252. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.-Y.; Kim, S.-W.; Park, J.-J. Comparative flexural behavior of ultra-high-performance concrete reinforced with hybrid straight steel fibers. Constr. Build. Mater. 2017, 132, 219–229. [Google Scholar] [CrossRef]

- Banthia, N.; Soleimani, S.M. Flexural response of hybrid fiber-reinforced cementitious composites. ACI Mater. J. 2005, 102, 382–389. [Google Scholar] [CrossRef]

- Banthia, N.; Sappakittipakorn, M. Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. Cem. Concr. Res. 2007, 37, 1366–1372. [Google Scholar] [CrossRef]

- Rashiddadash, P.; Ramezanianpour, A.A.; Mahdikhani, M. Experimental investigation on flexural toughness of hybrid fiber reinforced concrete (HFRC) containing metakaolin and pumice. Constr. Build. Mater. 2014, 51, 313–320. [Google Scholar] [CrossRef]

- Lawler, J.S.; Wilhelm, T.; Zampini, D.; Shah, S.P. Fracture processes of hybrid fiber-reinforced mortar. Mater. Struct. 2003, 36, 197–208. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Singh, S.; Kaushik, S. Properties of steel fibrous concrete containing mixed fibres in fresh and hardened state. Constr. Build. Mater. 2008, 22, 956–965. [Google Scholar] [CrossRef]

- Banthia, N.; Nandakumar, N. Crack growth resistance of hybrid fiber reinforced cement composites. Cem. Concr. Compos. 2003, 25, 3–9. [Google Scholar] [CrossRef]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Qian, C.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Czarnecki, L.; Deja, J.; Furtak, K.; Halicka, A.; Kapliński, O.; Kaszyńska, M.; Kruk, M.; Kuczyński, K.; Szczechowiak, E.; Śliwiński, J. Ideas shaping innovation challenges of construction technology. In searching of construction development paradigm. Mater. Bud. 2017, 7, 28–33. [Google Scholar] [CrossRef]

- EN 14889-1:2006; Fibres for concrete—Part 1: Steel fibres—Definitions, specifications and conformity. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2006.

- EN ISO 6892-1:2016; Metallic materials—Tensile testing—Part 1: Method of test at room temperature. ISO: Geneva, Switzerland, 2016.

- EN 14845-1:2007; Test methods for fibres in concrete. Reference concretes. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2007.

- EN 12350-3:2019; Testing fresh concrete. Vebe test. Slovenian Institute for Standardization: Ljubljana, Slovenia, 2019.

- EN 14651:2005+A1:2007; Test method for metallic fibre concrete. Measuring the flexural tensile strength (limit of proportionality (LOP), residual). BSI: London, UK, 2007.

- RILEM FMC-50. Draft recommendation: Determination of the fracture energy of mortar and concrete by means of threepoint bend tests on notched beams. Mater. Struct. 1985, 18, 287–290. [CrossRef]

- RILEM TC 187-SOC: Experimental Determination of the Stress-Crack Opening Curve for Concrete in Tension; Final report of RILEM Technical Committee TC 187-SOC; RILEM: Paris, France, 2007.

- Kim, M.O.; Bordelon, A. Determination of total fracture energy for fiber-reinforced concrete. Am. Concr. Inst. ACI Spec. Publ. 2015, 2015, 55–69. Available online: https://www.researchgate.net/publication/282953394_Determination_of_total_fracture_energy_for_fiber-reinforced_concrete (accessed on 21 March 2022).

- ASTM C1018-97; Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 1997. [CrossRef]

- Pawelska-Mazur, M.; Kaszynska, M. Mechanical Performance and Environmental Assessment of Sustainable Concrete Reinforced with Recycled End-of-Life Tyre Fibres. Materials 2021, 14, 256. [Google Scholar] [CrossRef]

| Type of Fibre | Length (mm) | Diameter (mm) | Description | ||

|---|---|---|---|---|---|

| MSF | 50.5 | 1.00 | hooked-end steel fibres, homogeneous, round cross-section | ||

| RTSF | interval | median | interval | median | hybrid fibres of various lengths and diameters, treated (rubber and textile contaminants < 0.5%) |

| 7.4–81.6 | 40.2 | 0.17–1.34 | 0.23 | ||

| Type of Fibre | Average Diameter of Fibres (mm) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|

| RTSF | 0.30 ± 0.08 | 1418 ± 54 | 158.8 ± 22.5 |

| 1.34 ± 0.06 | 1653 ± 40 | 191.8 ± 31.2 | |

| MSF | 1.00 ± 0.04 | 1082 ± 26 | 201.6 ± 17.8 |

| Component | Content (kg/m3) |

|---|---|

| Portland cement CEM I 42.5 R | 310 |

| Tap water | 171 |

| Natural aggregate 0/2 mm (sand) | 432 |

| Natural silica-based aggregate 2/8 mm (gravel) | 902 |

| Natural silica-based aggregate 8/16 (gravel) | 545 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michalik, A.; Chyliński, F.; Bobrowicz, J.; Pichór, W. Effectiveness of Concrete Reinforcement with Recycled Tyre Steel Fibres. Materials 2022, 15, 2444. https://doi.org/10.3390/ma15072444

Michalik A, Chyliński F, Bobrowicz J, Pichór W. Effectiveness of Concrete Reinforcement with Recycled Tyre Steel Fibres. Materials. 2022; 15(7):2444. https://doi.org/10.3390/ma15072444

Chicago/Turabian StyleMichalik, Agnieszka, Filip Chyliński, Jan Bobrowicz, and Waldemar Pichór. 2022. "Effectiveness of Concrete Reinforcement with Recycled Tyre Steel Fibres" Materials 15, no. 7: 2444. https://doi.org/10.3390/ma15072444

APA StyleMichalik, A., Chyliński, F., Bobrowicz, J., & Pichór, W. (2022). Effectiveness of Concrete Reinforcement with Recycled Tyre Steel Fibres. Materials, 15(7), 2444. https://doi.org/10.3390/ma15072444